High-protection flexible vertical anti-seepage system

A high-protection and flexible technology, applied in the field of flexible vertical anti-seepage systems, can solve problems such as joint deformation, and achieve the effect of improving sealing and structural strength, increasing contact area, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

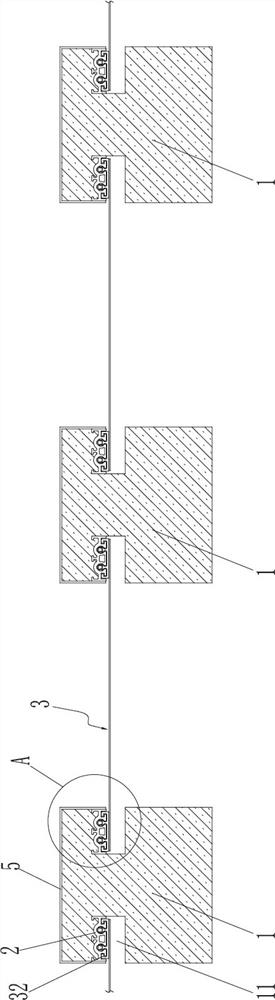

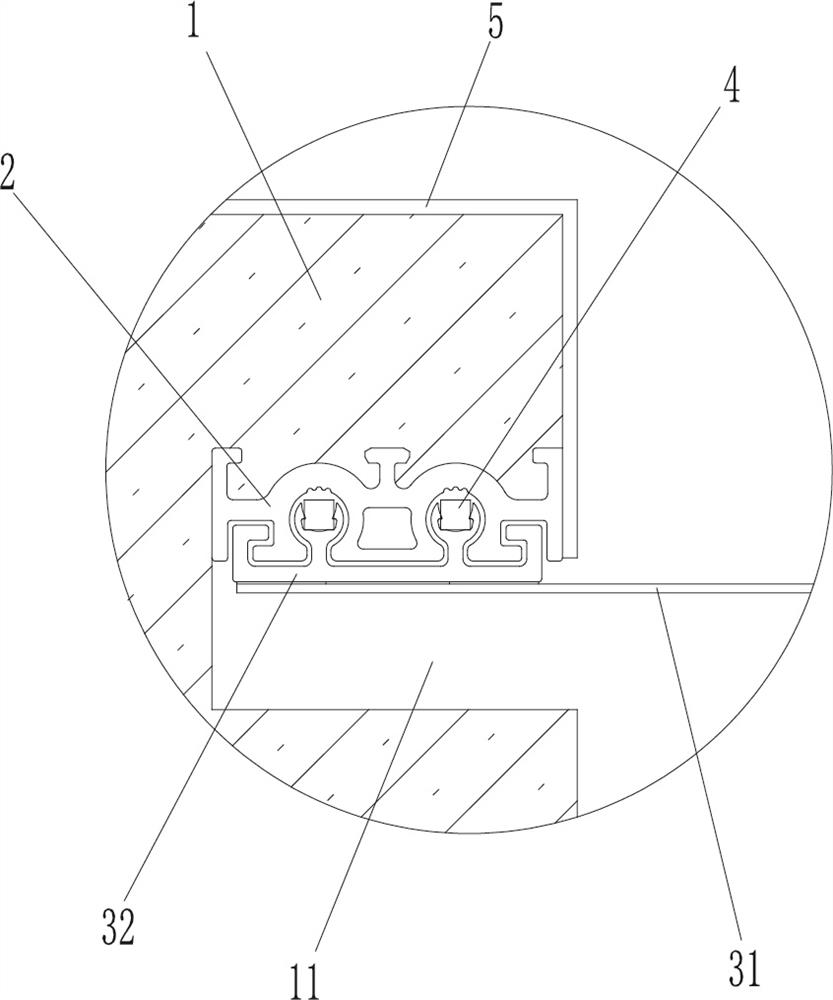

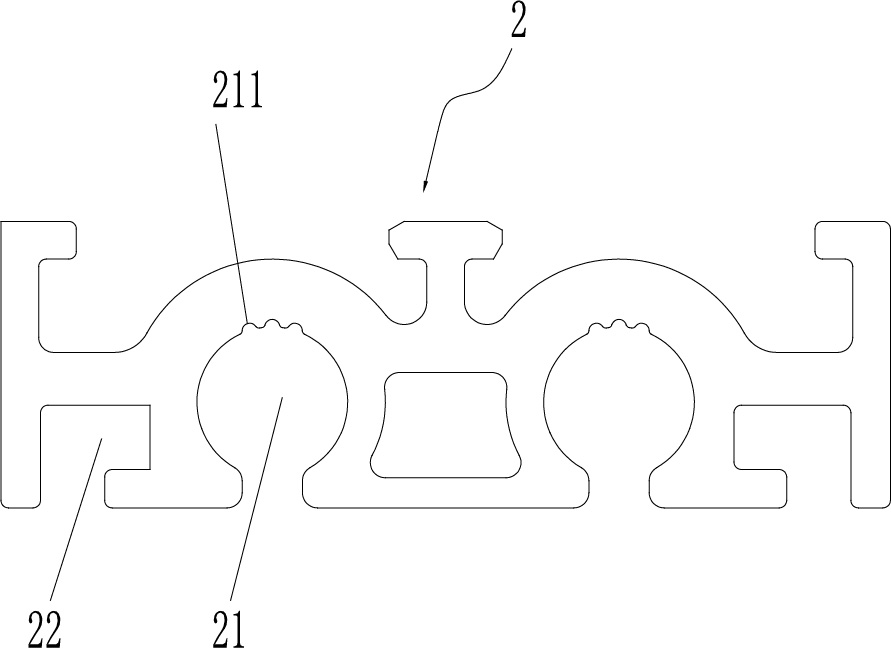

[0037] refer to Figure 1-8As shown, it is a specific embodiment of the invention: a high-protection flexible vertical anti-seepage system, including: a plurality of locking post modules 1 arranged at intervals, and the locking post modules 1 include a set of Two fitting grooves 11, the fitting grooves 11 are provided with a snap-in embedded part 2 for snap-fitting with the snap-fit part 32; HDPE membrane group 3, which includes a first HDPE geomembrane 31 and a geomembrane fixed at its two ends Locking piece 32, said locking piece 32 is used to be connected on said locking embedded part 2; The two ends of said HDPE membrane group 3 are respectively connected on adjacent two said locking column modules 1 , the fitting gap between the locking embedded part 2 and the locking part 32 is filled with the expansion water-stop strip 4 . The locking column module 1 itself has high strength, bending resistance, and anti-seepage coefficient, and it is used as an intermediate connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com