A long-lasting asphalt pavement anti-skid wear layer

A kind of asphalt pavement, long-term technology, applied in the direction of cohesive pavement paved on site, roads, roads, etc., can solve the problems of reduced adhesion of aggregate surface, increased surface structure depth, peeling of asphalt and aggregate, etc., to achieve improvement Driving conditions, low temperature brittleness, and convenient construction

Active Publication Date: 2022-04-01

SHANDONG TRANSPORTATION INST +2

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] With the increase of asphalt pavement use time, the surface of some common aggregates (such as limestone) will be polished, and its skid resistance will decrease, which will affect driving safety

In addition, after long-term action by vehicles, the surface adhesion of ordinary aggregates will be greatly reduced, which will cause asphalt and aggregates to peel off, resulting in road surface diseases such as rutting, oil flooding, and water damage.

[0004] Now most of the common aggregates are used as fillers, so that the asphalt pavement will reduce the skid resistance of the pavement under the long-term vehicle load, increase the depth of the surface structure, and cause serious oil and water damage.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

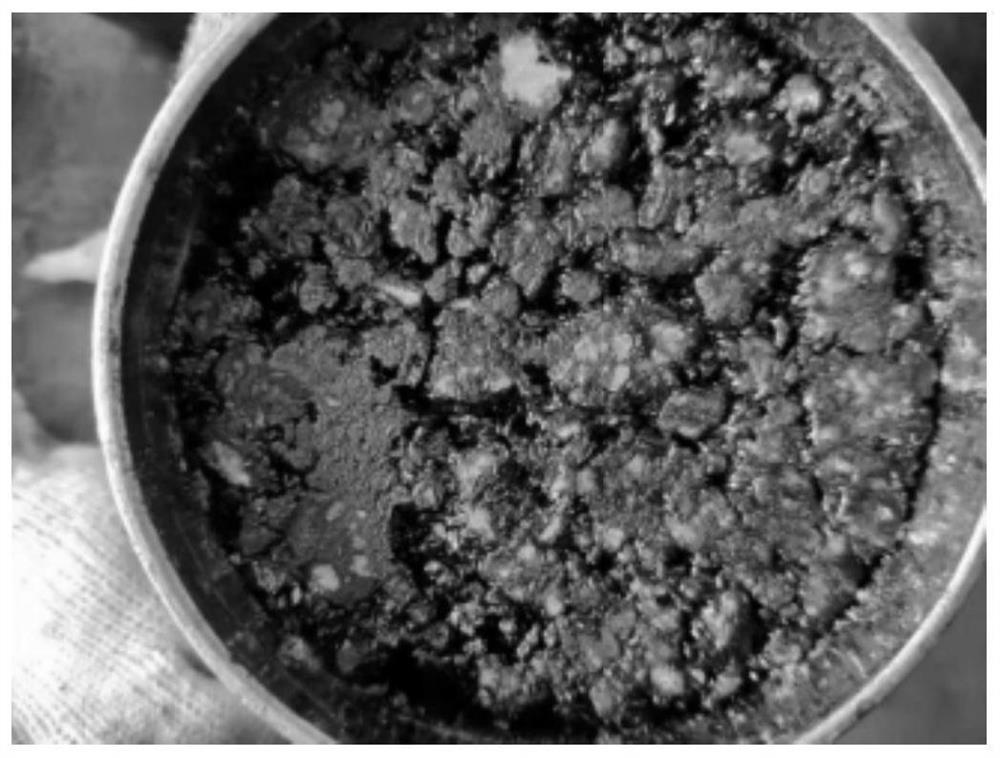

[0049] The steel slag from Taishan Iron and Steel Plant is used to replace the coarse aggregate (basalt), and the substitution ratio is 45% of the volume of the coarse aggregate (basalt).

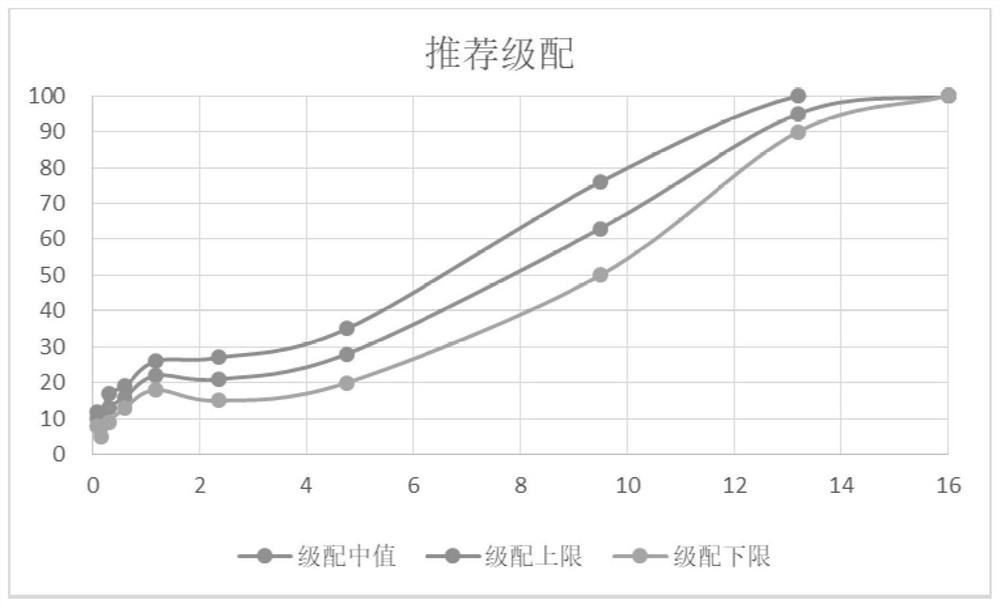

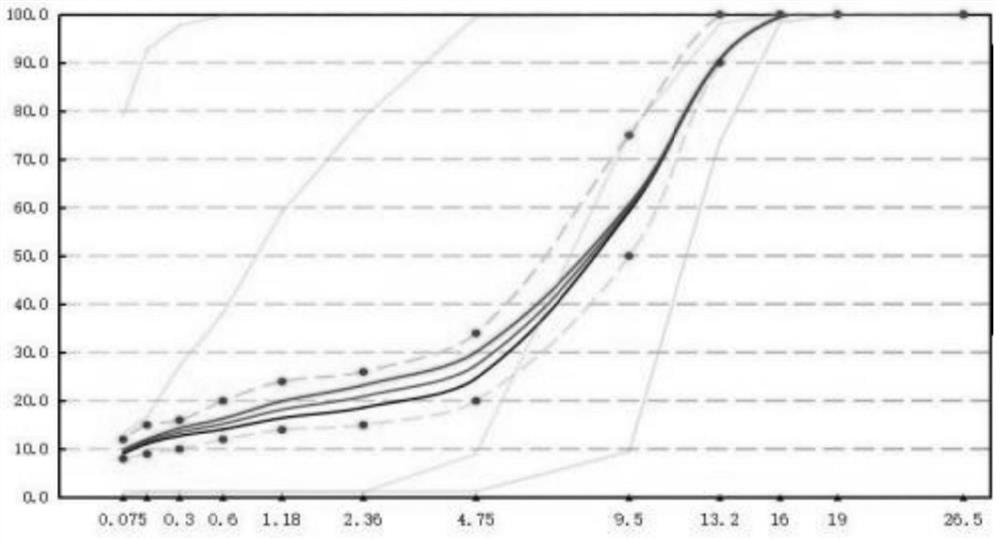

[0050] 1. Target mix design

[0051] 1 Steel slag raw material detection

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a permanent asphalt pavement anti-skid wear layer, comprising: high-performance aggregate, ordinary aggregate, and asphalt mixture; wherein, the polishing value of the high-performance aggregate is ≥ 50, and the wear value is 13-18%. ; The polishing value of the common aggregate is >42 and <50, and the abrasion value meets the specification requirements. The present invention blends high-performance aggregates and ordinary aggregates, and the ordinary aggregates and high-performance aggregates have a tight intercalation force, which increases the overall skid resistance of the road surface. As the use time increases, the performance of the high-performance aggregates The polishing value remains almost unchanged, and the performance indicators measured on the road surface, such as the swing value and the depth of the structure, have little attenuation change. The anti-slip performance of the road surface is extended, the driving safety is greatly improved, and the durability is also improved.

Description

technical field [0001] The invention belongs to the field of pavement anti-skid and wear layers, in particular to a permanent asphalt pavement anti-skid wear layer. Background technique [0002] The information disclosed in this background section is only intended to increase the understanding of the general background of the present invention, and is not necessarily taken as an acknowledgment or any form of suggestion that the information constitutes the prior art already known to those skilled in the art. [0003] With the increase of asphalt pavement use time, the surface of some common aggregates (such as limestone) will be polished, and its skid resistance will decrease, which will affect driving safety. In addition, after long-term action by vehicles, the surface adhesion of ordinary aggregates will be greatly reduced, which will cause asphalt and aggregates to peel off, resulting in road surface diseases such as rutting, oil flooding, and water damage. [0004] At pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B26/26E01C7/18E01D19/12C04B111/20C04B111/52

CPCC04B26/26E01C7/18E01D19/125C04B2111/0075C04B2111/00362C04B2111/20C04B2111/2038C04B2111/52C04B14/14C04B18/142C04B18/141

Inventor 韦金城段叔瑜安平闫翔鹏陈兴静张正超王光勇丁海洋徐希忠刘卓雨张晓萌吴文娟夏雨孙岳李广

Owner SHANDONG TRANSPORTATION INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com