Equipment and process for purifying helium from BOG gas

A gas and equipment technology, applied in the field of BOG gas purification equipment and its process, can solve the problems of high-purity restriction of helium, low temperature blockage of substances, increased refrigeration capacity and energy consumption, etc., and achieves reasonable process, increased recovery rate, high Effects of yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

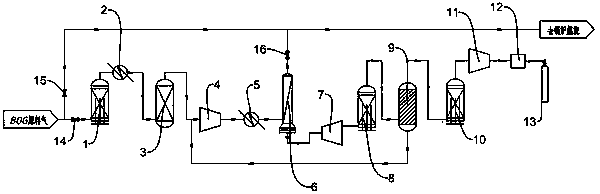

[0034] Embodiment: according to specification figure 1 It can be seen that when the BOG helium extraction device is put into use, close the hand valve 15 of the BOG raw material gas to remove the fuel gas pipe network, open the hand valve 14 of the BOG raw material gas to remove the helium device, and open the hand valve 16 of the non-permeable gas of the membrane separator to remove the BOG fuel gas. The BOG purification helium system was put into use. When the BOG purification helium system is overhauled, open the hand valve 15 of the BOG raw material gas to fuel gas pipe network, close the hand valve 14 of the BOG raw material gas to the helium extraction device, close the non-permeable gas of the membrane separator to remove the BOG fuel gas hand valve 16, and BOG fuel The gas pipe network can supply gas normally, without affecting the use of subsequent users.

[0035] According to the manual attached figure 1It can be known that the raw material gas and air are mixed an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com