Construction method for rock-fill concrete dam

A technology of rockfill concrete and construction methods, which is applied in water conservancy projects, sea area projects, infrastructure projects, etc., can solve the problems of reducing concrete hydration heat, speeding up construction, and low construction speed, so as to reduce the temperature rise of adiabatic, cement The effect of small quantity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

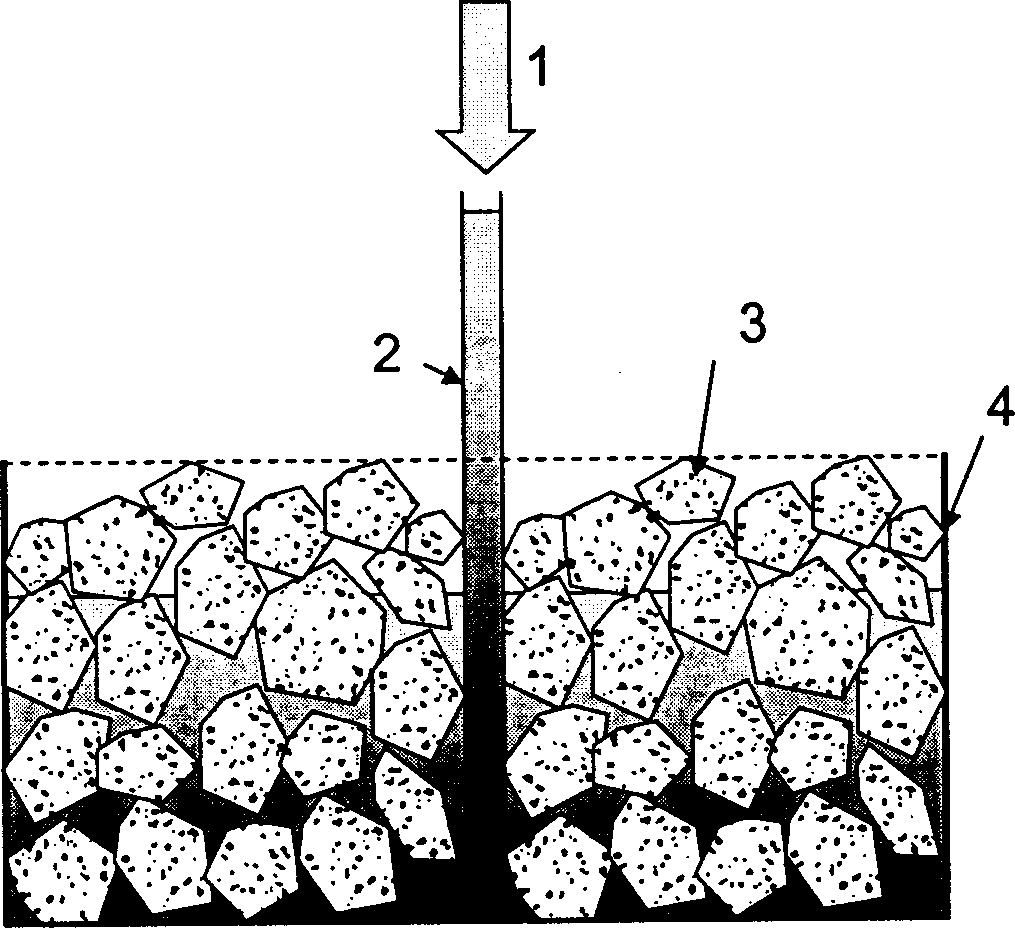

[0028] Example 1: Construction method of rockfill concrete core wall rockfill dam

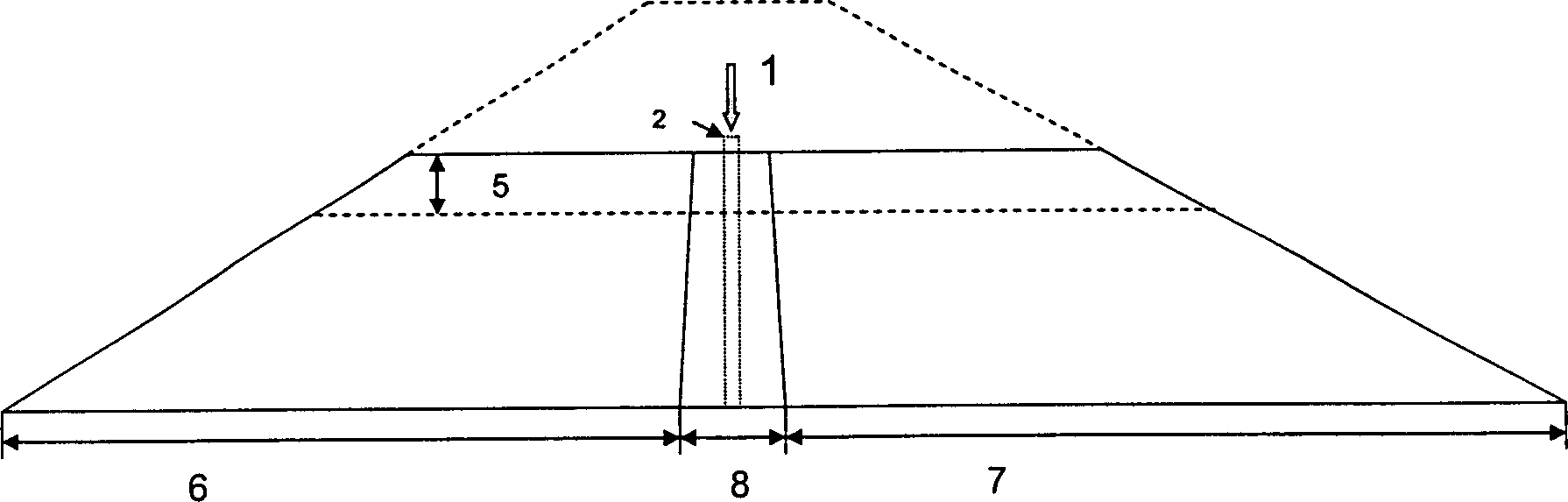

[0029] Such as figure 2 As shown, a rock-fill concrete core wall 8 is used as an anti-seepage body in a traditional rock-fill dam to construct a rock-fill concrete core wall rock-fill dam.

[0030] Firstly, according to the requirements of rockfill dams, the upstream dam body 6 and the downstream dam body 7 are uniformly filled, but during the filling process, the grouting pipe 2 is buried in the core wall, and when the dam body is filled to a certain construction layer thickness 5, use These grouting pipes 2 are used for rockfill concrete construction to form a rockfill concrete core wall. This construction method can be constructed without template 4 at all. The self-compacting concrete 1 automatically forms a rock-fill concrete core wall after the flow in the rock-fill body stops. Seams can be constructed in the Makinac way.

Embodiment 2

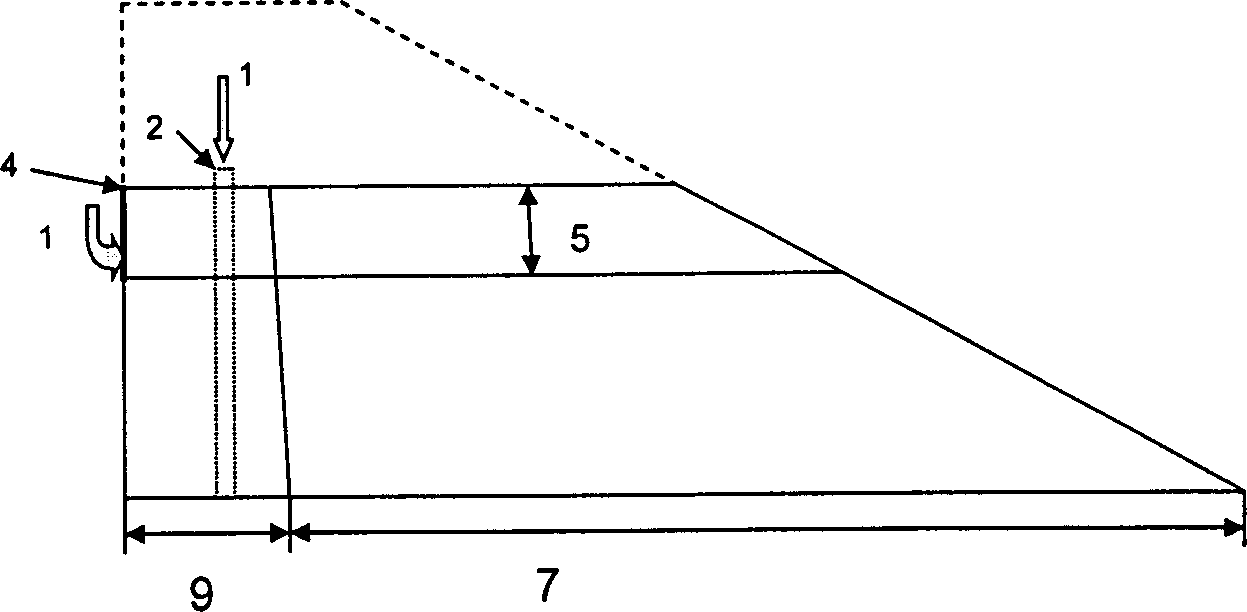

[0031] Example 2: Construction method of rockfill concrete hybrid dam

[0032] On the upstream side of the dam, the formwork 4 is erected, and the rockfill body 3 is first filled, and then the rockfill concrete construction is carried out on the upstream side, and the concrete retaining wall 9 is formed on the upstream side, and it is used as an anti-seepage body at the same time, see image 3 . If the dam is high and the thickness of the concrete retaining wall 9 on the upstream side is relatively large, not only the self-compacting concrete needs to be poured from the grouting opening reserved on the side 4 of the upstream formwork, but also the pre-embedded grouting pipe 2 needs to be poured from the top.

[0033] Since the rockfill concrete is used for construction, the aggregates of the gravity retaining wall 9 on the upstream side and the rockfill body 7 on the downstream side interlock with each other, which is beneficial to the joint action of the two under the action ...

Embodiment 3

[0035] Example 3: Construction method of rock-fill concrete gravity dam or arch dam

[0036] In order to further reduce the volume of the dam body, it is also possible to pour the rock-fill concrete gravity dam or arch dam by injecting self-compacting concrete 1 across the entire section to form the full-section rock-fill concrete, see Figure 4 . This construction needs to set the formwork 4 on the upstream and downstream faces. Since there is less cement in the rockfill concrete of the dam and the adiabatic temperature rise is low, on the basis of temperature control measures such as controlling the injection temperature of the self-compacting concrete 1 of the dam, it is possible to carry out pouring through the warehouse without burying cooling water pipes, which can save construction costs. On this basis, to achieve the purpose of rapid construction. In addition, combined with the rock-fill concrete hybrid dam, in a water conservancy project, the rock-fill concrete hybr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com