Patents

Literature

39results about How to "Reduce low temperature brittleness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

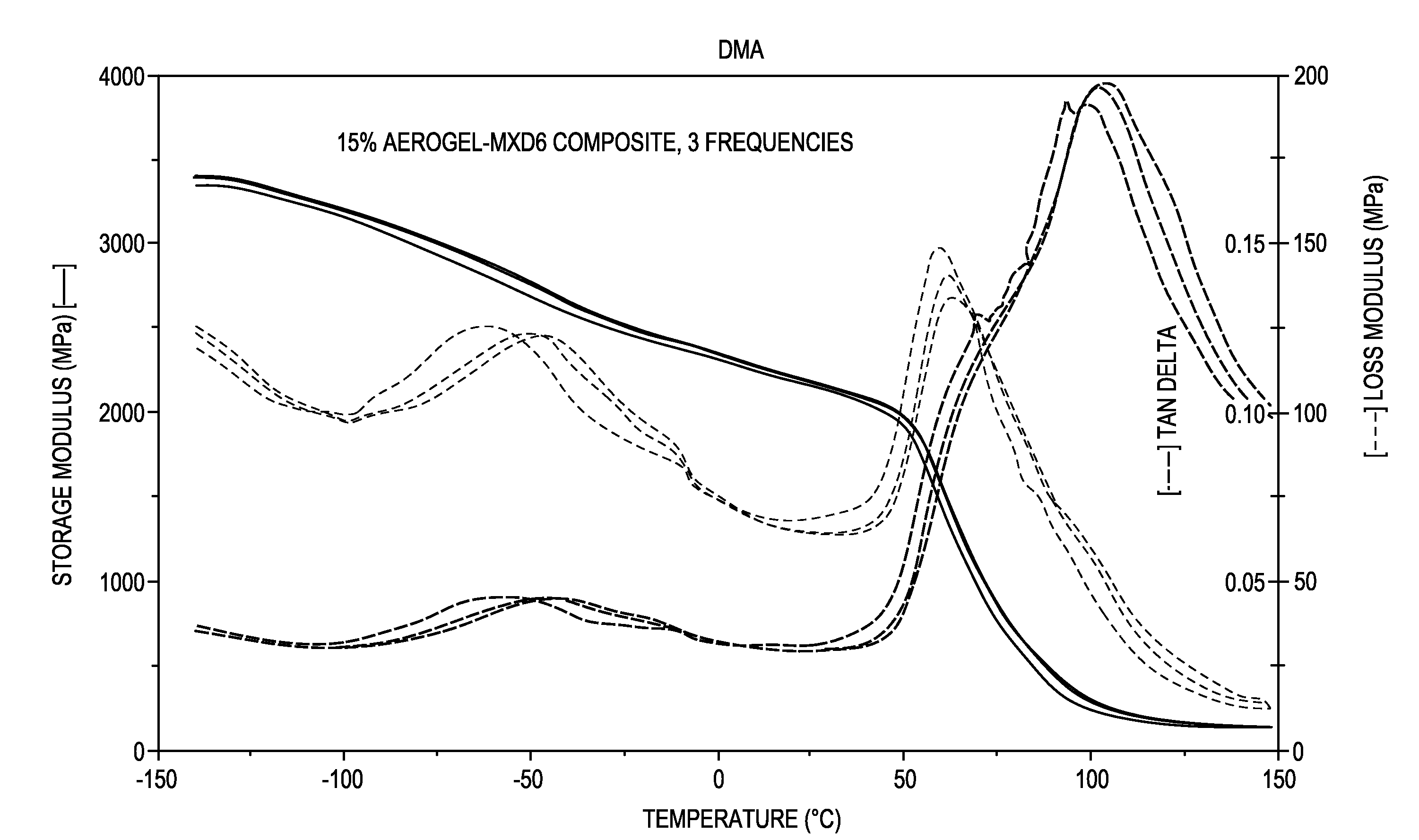

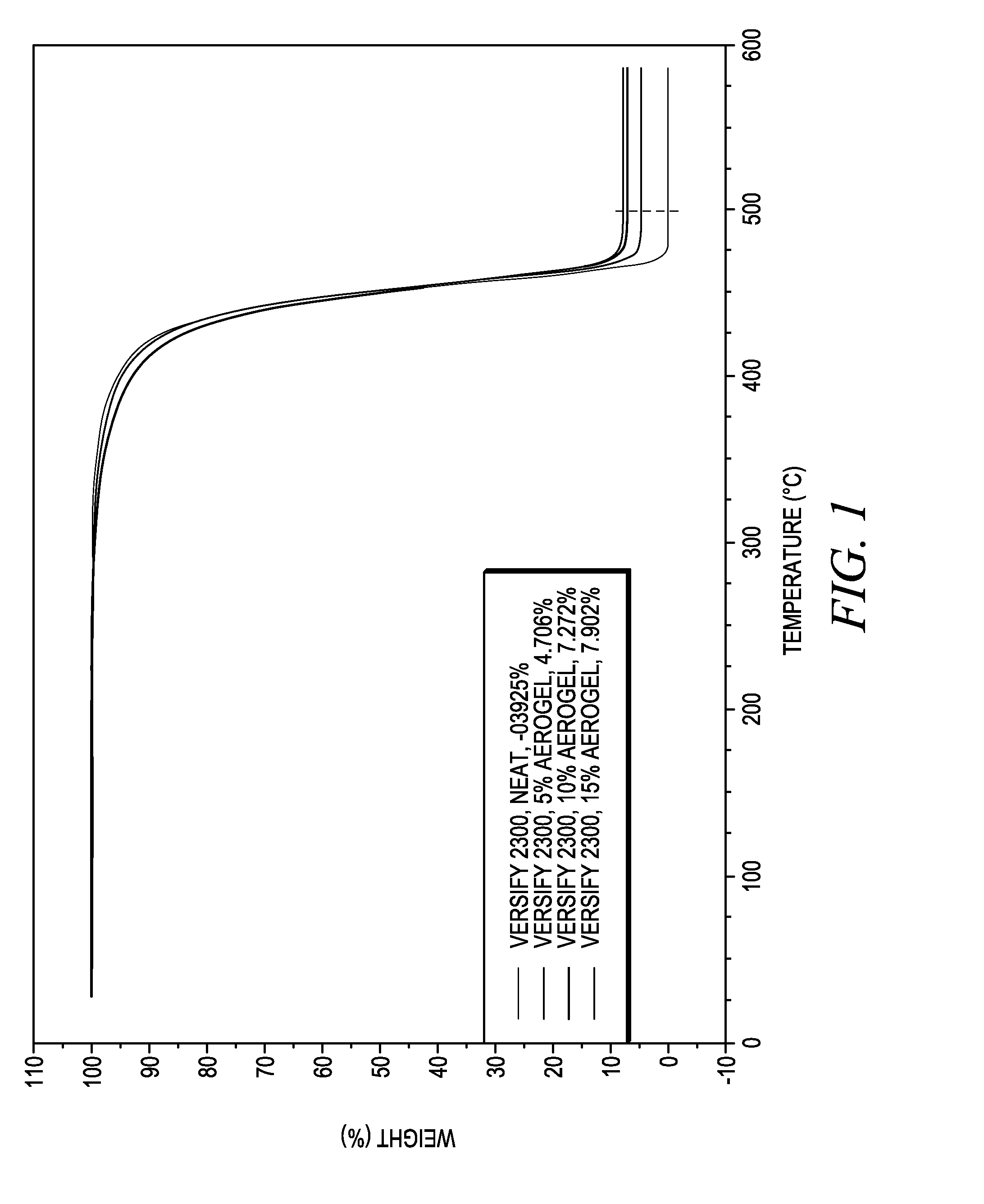

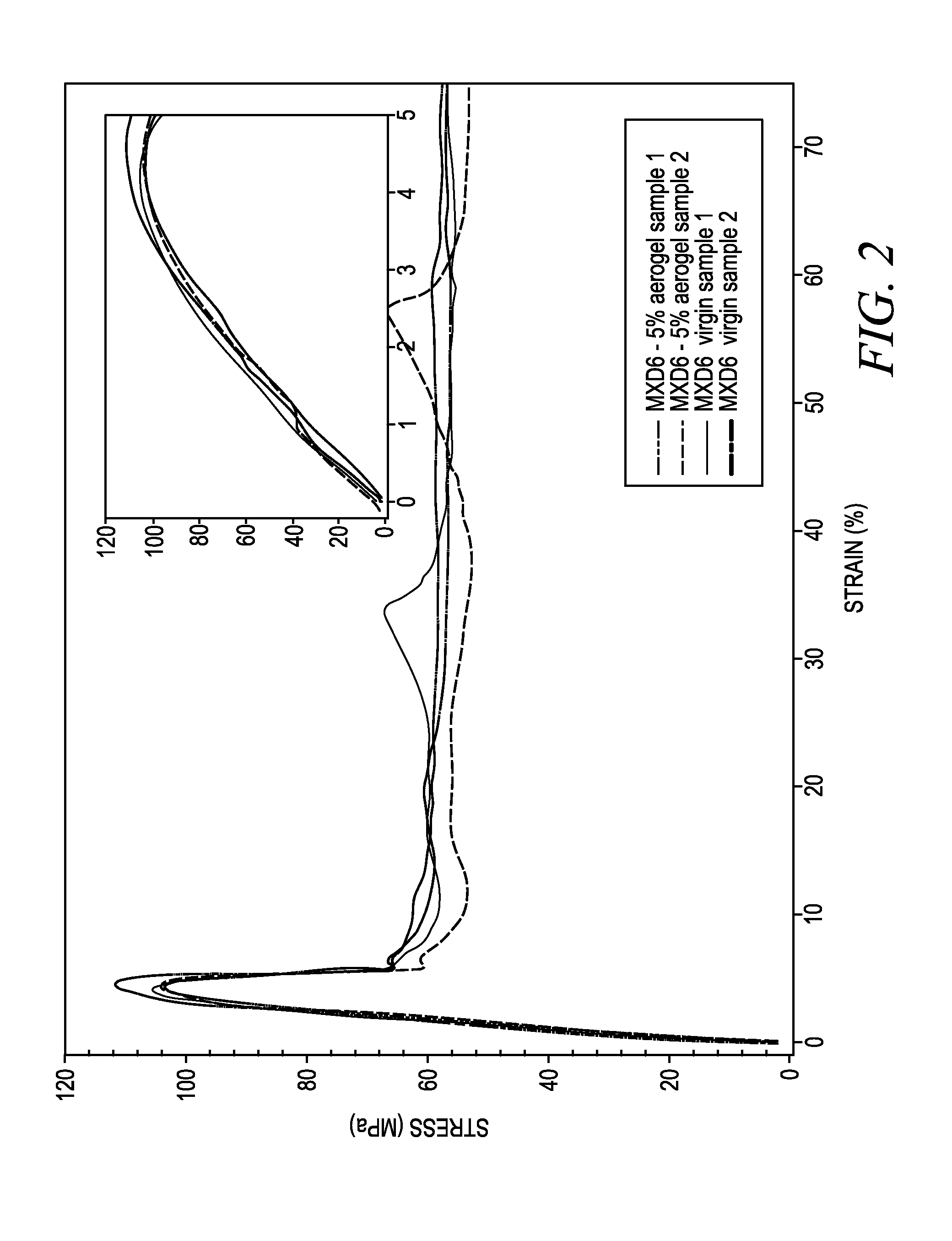

Aerogel / Polymer Composite Materials

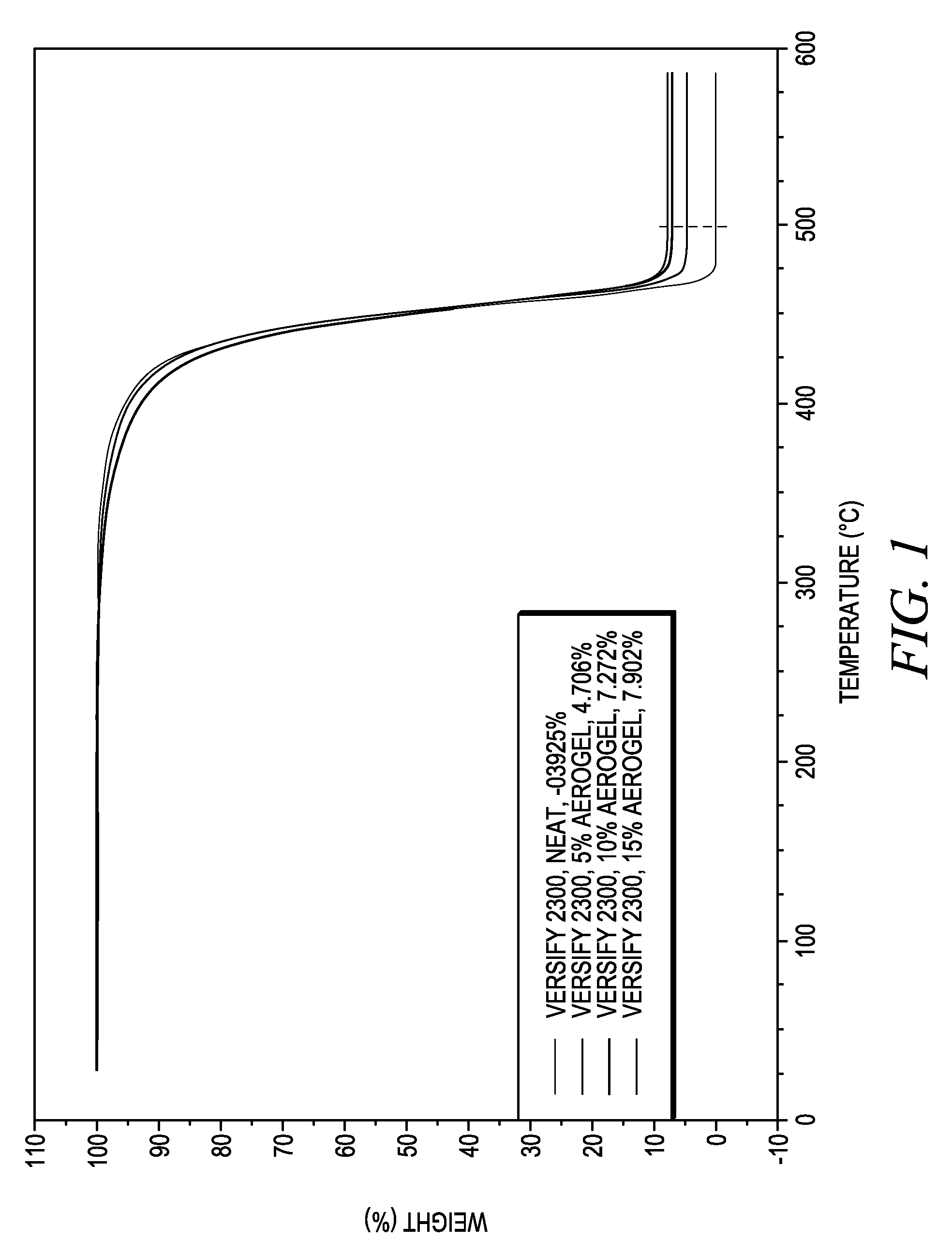

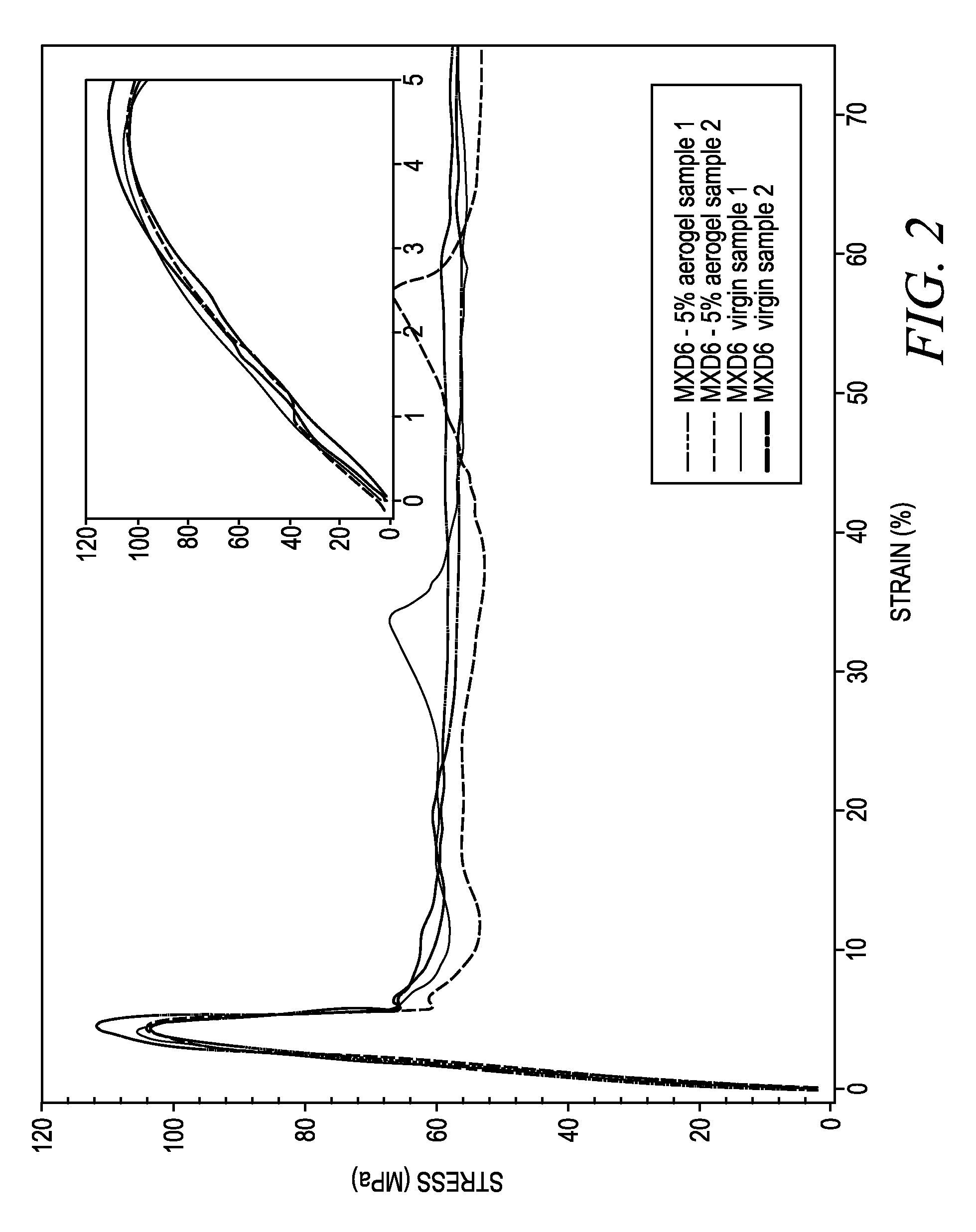

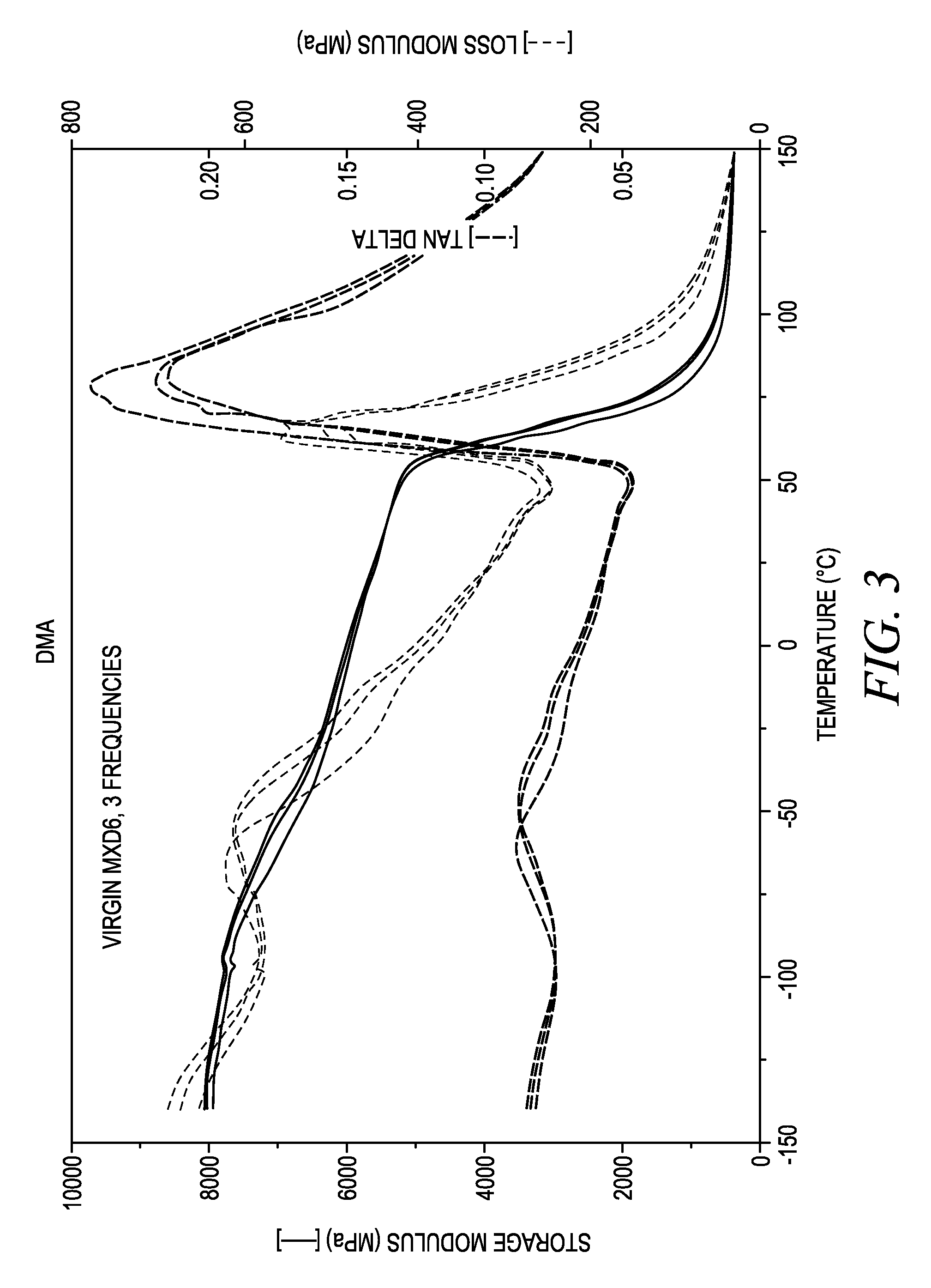

ActiveUS20070259169A1Improve thermal performanceDecrease low temperature brittlenessLayered productsSpecial tyresThermal insulationPolymer composites

The invention provides new composite materials containing aerogels blended with thermoplastic polymer materials at a weight ratio of aerogel to thermoplastic polymer of less than 20:100. The composite materials have improved thermal insulation ability. The composite materials also have better flexibility and less brittleness at low temperatures than the parent thermoplastic polymer materials.

Owner:NASA

Low-hydrogen electrode with favorable low-temperature impact toughness

ActiveCN102825399AImprove low temperature impact toughnessSimple welding processWelding/cutting media/materialsSoldering mediaFerrosiliconWeld seam

The invention provides a low-hydrogen electrode with favorable low-temperature impact toughness, wherein the electrode using corresponds to a top low-carbon steel H08A welding core of the requirement of GB / T3429-2002, and electrode medicine skin comprises the following components in percentage by weight: 35-45% of marble, 15-18% of fluorite, 4-8% of silicon micro powder, 4-8% of ferromanganese, 5-8% of ferrosilicon, 8-11% of ferrotitanium, 3-6% of rutile, 1-3% of mica, 6-10% of ferrous powder and 0.5-1.5% of magnesium powder, wherein the fluorite is characterized in that CaF2>=95%, SiO2<=4.5%, S<=0.020%, P<=0.030%, and 100% of meshes of granularity is 100 meshes of fluorite. According to the invention, through controlling the adding amount of fluorite and controlling the fluorite granularity 100% of 100 meshes, the obtained low-hydrogen electrode has good welding process performance, and the welding seam tissue low-temperature brittleness is lowered obviously.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

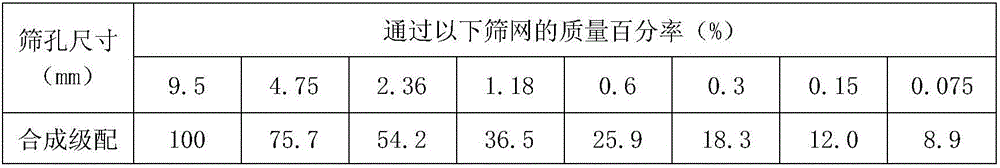

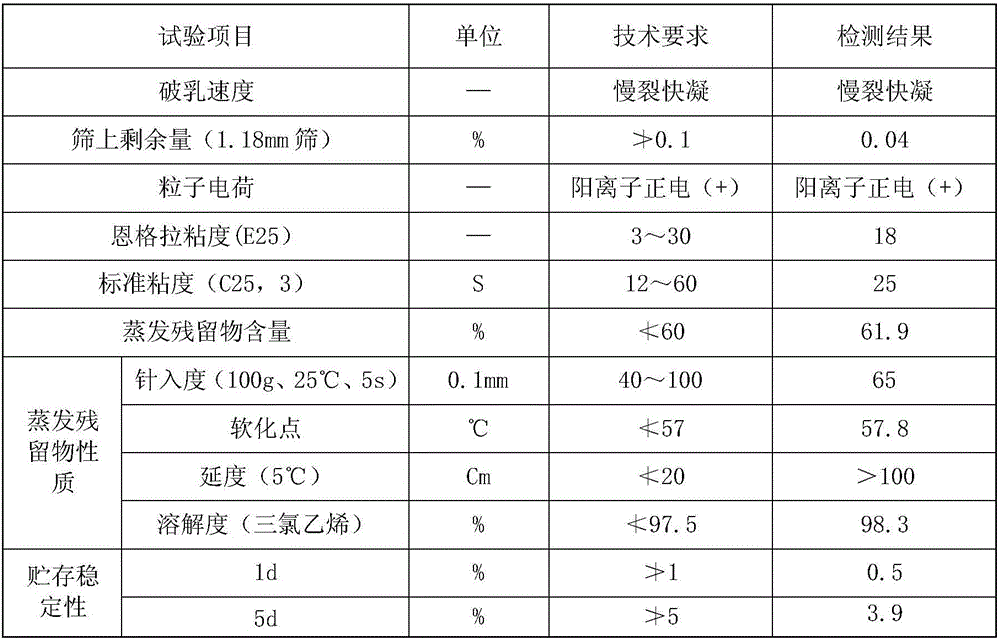

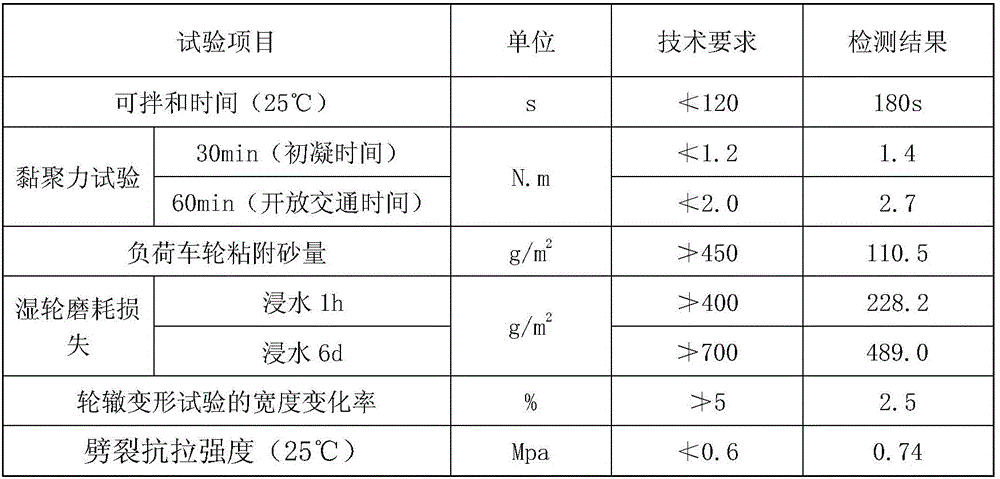

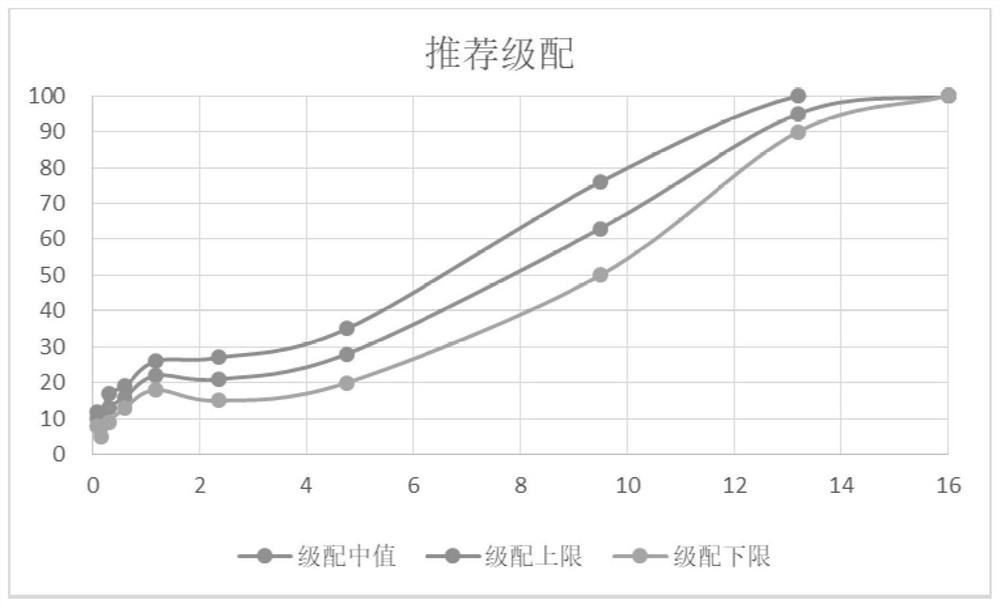

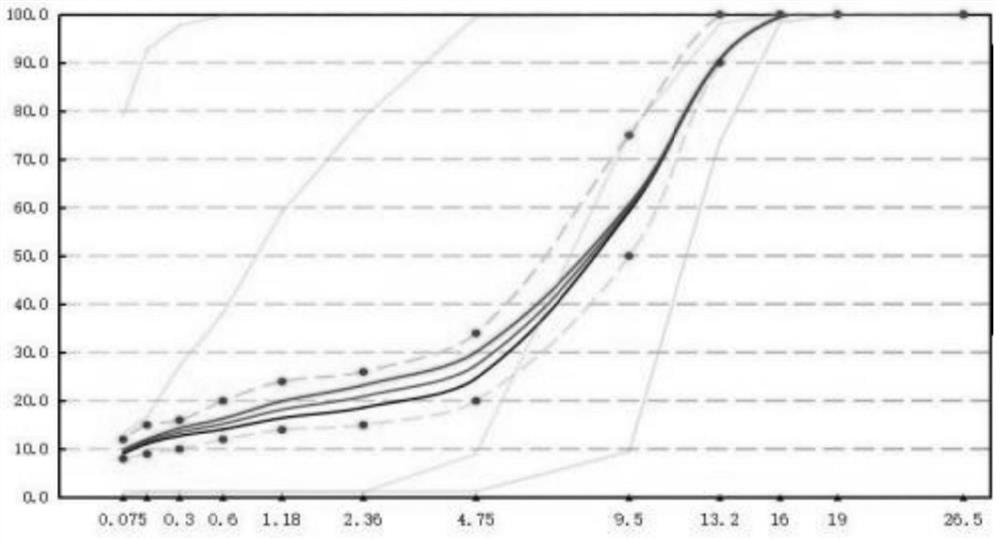

Super-viscose fiber wearing layer cold-mixed asphalt mixture and preventive maintenance method of asphalt pavement

InactiveCN106007489AReduce energy consumptionAvoid energy consumptionRoads maintainenceFiberPolymer modified

The invention relates to a pavement construction material and a pavement construction method, in particular to a cold-mixed asphalt mixture for a super-viscous fiber wear layer and a preventive maintenance method for an asphalt pavement. The composition and mass percentage of the ultra-viscosity fiber wearing layer cold mix asphalt mixture of the present invention are: polymer modified emulsified asphalt (9-15)%, aggregate (75-80)%, filler (0.5-3)% , fiber (0.1~0.3)%, rubber powder (0~3)%, water (5~10)%, the total amount is 100%. The material of the invention has good wear resistance, adhesion and water resistance, strong anti-crack ability of the construction road surface, good stability and convenient construction.

Owner:JIANGSU TIANNUO ROAD MATERIAL TECH

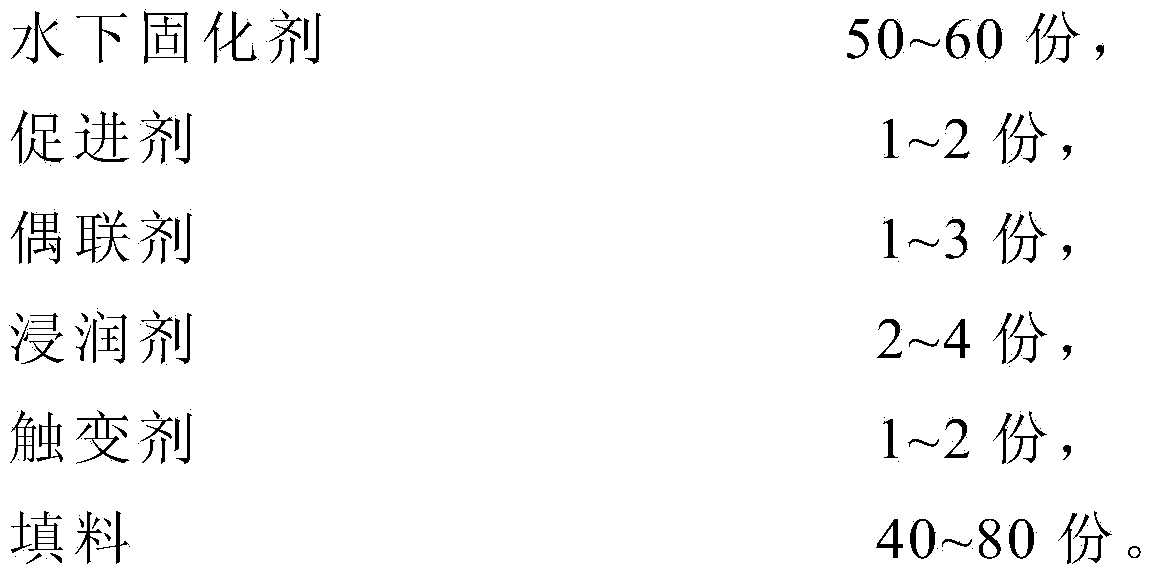

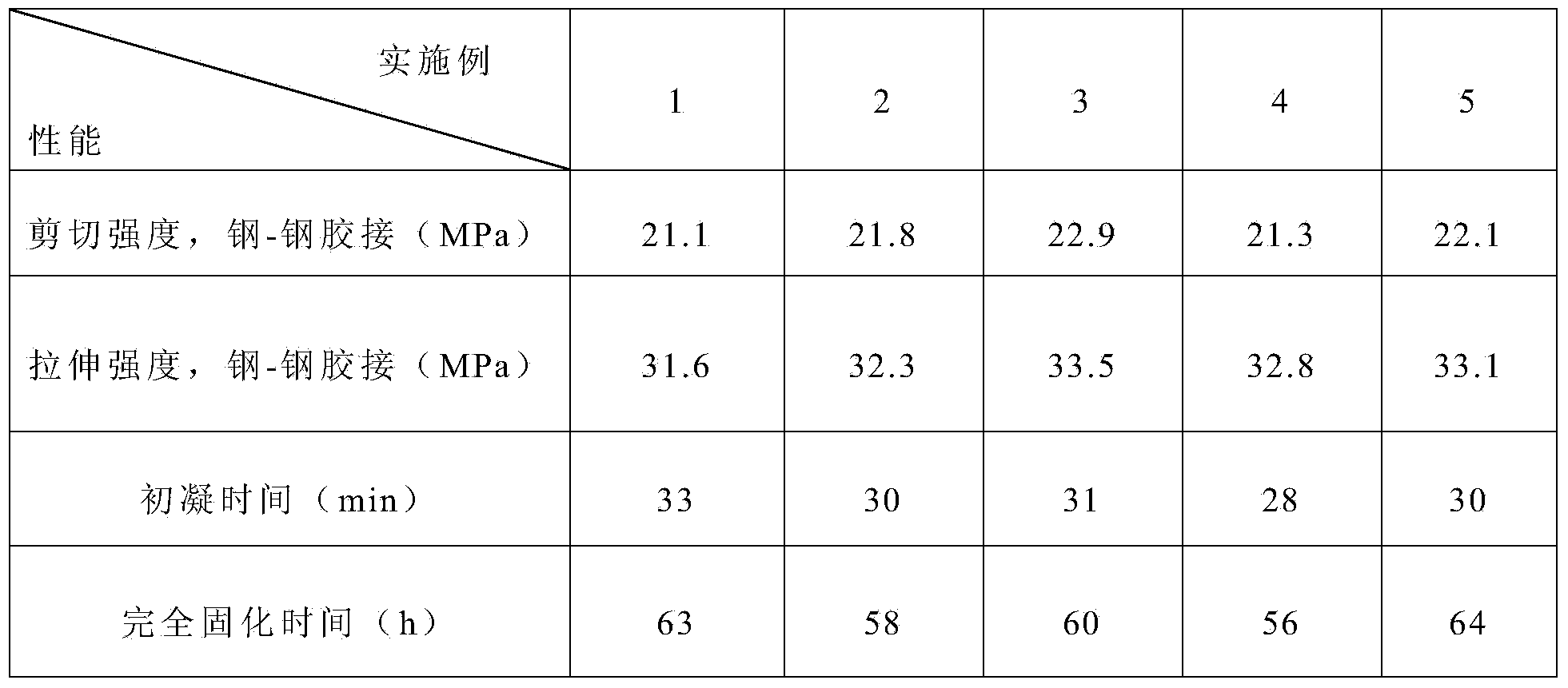

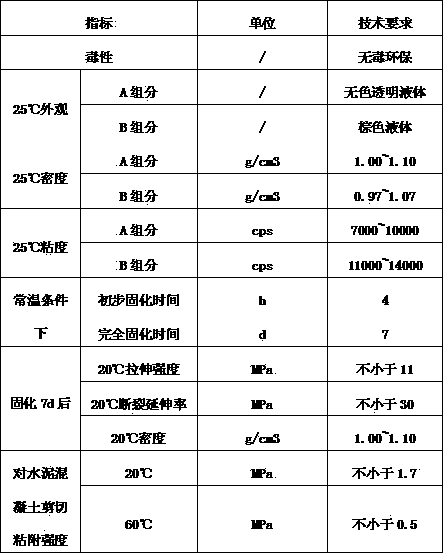

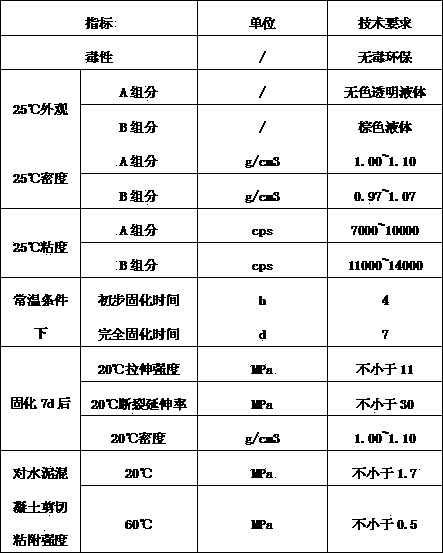

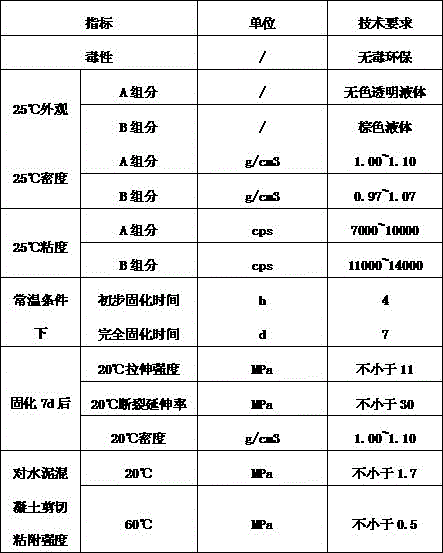

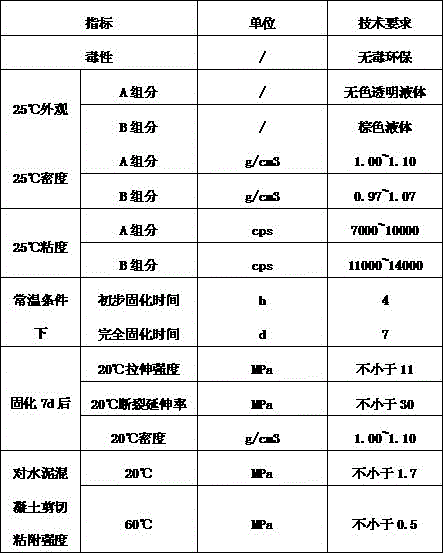

High-strength underwater structure adhesive and preparation method thereof

ActiveCN103965820AImprove brittlenessImprove toughnessNon-macromolecular adhesive additivesEpoxy resin adhesivesAdhesiveUnderwater

The invention discloses a high-strength underwater structure adhesive and a preparation method thereof. The adhesive is prepared by mixing a component A and a component B according to a weight ratio of 1:1, wherein the component A comprises the following components in parts by weight: 30-48 parts of nano rubber modified epoxy resin, 50-70 parts of bisphenol A epoxy resin and 4-6 parts of thixotropic agent; the component B comprises the following components in parts by weight: 50-60 parts of underwater curing agent, 1-2 parts of accelerant, 1-3 parts of coupling agent, 2-4 parts of moistening agent, 1-2 parts of thixotropic agent and 40-80 parts of packing. Practical application shows that the high-strength underwater structure adhesive has the characteristics of complete underwater adhesion, underwater curing, high adhesion strength and short curing time, can be applied to repairing in an adhesion manner, sealing to stop leakage, and curing of various underwater buildings, and is simple in production method and process and is easy to operate.

Owner:WUHAN JIANFU NEW MATERIALS

Aerogel/polymer composite materials

ActiveUS7790787B2Reduce low temperature brittlenessLayered productsSpecial tyresPolymer scienceThermal insulation

The invention provides new composite materials containing aerogels blended with thermoplastic polymer materials at a weight ratio of aerogel to thermoplastic polymer of less than 20:100. The composite materials have improved thermal insulation ability. The composite materials also have better flexibility and less brittleness at low temperatures than the parent thermoplastic polymer materials.

Owner:NASA

HDPE (high-density polyethylene) double-wall corrugated pipe

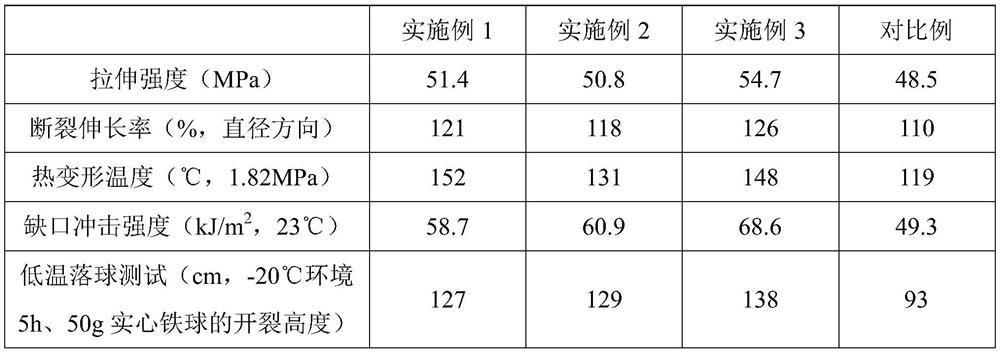

The invention discloses an HDPE (high-density polyethylene) double-wall corrugated pipe. The pipe comprises the following raw materials in parts by weight: 15-55 parts of HDPE, 3-18 parts of LDPE (low-density polyethylene), 6-24 parts of LLDPE (linear low-density polyethylene), 2-20 parts of EVA (ethylene vinyl acetate), 4-18 parts of drawing grade polypropylene, 5-10 parts of attapulgite powder, 1-10 parts of white carbon black, 1-10 parts of zirconium sulfate, 10-20 parts of graphite, 5-15 parts of nano-carbon, 8-20 parts of polyimide fiber, 0.5-4 parts of a silane coupling agent KH151, 1-2 parts of diphenyl ketone, 1-10 parts of a composite lubricating agent, 0.01-0.2 part of nano-silver, 0.5-5 parts of flavonols, 0.5-5 parts of zinc stearate, 1-5 parts of polyacrylamide, 5-10 parts of methyl methacrylate, 1-5 parts of 2, 4-dichlorobenzoyl peroxide and 10-20 parts of 6-ethoxy-2, 2, 4-trimethyl-1, 2-dihydroquinoline. According to the pipe prepared from the raw materials disclosed by the invention, mechanical properties, impact resistance, deformability, anti-aging performance and anti-fouling performance are obviously and greatly upgraded.

Owner:江苏诺贝尔塑业股份有限公司

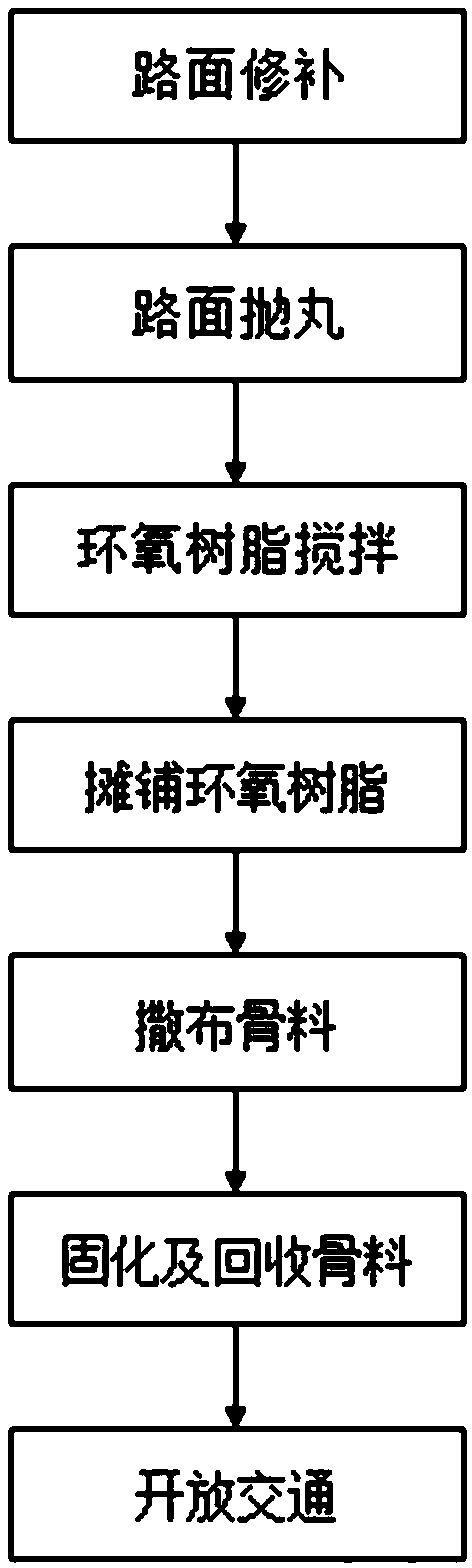

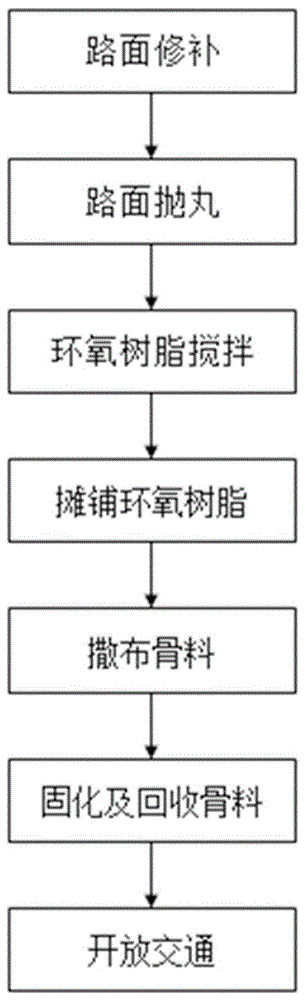

Construction process of colored pavement epoxy non-slip wearing layer structure

ActiveCN103938513ASimple construction processEasy constructionIn situ pavingsPaving detailsEpoxyRoad surface

The invention discloses a construction process of a colored pavement epoxy non-slip wearing layer structure. The construction process comprises the following steps: (1) pavement patching; (2) pavement shot blasting; (3) epoxy resin stirring; (4) paving of epoxy resin; (5) spreading of aggregates; (6) curing and recovering of the aggregates; and (7) opening of transit. Compared with the prior art, the construction process has the advantages that the wearing layer structure is simple in process, easy to operate, good in non-slip performance, high in bonding strength, small in thickness, convenient in construction, rapid in curing and high in material water resistance; running noise of vehicles is lowered; driving conditions are improved; the wearing layer structure is excellent in corrosion resistance, high in flame retardant property, high in ductility, uniform in expansion, high in low-temperature resistance, low in low-temperature brittleness, excellent in thermal ageing resistance, high in high-temperature stability and high in wear resistance, the surface aggregate is high in wear resistance, a conventional road elevation and the conventional clear height of a bridge are not changed, existing various structural and non-structural pavement diseases can be repaired at a time, the maintenance cost is saved, and the service life of a pavement is greatly prolonged.

Owner:上海仁路科技有限公司

Surface treatment process for enhancing low-temperature resistance of plastic

The invention relates to a surface treatment process for enhancing the low-temperature resistance of plastic. The surface treatment process specifically comprises the steps of degreasing plastic, swelling plastic, etching plastic, carrying out preliminary conditioning, activating plastic, preparing a low-temperature-resistant layer, carrying out treatment by oxidizing flame, plating the low-temperature-resistant layer, washing with water and drying. The surface treatment process disclosed by the invention has the advantages that the process is simple, the treatment time is shortened, the low-temperature resistance of plastic can be significantly improved, and the temperature brittleness of plastic is reduced; the treated plastic has the characteristics of relatively high surface smoothness and more beautiful appearance.

Owner:CHUZHOU HONGYUAN SPRAYING

Thick-gauge steel plate with excellent low-temperature aging performance, and manufacturing method thereof

The invention provides a thick-gauge steel plate with excellent low-temperature aging performance, and a manufacturing method thereof. The thick-gauge steel plate with excellent low-temperature aging performance is composed of the chemical components of, by weight: no more than 0.20wt% of C, no more than 0.50wt% of Si, no more than 1.60wt% of Mn, 0.020-0.050wt% of Nb, 0.010-0.050wt% of Ti, 0.015-0.050wt% of Als, no more than 0.015wt% of P, no more than 0.012wt% of S, and balance of Fe and unavoidable impurities. Through low-carbon micro-alloying, and through the controlling over rolling, cooling, and normalizing treatment, the steel plate has good low-temperature aging impact performance. The thick-gauge steel plate provided by the invention satisfies -50 DEG C impact work requirements before and after aging, and has uniform tissue and excellent properties. With the steel plate, an ultrasonic flaw detection requirement is satisfied, and the requirement for a structural steel plate for an offshore oil platform is satisfied.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Steel wire mesh skeleton composite tube

The invention discloses steel wire mesh skeleton composite tube. The tube is prepared from the following raw materials in parts by mass: 15-55 parts of HDPE, 3-18 parts of LDPE, 6-24 parts of LLDPE, 2-20 parts of EVA, 4-18 parts of drawing-grade polypropylene, 5-10 parts of montmorillonite, 10 parts of white carbon black, 1-10 parts of barium sulfate, 10-20 parts of graphite, 5-15 parts of carbon nanotube, 8-20 parts of polyimide fibers, 0.5-4 parts of a silane coupling agent KH151, 1-2 parts of diphenyl ketone, 1-10 parts of a composite lubricant, 0.01-0.2 part of nano-silver, 0.5-5 parts of flavonol, 0.5-5 parts of zinc stearate, 1-5 parts of polyacrylamide, 5-10 parts of methyl methacrylate, 1-5 parts of 2,4-dichlorobenzoyl peroxide and 10-20 parts of 6-ethoxy-2,2,4-trimethyl-1,2-dihydro-quinoline. The mechanical properties, impact property, deformation degree, aging resistance and stain resistance of the tube prepared from the raw materials are significantly and greatly increased.

Owner:深圳市心立方节能新技术有限公司

Rubber for low-temperature resistant rubber hose for refrigerator

InactiveCN102993514AReduce low temperature brittlenessReduced use of polar materialsPolymer scienceSulfenamide

The invention relates to rubber for a low-temperature resistant rubber hose for a refrigerator. The rubber is characterized by comprising the following raw materials in proportion: 20-40 parts of 1# natural rubber, 80-120 parts of 1502-type butadiene styrene rubber, 0.9-1.1 parts of sulphur, 4-6 parts of zinc oxide, 1-1.2 parts of stearic acid, 60-80 parts of spraying carbon black, 15-25 parts of o-dibutyl ester, 2-4 parts of NOBS (N-(Oxidiethylene)-2-benzothiazolyl sulfenamide) accelerant C11H12N2S2O and 2-4 parts of 4010 antiaging agent. The rubber for low-temperature resistant rubber hose for the refrigerator has the improved low-temperature resistant performance and reduced low-temperature brittleness.

Owner:XIAN ZHITAI RUBBER & PLASTIC IND

Preparation method of composite thermoplastic elastomer modified asphalt

InactiveCN107652698AImprove diffusion abilityReduce diffuseBuilding insulationsVulcanizationPolymer science

The invention discloses a preparation method of a composite thermoplastic elastomer modified asphalt, and belongs to the technical field of a composite material. After immersing fly ash by hydrochloric acid, the anion spreading ability is strong, and the anion can cross through a hydration shell at the surface of the fly ash grain and actively react with the inner part to generate hydrated calciumaluminate, thus a coating layer is ruptured for the expansion of a hydrate, and its specific area is increased, and the adsorbability is stronger; polysulfide bond in the silane coupling agent is added to participate in vulcanization of butadiene styrene rubber, thus a crosslinking network is formed, and the interface bonding force between the fly ash and the rubber is enhanced; the tear intensity of butadiene styrene rubber is improved, and the compatibility with asphalt is good; moreover, the temperature sensitivity of the asphalt mortar is reduced. The preparation method has the advantagesof solving the problems that the performance of the SBS modified asphalt is reduced for the compatibility of modifier SBS and the asphalt applied at present is poor, and the SBS modified asphalt is easy to separate after thermal storage for a long time.

Owner:蒋春霞

PP corrugated pipe modified by ethylene propylene rubber (EPR)

InactiveCN105860267AReduce low temperature brittlenessImprove toughnessFlexible pipesUltimate tensile strengthPolypropylene

The invention discloses a PP corrugated pipe modified by ethylene propylene rubber (EPR). The PP corrugated pipe modified by the ethylene propylene rubber (EPR) comprises an outer wall pipe body and an inner wall pipe body, and the outer wall pipe body is composed of, by mass, 40-60 parts of polypropylene resin, 20-30 parts of nano calcium carbonate, 10-15 parts of ethylene propylene rubber (EPR) compound modifier, 1-3 parts of a colouring agent and 1-3 parts of a defoaming agent; the inner wall pipe body is composed of, by mass, 40-60 parts of polypropylene resin, 20-30 parts of nano calcium carbonate, 10-15 parts of ethylene propylene rubber (EPR) compound modifier, 1-3 parts of the colouring agent and 1-3 parts of the defoaming agent. By means of the PP corrugated pipe modified by the ethylene propylene rubber (EPR), low-temperature brittleness of the PP corrugated pipe can be lowered, toughness of an FRPP corrugated pipe in a low-temperature environment is improved, and non-notched impact strength, elongation at break and melt flowability of the PP corrugated pipe are all remarkably improved.

Owner:TAIZHOU YAMEIYUHE NEW MATERIAL

FRPP corrugated pipe being relatively high in low-temperature toughness

InactiveCN104804305AImprove low temperature brittlenessReduce low temperature brittlenessDefoaming AgentsLow-density polyethylene

The invention discloses an FRPP corrugated pipe being relatively high in low-temperature toughness. The FRPP corrugated pipe is prepared from the following components by mass: 18-25 kg of PP raw materials, 18-25 kg of PE raw materials, 12-18 kg of low-density polyethylene, 40-45 kg of active calcium powder, 1-3 kg of black master batch and 1-3 kg of a defoaming agent. Such components are uniformly stirred by a blending machine, and the stirred components are processed for extrusion forming. The prepared FRPP corrugated pipe has the following advantages: the organization of the FRPP corrugated pipe is improved, the low temperature brittleness of the FRPP corrugated pipe can be effectively reduced, the probability that the FRPP corrugated pipe is easily damaged under low temperatures is 3% or lower, and the toughness of the FRPP corrugated pipe under low temperature environments is obviously improved.

Owner:GUIYANG XINGSU PIPE IND CO LTD

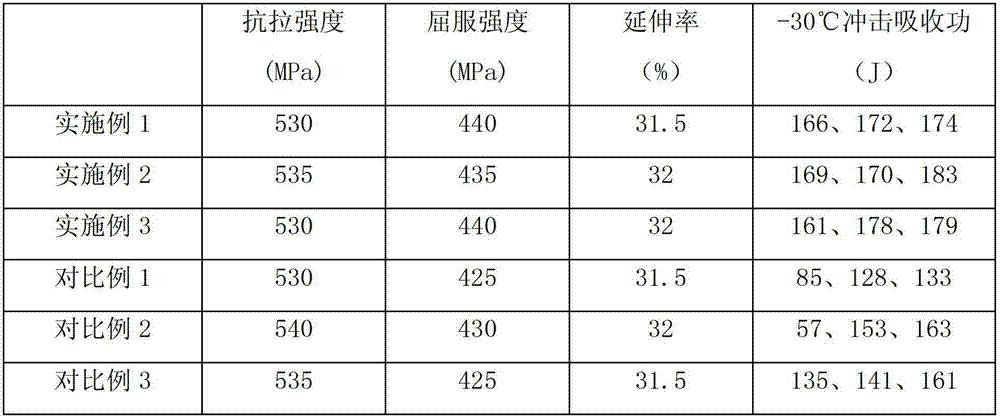

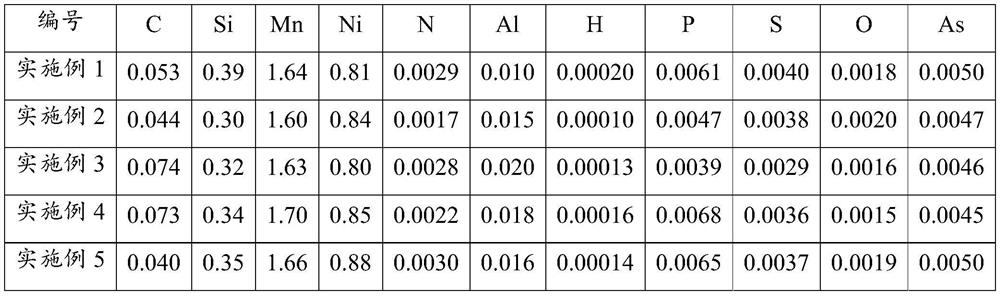

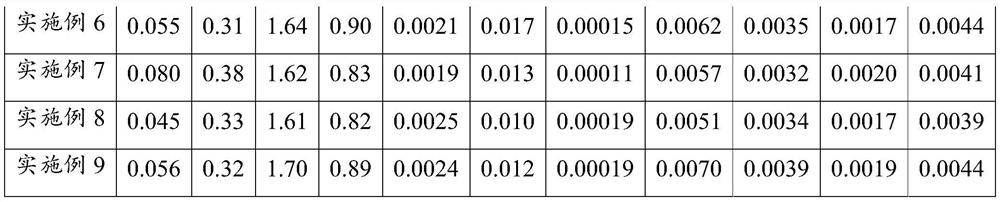

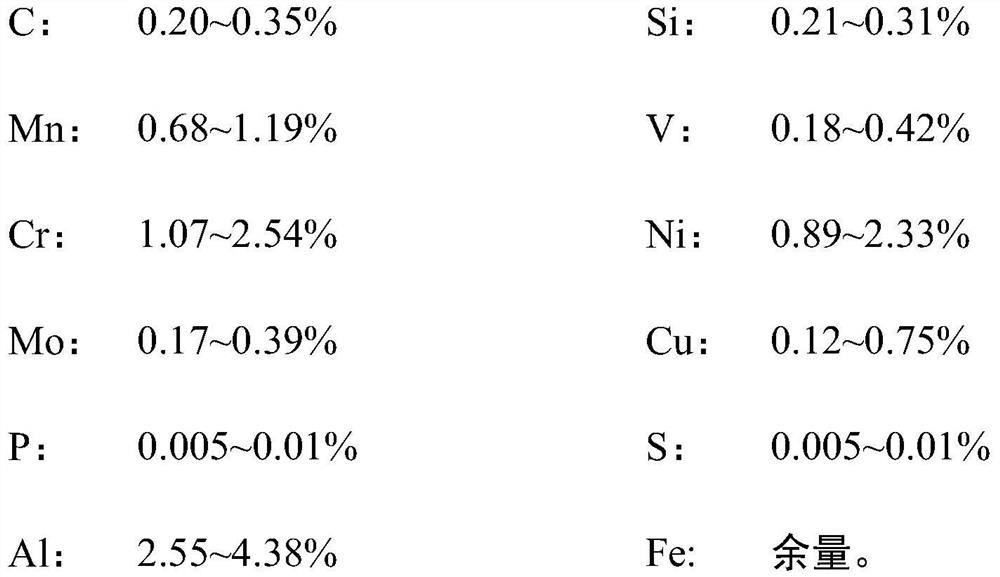

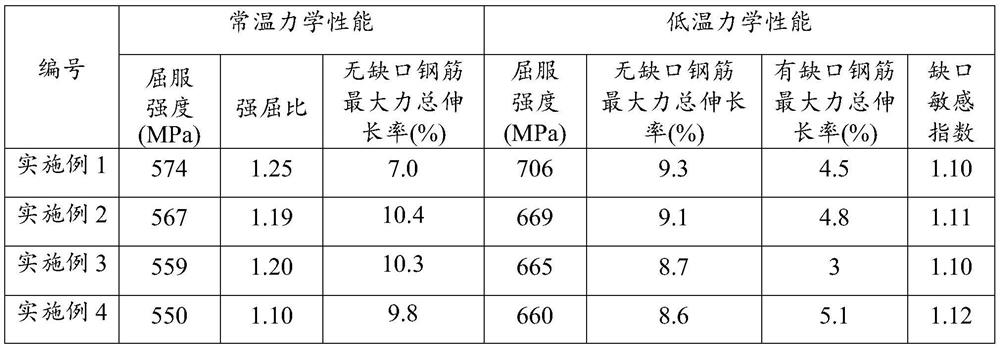

Low-temperature steel bar and production method thereof

ActiveCN113186466AAchieve performance requirementsLow production costProcess efficiency improvementRebarImpurity

The invention discloses a low-temperature steel bar and a production method thereof. The low-temperature steel bar comprises the following chemical components in percentage by mass: 0.8-0.9% of Ni, 1.6-1.7% of Mn, 0.3-0.4% of Si, 0.04-0.08% of C, 0.01-0.02% of Al, less than or equal to 0.007% of P, less than or equal to 0.004% of S, less than or equal to 0.002% of O, less than or equal to 0.003% of N, less than or equal to 0.005% of As, less than or equal to 0.0002% of H and the balance of Fe and inevitable impurities. The production method thereof comprises the steps of KR molten iron pretreatment, converter smelting, LF furnace refining, RH furnace refining, continuous casting and steel rolling. According to the steel bar and the production method thereof, component design and mass production of the low-temperature steel bar are completed at low cost, and the effects of strictly controlling impurity elements, inclusions and surface quality and reducing low-temperature brittleness are achieved.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +1

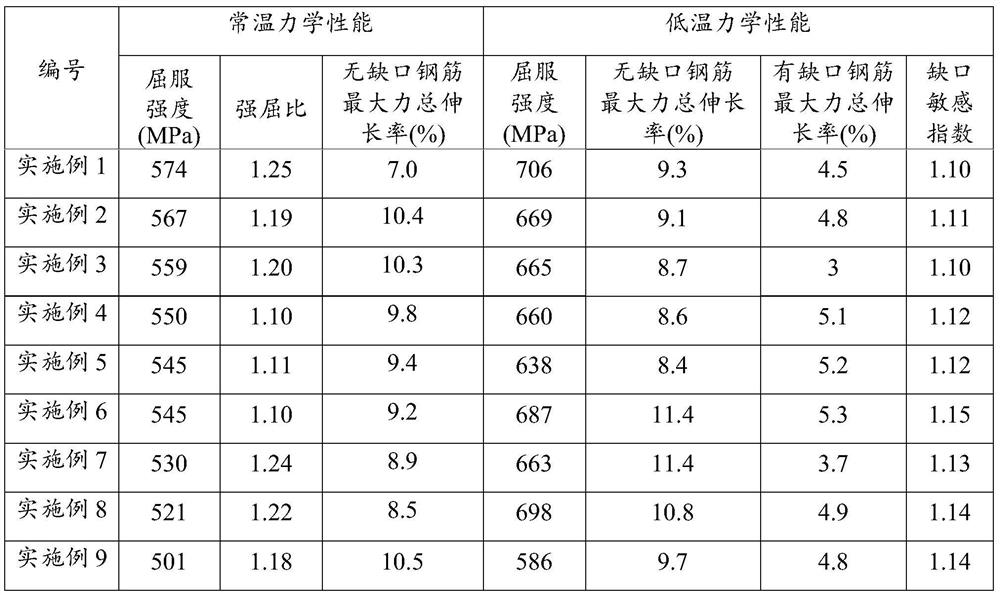

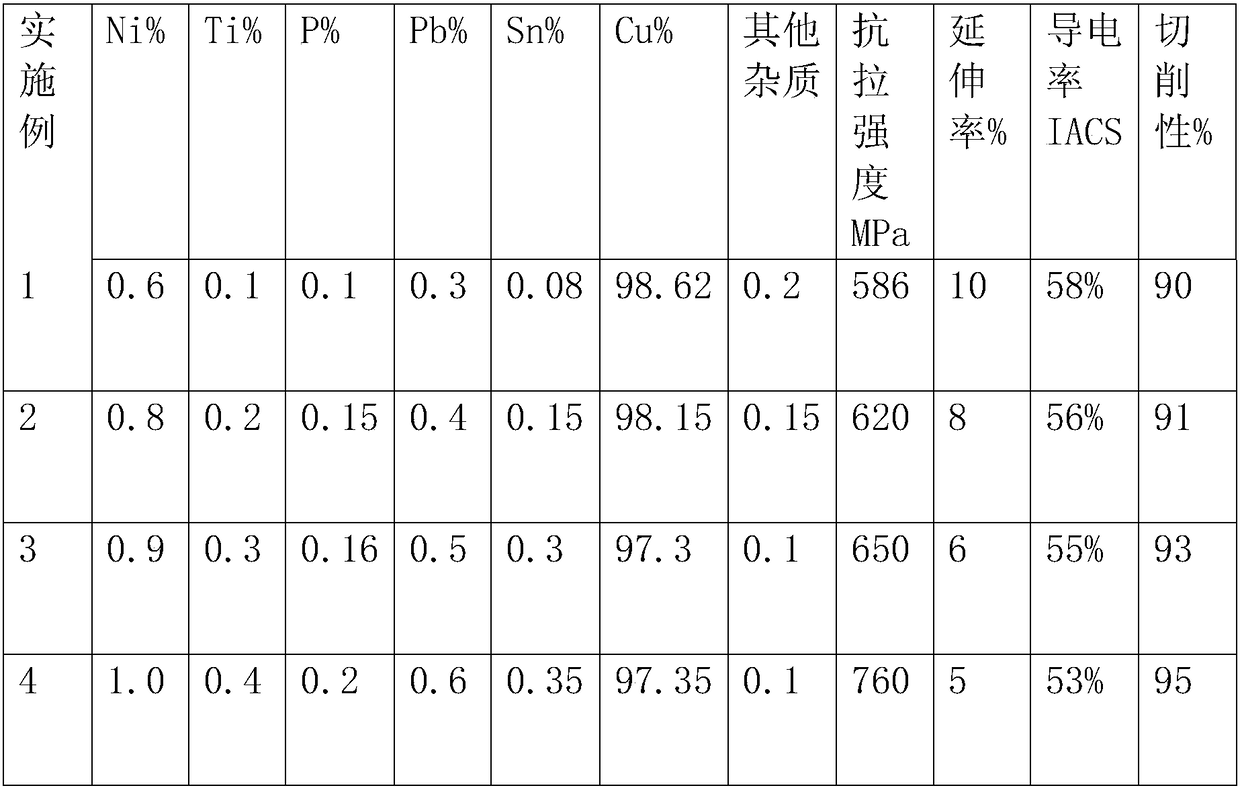

Copper alloy and preparation method and application thereof

ActiveCN107541613AHigh strengthImprove mechanical propertiesCoupling contact membersHigh intensityTitanium

The invention relates to a copper alloy material and a preparation method and application thereof. The copper alloy material comprises, by weight, 0.2-0.8 part of lead, 0.5-1.2 parts of nickel, 0.01-0.2 part of phosphorus, 0.01-0.5 part of titanium, 0.05-0.5 part of stannum, and 96.7-98.8 parts of copper. The copper content of the copper alloy material is greater than 97%, methods of aging strengthening, deformation strengthening, microelement alloying strengthening are comprehensively adopted, and the alloy material with high strength and high electric conduction is obtained. The alloy has nomagnetism and no low-temperature brittleness, the abrasion resistance is high, the corrosion resistance is high, sparks does not occur by impacting, requirements of copper alloy used for high-power connectors in industries such as transportation, aerospace and communications are met; and the alloy is easy to turn and applicable for high-speed automatic lathe machining.

Owner:沈阳慧坤新材料科技有限公司

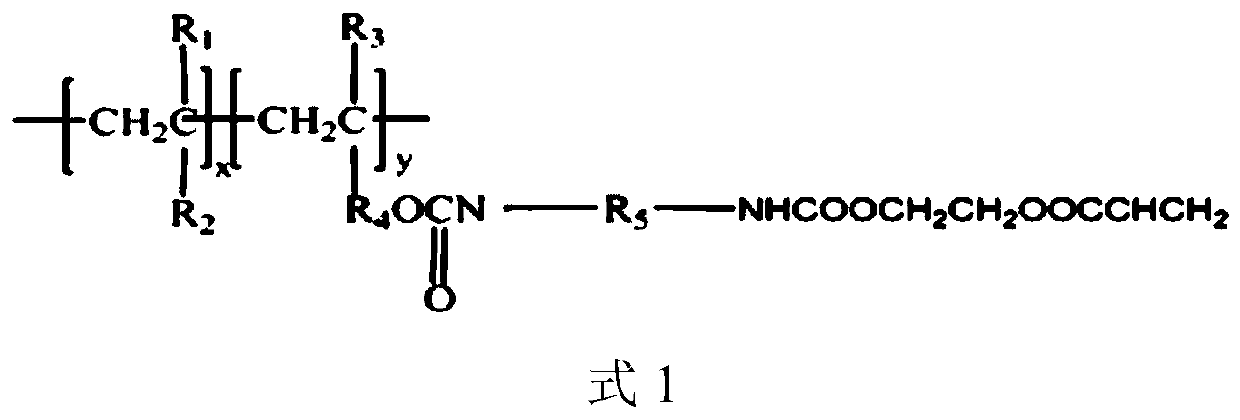

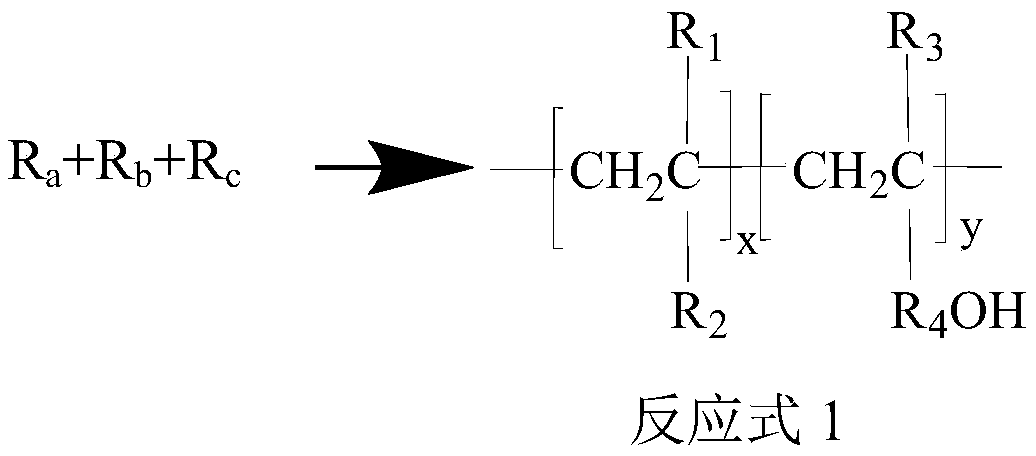

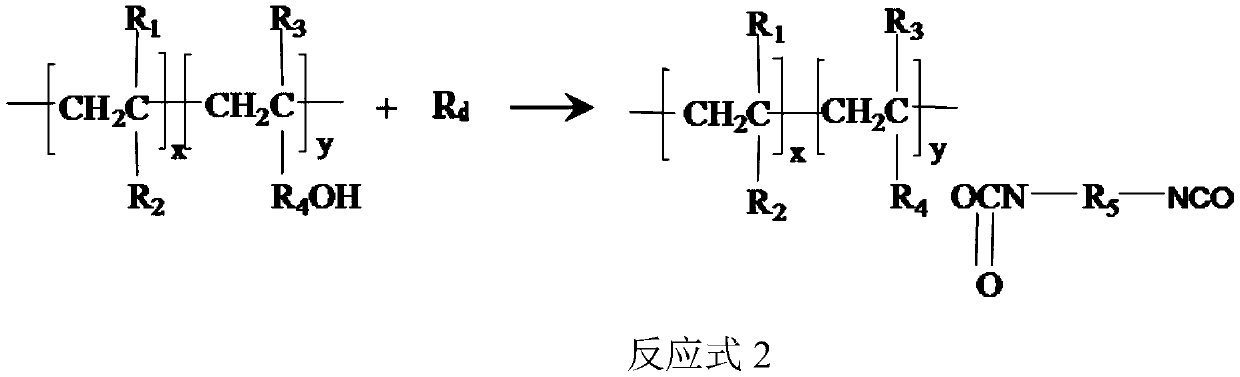

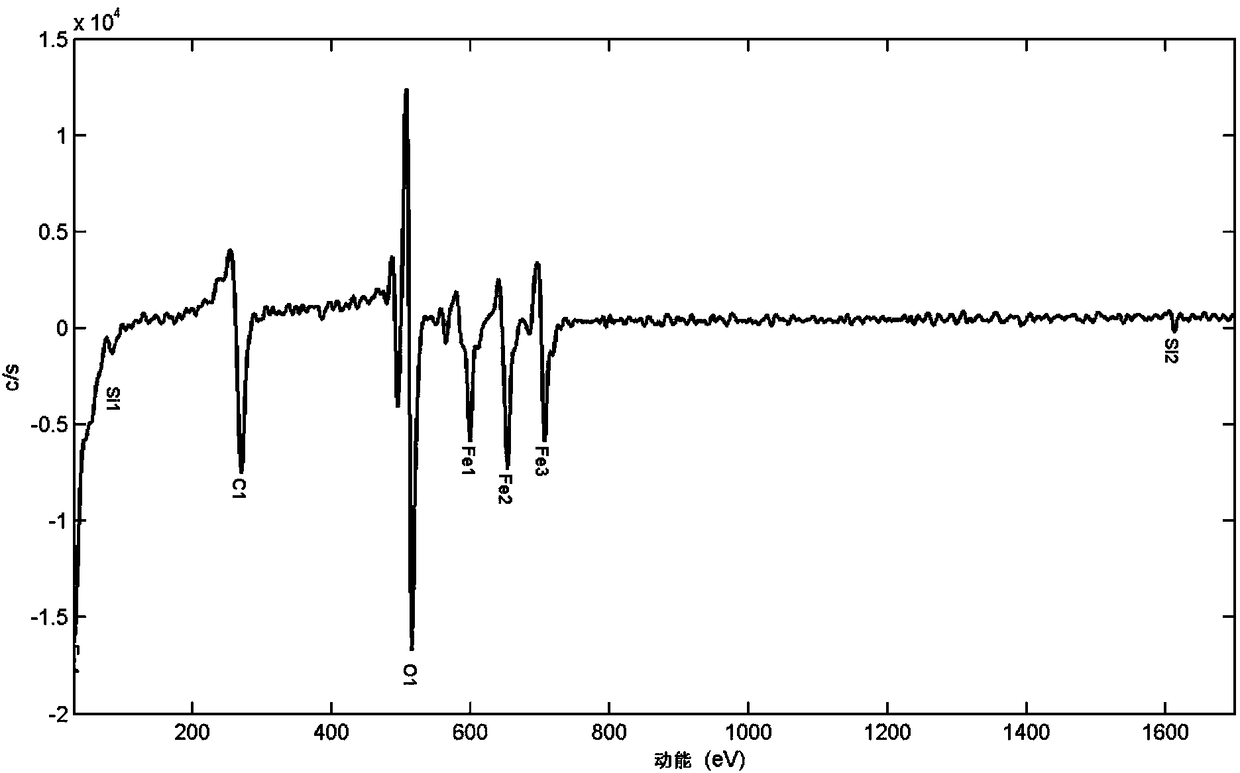

Hydroxyl-terminated polyurethane methacrylic resin as well as preparation method and application thereof

ActiveCN110903459AReduce low temperature brittlenessIncrease high temperature flexibilityPolyurea/polyurethane coatingsMethacrylateEndcapping

The invention discloses hydroxyl-terminated polyurethane methacrylic resin as well as a preparation method and an application thereof; the structural general formula of the hydroxyl-terminated polyurethane methacrylic resin is represented by a formula 1, and the preparation method comprises the steps: carrying out copolymerization reaction on a hydroxyl acrylate body, and carrying out addition reaction and substitution reaction under catalytic conditions to obtain the hydroxyl-terminated polyurethane methacrylic resin. A hydroxyl-terminated polyurethane methacrylic resin base liquid is prepared from the prepared hydroxyl-terminated polyurethane methacrylic resin, a (methyl) acrylate monomer, an accelerant and a drying aid, and then an initiator is added to prepare a hydroxyl-terminated polyurethane methacrylic resin waterproof coating. The hydroxyl-terminated polyurethane methacrylic resin has the advantages that the low-temperature brittleness is reduced, the high-temperature flexibility is improved; hydroxyl is adopted for terminating and double bonds with activity are introduced, so the curing performance of the resin is enhanced, and the hydroxyl-terminated polyurethane methacrylic resin has great application and popularization value in the aspects of waterproof coatings and bonding materials.

Owner:重庆沥智路桥工程有限公司

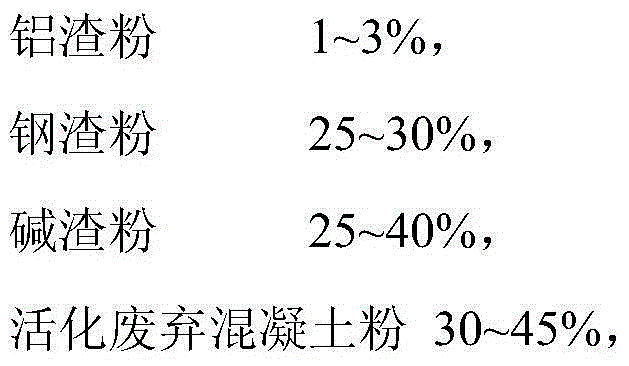

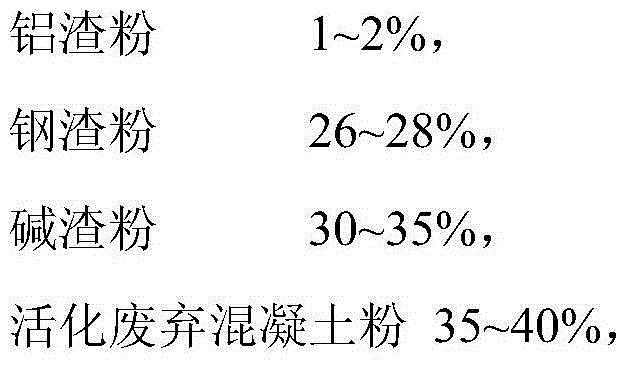

High-viscosity asphalt and preparation method thereof

The invention discloses high-viscosity asphalt and a preparation method thereof. The high-viscosity asphalt consists of matrix asphalt, epoxy resin and an additive. The additive is prepared from the following raw material 1 and raw material 2: the raw material 1 consists of the following components in percentage by weight: 1 to 3 percent of aluminum slag powder, 25 to 30 percent of steel slag powder, 25 to 40 percent of alkali slag powder and 30 to 45 percent of activated waste concrete powder; the raw material 2 is water; the water is 20 to 30 percent of the total weight of the raw material 1. The high-viscosity asphalt consists of the following components in percentage by weight: 88 to 96 percent of matrix asphalt, 1 to 5 percent of epoxy resin and 3 to 7 percent of an additive. The high-viscosity asphalt has the characteristics of low low-temperature brittleness, high durability, high weather resistance and high viscosity at 60 DEG C.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

A steel mesh skeleton composite pipe

The invention discloses a steel mesh skeleton composite pipe, which comprises the following raw material components in parts by mass: 15-55 parts of HDPE, 3-18 parts of LDPE, 6-24 parts of LLDPE, 2-20 parts of EVA, drawing grade 4-18 parts of polypropylene, 5-10 parts of montmorillonite, 1-10 parts of white carbon black, 1-10 parts of barium sulfate, 10-20 parts of graphite, 5-15 parts of carbon nanometer, 8- 20 parts, 0.5-4 parts of silane coupling agent KH 151, 1-2 parts of benzophenone, 1-10 parts of composite lubricant, 0.01-0.2 parts of nano silver, 0.5-5 parts of flavonol, 0.5 parts of zinc stearate -5 parts, 1-5 parts of polyacrylamide, 5-10 parts of methyl methacrylate, 1-5 parts of 2,4-dichlorobenzoyl peroxide, 6-ethoxy-2,2,4- 10-20 parts of trimethyl-1,2-dihydroquinoline. The mechanical properties, impact resistance, deformability, anti-aging performance and anti-fouling performance of the pipe made of the raw material of the invention are significantly and greatly improved.

Owner:深圳市心立方节能新技术有限公司

High strength IF steel with excellent corrosion resistance and manufacturing method thereof

The invention discloses high strength IF steel with excellent corrosion resistance. The high strength IF steel comprises the following chemical elements in percentage by mass: greater than 0 but lessthan or equal to 0.009% of C, greater than 0 but less than or equal to 0.01% of Si, 0.2-0.8% of Mn, 0.02-0.08% of P, 0.005-0.025% of Nb, 0.005-0.025% of Ti, 0.0001-0.001% of B, 0.01-0.09% of Al, lessthan or equal to 0.005% of N, less than or equal to 0.015% of S and the balance of Fe and other inevitable impurities. The invention also discloses a manufacturing method of the high strength IF steelcorrespondingly. The manufacturing method comprises the following steps: smelting and casting; hot rolling; and annealing. The tensile strength of the high strength IF steel disclosed by the invention is greater than or equal to 360MPa, and the surface potential representing the corrosion resisting property of the steel is greater than or equal to -410mV.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

High and low temperature resistant plastic bottle cap and manufacturing process thereof

PendingCN113980380AGood high and low temperature resistanceImprove shear resistanceLow-density polyethyleneMasterbatch

The invention provides a high and low temperature resistant plastic bottle cap and a manufacturing process thereof, and belongs to the field of high performance plastics, wherein the high and low temperature resistant plastic bottle cap comprises the following components in parts by mass: 60-75 parts of high density polyethylene, 8-16 parts of temperature resistant modified masterbatch, 4-8 parts of low molecular weight branched polyethylene, 1-4 parts of maleic anhydride grafted polypropylene, 1-4 parts of pentadiene, 2-4 parts of a filler, and 1-10 parts of a first auxiliary agent; the temperature-resistant modified master batch is composed of low-density polyethylene, a temperature-resistant modifier and a second auxiliary agent in a mass ratio of 50:(25-45):(1-5); and on the basis of an existing HDPE material, the modifier is added, so that the high and low temperature resistance of the HDPE material is improved.

Owner:连云港市鼎尚包装有限公司

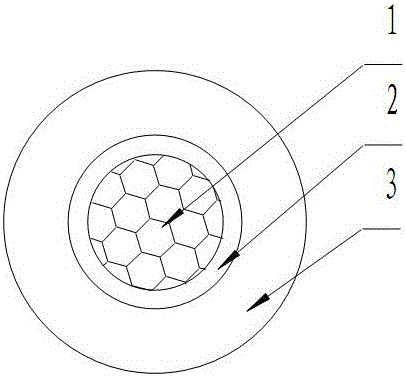

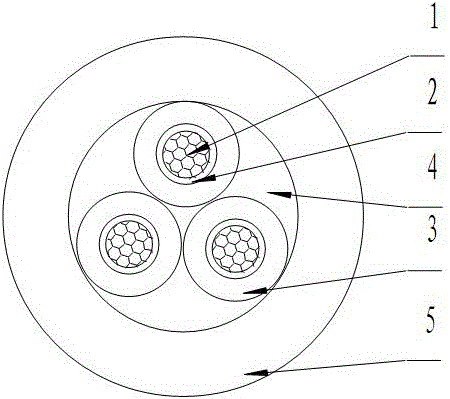

Heat and cold resistant flexible cable

ActiveCN103531277BStrong adaptability to ambient temperatureImprove low temperature resistanceRubber insulatorsPlastic/resin/waxes insulatorsElectrical conductorInsulation layer

The invention discloses a heat-resistant and cold-resistant flexible cable. For a single-core structure, it includes a conductor and an insulating layer covering the periphery of the conductor. The insulating layer is a silica gel insulating layer, and there is a heat insulating layer between the conductor and the insulating layer, and the heat insulating layer is covered with polyimide paper. For the multi-core structure, it includes a plurality of cable cores and sheaths covering the periphery of the multiple cable cores. The plurality of cable cores are twisted into a spiral shape, and there are fillers in the gaps between the cable cores. The cable core is the aforementioned Heat and cold resistant flexible single core cable. It has good flexibility, can withstand both high temperature and low temperature, and can meet the requirements of mobile appliances in various temperature environments.

Owner:TBEA DEYANG CABLE CO LTD

A Construction Technology of Epoxy Antiskid Wear Layer Structure on Colored Pavement

ActiveCN103938513BSimple construction processEasy constructionIn situ pavingsPaving detailsEpoxyThermal ageing

The invention discloses a construction process of a colored pavement epoxy non-slip wearing layer structure. The construction process comprises the following steps: (1) pavement patching; (2) pavement shot blasting; (3) epoxy resin stirring; (4) paving of epoxy resin; (5) spreading of aggregates; (6) curing and recovering of the aggregates; and (7) opening of transit. Compared with the prior art, the construction process has the advantages that the wearing layer structure is simple in process, easy to operate, good in non-slip performance, high in bonding strength, small in thickness, convenient in construction, rapid in curing and high in material water resistance; running noise of vehicles is lowered; driving conditions are improved; the wearing layer structure is excellent in corrosion resistance, high in flame retardant property, high in ductility, uniform in expansion, high in low-temperature resistance, low in low-temperature brittleness, excellent in thermal ageing resistance, high in high-temperature stability and high in wear resistance, the surface aggregate is high in wear resistance, a conventional road elevation and the conventional clear height of a bridge are not changed, existing various structural and non-structural pavement diseases can be repaired at a time, the maintenance cost is saved, and the service life of a pavement is greatly prolonged.

Owner:上海仁路科技有限公司

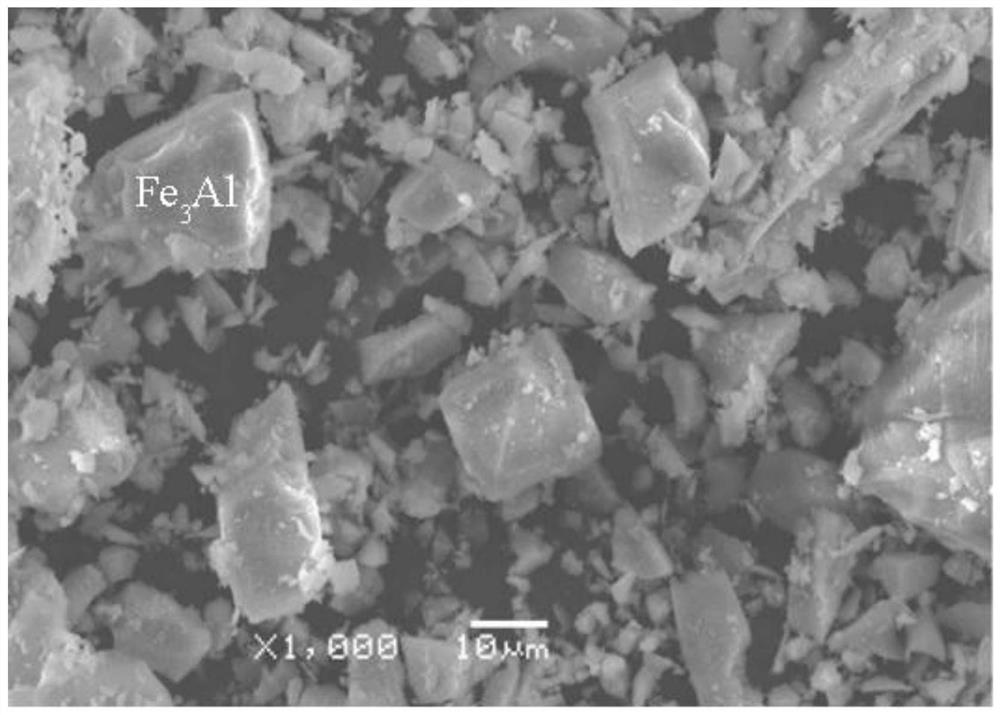

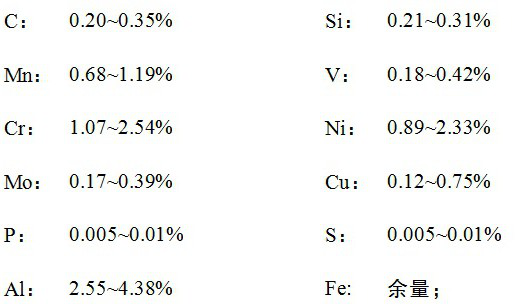

High-speed train brake disc material with stable friction coefficient and preparation method thereof

ActiveCN112159930BImprove friction performanceImprove stabilityTransportation and packagingMetal-working apparatusBrakePhysics

Owner:NANJING INST OF TECH

Low-hydrogen electrode with favorable low-temperature impact toughness

ActiveCN102825399BImprove low temperature impact toughnessSimple welding processWelding/cutting media/materialsSoldering mediaFerrosiliconWeld seam

The invention provides a low-hydrogen electrode with favorable low-temperature impact toughness, wherein the electrode using corresponds to a top low-carbon steel H08A welding core of the requirement of GB / T3429-2002, and electrode medicine skin comprises the following components in percentage by weight: 35-45% of marble, 15-18% of fluorite, 4-8% of silicon micro powder, 4-8% of ferromanganese, 5-8% of ferrosilicon, 8-11% of ferrotitanium, 3-6% of rutile, 1-3% of mica, 6-10% of ferrous powder and 0.5-1.5% of magnesium powder, wherein the fluorite is characterized in that CaF2>=95%, SiO2<=4.5%, S<=0.020%, P<=0.030%, and 100% of meshes of granularity is 100 meshes of fluorite. According to the invention, through controlling the adding amount of fluorite and controlling the fluorite granularity 100% of 100 meshes, the obtained low-hydrogen electrode has good welding process performance, and the welding seam tissue low-temperature brittleness is lowered obviously.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

Low-temperature steel bar and its production method

ActiveCN113186466BAchieve performance requirementsLow production costProcess efficiency improvementChemical compositionRebar

The invention discloses a low-temperature steel bar and a production method thereof, the chemical composition of which is calculated by mass percentage: Ni 0.8-0.9%, Mn 1.6-1.7%, Si 0.3-0.4%, C 0.04-0.08%, Al 0.01-0.02 %, P≤0.007%, S≤0.004%, O≤0.002%, N≤0.003%, As≤0.005%, H≤0.0002%, and the rest are Fe and unavoidable impurities. The production methods include KR molten iron pretreatment, Converter smelting, LF furnace refining, RH furnace refining, continuous casting and rolling. The invention completes the composition design and mass production of the low-temperature steel bar at a relatively low cost, and achieves the effects of strictly controlling impurity elements, inclusions and surface quality, and reducing low-temperature brittleness.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +1

High-viscosity asphalt and preparation method thereof

InactiveCN103421330BReduce low temperature brittlenessReduce manufacturing costBuilding insulationsEpoxySlag

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

A kind of copper alloy and its preparation method and application

ActiveCN107541613BHigh strengthImprove mechanical propertiesCoupling contact membersHigh intensityTitanium

The invention relates to a copper alloy material and a preparation method and application thereof. The copper alloy material comprises, by weight, 0.2-0.8 part of lead, 0.5-1.2 parts of nickel, 0.01-0.2 part of phosphorus, 0.01-0.5 part of titanium, 0.05-0.5 part of stannum, and 96.7-98.8 parts of copper. The copper content of the copper alloy material is greater than 97%, methods of aging strengthening, deformation strengthening, microelement alloying strengthening are comprehensively adopted, and the alloy material with high strength and high electric conduction is obtained. The alloy has nomagnetism and no low-temperature brittleness, the abrasion resistance is high, the corrosion resistance is high, sparks does not occur by impacting, requirements of copper alloy used for high-power connectors in industries such as transportation, aerospace and communications are met; and the alloy is easy to turn and applicable for high-speed automatic lathe machining.

Owner:沈阳慧坤新材料科技有限公司

A long-lasting asphalt pavement anti-skid wear layer

ActiveCN111018408BExtended service lifeSimple processIn situ pavingsBridge structural detailsStructural engineeringRoad surface

The invention relates to a permanent asphalt pavement anti-skid wear layer, comprising: high-performance aggregate, ordinary aggregate, and asphalt mixture; wherein, the polishing value of the high-performance aggregate is ≥ 50, and the wear value is 13-18%. ; The polishing value of the common aggregate is >42 and <50, and the abrasion value meets the specification requirements. The present invention blends high-performance aggregates and ordinary aggregates, and the ordinary aggregates and high-performance aggregates have a tight intercalation force, which increases the overall skid resistance of the road surface. As the use time increases, the performance of the high-performance aggregates The polishing value remains almost unchanged, and the performance indicators measured on the road surface, such as the swing value and the depth of the structure, have little attenuation change. The anti-slip performance of the road surface is extended, the driving safety is greatly improved, and the durability is also improved.

Owner:SHANDONG TRANSPORTATION INST +2

Cold resistant rubber part for pneumatic hydraulic system

The invention provides a cold resistant rubber part for a pneumatic hydraulic system. The rubber raw material of the cold resistant rubber part comprises the following components in parts by weight: 100-140 parts of No.1 natural rubber, 20-40 parts of 9000 type butadiene rubber, 0.5-0.7 part of sulphur, 20-30 parts of zinc oxide, 2-3 parts of antiager NBC (the Chinese name is N,N-dibutyl dithiocarbamate nickelous formate), 30-50 parts of FEF330 carbon black (the Chinese name is fast extruding furnace black), 1.5-2 parts of stearic acid, 1.5-2 parts of paraffin, 10-12 parts of channel black, 70-90 parts of calcium carbonate, 1.5-2 parts of vaseline, 1-1.2 parts of accelerant TT (the Chinese name is tetramethyl thiuram disulfide, and the molecular formula is C6H12N2S4 ), and 1.5-2 parts of antiager D (the Chinese name is N-phenyl-2-naphthylamine, and the molecular formula is C16H13N). As non-polar rubber is adopted in a rubber formula and the usage amount of a plasticizer is increased, the free movement ability of a macromolecular chain is increased, thus the cold brittleness of the rubber is reduced.

Owner:XIAN ZHITAI RUBBER & PLASTIC IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com