Track base without broken stones, and building method

A ballastless track and subgrade technology, which is applied to roads, tracks, and infrastructure engineering, can solve the problems of large total settlement and post-construction settlement, difficulty in controlling post-construction settlement, and difficult control of differential settlement, so as to reduce maintenance The effect of small workload, small cumulative deformation, and small track deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

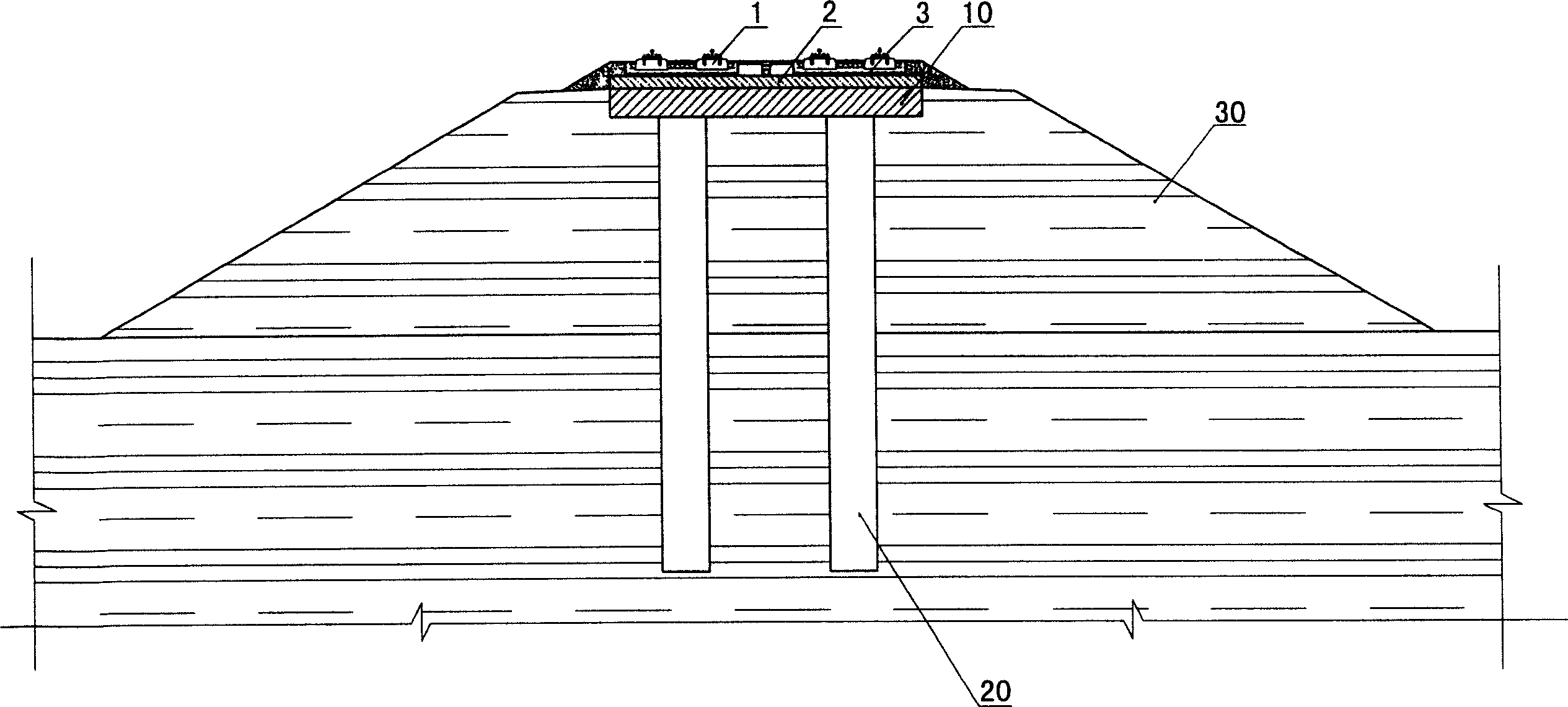

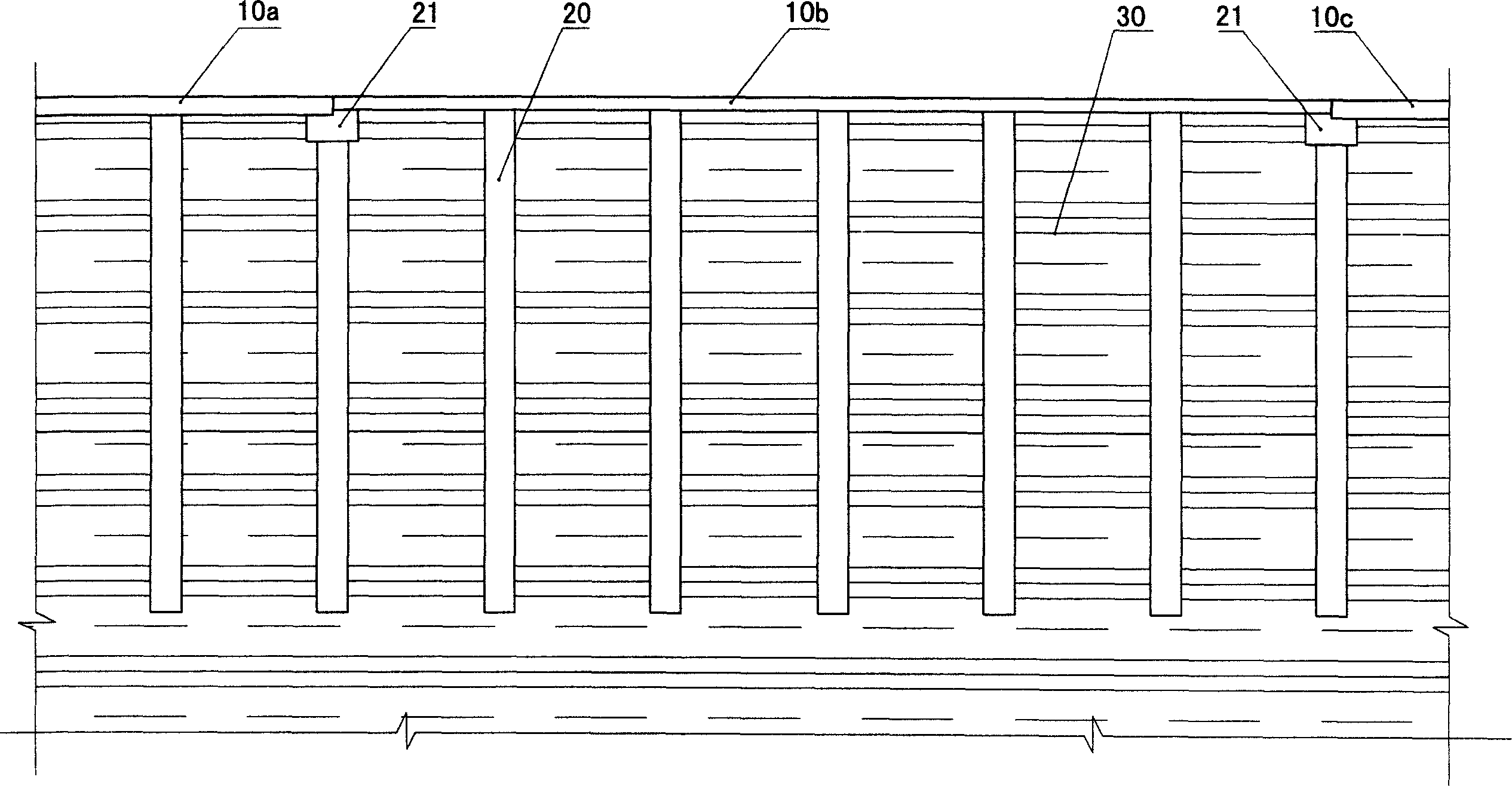

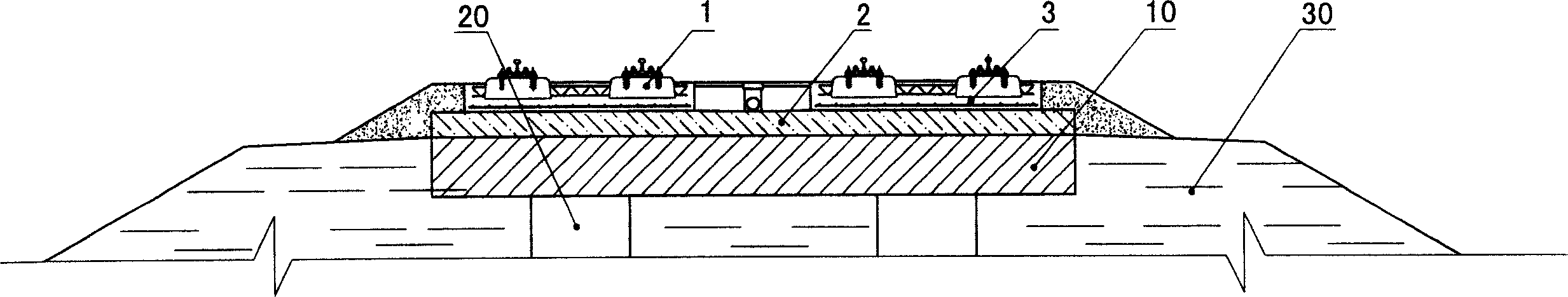

[0025] refer to figure 1 , the ballastless track subgrade of the present invention is characterized in that it includes: reinforced concrete support piles 20, arranged at intervals along the longitudinal direction of the subgrade; reinforced concrete bearing plates 10, rigidly fixed on the upper end of the reinforced concrete support piles 20; It is built between the reinforced concrete bearing plate 10 and the subgrade foundation. The ballastless track subgrade of the present invention combines the respective characteristics of the sleeper-embedded ballastless track and the flexible filled layer slab-type ballastless track and the pile foundation structure, and fully utilizes the joint action principle of pile-slab-soil to meet the requirements of the ballastless track. It overcomes the shortcomings of large settlement and differential settlement of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com