Super-viscose fiber wearing layer cold-mixed asphalt mixture and preventive maintenance method of asphalt pavement

A technology for cold mix asphalt and asphalt pavement, which is applied in the field of cold mix asphalt mixture of super viscous fiber wear layer and preventive maintenance of asphalt pavement, can solve the problems of inability to repair local diseases of the pavement, the scope of application of the process is small, and the durability of the pavement is low. Achieve high water resistance, fast construction, and improve adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The engineering summary of the application of this embodiment is: a road section in a certain country is a two-way four-lane first-class highway, and the design speed is 100Km / h. The original pavement is epoxy asphalt horseshoe grease macadam mixture SMA-13, the overall pavement structure is complete, and the main disease is network cracks with a width of 1-5mm. The preventive maintenance test of the super-viscous fiber wearing layer in this embodiment is selected to be implemented on this road section, and the designed thickness of the super-viscous fiber wearing layer is 11 mm.

[0026] 1), using special equipment for super viscous fiber wearing course to prepare super viscous fiber wearing course cold mix asphalt mixture;

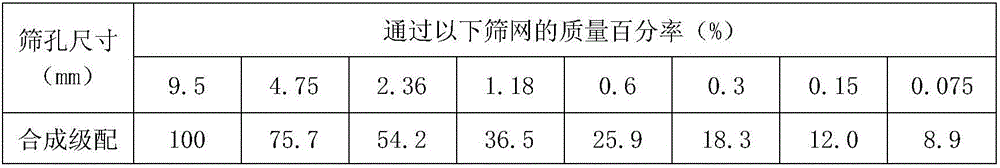

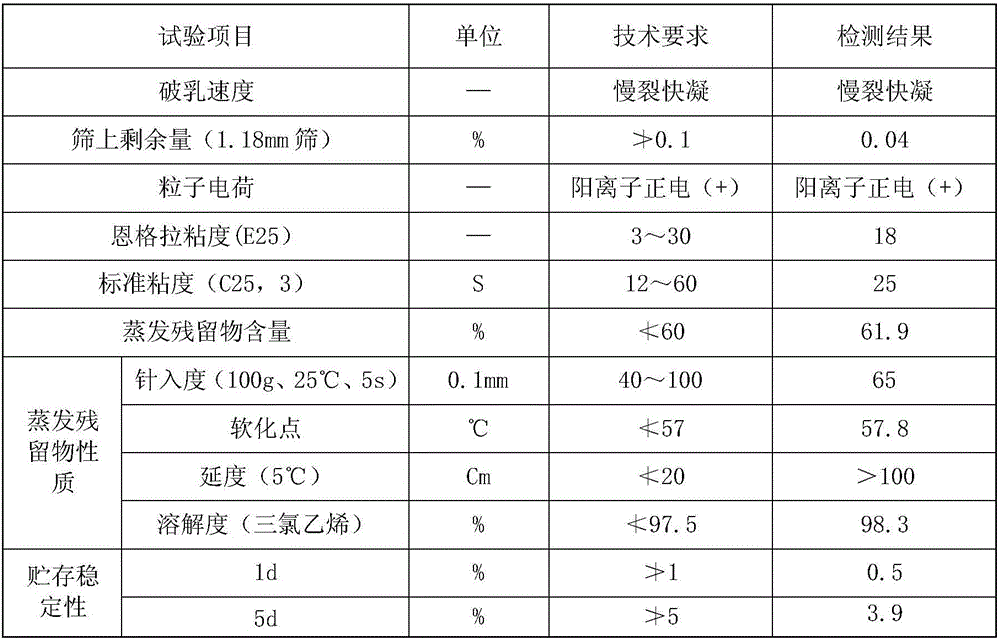

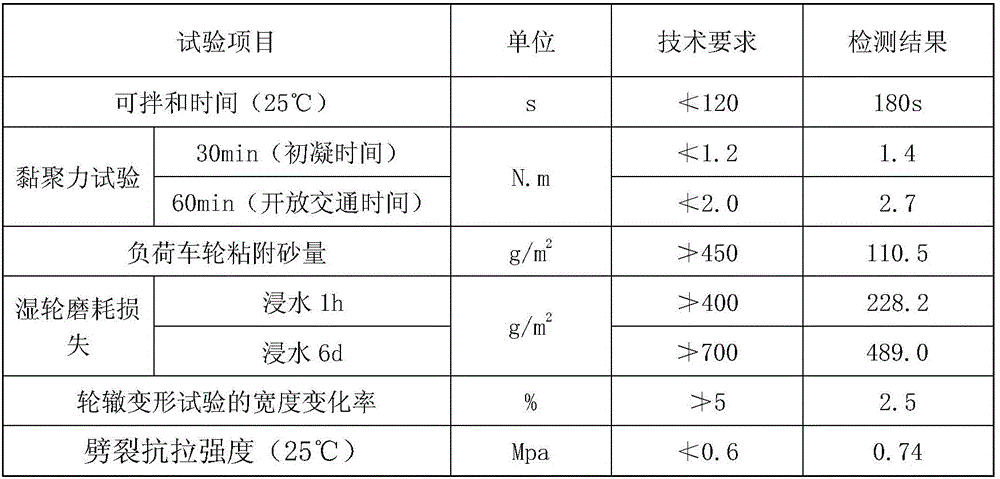

[0027] The superviscosity fiber wear layer mixture used in this step is composed of aggregate, polymer modified emulsified asphalt, glass fiber, filler and water. The aggregate is made of basalt coarse aggregate produced by Shangpei Town Stone Fac...

Embodiment 2

[0046] The engineering summary of the application of this embodiment is: a road section in a certain province is a fourth-grade road with a road surface width of 6.5m and a design speed of 60Km / h. The original pavement is ordinary asphalt concrete AC-13, and the overall pavement structure is complete. The main defects are network cracks with a width of 1-5 mm and slight ruts with a depth of 5 mm. In this embodiment, the preventive maintenance test of the super-viscous fiber wearing layer is selected to be implemented on this road section, and the designed thickness of the super-viscous fiber wearing layer is 8mm.

[0047] 1), using special equipment for super viscous fiber wearing course to prepare super viscous fiber wearing course cold mix asphalt mixture;

[0048] The superviscosity fiber wear layer mixture used in this step is composed of aggregates, polymer modified emulsified asphalt, glass fibers, fillers and water. The aggregates are basalt coarse aggregates produced b...

Embodiment 3

[0067] The engineering summary of this embodiment is: a road section in a certain province is a third-class road with a road width of 7.5m and a design speed of 60Km / h. The original pavement is ordinary asphalt concrete AC-13, and the overall pavement structure is complete. The main diseases are asphalt film shedding, poor skid resistance, slight water damage and slight rutting with a depth of 5mm. In this embodiment, the preventive maintenance test of the super-viscous fiber wearing layer is selected to be implemented in this road section, and the designed thickness of the super-viscous fiber wearing layer is 14 mm.

[0068] 1), using special equipment for super viscous fiber wearing course to prepare super viscous fiber wearing course cold mix asphalt mixture;

[0069] The super viscous fiber wearing layer mixture used in this step is composed of aggregate, polymer modified emulsified asphalt, glass fiber, filler and water. The mixed aggregates (4.75mm-9.5mm) and fine aggre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com