Strengthening and repairing construction method for rockfill core wall dam

A construction method and core wall dam technology, which can be applied to dams, barrages, sea area projects, etc., can solve the problems of insufficiency of economy, environmental protection, and long construction period, so as to improve the anti-seepage coefficient of the dam body, shorten the construction period, and exert social benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

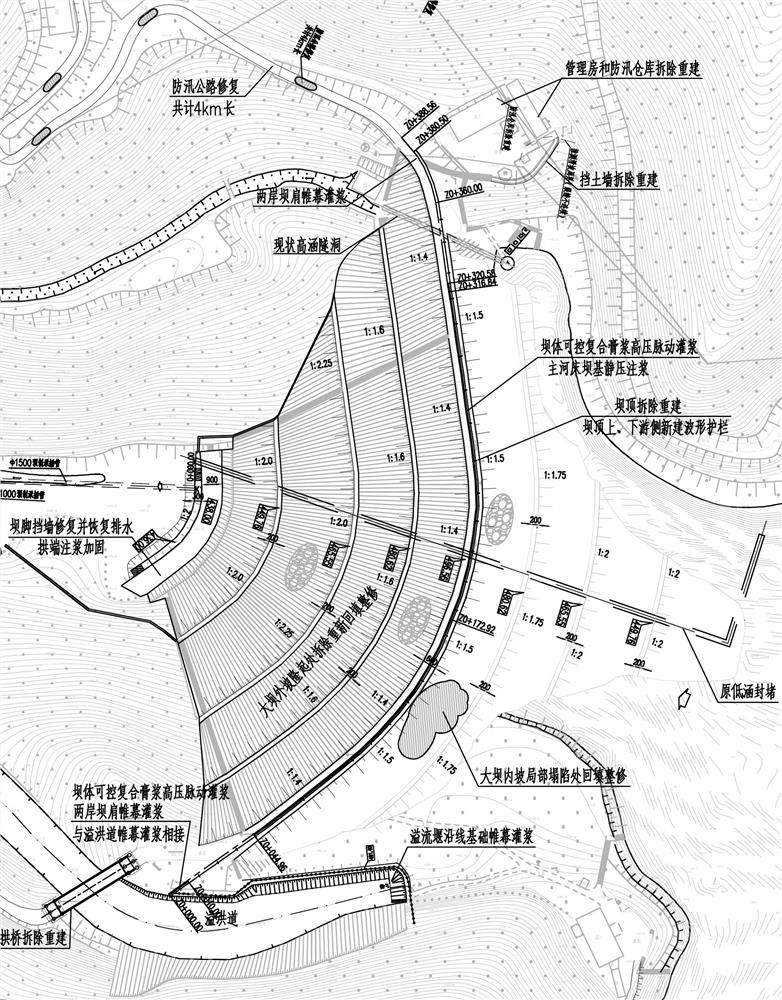

[0084] A construction method for strengthening and repairing a rock-fill core wall dam, comprising the following steps:

[0085] S1, dam crest: demolition and reconstruction, so that the dam crest elevation meets the requirements of the current code;

[0086] S2, the subsidence and uplift of the dam slope: refurbishment, adopt the method of backfilling after excavation to restore the appearance quality;

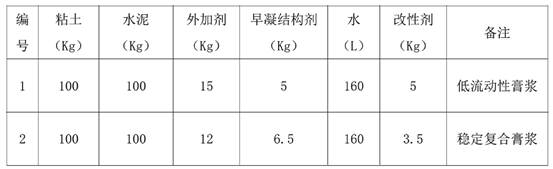

[0087] S3, dam body: use controllable composite paste high-pressure pulsation grouting;

[0088] S4, main riverbed dam foundation: adopt static pressure grouting;

[0089] S5, both sides of the dam foundation and abutment: use curtain grouting;

[0090] S6, found...

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com