Debris flow multi-stage dissipative blocking structure

A debris flow and dissipation technology, applied in infrastructure engineering, protective equipment, dams, etc., can solve the problems of difficult to achieve long-term safety of governance projects, limited use range and blocking height, flexible net easily deformed, etc., to reduce later maintenance. The effect of workload, optimized load distribution, and reduced construction and installation workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

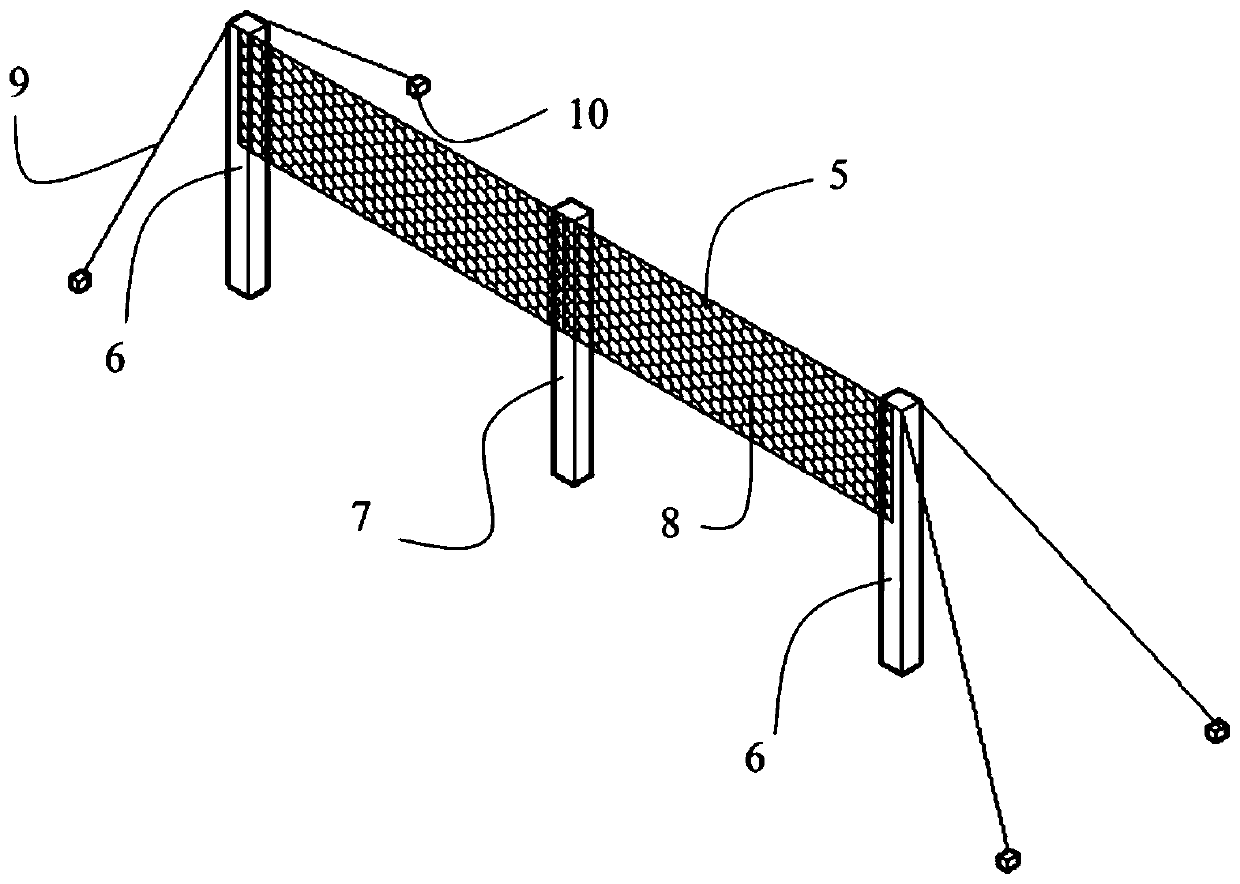

[0070] refer to figure 2 , the flexible retaining net structure in the debris flow multi-stage dissipative retaining structure system in this example includes two end support columns 6, a middle support column 7 located between the two end support columns 6, and a The top support rope 5 and the metal flexible net 8 between the support columns 6, the top support rope 5 is tensioned by the end support column 6 and the middle support column 7, and the metal flexible net 8 is connected with the top support rope 5; the end support column 8 It is connected with the end support rope 9, and the end of the end support rope 9 is connected with the anchor block 10, and the anchor block 10 is fixed in the stable formation.

[0071] The supporting rope 5 of this example adopts a stainless steel wire rope, and the metal flexible net 8 then adopts a stainless steel wire braided net to form.

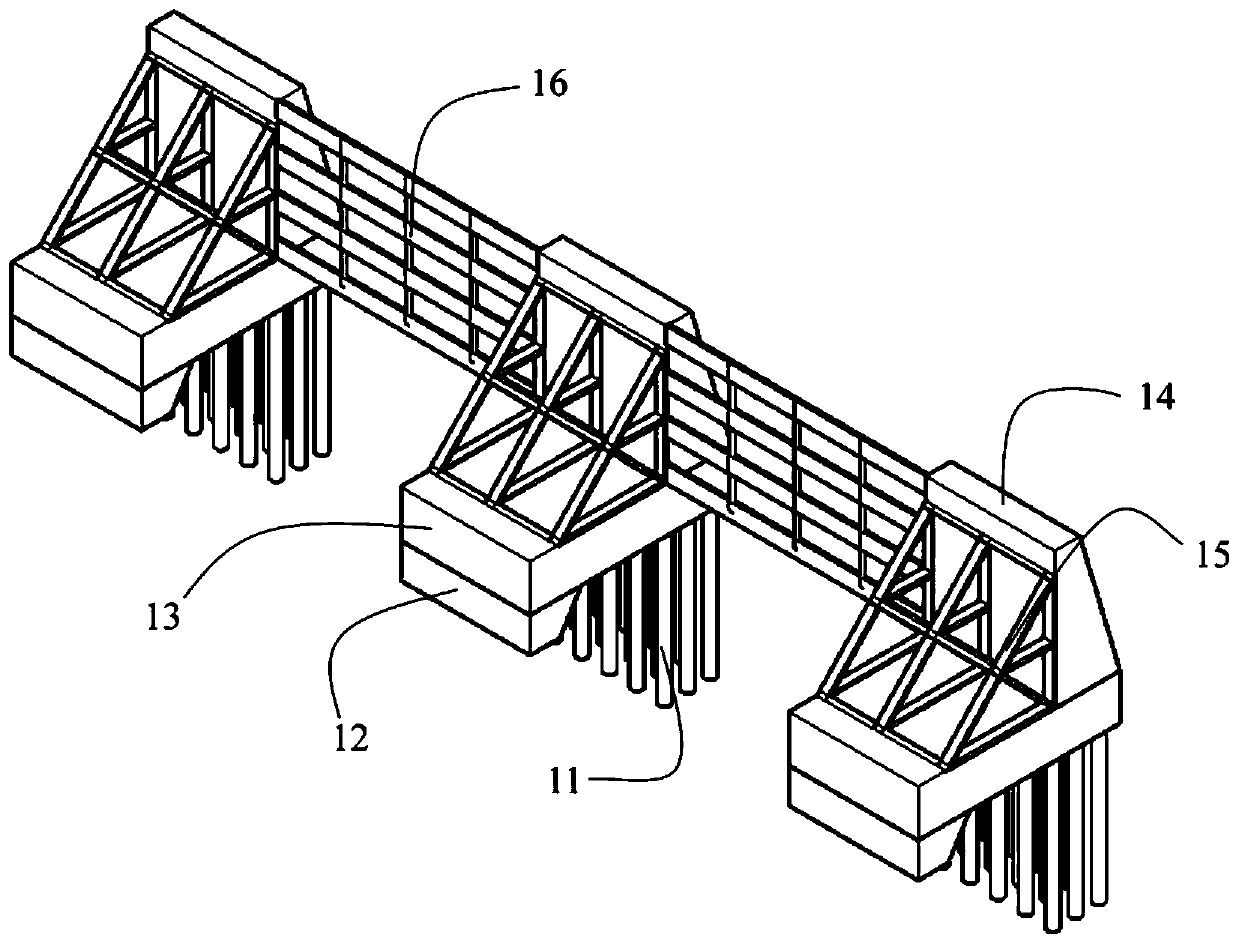

[0072] refer to image 3 , the pile-supported grid wall structure in the debris flow multi-stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com