Construction method of sludge storage tank for dredging

A construction method and technology for dredging and dredging are applied in the construction field of mud storage tanks for dredging and dredging, which can solve the problems of high construction cost, long construction period, and expenses, and achieve the effects of short construction period, low cost and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

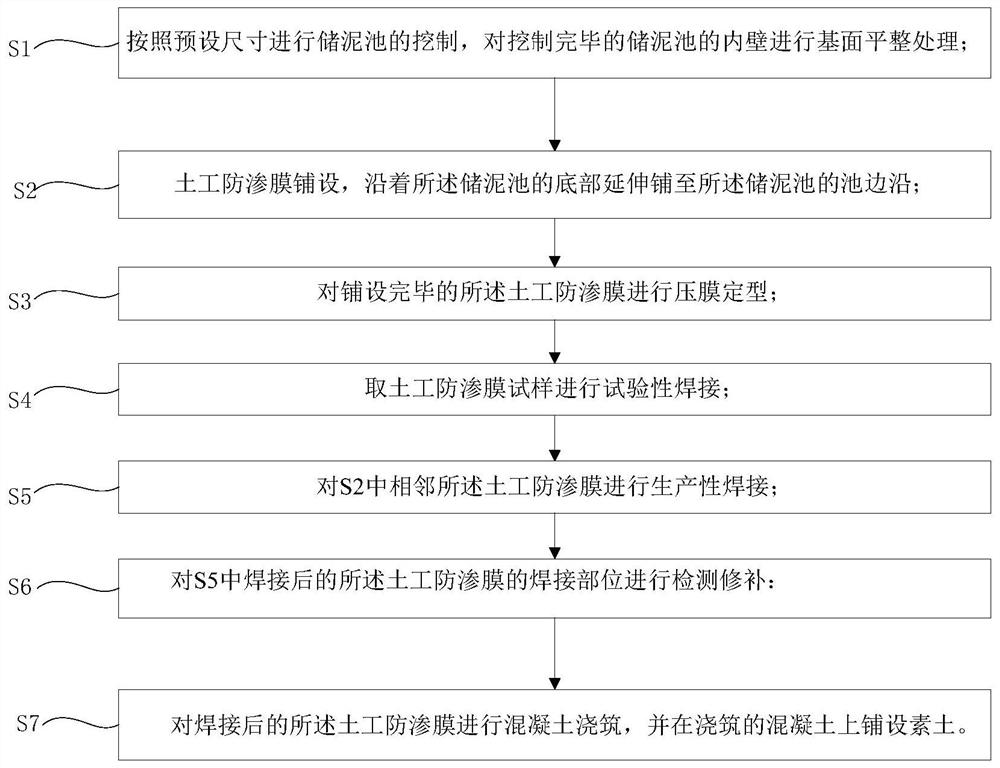

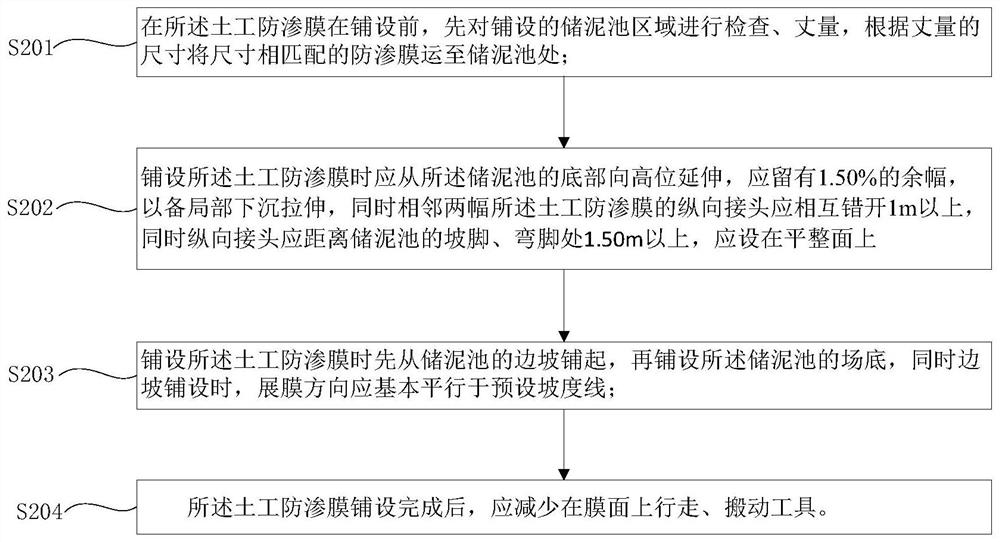

[0028] Example, a construction method of a mud storage tank for dredging and dredging, such as figure 1 with figure 2 As shown, the construction method includes the following steps:

[0029] S1: Carry out the excavation of the mud storage tank according to the preset size, and perform the base leveling treatment on the inner wall of the dug mud storage tank;

[0030] Optionally, in step S1, the base surface leveling treatment includes laying an 8cm to 15cm thick sand and gravel cushion on the bottom of the mud storage tank for leveling, while making the sidewall surface of the mud storage tank at a vertical depth Keep a flat surface within 2.5cm, that is, no sharp objects within 2.5cm of the vertical depth of the mud storage tank, such as prismatic objects or pyramid-shaped objects, or cylindrical or polygonal objects, etc., preferably sandstone The thickness of the cushion can be 10cm;

[0031] S2, laying a geotechnical anti-seepage membrane, extending along the bottom of the mud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com