High and low temperature resistant plastic bottle cap and manufacturing process thereof

A high and low temperature resistant, plastic technology, applied in the field of plastic bottle caps and its manufacturing process, can solve the problems of low temperature resistance, easy deformation, toughness, poor impact resistance, etc., to improve high and low temperature resistance, enhance toughness and resistance Impact, improve the effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

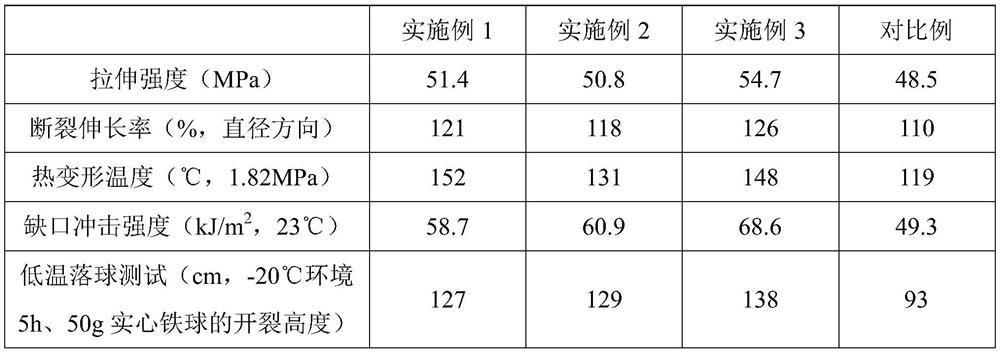

[0032] This example relates to a high and low temperature resistant plastic bottle cap material, which includes the following components in parts by mass: 65 parts of high-density polyethylene, 12 parts of temperature-resistant modified masterbatch, and 6 parts of low molecular weight branched polyethylene , 3 parts of maleic anhydride grafted polypropylene, 2 parts of pentadiene, 3 parts of nano-calcium carbonate, 1 part of antioxidant, 0.5 part of HDPE-GMAH compatibilizer;

[0033] The temperature-resistant modified masterbatch is composed of low-density polyethylene, a temperature-resistant modifier and nano-silica, and its mass ratio is 50:35:2;

[0034] The density of the high-density polyethylene is 0.935g / cm 3 , the melt flow rate is 15g / 10min;

[0035] The low molecular weight branched polyethylene is a copolymer of ethylene and hexene, with a weight average molecular weight of 5910, a dispersion coefficient of 1.1, and a branched content of 3.4 branches per 1000 main...

Embodiment 2

[0043] This embodiment relates to a high and low temperature resistant plastic bottle cap material, which is the same as in Embodiment 1, except that the temperature-resistant modifier is a second modifier, and the preparation method of the second modifier includes the following steps :

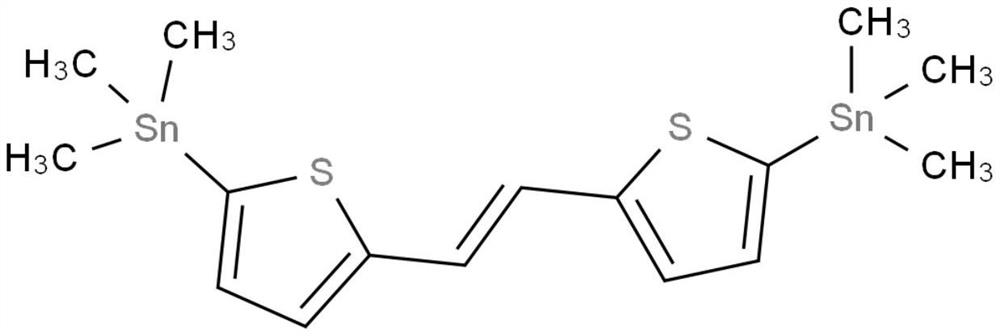

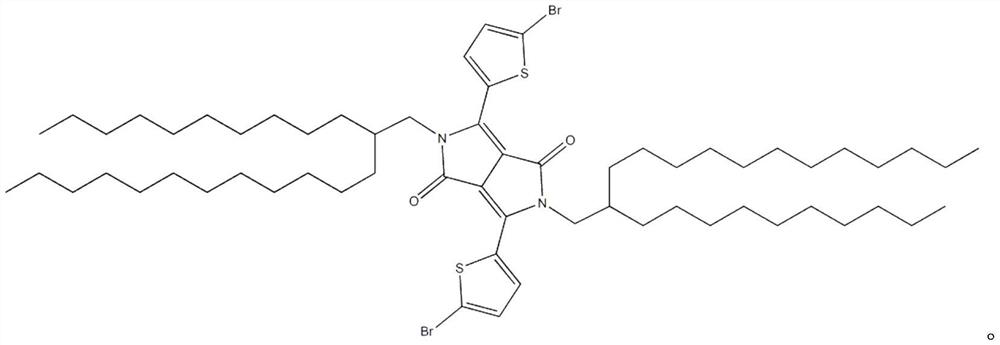

[0044] Weigh 1,2-bis(5-(trimethyltinyl)thiophen-2-yl)ethylene (CAS No.: 477789-30-3) and 3,6-bis(5-bromothiophen-2-yl) )-2,5-bis(2-decyltetradecyl)-2,5-dihydropyrrole-1,4-dione (provided by Jiangsu Gia Biotechnology Co., Ltd.) and dissolved in dry toluene solution , after mixing well, add tridibenzylideneacetone dipalladium and toluene phosphoric acid, mix well again and close the reaction system, heat and stir the reaction under microwave conditions, microwave power 300-500W, heating temperature 100-200°C, stirring reaction time In 50-60 minutes, after the reaction is completed, add the chlorobenzene solution of trimethyl(phenyl)tin, fully stir and cool, add trichlorethylene to dilute after...

Embodiment 3

[0047] This example relates to a high and low temperature resistant plastic bottle cap material, which includes the following components in parts by mass: 65 parts of high-density polyethylene, 12 parts of temperature-resistant modified masterbatch, and 6 parts of low molecular weight branched polyethylene , 3 parts of maleic anhydride grafted polypropylene, 2 parts of pentadiene, 3 parts of nano-calcium carbonate, 1 part of antioxidant, 0.5 part of HDPE-GMAH compatibilizer;

[0048] The temperature-resistant modified masterbatch is composed of low-density polyethylene, a temperature-resistant modifier and nano-silica, and its mass ratio is 50:35:2;

[0049] The density of the high-density polyethylene is 0.935g / cm 3 , the melt flow rate is 15g / 10min;

[0050] The low molecular weight branched polyethylene is a copolymer of ethylene and hexene, with a weight average molecular weight of 5910, a dispersion coefficient of 1.1, and a branched content of 3.4 branches per 1000 main...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com