Waterproof method for prefabricated reinforced concrete box culvert interfaces and interface water stopper

A reinforced concrete and waterstop technology, which is applied to the waterproof field of interface waterstops and prefabricated reinforced concrete box culvert interfaces, can solve the problems of uncontrollable compression of O-shaped rubber rings, difficulties in concrete products, etc., and achieves high waterproof reliability. , The effect of strong adaptability to deformation and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

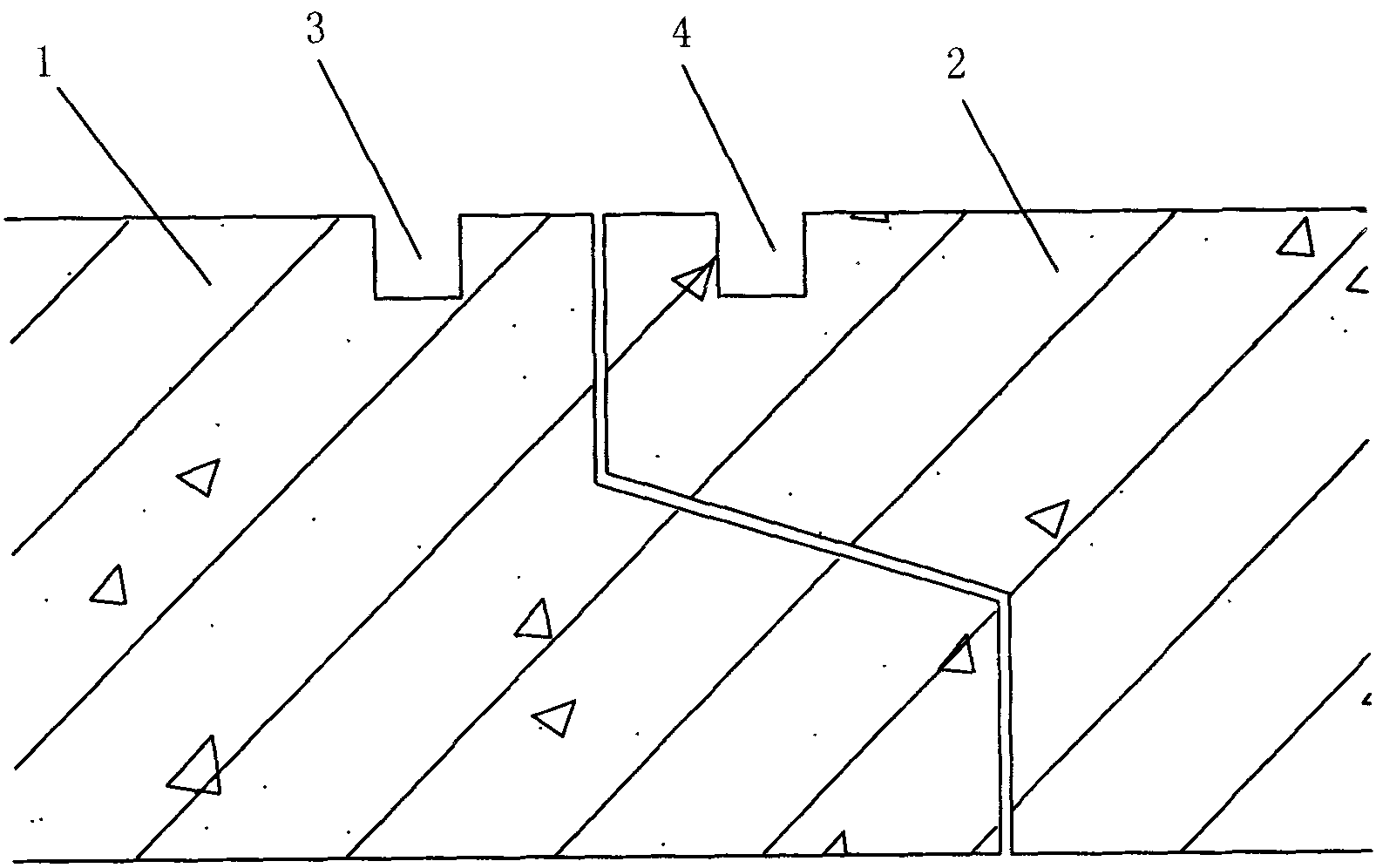

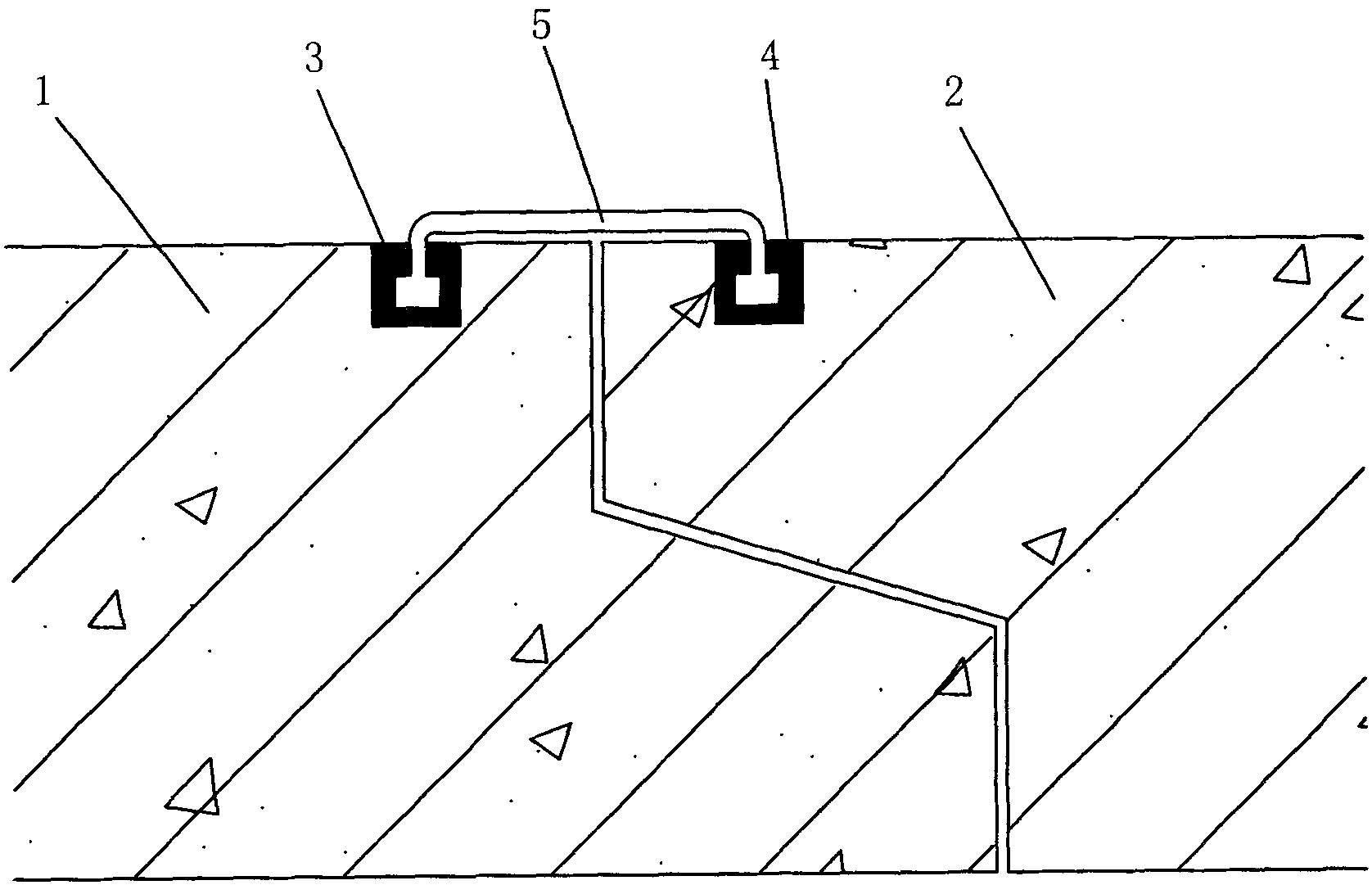

[0018] The waterproof method of prefabricated reinforced concrete box culvert interface of the present invention, as figure 1 , 2 ,include:

[0019] A first groove 3 is preset at a predetermined position from the first box culvert interface 1, and a second groove 4 is preset at a predetermined position from the second box culvert interface 2; the groove can be set when the box culvert is prefabricated ;

[0020] Inject epoxy resin adhesive into the first groove 3 and the second groove 4 respectively, which can be injected with a glue gun or an injection tool;

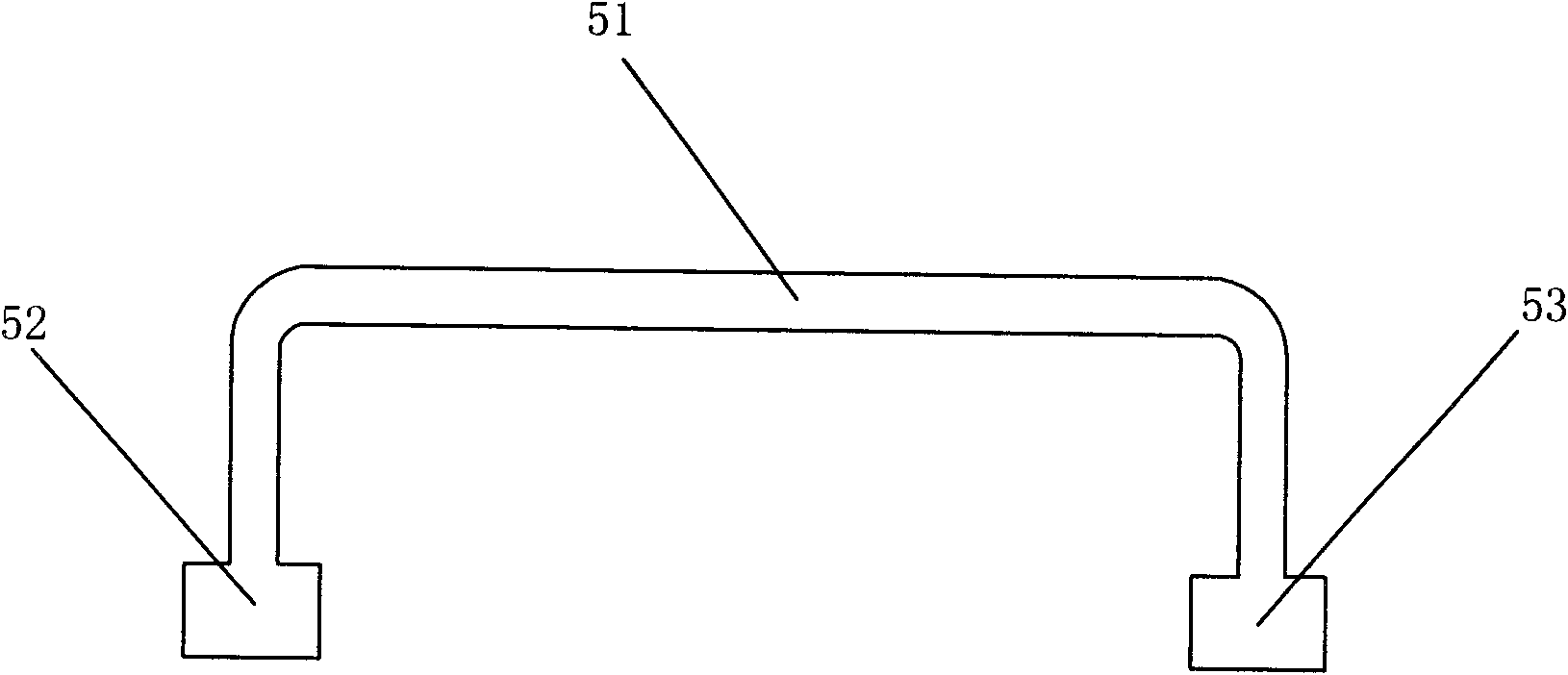

[0021] Insert the two wings of the interface waterstop 5 into the first groove 3 and the second groove 4 respectively, and after the epoxy resin adhesive is solidified, bond the two wings of the interface waterstop 5 to the first groove 3 And in the second groove 4; wherein, as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com