High strength IF steel with excellent corrosion resistance and manufacturing method thereof

A manufacturing method and high-strength technology, applied in the field of high-strength IF steel and its manufacturing, can solve the problems of high-strength cold-rolled sheets such as low corrosion resistance, easy to rust, and users cannot use them normally, and achieve high corrosion resistance and mechanical strength. good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

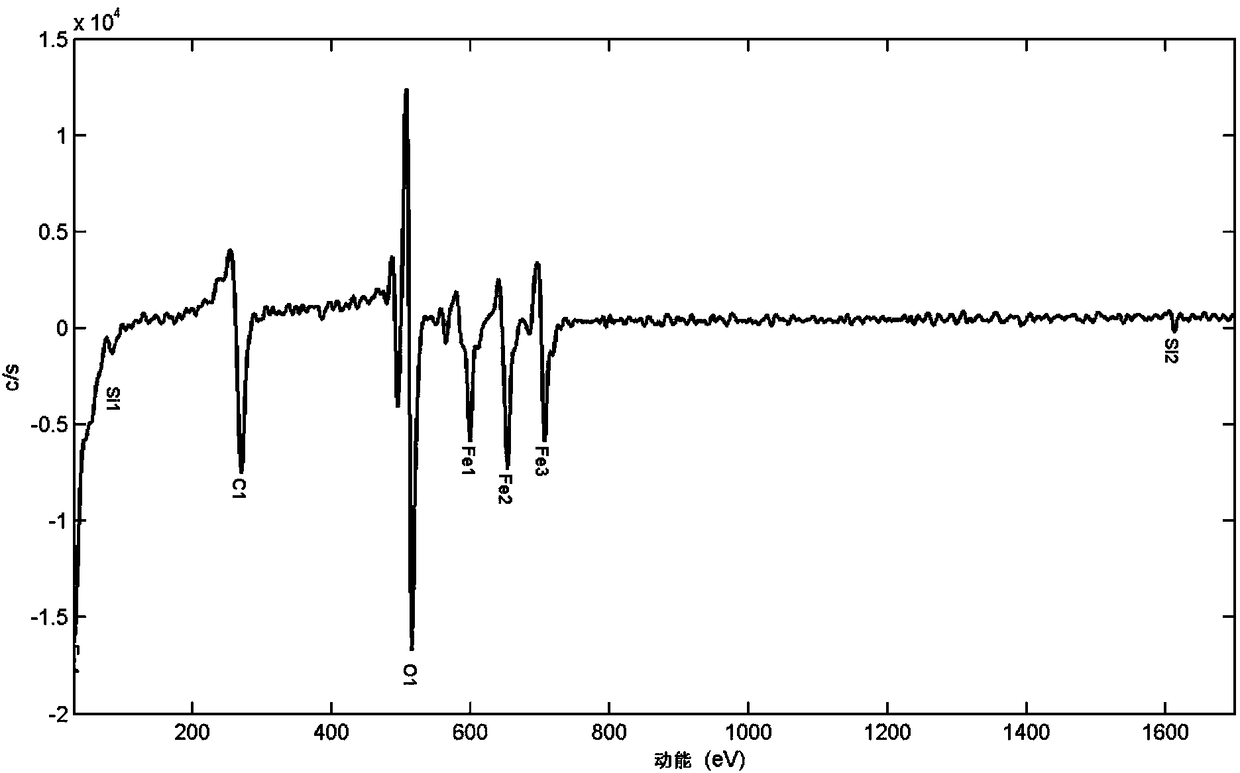

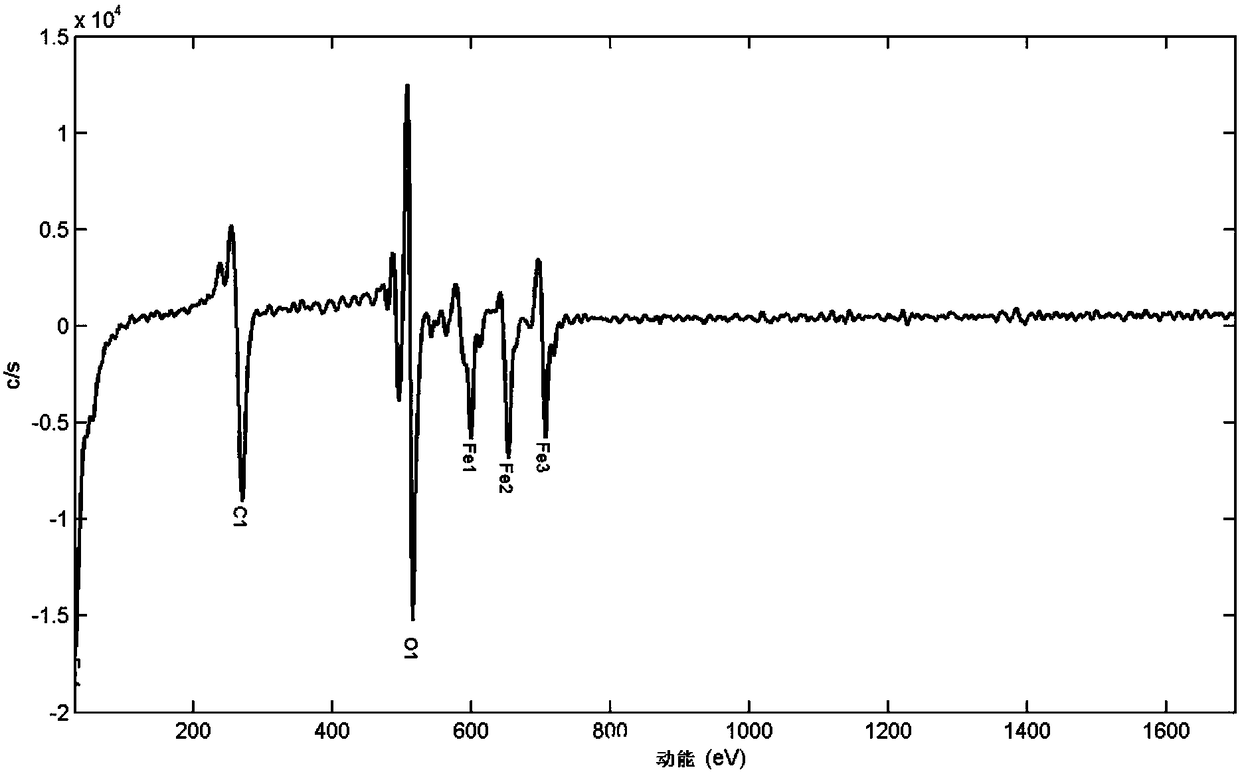

Image

Examples

Embodiment 1-6

[0036] The high strength IF steel of embodiment 1-6 of the present invention adopts following steps to make:

[0037] (1) Smelting and casting: carry out smelting and casting according to the mass ratio of each chemical element listed in Table 1 to obtain the continuous casting slab;

[0038] (2) Hot rolling: put the continuous casting slab obtained in step (1) into a heating furnace for heating, the temperature of the furnace is 1150-1250°C, and then rolling, the final rolling temperature is controlled at 750-960°C, after When the cooled steel plate reaches the coiler, the temperature is controlled at 600-740°C;

[0039] (3) Annealing: heat the steel plate to 700-900°C for 30-120s, then cool to 600-750°C within 10-35s, control the annealing speed to 100-350m / s; control the dew point of the atmosphere in the annealing furnace It is -30~0℃.

[0040] Table 1 lists the mass percentage ratio of each chemical element in the high-strength IF steel of Examples 1-6 and the existing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com