Gravity concrete faced rockfill dam and construction method thereof

A technology of face rockfill dam and construction method, which is applied to dams, barrages, weirs, etc., can solve problems such as easy cracks in the faceplate, and achieve the effect of reducing the probability of cracks, low cement consumption, and small deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

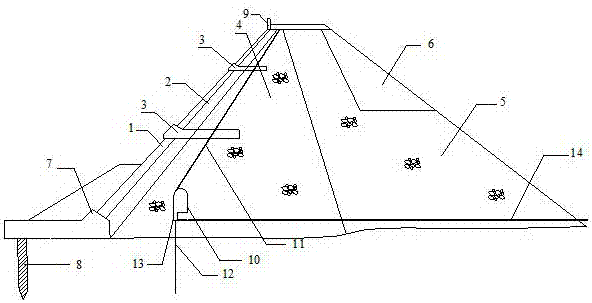

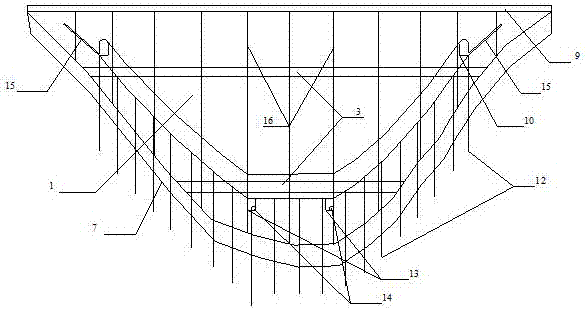

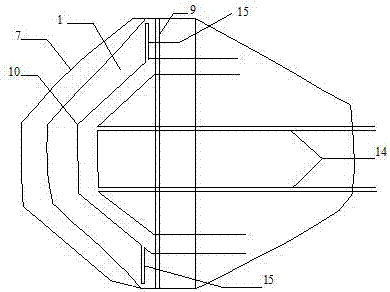

[0035] Embodiment 1: as Figure 1-3 As shown, a gravity face rockfill dam includes a concrete face 1, a cushion layer 2, an L-shaped slab 3, a rockfill concrete area 4, a main rockfill area 5, a secondary rockfill area 6, a plinth 7, seepage control Curtain 8, wave wall 9, drainage corridor 10, dam body drainage pipe 11, dam foundation drainage hole 12, water collection well 13, dam foundation drainage pipe 14, dam abutment drainage pipe 15, transverse joint 16;

[0036] The concrete face plate 1 is laid on the upstream side of the dam body, the rockfill concrete area 4 is located on the foundation, the section is trapezoidal, the dam bottom is wide and the dam top is narrow, and the downstream slope ratio is about 1:0.2~1:0.5. Transverse joints 16 are arranged at regular intervals along the dam axis, concrete face plate 1 is placed on the toe board 7, the toe board 7 is placed on the bedrock and its lower part is closely connected with the anti-seepage curtain 8, and concrete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com