Patents

Literature

35results about How to "Strong ability to adapt to deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

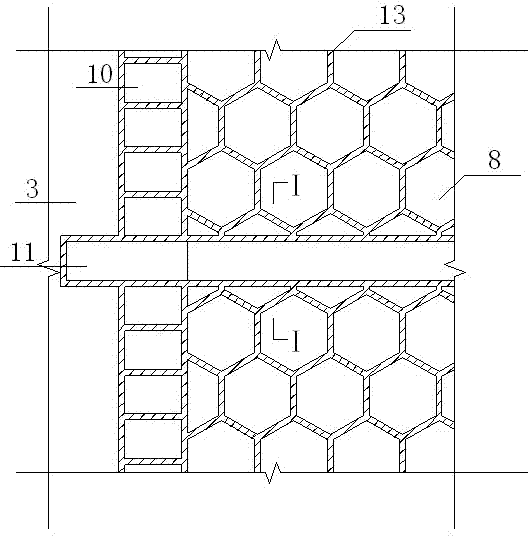

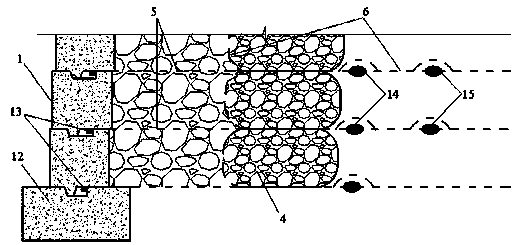

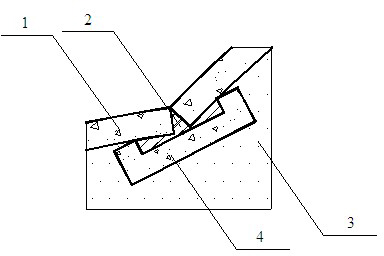

Arrangement method of ecological gabion chamber revetment type

InactiveCN102704441ARestoring Biodiversity TraitsRestoring Diversity TraitsCoastlines protectionReceptacle cultivationRiver routingEngineering

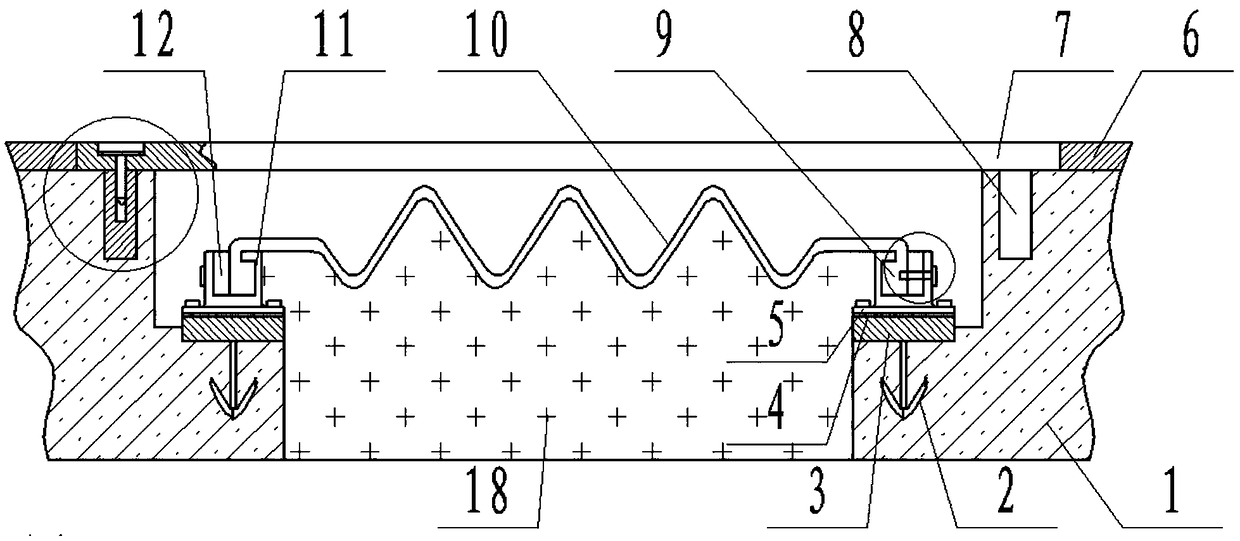

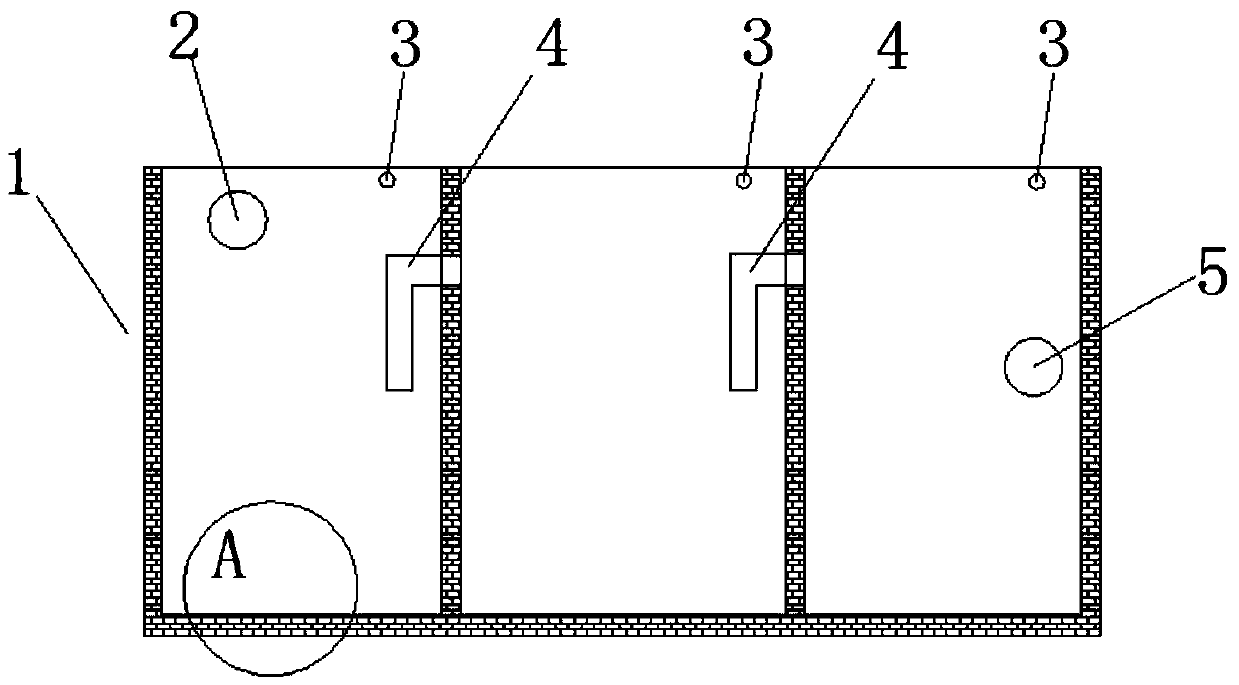

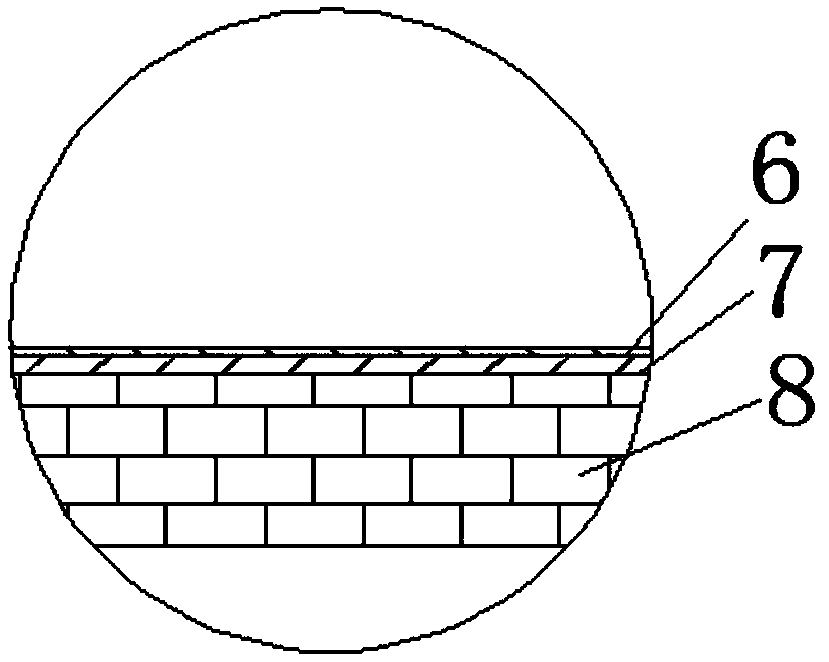

The invention relates to an arrangement method of an ecological gabion chamber revetment type, and belongs to a revetment structure type in river training works. A stepped sandstone cushion layer is laid on the revetment of a river; a sinuous ecological gabion chamber is arranged on the stepped sandstone cushion layer; and plants are planted in the sinuous ecological gabion chamber. The arrangement method has the advantages of novel structure, reliable operation, wide application range, capabilities of improving the engineering safety and favorably improving water eco-environments of rivers and lakes and great application prospect.

Owner:CHINA WATER NORTHEASTERN INVESTIGATION DESIGN & RES

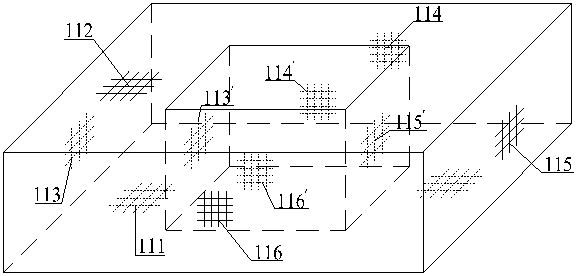

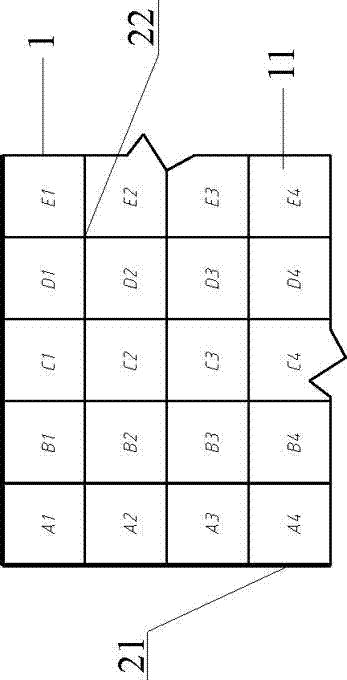

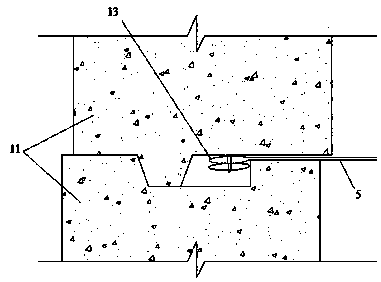

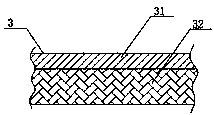

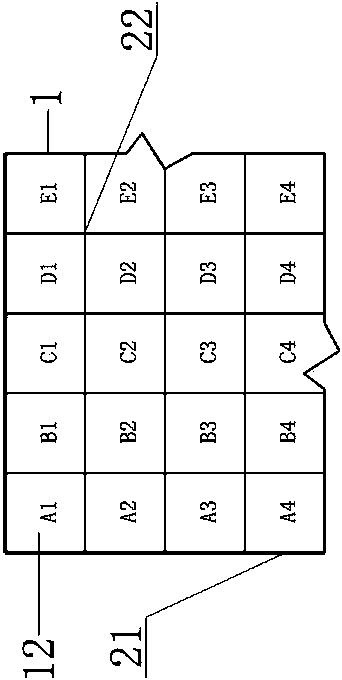

Method for dredging soft foundation by dredger fill and reinforcement

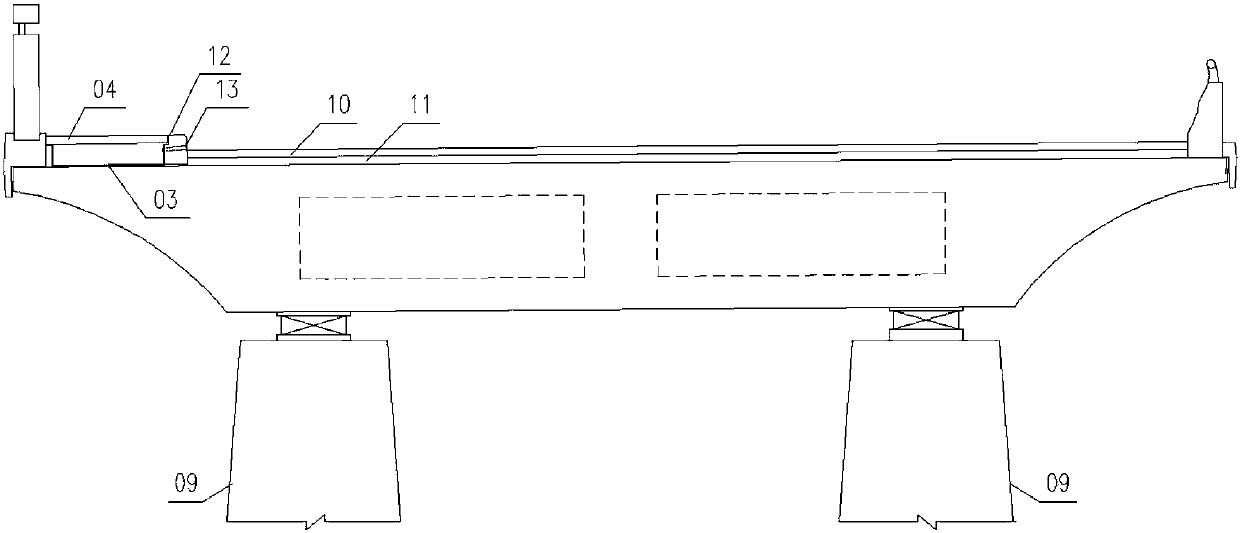

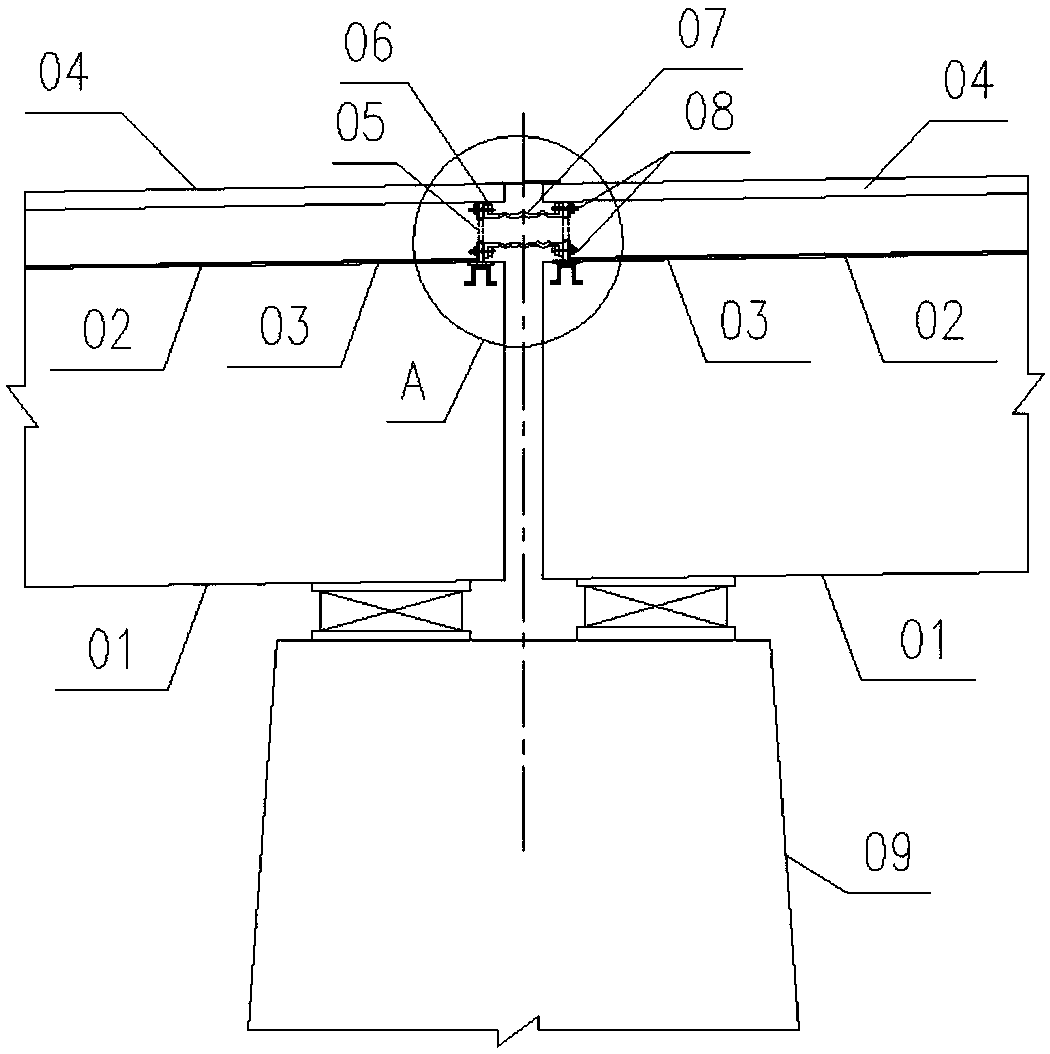

ActiveCN102817354AShorten the drainage distanceShorten the timeSoil preservationDrainage networkBuilding construction

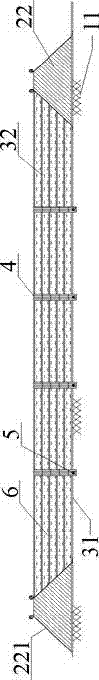

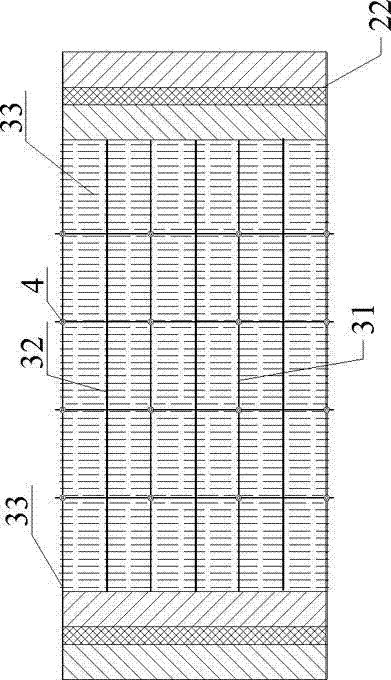

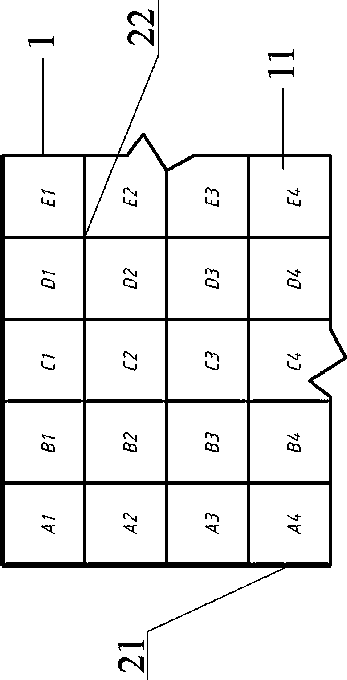

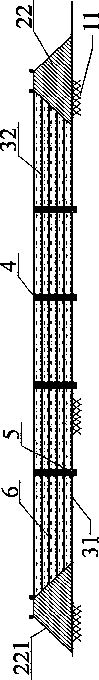

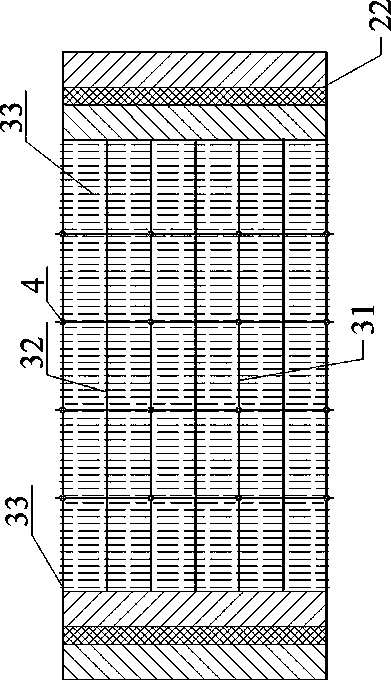

The invention relates to the field of building foundations, in particular to a method for dredging a soft foundation by dredger fill and reinforcement. The method includes: a, zoning for dredger fill; b, forming a primary drainage system; and c, performing layered and zonal filling and reinforcement. The method is characterized in that in zoning for dredger fill, each filling unit (11) is 20000m<2>-50000m<2> in area; in formation of the primary drainage system, digging crisscross blind ditches (31) on the surface of the filling unit (11), and laying corrugated filter pipes (32) and drain boards (33) on the surface for the filling unit (11); and in layered zonal filling and reinforcement, filling the filling area (1) level by level, and reinforcing with all levels of drainage networks. The method is convenient in construction, short in construction period, effective in foundation treatment and low in construction cost.

Owner:BAOSTEEL ENG & TECH GRP

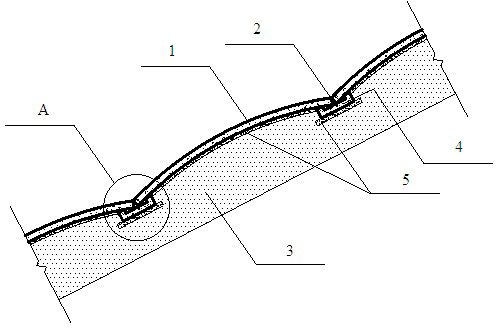

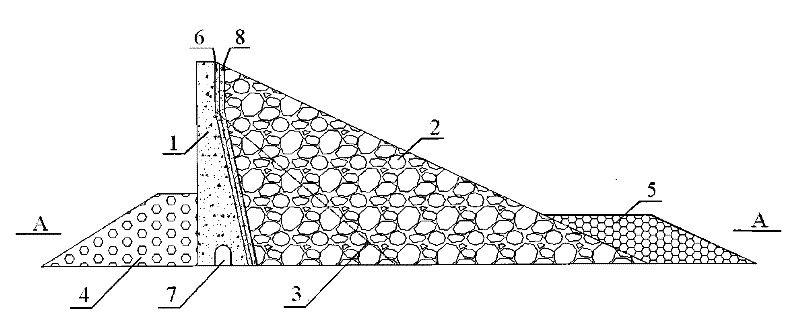

Fill channel anti-frost heaving and anti-seepage structure and construction method

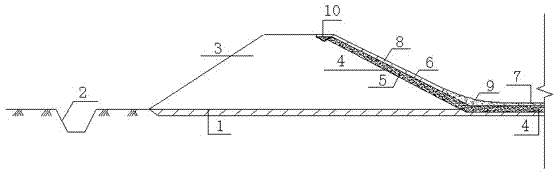

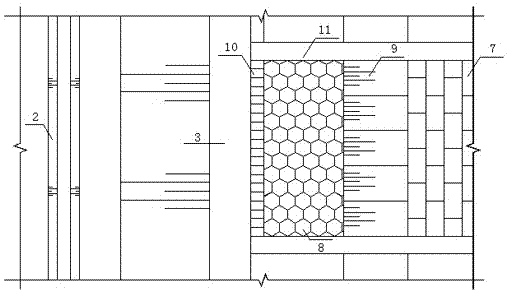

ActiveCN104514216AGuaranteed compactnessGuaranteed StrengthIrrigation ditchesMarine site engineeringStress concentrationStress conditions

The invention discloses a fill channel anti-frost heaving and anti-seepage structure and a construction method. The structure is characterized in that drainage channels are arranged on the two sides of the channel; a wind-blown sand layer is arranged on the bottom and two sides of an embankment of the channel; a plastic film is arranged on the wind-blown sand layer; a slope toe on a connection position of the bottom and the embankment of the channel is cast-in-place concrete; prefabricated concrete blocks are laid on the plastic film; and a capping concrete board is arranged on the top of the embankment of the channel. The construction method comprises the following steps: digging a drainage open channel; clearing channel base earth; carrying out filling to form the embankment of the channel; laying wind-blown sand; laying the plastic film; casting the arc channel-bottom concrete in place; laying the prefabricated concrete blocks; and laying the capping concrete board. The problems of the common channel design such as seepage, frost heaving and destruction, and not stable quality are eliminated, the wind-blown sand layer is arranged on the bottom and the two sides of the embankment of the channel, the foundation bearing force is increased, the frost heaving is lightened; the polyethylene plastic film is laid on the wind-blown sand layer to prevent seepage of the channel; concrete is arranged on the film to prevent water flow from scouring and seeping; the concrete arc channel bottom is cast in place, the stress condition is good and the stress concentration is prevented; and the drainage open channel prevents underground water retention and eliminates frost heaving.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

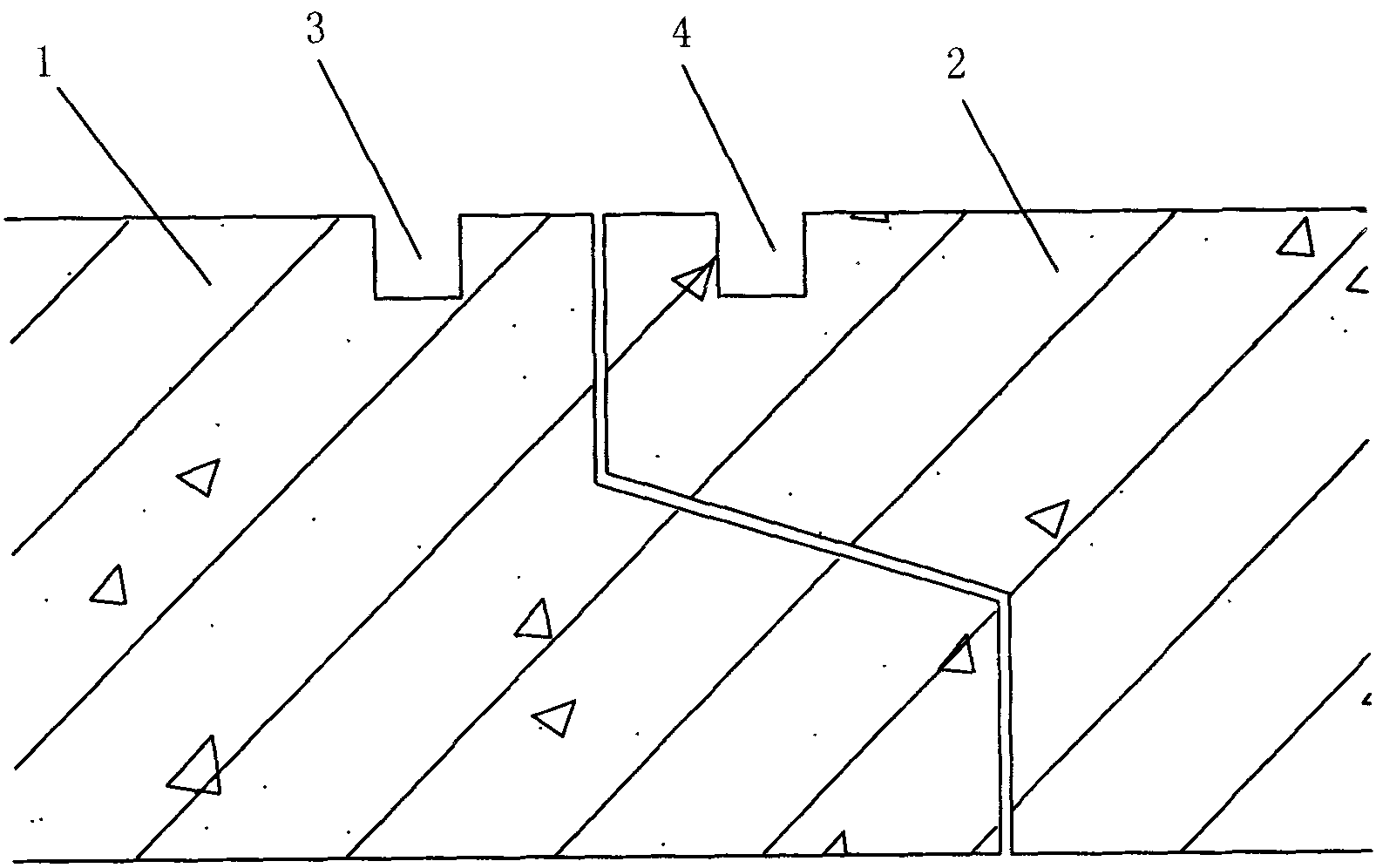

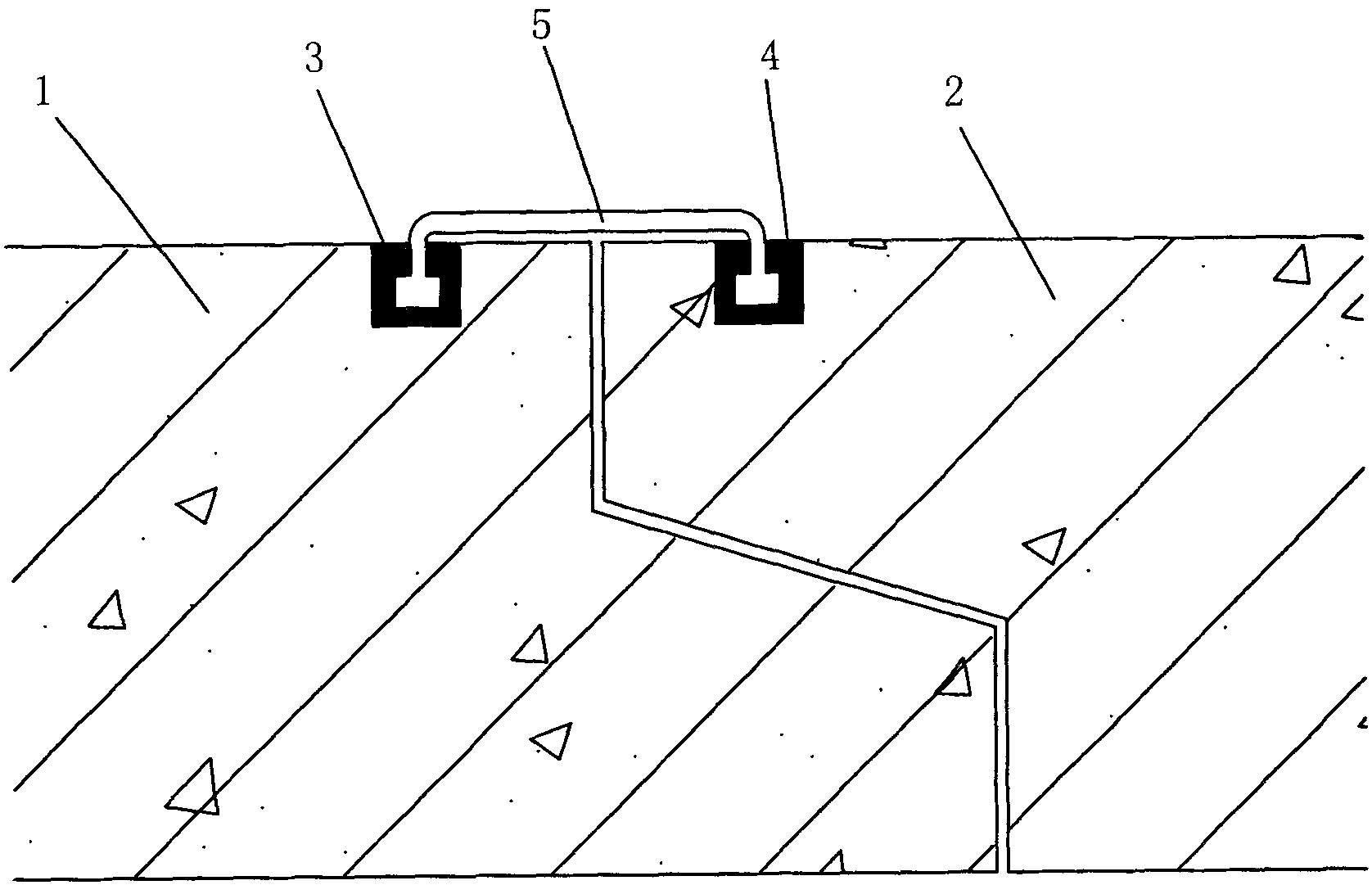

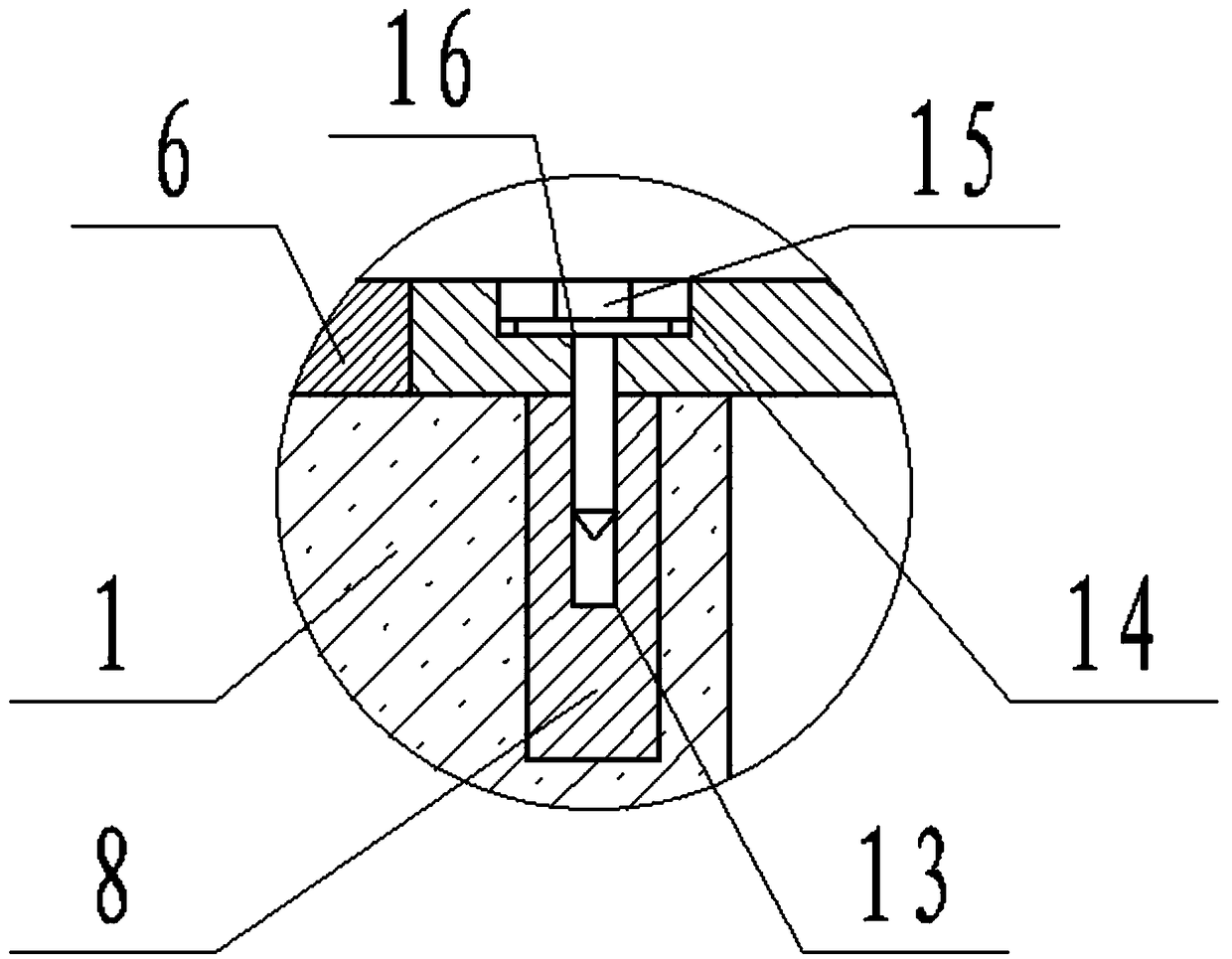

Waterproof method for prefabricated reinforced concrete box culvert interfaces and interface water stopper

InactiveCN102251491ADimensional tolerance requirements are not strictImprove waterproof reliabilityArtificial islandsGround-workEpoxyRubber ring

The invention discloses a waterproof method for prefabricated reinforced concrete box culvert interfaces and an interface water stopper. The waterproof method comprises the following steps of: pre-forming a first groove at a predetermined position far from a first box culvert interface, and pre-forming a second groove at a predetermined position far from a second box culvert interface; injecting epoxy resin adhesive into the first groove and the second groove respectively; and plugging two wings of the interface water stopper into the first groove and the second groove respectively, and sticking the two wings of the interface water stopper in the first groove and the second groove after the epoxy resin adhesive is solidified, wherein the two wings of the interface water stopper are provided with an anchoring part respectively, and the transverse size of the section of the anchoring part is greater than that of the middle section of the interface water stopper. According to the waterproof method for the box culvert interfaces, the two wings of the interface water stopper are stuck into the grooves of the box culvert interfaces to finish sticking, and the interface water stopper is adopted for preventing water; and compared with a conventional O-shaped rubber ring waterproof method, the method has the advantages of high waterproof reliability and long service life.

Owner:深圳市城市优筑科技有限公司

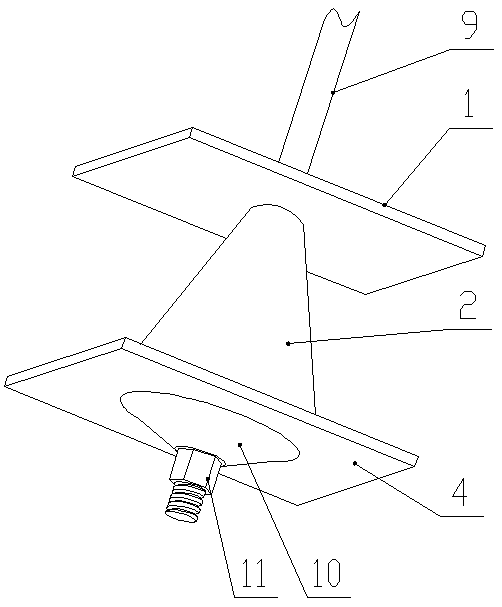

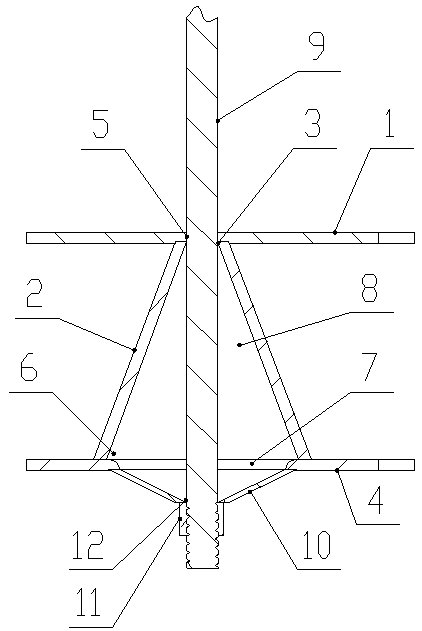

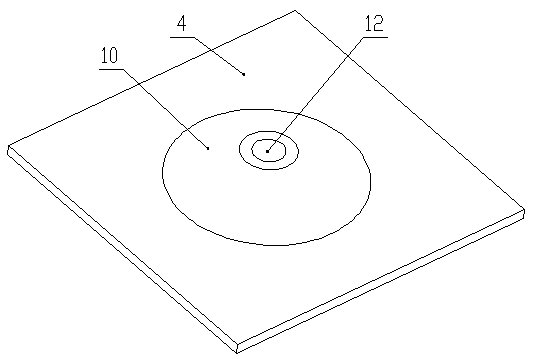

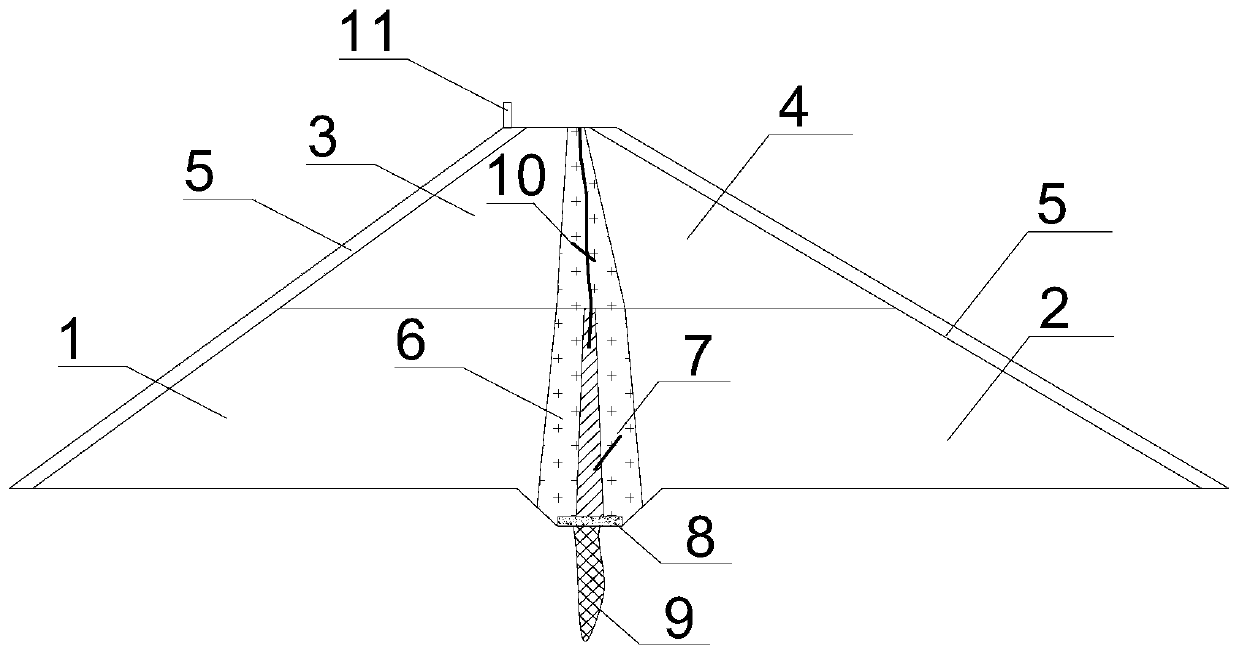

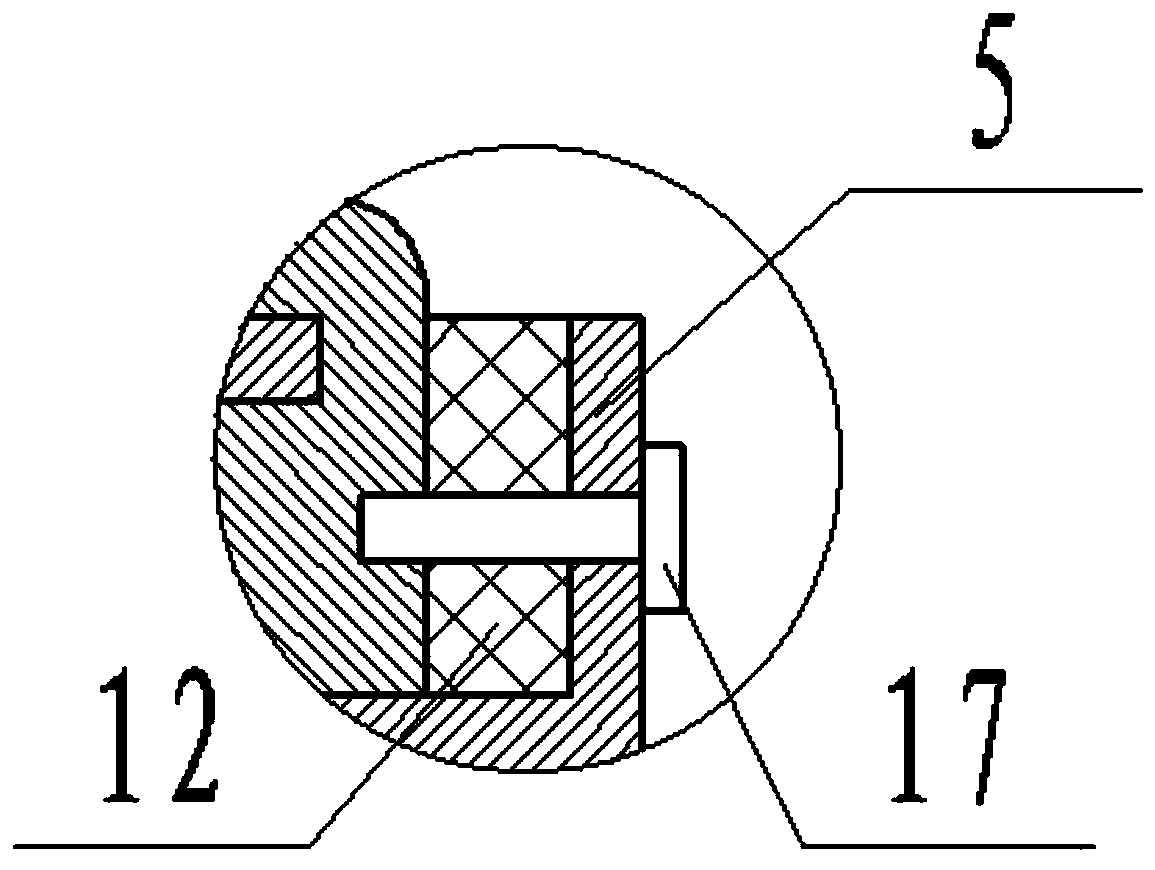

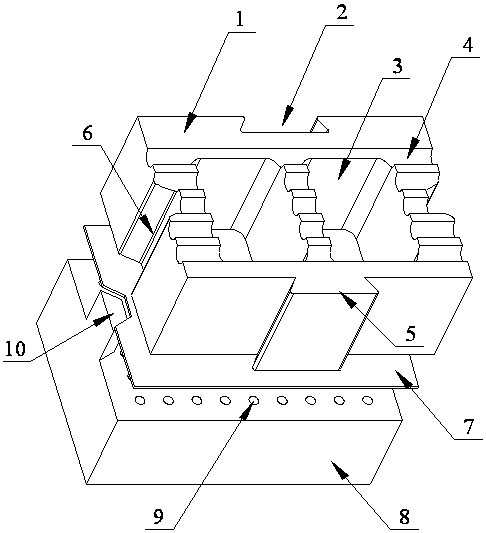

High impact and large transformation resisting energy absorption anchoring tray component and energy absorption anchoring method thereof

ActiveCN108868856AReduce harmReduce supporting costsClimate change adaptationAnchoring boltsSupporting systemEnergy absorption

The invention discloses a high impact and large transformation resisting energy absorption anchoring tray component which comprises a common flat anchoring tray, a conical steel pipe and a dish-shapedtray arranged in turn from top to bottom, wherein the conical steel pipe is a conical barrel structure with thin top and thick bottom; the upper end of the conical steel pipe is fixedly connected with the lower surface of the common flat anchoring tray; the lower end of the conical steel pipe is fixedly connected with the upper surface of the dish-shaped tray; a first anchor rod through hole is formed in the common flat anchoring tray; a second anchor rod through hole is formed in the dish-shaped tray; the center lines of the first anchor rod through hole, the conical steel pipe and the second anchor rod through hole are overlapped. The invention also discloses an energy absorption anchoring method of the high impact and large transformation resisting energy absorption anchoring tray component. The high impact and large transformation resisting energy absorption anchoring tray component disclosed by the invention has the characteristics of rare deformation unloading or breakage, strong deformation adaptability, continuous yielding, convenience in mounting and the like,the support cost of a deep rock grooundpressure roadway of a mine is reduced, the safety factor of production in the mine is improved, and the effectiveness and safety of a deep roadway surrounding rock anchor rod support system is guaranteed.

Owner:HENAN POLYTECHNIC UNIV

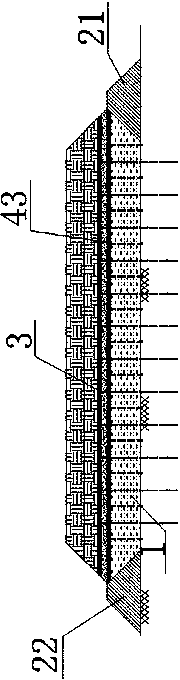

Reinforced soil blocking wall with deformation buffering area and construction method for reinforced soil blocking wall

PendingCN107869152AWith drainage functionIncrease stiffnessArtificial islandsEmbankmentsEngineeringDistortion

The invention discloses a reinforced soil blocking wall with a deformation buffering area and a construction method for the reinforced soil blocking wall. According to the soil blocking wall, the deformation buffering area is arranged between a package reinforced body and a wall face plate, by means of the arrangement of the deformation buffering area, a reinforced soil body on the rear of the deformation buffering area is avoided from making contact with the wall face plate directly, and the deformation buffering area is of a reinforced soil structure, the effective buffering is performed onthe deformation caused by a side direction soil pressure of the reinforced soil body, so that the horizontal displacement of a wall face and the subsidence of a wall top are further decreased, and meanwhile the deformation buffering area has a drainage function. According to the construction method for the reinforced soil blocking wall, the construction of the deformation buffering area is added in an existing construction process of the reinforced soil blocking wall, three parts of the wall face plate, the deformation buffering area and the package reinforced body are constructed simultaneously, the construction is simple and convenient, the supporting and protecting effects are effectively improved, and the construction efficiency can be guaranteed. The reinforced soil blocking wall withthe deformation buffering area of this type has many advantages that the rigidity is large, the deformation is small, the deformation capacity adapting to a foundation is good, the shock resistance is good, the land is saved, the construction is simple and convenient, and the like.

Owner:SHIJIAZHUANG TIEDAO UNIV

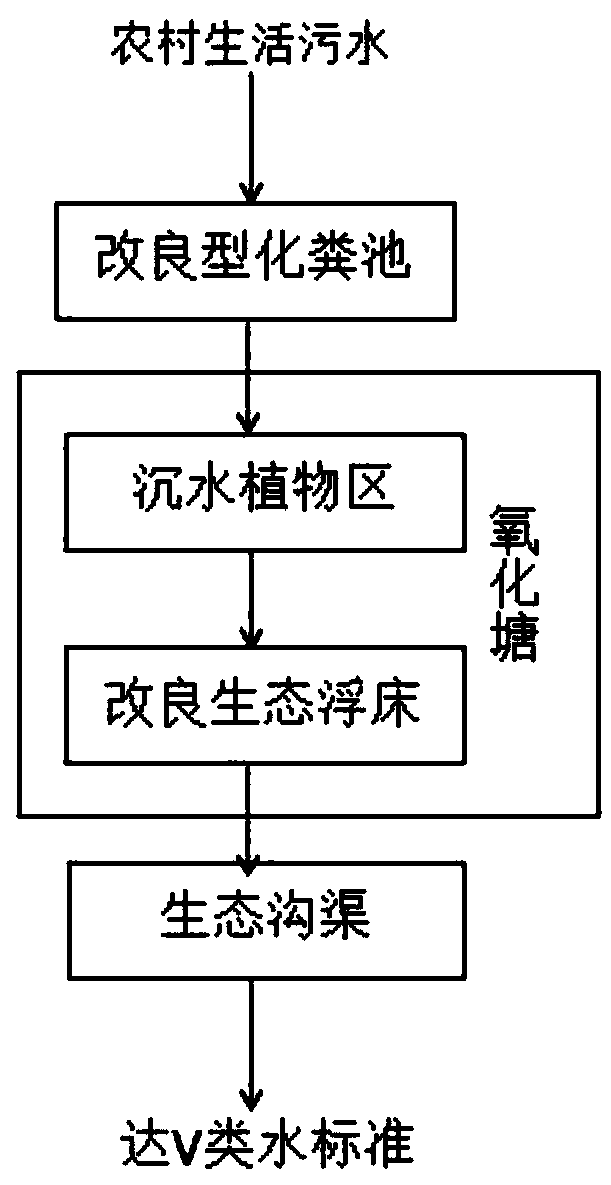

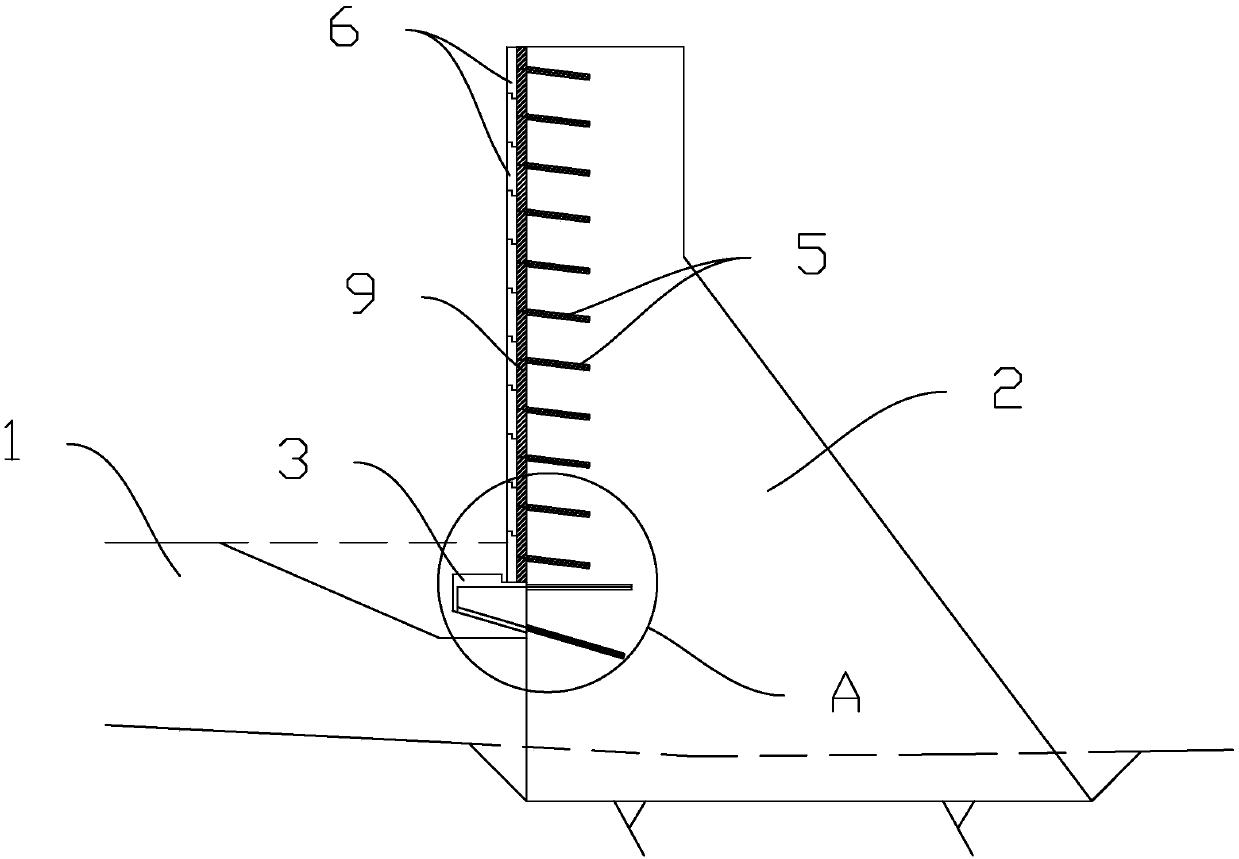

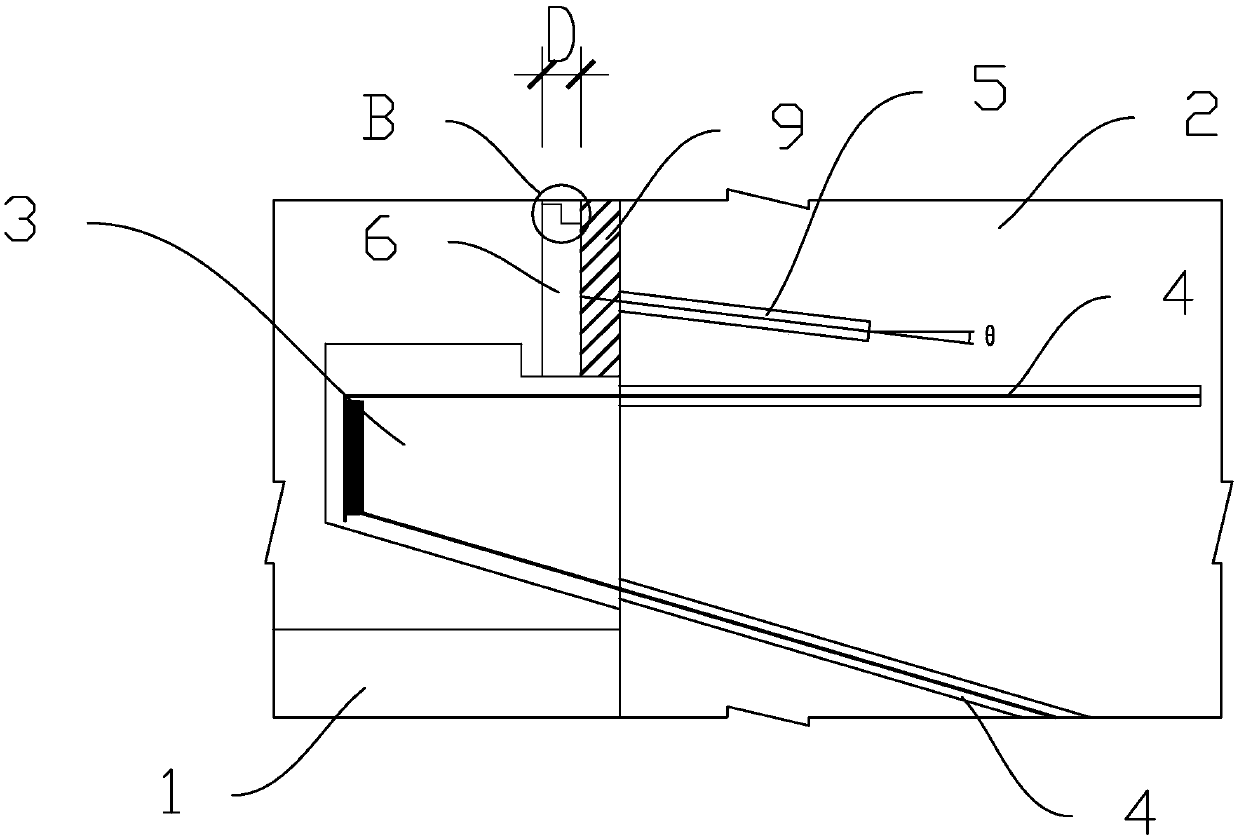

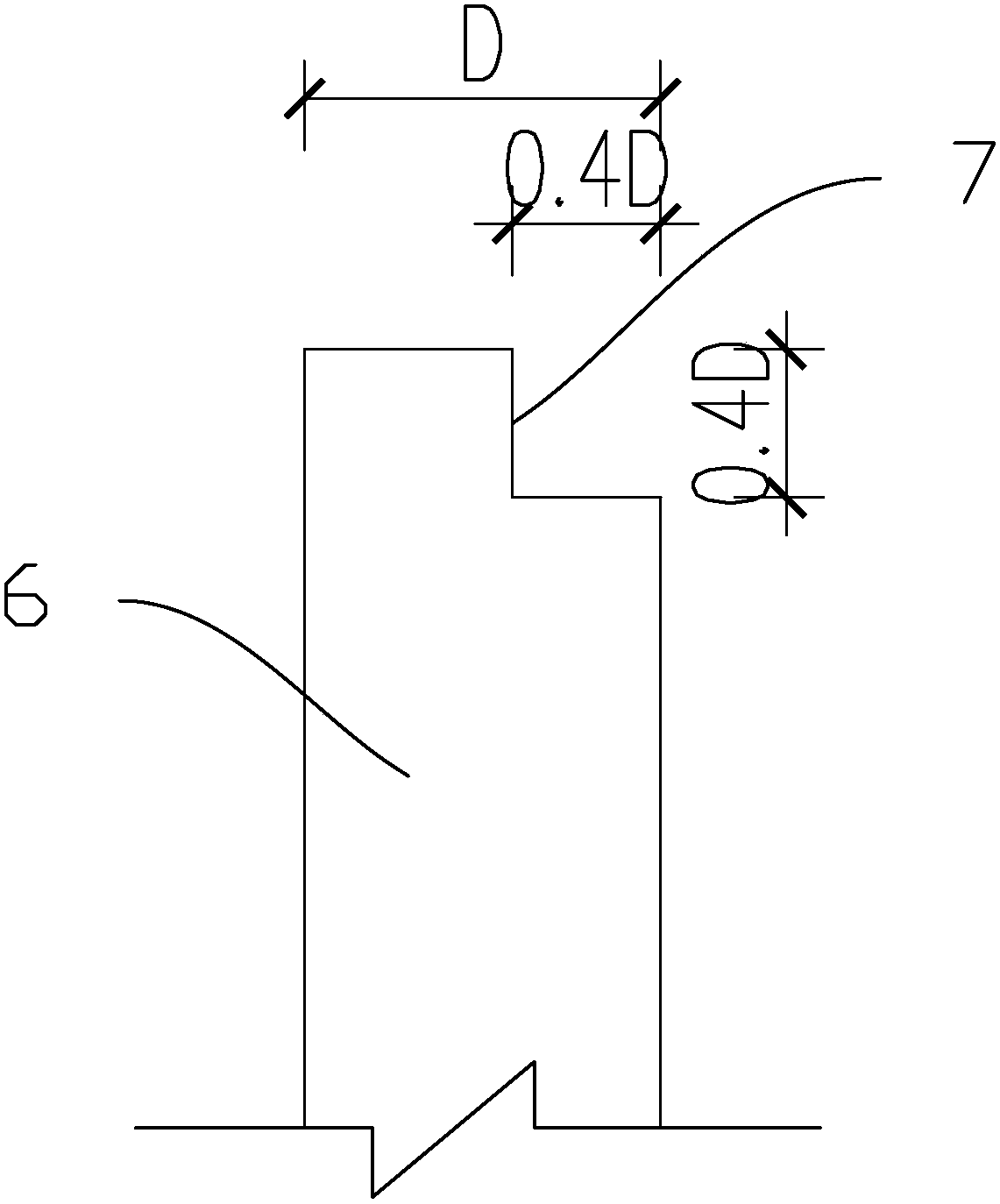

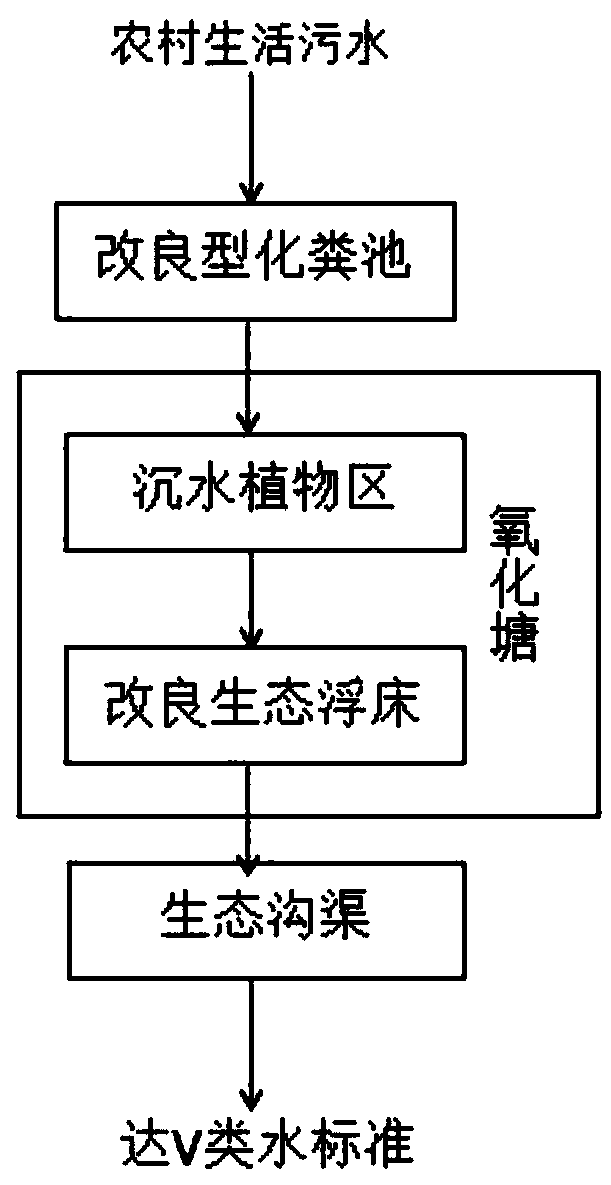

Rural domestic wastewater treatment system based on small watershed morphology

ActiveCN108911158ANo secondary pollutionLess investmentBiological sludge treatmentBiological water/sewage treatmentDispersityTerrain

The invention relates to the technical field of rural domestic sewage treatment, particularly to a rural domestic wastewater treatment system based on small watershed dispersity. According to the present invention, the rural domestic wastewater treatment process using the improved three-grid septic tank-oxidation pond-ecological ditch as the main body is constructed based on local conditions by completely considering the ditches formed by the abundant rainfall and the mountainous hilly terrain in the vast rural areas of southern China, the energy-consuming equipment such as pumps and the likeare not required to be additionally arranged, the additional power-free requirement is achieved, and the rural domestic wastewater treatment system has advantages of less investment, good effect, convenient operation and maintenance, no secondary pollution and the like, and the final effluent can achieve the Class V standard of Environmental Quality Standards For Surface Water (GB3838-2002).

Owner:JIANGXI ACADEMY OF SCI

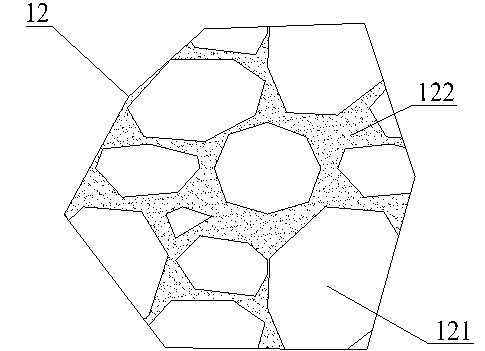

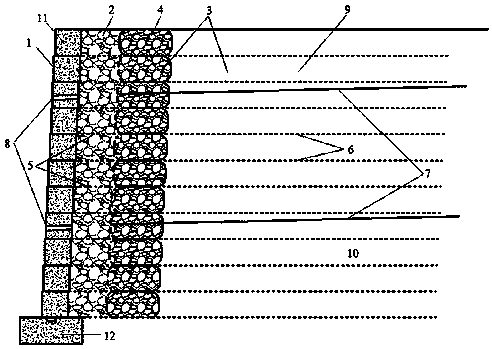

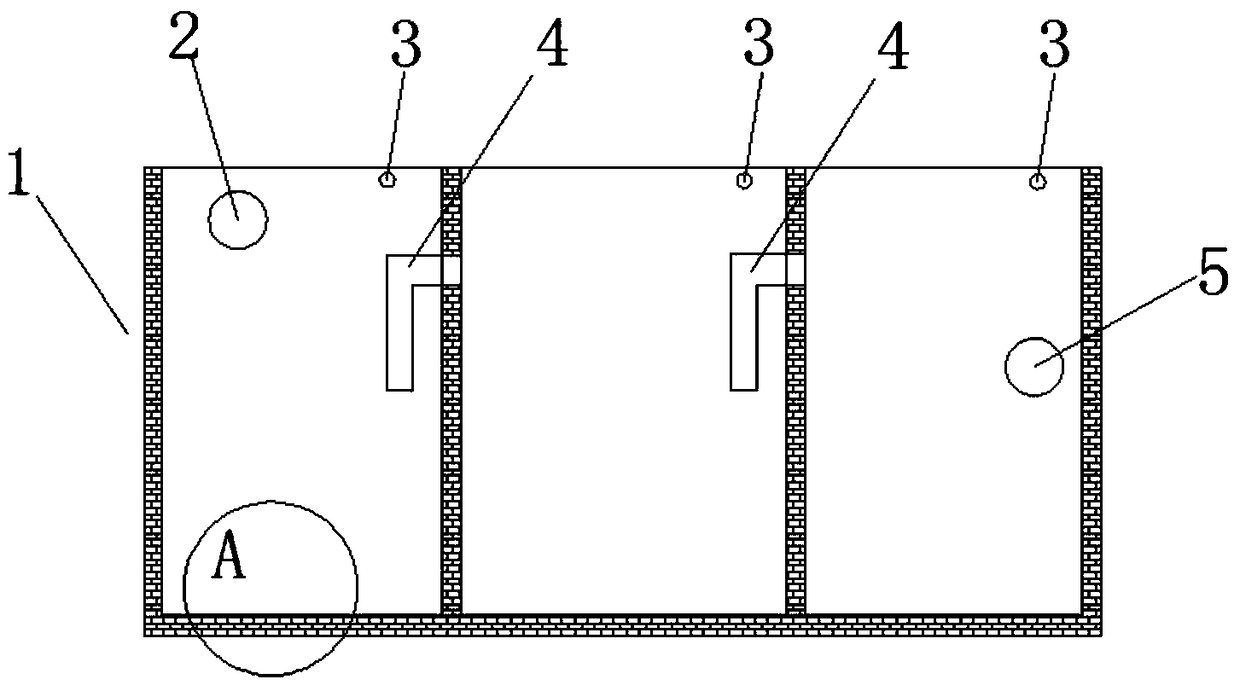

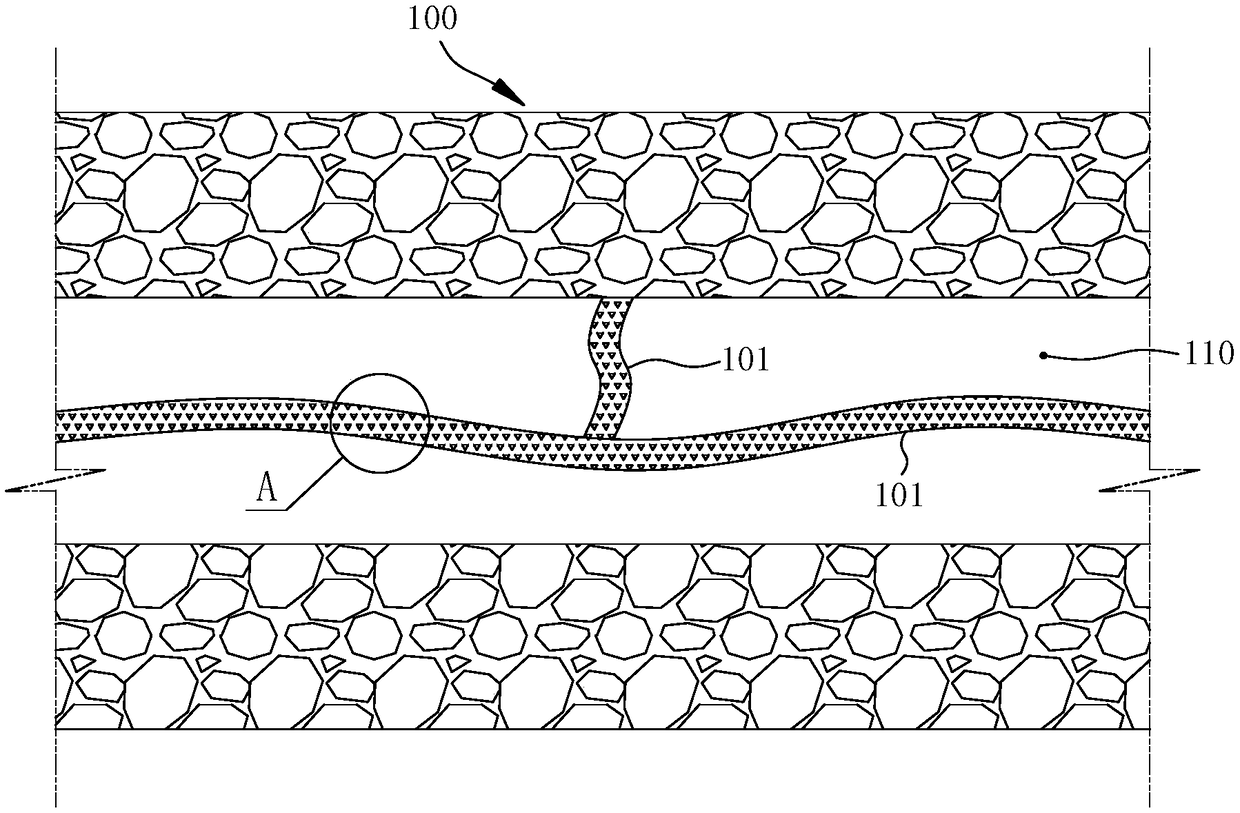

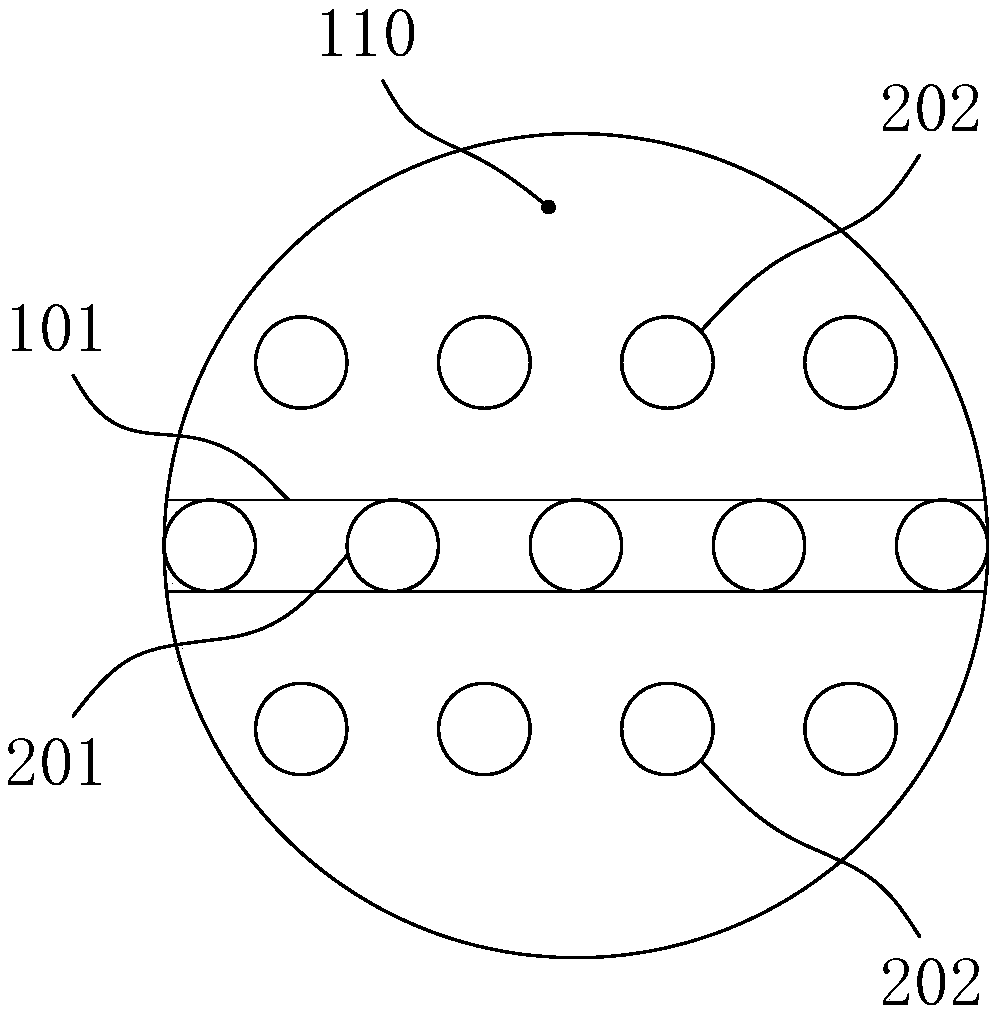

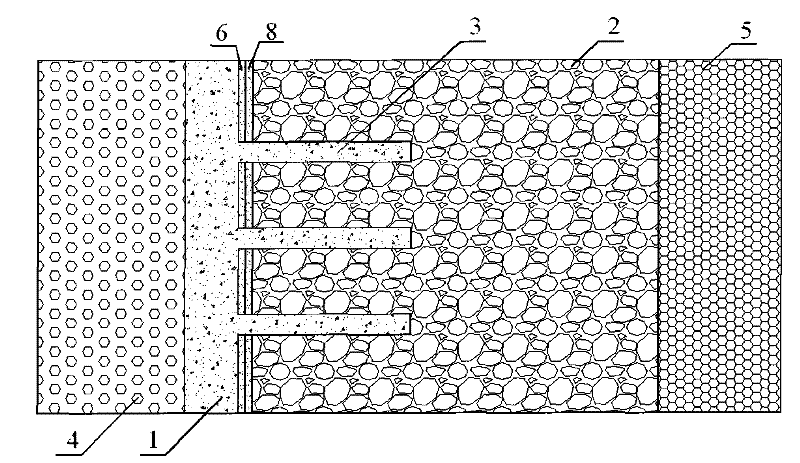

Core-wall rockfill dam

PendingCN111395267AImprove anti-seepage effectStrong ability to adapt to deformationProtective foundationEarth-fill damsSoil scienceGeomembrane

The invention discloses a core-wall rockfill dam comprising gabions, self-compacting concrete, upstream geotextile, downstream geotextile, an upstream rockfill area, a downstream rockfill area, a copper sheet water stop, a concrete base, a grouting gallery and the like. The self-compacting concrete replaces a traditional clay core wall or bituminous concrete core wall. The gabions and the geotextile are used for replacing a traditional transition area. The gabions are utilized to achieve the functions of stabilizing and protecting the core wall. By means of the watertightness of the geomembrane, the seepage-proof function is achieved. According to the core-wall rockfill dam, the type is simple, dam body section partitioning is optimized, the construction speed is rapid, construction interference is little, and construction and later-period overhauling are convenient.

Owner:CHINA WATER RESOURCES BEIFANG INVESTIGATION DESIGN & RES

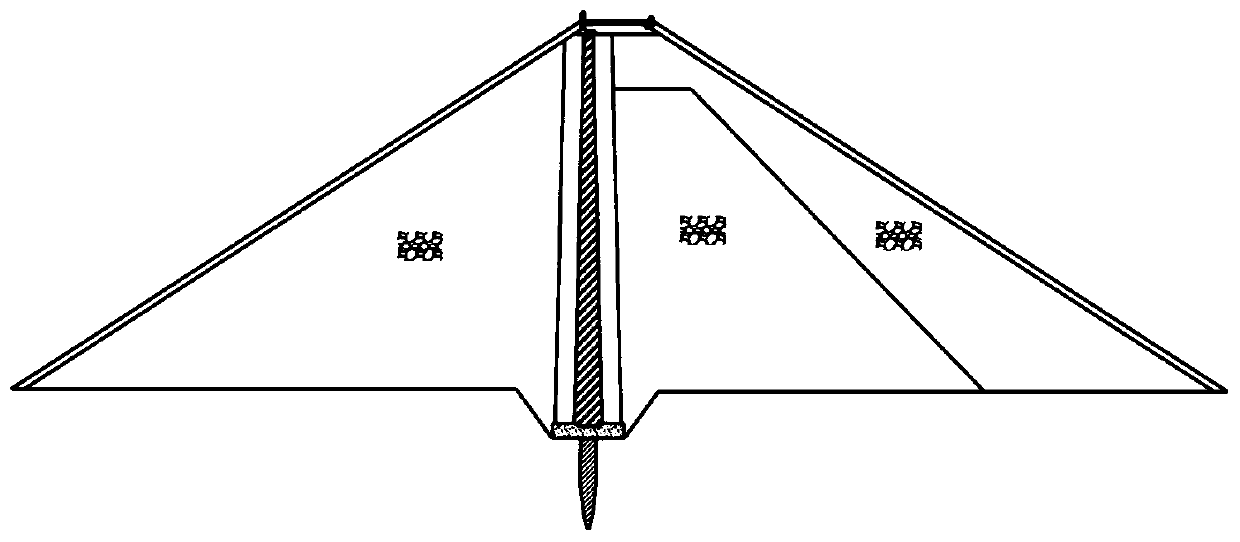

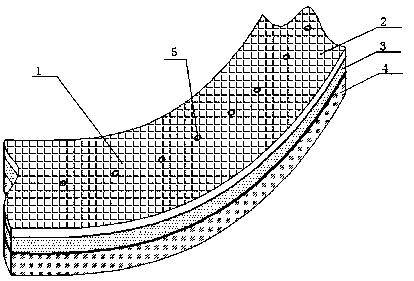

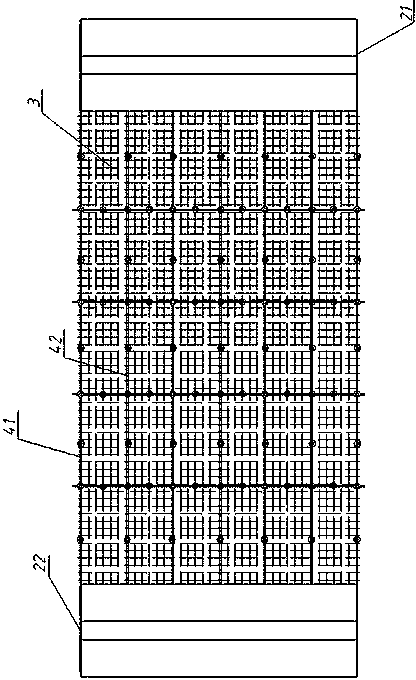

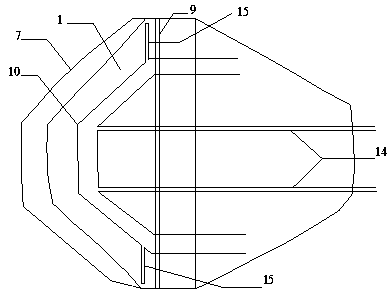

Arched combined faceplate for earth-rock dam and construction method thereof

ActiveCN102587329AGood anti-seepage effectStrong ability to adapt to deformationEarth-fill damsRock-fill damsTension stressCushion

The invention discloses an arched combined faceplate for an earth-rock dam and a construction method thereof. The arched combined faceplate is formed by combining and splicing a plurality of arched concrete slabs through slots; the slots are spliced in a vertically and horizontally staggered manner according to the size of the arched combined faceplate; and gaps between the faceplates and the slots are filled by adopting asphalts. The arched concrete slabs are identical in shape and have the side length of 16-22m and the thickness of 0.3-0.5m. The arched concrete slabs are spherical crown-shaped, and the height of a crown top is one quarter of the side length, or the arched concrete slabs are parabolic, and the height of the top point is one quarter of the side length. The slots have the width of 1.5-2m, the heights of the slots are one quarter of the side length of the slots, and the gaps between the faceplates after combination is 1-2cm. The thickness of the asphalts in the slots is 0.3-0.5m. The construction method of the arched combined faceplate comprises the technological steps of laying cushion layers, splicing the slots, splicing the arched concrete slabs, asphalting in the slots and the like. The arched combined faceplate provided by the invention has the advantages that tensile stress and cracks are not easy to occur, the quality control is high, the construction is convenient, the construction period is short, the construction cost is low and the effect is good.

Owner:HOHAI UNIV

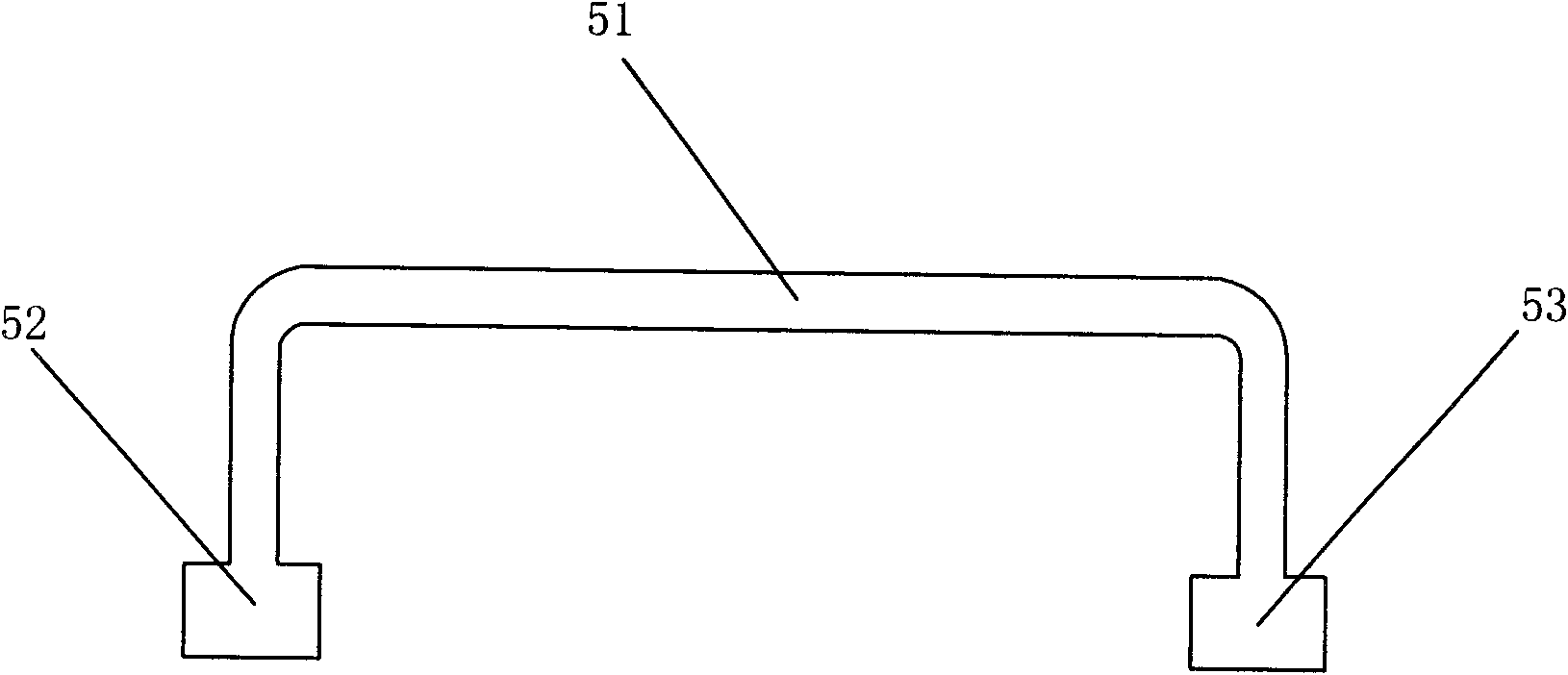

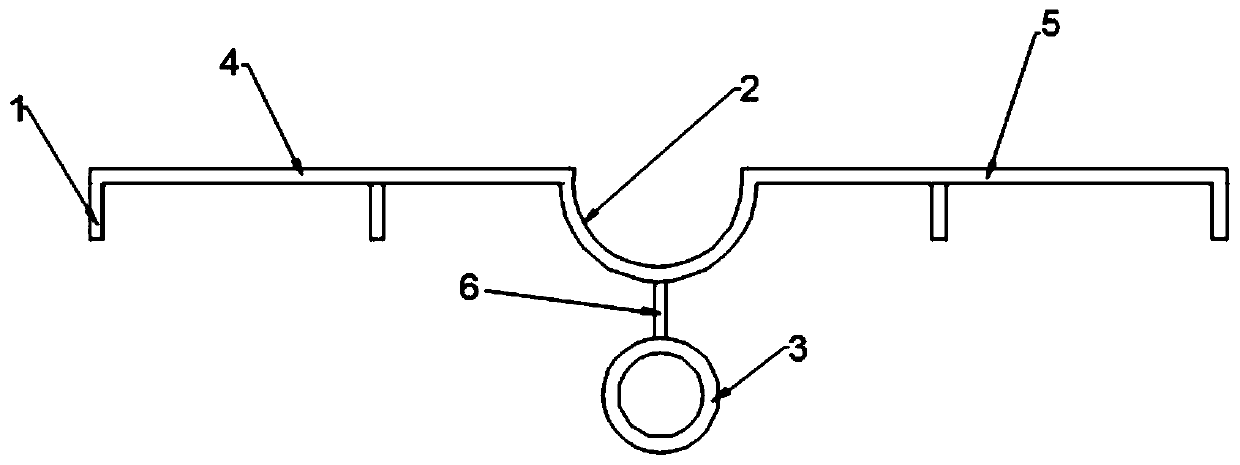

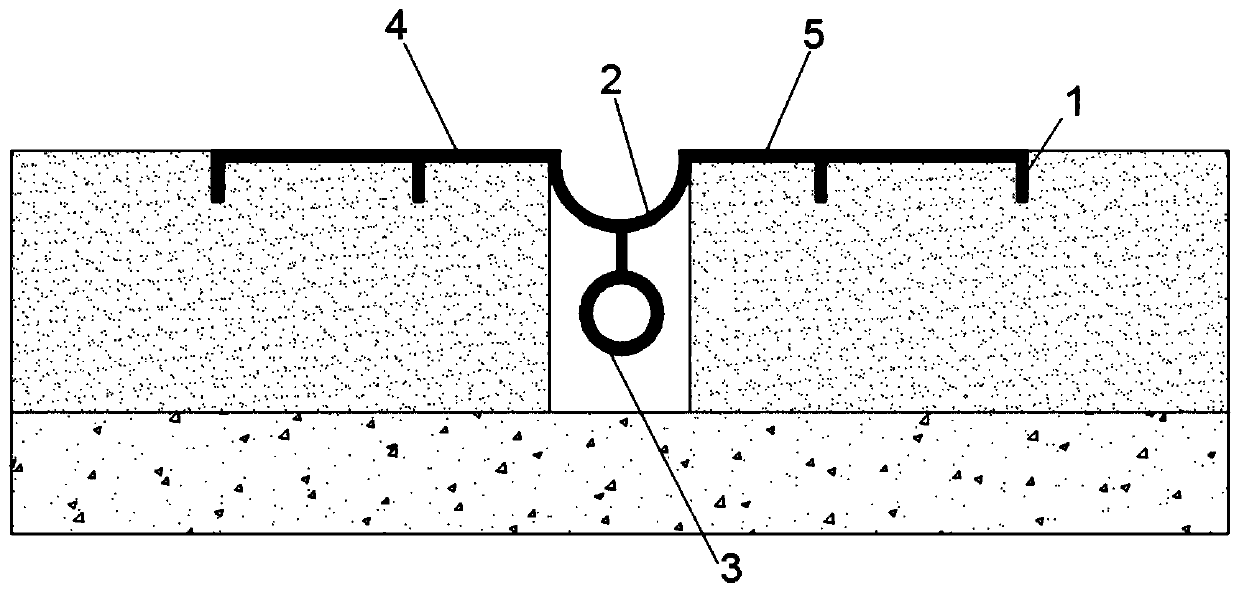

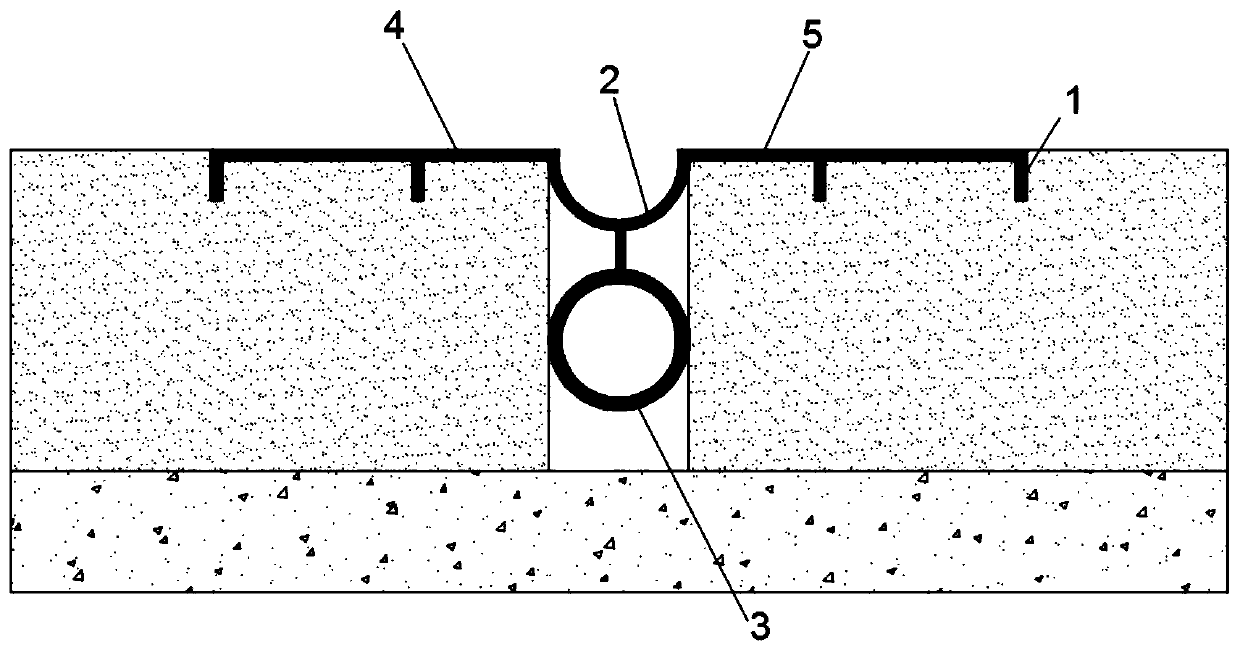

Combined back-pasting type water stop belt

InactiveCN109736453AImprove waterproof performancePlay a role of double insuranceBuilding insulationsRubber materialEngineering

A combined back-pasting type water stop belt comprises a first connecting plate, a second connecting plate, convex ribs, connecting ribs, a central arc-shaped part and a hydrophilic rubber circular pipe; the first connecting plate, the second connecting plate and the central arc-shaped part are made of rubber materials; the first connecting plate and the second connecting plate are fixedly connected with two side edges of the central arc-shaped part respectively; the arc surface of the central arc-shaped part is downward; a plurality of convex ribs are arranged on the lower surfaces of the first connecting plate and the second connecting plate; the bottom of the central arc-shaped part is fixedly connected with the hydrophilic rubber circular pipe through the connecting ribs, and the hydrophilic rubber circular pipe is parallel to the central arc-shaped part; The bottom of the central arc-shaped part is connected with the hydrophilic rubber circular pipe through the connecting ribs; the central arc-shaped part has a sealing effect on a construction joint, the hydrophilic rubber circular pipe expands when meeting water and can fill the construction joint, a double-safety effect is achieved; and even if the central arc-shaped part or the connecting plate is punctured, the hydrophilic rubber circular pipe can also have a good waterproof effect.

Owner:NORTHEASTERN UNIV LIAONING

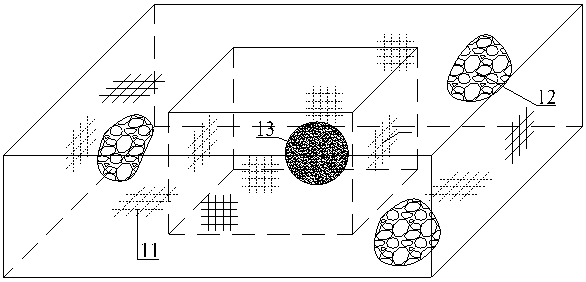

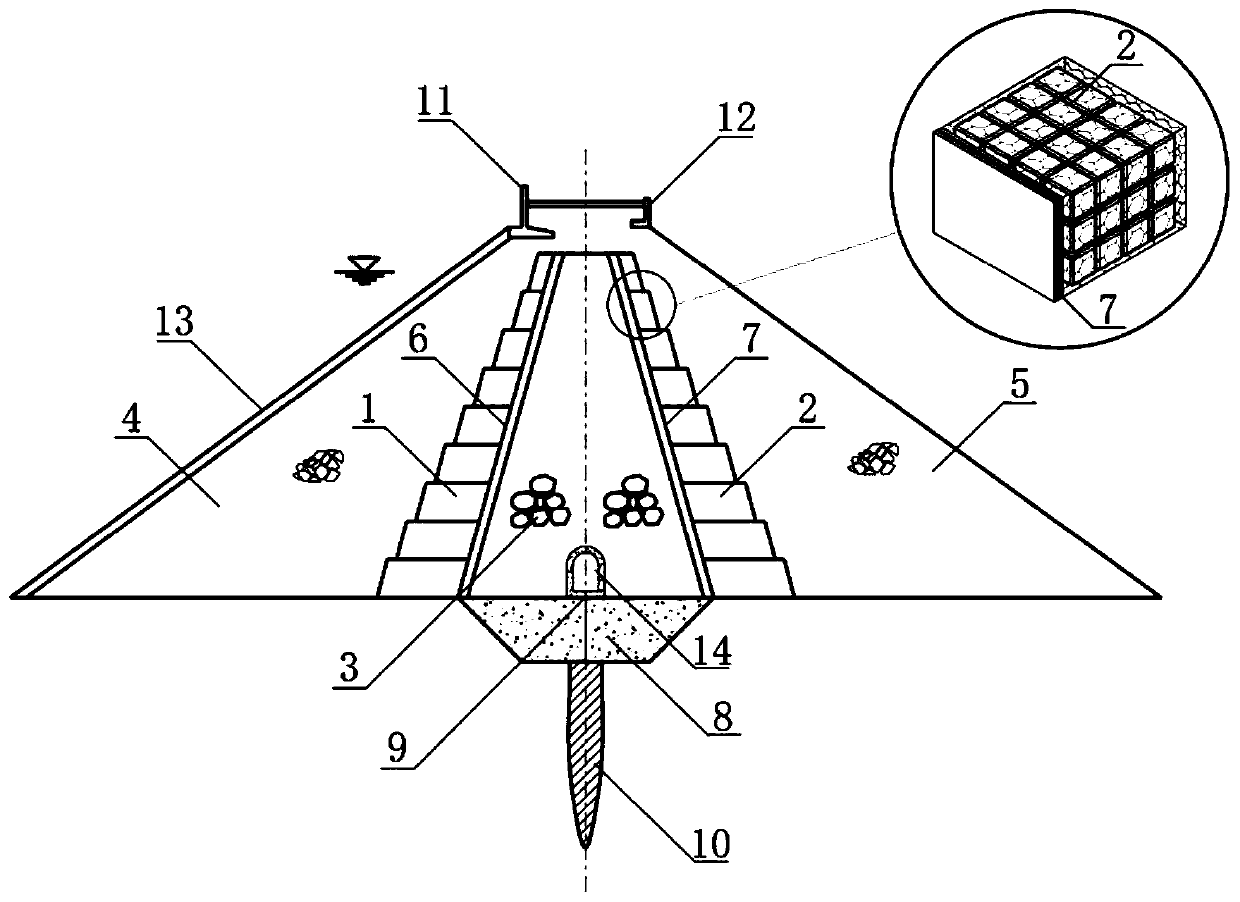

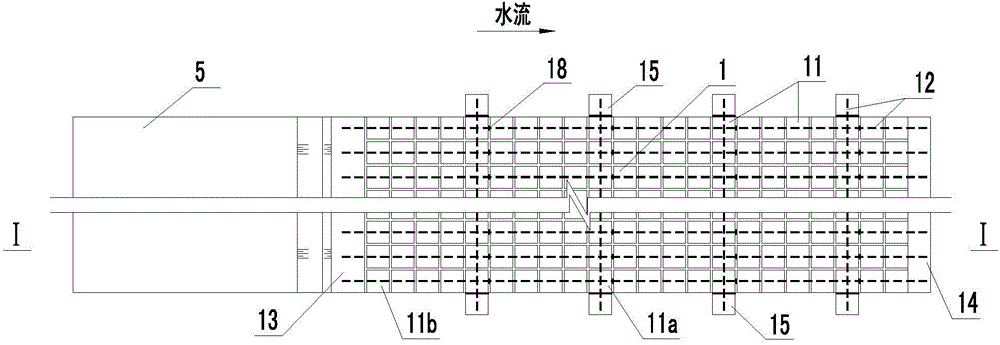

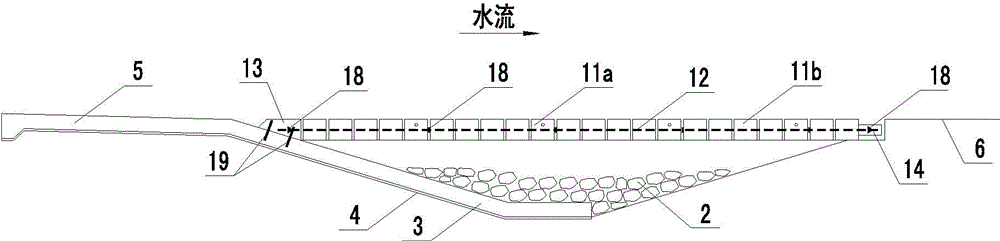

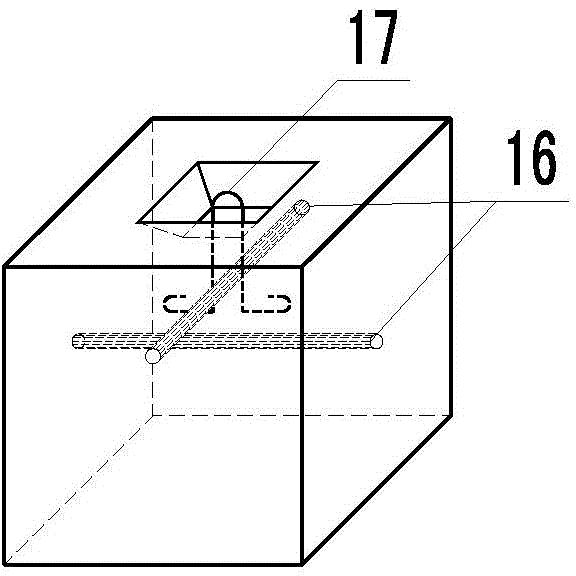

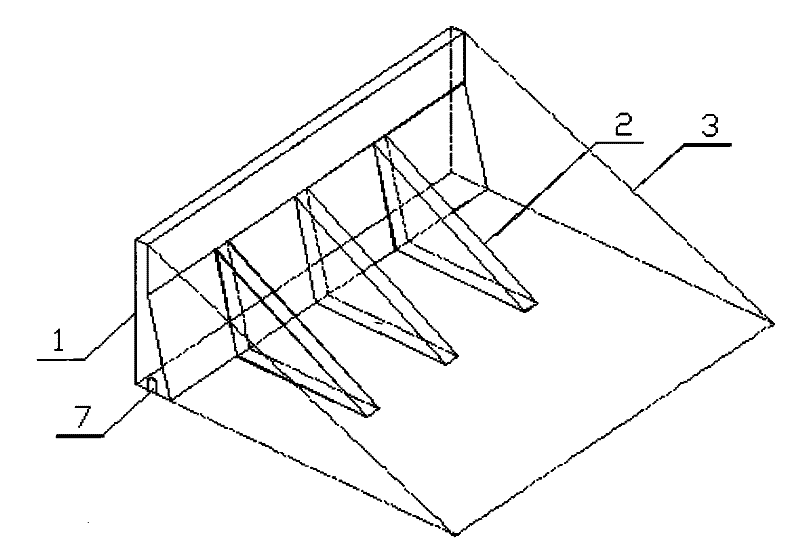

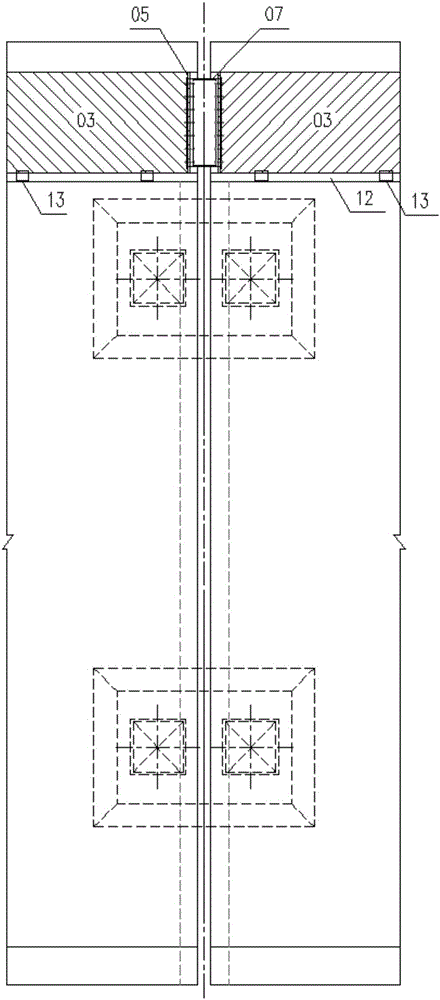

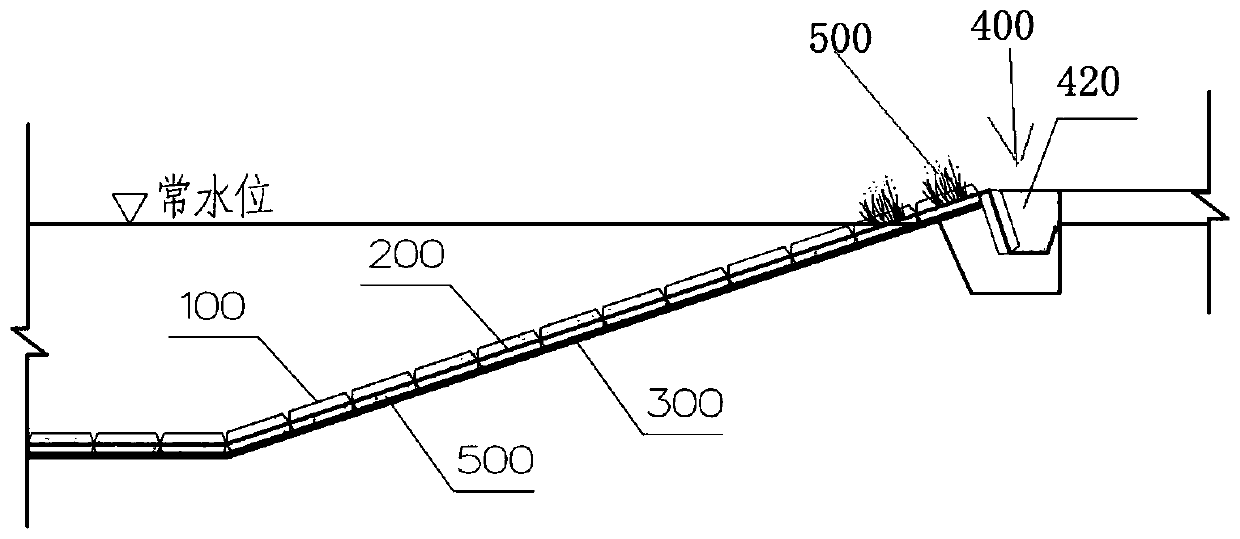

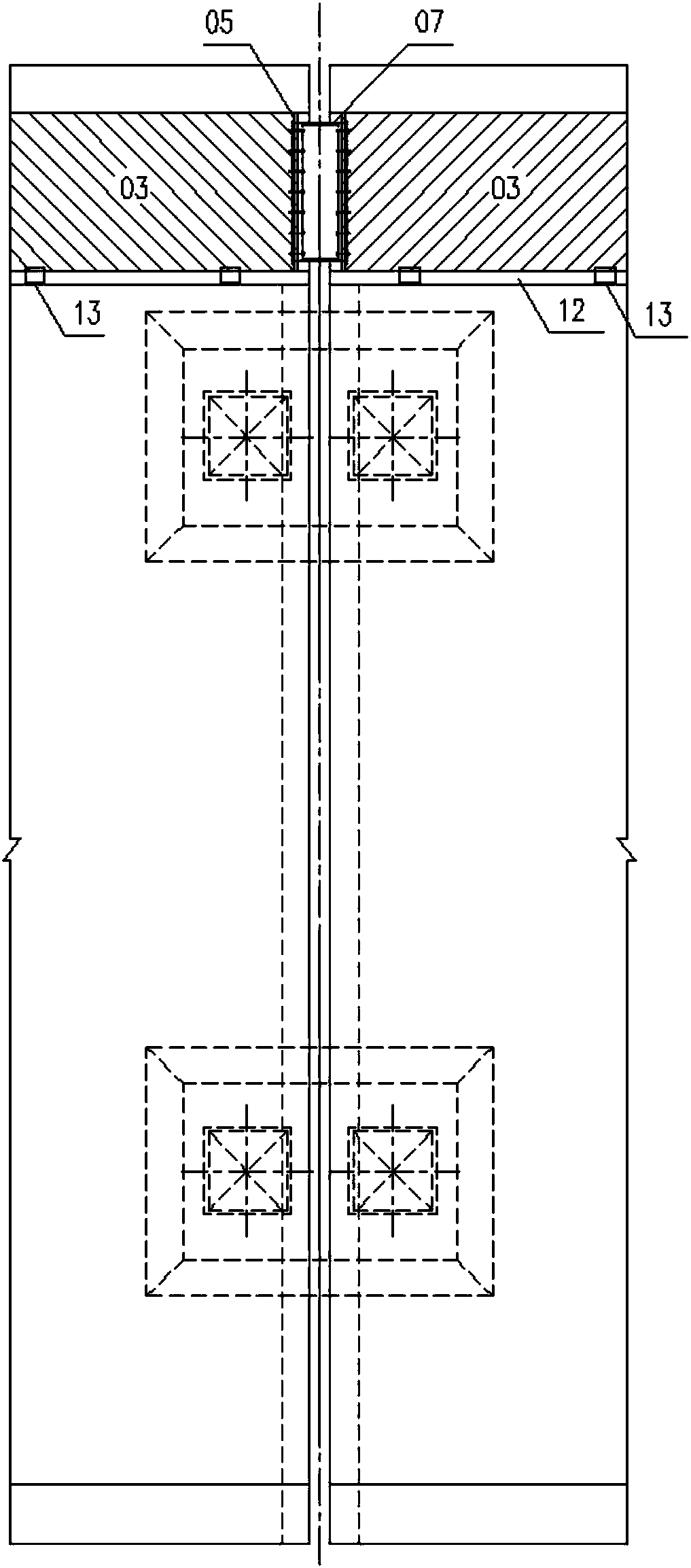

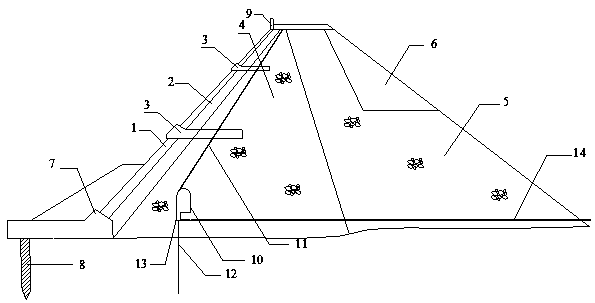

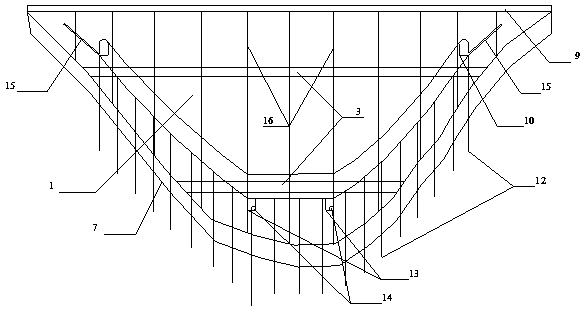

Scour-preventing groove for chain precast block protective surface

ActiveCN104963323AIncrease spacingStrong ability to adapt to deformationBarrages/weirsWater flowStructural engineering

The invention discloses a scour-preventing groove for a chain precast block protective surface. The scour-preventing groove for the chain precast block protective surface comprises the chain precast block protective surface, a riprap layer and an apron groove bottom extension section. The apron groove bottom extension section is located on the bottom layer. The apron groove bottom extension section and a riverbed surface connected with the apron groove bottom extension section are filled with the riprap layer. The chain precast block protective surface is arranged on the riprap layer and comprises precast blocks, chain ropes, anchoring piers, anchoring beams and anchoring heads. The precast blocks include the A type precast blocks and the B type precast blocks. Through chain holes are only formed in the centers, in the water flowing direction, of the B type precast blocks. Through chain holes are formed both in the centers, in the water flowing direction and the centers, in the direction perpendicular to the water flowing direction, of the A type precast blocks. The chain ropes penetrate into the chain holes to be connected with the precast holes in series. One upstream end of each chain rope arranged in the water flowing direction is anchored in the corresponding anchoring pier, and one downstream end of each chain rope arranged in the water flowing direction is anchored in the corresponding anchoring beam. The two ends of each chain rope arranged in the direction perpendicular to the water flowing direction are anchored in the corresponding anchoring heads. The scour-preventing groove for the chain precast block protective surface is high in deformation adaptability, high in water permeability, high in roughness, environmentally friendly, economical, high in durability and wide in application range.

Owner:浙江省水利水电勘测设计院有限责任公司

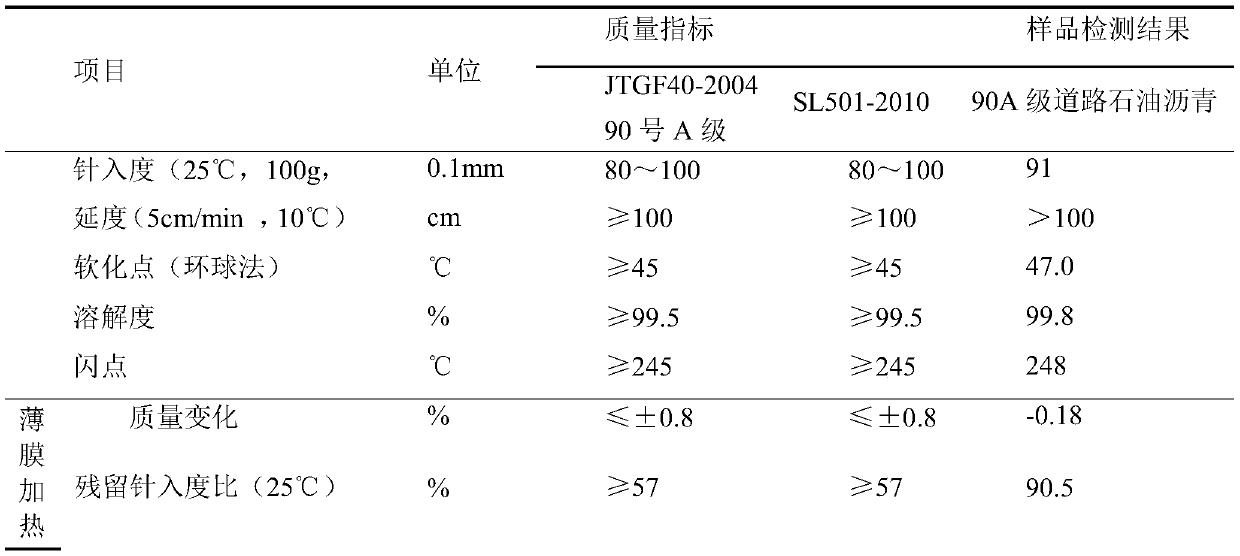

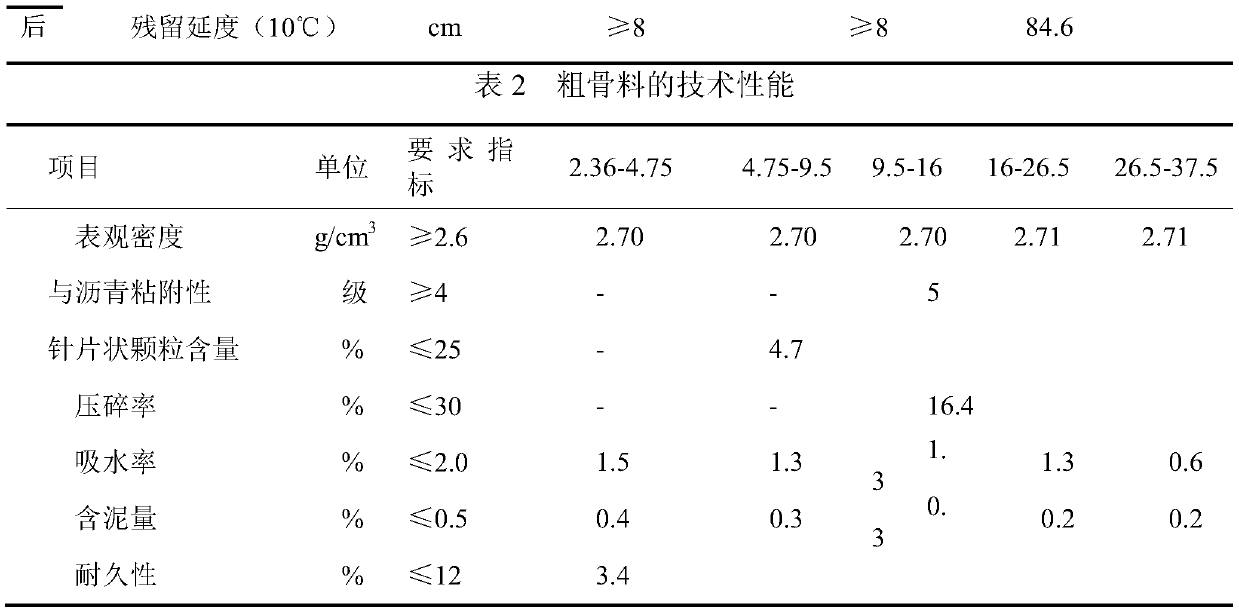

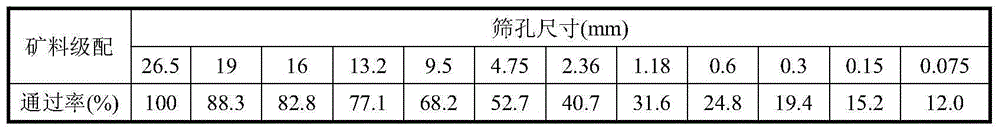

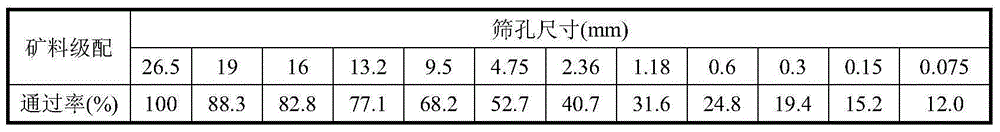

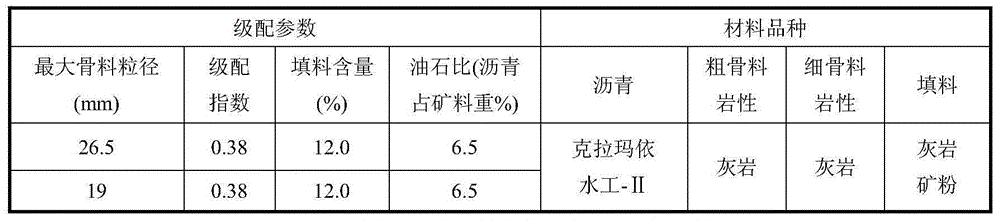

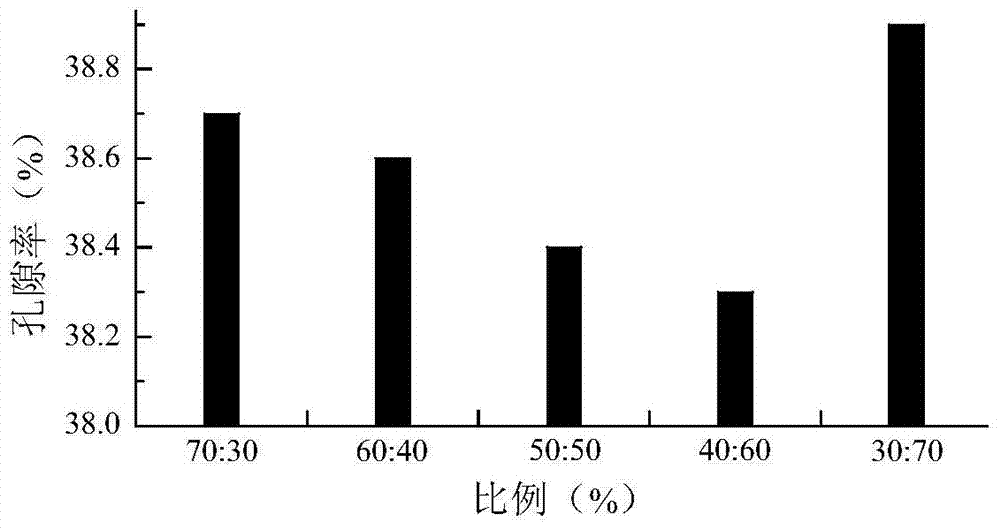

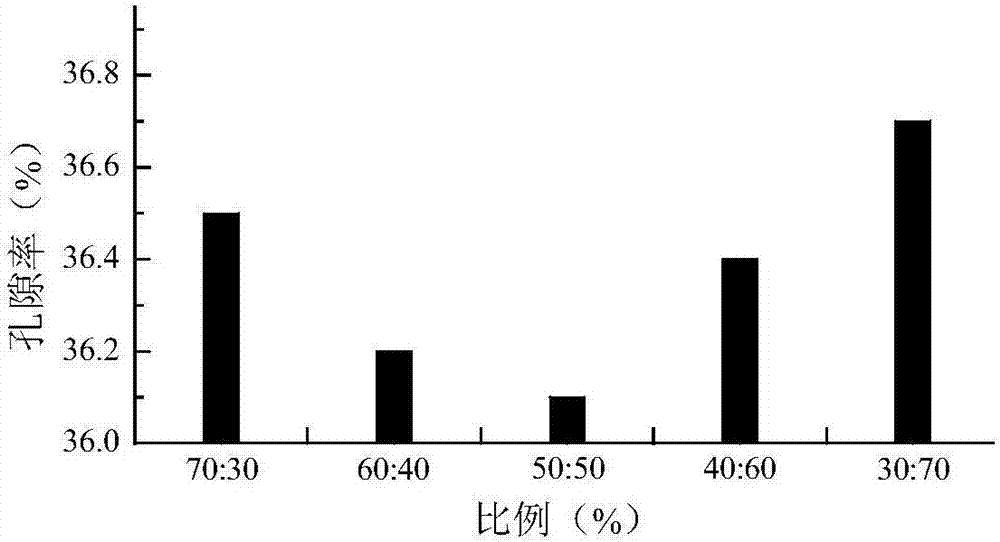

Large-particle-size aggregate core wall asphalt concrete and mix proportion optimization method thereof

ActiveCN111470806AReduce dosageHigh strengthDesign optimisation/simulationResourcesArchitectural engineeringStructural engineering

The invention discloses a large-particle-size aggregate core wall asphalt concrete which is screened out through a square hole screen with the side length of screen holes being 37.5 mm, the thicknessof an asphalt film of the asphalt concrete is 6.748-8.688 microns, the grading index is 0.42-0.48, the use amount of a filler is 10%-12%, and the use amount of asphalt is 5.5%-6.1%. The invention further discloses a proportion optimization method of the large-particle-size aggregate core wall asphalt concrete. According to the asphalt concrete, large-particle-size aggregate is adopted; the arge-particle-size aggregate core wall asphalt concrete is high in strength, high in deformation adaptability and obviously low in asphalt consumption, the construction efficiency is improved, engineering investment is saved, test data obtained through a large test piece and the PPR technology are utilized, the optimal asphalt film thickness is introduced to serve as the evaluation standard, and the problem that optimization cannot be achieved without experience depending on the increase of the mix proportion of aggregate is solved.

Owner:XINJIANG AGRI UNIV

Mixed anti-seepage dam

PendingCN110939104ASimplify construction proceduresEven by forceEarth-fill damsRock-fill damsRockfill materialSoil science

The invention discloses a mixed anti-seepage dam. The mixed anti-seepage dam comprises an upstream lower rockfill material, a downstream lower rockfill material, an upstream upper rockfill material, adownstream upper rockfill material, a dry stone revetment, transition materials, an asphalt concrete core wall, a concrete base, curtain grouting and a wave wall, wherein the asphalt concrete core wall is arranged in the transition materials positioned between the upstream lower rockfill material and the downstream lower rockfill material; a high-strength reinforced geomembrane is arranged in thetransition materials positioned between the upstream upper rockfill material and the downstream upper rockfill material to replace the asphalt concrete core wall; the upper half part of a traditionalasphalt concrete core wall dam is changed into the high-strength reinforced polyethylene geomembrane, and the anti-seepage effect is achieved through the watertightness of the geomembrane; and the upstream rockfill material and the downstream rockfill material are rockfill materials with the large deformation modulus. The dam body is simple in form and high in construction speed, the requirementfor the upstream rockfill material and the downstream rockfill material is low, and the mixed anti-seepage dam has good popularization value for projects with insufficient dam building materials in dam site areas.

Owner:CHINA WATER RESOURCES BEIFANG INVESTIGATION DESIGN & RES

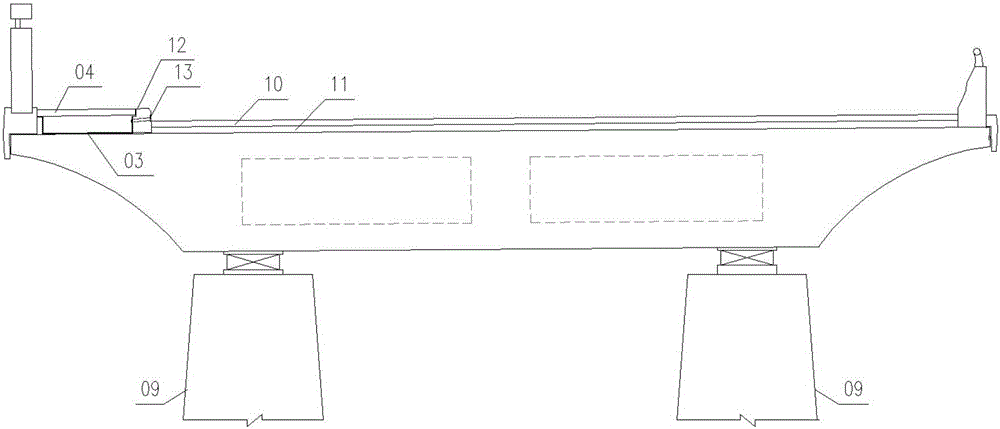

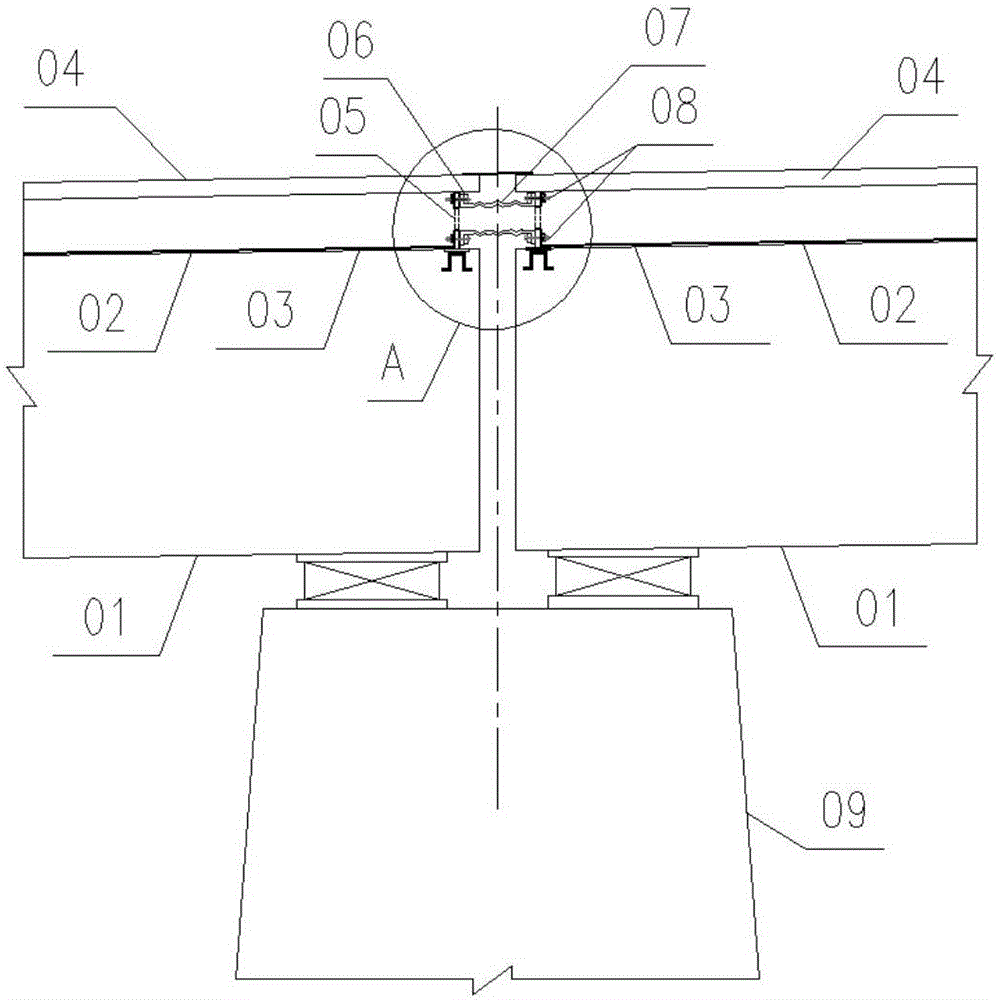

Rapid installing expansion joint for railway bridge

PendingCN109457603ASimple structureEasy to operateBridge structural detailsEngineeringExpansion joint

The invention discloses a rapid installing expansion joint for a railway bridge. The expansion joint comprises a bridge foundation, a fixing anchoring nail, a prefabricated steel plate and a bufferingcushion, the prefabricated steel plate is arranged on the bridge foundation, the fixing anchoring nail is arranged below the prefabricated steel plate, the buffering cushion is arranged on the prefabricated steel plate, a fixing seat is installed on the buffering cushion, an installing groove is formed in the fixing seat, connecting joints are arranged in the installing groove, a rubber waterstopis arranged between the connecting joints, and pressing blocks are arranged on one sides of the connecting joints. The expansion joint has the advantages that the structure is simple, the expansion joint is usually fixedly connected through bolts, the operation is convenient, the rubber waterstop which is arranged on the expansion joint has better elasticity, wear resistance performance, anti-ageing performance and anti-tearing performance, the adaption deformation capability is high, the waterproofing performance is good, concrete pouring is not needed in the installing process of the expansion joint, the installing time of the expansion joint is effectively saved, and the maintenance is convenient.

Owner:GUIZHOU UNIV

Hydraulic asphalt concrete antiseepage material with large particle size

InactiveCN105152580AImprove daily construction intensityImprove anti-seepage effectEarth-fill damsRock-fill damsLarge particleMaterials science

The invention discloses a hydraulic asphalt concrete antiseepage material with a large particle size and a a rock-fill dam constructed therefrom. The antiseepage material mineral aggregate grading index is 0.38, the maximum aggregate particle size in the mineral aggregate is 26.5mm, and the asphalt-aggregate ratio of the antiseepage material asphalt usage amount is 6.5%. The material can meet the requirement of the rolling type asphalt concrete core technology standard, in practical engineering, the hydraulic asphalt concrete antiseepage material with a large particle size can raise bearing capability of the heated bitumen mixture, rolling apparatuses used for construction of the rolling type asphalt concrete core and transitional materials at two sides are unified, cost of the rolling type asphalt concrete core construction equipment, workloads of maintenance and management, and construction cost of the rolling type asphalt concrete core engineering are reduced. The spreading thickness in rolling type asphalt concrete core construction is increased, daily construction intensity of the rolling type asphalt concrete core construction is increased, and a technology support for the rolling type asphalt concrete core engineering construction progress is provided.

Owner:SINOHYDRO BUREAU 7 CO LTD

A method for repairing cracks in earth-rock dam body

ActiveCN106638475BReduce disturbanceAvoid crackingMarine site engineeringSoil preservationSlurryWater level

The invention belongs to the technical field of hydraulic and hydropower engineering, and in particular, discloses an earth and rockfill dam body crack repair method with short construction period and good repair effect. The repair method comprises the following steps: firstly, the high polymer grouting is performed for dam body cracks; the characteristic of quick volume expansion and dispersion of high polymer slurry after the polymerization reaction is used for fully filling the dam body cracks and holes in soil around the dam body cracks in the expansion and dispersion process; and then, the high polymer grouting is performed for two sides of the dam body cracks, so that the soil and high polymers in a certain range around the dam body cracks are glued to form high polymer grouting compound bodies to finish repair of the dam body cracks. As the high polymers are used for grouting, the maintenance is not needed, the construction period is largely shortened, and the repair is fast; and the formed high polymer grouting compound bodies are flexible bodies, are high in tensile strength and deformation adapting capacity, and can prevent the dam body cracks from cracking again due to such factors as water level change to achieve good repair effect.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

Dredged Soft Soil Foundation Treatment Method Simultaneously Developed by Filling and Reinforcement

ActiveCN102817354BAvoid entry problemsShorten the drainage distanceSoil preservationDrainage networkBuilding construction

The invention relates to the field of building foundations, in particular to a method for dredging a soft foundation by dredger fill and reinforcement. The method includes: a, zoning for dredger fill; b, forming a primary drainage system; and c, performing layered and zonal filling and reinforcement. The method is characterized in that in zoning for dredger fill, each filling unit (11) is 20000m<2>-50000m<2> in area; in formation of the primary drainage system, digging crisscross blind ditches (31) on the surface of the filling unit (11), and laying corrugated filter pipes (32) and drain boards (33) on the surface for the filling unit (11); and in layered zonal filling and reinforcement, filling the filling area (1) level by level, and reinforcing with all levels of drainage networks. The method is convenient in construction, short in construction period, effective in foundation treatment and low in construction cost.

Owner:BAOSTEEL ENG & TECH GRP

Concrete-enrockment mixed dam and construction method thereof

ActiveCN101718086BLower the volumeSave amountEarth-fill damsRock-fill damsManufacturing cost reductionEngineering

Owner:HOHAI UNIV

Bridge deck drainage supporting facility

ActiveCN106320172ASolve the problem of exposureImprove sealingBridge structural detailsBridge deckExpansion joint

The invention discloses a bridge deck drainage supporting facility. A drainage channel is formed in the outer side of a bridge deck pavement edge curb and provided with an open rectangular section, a footpath cover plate covers the upper portion of the drainage channel, the outside of the drainage channel is wrapped with a stainless steel plate, rainwater holes are formed in the curb, the drainage channel extends into linking roads at two ends of a bridge along the bridge, a spherical rubber expansion joint for water passage is formed in the position of the drainage channel passing an expansion seam, two ends of the rubber expansion joint are fastened on vertical seal head steel plates of the drainage channel through flange plates and bolts, openings are formed in the vertical seal head steel plates of the drainage channel and correspond to the expansion joint, the stainless steel plate externally wrapping the drainage channel is crimped at the openings of the seal head steel plates, the stainless steel plate, the rubber expansion joint and the flange plates are jointly anchored on a steel plate, a plurality of spheres are formed on the vertical surface of the rubber expansion joint, the displacement deformation requirement of beams on two sides of the expansion seam is met, and the cross section of the expansion joint is rectangular. The bridge deck drainage supporting facility can solve the problems that a drainage pipe of a traditional bridge deck drainage scheme is exposed, joints frequently leak and the like.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

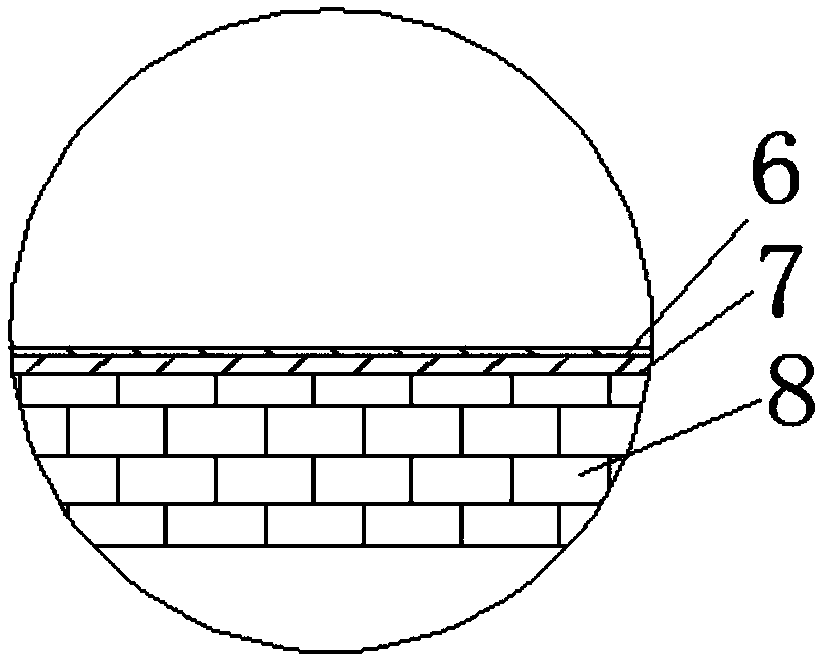

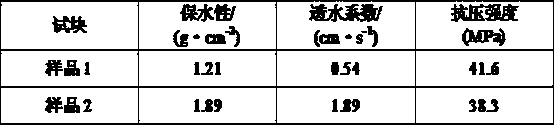

Water purifying type greening brick applied to ecologic slope protection and preparation method thereof

InactiveCN110066159AStrong structural stabilityReduce penetrationCoastlines protectionExcavationsPorosityBrick

The invention discloses a water purifying type greening brick applied to ecologic slope protection. The greening brick comprises a soil wrapping hollow building block, a composite drainage net and a water permeable porous building block which are sequentially arranged from top to bottom; the soil wrapping hollow building block is prepared from dredged spoil, zeolite, coal ash, portland cement, water glass, lignosulfonate and water; the water permeable porous building block is prepared from ceramic particles, clay, an admixture, portland cement, a pore forming agent, hydroxypropyl methyl cellulose and water. The invention further discloses a preparation method of the water purifying type greening brick. The soil wrapping hollow building block is light and high in structure stability, the water permeable porous building block is good in water permeability and high in porosity, according to the water purifying type greening brick, by combining the soil wrapping hollow building block, thecomposite drainage net and the water permeable porous building block, effective ecologic slope protection can be achieved, and rainwater can be absorbed, filtered, purified, drained and protected.

Owner:SHENGSHI LANDSCAPE GRP CO LTD

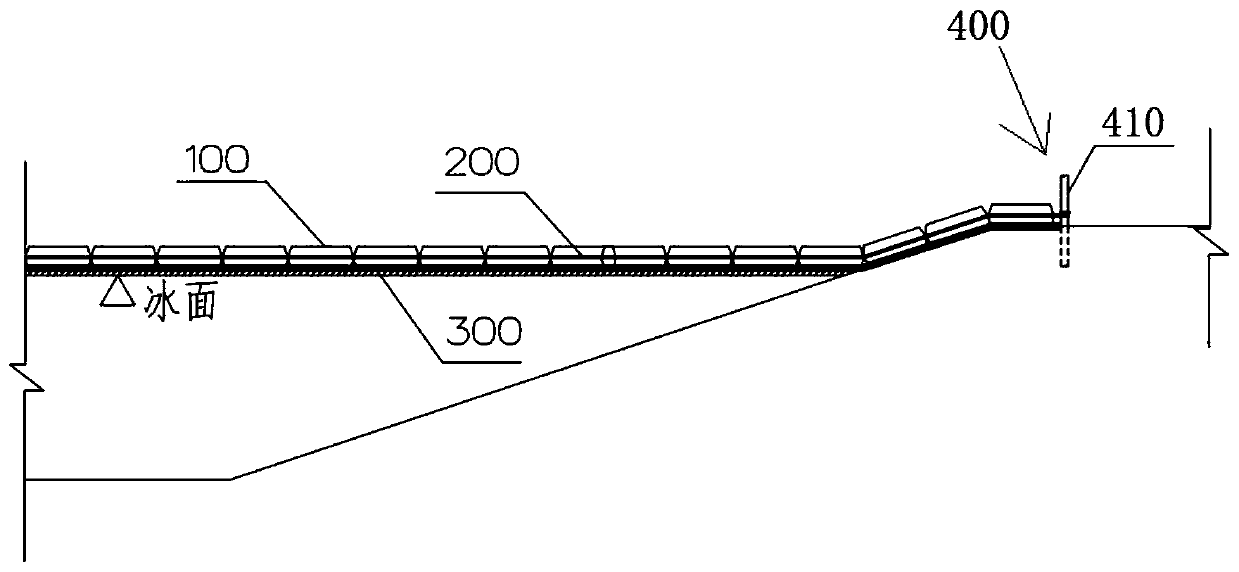

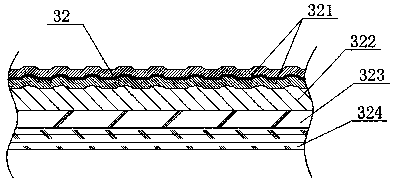

Flexible integral ecological slope protection structure for cold region and construction method of flexible integral ecological slope protection structure for cold region

PendingCN111455931AGood flexibility and integrityStrong ability to adapt to deformationCoastlines protectionReceptacle cultivationEnvironmental resource managementStructural engineering

The invention discloses a flexible integral ecological slope protection structure for a cold region. A method for the flexible integral ecological slope protection structure comprises a plurality of armor blocks being high in intensity and high in impact resistance, which are built on the slope, a pull resisting connecting facility for connecting the armor blocks, a filtering reversing soil protecting facility paved at the bottoms of the armor blocks, a positioning structure arranged to fix the pull resisting connecting facility, and a stuffing material stuffed in the armor blocks. The invention further discloses a construction method of the flexible integral ecological slope protection structure for a cold region.

Owner:SHANGHAI WATER ENG DESIGN & RES INST

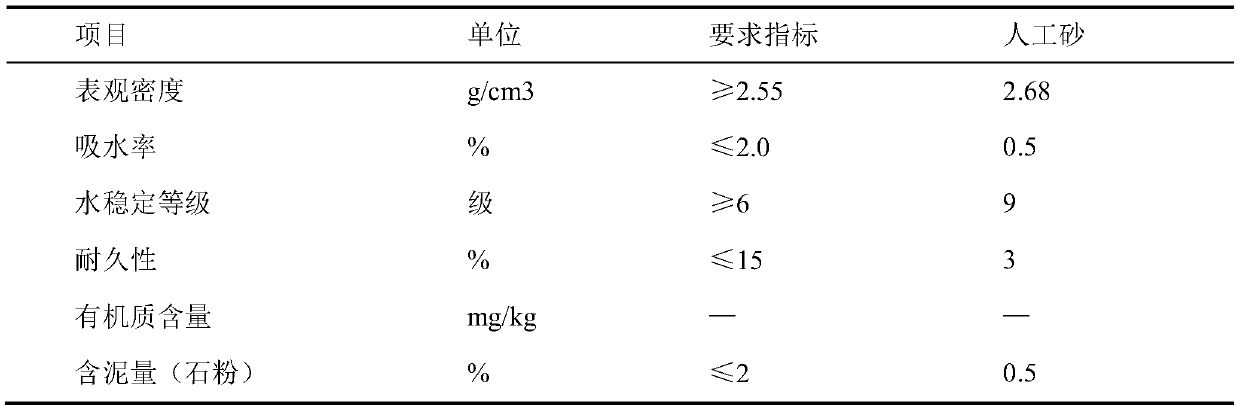

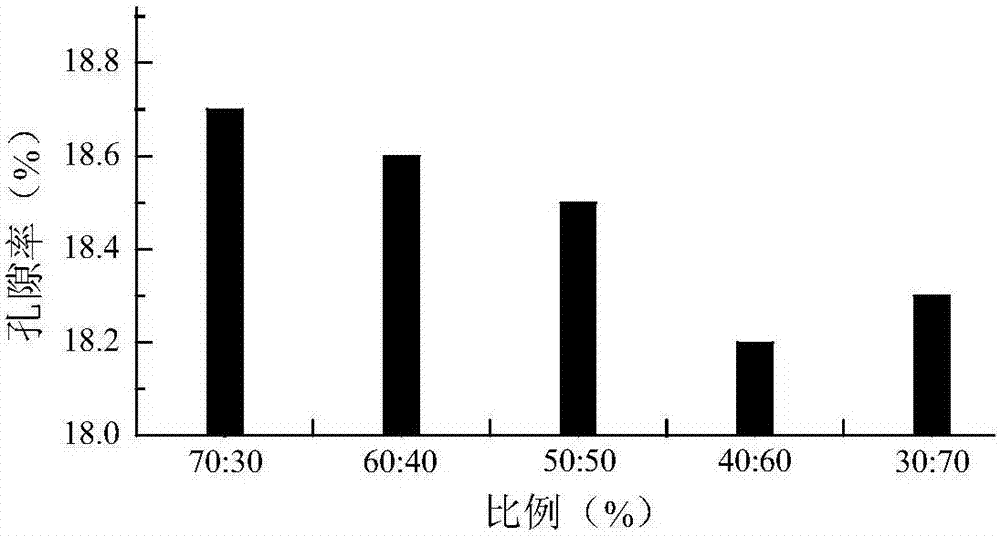

A kind of room temperature asphalt concrete and preparation method thereof

ActiveCN105621955BHigh mechanical strengthStrong ability to adapt to deformationPorosityRoom temperature

The invention belongs to the technical field of water conservancy and hydropower engineering, and particularly relates to room-temperature bituminous concrete and a preparation method thereof. The room-temperature bituminous concrete is prepared from the following raw materials: in percentage by weight, 8%-13% of aggregate with the particle diameter larger than 9.5mm and smaller than or equal to 16mm, 16%-21% of aggregate with the particle diameter larger than 4.75mm and smaller than or equal to 9.5mm, 25%-26% of aggregate with the particle diameter larger than 2.36mm and smaller than or equal to 4.75mm, 38%-40% of aggregate with the particle diameter larger than 0.075mm and smaller than or equal to 2.36mm and 6.0% of aggregate with the particle diameter smaller than or equal to 0.075mm; the ratio of the bitumen to aggregate is 6.5%-7.0% and represents the ratio of the weight of the room-temperature bitumen to the total weight of the aggregate and padding. The room-temperature bituminous concrete provided by the invention solves the problems that conventional room-temperature bituminous concrete cannot be applied to an anti-seepage structure of the water conservancy and hydropower engineering due to high porosity and poor anti-seepage performance.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

Method for preparing flexible electron and flexible electron

ActiveCN113840471ASimple manufacturing processImprove fill rateFinal product manufactureCircuit metal processingManufacturing technologyLiquid state

The invention provides a method for preparing a flexible electron. The method comprises the following steps: S1, pouring liquid GaIn liquid metal or liquid GaInSn liquid metal into a silicone tube by using a negative pressure method; s2, the silicone tube filled with the liquid metal is stored in a low-temperature environment until the liquid metal is crystallized and solidified; s3, the crystallized and solidified liquid metal is taken out of the silicone tube, and a metal wire is obtained; s4, constructing a circuit pattern by using metal wires to obtain a target circuit; s5, using liquid silica gel to package the target circuit; and S6, after the liquid silica gel is cured, heating is carried out, so that the solid metal wires are molten into liquid, and the flexible electron is obtained. The invention also provides a flexible electronic equipment. The method has the beneficial effects that the manufacturing process for preparing the flexible electronics from the liquid metal can be simplified, the yield is improved, and the cost is reduced.

Owner:HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN (INSTITUTE OF SCIENCE AND TECHNOLOGY INNOVATION HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN)

Restoration Structure and Construction Method of Sick Concrete Gravity Dam in Severe Cold Area

ActiveCN105735206BRealize anti-seepage repairImprove anti-seepage effectGravity damsBituminous concreteCold area

The invention relates to a repair structure and a construction method of a pathological concrete gravity dam in a severe cold area. The invention aims to provide the repair structure and the construction method of the pathological concrete gravity dam in the severe cold area, which have the advantages of simple structure, convenience in construction, safety and reliability. The repair structure of the pathological concrete gravity dam in the severe cold area adopts the technical scheme that the repair structure is used for repairing the part, of which the anti-seepage performance is poor, of the water attaining surface of a dam body of the concrete gravity dam, brackets are arranged on the water attaining surface of the dam body and below the part of which the anti-seepage performance is poor, concrete protection plates which are formed in a way that a plurality of concrete precast blocks are overlapped and spliced and cover the water attaining surface of the dam body are arranged above the brackets and at a certain distance away from the water attaining surface of the dam body, the lower ends of the concrete protection plates are supported on the brackets, bituminous concrete anti-seepage plates are arranged between the concrete protection plates and the dam body, and the lower ends of the bituminous concrete anti-seepage plates are supported on the brackets. The repair structure and the construction method are suitable for structure repairing and other similar projects of the pathological concrete gravity dam of which the dam height is below 50 m in the severe cold area.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

A Rural Domestic Sewage Treatment System Based on Small Watershed Form

ActiveCN108911158BNo secondary pollutionLess investmentBiological sludge treatmentBiological water/sewage treatmentDispersityTerrain

The invention relates to the technical field of rural domestic sewage treatment, particularly to a rural domestic wastewater treatment system based on small watershed dispersity. According to the present invention, the rural domestic wastewater treatment process using the improved three-grid septic tank-oxidation pond-ecological ditch as the main body is constructed based on local conditions by completely considering the ditches formed by the abundant rainfall and the mountainous hilly terrain in the vast rural areas of southern China, the energy-consuming equipment such as pumps and the likeare not required to be additionally arranged, the additional power-free requirement is achieved, and the rural domestic wastewater treatment system has advantages of less investment, good effect, convenient operation and maintenance, no secondary pollution and the like, and the final effluent can achieve the Class V standard of Environmental Quality Standards For Surface Water (GB3838-2002).

Owner:JIANGXI ACADEMY OF SCI

A bridge deck drainage supporting facility

ActiveCN106320172BSolve the problem of exposureImprove sealingBridge structural detailsBridge deckExpansion joint

The invention discloses a bridge deck drainage supporting facility. A drainage channel is formed in the outer side of a bridge deck pavement edge curb and provided with an open rectangular section, a footpath cover plate covers the upper portion of the drainage channel, the outside of the drainage channel is wrapped with a stainless steel plate, rainwater holes are formed in the curb, the drainage channel extends into linking roads at two ends of a bridge along the bridge, a spherical rubber expansion joint for water passage is formed in the position of the drainage channel passing an expansion seam, two ends of the rubber expansion joint are fastened on vertical seal head steel plates of the drainage channel through flange plates and bolts, openings are formed in the vertical seal head steel plates of the drainage channel and correspond to the expansion joint, the stainless steel plate externally wrapping the drainage channel is crimped at the openings of the seal head steel plates, the stainless steel plate, the rubber expansion joint and the flange plates are jointly anchored on a steel plate, a plurality of spheres are formed on the vertical surface of the rubber expansion joint, the displacement deformation requirement of beams on two sides of the expansion seam is met, and the cross section of the expansion joint is rectangular. The bridge deck drainage supporting facility can solve the problems that a drainage pipe of a traditional bridge deck drainage scheme is exposed, joints frequently leak and the like.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

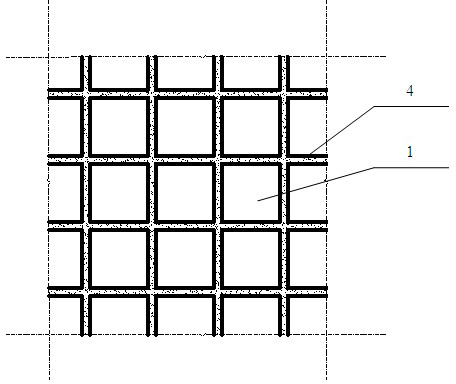

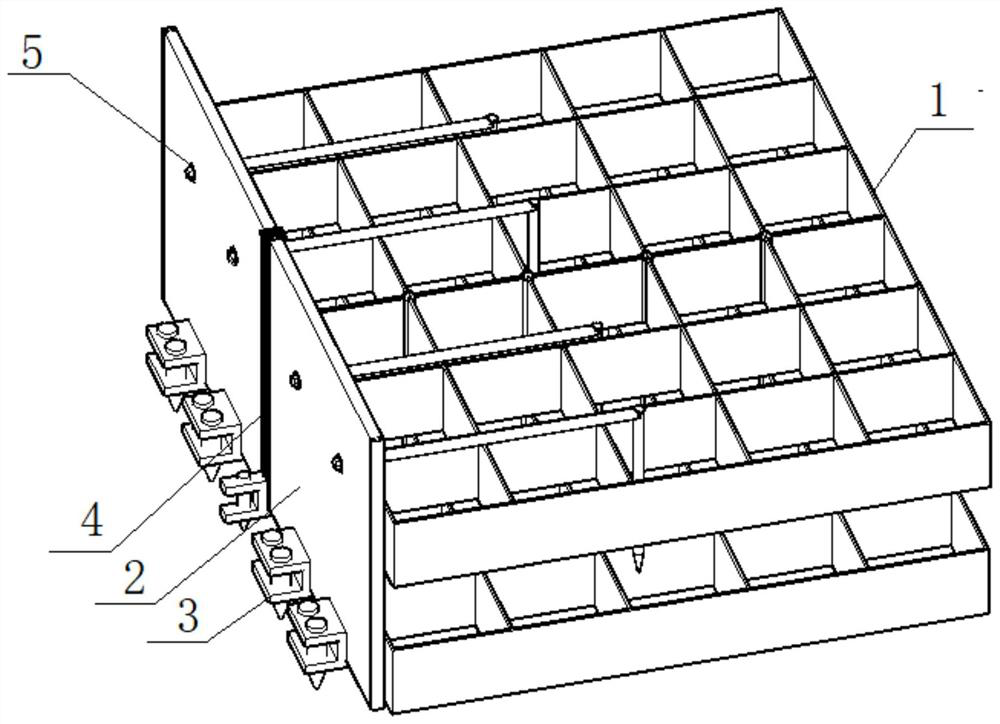

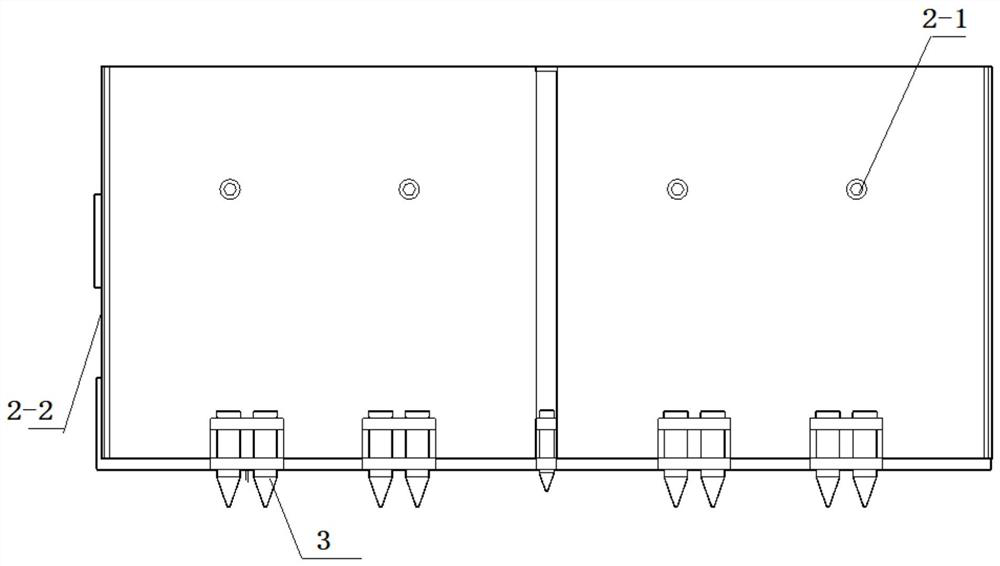

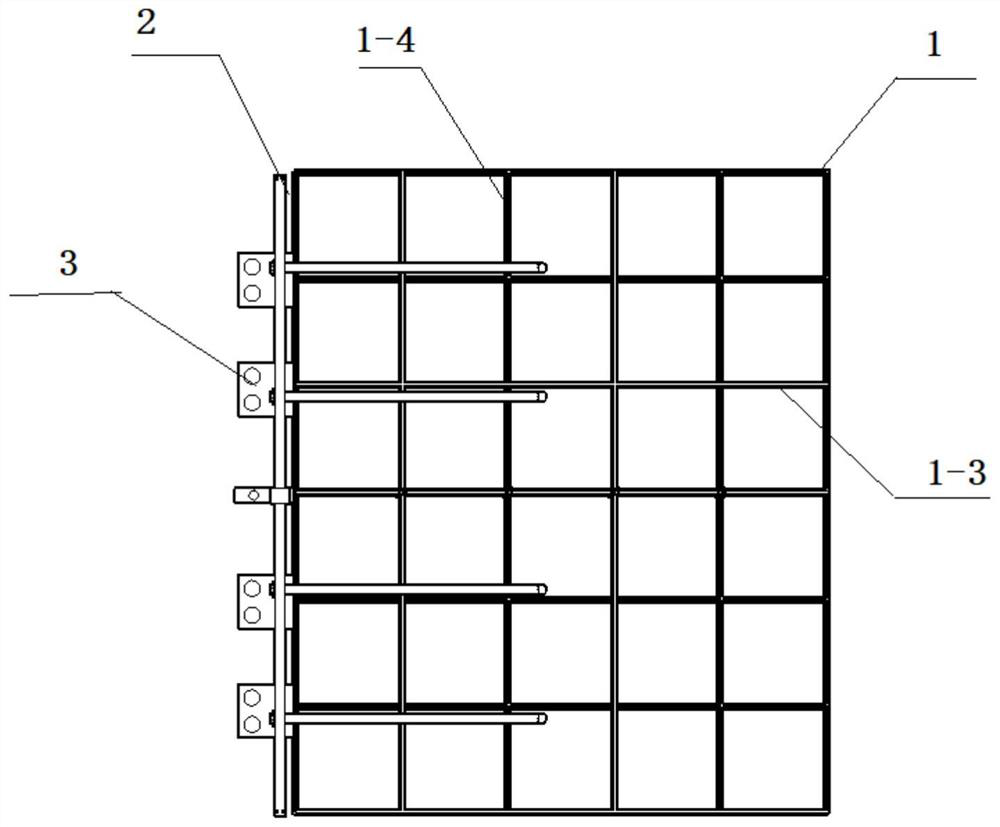

Fabricated light high-strength lattice frame flexible retaining wall and mounting method thereof

PendingCN113089718AIncrease weightLow costArtificial islandsRoadwaysCantileverMechanical engineering

The invention provides a fabricated light high-strength lattice frame flexible retaining wall and a mounting method thereof. According to the fabricated light high-strength lattice frame flexible retaining wall and the mounting method thereof, concrete retaining wall forms such as a balance weight type, a cantilever type or a counterfort type are replaced, and the purposes of beautifying the environment and reducing the construction cost are achieved. The fabricated light high-strength lattice frame flexible retaining wall is a novel supporting and retaining structure which is formed by stacking lattice frame layers composed of injection molding lattice frame prefabricated parts and wall body filling materials according to a certain gradient and interlayer spacing and filling and compacting the lattice frame layers with the filling materials. According to the fabricated light high-strength lattice frame flexible retaining wall, a high-strength lattice can be mainly applied to retaining protection of a road slope, and the action character of the high-strength lattice is mixed with interaction of four influence factors including a wall body, a reinforced layer, filling behind the wall and a foundation.

Owner:CHANGAN UNIV +1

An anti-seepage structure for groundwater

ActiveCN109252550BEnsure normal drainageImprove anti-seepage performanceProtective foundationSoil scienceGeomembrane

The invention discloses a groundwater anti-seepage structure. The groundwater anti-seepage structure has the advantages that groundwater can be subjected to anti-seepage treatment, and accordingly, unfavorable natural phenomena caused by groundwater seepage, such as swamping, salinization, landslide and land subsidence, are avoided; under long-term infiltration, a geotextile protective layer protects geotextiles to ensure the anti-seepage effect; the groundwater anti-seepage structure has the advantages of reasonableness, safety, feasibility and the like; the landfill volume per unit area is high, the construction cost is low, the adaptability to deformation is high, water pollution is avoided, the engineering quantity is low, and the construction speed is high; a vacuum oil film is formedbetween contact surfaces of the two-layer geotextiles of an initial anti-seepage layer, so that the water anti-seepage performance can be improved greatly; through injection of quick-setting waterproofing agent slurry, grouting suction holes can be sealed through grouting, and the firmness of the groundwater anti-seepage structure can be improved; the drainage performance of a geotechnical composite drainage net can be guaranteed, and accordingly, the anti-seepage effect of an expansion anti-seepage layer is improved conveniently.

Owner:临沂会宝岭铁矿有限公司

Newly Filled Sludge Foundation Treatment Method

The invention relates to the field of building foundations, in particular to a treatment method of a recent dredger-fill silt foundation. The treatment method of the recent dredger-fill silt foundation includes three phases, namely surface vacuum dewatering joint-preloading, vacuum joint preloading and composite foundation. The treatment method is characterized by including the steps: in surface vacuum dewatering joint-preloading, treating the foundation by a, zoning; b, spreading a vacuum dewatering joint-preloading cushion; c, spreading a film and d, evacuating; in vacuum joint preloading, treating the foundation by a, spreading drain boards; b, spreading a film; c, performing vacuum joint preloading and d, performing low-energy forced ramming or impact rolling; and in the phase of composite foundation, adopting conventional composite foundation methods. The treatment method is safe in construction, short in construction period, effective in foundation treatment, low in construction cost, especially suitable for projects of land aggradation by reclamation, which are super-high in water content and ultralow in strength and need instant foundation treatment after filling.

Owner:BAOSTEEL ENG & TECH GRP

A gravity face rockfill dam and its construction method

ActiveCN107354917BReduce distortionImprove securityEarth-fill damsRock-fill damsThick plateUplift pressure

The invention relates to a gravity concrete faced rockfill dam and a construction method thereof, and belongs to the technical field of water conservancy projects. The gravity concrete faced rockfill dam comprises a concrete panel, a cushion layer, L-shaped thick plates, a rockfill concrete area and other components. The concrete panel is laid on the upstream face of the upstream side of a dam body, and the cushion layer is arranged on the downstream side of the concrete panel. The downstream side of the cushion layer is the rockfill concrete area, the L-shaped thick plates are arranged at a certain interval along the dam height and can be horizontally arranged, the plate ends face the downstream position and go deep into the rockfill concrete area, the other ends of the L-shaped thick plates are big head ends and face the upstream position, and the concrete panel is supported. The downstream side of the rockfill concrete area is a main rockfill area and a secondary rockfill area, and the function of restraining deformation of the rockfill concrete area is achieved. A drainage gallery is located in the rockfill concrete area, upstream seepage water of the dam body and a dam foundation is discharged, the uplift pressure of the dam foundation is reduced, and stability of the dam body is improved. According to the gravity concrete faced rockfill dam and the construction method thereof, the beneficial effects of a gravity dam and the concrete faced rockfill dam are fully utilized, the deformation of the panel is reduced, the probability of panel damage is reduced, and safety of the high concrete faced rockfill dam is ensured.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com