Rubber for low-temperature resistant rubber hose for refrigerator

A technology of low temperature resistance and refrigerator, applied in the rubber field, can solve the problems of poor low temperature performance and brittleness of rubber, and achieve the effect of increasing low temperature softener and reducing low temperature brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 Its rubber raw material proportioning is: 20 parts of 1# natural rubber, 80 parts of 1502 type styrene-butadiene rubbers, 0.9 part of sulfur, 4 parts of zinc oxides, 1 part of stearic acid, 60 parts of spray carbon blacks, ortho-dibutyl 15 parts of ester, NOBS accelerator (Chinese name: N-(oxyethylene)-2-benzothiazole sulfenamide, molecular formula: C 11 h 12 N 2 S 2 O) 2 parts, 4010 anti-aging agent (Chinese name: N-phenyl-N'-cyclohexyl-p-phenylenediamine, molecular formula: C15H18N2) 2 parts. The weight unit of each part in the component is determined according to production needs, such as 1 kilogram per part.

[0021] The specific production steps are as follows:

[0022] Compound production

[0023] ⑴ Weigh various ingredients according to the specific formula ratio;

[0024] (2) Add 20 parts of 1# natural rubber and 80 parts of 1502 type styrene-butadiene rubber to the rubber mixer and mix for 2 minutes. After mixing for 2 minutes, add 0.9 parts ...

Embodiment 2

[0032] The production process of embodiment 2 is identical with embodiment 1, and difference is that the rubber material component ratio is different, and the rubber material composition of embodiment 2 is calculated as follows by component: 1# natural rubber 30 parts, 1502 type styrene-butadiene rubber 100 parts , 1 part of sulfur, 5 parts of zinc oxide, 1.1 parts of stearic acid, 70 parts of spray carbon black, 20 parts of o-dibutyl ester, NOBS accelerator (Chinese name: N-(diethylene oxide)-2-benzo Thiazole sulfenamide, molecular formula: C 11 h 12 N 2 S 2 O) 3 parts, 4010 anti-aging agent (Chinese name: N-phenyl-N'-cyclohexyl-p-phenylenediamine, molecular formula: C15H18N2) 3 parts.

Embodiment 3

[0033] The production process of embodiment 3 is identical with embodiment 1, and difference is that the rubber material component ratio is different, and the rubber material composition of embodiment 3 is calculated as follows by component: 1# natural rubber 40 parts, 1502 type styrene-butadiene rubber 120 parts , 1.1 parts of sulfur, 6 parts of zinc oxide, 1.2 parts of stearic acid, 80 parts of spray carbon black, 25 parts of o-dibutyl ester, NOBS accelerator (Chinese name: N-(diethylene oxide)-2-benzo Thiazole sulfenamide, molecular formula: C 11 h 12 N 2 S 2 O) 4 parts, 4 parts of 4010 anti-aging agent (Chinese name: N-phenyl-N'-cyclohexyl-p-phenylenediamine, molecular formula: C15H18N2).

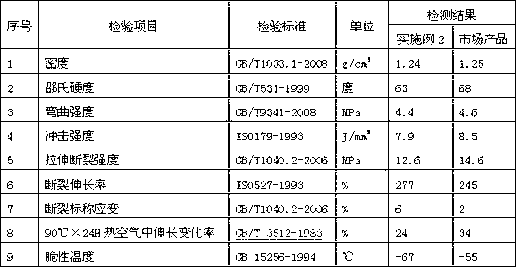

[0034] Performance comparison of three kinds of embodiments

[0035]

[0036] Embodiment 2 formula compares with current market product

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com