Construction process of colored pavement epoxy non-slip wearing layer structure

A construction process and a wear layer technology, which is applied in the construction process field of epoxy anti-skid wear layer structure of colored pavement, can solve the problems of inability to repair and form pavement diseases, complex construction process, easy aging and fading, etc., and achieves excellent thermal aging performance and construction. Simple process and the effect of improving driving conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with embodiment the present invention is further described in detail.

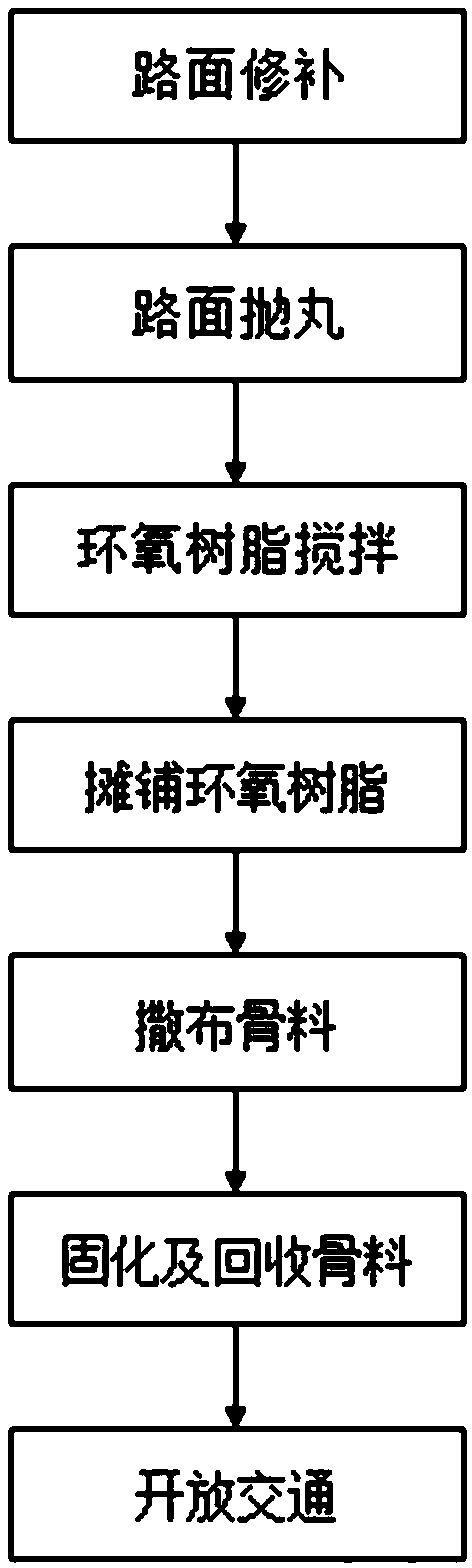

[0029] Such as figure 1 Shown, a kind of construction technology of epoxy antiskid wearing layer structure of colored pavement, comprises the following steps:

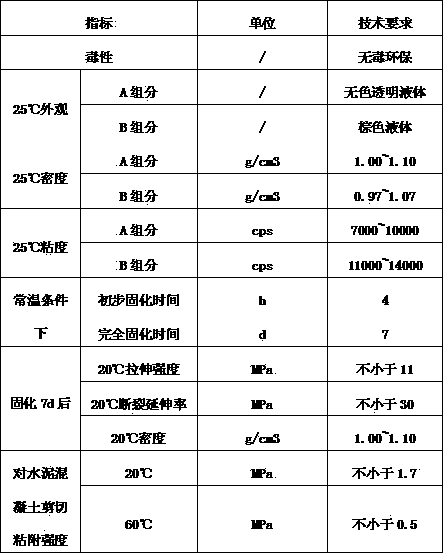

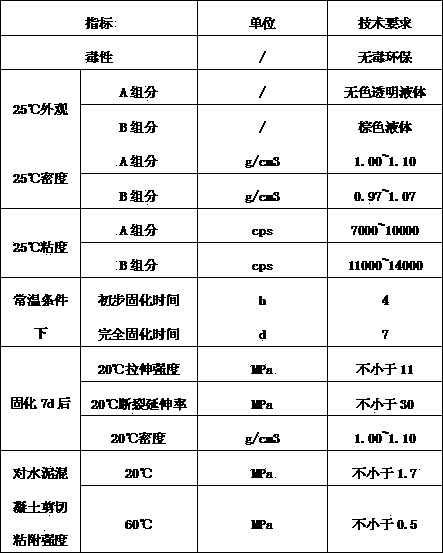

[0030] (1) Pavement repair: Find the damaged part on the road surface, delineate the damaged area, use a cutting machine to cut open the damaged area, remove the damaged pavement material, and form a neat groove. The groove depth must be strictly guaranteed, non-structural repair, The depth of slotting depends on the depth of damage to the road surface. For structural repairs, the depth of slotting depends on the depth of damage to the overall road. The depth of excavation on conventional roads is 2-20cm. The corners of the incision section are treated, and the incision is thoroughly dedusted with strong, dry, oil-free compressed air to ensure that there is no residue; the A and B two-component special epoxy resin is e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com