Concrete gravity dam deformation optical fiber sensing monitoring technology and concrete gravity dam deformation optical fiber sensing monitoring system

A gravity dam and sensing technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem that the process structure mechanism is not suitable for large-volume concrete high dam projects, etc., to improve the effectiveness and technological level, without electromagnetic interference , The effect of fast performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

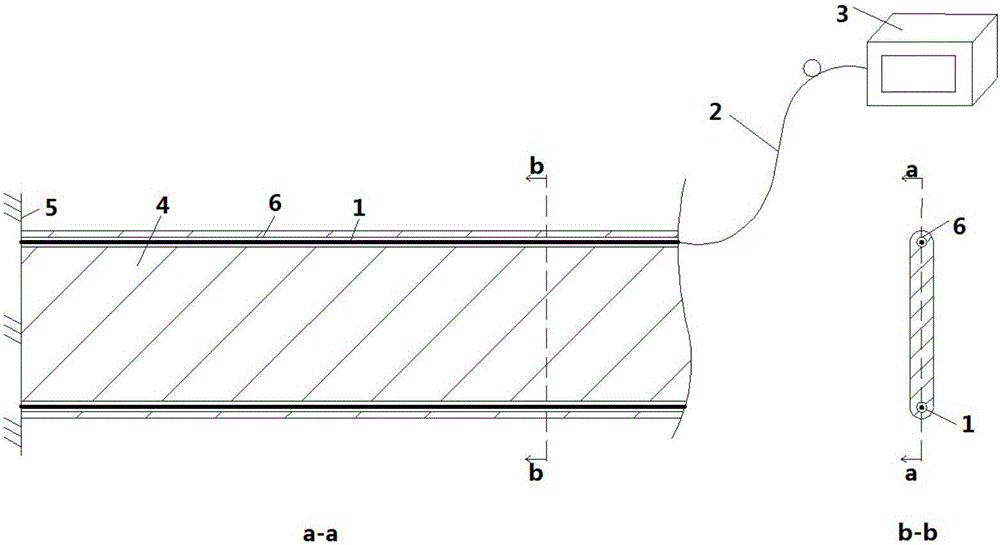

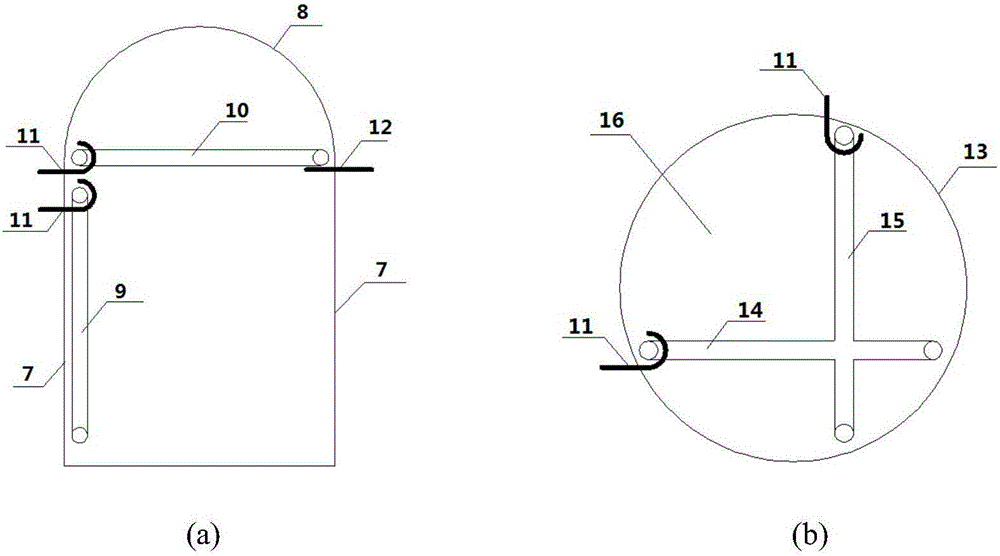

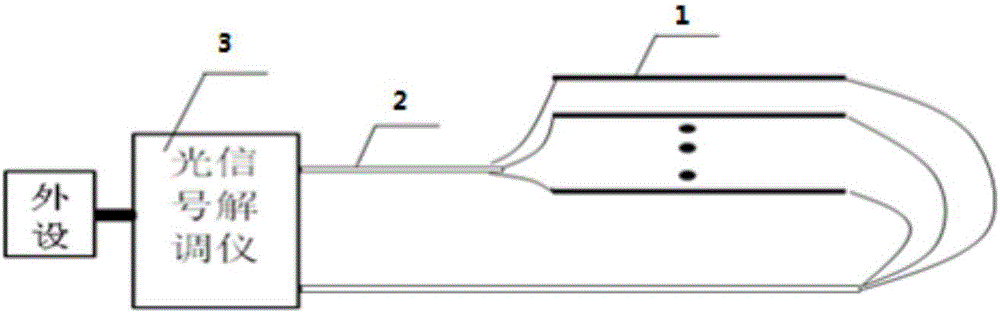

[0052] (1) The laying and installation of the optical fiber monitoring board in the corridor: figure 2 (a), the vertical monitoring board (for observing the vertical displacement and horizontal displacement and joints in the transverse direction) is installed close to the upstream (or downstream) side wall of the corridor, and the top is fixed with expansion bolts (or embedded parts). The horizontal monitoring plate (to observe the longitudinal and transverse horizontal displacement and joints of each dam section along the way) is installed at the bottom of the roof arch of the corridor, and its upstream side is fixed with expansion bolts, and the downstream side is supported by steel strips to form a simple support. The total station is used for control and measurement during the installation work to ensure accurate positioning and leveling, and to ensure the levelness of the top of the vertical plate and the horizontal plate; the installation of the joints between the plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com