Concrete composition containing ultra-fine carbonate rock powder and preparation method thereof

A technology of concrete composition and carbonate rock, which is applied in the field of concrete building materials to achieve the effects of cost reduction, low energy consumption and water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

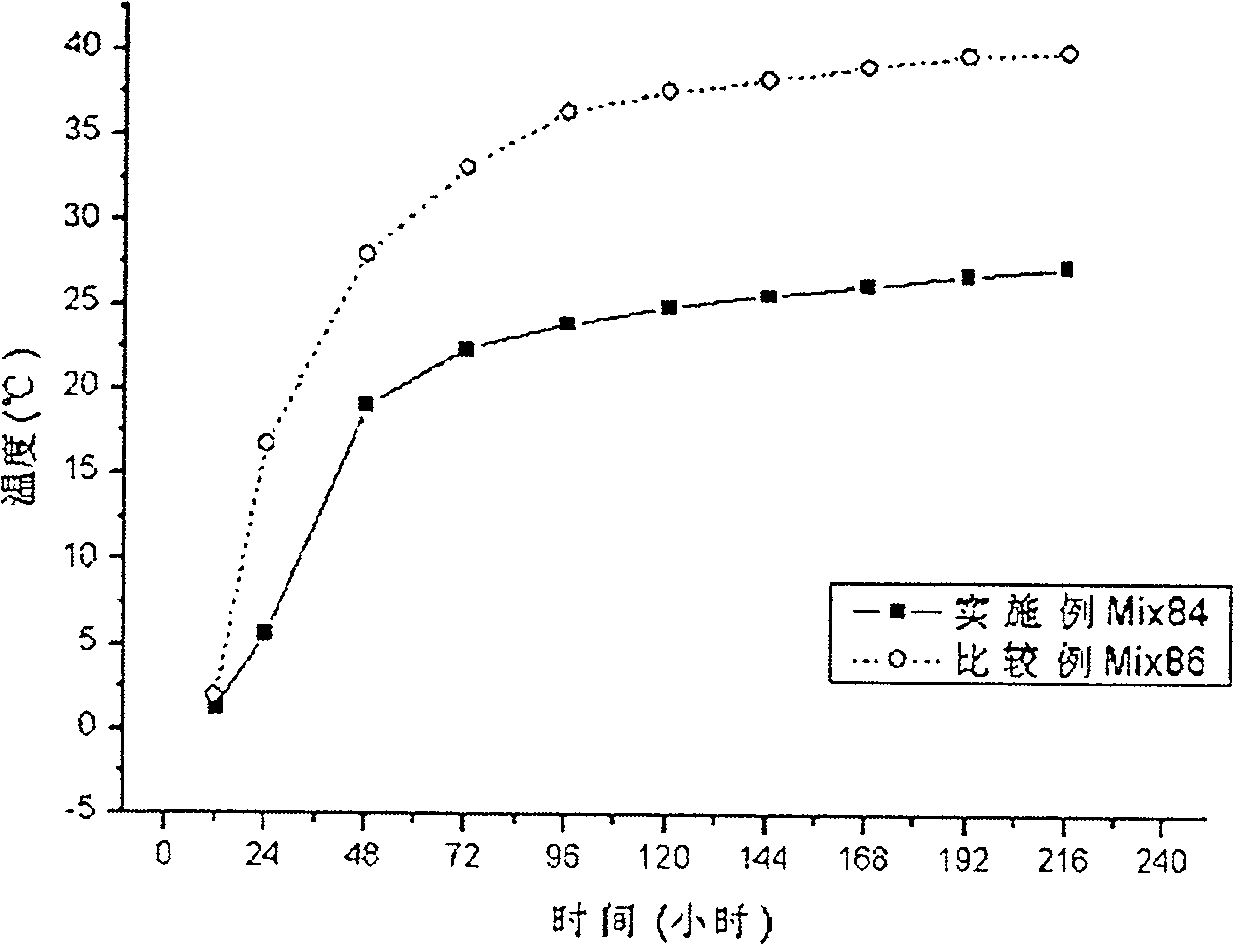

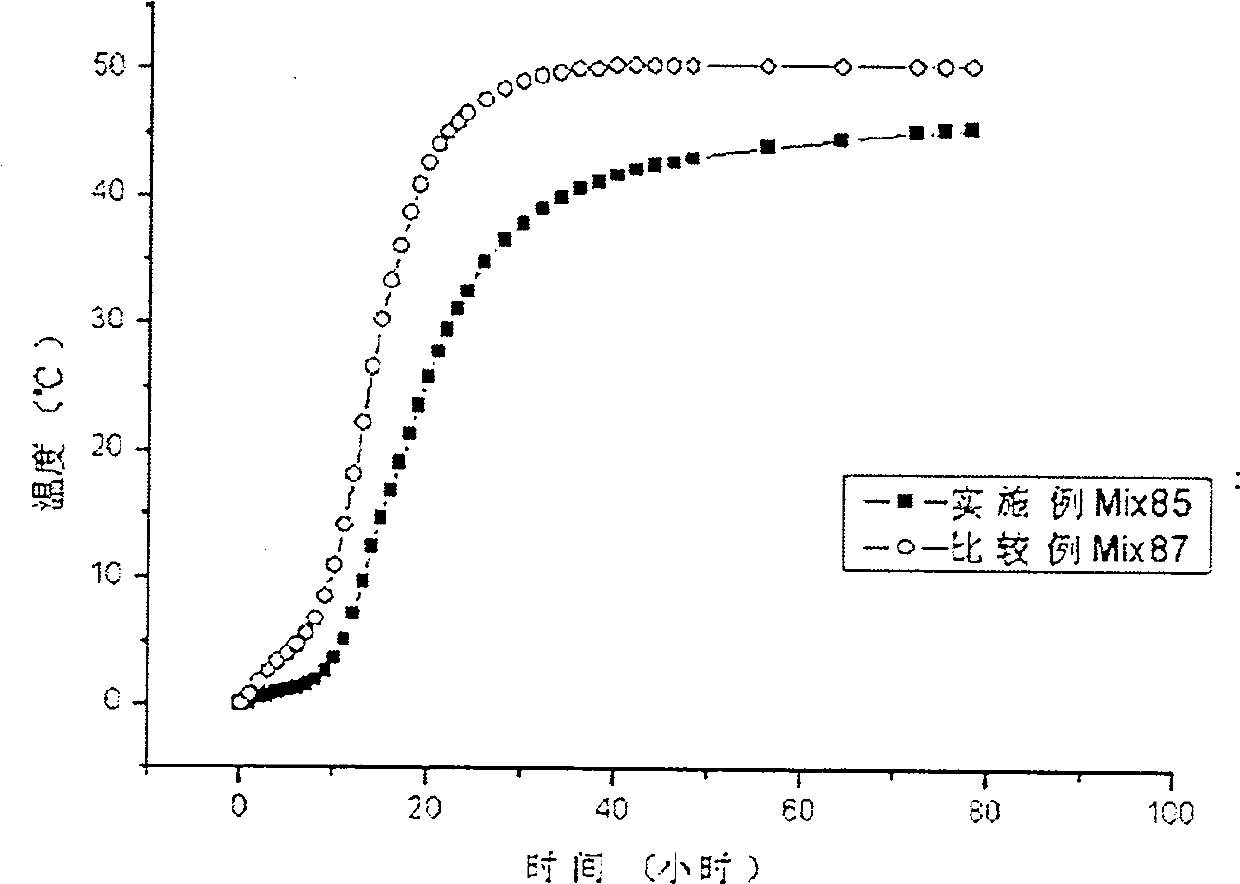

Examples

Embodiment 1

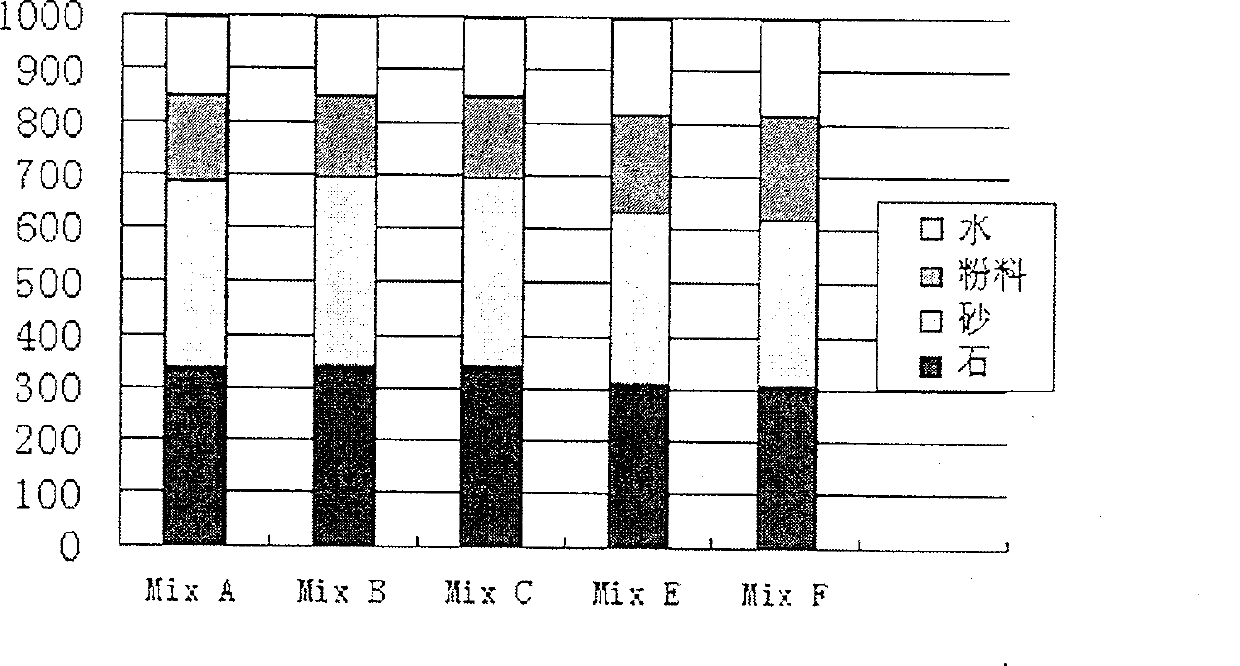

[0046]According to the following raw materials and the concrete mixing ratio shown in Table 3, the concrete was prepared and the compressive strength was measured. In Table 3, Mix01-Mix06 are the mixing ratios of the examples. Cement, ground slag and ultrafine carbonate rock powder are used to form a multi-element powder, and polycarboxylic acid superplasticizer is added. The cement and ground slag each account for 50% of the cementing material; the ultra-fine carbonate rock powder accounts for 20%-37% of the total powder material in the concrete. In Table 3, Mix07-Mix12 are the mixing ratios of the comparative example, without superfine carbonate rock powder.

[0047] (1) Raw materials:

[0048] Cement: Luquan Dingxin Ordinary Portland Cement P.O 42.5;

[0049] Mineral admixture: use Beijing Shougang's finely ground slag, specific gravity 2.9, fineness specific surface area: 400m 2 / kg;

[0050] Sand: medium sand;

[0051] Crushed stone: 5-20mm crushed stone;

[0052] Superplasti...

Embodiment 2

[0065] Example 2: Concrete was prepared according to the following raw materials and the concrete mixing ratio shown in Table 5, and the compressive strength was measured. In Table 5, Mix13-Mix17 are the mixing ratios of the examples. Cement, fly ash and ultrafine carbonate rock powder are used to form a multi-element powder, and polycarboxylic acid superplasticizer is added. Cement and fly ash each account for 50% of the cementing material; ultra-fine carbonate rock powder accounts for 28%-29% of the powder material content in concrete. In Table 5, Mix18-Mix22 is the mixing ratio of the comparative example, without superfine carbonate rock powder.

[0066] (1) Raw materials:

[0067] Cement, sand, crushed stone, ultra-fine carbonate rock powder: same as Example 1; mineral admixture: use fly ash from Beijing Shijingshan Thermal Power Plant; superplasticizer: Basfir Chemical Building Materials Glenium Ace68 polycarboxylic acid Water reducing agent.

[0068] (2) The test method is t...

Embodiment 3

[0076] Example 3: Concrete was prepared according to the following raw materials and the concrete mix ratio shown in Table 7, and the compressive strength was measured. The mixing ratio of Mix23-Mix26 in Table 7 is an example. Cement, ground slag and ultrafine carbonate rock powder are used to form a multi-element powder, and a naphthalene-based superplasticizer is added. Cement and ground slag each account for 50% of the cementing material; ultra-fine carbonate rock powder accounts for 28%-37% of the powder material content in concrete. The mixing ratio of Mix27-Mix29 in Table 7 is a comparative example, without superfine carbonate rock powder.

[0077] (1) Raw materials:

[0078] Cement, sand, crushed stone, ultra-fine carbonate rock powder: the same as Example 1; mineral admixture: ground slag produced by Beijing Shougang, specific gravity 2.9, fineness specific surface area: 400m 2 / kg; Superplasticizer: Tianjin Yongyang UNF-5 naphthalene series superplasticizer.

[0079] (2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com