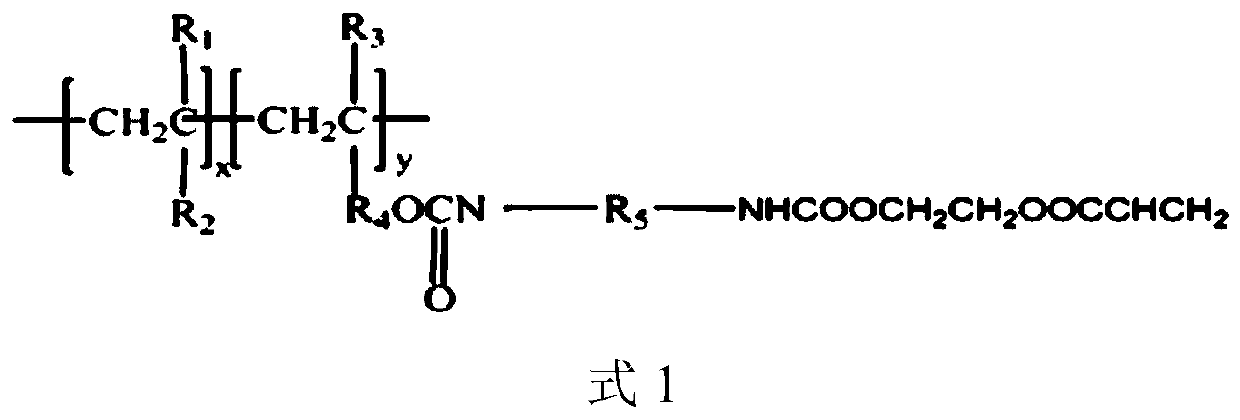

Hydroxyl-terminated polyurethane methacrylic resin as well as preparation method and application thereof

A technology of polyurethane methacrylic acid and hydroxyacrylate, which is applied in the field of resin, can solve the problems of poor curing performance, severe aging performance decay of waterproof coating, poor resistance to hot melt, etc., and achieve excellent waterproof and anti-corrosion performance, extended durability, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

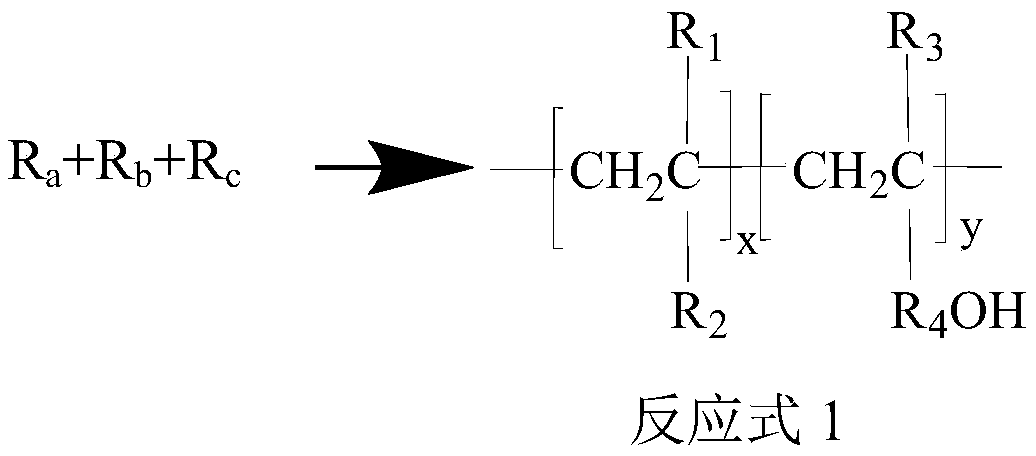

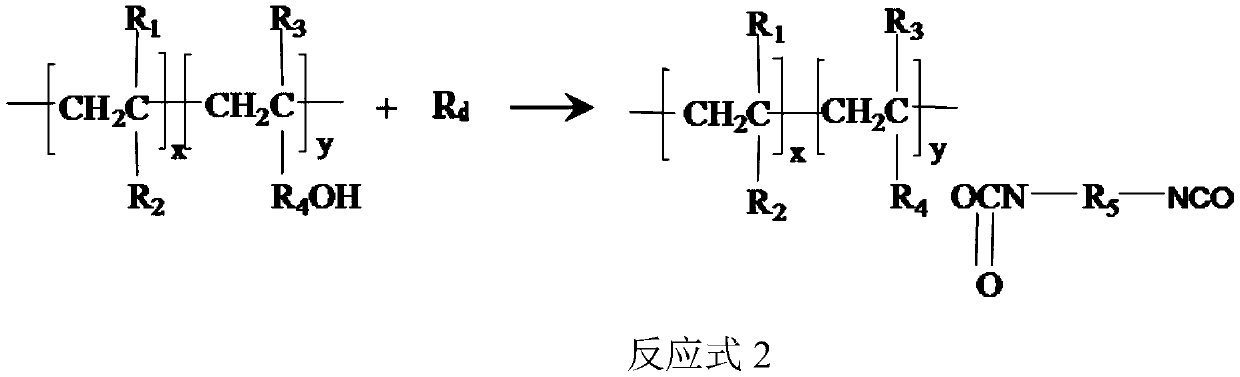

Method used

Image

Examples

Embodiment 1

[0050] The specific preparation process of the hydroxyl-terminated polyurethane methacrylic resin of the present embodiment is as follows:

[0051] a. Mix butyl acrylate and 2-ethylhexyl acrylate according to the mass ratio of 1:1 to obtain 312g mixture, add 4g benzoyl peroxide initiator to dissolve evenly, heat to 88°C, pass N 2 Protection, first slowly add 72g of acrylic acid dropwise while stirring, continue to slowly add 116g of hydroxyethyl acrylate dropwise after the addition is complete, continue to react for 0.5h until the viscosity of the mixture increases but can flow smoothly, then cool down to 45°C and continue to react for 20h , until the material reacts completely to gel, then cool the gel mixture naturally and then dry it in vacuum, mix the dried mixture with methyl methacrylate solution according to the mass ratio of 1:1 and dissolve completely to obtain the hydroxyacrylate body Copolymer solution;

[0052] b. Add isophorone diisocyanate into the reaction flas...

Embodiment 2

[0058] The difference between this embodiment and embodiment 1 is as follows:

[0059] In the specific process of preparing hydroxyl-terminated polyurethane methacrylic resin: ①In step a, the initiator is dipentyl peroxide, the amount of hydroxyethyl acrylate added is 130g and the temperature is lowered to 40°C; ②In step b, isoflurane ketone diisocyanate is replaced by dicyclohexylmethane diisocyanate; 3. in the step c, the polyurethane methacrylic resin prepolymer and hydroxyethyl acrylate are reacted according to the mass ratio of 1:2 to 1:1.5. .

[0060] In the specific process of preparing waterproof coatings: 140g of hydroxyl-terminated polyurethane methacrylic resin was replaced by 160g, 56g of butyl methacrylate was replaced by 36g of 2-ethylhexyl acrylate, and the accelerator was N-methyl-N-hydroxy Ethyl-p-toluidine and drying aid are polyamide waxes.

[0061] Except above difference, all the other are identical with embodiment 1.

Embodiment 3

[0063] The difference between this embodiment and embodiment 1 is as follows:

[0064] In the specific process of preparing hydroxyl-terminated polyurethane methacrylic resin: ① in step a, butyl acrylate is replaced by butyl methacrylate, the amount of the mixture is 338g, 72g acrylic acid is replaced by 86g methacrylic acid and hydroxyethyl acrylate is replaced by hydroxypropyl acrylate; 2. isophorone diisocyanate is replaced by the mixture of dicyclohexylmethane diisocyanate and methylene diphenyl diisocyanate in the step b; 3. in the step b and c, the catalyst is stannous octoate and the polymerization inhibitor is 0.002% hydroquinone.

[0065] In the specific process of preparing waterproof coatings: 140g of hydroxyl-terminated polyurethane methacrylic resin is replaced by 150g, 56g of butyl methacrylate is replaced by a mixture of 46g of methyl methacrylate and butyl acrylate, and the accelerator is N,N-di Methyl-p-toluidine and drying aid are cellulose acetate butyrate....

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com