Rapid installing expansion joint for railway bridge

A technology for bridge expansion joints, applied in the field of bridge expansion joints, which can solve problems affecting driving speed, comfort and safety, difficulty in maintenance of expansion joints, driving safety accidents, etc., and achieves simple structure, good elasticity, and waterproof performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

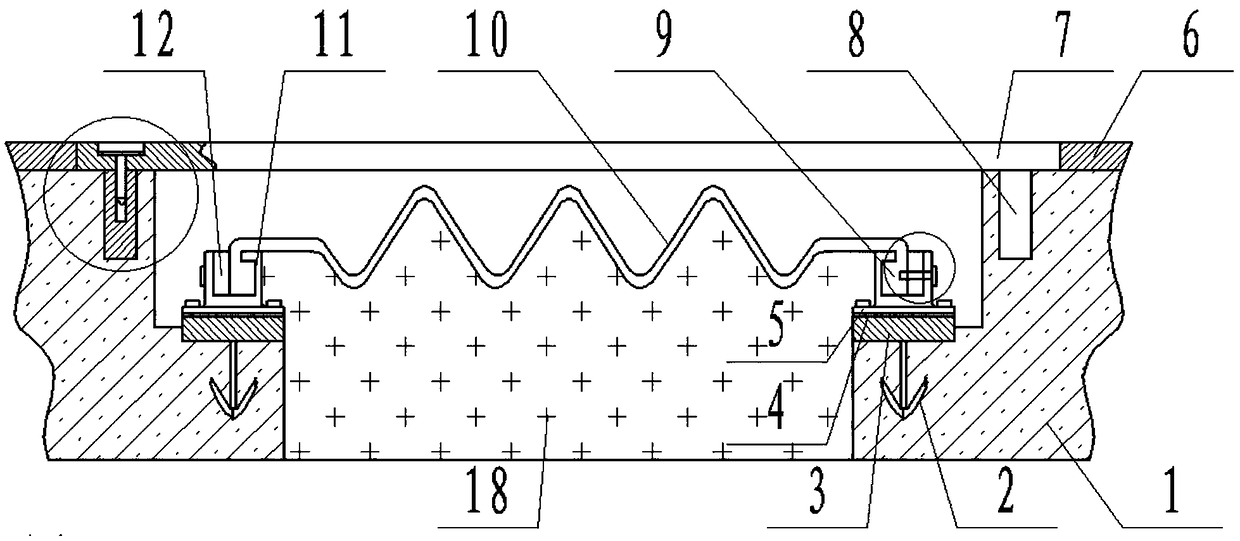

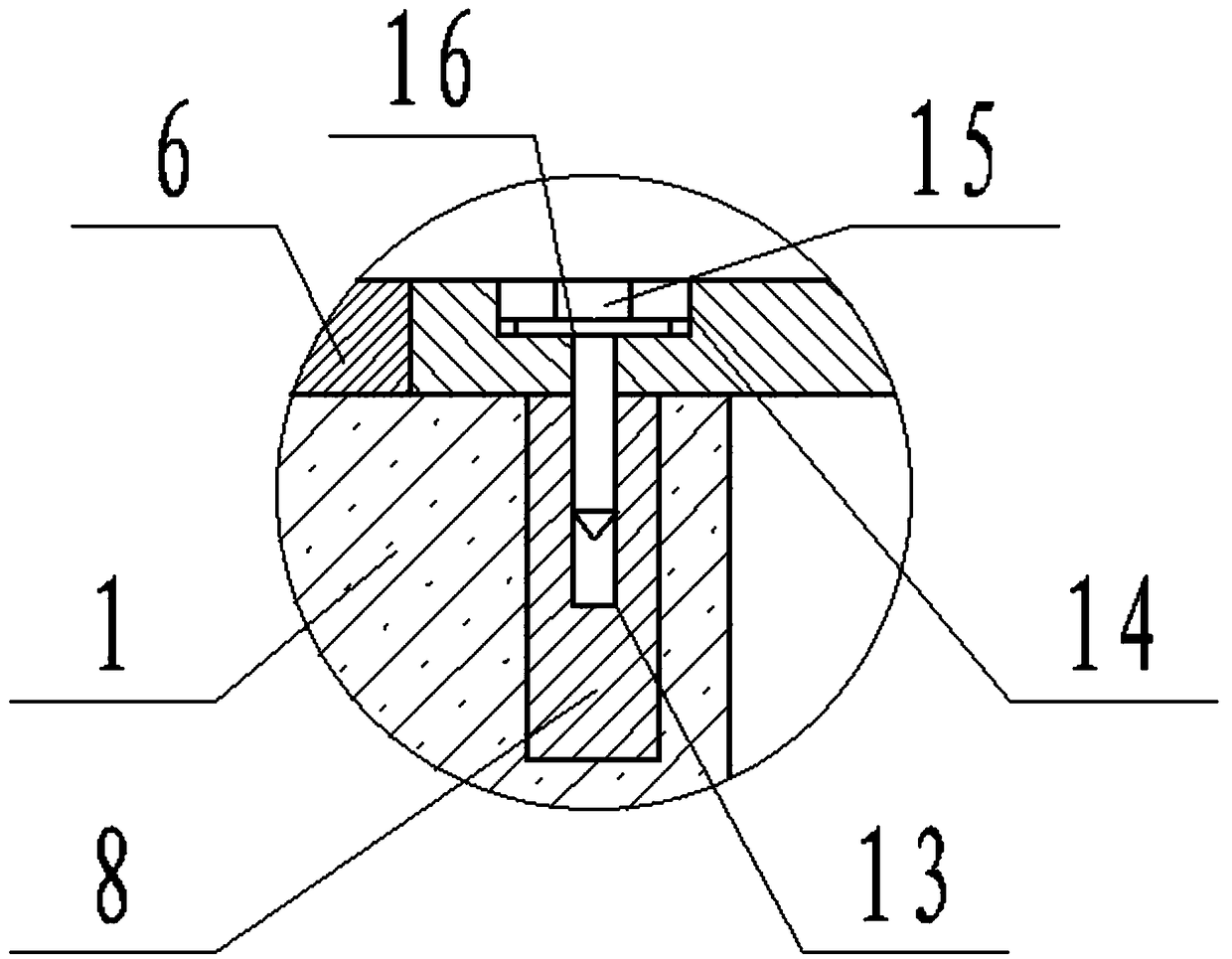

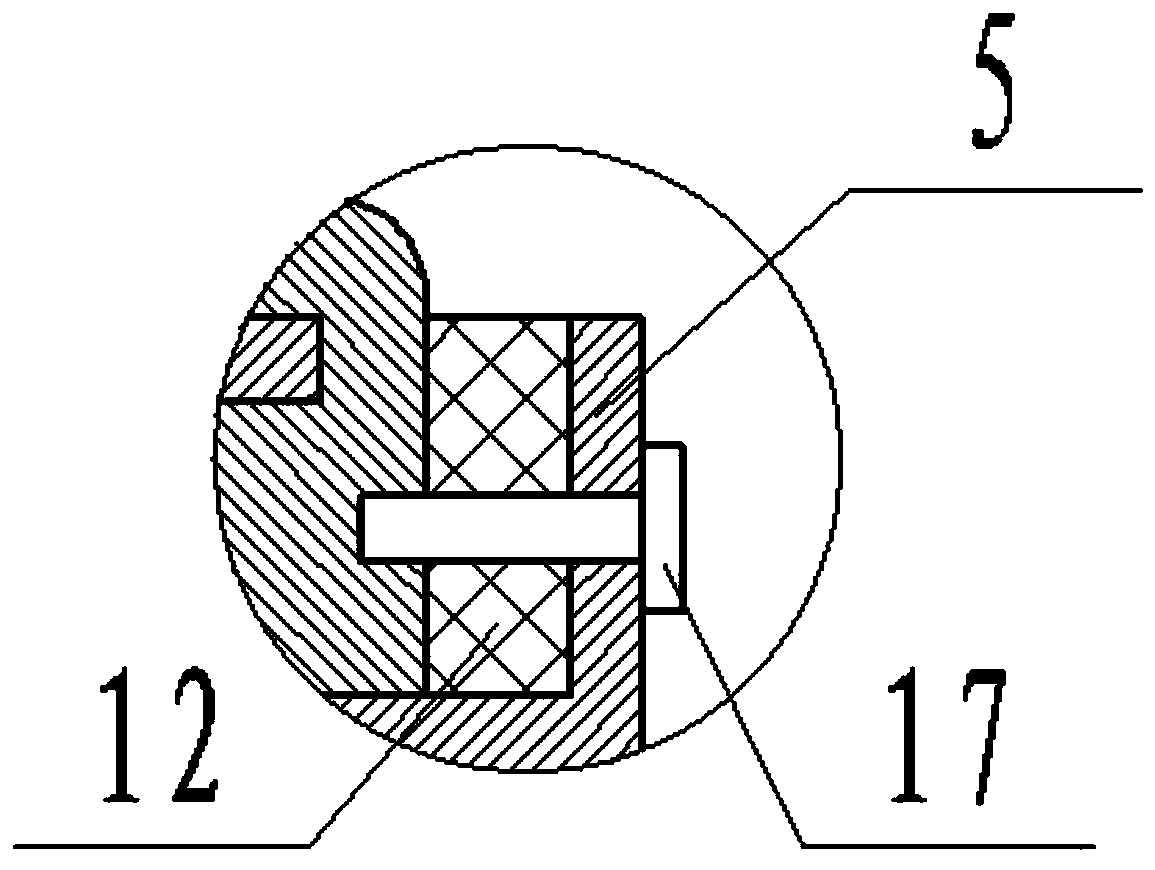

[0026] The present invention will be further described below in conjunction with accompanying drawing:

[0027] Such as Figure 1-Figure 3 As shown, the rapid installation expansion joints for railway bridges include bridge foundation 1, fixed anchors 2, prefabricated steel plates 3 and buffer pads 4, prefabricated steel plates 3 are arranged on the bridge foundation 1, and prefabricated steel plates 3 are used to install fixing seats 5, prefabricated The bottom of the steel plate 3 is provided with a fixed anchor 2, the fixed anchor 2 can effectively ensure the stability of the prefabricated steel plate 3, the prefabricated steel plate 3 is provided with a buffer pad 4, the buffer pad 4 is provided with a fixed seat 5, and on the fixed seat 5 An installation groove 11 is provided, and the installation groove 11 is used to fix the rubber waterstop 10. The connector 9 is arranged in the installation groove 11, and the rubber waterstop 10 is arranged between the connectors 9. On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com