Low-temperature steel bar and its production method

A technology of low temperature steel bar and production method, applied in the field of iron and steel materials, can solve problems such as unfavorable market promotion, lack of rationality, increase in production cost, etc., and achieve the effects of reducing production cost, excellent performance, and reducing low temperature brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

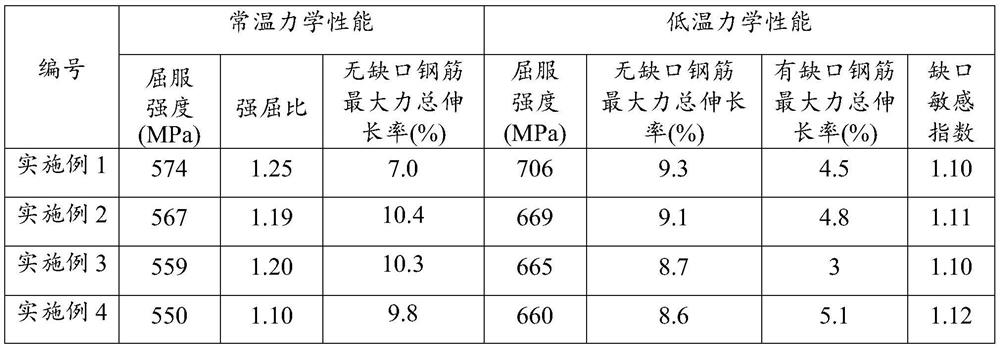

Examples

Embodiment Construction

[0022] As mentioned in the background technology, in the prior art, due to the addition of a large amount of alloy elements, the production cost is greatly increased, which is not conducive to market promotion, and the iron and steel smelting and rolling process methods used also lack certain rationality. Based on this, the present invention aims to Reduce the use of alloying elements, reduce the content of inclusions in low-temperature steel bars, strictly control the surface quality, reduce the low-temperature brittleness of steel bars, and obtain better impact resistance.

[0023] Specifically, in one embodiment of the present invention, the chemical composition of the low-temperature steel bar is: Ni 0.8-0.9%, Mn 1.6-1.7%, Si 0.3-0.4%, C 0.04-0.08%, Al 0.01~0.02%, P≤0.007%, S≤0.004%, O≤0.002%, N≤0.003%, As≤0.005%, H≤0.0002%, and the rest are Fe and unavoidable impurities.

[0024] Based on a large amount of experimental data, each chemical composition in the low-temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strong bend ratio | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com