Coil rod for pre-stressed steel strand and production method of coil rod

A technology of prestressed steel strands and production methods, which is applied in the field of wire rod manufacturing, can solve problems such as broken wires during drawing, and achieve the effects of fine grains, small interlamellar spacing of sorbite, and increased drawing speed

Inactive Publication Date: 2015-05-27

宣化钢铁集团有限责任公司

View PDF4 Cites 37 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] At present, the wire rods for prestressed steel strands are mainly SWRH82B, and the production process adopts the traditional technology; the wire rods for prestressed steel strands with a diameter of 12.5mm and a tensile strength of 1150MPa~1200MPa are drawn when they are drawn. The drawing speed is generally controlled at 4.0m / s. If the drawing speed exceeds 4.0m / s, it is very easy to cause broken wires during drawing.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-8

[0043] Embodiment 1-8: The wire rod 80MnCr for the prestressed steel strand adopts the following specific process.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

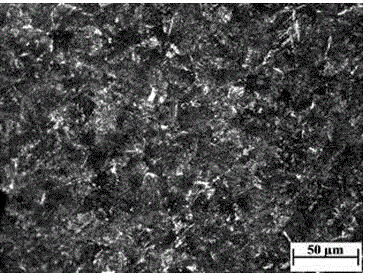

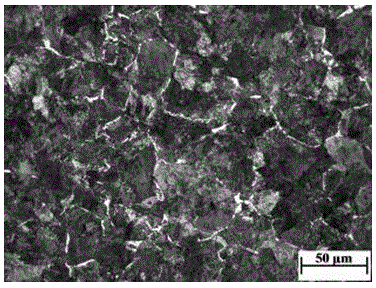

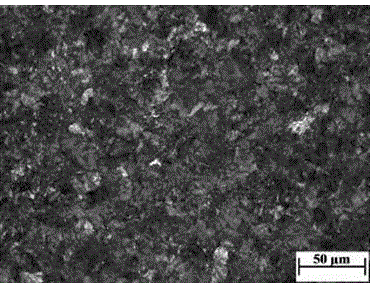

The invention discloses a coil rod for a pre-stressed steel strand and a production method of the coil rod. The production method comprises the following steps: smelting in a rotary furnace; refining in an LF; continuously casting; heating; carrying out controlled rolling and controlled cooling. In the continuous casting step, a casting blank consists of the following chemical components in percentage by weight:0.78-0.82 percent of C, 0.20-0.25 percent of Si, 0.75-0.80 percent of Mn, 0.20-0.25 percent of Cr, smaller than or equal to 0.012 percent of P, smaller than or equal to 0.010 percent of S and 0.02-0.03 percent of V. The controlled rolling and controlled cooling step comprises steps of rolling, spinning, cooling and collecting and coiling; in the rolling step, the rolling temperature is 1000+ / -15 DEG C; the precision rolling temperature is 920 to 950 DEG C; in the spinning step, the spinning temperature is 860 to 880 DEG C. According to the method, based on optimization and control of the chemical components, by regulating and controlling the steel rolling process, the sorbite rate of the coil rod is increased, the interlamellar spacing of the sorbite is reduced, and generation of poor tissues is avoided, so that the coil rod has the characteristics of high intensity, high plasticity and low pole difference and satisfies the use requirement that the wire is not broken at a high-pulling speed; the pulling speed is increased; the wire breaking rate is reduced; therefore the production efficiency is improved to some degree.

Description

technical field [0001] The invention relates to a method for manufacturing wire rods, in particular to a method for manufacturing wire rods for prestressed steel strands. Background technique [0002] Prestressed steel strand is a new material with rapid development in China in recent years. It is widely used in railway engineering, high-rise buildings, cross-river cable-stayed bridges, suspension bridges, water conservancy facilities, nuclear power plant domes, sports factory pavilions, offshore platforms, etc. High, heavy and special" key building structure projects, the products are widely used, and the market prospect is good. [0003] SWRH82B has good dimensions and surface quality, and is superior in metallographic structure, decarburization layer and mechanical properties. It can be used to manufacture high-strength prestressed steel strands, galvanized steel strands, etc. It is an important tool for deep processing in the metal products industry. raw material. SWRH...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/24C21D8/06B21C37/04

Inventor 闫卫兵姜碧涛沈俊杰李娜王海宾张玉海王建忠孙先焦曹新刚

Owner 宣化钢铁集团有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com