Patents

Literature

204 results about "Gravity dam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gravity dam is a dam constructed from concrete or stone masonry and designed to hold back water by primarily using the weight of the material alone to resist the horizontal pressure of water pushing against it. Gravity dams are designed so that each section of the dam is stable and independent of any other dam section.

Method for calculating stability safety factor of concrete gravity dam under multi-dam-section combined skid resistance condition

ActiveCN104652373AClear conceptAssume reasonableInformaticsSpecial data processing applicationsStatically indeterminateEngineering

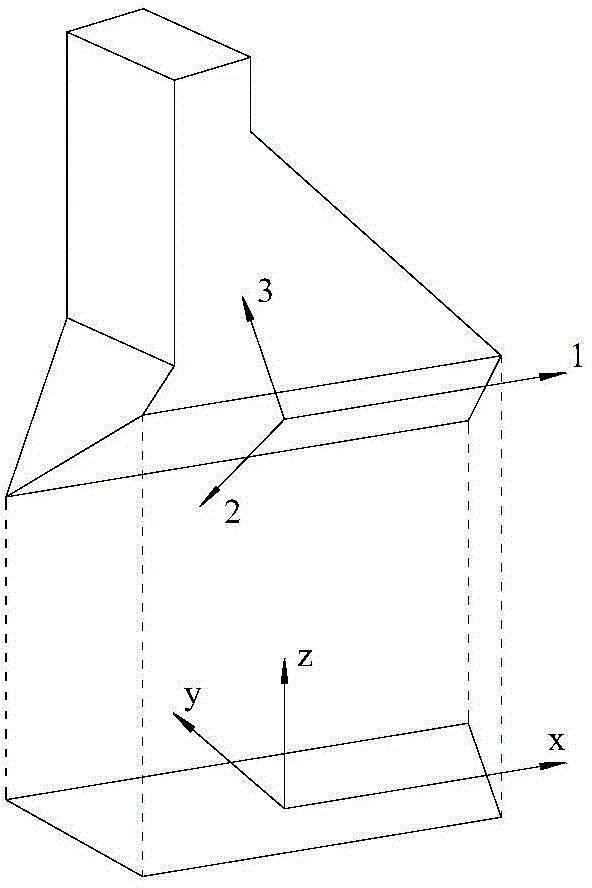

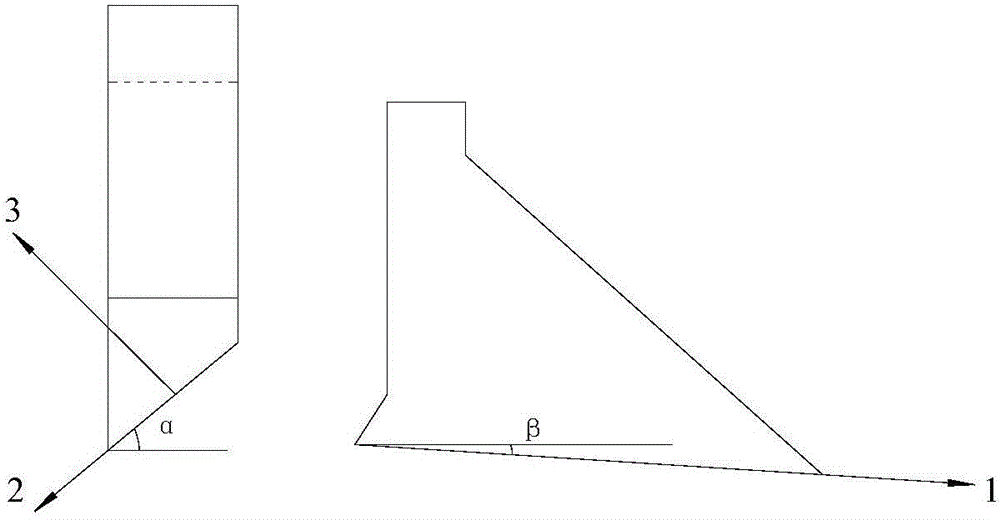

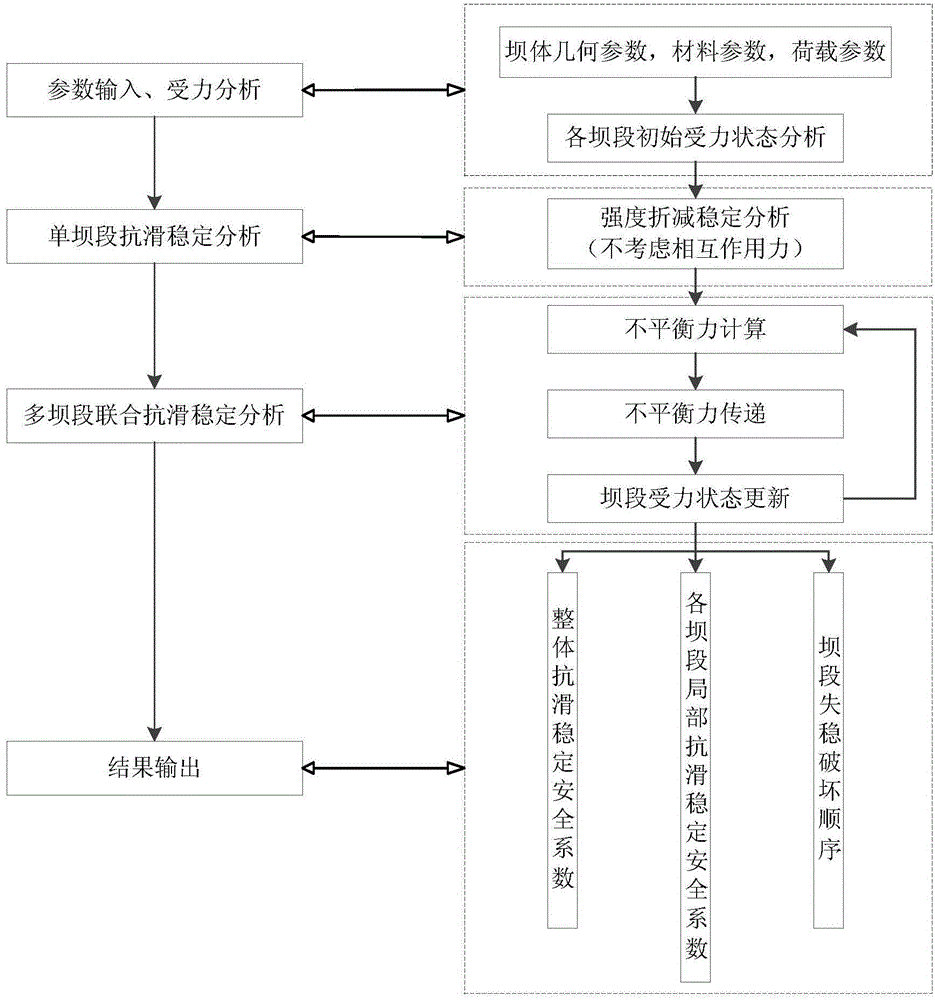

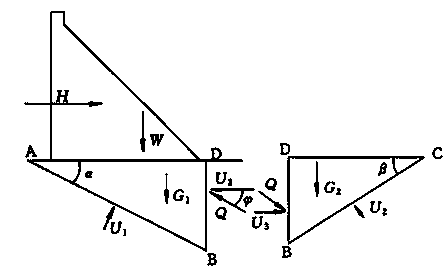

The invention relates to a method for calculating the stability safety factor of a concrete gravity dam under a multi-dam-section combined skid resistance condition and belongs to the field of gravity dam stability analysis. According to the method, a three-dimensional stability analysis calculation model is established on the basis of a three-dimensional rigid body limit balance analysis and strength reduction method by aiming at a situation that key slots are formed or grouting is performed between dam sections of the concrete gravity dam so as to combine slide resistance; by introducing a plurality of reasonable assumption and unbalanced force transfer concepts, the statically indeterminate problem of combined anti-sliding stability of multiple dam sections along a dam foundation surface is converted into a statically determinate problem; on the basis of solving out the independent anti-sliding safety factor of the dam sections, the transfer of unbalanced forces of adjacent dam sections on a river valley side is considered, circulation calculation is performed, and the overall stability safety factor of combined slide resistance of multiple dam sections, the sequence of sequentially achieving limit balance by each dam section and the local stability safety factor of the dam sections are solved out. The method has the characteristics of easiness for realization of programming, reasonable calculation result and the like, and is convenient in popularization and application in practical engineering.

Owner:HOHAI UNIV

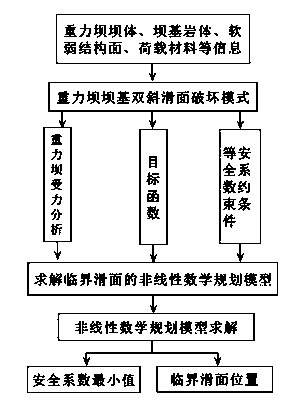

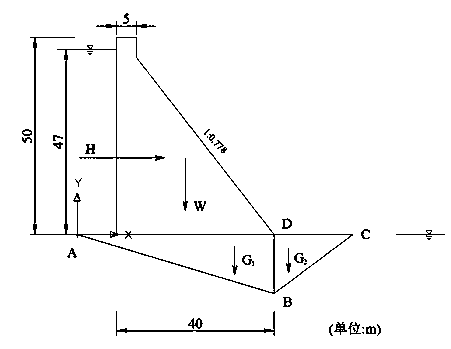

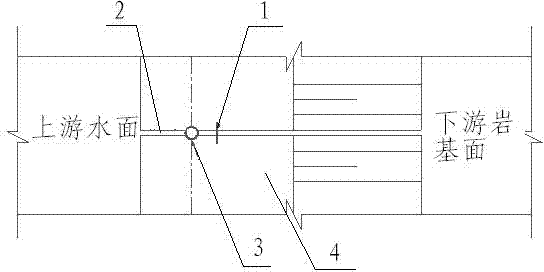

Method of calculating deep antiskid stable critical slipping plane of dam foundation of gravity dam

ActiveCN103469780AMethod concept is clearImprove calculation accuracyIn situ soil foundationBedrockEngineering

The invention discloses a method of calculating a deep antiskid stable critical slipping plane of a dam foundation of a gravity dam and belongs to the field of stability analysis for gravity dams. Aiming at the condition that slip possibly occurs because the low-gradient weak structural plane of the dam foundation of the gravity dam is not exposed but part of downstream bedrock is possibly subjected to clipping, the method comprises the following steps: establishing a nonlinear mathematic programming model of deep antiskid stability analysis for the gravity dam by taking variable of locations subjected to clipping and slipping plane damage on the downstream bedrock as an optimization variable, the deep antiskid stability factor of the gravity dam as an objective function and an equal safety factor normal equation as a constraint condition; solving out a worst critical slipping plane subjected to clipping damage on the downstream rock mass and a safety factor minimal value corresponding to the worst critical slipping plane. The method disclosed by the invention has the characteristics of definite concept, high calculation precision and the like, and can be applied to deep antiskid stability analysis for the gravity dam.

Owner:KUNMING UNIV OF SCI & TECH

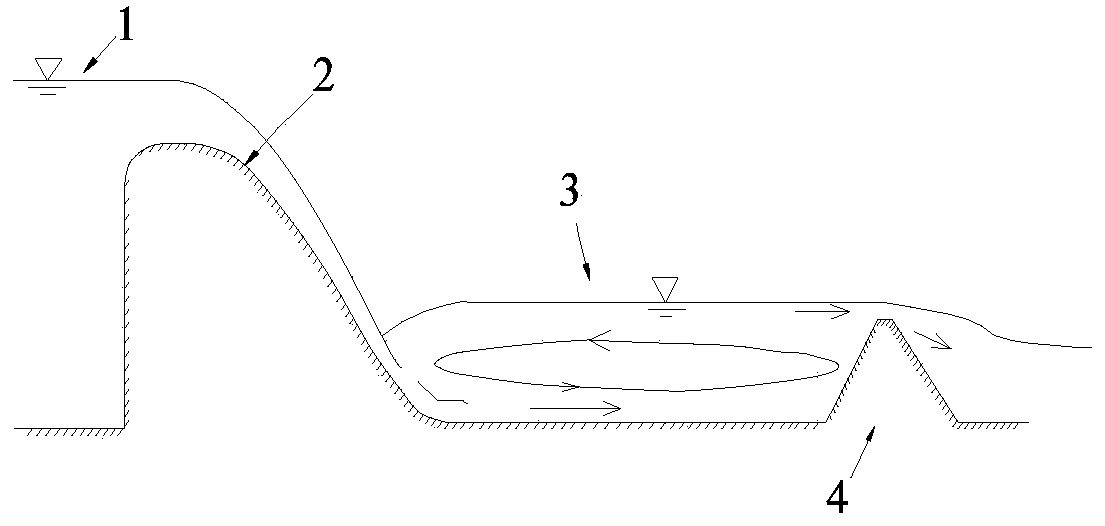

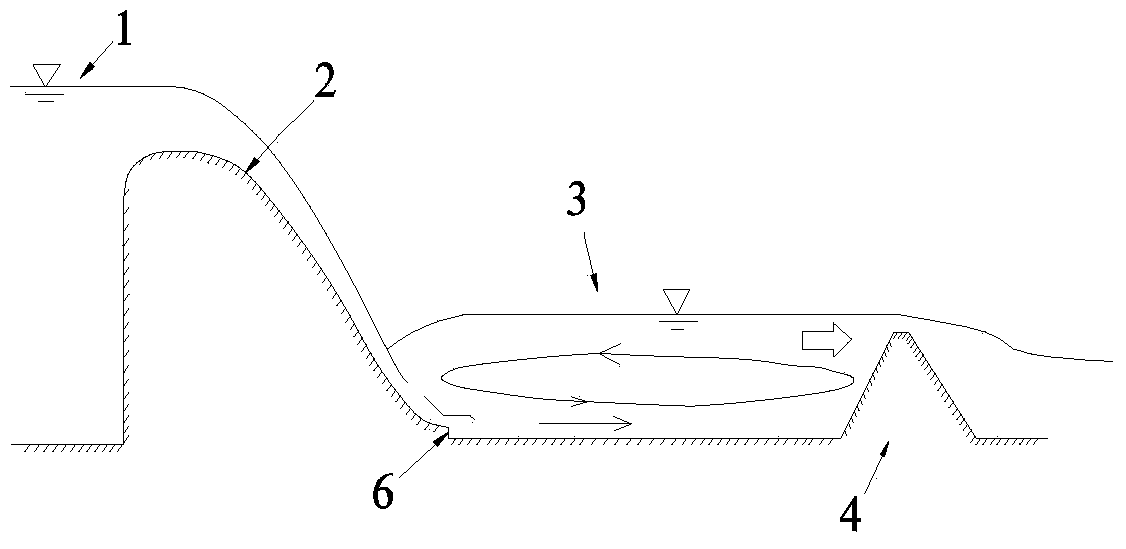

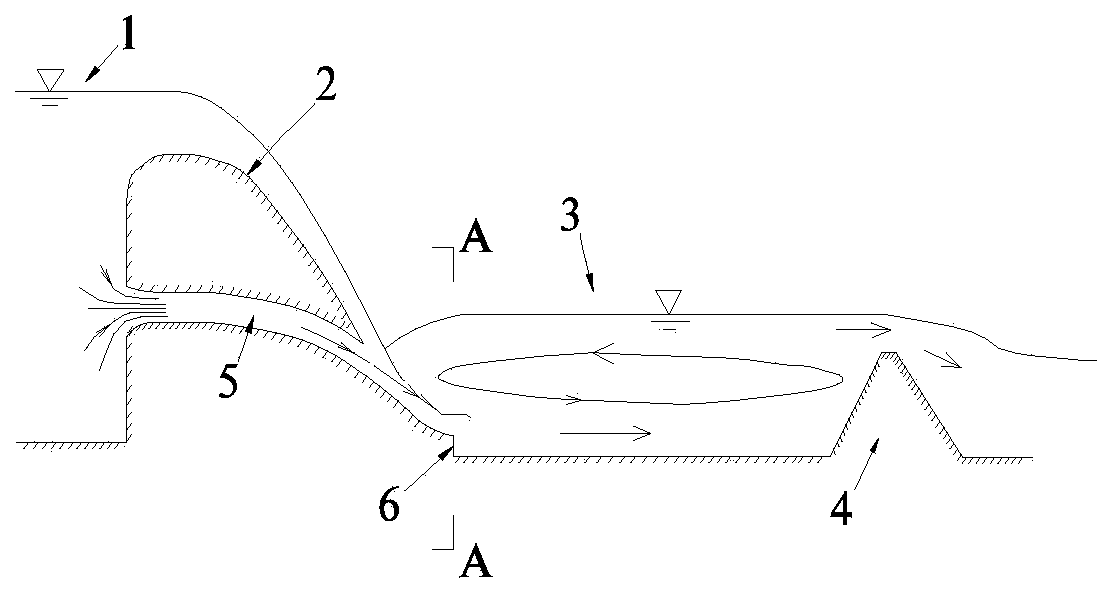

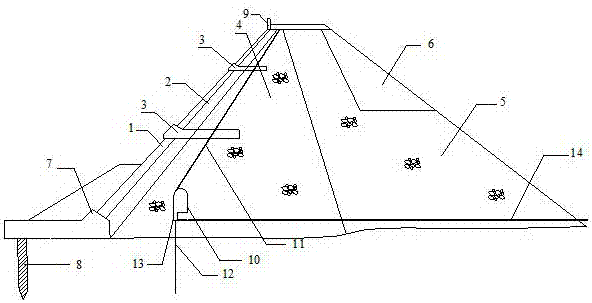

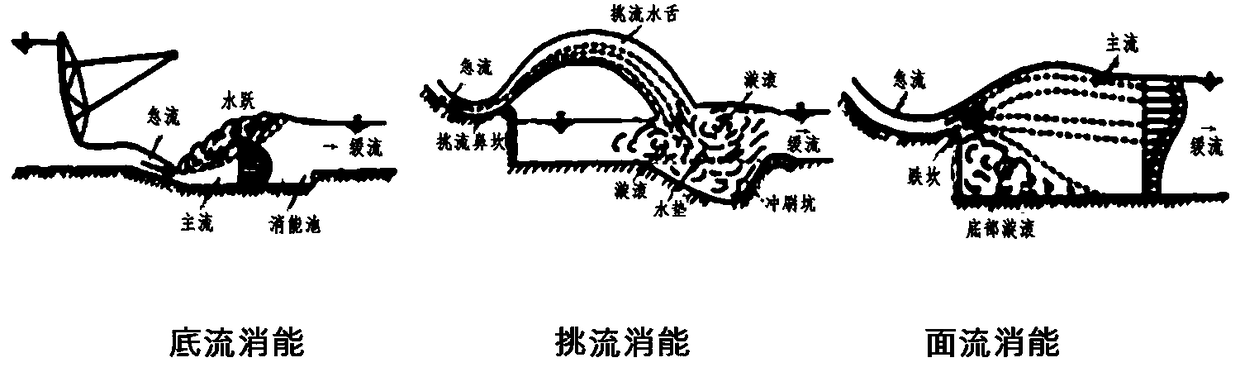

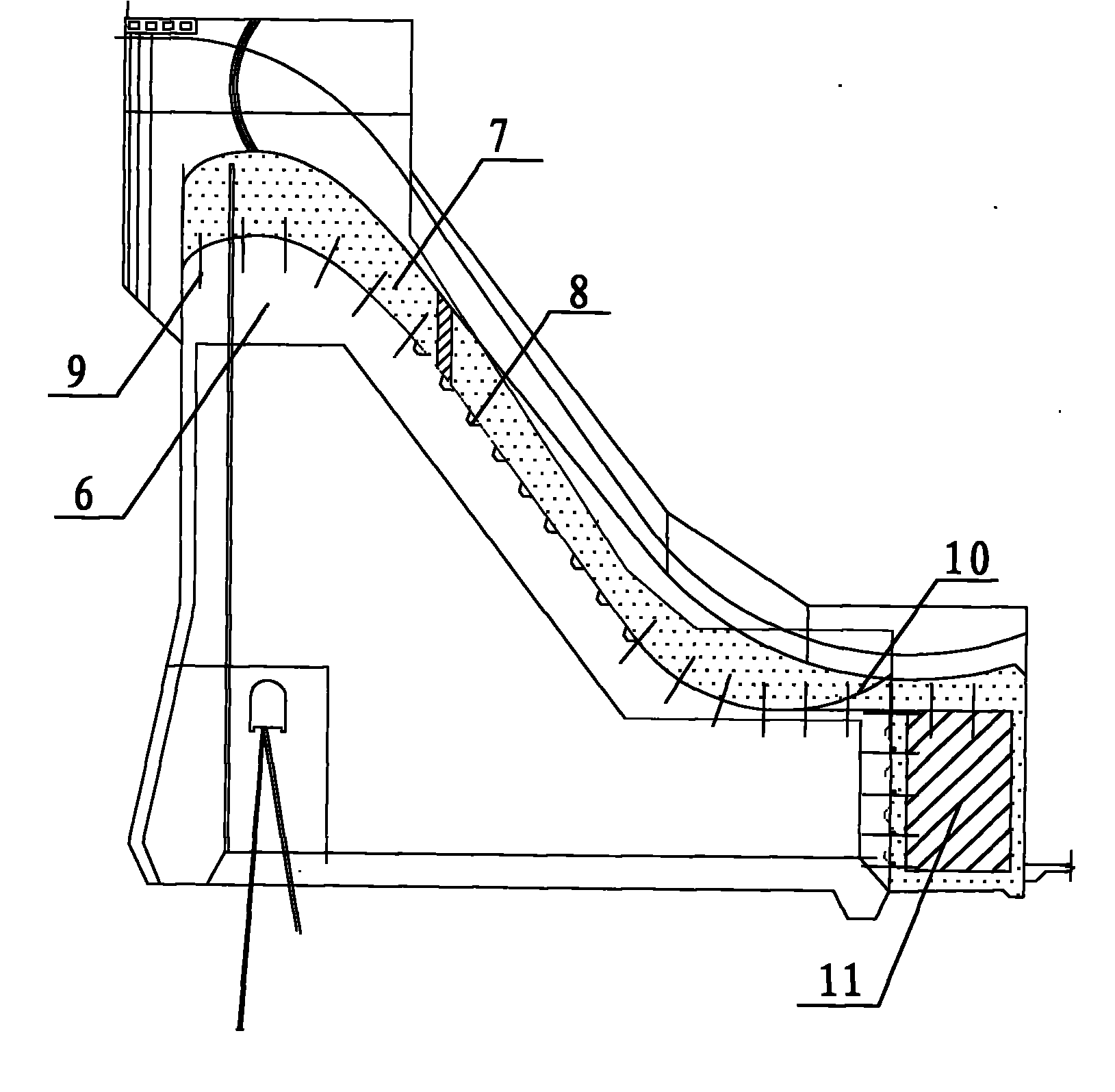

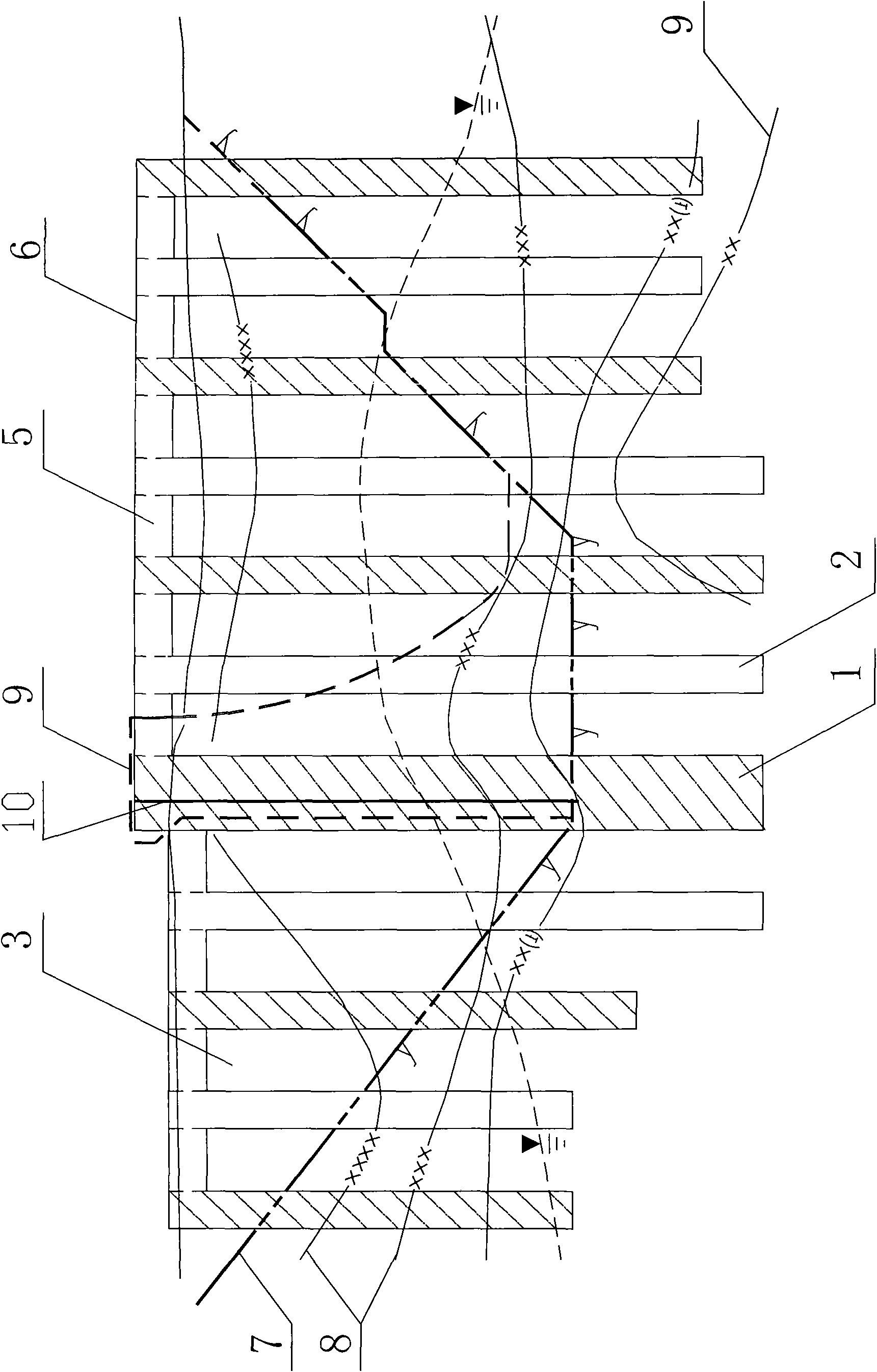

Classified pool-inlet high-dam flood discharge energy dissipater for bottom flow and energy dissipating method

The invention discloses a classified pool-inlet high-dam flood discharge energy dissipater for bottom flow. The classified pool-inlet high-dam flood discharge energy dissipater comprises a gravity dam and an absorption basin. At least two different elevation positions in a body of the gravity dam are provided with flow discharging channels extending downstream respectively, and falling banks are arranged below outlets of the flow discharging channels, wherein the falling banks are internally provided with ventilation galleries and ventilation holes. At least three levels of steps are sequentially arranged in the absorption basin from the upstream part to the downstream part. When flow passes through the top and the interior of the dam at the same time, the outlets of the flow discharging channels are sequentially located on vertical faces of the steps, with the corresponding level numbers from the upstream part to the downstream part, in the absorption basin from high to low according to the elevation of the outlets. When the flow only passes through the interior of the dam, the outlets of all the flow discharging channels are sequentially located on the vertical face at the starting position of the first-level step in the absorption basin and the vertical faces of the steps with the corresponding level numbers from the upstream part to the downstream part in the absorption basin from high to low according to the elevations of the outlets. With the energy dissipater, water in a reservoir enters the absorption basin from the flow discharging channels at the different elevations or from the top of the gravity dam and the flow discharging channels of the different elevations, and the water is scattered on the faces of the steps with the corresponding level numbers from the upstream part to the downstream part respectively in the absorption basin for energy dissipation.

Owner:SICHUAN UNIV

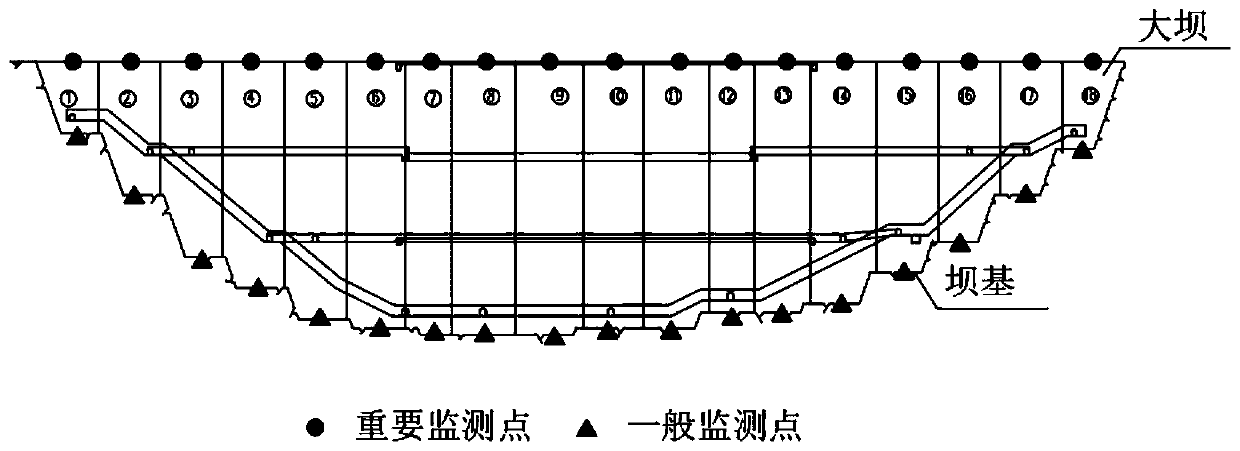

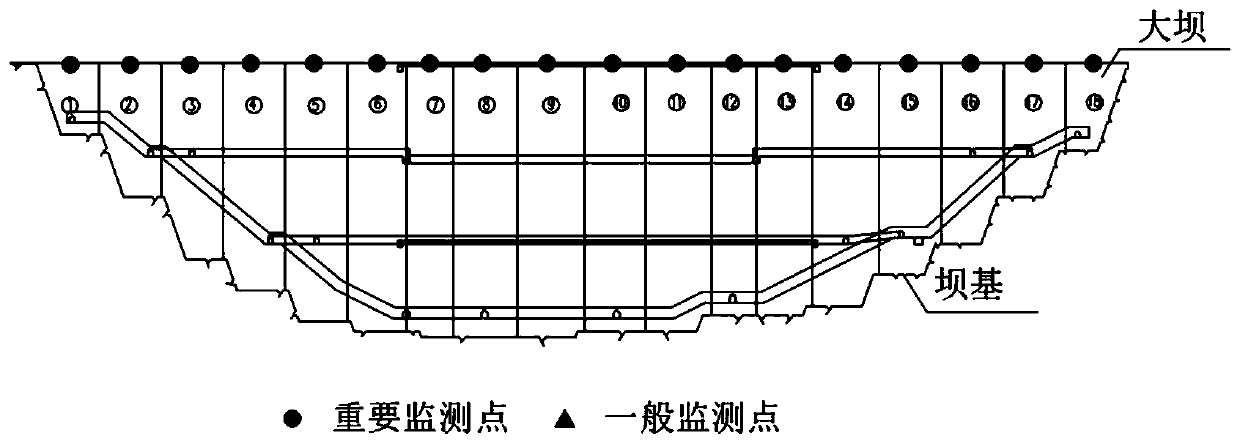

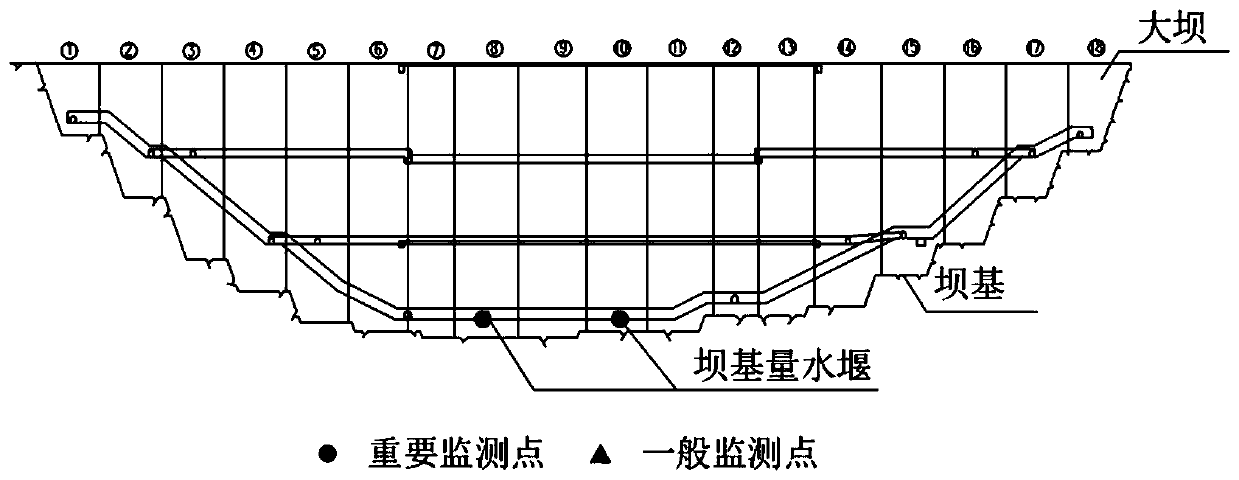

Concrete dam long-term operation safety early warning method

ActiveCN111256754AImprove reliabilityFluid pressure measurementAlarmsEarly warning systemStructural engineering

The invention discloses a concrete dam long-term operation safety early warning method which comprises the following steps: selecting key monitoring parts and measuring points according to the workingcharacteristics and damage types of a concrete dam, grading the measuring points with reliable measured values, and drawing up dam safety early warning indexes according to the measured value data ofthe concrete dam; and carrying out safety early warning on the concrete dam by adopting a comprehensive early warning system of measuring point grading and considering the spatial correlation index.Whether the dam is in a safe operation state or not is rapidly evaluated, analyzed and early warned through the real-time monitoring data of the concrete gravity dam; and dam monitoring value abnormality is discovered in time according to the importance levels of the measuring points and the index association relationship, the dam operation warning condition is identified, and support is providedfor rapid safety early warning of long-term operation of the concrete gravity dam and management scheduling in response to the warning condition.

Owner:HOHAI UNIV

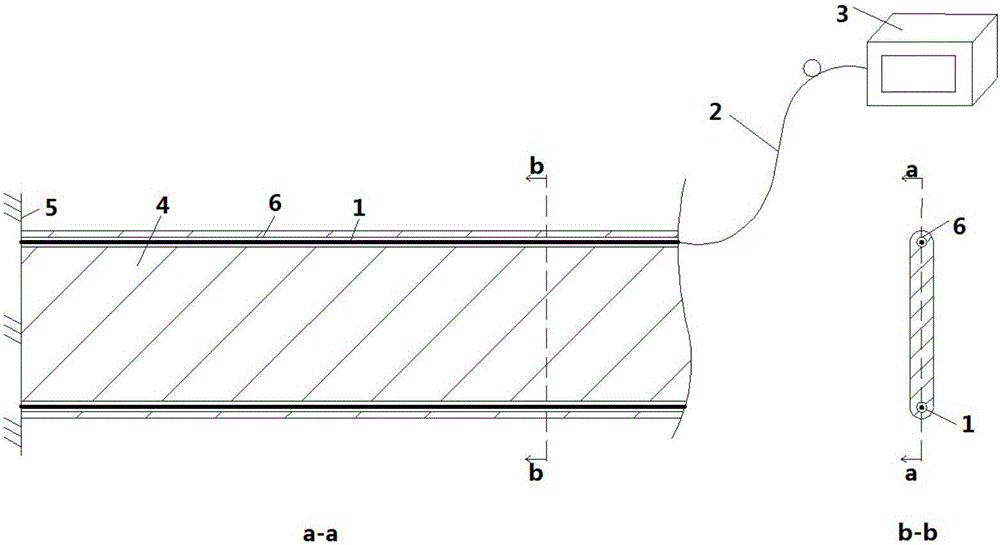

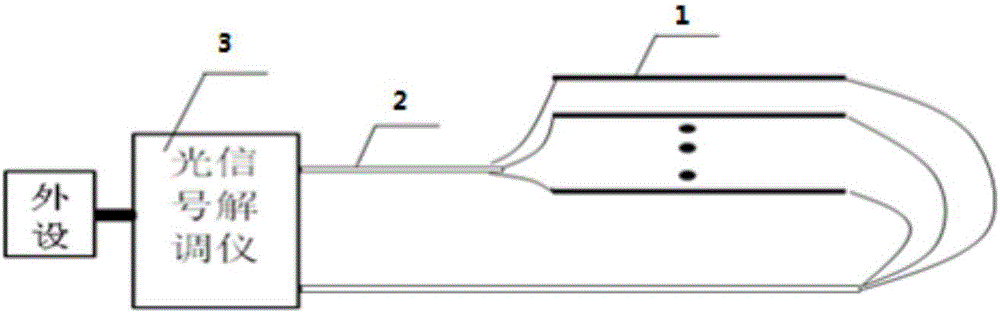

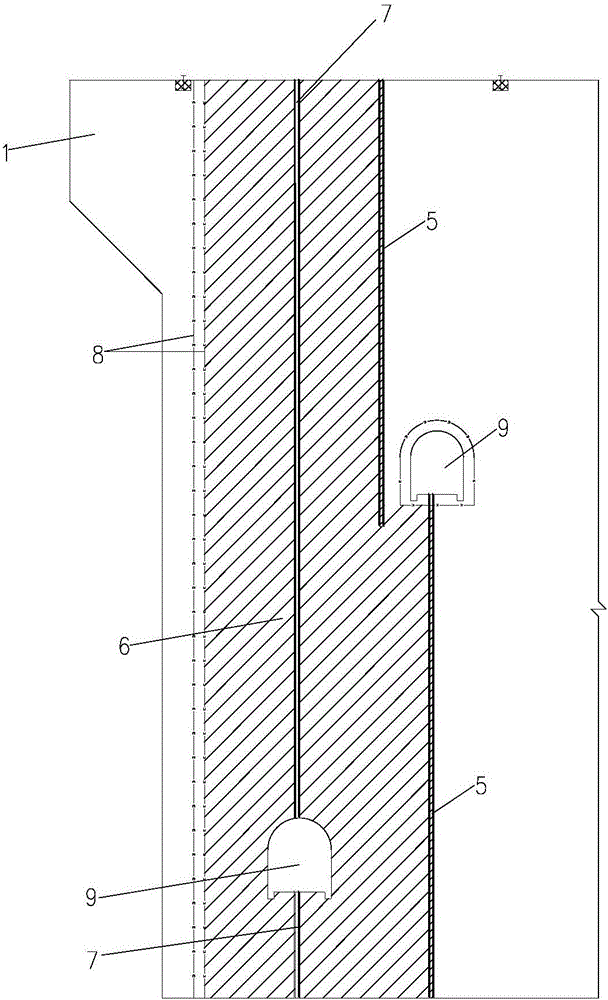

Concrete gravity dam deformation optical fiber sensing monitoring technology and concrete gravity dam deformation optical fiber sensing monitoring system

InactiveCN106091967AImprove effectivenessImprove the level of technologyUsing optical meansShaped beamBedrock

The invention discloses a distribution-type optical fiber sensing system and a technical scheme, which are used to realize integrated on-line remote measurement of dam body-batholith internal deformation three components of a gravity dam, a dam body joint, and diastrophism, cracking, and extrusion of a bedrock tectonic belt, and is used to realize dam multidimensional-large scale spacetime full coverage. A plate-shaped beam of a novel optical fiber packaging structure---narrow rectangular section is provided, and the tension-compression sides of the plate-shaped beam are provided with microtubes to form an Euler elastic beam, and then the force-light direct conversion of the optical fiber is realized. An arrangement type of a sensing system in the gallery and the vertical shaft of the dam-bedrock, the comprehensive use of the sensing system, and an optical fiber laying technology are provided. The multifunctional integration of the optical fiber monitoring is achieved, construction is facilitated, the survival rate of the optical fiber is guaranteed, and application is convenient. An optical signal demodulation device adopts a high precision PPP-BOTDA or a hybrid Brillioun-Rayleigh system, and is multifunctional for being used for projects of monitoring a concrete temperature-reservoir water temperature, a slit position in front of a dam(factory), and a reservoir slit, and other optical fiber monitoring projects, and therefore upgrading and updating of a safety monitoring system are prompted.

Owner:SICHUAN UNIV

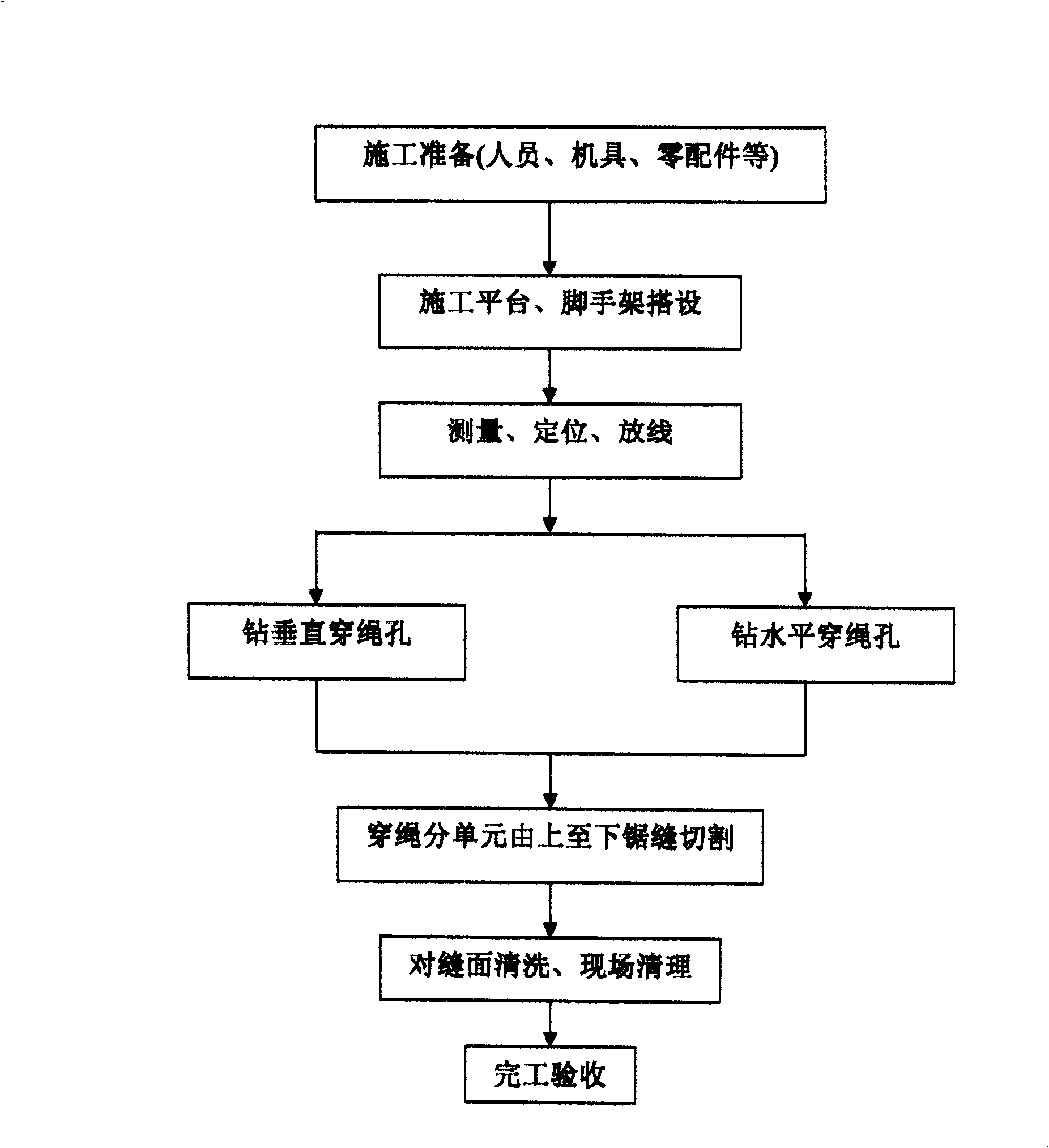

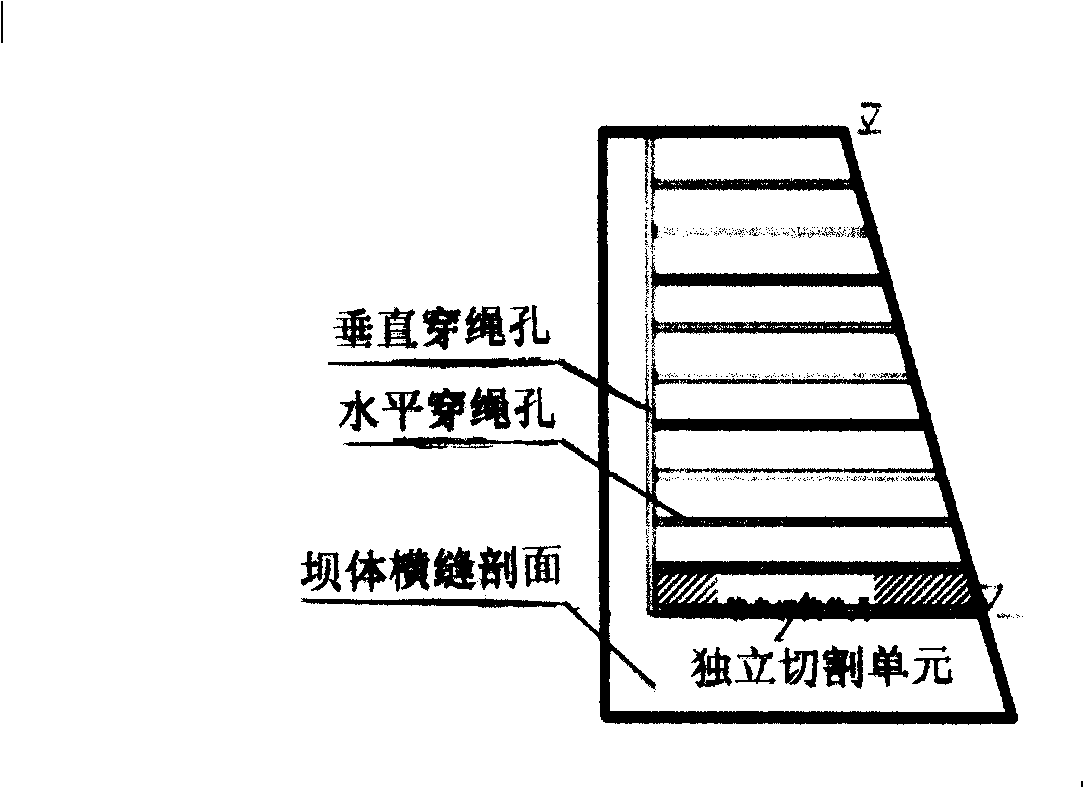

Large area sawed joint cutting construction method of concrete gravity dam cross joint

ActiveCN101270573ADoes not affect safe operationLow costStone-like material working toolsDrilling machines and methodsRock coreEngineering

The invention discloses a concrete gravity dam transverse joint large area sawing and cutting construction method which consists two parts of drilling and cutting; the construction method is carried out according to the following steps: selecting a full hydraulic drill as a drilling tool; confirming the drilled parameters; drilling and fetching the core; cataloging the fetched rock core; measuring the hole deviation of drilling; selecting a diamond wire saw to sew and cut; the cutting method, selecting horizontal drilling to finish the transverse joint cutting of the dam, selecting a diamond rope and confirming the cutting parameters; the linear speed of cutting should reach 18m / s to 22m / s; the cutting washing liquid pump amount at least reaches 70L / min, then the dam can be under a normal running state; the sawing construction does not affect the dam to run safely, does not damage the dam body structure, does not damage the transverse joint of the dam body to stop water, has a low cost, has a fast construction speed, has a high construction precision and can be broadly applied in the reinforcing and alternation constructions of the old dams and disabled dams in the engineering fields of water conservancy and hydropower.

Owner:SINOHYRDO ENG BUREAU 3 CO LTD +1

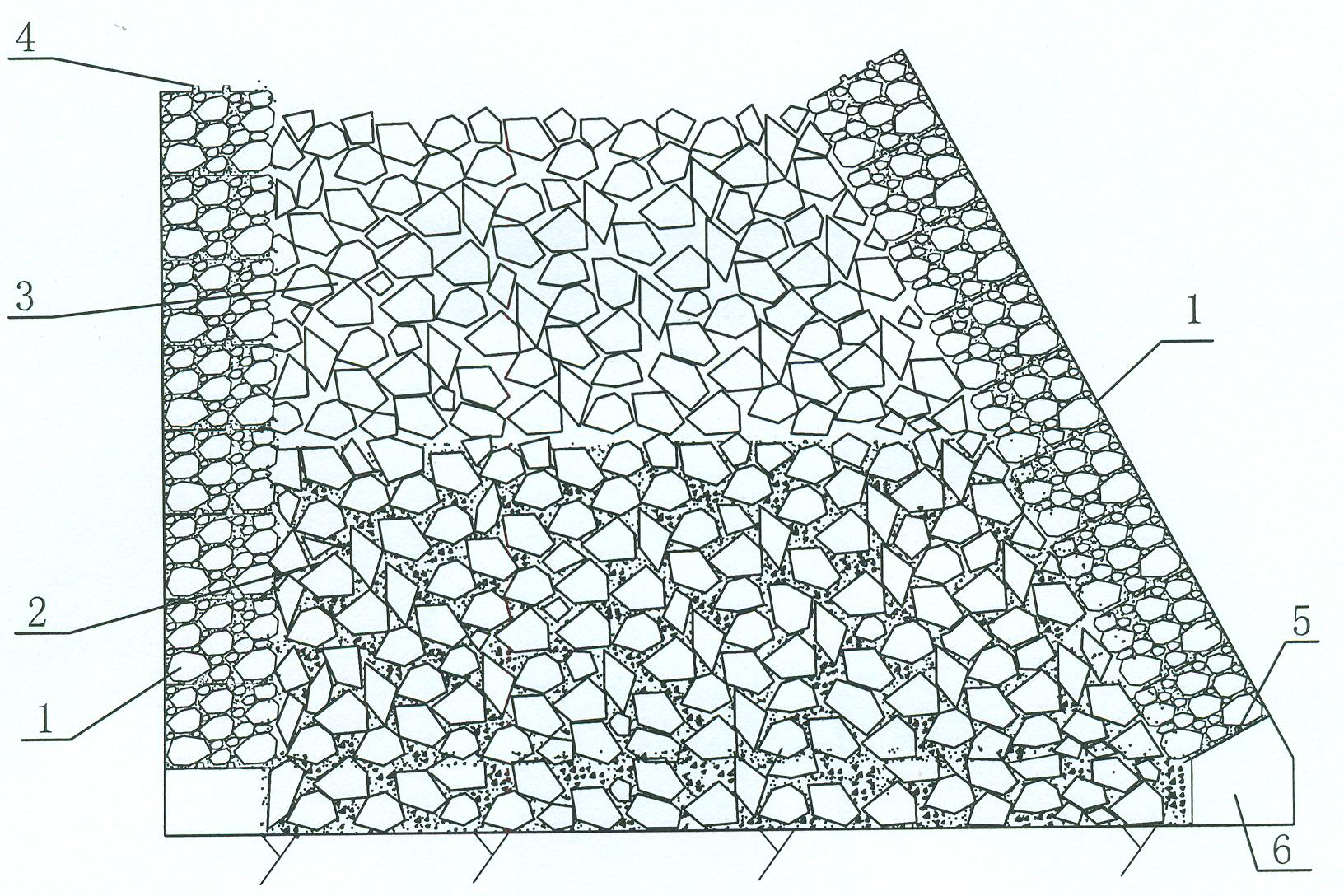

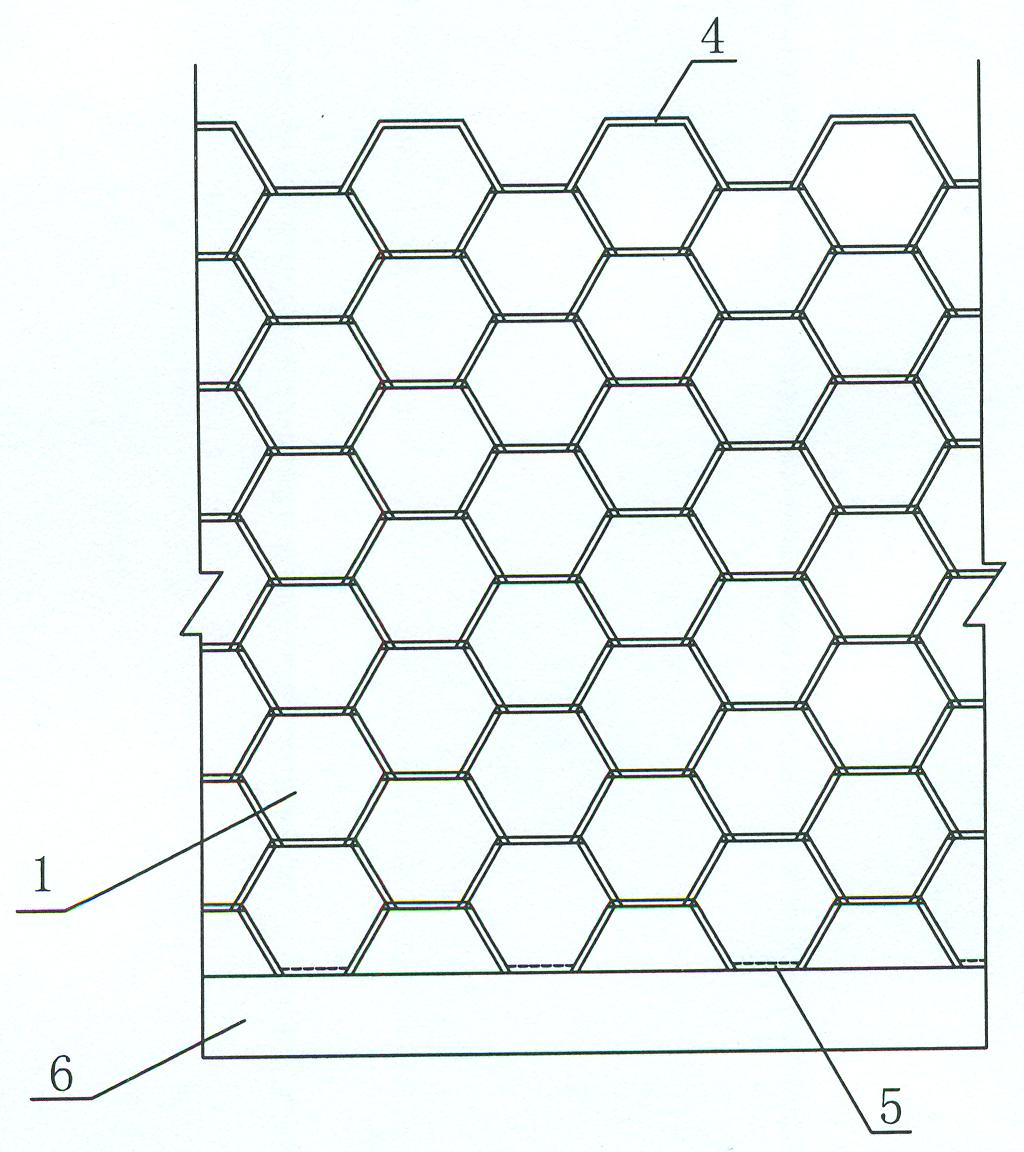

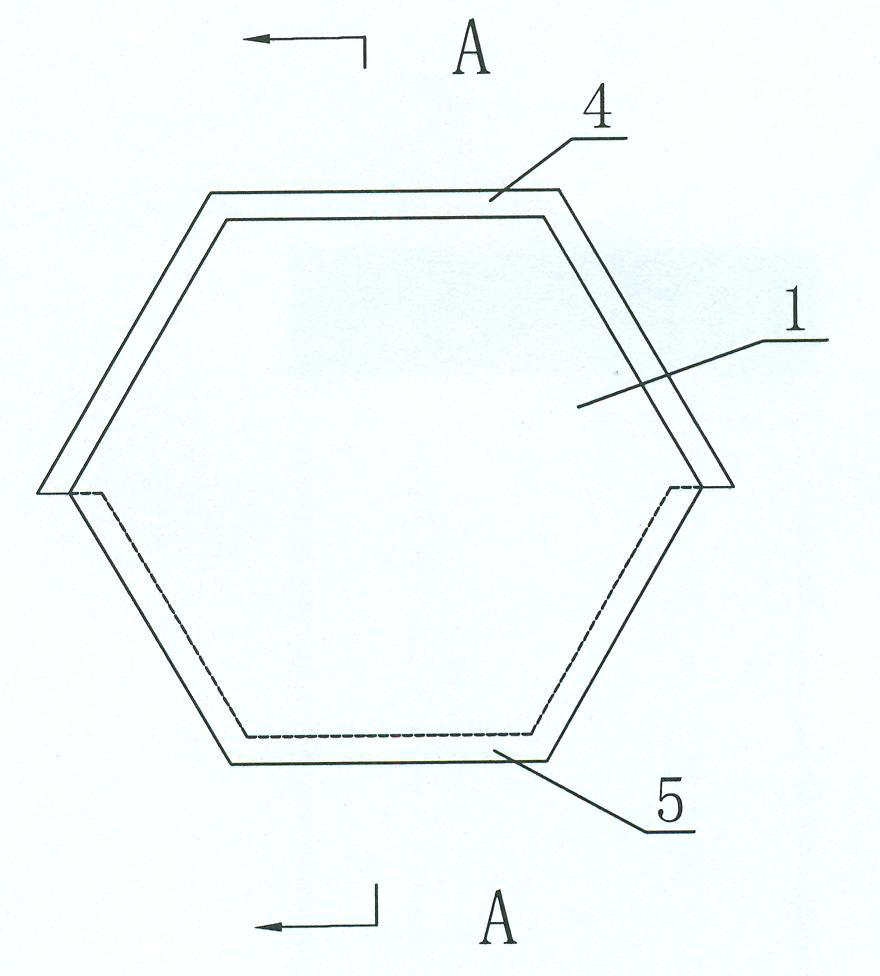

Construction method of scour-filled mortar stone dam with masonry masonry prefabricated block masonry dam shell

InactiveCN102277860AAdapt to ascent speedImprove self stabilityWall damsArchitectural engineeringRevetment

The invention discloses a construction method for a fill mortar junction stone dam of a mortar stone precast block masonry dam shell. The method comprises the following steps of: pre-casting natural graded stone into hexagonal prism mortar stone precast blocks; building the hexagonal prism mortar stone precast blocks into a dam shell with a crane or other hoisting equipment at upstream and downstream positions of the fill mortar junction stone dam; and filling a dam body in the dam shell at one time with a fill mortar junction stone dam construction method to form a fill mortar junction stonedam body. By adopting the method, local natural stone can be fully utilized; the method has the advantages of simple construction process, high construction speed, low construction cost and contribution to energy conservation and environment friendliness; the dam shell has the advantages of selectable shape and strong stereoscopic impression; and more significantly, an arch action can be achievedafter masonry of the hexagonal prism precast blocks, the stress distribution can be adjusted automatically, and the stability of the dam shell is enhanced. Meanwhile, the technology can be widely applied to dam shells, debris retaining dam protective coverings and the like of gravity dams such as dyke revetments, flood prevention and tide protection banks, masonry retaining wall protective coverings, cemented masonry dams or fill mortar junction stone dams and the like.

Owner:沈阳乾玉水利有限公司

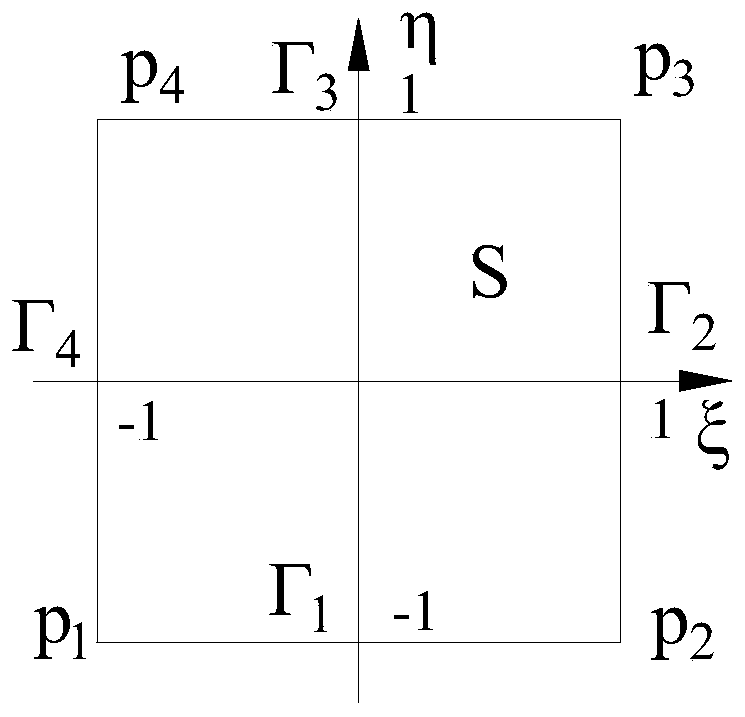

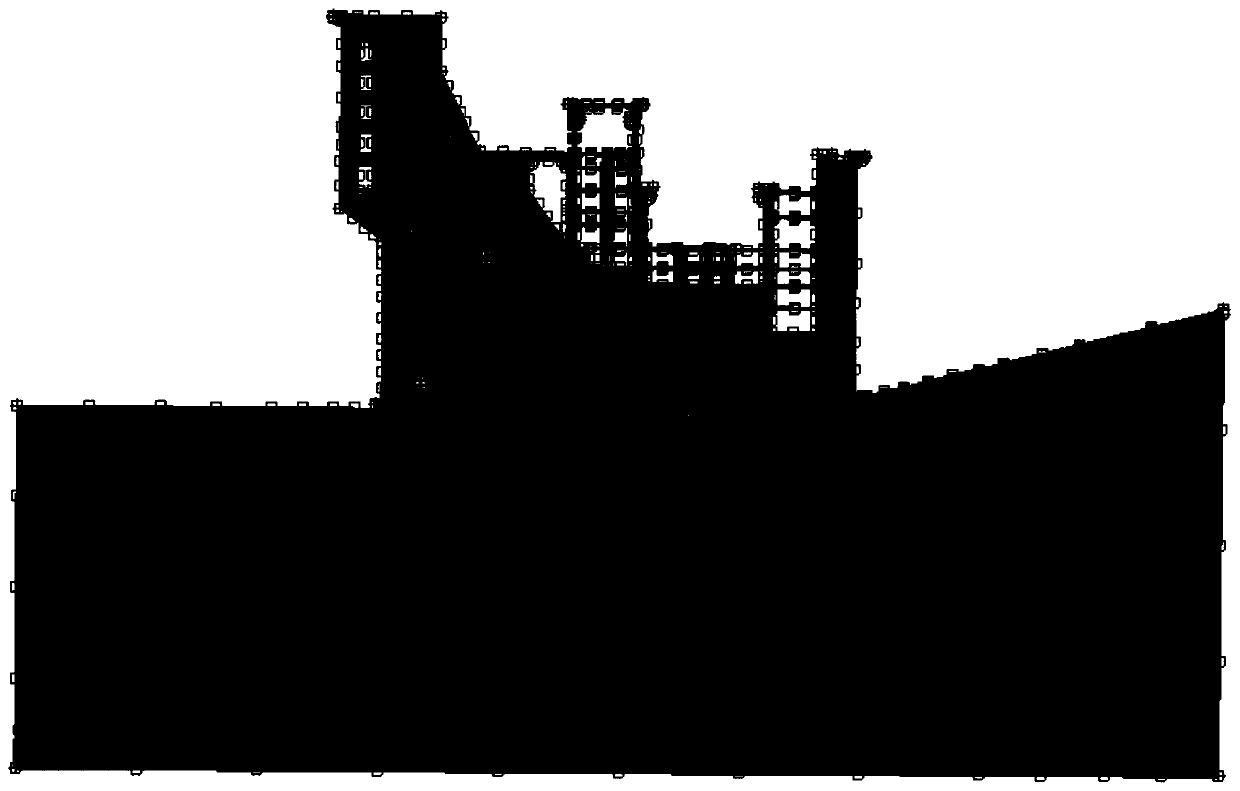

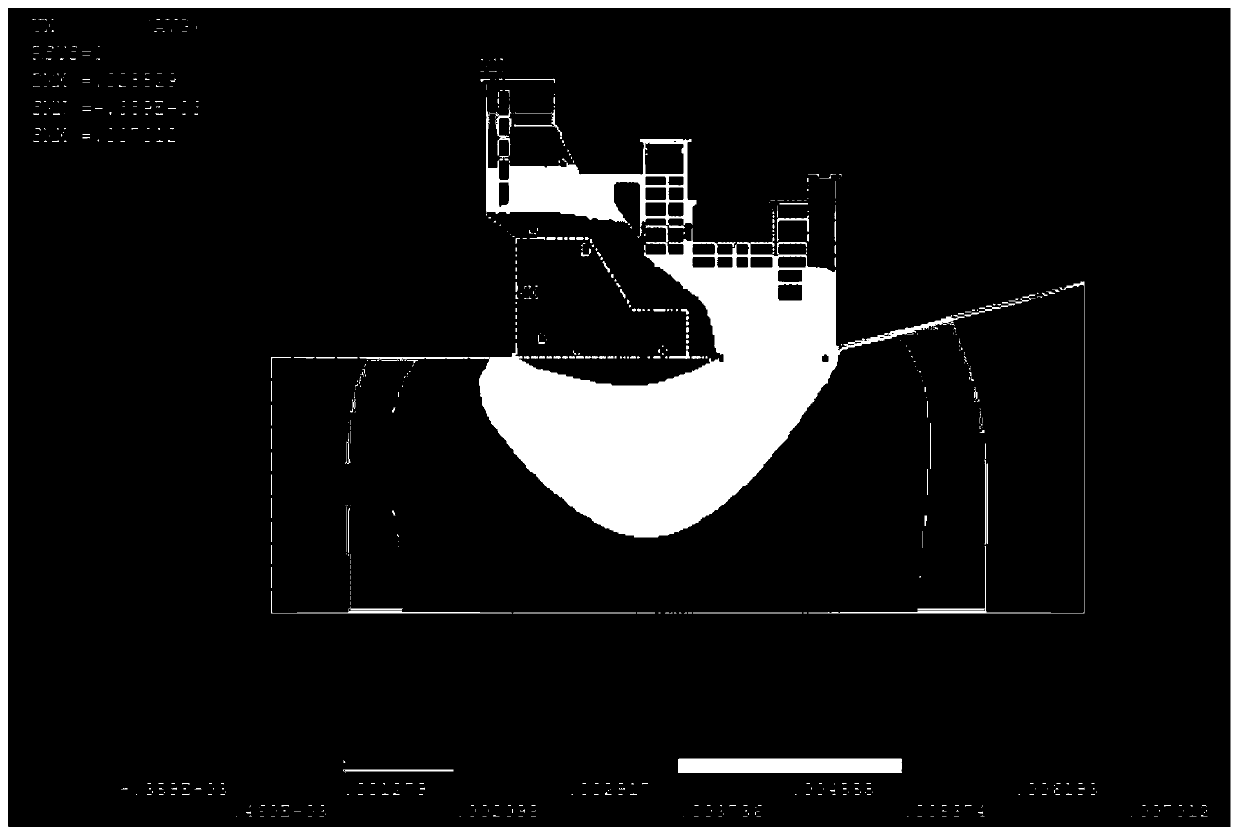

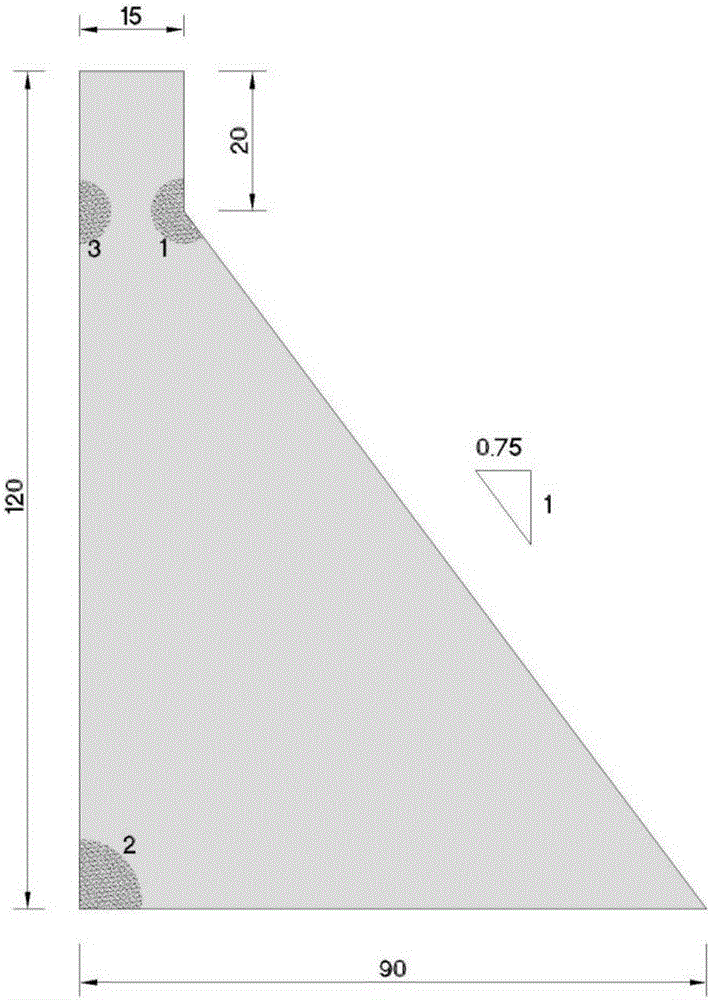

High-precision numerical simulation calculation method for carrying out static characteristic analysis on concrete gravity dam based on h-p type finite element method

ActiveCN110046400AAvoid double countingGood inheritanceGeometric CADDesign optimisation/simulationExtended finite element methodMixed finite element method

The invention relates to a high-precision numerical simulation calculation method for carrying out static characteristic analysis on concrete gravity dam based on h-p type finite element method, and belongs to the technical field of simulation. The high-precision numerical simulation calculation method for carrying out static characteristic analysis on concrete gravity dam based on h-p type finiteelement method comprises the following steps of building a calculation model of the hydraulic concrete gravity dam; calculating a displacement field and a stress field of the hydraulic concrete gravity dam model by a h-p type finite element method; judging whether the obtained displacement field and stress field meet the precision requirement or not, if the obtained displacement field and stressfield do not meet the precision requirement, encrypting the grid again, improving the order of the interpolation polynomial, and repeating the steps until a satisfactory result is obtained. The invention provides a novel high-precision finite element calculation and analysis method for a concrete gravity dam in order to solve the problems that an existing concrete gravity dam model based on traditional finite element static analysis is too long in calculation time, too large in error and low in precision.

Owner:KUNMING UNIV OF SCI & TECH

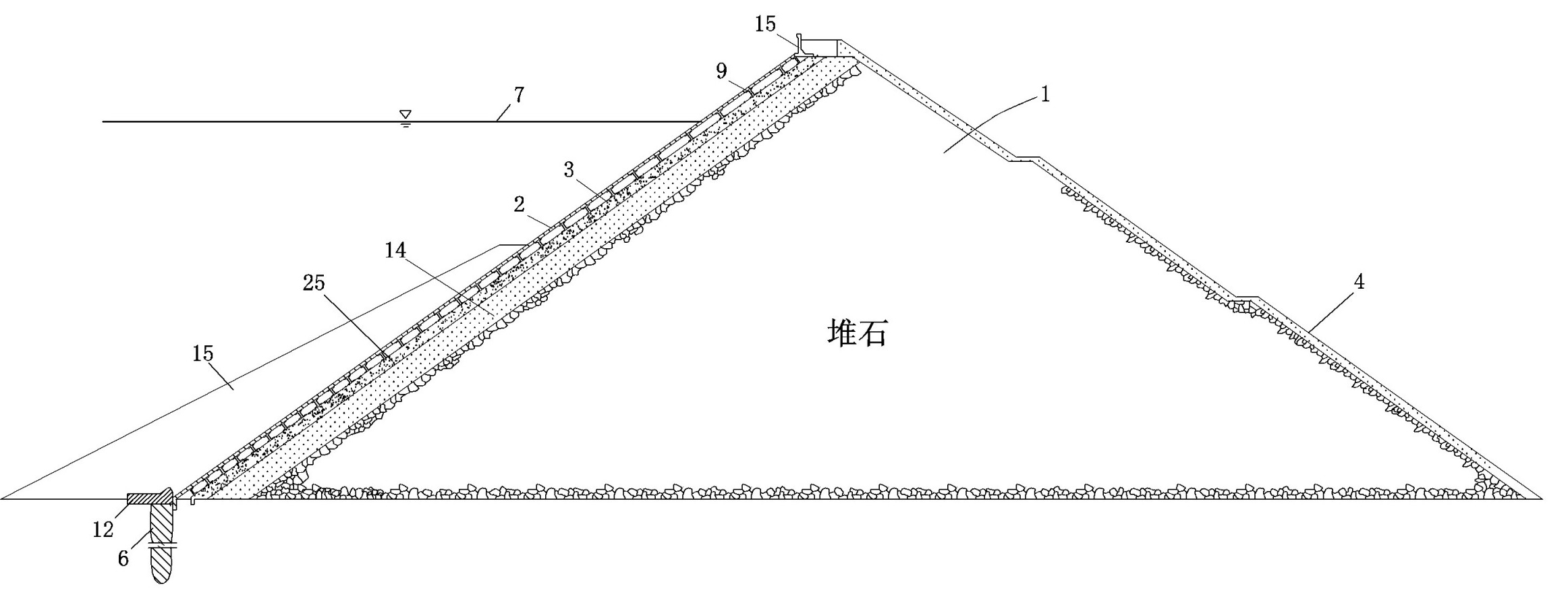

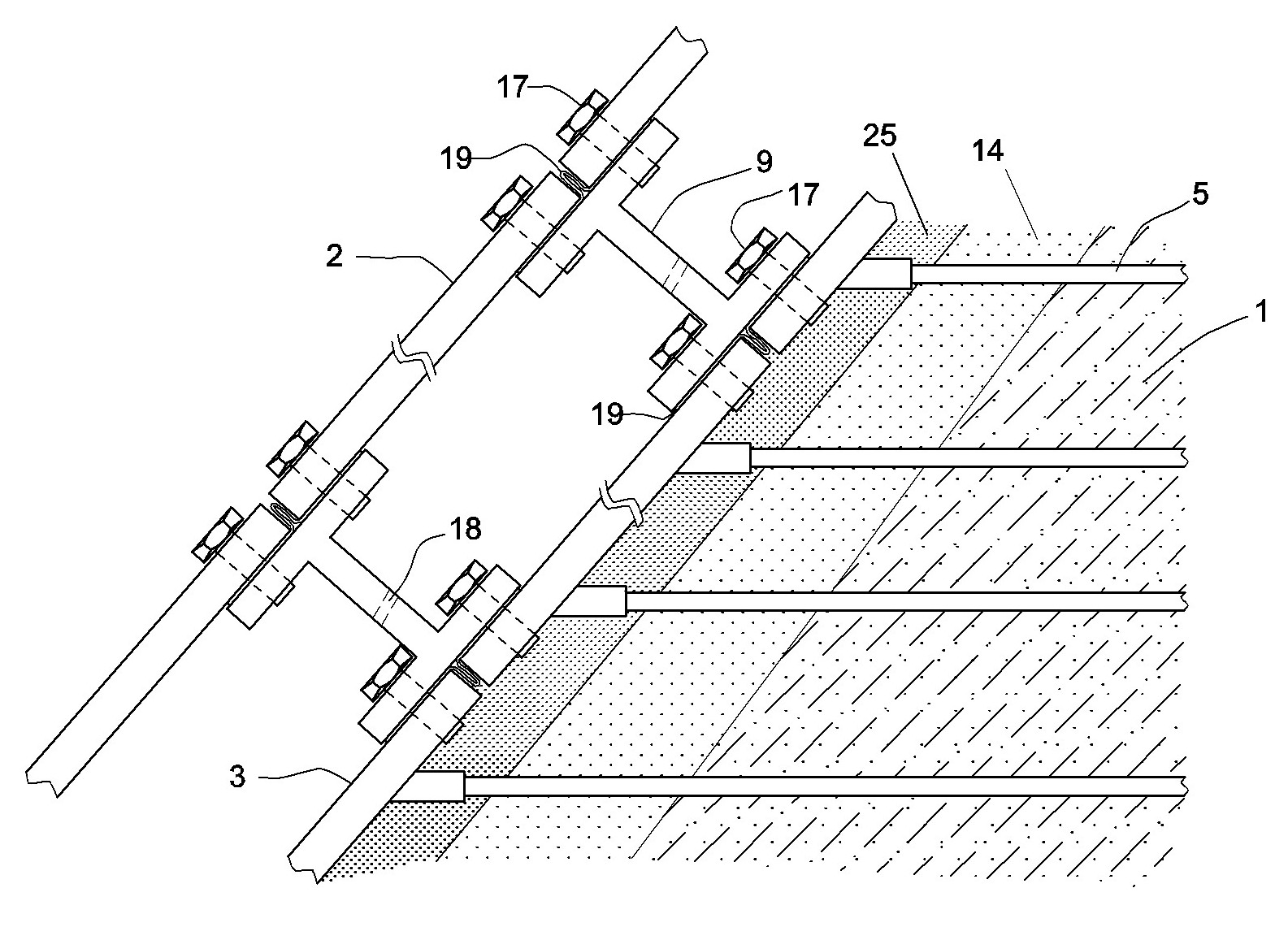

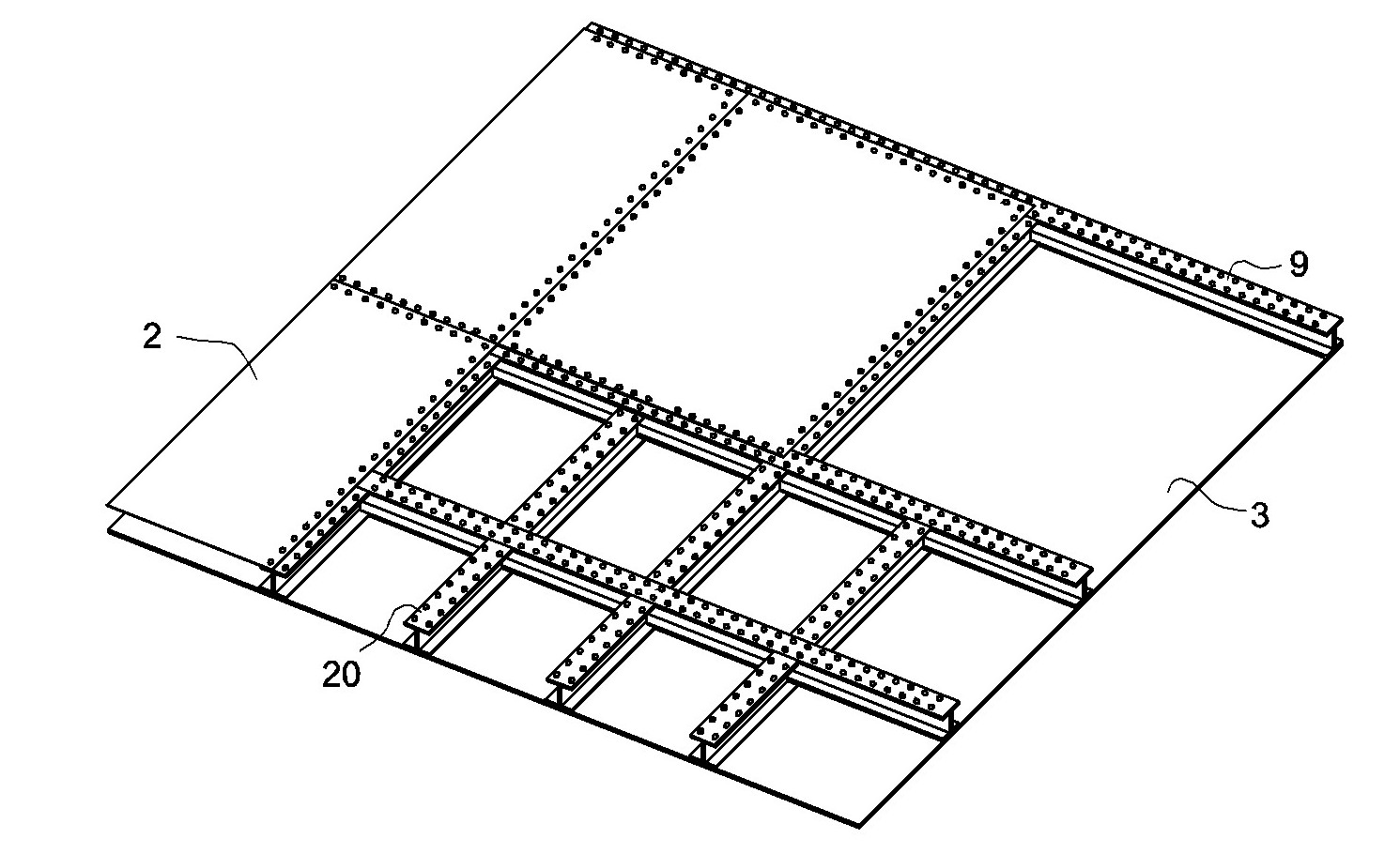

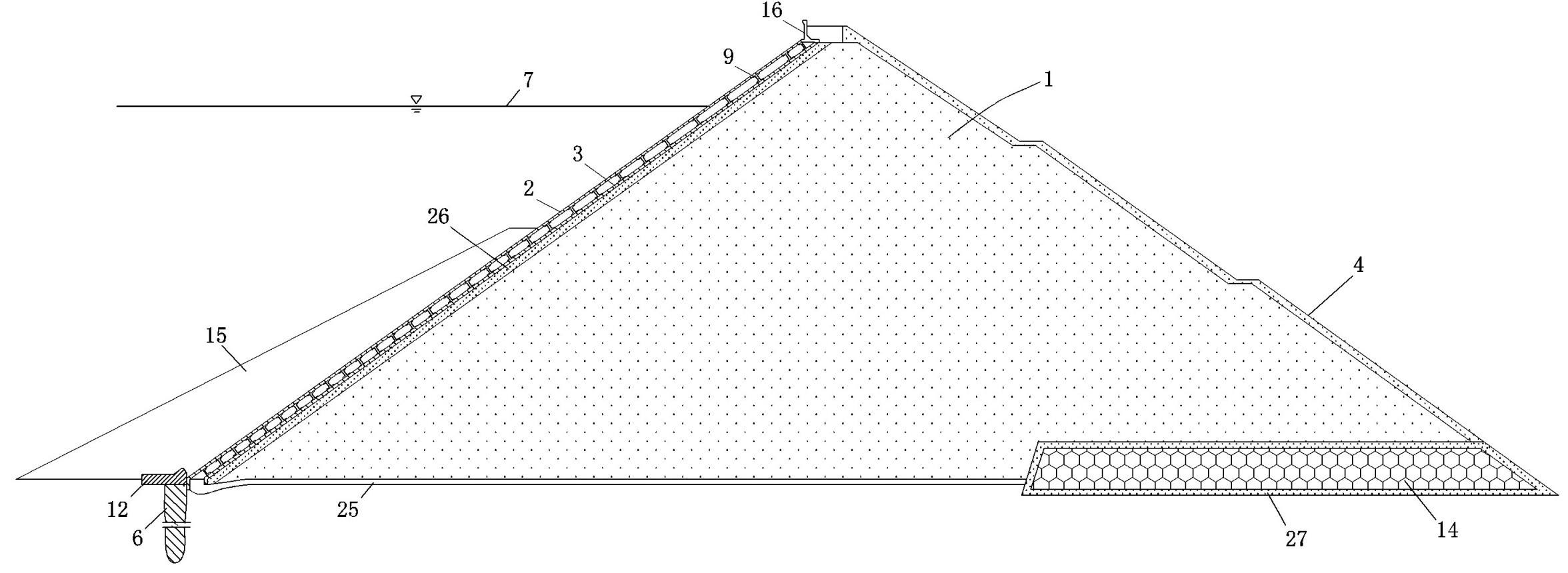

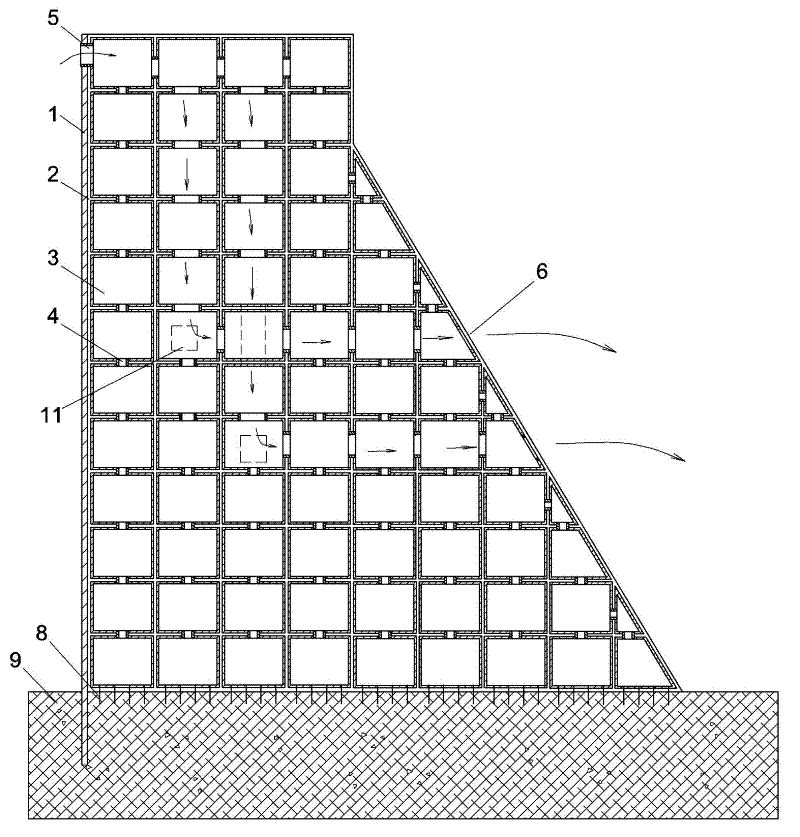

Gravity concrete faced rockfill dam and construction method thereof

ActiveCN107354917AReduce distortionImprove securityEarth-fill damsRock-fill damsThick plateUplift pressure

The invention relates to a gravity concrete faced rockfill dam and a construction method thereof, and belongs to the technical field of water conservancy projects. The gravity concrete faced rockfill dam comprises a concrete panel, a cushion layer, L-shaped thick plates, a rockfill concrete area and other components. The concrete panel is laid on the upstream face of the upstream side of a dam body, and the cushion layer is arranged on the downstream side of the concrete panel. The downstream side of the cushion layer is the rockfill concrete area, the L-shaped thick plates are arranged at a certain interval along the dam height and can be horizontally arranged, the plate ends face the downstream position and go deep into the rockfill concrete area, the other ends of the L-shaped thick plates are big head ends and face the upstream position, and the concrete panel is supported. The downstream side of the rockfill concrete area is a main rockfill area and a secondary rockfill area, and the function of restraining deformation of the rockfill concrete area is achieved. A drainage gallery is located in the rockfill concrete area, upstream seepage water of the dam body and a dam foundation is discharged, the uplift pressure of the dam foundation is reduced, and stability of the dam body is improved. According to the gravity concrete faced rockfill dam and the construction method thereof, the beneficial effects of a gravity dam and the concrete faced rockfill dam are fully utilized, the deformation of the panel is reduced, the probability of panel damage is reduced, and safety of the high concrete faced rockfill dam is ensured.

Owner:KUNMING UNIV OF SCI & TECH

Gravity dam telescopic joint water stop failure backwater fast closing treating method

ActiveCN104846784AEliminate hidden dangersLess investmentMarine site engineeringWater leakagePore water pressure

The invention relates to a gravity dam telescopic joint water stop failure backwater fast closing treating method and belongs to the telescopic joint backwater closing treatment of gravity water blocking building structures of the water conservancy project. The method includes drilling, testing the seepage condition, adopting the auxiliary seepage reducing measure, placing a mechanical grouting pipe and a concrete grouting pipe, first injecting a quick condensing high expansion polyurethane grouting material, and then injecting a special anti-scouring cement base material to close a drilling port and complete the grouting process. The method has the advantages of being capable of quickly treating water leakage caused by telescopic joint water stop damage, capable of achieving water carrying operation, not required to empty a reservoir or not affecting normal water reservation and capable of quickly repairing the damaged water stop by using the material characteristics and the seepage water pressure to achieve low-loss quick repair engineering and remove engineering hidden hazards, greatly saving engineering investment, saving water resources, quickly solving the engineering problems without affecting normal operation of the engineering.

Owner:吉林省银河水利水电新技术设计有限公司

Steel structure combined-type sandwich steel plate rock-fill dam

ActiveCN102155004AEasy to buildLower performance requirementsEarth-fill damsRock-fill damsRiver bedPolyurea

The invention relates to a steel structure combined-type sandwich steel plate rock-fill dam, comprising a cushion layer region, a transition region, a rock fill region, a wave wall and a downstream slope protection. A water blocking panel, two side toe boards and a river bed toe board jointly form an impermeable structure, a combined-type sandwich steel plate of an upstream riverside surface of a dam body comprises an inner steel plate and an outer steel plate as well as a support skeleton, a plurality of fixed joint bars which are deeply inserted in the dam body are transversely arranged on the back surface of an inner single steel plate, and all the surfaces, the joint bars and butt joints or connecting bolts are all coated with a layer of antiseptic impermeable coating polyurea material. The rock-fill dam provided by the invention has the advantages of a gravity dam and a steel structure dam, is stable and is easy to construct, the structural form is flexible, the rock-fill dam can better adapt to topographic conditions, the performance requirement on damming material is low, multiple building materials can be used, environmental disruption produced by damming is reduced, and the rock-fill dam can be processed in batch in a factory, the site construction speed is fast, and the rock-fill dam is convenient to maintain or replace.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

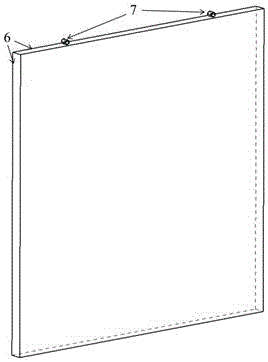

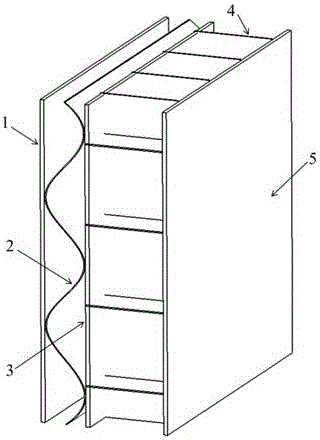

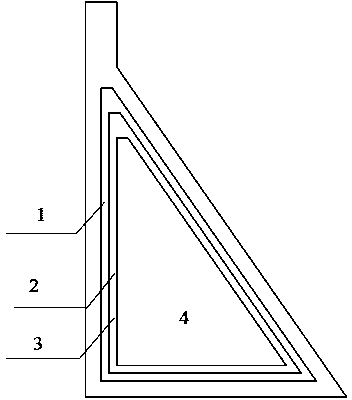

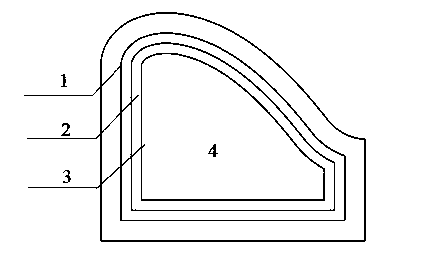

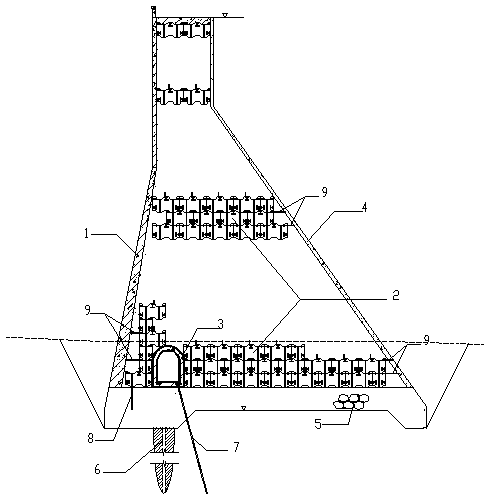

Protection device for underwater anti contact explosion of concrete gravity dam heel

The invention discloses a protection device for the underwater anti contact explosion of a concrete gravity dam heel. The protection device comprises a front panel arranged in sequence from the front to the back, a wave panel, a middle panel, a support partition board and a back panel; the peripheries of the front panel, the middle panel and the back panel are sealed and fixedly connected through a side panel, the wave panel and the front panel and the middle panel are not fixedly connected, the support partition board is used for partitioning the middle panel and the back panel, the support partition board is formed by multiple vertical plates connected together with multiple horizontal plates, and the vertical plates and the horizontal plates partitions the place between the middle panel and the back panel into multiple small cavities which can store sealed air. The deformation and breakage of the front panel and the wave panel are utilized by the protection device to absorb part of the energy from the explosion, then the wave resistance and mismatch resistance principle of the air and the surrounding water medium is utilized, the explosion shock waves are further reflected and attenuated, thus the anti-explosion protection of the gravity dam is increased; the protection device has the advantages of being good in anti-explosion ability, high in residual intensity, simple in structure, and rapid and destruction-free in protection deploying.

Owner:WUHAN UNIV

Steel structural panel sand gravel dam

ActiveCN102155005AEasy to buildLower performance requirementsEarth-fill damsRock-fill damsPolyureaGravity dam

The invention relates to a steel structural panel sand gravel dam, which comprises a dam body and a drainage system thereof, a seepage preventing structure and a downstream protection slope. A steel structural combined panel on the upstream water surface of the dam body comprises steel plates of inner and outer layers and a supporting skeleton between the steel plates, the water back surface of the single steel plate of the inner layer is transversely provided with a plurality of fixed insertion ribs inserted into the damp body, and a layer is anticorrosion seepage-proof coating polyurea material is assisted on all the surfaces of the steel structural combined panel, the insertion ribs and butted seams or connecting bolts. The dam simultaneously has the advantages of a gravity dam and a steel structured dam, and the inner plates and the dam body are combined into a whole so that the dam is firmer. The dam is stable and easily built, has flexible structural form, can better adapt to the topographic conditions, has low requirements for damming materials, can be built by using multiple building materials, reduces environmental destroy due to damming, can be processed in batch in a factory, has high field construction speed, and is convenient for maintenance or replacement.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

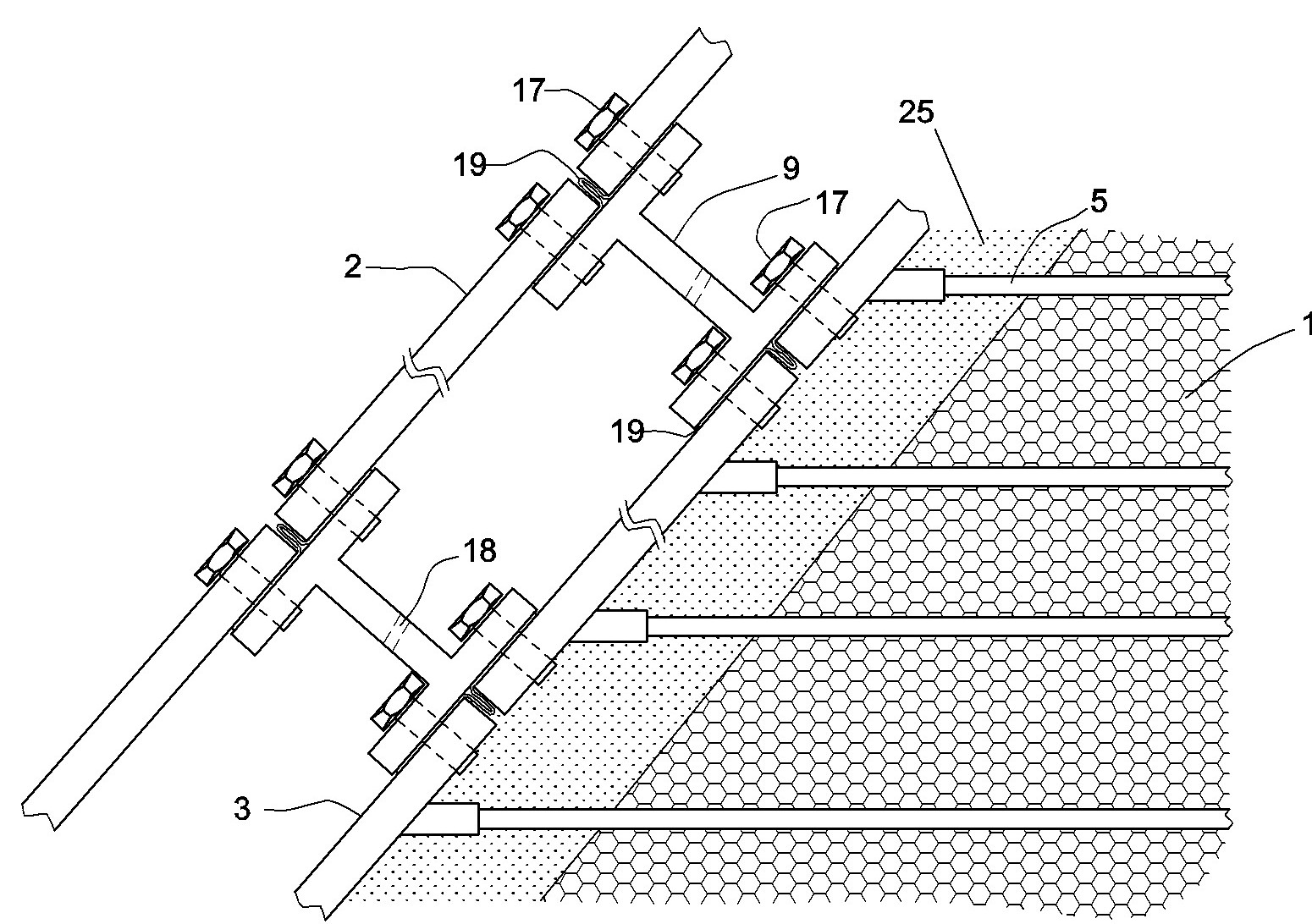

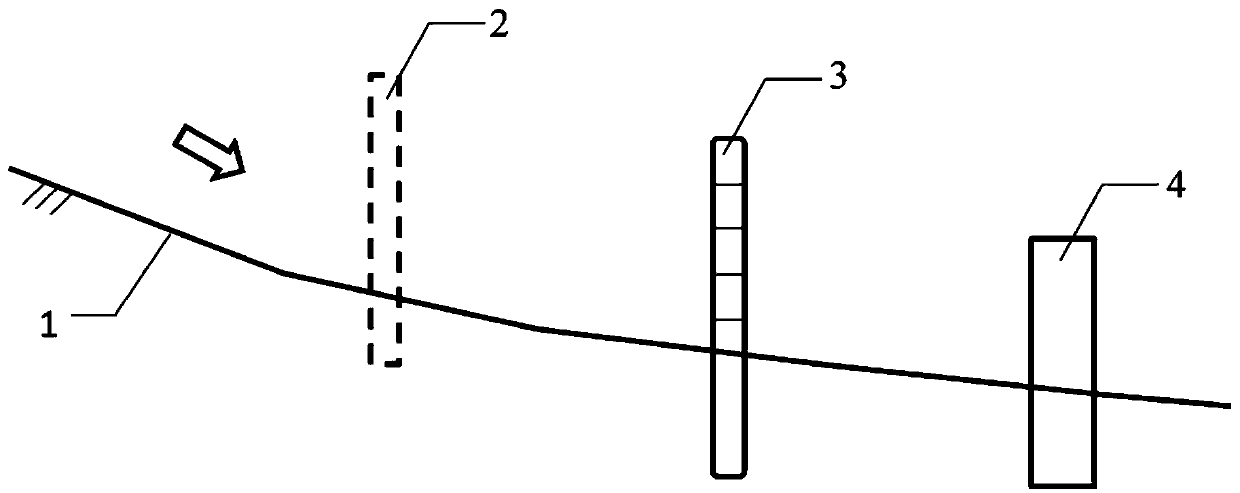

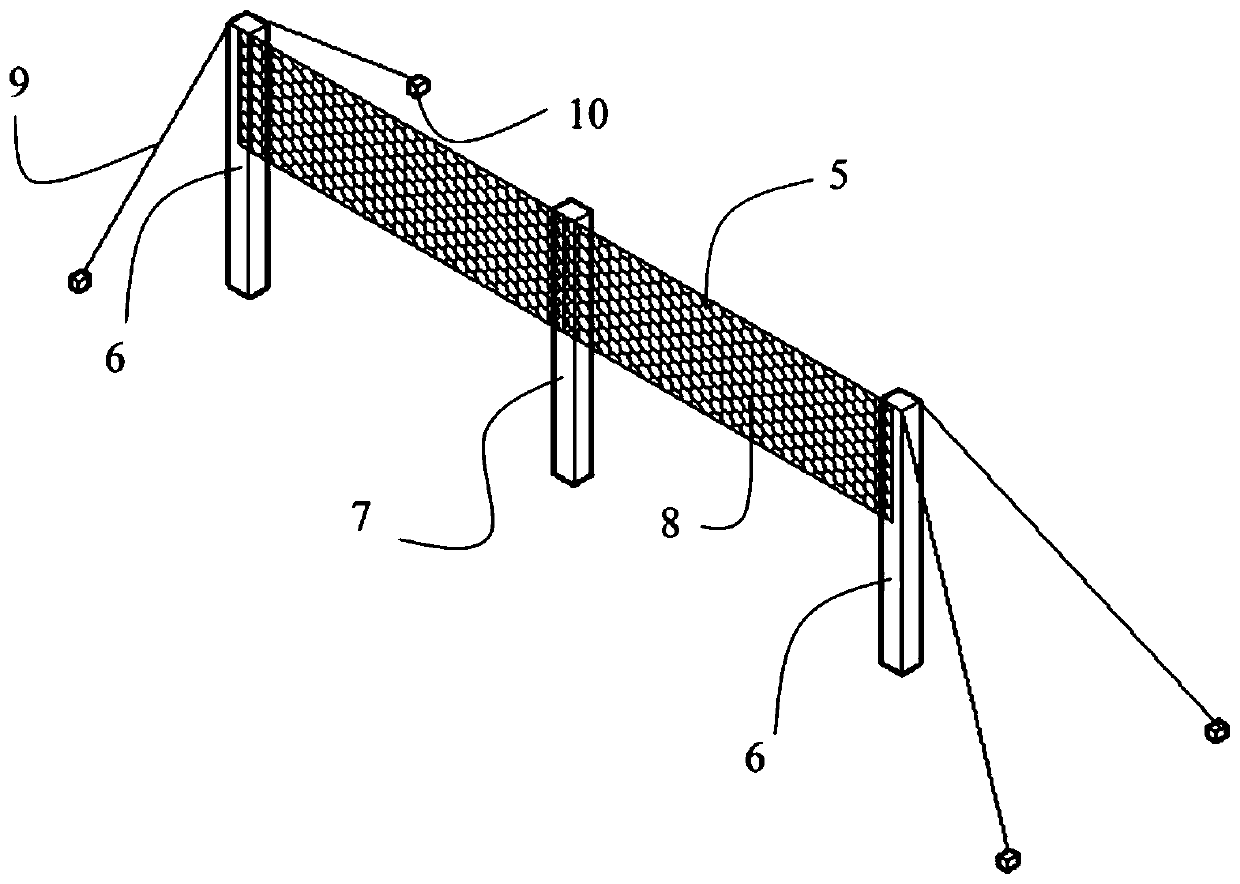

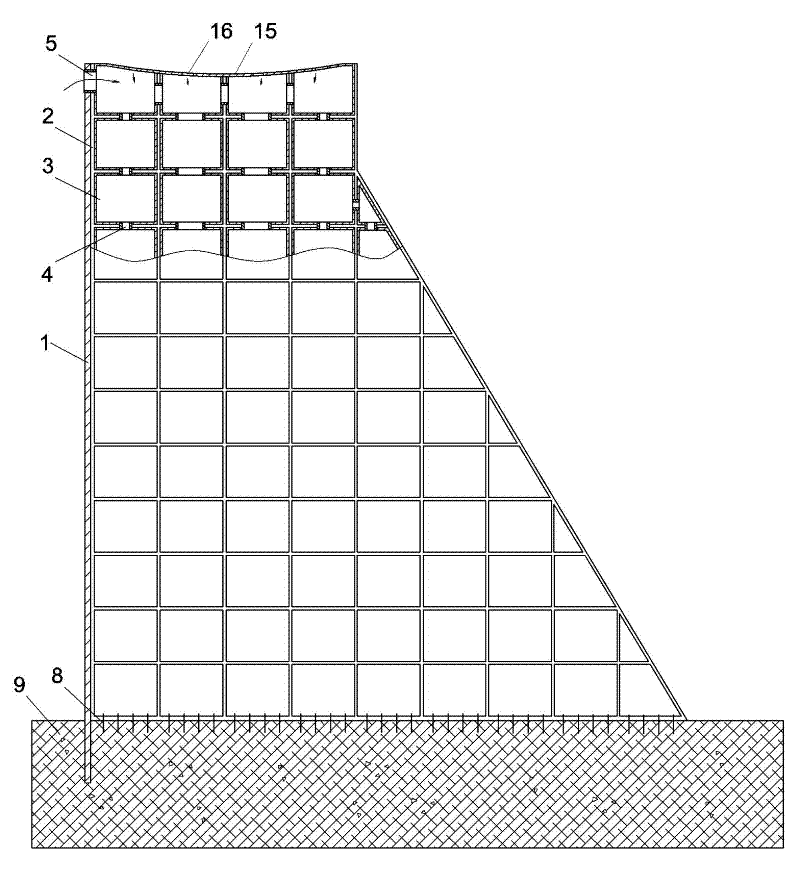

Debris flow multi-stage dissipative blocking structure

PendingCN110004882AConsume impact energyReduce shockProtective constructionFoundation engineeringButtressEngineering

The invention relates to the technique of prevention of geological hazards, in particular to a debris flow prevention technique. The invention discloses a debris flow multi-stage dissipative blockingstructure, thus damage action of a debris flow can be lowered, and the disaster loss is relieved. According to the debris flow multi-stage dissipative blocking structure, from flowing area of the debris flow to the accumulation area, the debris flow multi-stage dissipative blocking structure is arranged in a step-by-step mode along debris flow channels from the upstream to downstream, and at leastincludes a flexible blocking net, a pile-carrying-type grid wall and a permeable buttress-type gravity dam. According to the debris flow multi-stage dissipative blocking structure, according to different geological conditions, types of the debris flows and the like, the matching structure of the flexible blocking net 2, the pile-carrying-type grid wall 3 and the permeable buttress-type gravity bam is reasonably selected, benefits of the investment in engineering construction can be given full play to the maximum extent, and cost benefit optimization is achieved. The debris flow multi-stage dissipative blocking system is very suitable for prevention of the debris flow disasters.

Owner:SOUTHWEST JIAOTONG UNIV

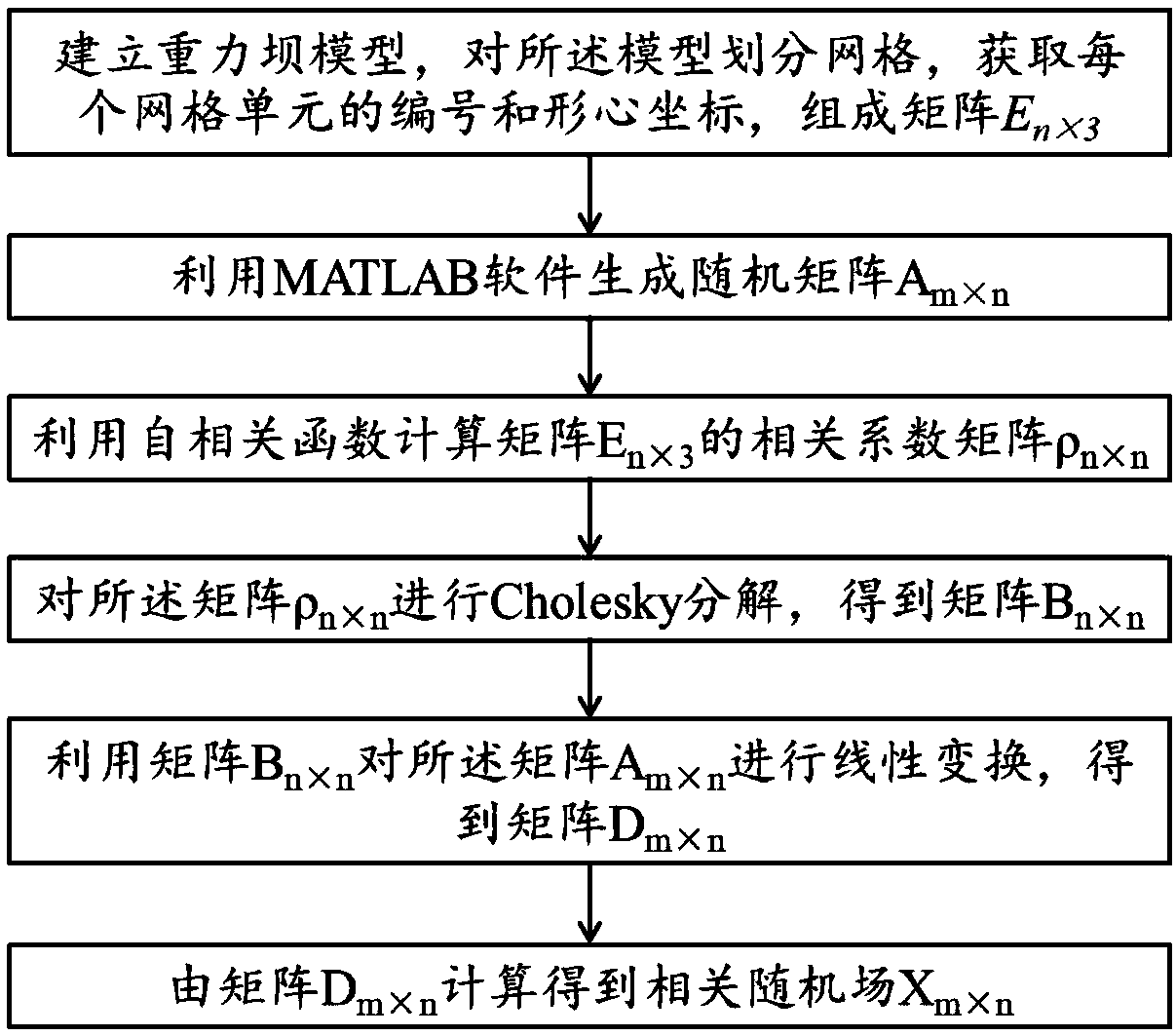

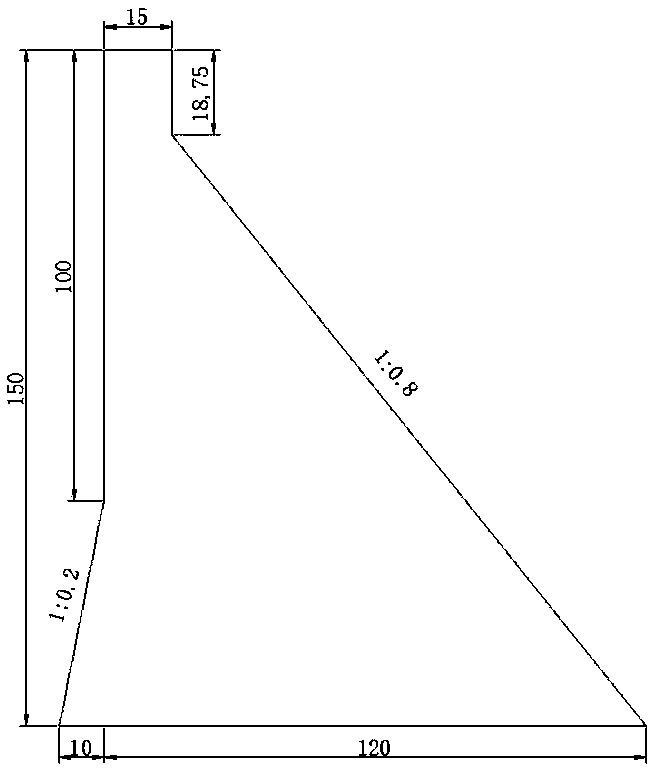

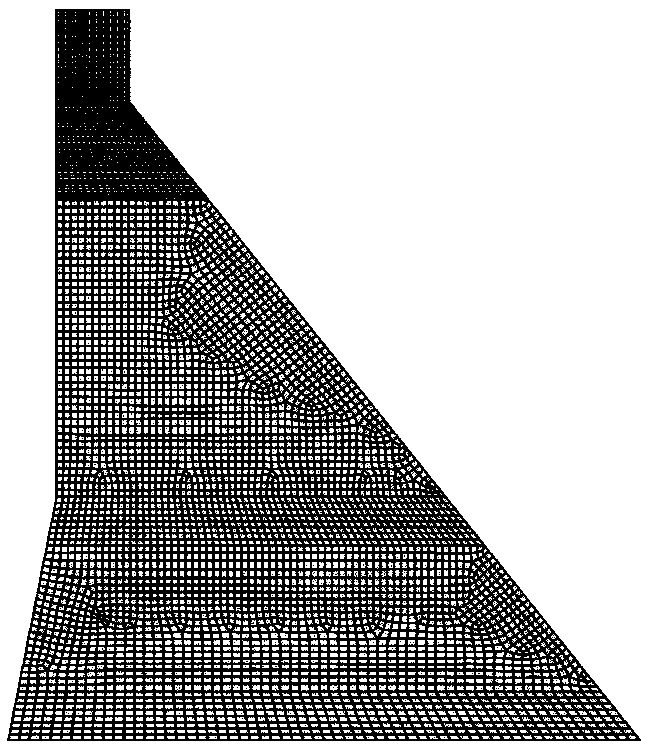

Simulation method for parameter spatial variability of concrete gravity dam material

ActiveCN108629111AIn line with engineering practiceAccurate data supportGeometric CADDesign optimisation/simulationSelf correlationMATLAB

The invention provides a simulation method for parameter spatial variability of a concrete gravity dam material. The method comprises the following steps that a gravity dam model is established and subjected to grid division, a number and shape center coordinates of each grid unit are acquired, and a matrix En*3 is formed; MATLAB software is used for generating a random matrix Am*n; a self-correlation function is used for calculating a correlation coefficient matrix rhon*n of the matrix En*3; the matrix rhon*n is subjected to Cholesky decomposition, and an upper triangular matrix Bn*n is obtained; the matrix Bn*n is used for conducting linear transformation on the matrix Am*n to obtain a matrix Dm*n; the matrix Dm*n is calculated to obtain a related random field Xm*n. The simulation methodbetter accords with engineering practice, and the more accurate data support can be provided for safe running of a gravity dam in the later result.

Owner:SICHUAN UNIV

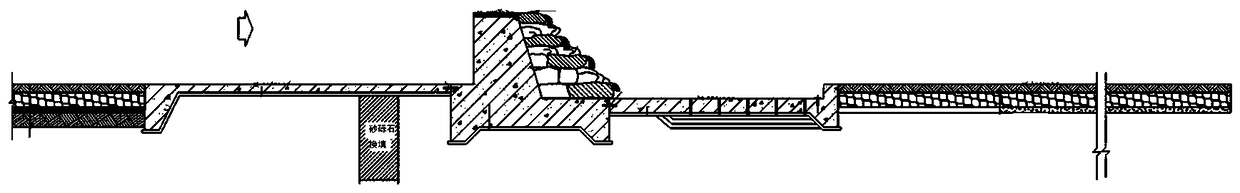

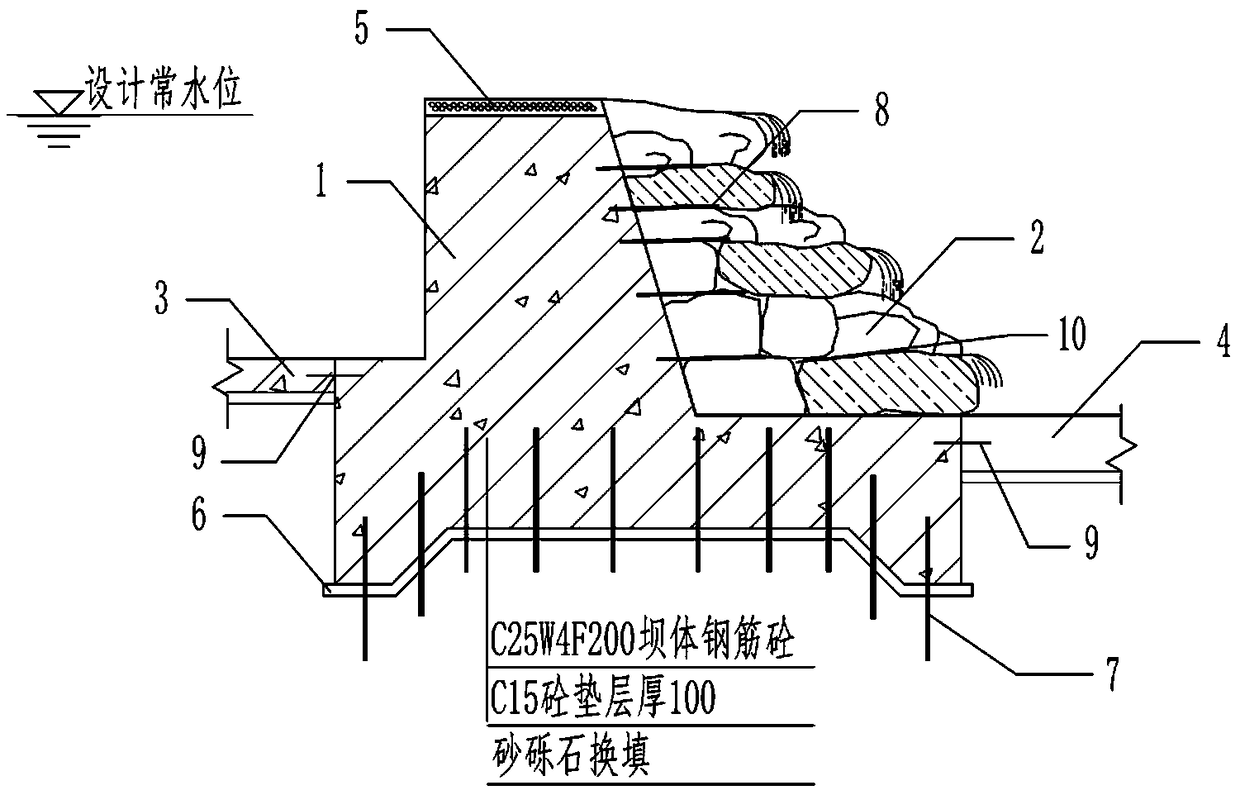

Artificial landscape overflow dam construction method with energy dissipation effect

ActiveCN109208545AImprove the landscape effectLess investmentWall damsHydraulic structureEngineering

The invention belongs to the fields of energy dissipation technology and urban landscape construction of hydraulic structures, and provides an artificial landscape overflow dam construction method with an energy dissipation effect. The artificial landscape overflow dam construction method with the energy dissipation effect solves the problems such as long construction period and high constructioncost due to silencing of an existing landscape dam. The method is characterized in that a structure combining a thin concrete overflow dam and masonry landscape stones is adopted; concrete and the masonry landscape stones form a gravity dam to resist the horizontal load of upstream water pressure; the masonry landscape stones are utilized to form a natural water falling atmosphere generating structural dam body with the energy dissipation effect. With the adoption of the construction method, the size of the concrete gravity dam is reduced; the construction of the energy dissipation structure at the back of a dam is simplified; and moreover, the landscape waterfall and energy dissipation effects are realized; the operation of the dam body is safe; the service life of the dam body is prolonged; and the engineering investment is saved.

Owner:CHINA SHANXI SIJIAN GRP

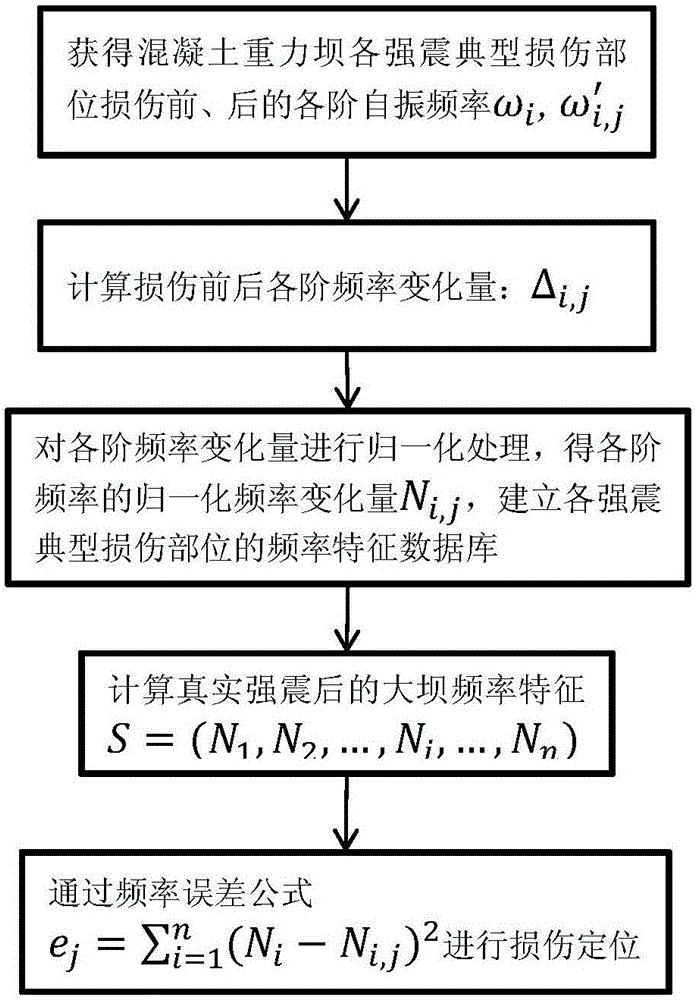

Concrete gravity dam strong shock damaged part quick identification method based on frequency errors

InactiveCN105738480ALimit efficiencyLimit ApplicabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringFrequency characteristic

The invention discloses a frequency error-based rapid identification method for strong earthquake damage parts of concrete gravity dams, which is suitable for the identification of strong earthquake damage parts of concrete gravity dams. The damage position identification method proposed by the invention can effectively reflect the frequency characteristics of the concrete gravity dam under different damage position conditions, and can quickly and accurately identify the damage position of the dam under the action of strong earthquakes. This method is simple to operate, without using a damage detector, and only needs to obtain the natural vibration frequencies of each order of the dam after the strong earthquake to quickly identify the damaged part of the strong earthquake, which has wide applicability.

Owner:WUHAN UNIV

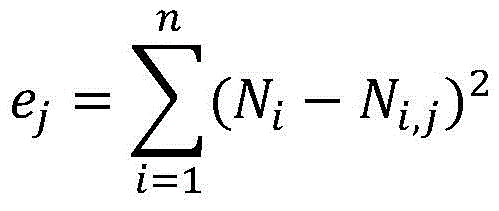

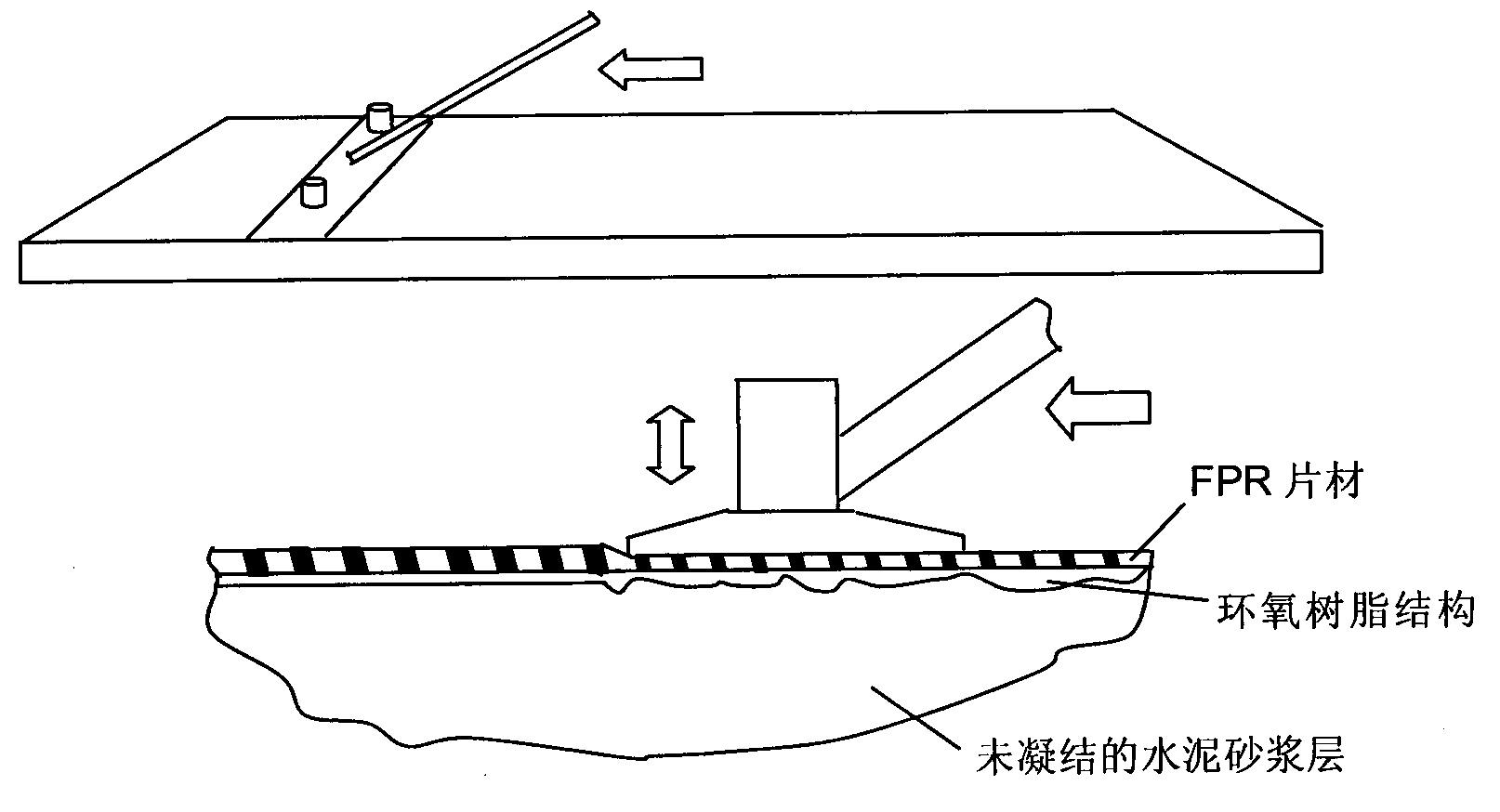

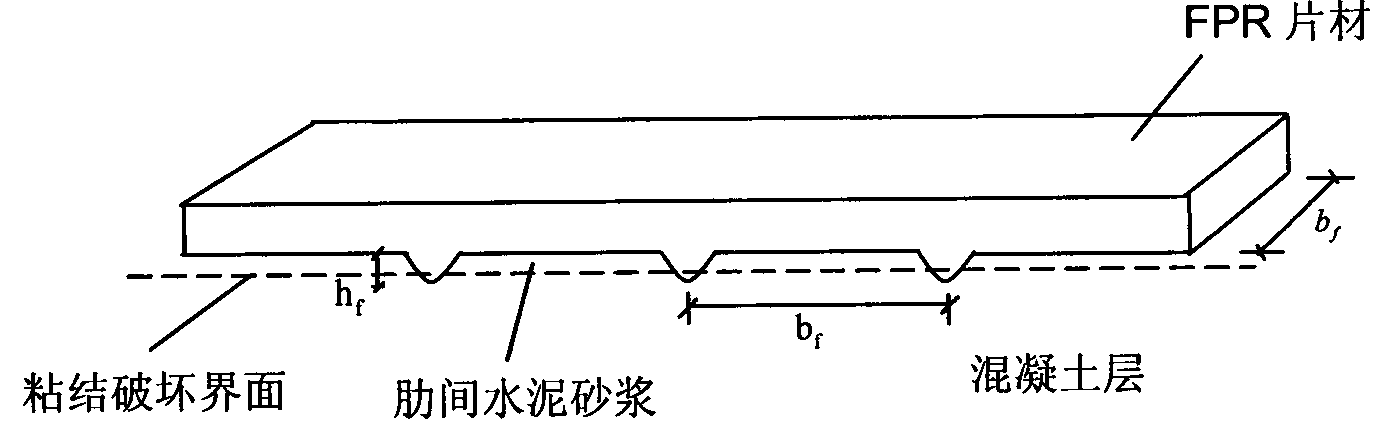

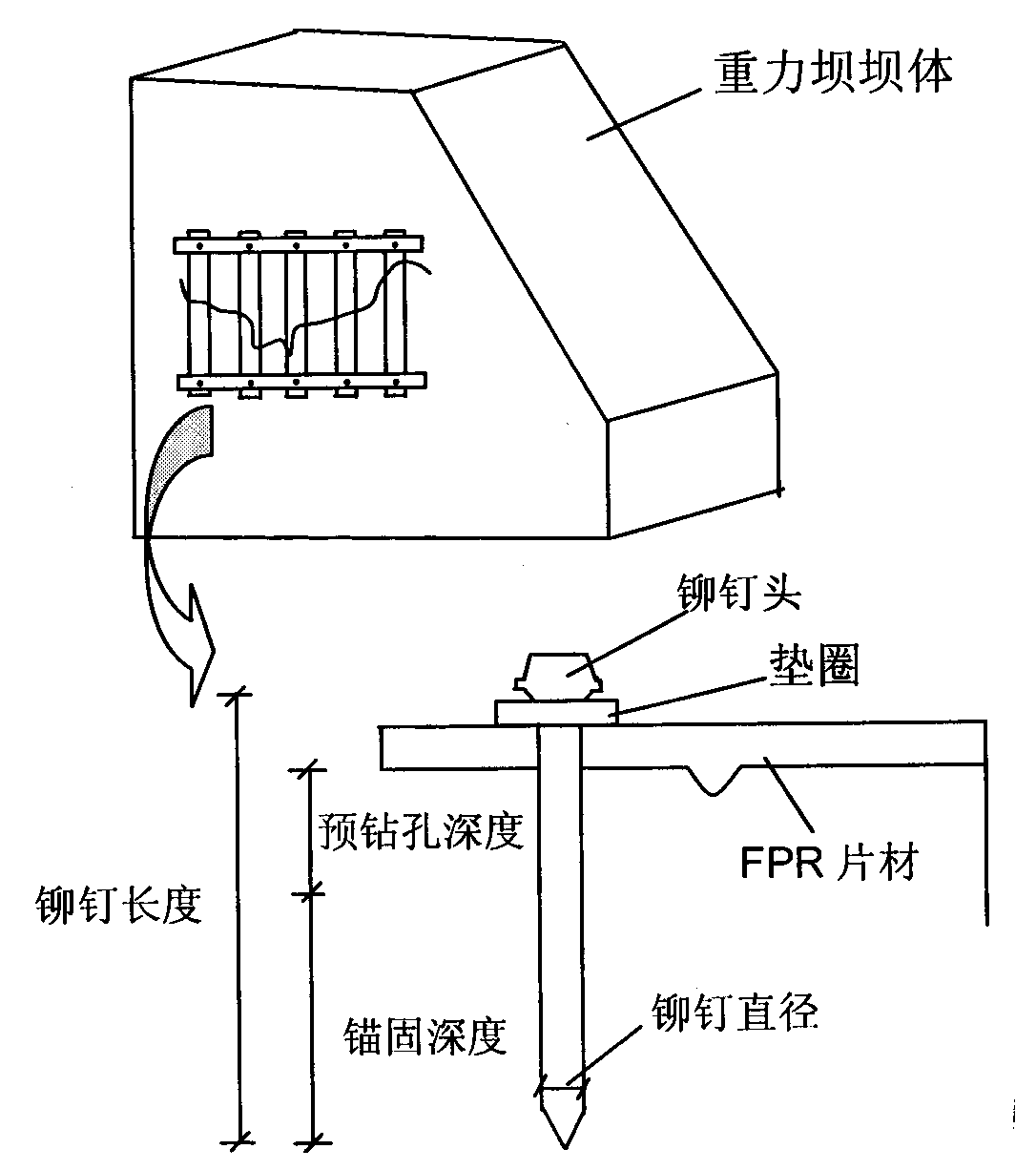

Fixing method for repairing old concrete gravity dam with cracks through FRP

The invention belongs to the field of structure engineering, material engineering and hydraulic and hydro-power engineering, and provides a fixing method for repairing an old concrete gravity dam with cracks through FRP. According to the method, the characteristics of low weight, high strength and corrosion resistance of FRP pieces are fully considered, an epoxy resin structure mixed with coupling reagents guarantees reliable bonding of the FRP pieces and the concrete gravity dam, and force is transmitted together. The grinding mode is used for embedding the FRP pieces with ribs to a non-congealed cement mortar face layer for repairing, and the FRP pieces and the non-congealed cement mortar face layer are tightly bonded and mechanically meshed. Rivets are used for mechanically anchoring the edges of the FRP pieces which is prone to stripping damage, the FRP pieces can not be easily stripped or subjected to brittle failure, and further expanding of the cracks is restrained. The method is simple and can be conveniently applied to engineering, the method can be used as an effective way for bonding, fixing and repairing the old concrete gravity dam with the cracks through the FRP pieces, design and construction for reinforcing the old concrete gravity dam through the FRP pieces can be guided, the expected protection requirement can be met through the design, and unnecessary economic waste is avoided.

Owner:凌贤长

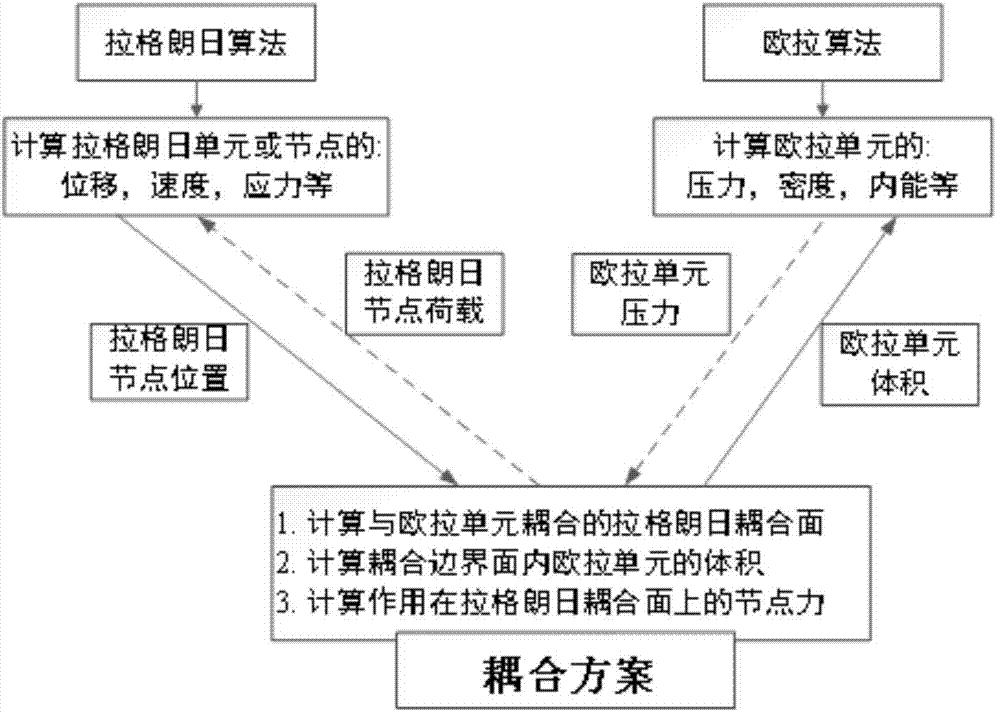

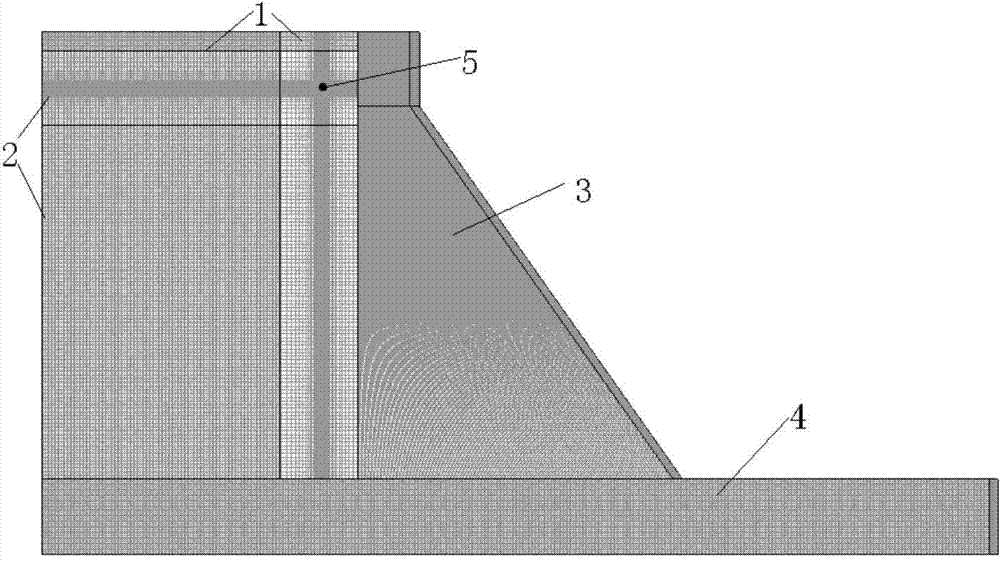

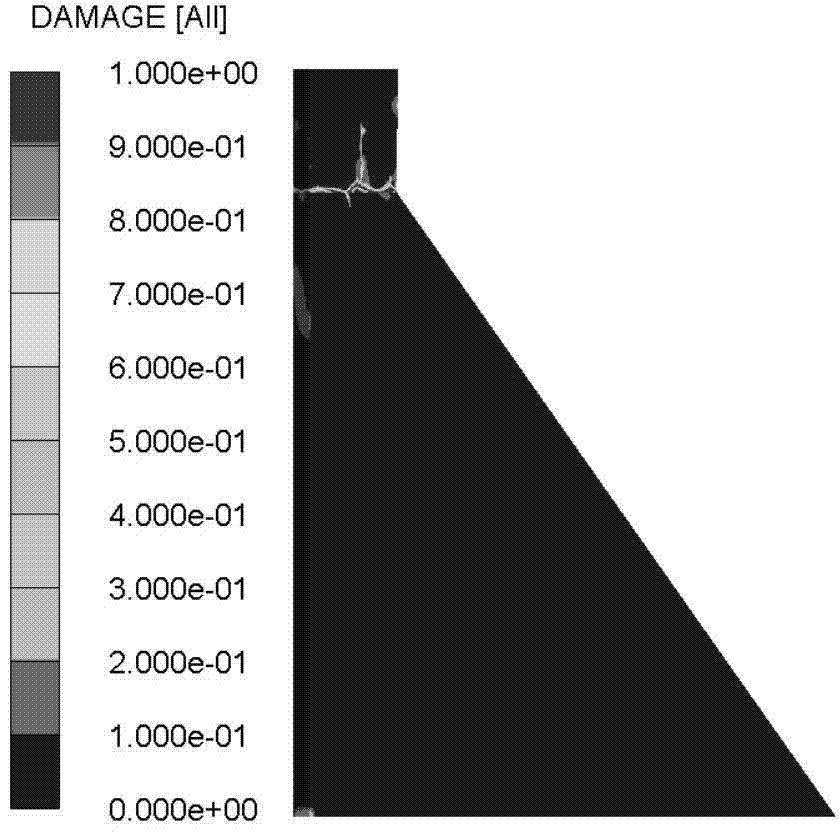

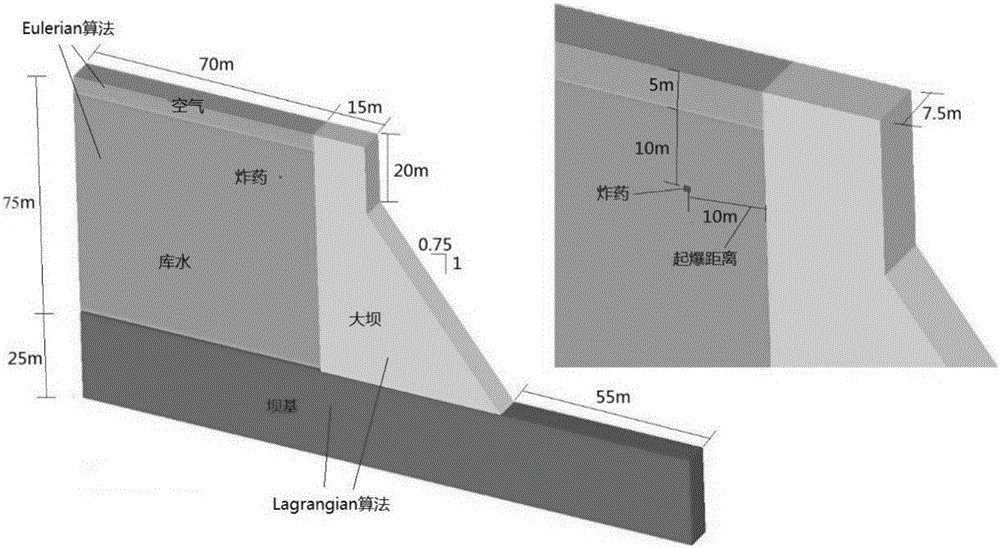

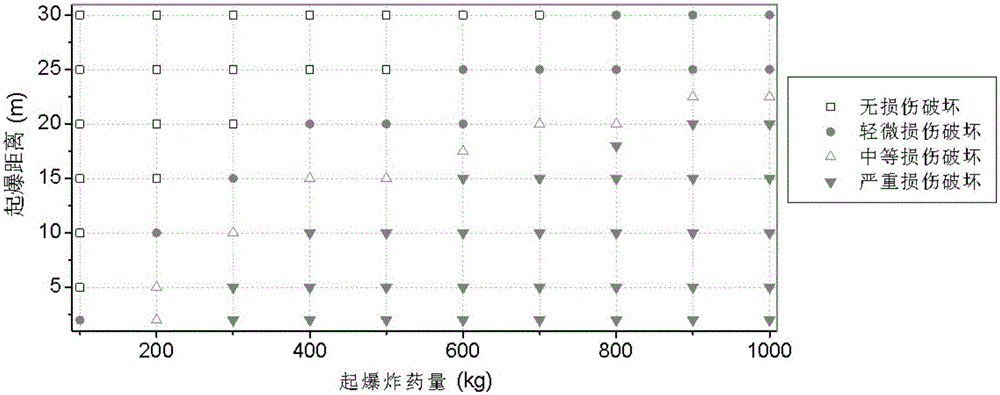

Anti-knock protection method for improvement of safety performance of concrete gravity dam

ActiveCN104732112AImprove anti-knock safety performanceAvoid damageSpecial data processing applicationsUnderwater explosionFully coupled

The invention discloses an anti-knock protection method for improvement of safety performance of a concrete gravity dam. The method includes the steps: step 1, acquiring characteristic parameters of the concrete gravity dam according to practical conditions; step 2, respectively establishing underwater explosion fully-coupled models corresponding to different reservoir water levels according to a Lagrangian-Eulerian full coupling method, carrying out numerical calculation on the basis of the underwater explosion fully-coupled models to acquire concrete gravity dam damage spatial distribution characteristics corresponding to different reservoir water levels; step 3, contrastively analyzing the concrete gravity dam damage spatial distribution characteristics corresponding to different reservoir water levels to acquire the optimal anti-knock safety performance of the concrete gravity dam when the reservoir water level is below the elevation of a downstream slope apron of the dam; step 4, lowering the reservoir water level to be below the elevation of the downstream slope apron of the dam in wartime. The anti-knock protection method for improvement of the safety performance of the concrete gravity dam has the advantages of high operability, easiness in implementation, low extra appropriation expenditure and remarkable improvement of the anti-knock performance of the concrete gravity dam and is especially applicable to improvement of the anti-knock safety performance of built concrete gravity dams.

Owner:WUHAN UNIV

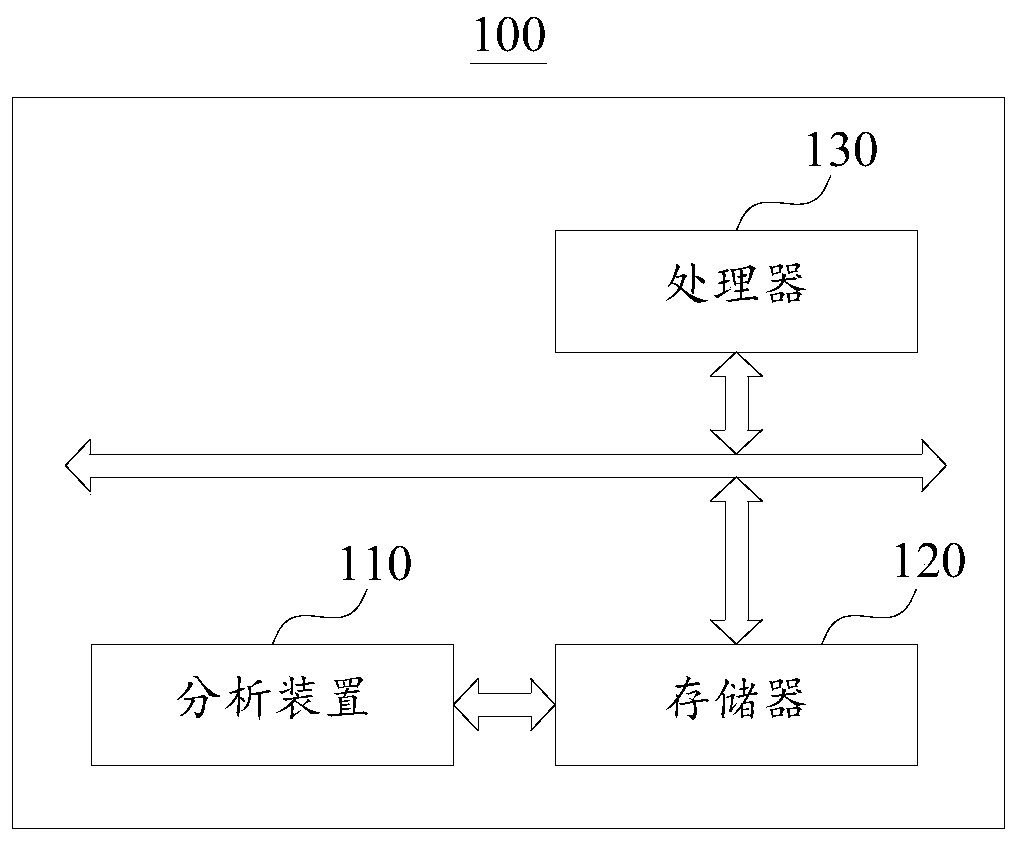

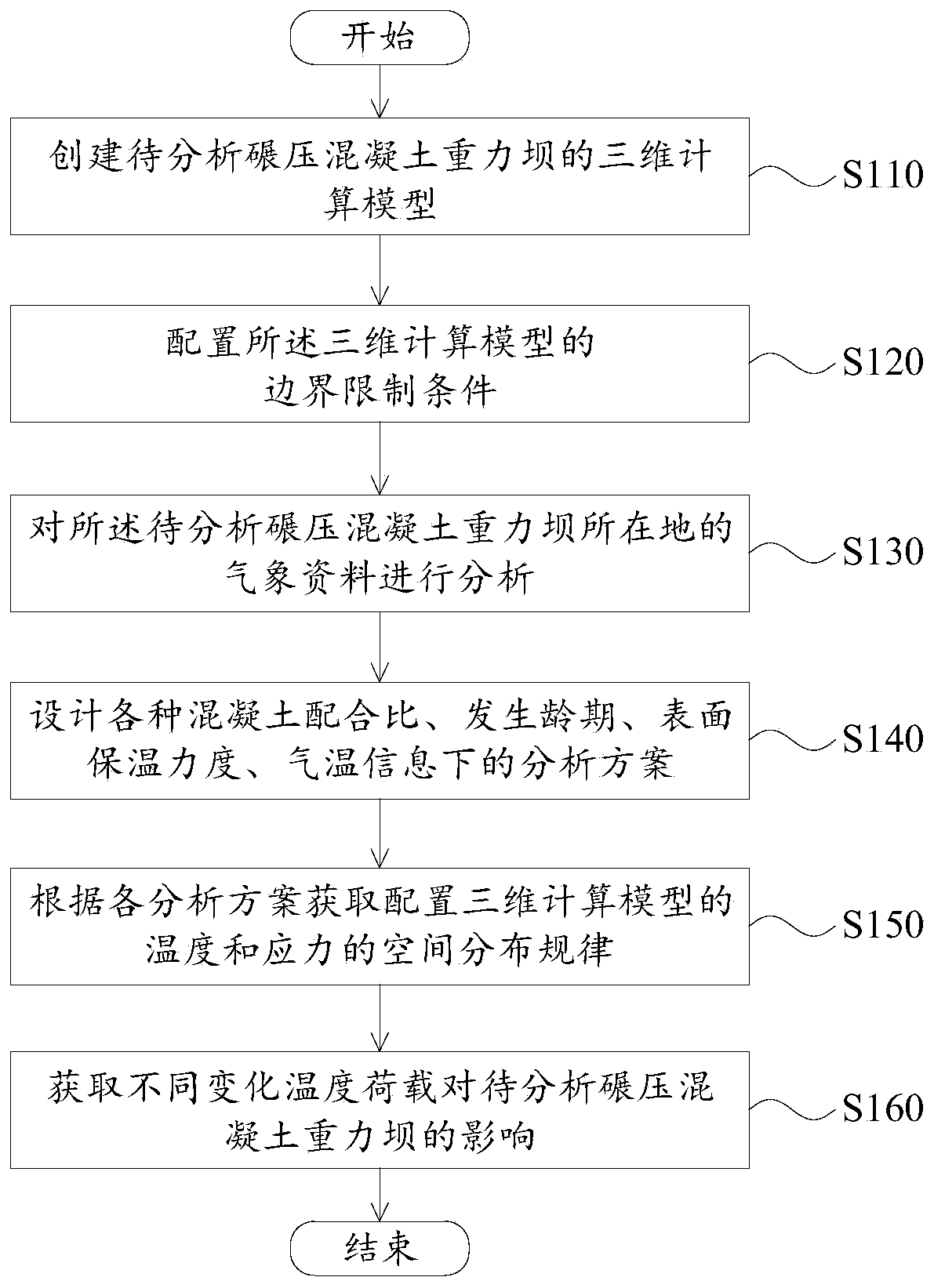

Method and device for analyzing the influence of variable temperature load on roller compacted concrete gravity dam

ActiveCN110119585AAvoid crackingGeometric CADDesign optimisation/simulationRoller-compacted concreteEngineering

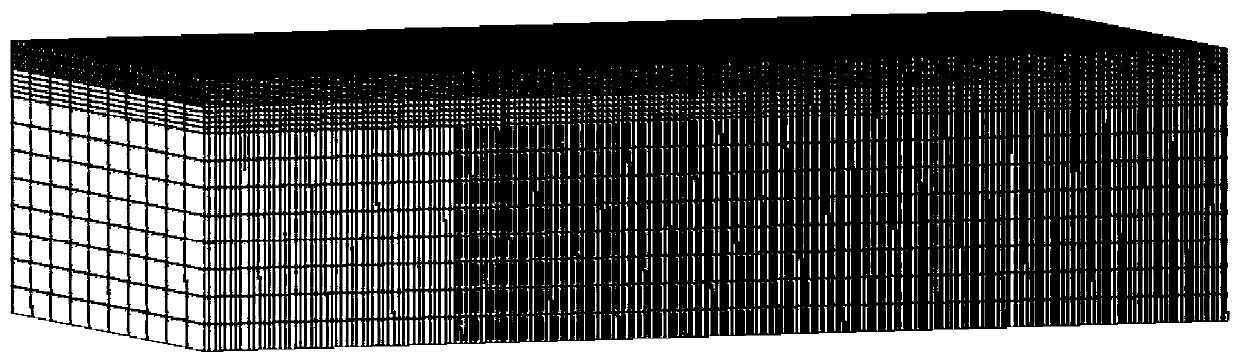

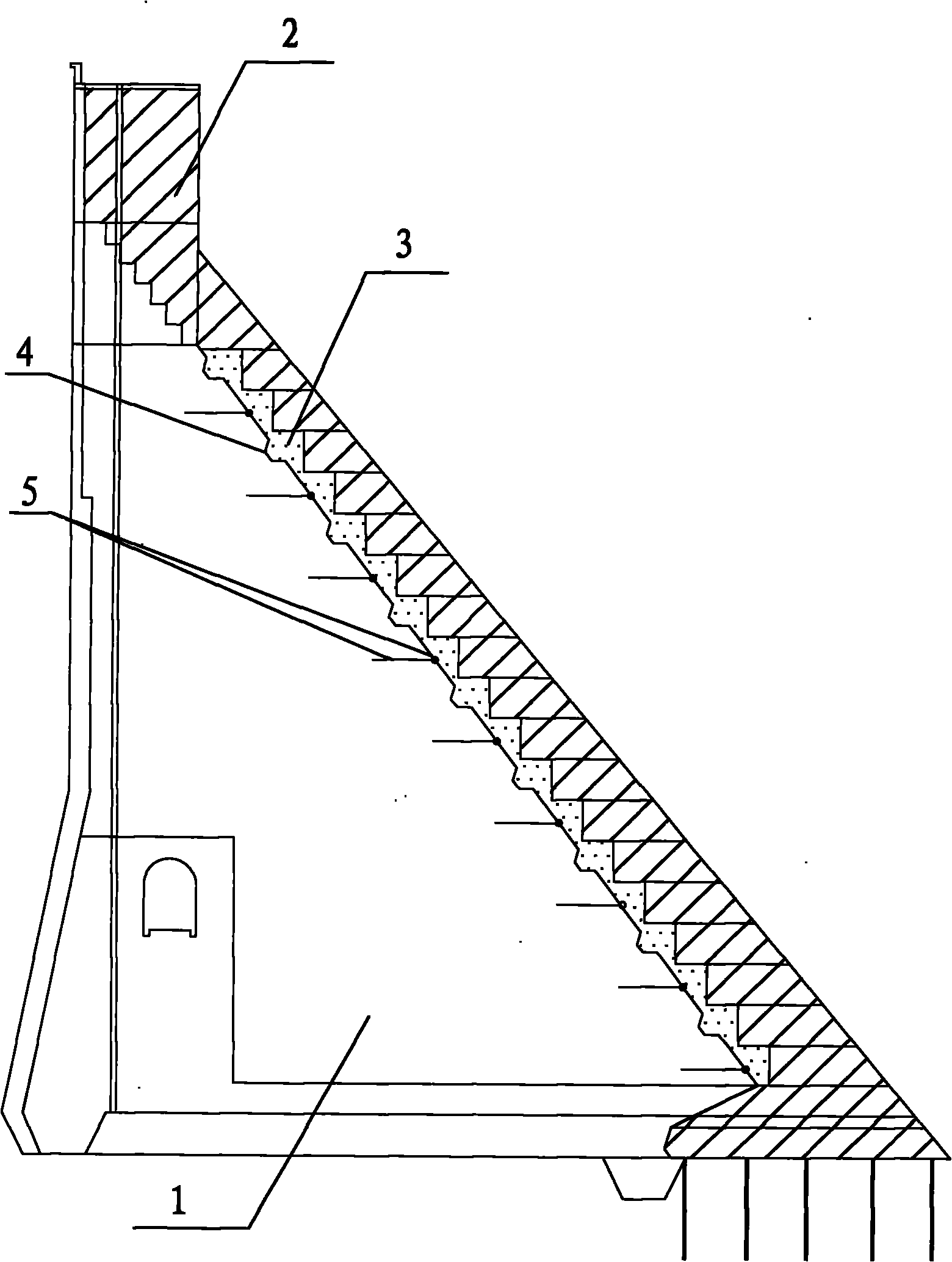

The invention discloses a method and a device for analyzing the influence of a variable temperature load on a roller compacted concrete gravity dam. According to the scheme, by analyzing different conditions of the roller compacted concrete gravity dam, the influence conditions of different change temperature loads on the roller compacted concrete gravity dam to be analyzed can be obtained. According to the scheme, a three-dimensional calculation model of the roller compacted concrete gravity dam to be analyzed is created. Boundary limiting conditions of the three-dimensional calculation modelare configured, meteorological data of the place where the roller compacted concrete gravity dam to be analyzed is analyzed and then analysis schemes under different conditions are designed. The configured three-dimensional calculation model is calculated under each analysis scheme to obtain the spatial distribution rule of the temperature and the stress of the three-dimensional calculation modelunder each analysis scheme. Finally, the calculation result of the three-dimensional calculation model is analyzed under the analysis scheme to obtain the influence of different change temperature loads on the roller compacted concrete gravity dam to be analyzed.

Owner:华电福新周宁抽水蓄能有限公司 +1

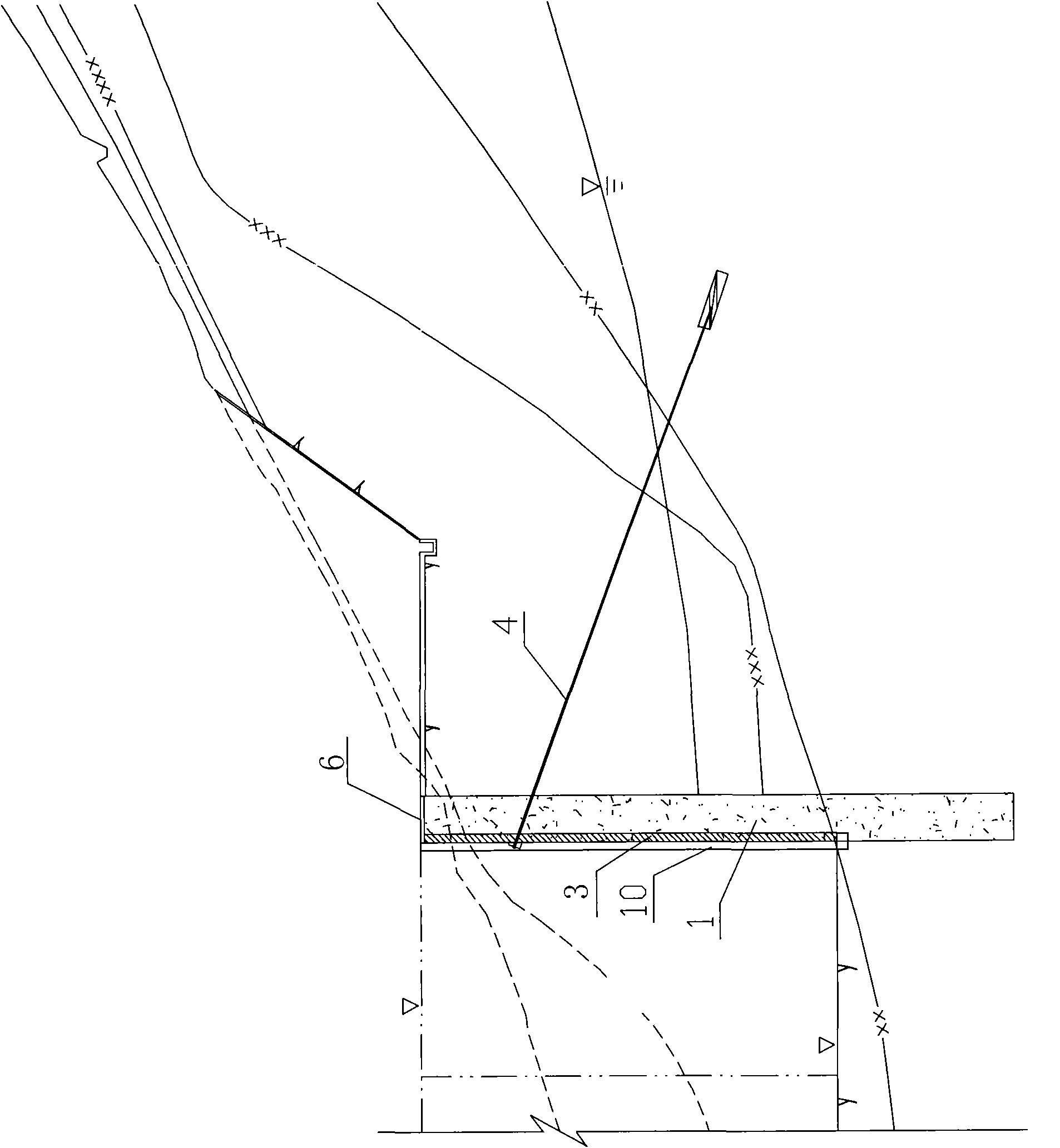

Novel key groove for back-upper heightening of stone-laying gravity dam

ActiveCN102011377AStrong shear resistanceOvercomes the adverse effects of the initial heat of hydrationGravity damsTemperature stressEngineering

The invention provides a reinforced key groove for back-upper heightening of a stone-laying gravity dam and relates to a novel key groove in a hydro-structure. The key groove for the back-upper heightening of the stone-laying gravity dam is characterized in that before being heightened, the original water-retaining dam sections are heightened, a plurality of shear keys are buried in the orginal water-retaining dam sections, wherein one parts of shear keys are buried in the original water-retaining dam sections, and the other parts of shear keys are exposed, and then the dam is heightened. When the dam is heightened, a backfill cavity is formed between the original water-retaining dam sections and the heightened parts thereof so that the exposed parts of the shear keys drop in the backfill cavity, and finally micro-expansive concrete is filled in the backfill cavity finally. The novel key groove overcomes the adverse influences caused by the initial hydration heat of concrete as well as the defect of the difficult process of digging steps on original dams so that the dams are convenient to rapidly construct, and simultaneously also improves the temperature stress of newly cast large-size concrete so that the joint surface between a new dam body and an old dam body has stronger shearing resistance.

Owner:广东省水利电力勘测设计研究院有限公司

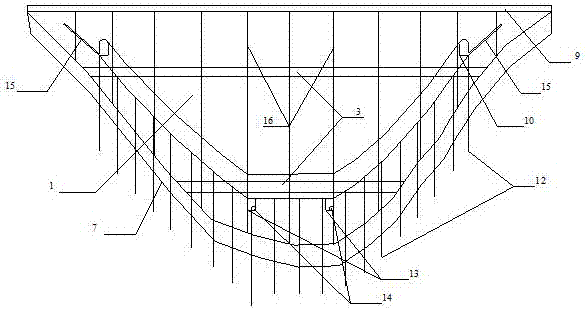

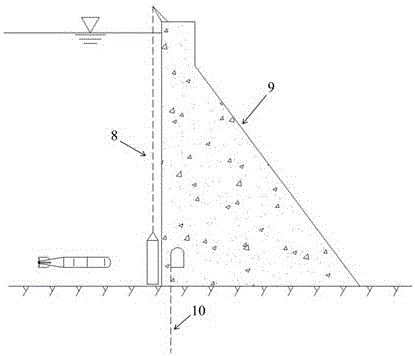

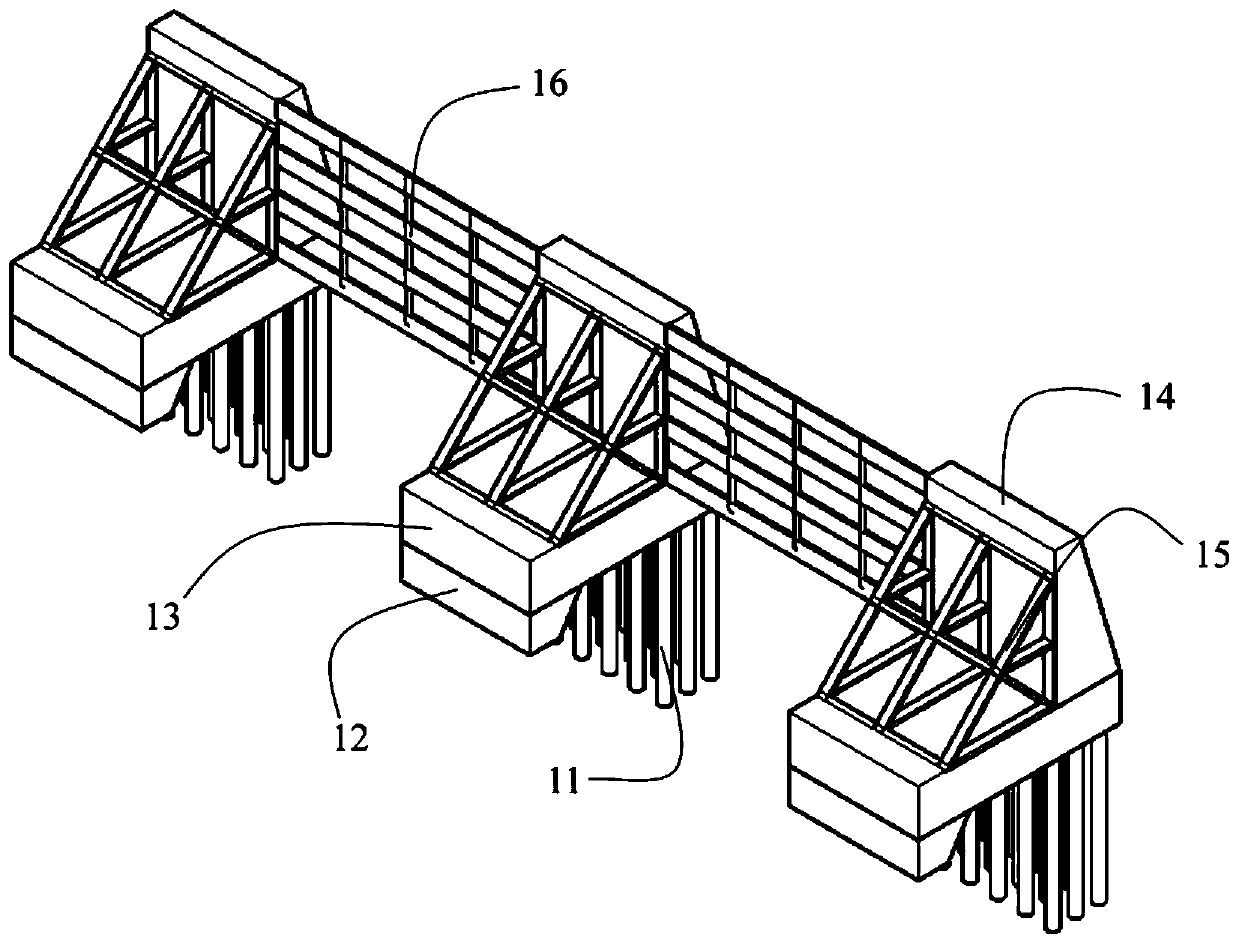

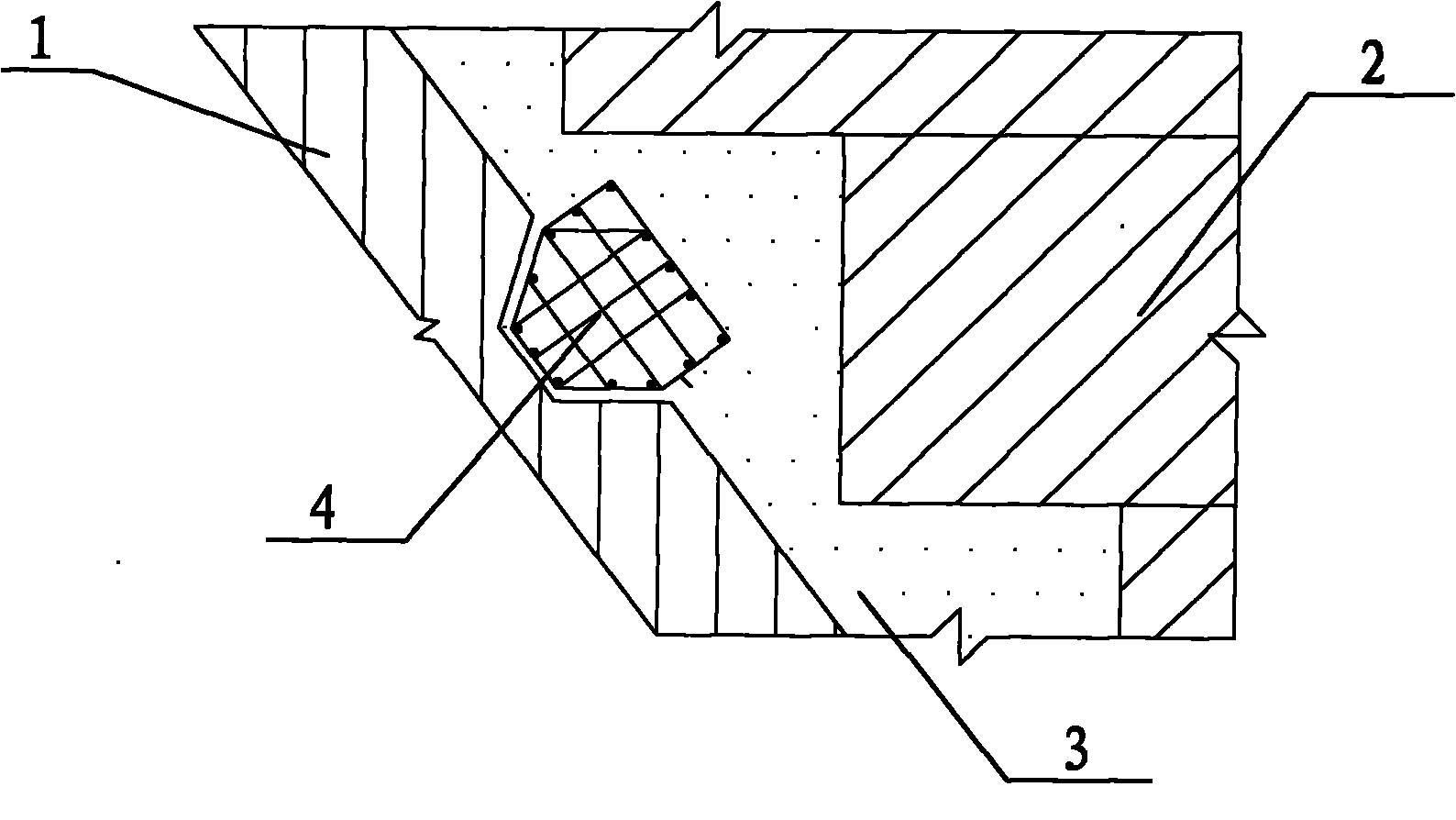

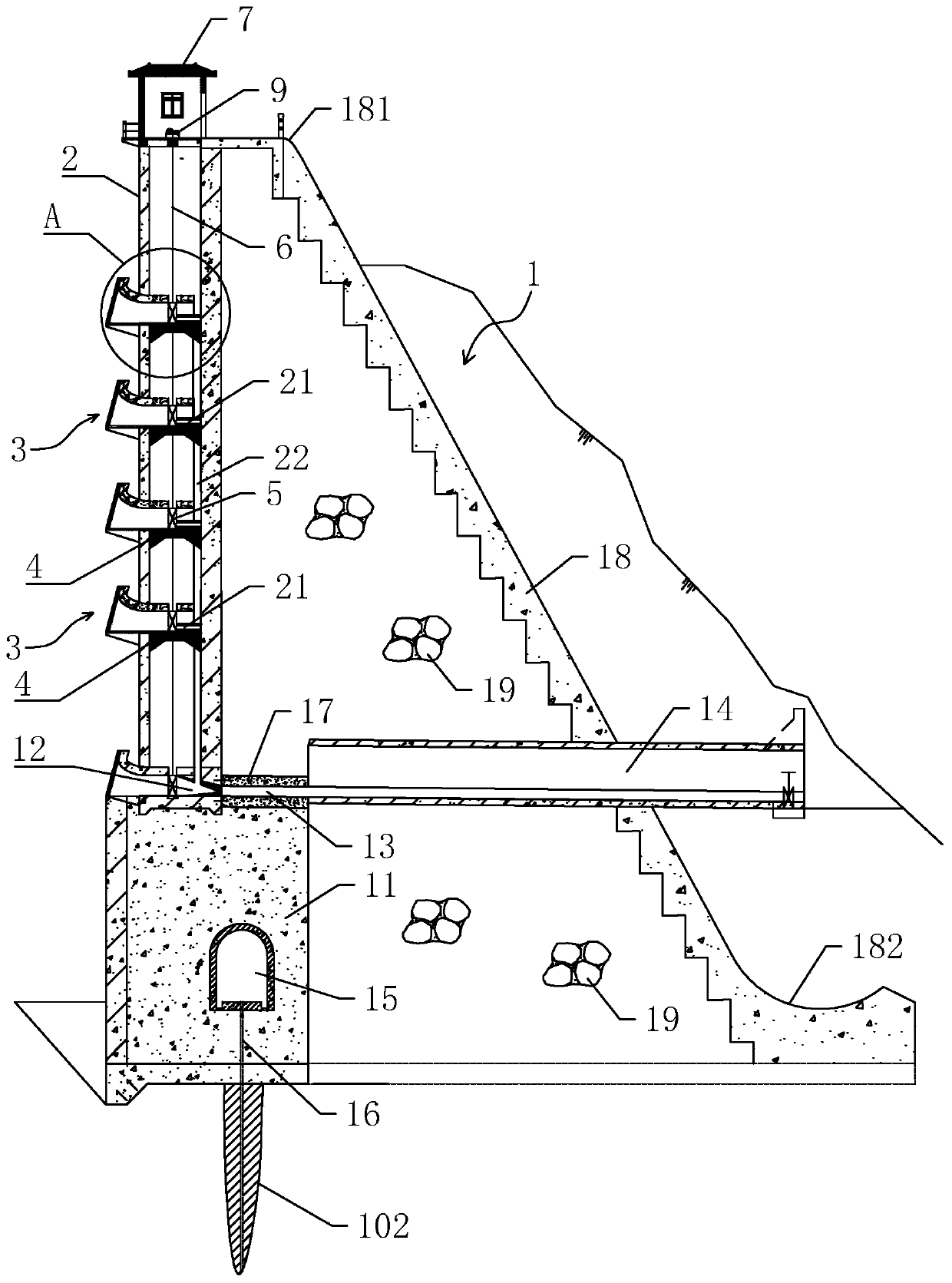

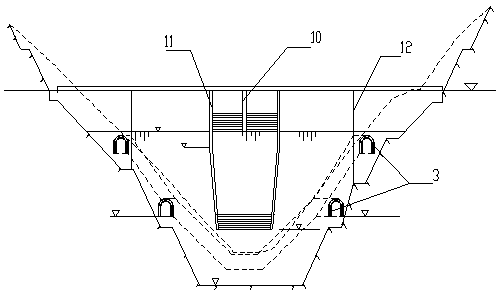

Coupling structure of gravity dam and unfavorable geological bank slope and the construction method thereof

The invention relates to a coupling structure of gravity dam and unfavorable geological bank slope and the construction method thereof, aiming at improving the strained condition of unfavorable geological bank slope and ensuring the stability of side slope in the form of active support. The technical scheme for solving the problem refers to a coupling structure of gravity dam and unfavorable geological bank slope and is characterized in that a group of anti-slide piles are evenly arranged at the joint of the gravity dam and unfavorable geological bank slope; the sloping surfaces among the adjacent anti-slide piles are provided with inter-pile plates; the upper part of the pile body of the anti-slide pile is provided with a prestress anchor rope; and a water-seal groove is arranged betweenthe dam body and the anti-slide pile connected with the dam body. The invention is mainly used in hydraulic and hydro-power engineering.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

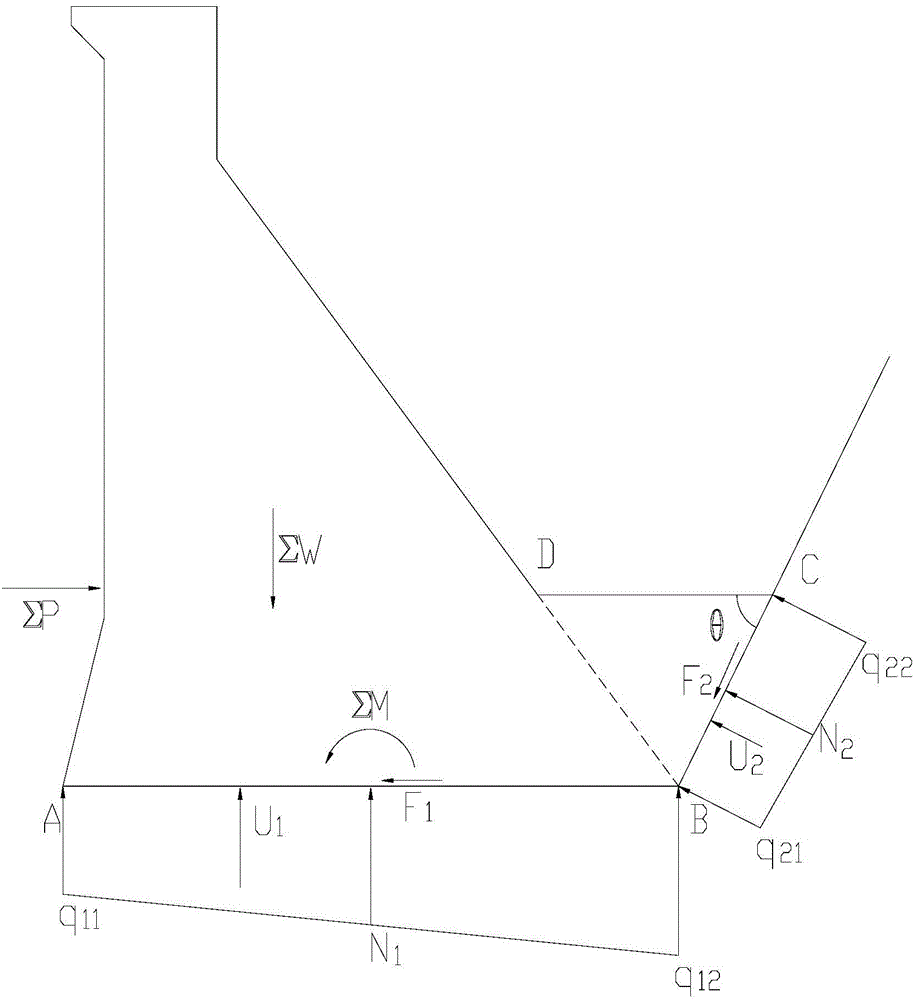

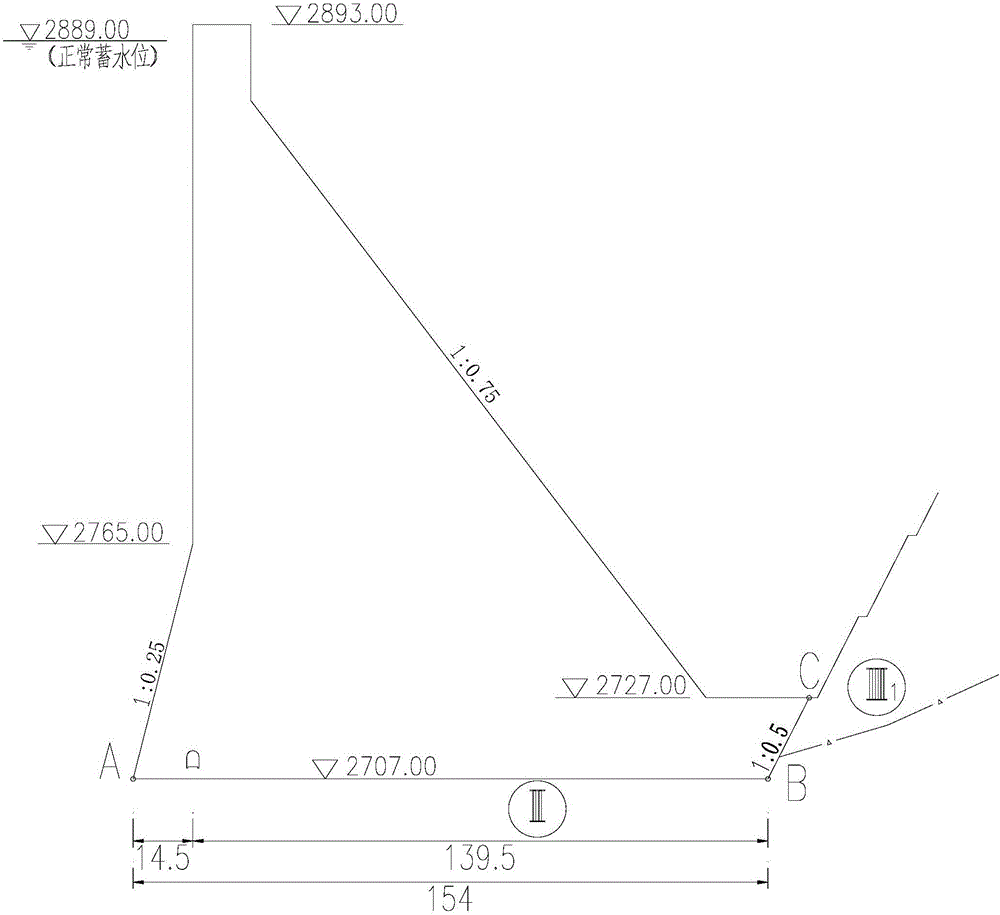

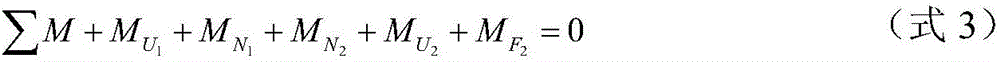

Method for calculating united sliding-resistant stability of dam and force-resisting mountain body

The invention belongs to the technical field of instability risk decision of a dam in water conservancy and hydropower engineering and provides a novel method for calculating united sliding-resistant stability of the dam and a force-resisting mountain body in order to overcome defects in calculation and analysis of the combined action of the dam and the force-resisting mountain body in the traditional technology. According to the method, the sliding-resistant stability of the concrete gravity dam under the action of the force-resisting mountain body is quantified accurately, reasonably and efficiently, and important basis is provided for structural design, reinforcement, optimization, safety evaluation, risk control and the like of dam sliding resistance assisted with downstream resistance blocks. The method comprises following steps: a, force analysis of the combined action of the dam and the force-resisting mountain body is performed; b, a mechanical equation for the united sliding-resistant stability of the dam and the force-resisting mountain body is established; c, mathematical analysis and mechanical assumption are performed on the equation; d, a limit equilibrium principle is adopted to solve a sliding-resistant stability safety factor. The calculating method is utilized to evaluate dam foundation stability, a process is simple and easy to understand, and the evaluation standard is adaptive to the specifications.

Owner:POWERCHINA CHENGDU ENG

Water storage tank type steel structural dam

ActiveCN102251502ASimple structure and stable and reliableExtended service lifeGravity damsWater storageStructural water

The invention relates to a water storage tank type steel structural dam, which comprises a truss structural dam body and a steel structural water retaining panel, wherein the lower end of the truss structural dam body is fixed on an inner concrete bearing platform of a riverbed, the steel structural water retaining panel is fixed on the water retaining surface of the truss structural dam body, a matched water tank is fixedly arranged in each cell encircled by the truss structure, the water tanks are communicated with one another, and the water tank at the upper end of the truss structure is provided with a water inlet and a water pump. The water storage tank type steel structural dam has simple, stable and reliable structure and simultaneously has the advantages of a steel structural dam and a gravity dam; and the lower end and two sides of the truss of the water storage tank type steel structural dam are easily fixed with the bearing platform and the side slope, so that the water storage tank type steel structural dam is easy in construction and maintenance. The water tanks can be industrially produced and constructed on site, so the construction efficiency is high. The dam has long service life and low cost, and is very suitable for popularization and implementation.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

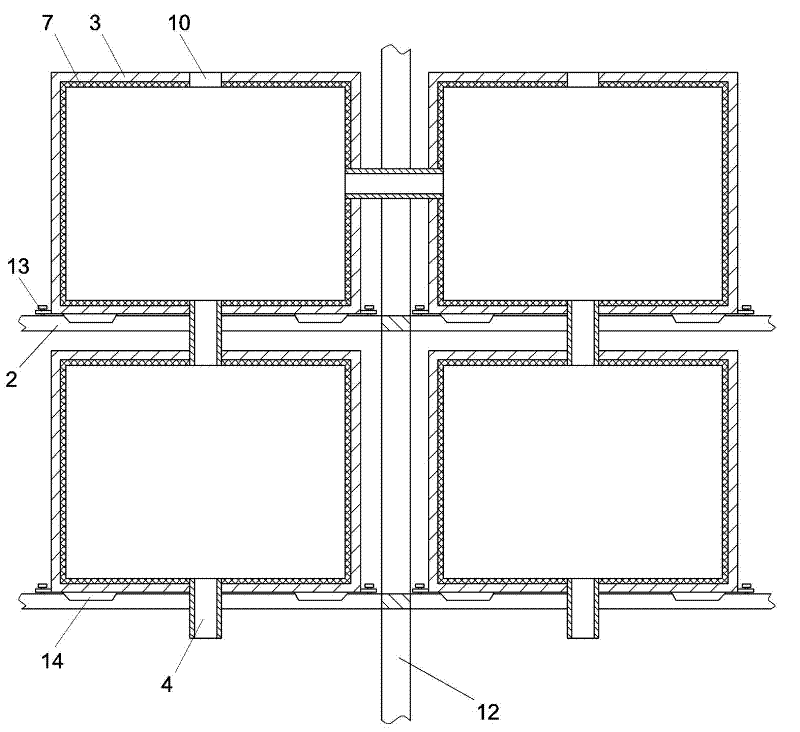

Water leakage treatment structure for transverse seam of concrete gravity dam

ActiveCN106498905AConvenient and efficient constructionGood water blocking effectGravity damsLeaking waterChemical grouting

The invention discloses a water leakage treatment structure for a transverse seam of a concrete gravity dam, relates to the field of water conservancy and hydropower engineering, and provides the water leakage treatment structure, which can meet water blockage requirements and can quickly and efficiently construct, for the transverse seam of the concrete gravity dam. The structure comprises a gravity dam with a plurality of dam sections, wherein the transverse seam is arranged between adjacent two dam sections; a water stop band for preventing the transverse seam from leaking water is formed in the gravity dam; a cement grouting hole and a water-blocking plug grouting hole are formed in the gravity dam; the water-blocking plug grouting hole and the cement grouting hole are formed across the transverse seam, and extend to the dam bottom from the dam top of the gravity dam; the water stop band, the cement grouting hole and the water-blocking plug grouting hole are sequentially formed from the upstream to the downstream in the water flow direction; a water blocking plug formed by chemical grouting is formed in the water-blocking plug grouting hole; and a cement filling structure formed by cement grouting is arranged in cement grouting hole and the transverse beam from the water stop band and the water blocking plug. The water leakage treatment structure can be used for sealing the transverse seam when the transverse seam of the concrete gravity dam leaks water.

Owner:POWERCHINA CHENGDU ENG

Composite material dam

InactiveCN103437326AImprove anti-seepage effectHigh strengthEarth-fill damsRock-fill damsRoller-compacted concreteRockfill material

The invention discloses a composite material dam, comprising a concrete dam shell, wherein a rockfill material is filled in the inner cavity of the concrete dam shell; a cushion layer and a transition layer are orderly arranged from outside to inside between the inner wall of the concrete dam shell and the rockfill material. The composite material dam has the combined advantages of a rolled rockfill dam and a rolled concrete gravity dam, and is good in impermeability, small in size, simple and convenient for construction, low in manufacture cost, and simple and beautiful in appearance; the composite material dam is mainly applicable to low dams having the dam height of less than 50 m.

Owner:POWERCHINA ZHONGNAN ENG

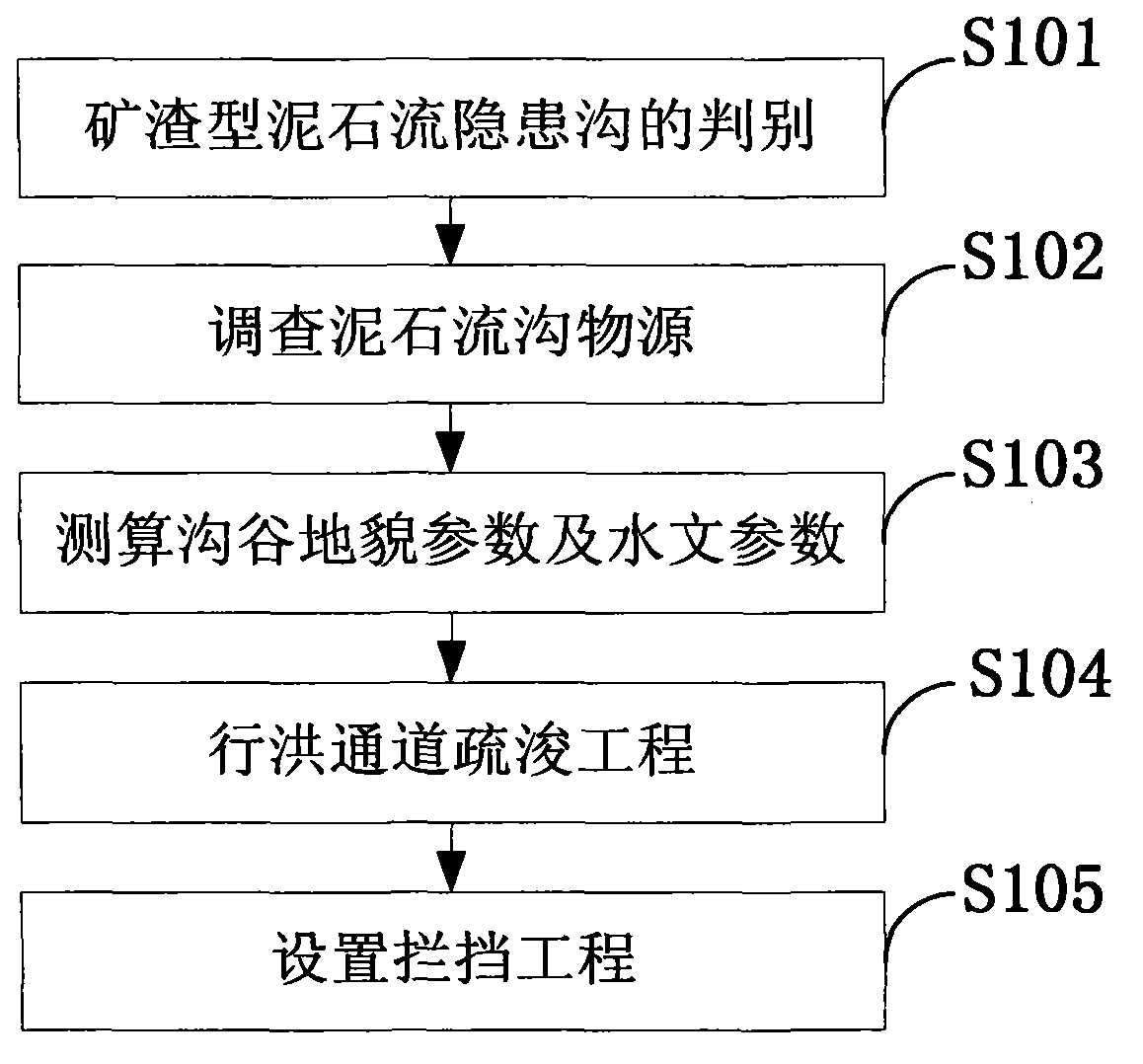

Slag type debris flow formation mechanism based prevention method

The invention discloses a slag type debris flow formation mechanism based prevention method. The prevention method comprises the steps of distinguishing a slag type debris flow hidden danger gully; investigating a debris flow gully material source; investigating gully geomorphic parameters and hydrogeological parameters; conducting a dredging project on a floodwater drawing-off passage; and conducting a slag stack blocking project. According to the method, a slag blocking measure which is high in water permeability is used, heavy rain and mountain torrents pass through a waste rock slag stack quickly, slag is prevented from entering the floodwater drawing-off passage to become the material source of debris flows, and prevention of formation of 'breaking blocking type debris flows' and reduction of disasters and losses can be achieved; and simultaneously, disaster effects of debris flows, which may be amplified due to dam breaking caused by the fact that debris flow gravity dams are built to accumulate debris flows, barrier dams block heavy debris flows and let small debris flows go and the like are reduced. Besides, the method is based on a prevention idea which gives first place to dredging, and light engineering measures such as galvanized wire boxes with the high water permeability are used, so that engineering costs of building of barrier dams and drainage channels are reduced, and the method has good practical application and popularization prospects.

Owner:XIAN CENT OF GEOLOGICAL SURVEY CGS

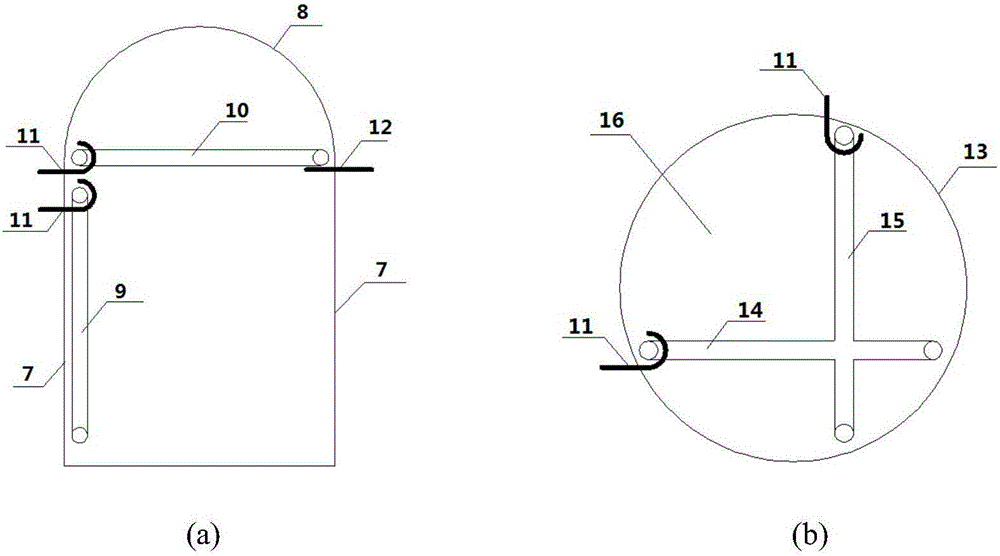

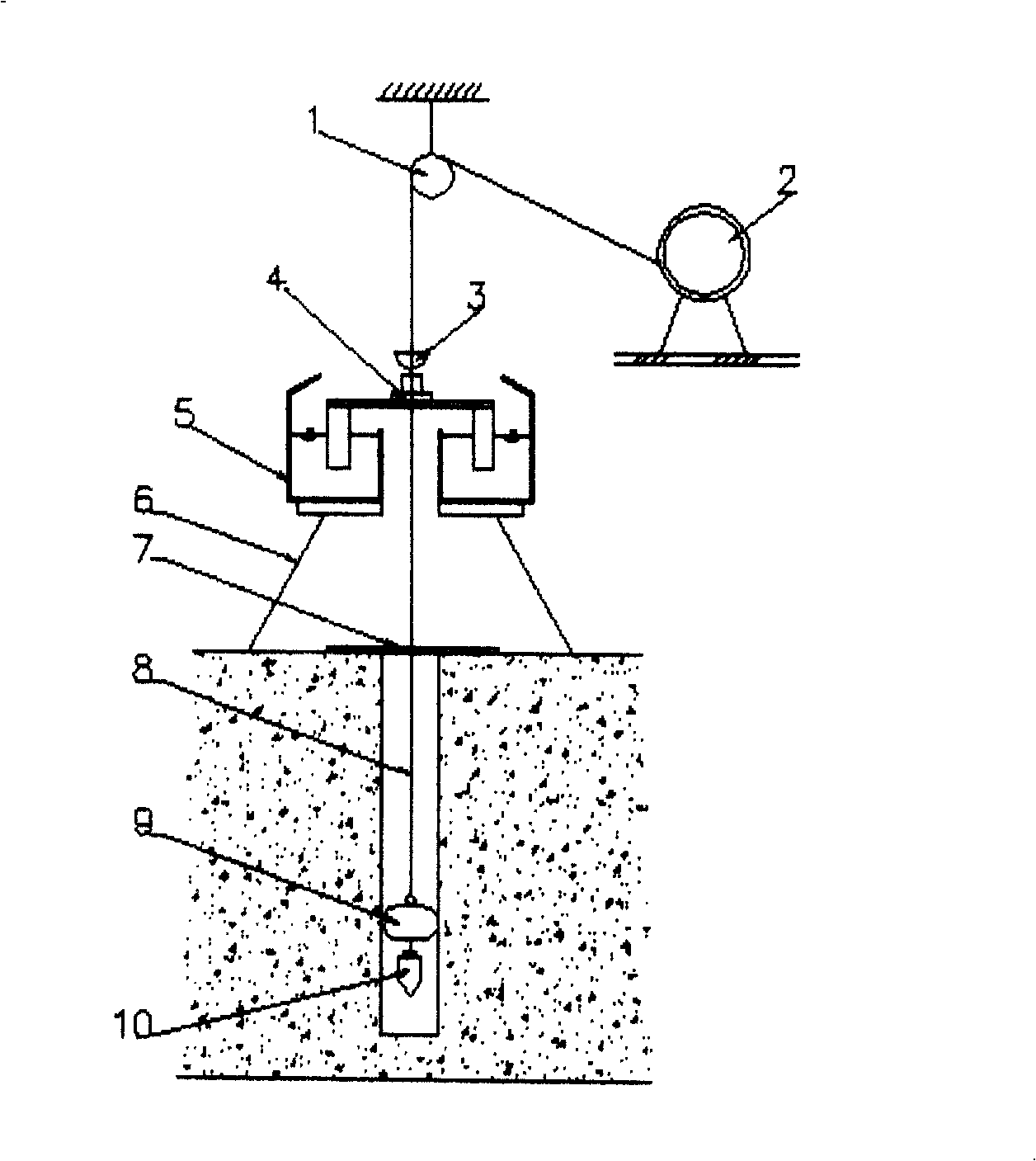

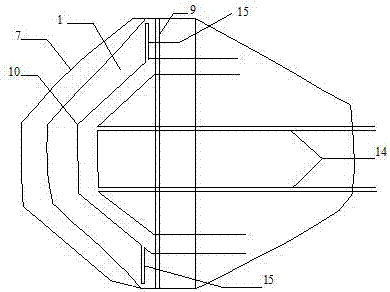

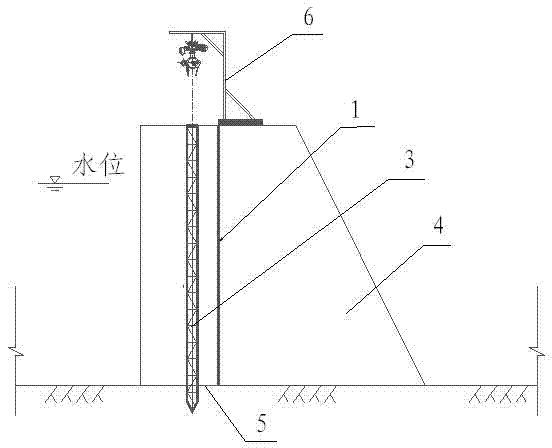

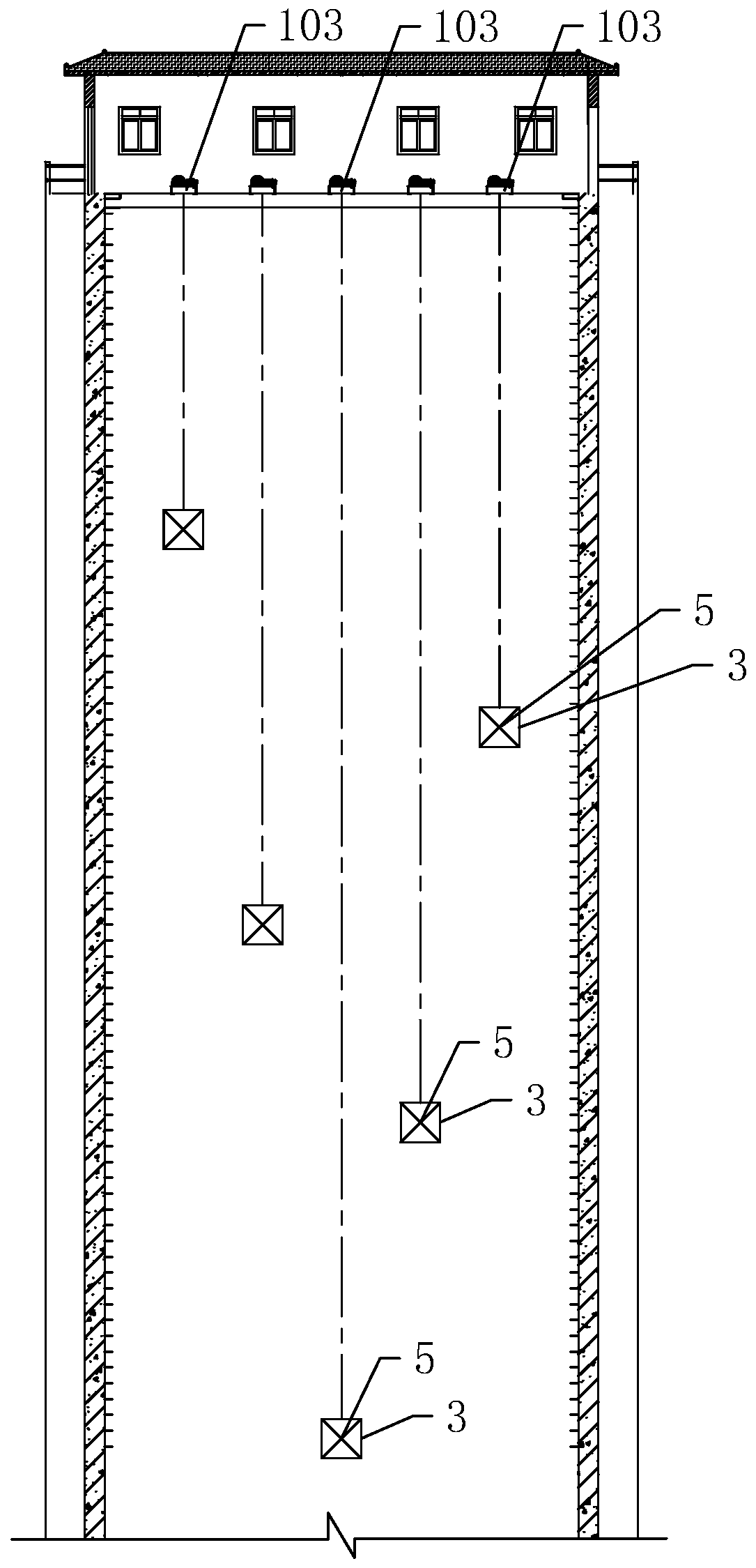

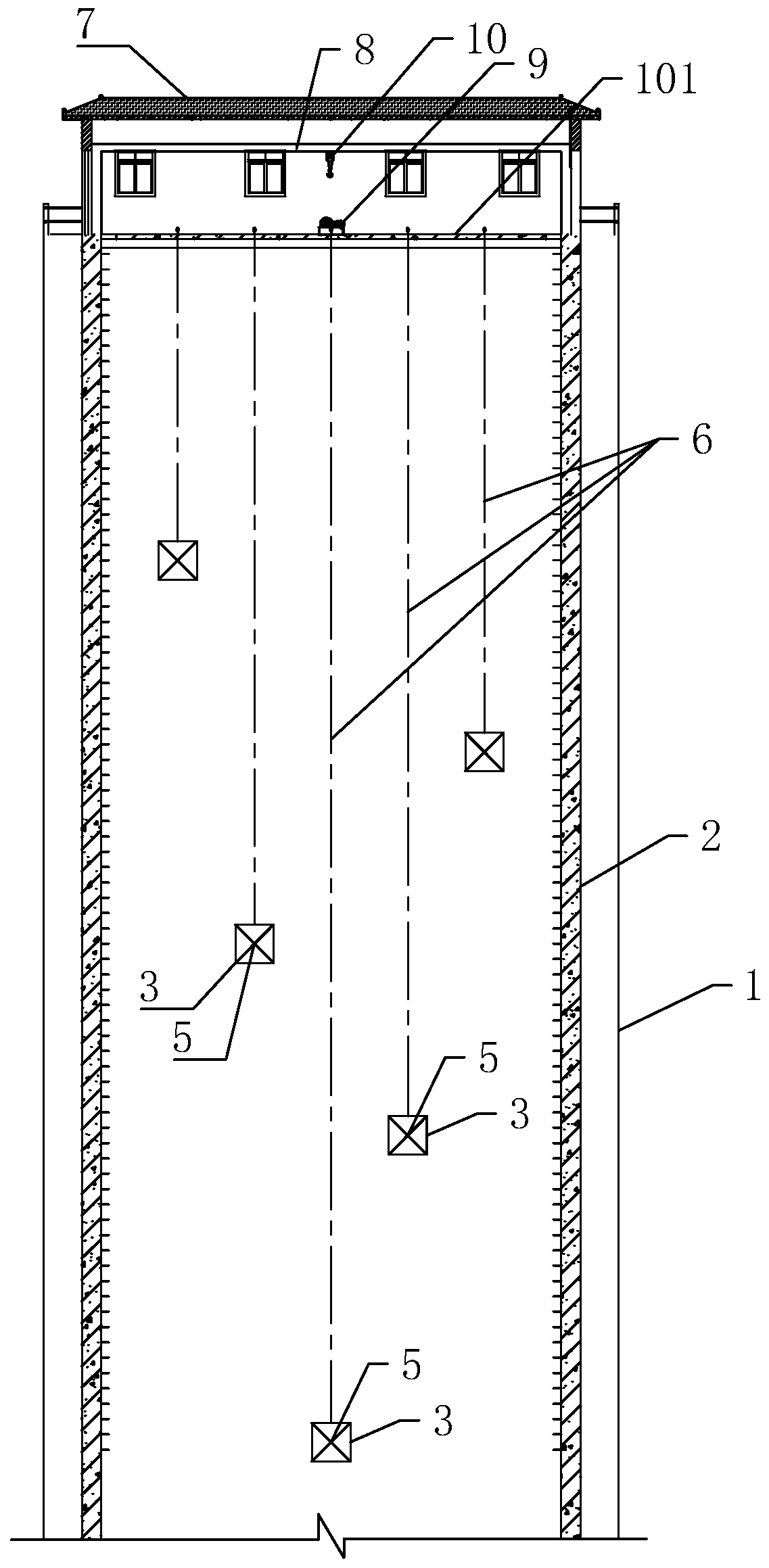

Layered water intake system for rockfill concrete gravity dam

ActiveCN110863471ANot easy to shakeFirmly connectedBarrages/weirsDrinking water installationWinchWater intake

The invention relates to a layered water intake system for a rockfill concrete gravity dam. The layered water intake system includes a dam body, a shaft, water intake opening structures, a support structure, opening and closing gates, a hoisting rope, a working room, a horizontal rail, an electric hoist, a winch and a bottom rail. The shaft is located on the inner side face of the dam body, the multiple water intake opening structures are arranged on the inner side of the shaft, water inlet pipe parts of the water intake opening structures extend into the shaft, the shaft is internally provided with the support structure, the opening and closing gates are assembled in water inlet pipes in a sliding manner, the hoisting rope is connected to the top of the opening and closing gates, the working room is arranged on the top of the dam body, and the top of the hoisting rope extends out of the inner bottom wall of the working room; and the horizontal rail is arranged on the top of the working room, the electric hoist is assembled on the horizontal rail in a sliding manner, the bottom wall is arranged on the inner bottom wall of the working room, the winch is assembled on the bottom railin a sliding manner, the electric hoist is used for dragging the winch to slide, and the top of the hoisting rope and a winding drum of the winch are detachably assembled. By means of the layered water intake system, one winch is used for controlling the multiple opening and closing gates to achieve lifting opening and closing, and the effects of reducing the cost and being short in construction period are achieved.

Owner:湖北志宏水利水电设计有限公司

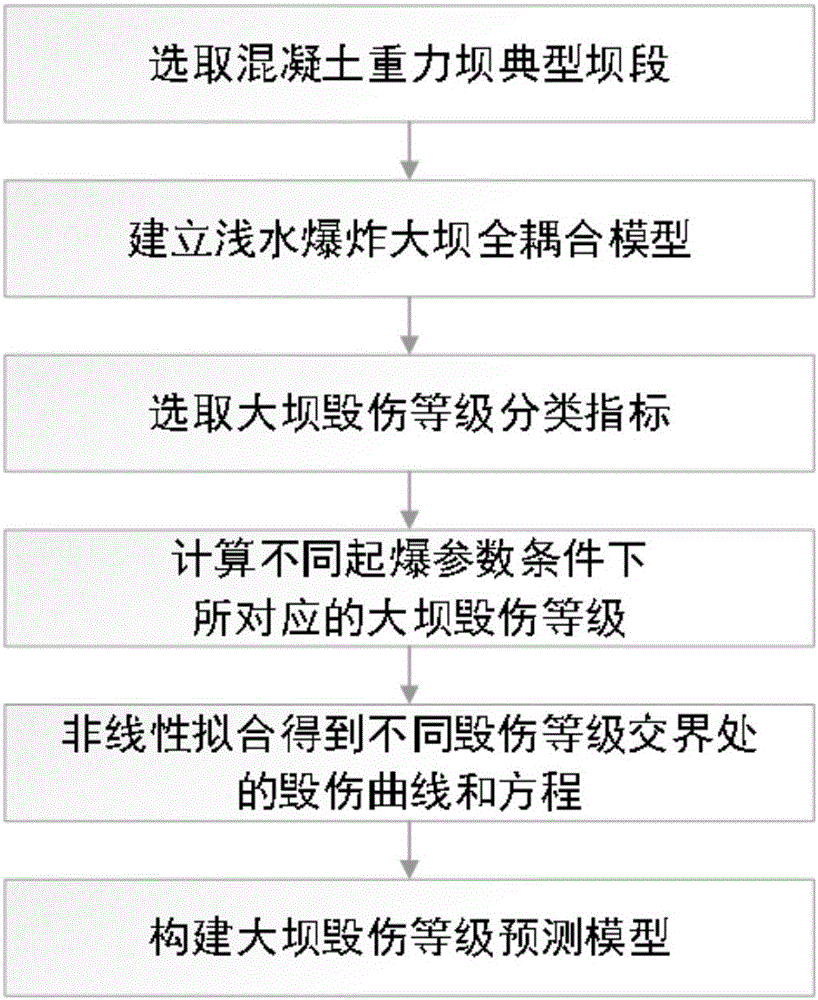

Method for rapidly predicting shallow-water explosion impact damage level of concrete gravity dam

InactiveCN105787258AAccurately assess damage and damage statusLittle engineering experienceSpecial data processing applicationsInformaticsCouplingEngineering

The invention discloses a method for rapidly predicting the shallow-water explosion impact damage level of a concrete gravity dam.The method comprises the following steps that 1, a typical cross section of the concrete gravity dam is selected to establish a shallow-water explosion dam full-coupling model; 2, dam damage level classification indexes are selected; 3, corresponding damage destruction levels under the conditions of different detonating parameters are calculated; 4, damage curves and equations of junctions of different damage levels are obtained through nonlinear fitting; 5, a dam damage level prediction model is established.The method does not need a field explosion test and can predict the damage destruction level of the dam under the load effect of shallow-water explosion impact only by relying on a numerical model with the verified reliability.The method can rapidly predict the damage destruction level of the dam under the conditions of any detonating equivalent and any detonating distance and can be used for rapid rescue and reinforcement after the dam suffers from bomb attack and determine an antiknock safe protective distance of the dam.

Owner:WUHAN UNIV

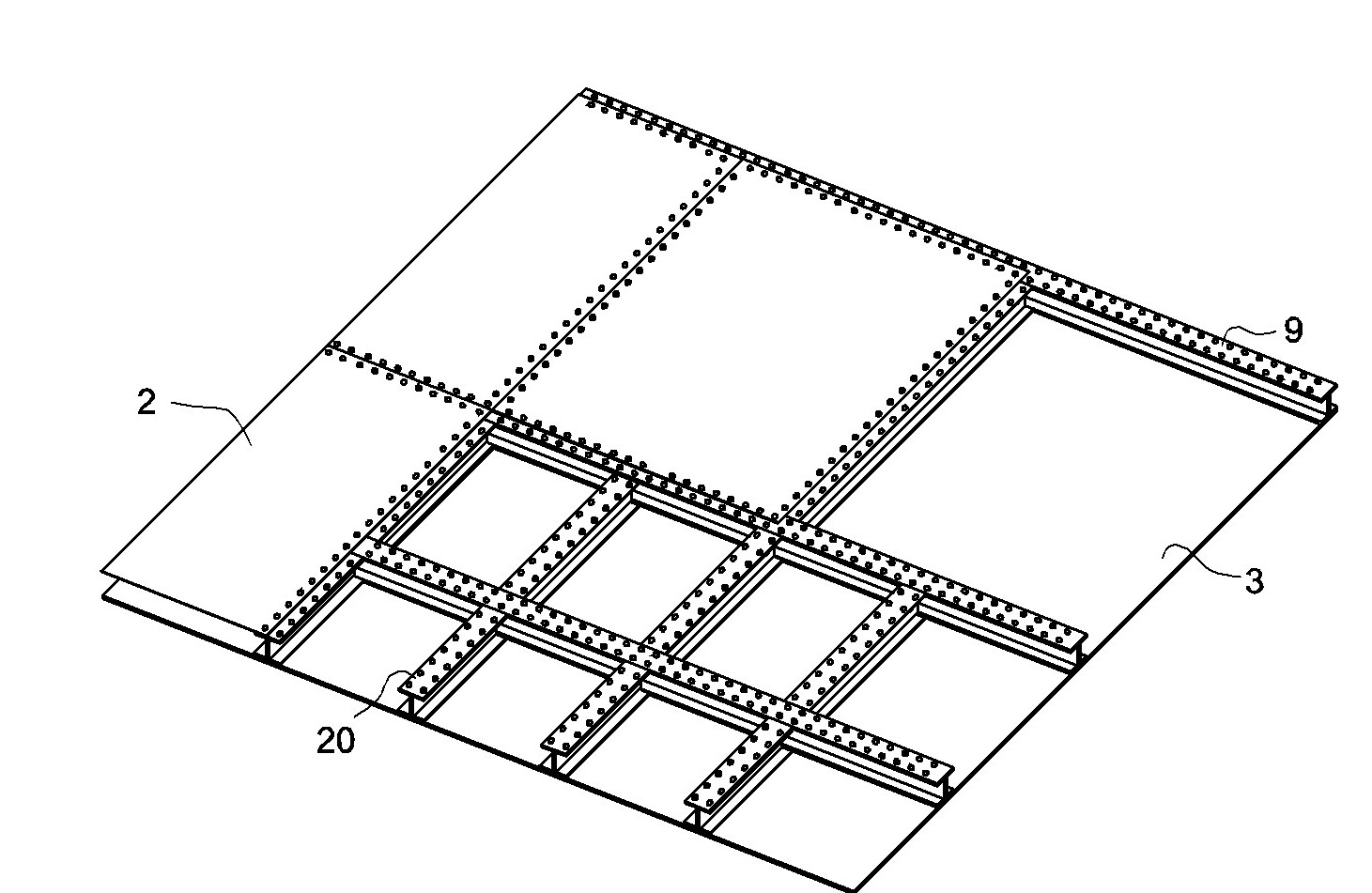

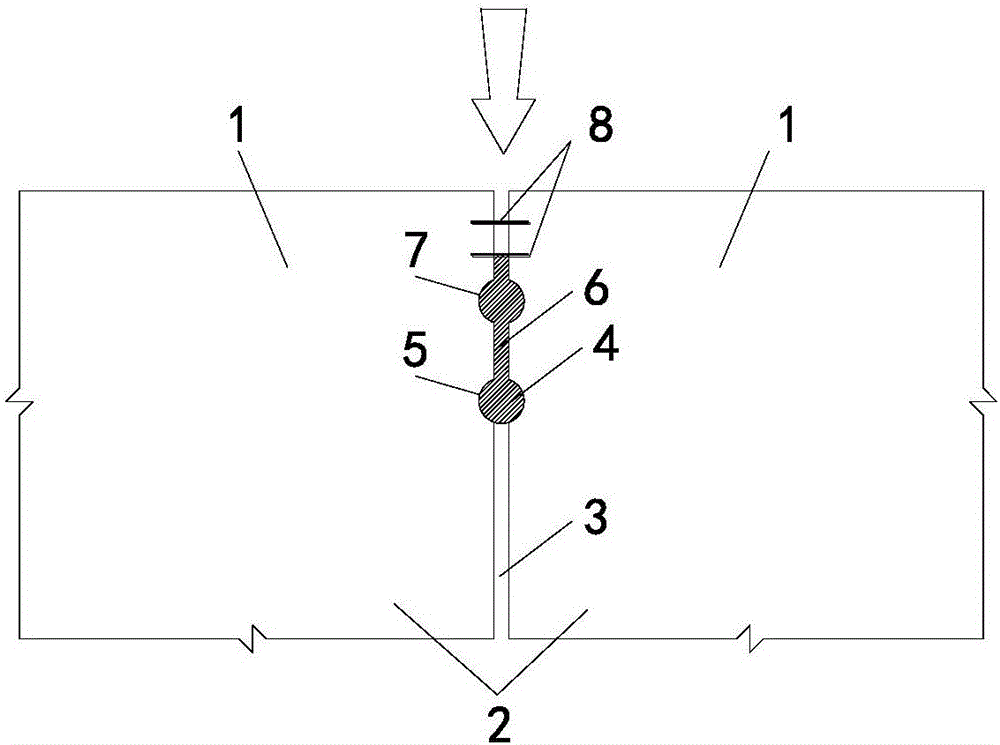

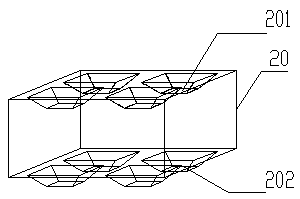

Detachable gravity dam and construction and dismounting method thereof

The invention relates to a detachable gravity dam and a construction and dismounting method thereof, and belongs to the technical field of water conservancy projects. The detachable gravity dam comprises a drainage grouting gallery, an anti-seepage curtain, a dam foundation drainage hole, a middle pier, a side pier and a transverse seam, and further comprises an upstream concrete panel, building block concrete, a downstream concrete panel, a plain concrete cushion layer and a dam foundation anchor bar; the building block concrete is formed by connecting prefabricated building blocks through bolts according to a certain sequence; the upstream concrete panel and the downstream concrete panel are correspondingly poured on the upper surface and the downstream side of a dam body, and the plainconcrete cushion layer is laid on the dam foundation, the detachable building block concrete is built on the plain concrete cushion layer, and the dam foundation anchor bar is arranged in each hoisting hole of the bottom-layer building block concrete. According to the detachable gravity dam and the construction and dismounting method thereof, the advantages of reliable quality and high construction efficiency of a prefabricated concrete component can be fully utilized, so that temperature cracks in the dam body are reduced, the safety of the gravity dam is ensured, meanwhile, the dam body is convenient to detach, and the economical and environment-friendly effects are realized.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com