Loudspeaker device

A speaker and monomer technology, applied in the field of electro-acoustic conversion, can solve the problems of waterproof failure of the speaker device, unable to completely fill the gap between the side surface of the monomer and the cover plate, etc., and achieve the effect of improving the waterproof yield and waterproof reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

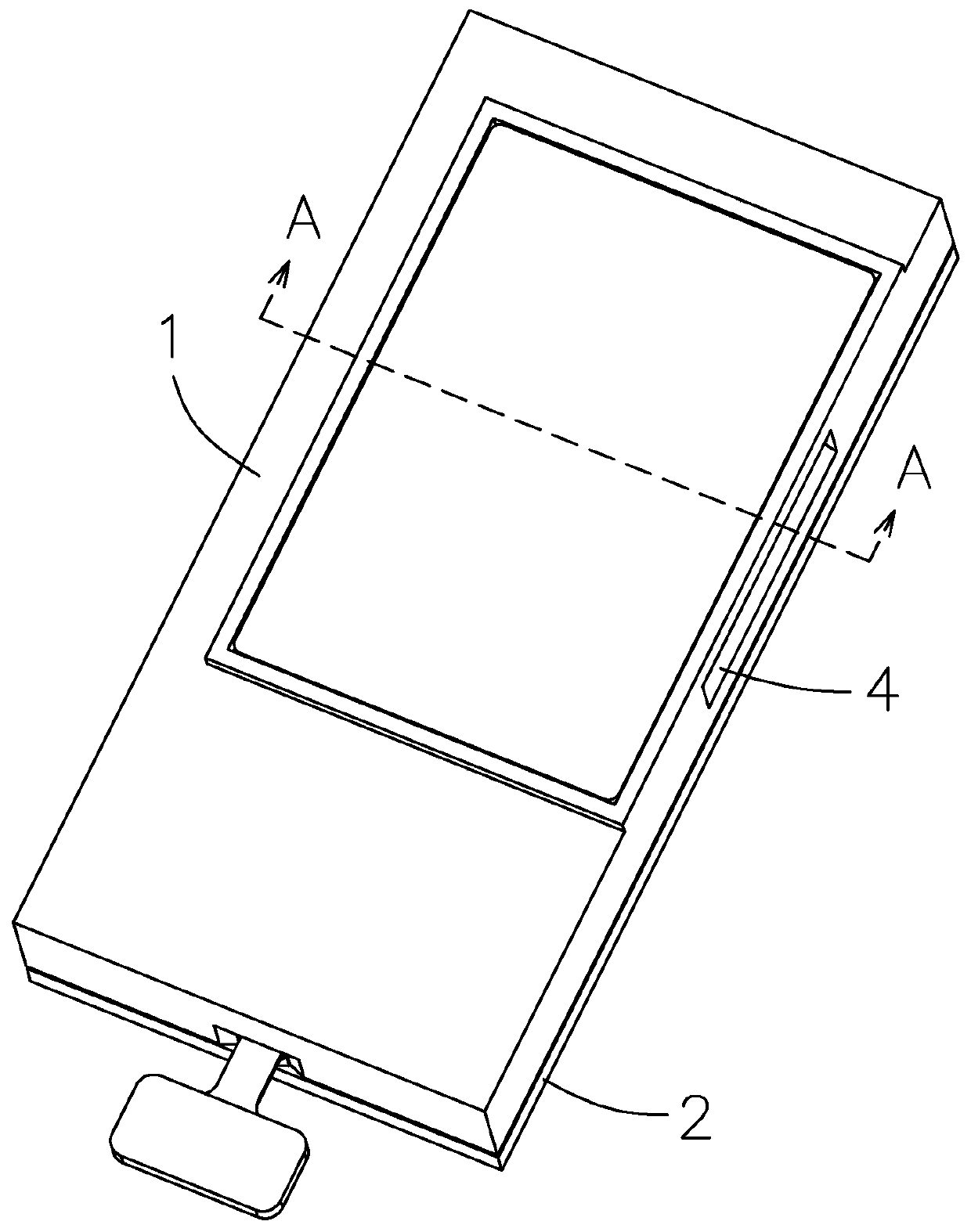

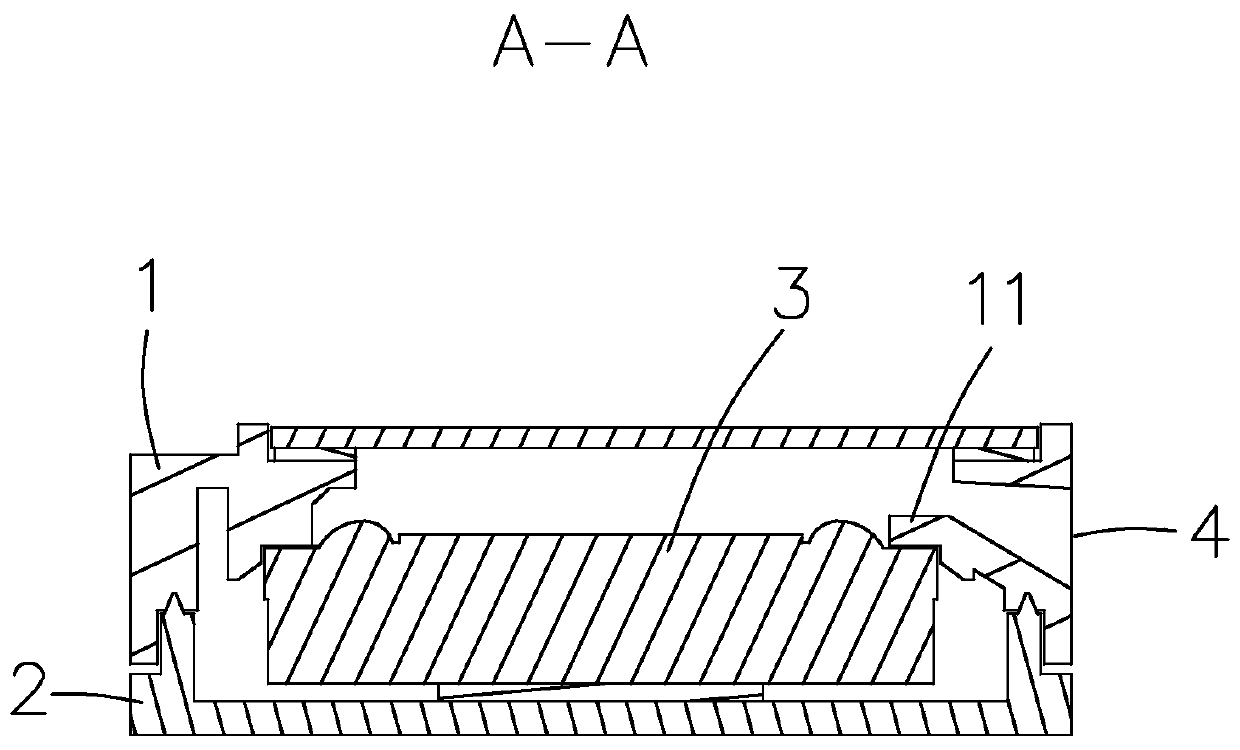

[0024] Such as Figure 3-Figure 7 As shown, a speaker device includes an upper cover 10, a lower cover 11 and a sounding unit 12, the upper cover 10 and the lower cover 11 are fixedly connected to form a receiving cavity 20, and the sounding unit 12 is installed on In the accommodating chamber 20, the upper cover 10 is provided with a sound outlet 101 and a support beam 102 is extended from the upper cover 10 toward the sound emitting unit 12, and the sound outlet 101 passes through the sound outlet channel and The accommodating cavity 20 is connected, the support beam 102 includes adjacent first surfaces 1021 and second surfaces 1022, and the sound emitting unit 12 includes a first end surface 121 close to the upper cover 10 and a first end surface close to the sound outlet. 101 and the second end surface 122 adjacent to the first end surface 121, the first surface 1021 is opposite to the first end surface 121 and sealed by filling the first adhesive 13 to form a first waterp...

Embodiment 2

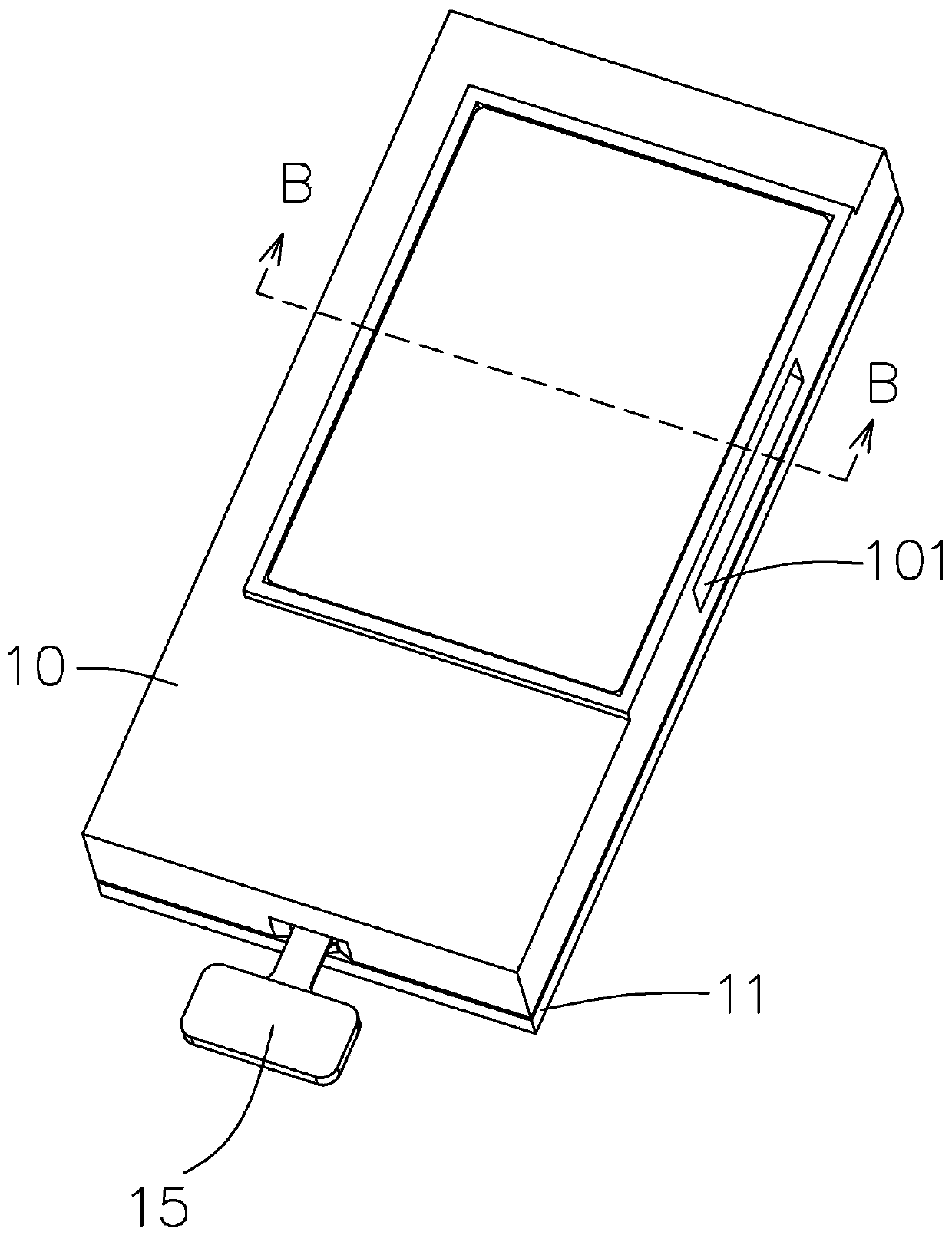

[0031] The difference between this embodiment and Embodiment 1 lies in that a positioning structure is also provided between the upper cover 10 and the sound emitting unit 12 . The setting of the positioning structure can make the sound emitting unit 12 be installed into the accommodation cavity 20 more conveniently.

[0032] In this embodiment, the positioning structure includes a positioning column 16 and a positioning groove 17, and the positioning column 16 and the positioning groove 17 are interchangeably arranged on the upper cover 10 and the sound emitting unit 12, namely The positioning post 16 is arranged on the upper cover 10, and the positioning groove 17 is arranged on the sound emitting unit 12; or the positioning post 16 is arranged on the sound emitting unit 12, and the positioning groove 17 It is arranged on the upper cover 10 . In this embodiment, the positioning post 16 and the positioning groove 17 are mated through insertion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com