Large-particle-size aggregate core wall asphalt concrete and mix proportion optimization method thereof

A technology of asphalt concrete and large particle size, which is applied in the field of hydraulic core wall asphalt concrete material and its processing and preparation. It can solve the problems that the mix ratio has no experience and cannot be optimized, and achieves improved construction efficiency, low asphalt consumption, and strong adaptability. The effect of shapeshifting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better understand the technical content of the present invention, specific examples are given to further illustrate the present invention.

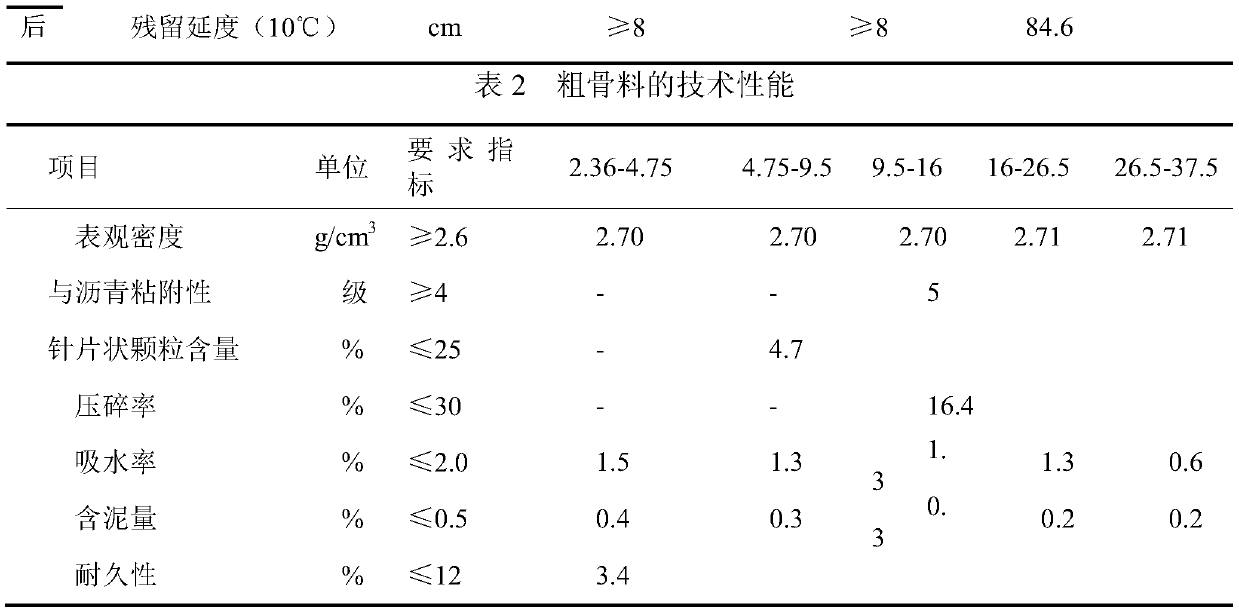

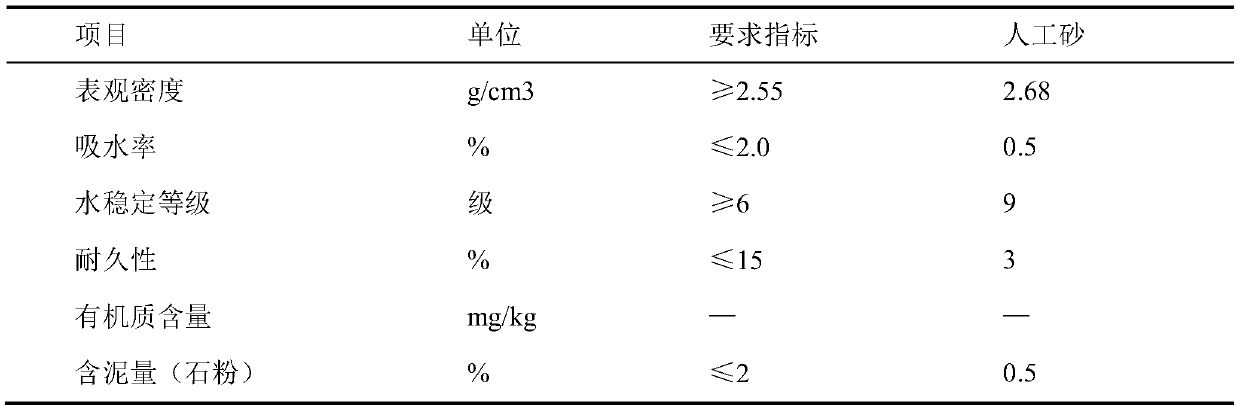

[0038] The aggregate of the present embodiment selects a square hole screen with a side length of 37.5 mm to carry out aggregate screening. The square hole screen with a side length of 37.5 mm is equivalent to a round hole screen with an aperture of 50 mm. The maximum particle size of the material is the maximum particle size of the undersize material sieved out of the square hole screen with a side length of 37.5 mm. In the following experiments, it is collectively referred to as asphalt concrete with a maximum particle size of 37.5 mm. The mix ratio A preferred method includes the following steps:

[0039] S1. In order to ensure the maximum compactness of the asphalt concrete in the core wall, the coarse aggregate is classified according to the particle size: the influence of the aggregate gradation deviation of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com