Cold resistant rubber part for pneumatic hydraulic system

A pneumatic-hydraulic, low-temperature-resistant technology, applied in the field of rubber, can solve problems such as slow rising speed and reduced work efficiency, and achieve the effects of reducing low-temperature brittleness, increasing the use of plasticizers, and improving free movement ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 concrete production steps are as follows:

[0021] Compound production

[0022] (1) Weigh various ingredients according to the specific formula ratio, and its rubber raw material components and weight ratio are: 1 # 100 parts of natural rubber, 20 parts of 9000 type butadiene rubber, 0.5 parts of sulfur, 20 parts of zinc oxide, 2 parts of anti-aging agent NBC (Chinese name: N, N-dibutyl dithiocarbamate nickel), FEF330 carbon black ( Chinese name: quick press carbon black) 30 parts, stearic acid 1.5 parts, paraffin wax 1.5 parts, channel black 10 parts, calcium carbonate 70 parts, vaseline 1.5 parts, accelerator TT (Chinese name: tetramethyl disulfide Thiuram, molecular formula: C 6 h 12 N 2 S 4 ) 1 part, antioxidant D (Chinese name: N-phenyl-2-naphthylamine, molecular formula: C 16 h 13 N) 1.5 parts. The weight unit of each part in the component is determined according to production needs, such as 1 kilogram per part.

[0023] ⑵ According to the ra...

Embodiment 2

[0031] The production process of embodiment 2 is identical with embodiment 1, and difference is that the rubber material component ratio is different, and the rubber material composition of embodiment 2 is as follows by weight component: 1 #120 parts of natural rubber, 30 parts of 9000 type butadiene rubber, 0.6 parts of sulfur, 25 parts of zinc oxide, 2.3 parts of antioxidant NBC (Chinese name: N, N-dibutyldithiocarbamate nickel), FEF330 carbon black ( Chinese name: quick press carbon black) 40 parts, stearic acid 1.7 parts, paraffin wax 1.7 parts, channel black 11 parts, calcium carbonate 80 parts, vaseline 1.7 parts, accelerator TT (Chinese name: tetramethyl disulfide Thiuram, molecular formula: C 6 h 12 N 2 S 4 ) 1.1 parts, antioxidant D (Chinese name: N-phenyl-2-naphthylamine, molecular formula: C 16 h 13 N) 1.7 parts.

Embodiment 3

[0032] Embodiment 3 production process is identical with embodiment 1, and difference is that rubber material weight component ratio is different, and the rubber material composition of embodiment 3 is calculated as follows by component: 1 # 140 parts of natural rubber, 40 parts of 9000 type butadiene rubber, 0.7 parts of sulfur, 30 parts of zinc oxide, 3 parts of anti-aging agent NBC (Chinese name: N, N-dibutyl dithiocarbamate nickel), FEF330 carbon black ( Chinese name: quick press carbon black) 50 parts, stearic acid 2 parts, paraffin wax 2 parts, channel black 12 parts, calcium carbonate 90 parts, vaseline 2 parts, accelerator TT (Chinese name: tetramethyl disulfide Thiuram, molecular formula: C 6 h 12 N 2 S 4 ) 1.2 parts, anti-aging agent D (Chinese name: N-phenyl-2-naphthylamine, molecular formula: C 16 h 13 N) 2 parts.

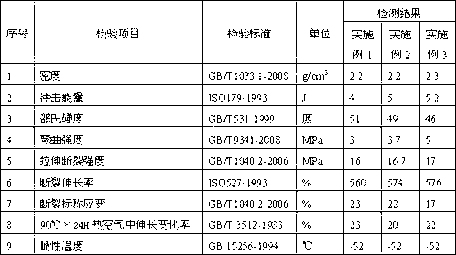

[0033] Performance comparison of three kinds of embodiments

[0034]

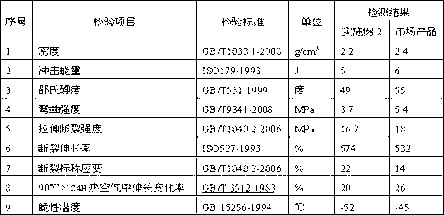

[0035] Embodiment 2 formula compares with current market product

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com