Core-wall rockfill dam

A technology for rockfill dams and core walls, applied in dams, barrages, water conservancy projects, etc., can solve the problems of lack of standards for asphalt concrete performance testing methods, high requirements for asphalt raw materials, and difficulty in crack repair, achieving good volume stability and avoiding problems. Hydraulic splitting, the effect of strong adaptability to deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

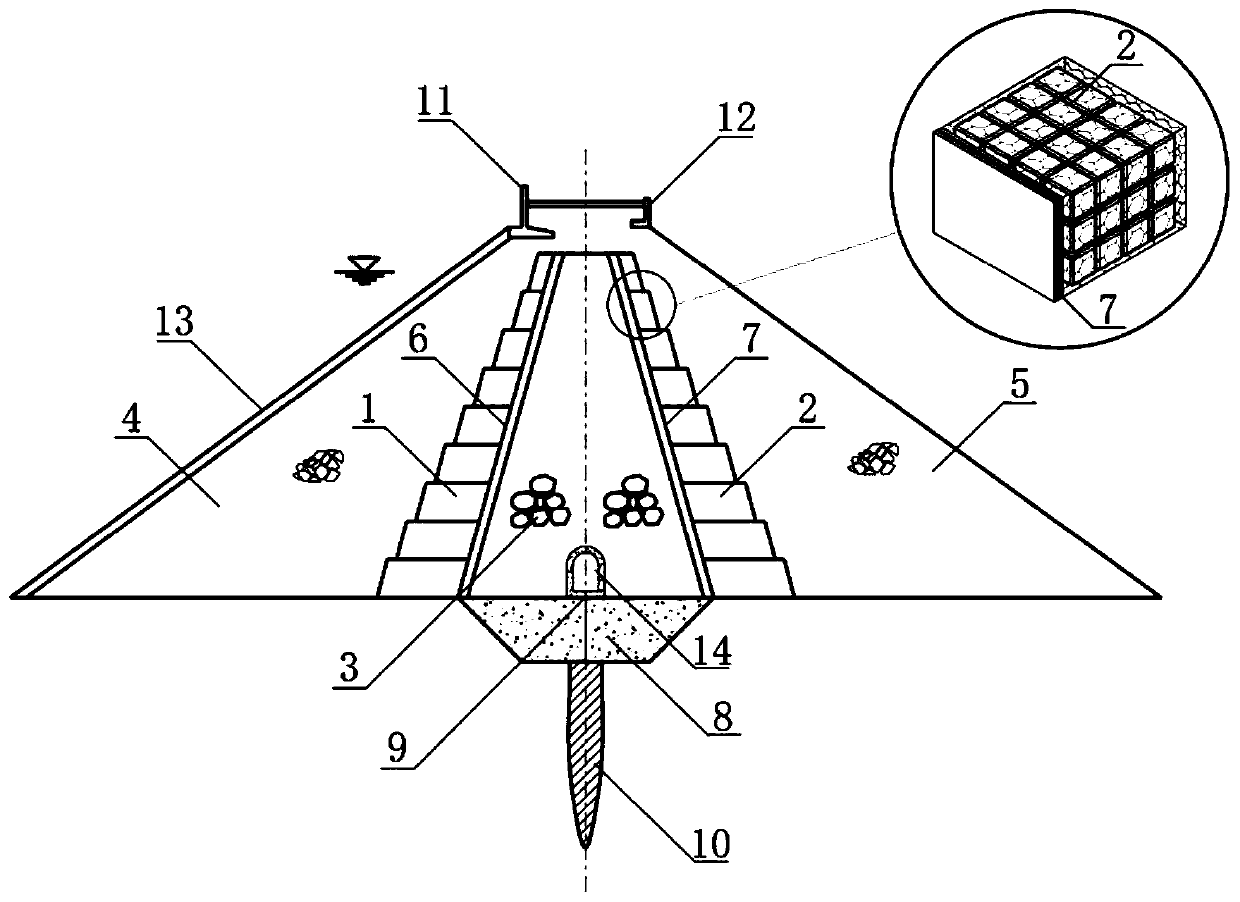

[0017] The present invention is described in further detail below in conjunction with the accompanying drawings and specific embodiments:

[0018] like figure 1 As shown in the figure, the core rockfill dam of the present invention includes an upstream dry masonry slope protection 13, an upstream rockfill area 4, an upstream transition layer, a core wall, a downstream transition layer, a downstream rockfill area 5, an upstream wave barrier 11, and a downstream barrier. The wave wall 12, the curtain grouting 10, and the grouting corridor 14 are characterized in that the upstream transition layer is the structure of the upstream lead wire gabion 1 and the upstream geomembrane 6, and the downstream transition layer is the structure of the downstream lead wire gabion 2 and the downstream geomembrane 7, and the upstream The lead wire gabion 1 and the downstream lead wire gabion 2 are closed with upstream geomembrane 6 and downstream geomembrane 7 respectively on the side close to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com