High-strength underwater structure adhesive and preparation method thereof

An underwater structure, high-strength technology, applied in the direction of adhesives, epoxy resin glue, non-polymer adhesive additives, etc., can solve the problems of easy dispersion, loss of activity, and decreased ability to open the ring, and achieve enhanced cold and heat resistance Alternating performance, increasing heat distortion temperature, and reducing low temperature brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

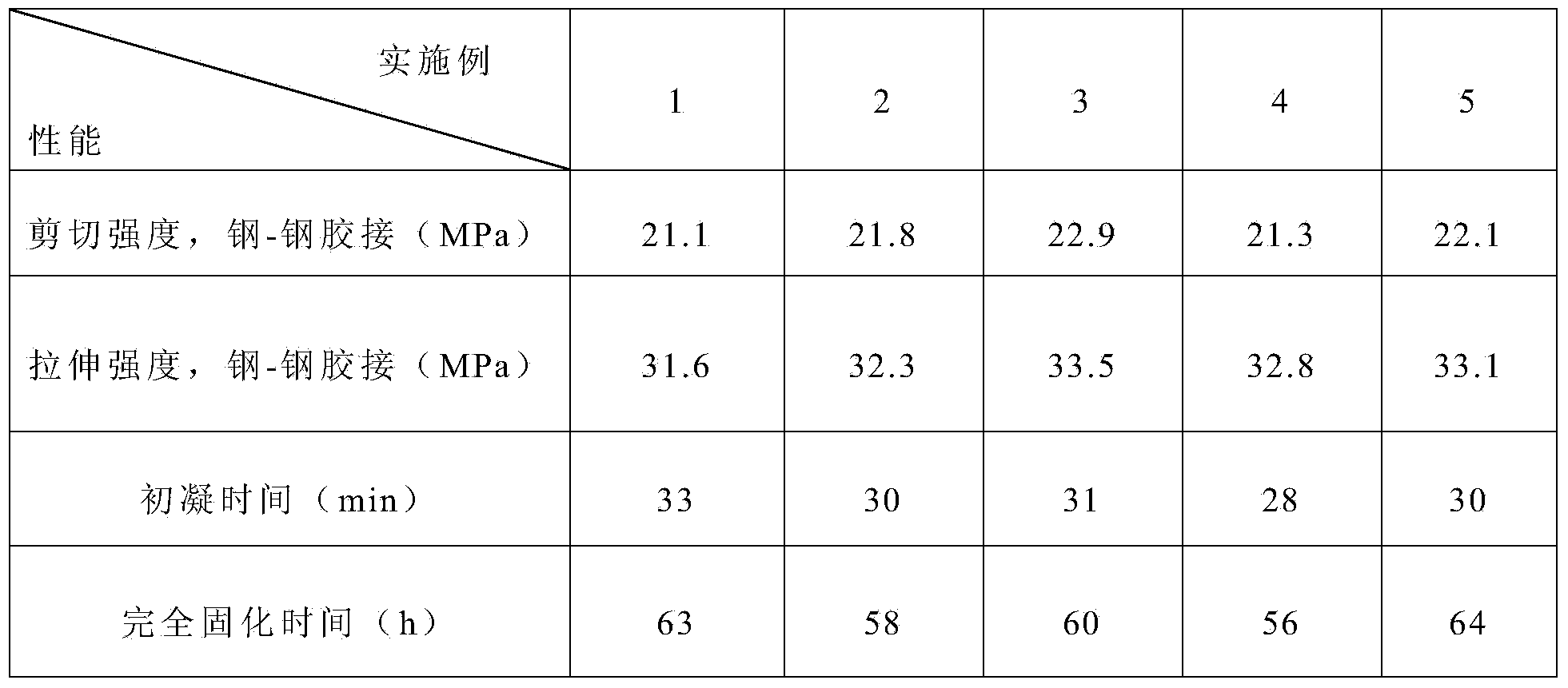

Examples

Embodiment 1

[0029] A high-strength underwater structural adhesive, which is formed by mixing component A and component B at a weight ratio of 1:1, wherein,

[0030] Component A includes by weight:

[0031] Take 44 parts of commercially available HH-0802, 62 parts of bisphenol A epoxy resin, and 4 parts of nano-silica;

[0032] Part B includes by weight:

[0033] 50 parts of commercially available 1085 underwater epoxy curing agent, 1 part of triethanolamine, 3 parts of 3-triethoxysilyl-1-propylamine, 3 parts of OP-10, 1 part of nano-silica, 700-800 Mesh silicon powder 54 parts.

Embodiment 2

[0035] A high-strength underwater structural adhesive, which is formed by mixing component A and component B at a weight ratio of 1:1, wherein,

[0036] Component A includes by weight:

[0037] Take 44 parts of HH-0801 produced by Zhuzhou Tongxin Industrial Development Co., Ltd., 60 parts of bisphenol A epoxy resin, and 6 parts of activated bentonite;

[0038] Part B includes by weight:

[0039] 50 parts of 1085 underwater epoxy curing agent produced by Changsha Puzhao Biochemical Technology Co., Ltd., 2 parts of DMP30 accelerator, 1 part of γ-glycidyl etheroxypropyl trimethoxysilane, 4 parts of OP-10 sizing agent, and 1 part of activated bentonite Parts, 50 parts of 400-500 mesh silica powder filler.

Embodiment 3

[0041] A high-strength underwater structural adhesive, which is formed by mixing component A and component B at a weight ratio of 1:1, wherein,

[0042] Component A includes by weight:

[0043] Zhuzhou Tongxin Industrial Development Co., Ltd. produced 48 parts of HH-0803, 57 parts of bisphenol A epoxy resin, and 5 parts of nano-silica;

[0044] Part B includes by weight:

[0045] 55 parts of 1085 underwater epoxy curing agent produced by Changsha Puzhao Biochemical Technology Co., Ltd., 1.5 parts of K54 accelerator, 1 part of 3-triethoxysilyl-1-propylamine, 2 parts of OP-10 wetting agent, nanometer two 2 parts of silicon oxide, 53 parts of 700-800 mesh silicon powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com