Arched combined faceplate for earth-rock dam and construction method thereof

An earth-rock dam and arch technology, applied in dams, barrages, weirs, etc., can solve problems such as poor deformation capacity of panels, and achieve the effects of low engineering cost, strong ability to adapt to deformation, and strong ability to resist earthquakes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

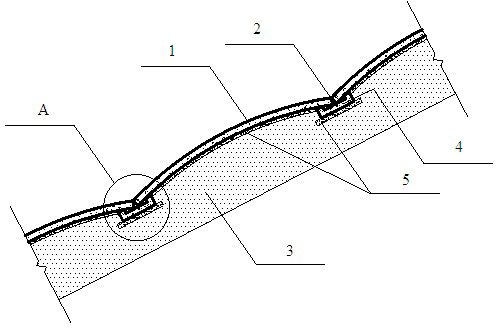

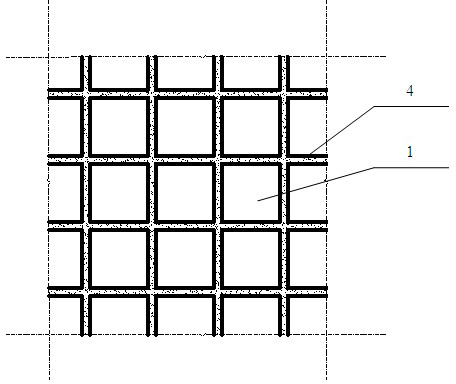

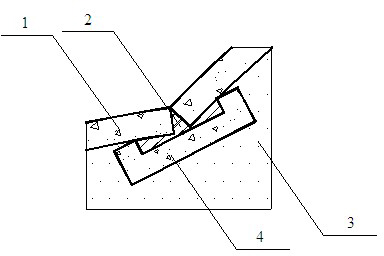

[0036] Such as Figure 1~Figure 6 As shown, an arch composite panel of an earth-rock dam is composed of multiple arch concrete slabs (1) combined and spliced through slots (4); the slots (4) are criss-crossed according to the size of the arch concrete slabs (1) Splicing; the gap between each arched concrete slab (1) and the slot (4) is filled with asphalt (2). The arched concrete slabs (1) have the same shape, the side length is 16m, 17m, 18m, 19m, 20m, 21m or 22m, and the thickness is 0.3m, 0.4m or 0.5m. The arched concrete slab (1) is in the shape of a spherical crown, and the height of the crown is 1 / 4 of the side length, or parabolic, and the height of the apex is 1 / 4 of the side length. A 5cm, 7.5cm or 10cm thick asphalt mortar layer (5) is laid between the arched concrete slab (1) and the cushion (3). The slot (4) is 1.5m, 1.75m or 2m wide, and its height is 1 / 4 of its side length. The gap between the combined arched concrete slabs (1) is not less than 1cm and not gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com