Patents

Literature

59results about How to "Does not affect the duration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

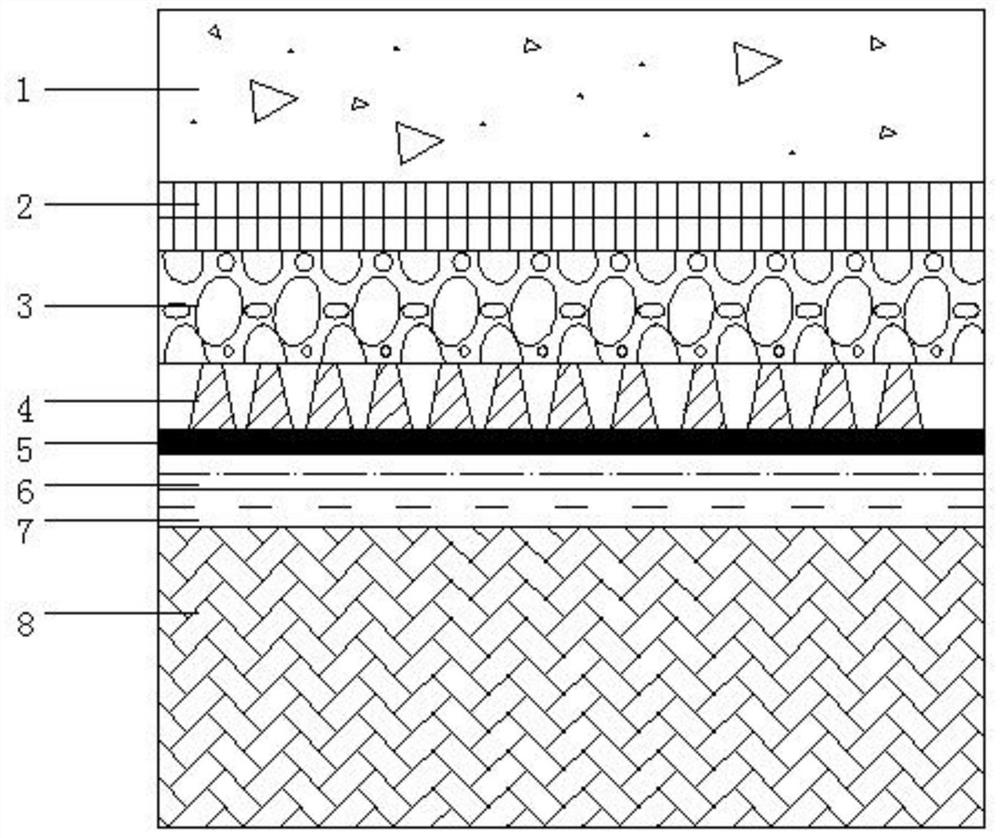

Construction method of basement roof polyvinyl chloride root thorn resistance waterproof roll

ActiveCN104695486AReasonable designEasy to operateProtective foundationBasementArchitectural engineering

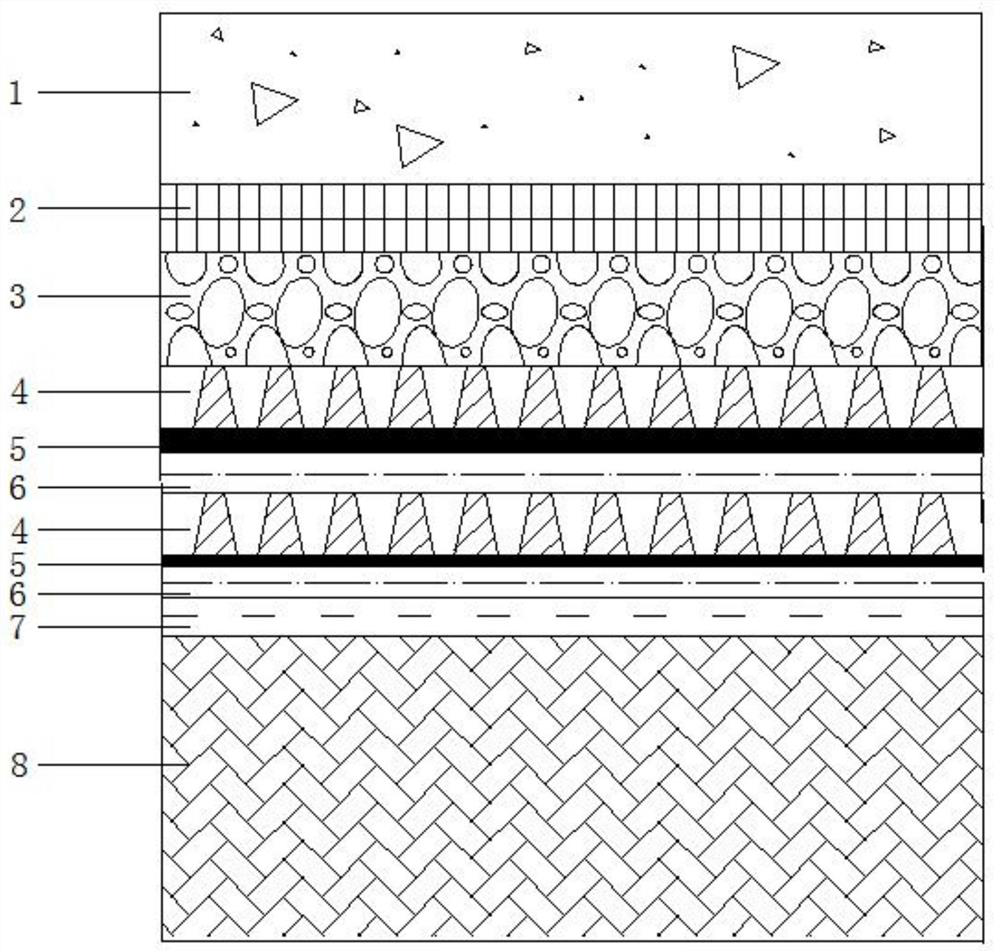

The invention discloses a construction method of a basement roof polyvinyl chloride root thorn resistance waterproof roll. The construction method is characterized by comprising the steps of: (a) construction preparation; (b) base layer treatment of the root thorn resistance waterproof roll; (c) construction of a reinforced additional layer in a node; (d) large surface construction of the polyvinyl chloride root thorn resistance waterproof roll; (e) head shrinkage treatment of the polyvinyl chloride root thorn resistance waterproof roll; and (f) cleaning, checking and acceptance of the polyvinyl chloride root thorn resistance waterproof roll. The construction method of the basement roof polyvinyl chloride root thorn resistance waterproof roll has the advantages of reasonable design and simple operation in production of the additional layer of the polyvinyl chloride root thorn resistance waterproof roll, no influence on construction period, lower investment, safe and reliable engineering quality, improvement of once acceptance pass percent, in particular prominent improvement of root thorn and water resistant in the node and elimination of subsequent node leakage hidden danger of a basement roof, and wide promotion and application prospect.

Owner:MCC5 GROUP CORP SHANGHAI

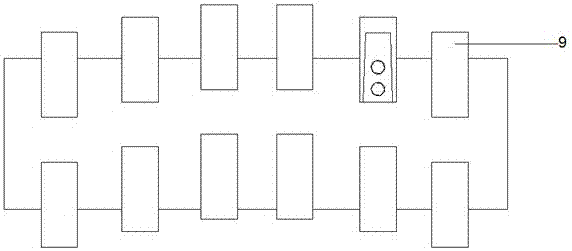

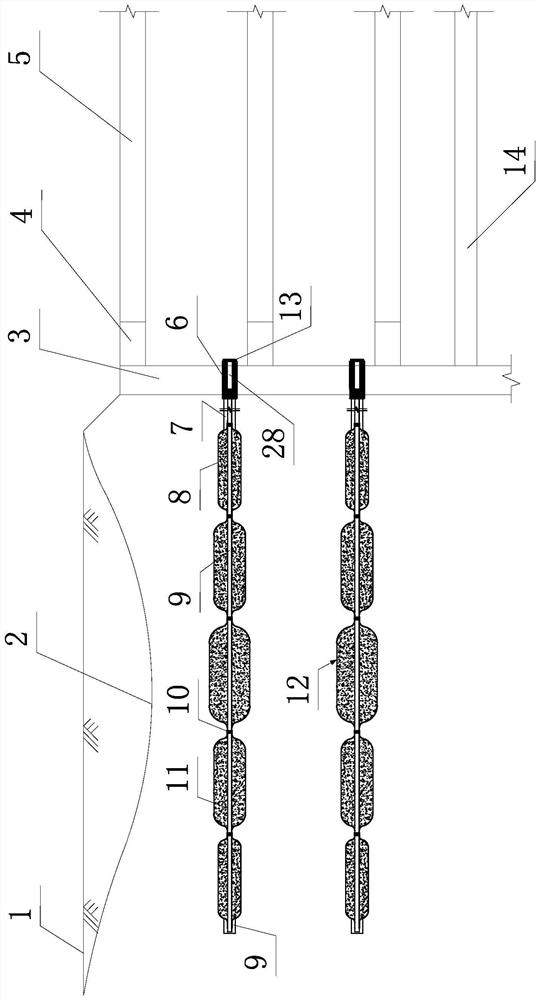

Method for dredging soft foundation by dredger fill and reinforcement

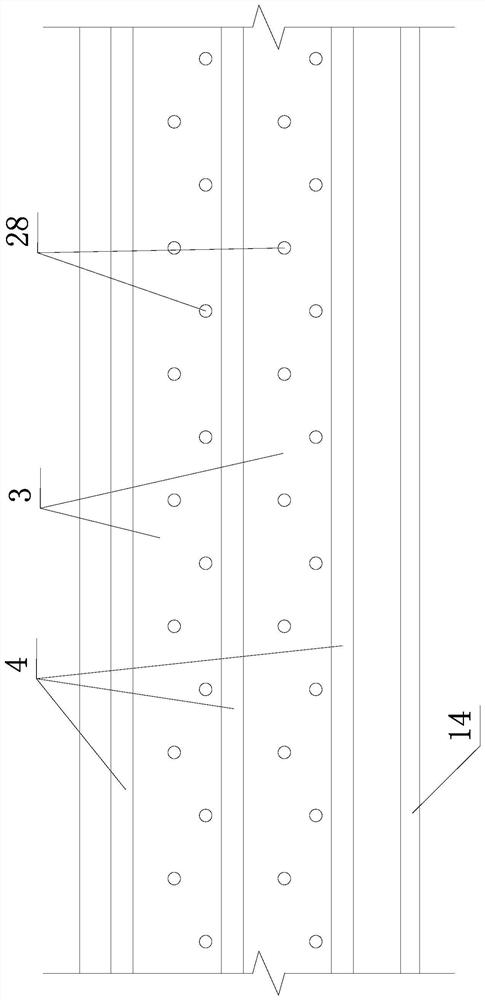

ActiveCN102817354AShorten the drainage distanceShorten the timeSoil preservationDrainage networkBuilding construction

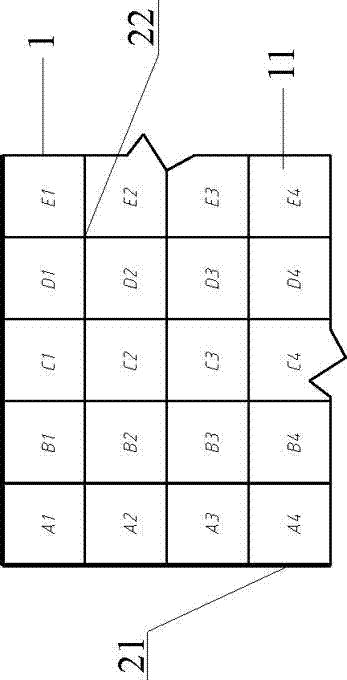

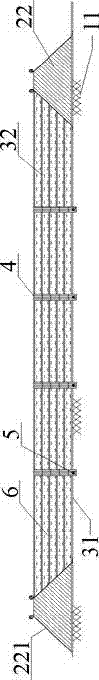

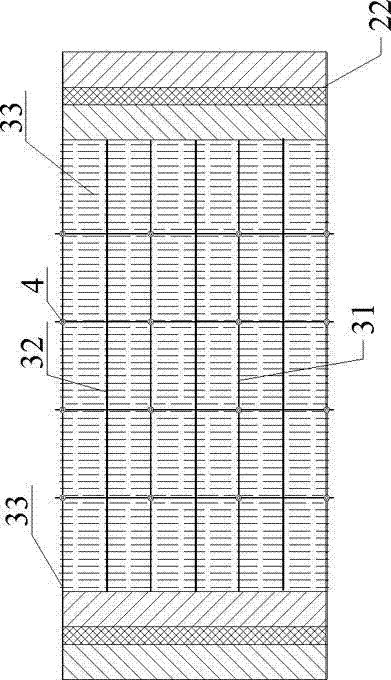

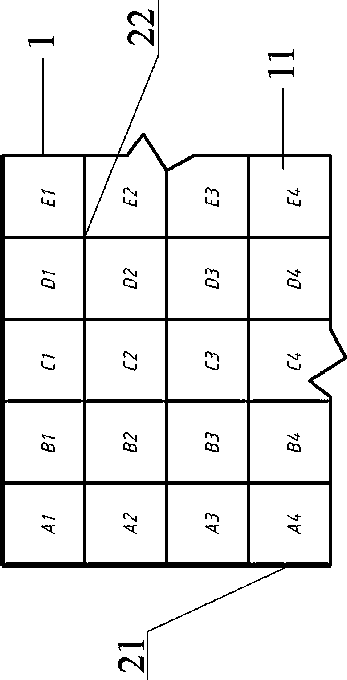

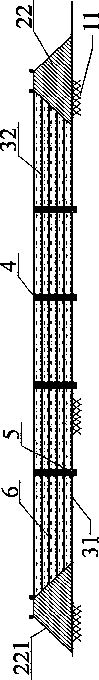

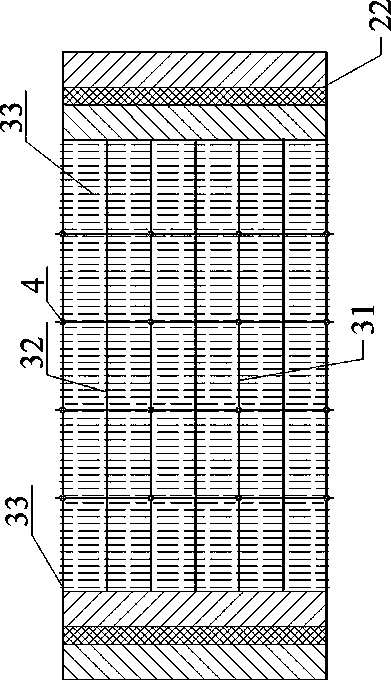

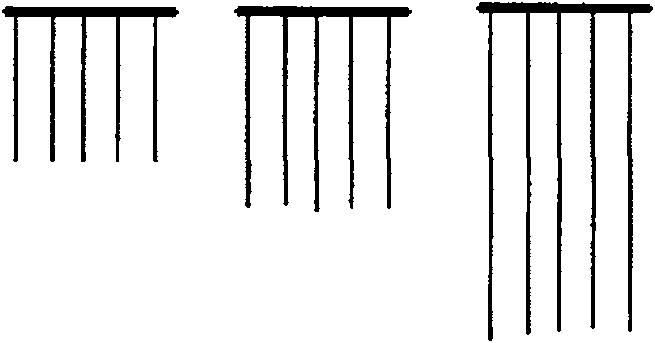

The invention relates to the field of building foundations, in particular to a method for dredging a soft foundation by dredger fill and reinforcement. The method includes: a, zoning for dredger fill; b, forming a primary drainage system; and c, performing layered and zonal filling and reinforcement. The method is characterized in that in zoning for dredger fill, each filling unit (11) is 20000m<2>-50000m<2> in area; in formation of the primary drainage system, digging crisscross blind ditches (31) on the surface of the filling unit (11), and laying corrugated filter pipes (32) and drain boards (33) on the surface for the filling unit (11); and in layered zonal filling and reinforcement, filling the filling area (1) level by level, and reinforcing with all levels of drainage networks. The method is convenient in construction, short in construction period, effective in foundation treatment and low in construction cost.

Owner:BAOSTEEL ENG & TECH GRP

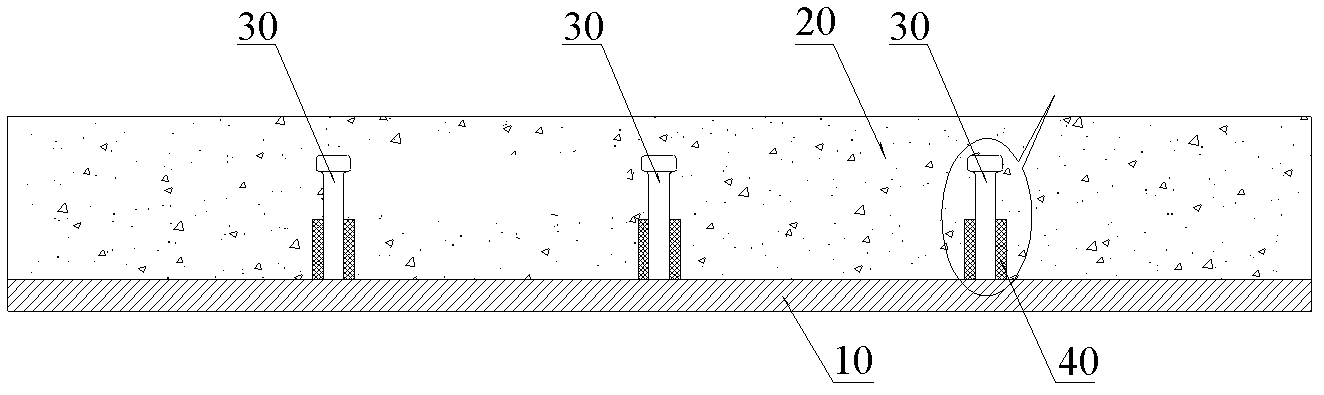

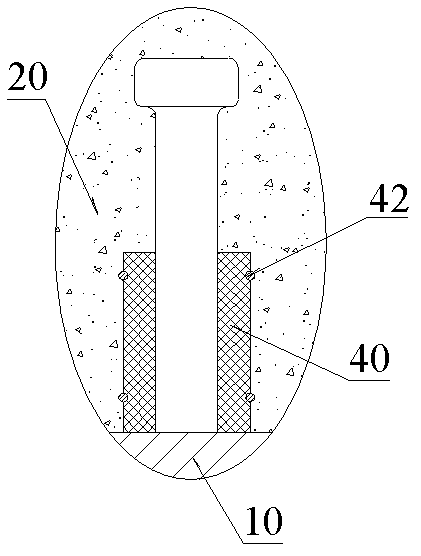

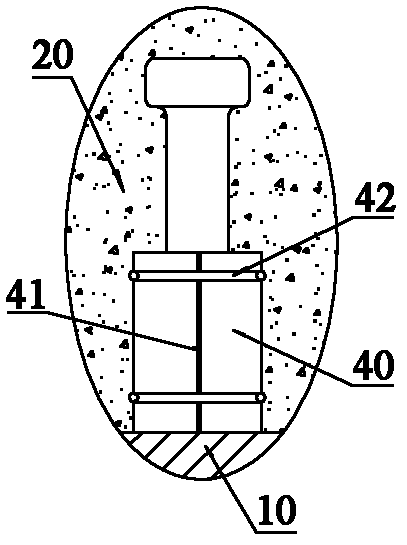

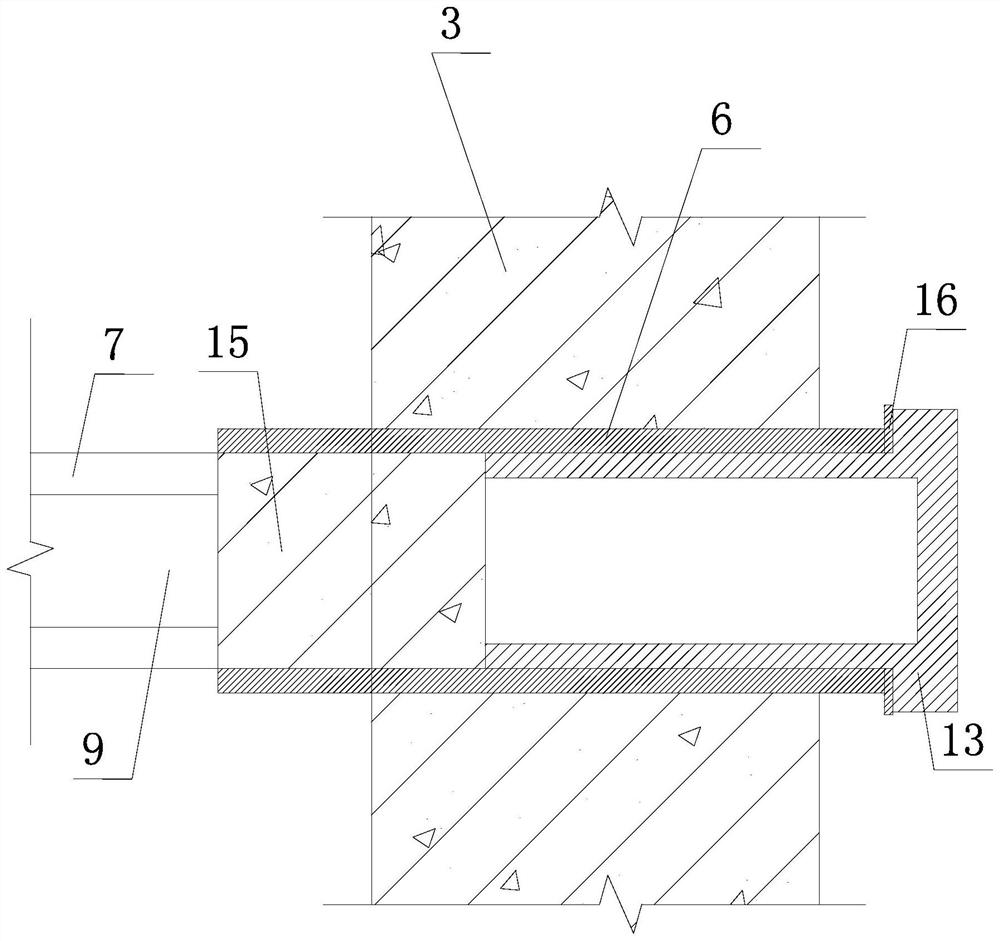

Shear force connection member for flexible welding nails of combined structure of steel and concrete

InactiveCN102493552AReduce tensile stressReduce relative shear stiffnessBridge structural detailsBuilding constructionsShear forceWelding

A shear force connection member for flexible welding nails of a combined structure of steel and concrete aims at effectively optimizing the arrangement scheme of the welding nails, greatly facilitates design and construction of the combined structure of the steel and the concrete and comprises steel members (10), concrete members (20) and the welding nails (30). The welding nails (30) are fixedly welded on the steel members (10) and embedded into the concrete members (20). Flexible rubber sleeves (40) are sleeved outside the root portions of the welding nails (30).

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

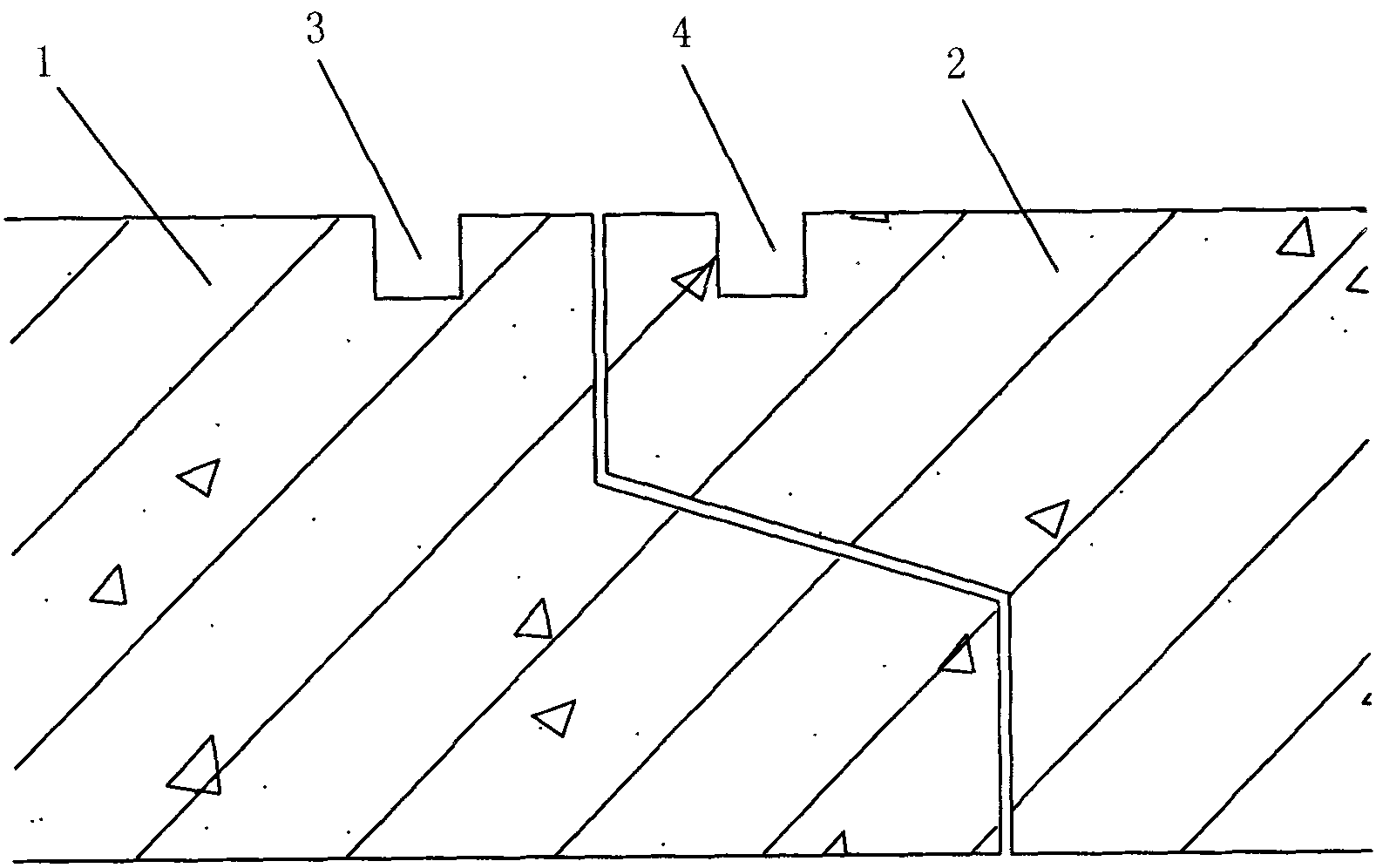

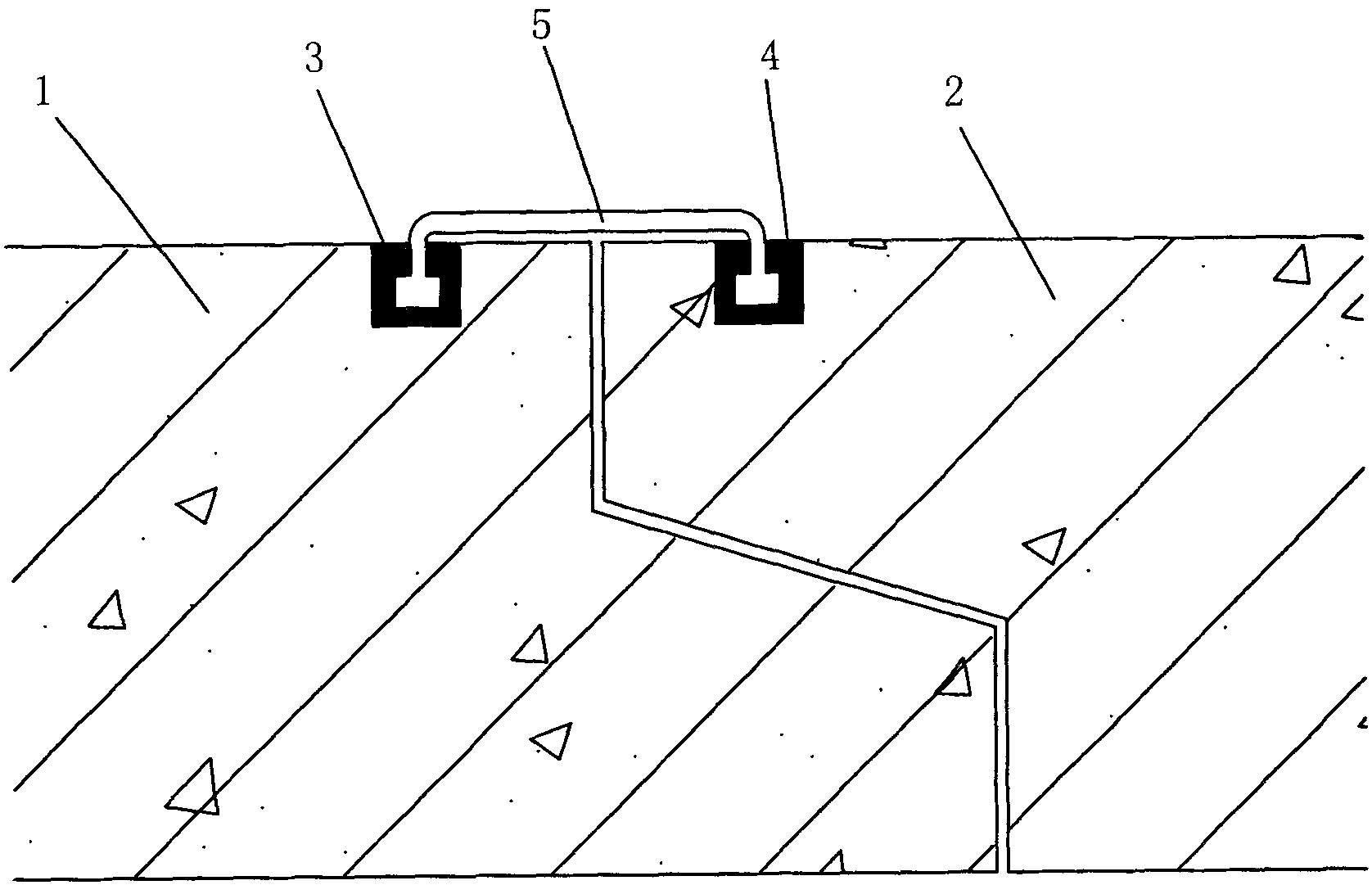

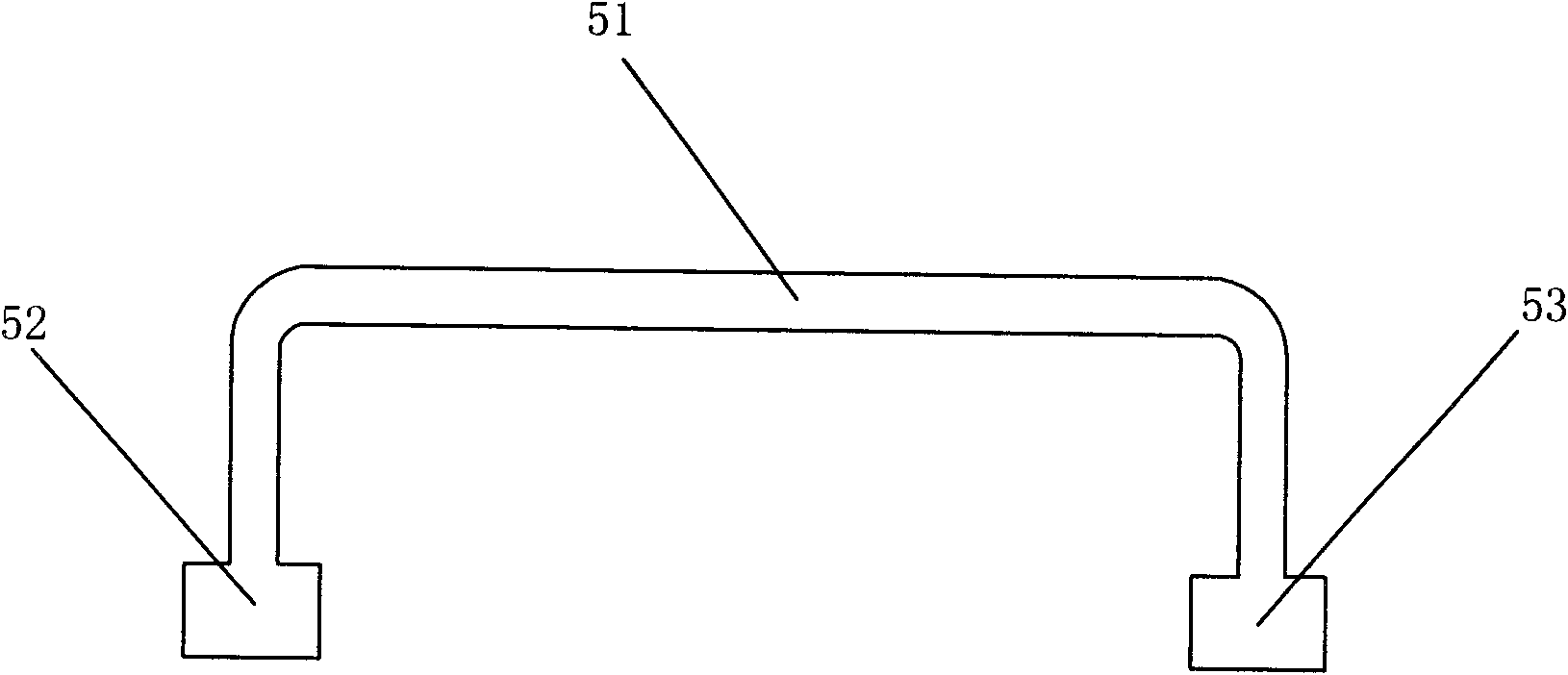

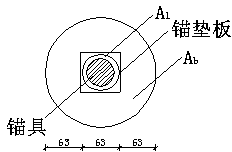

Waterproof method for prefabricated reinforced concrete box culvert interfaces and interface water stopper

InactiveCN102251491ADimensional tolerance requirements are not strictImprove waterproof reliabilityArtificial islandsGround-workEpoxyRubber ring

The invention discloses a waterproof method for prefabricated reinforced concrete box culvert interfaces and an interface water stopper. The waterproof method comprises the following steps of: pre-forming a first groove at a predetermined position far from a first box culvert interface, and pre-forming a second groove at a predetermined position far from a second box culvert interface; injecting epoxy resin adhesive into the first groove and the second groove respectively; and plugging two wings of the interface water stopper into the first groove and the second groove respectively, and sticking the two wings of the interface water stopper in the first groove and the second groove after the epoxy resin adhesive is solidified, wherein the two wings of the interface water stopper are provided with an anchoring part respectively, and the transverse size of the section of the anchoring part is greater than that of the middle section of the interface water stopper. According to the waterproof method for the box culvert interfaces, the two wings of the interface water stopper are stuck into the grooves of the box culvert interfaces to finish sticking, and the interface water stopper is adopted for preventing water; and compared with a conventional O-shaped rubber ring waterproof method, the method has the advantages of high waterproof reliability and long service life.

Owner:深圳市城市优筑科技有限公司

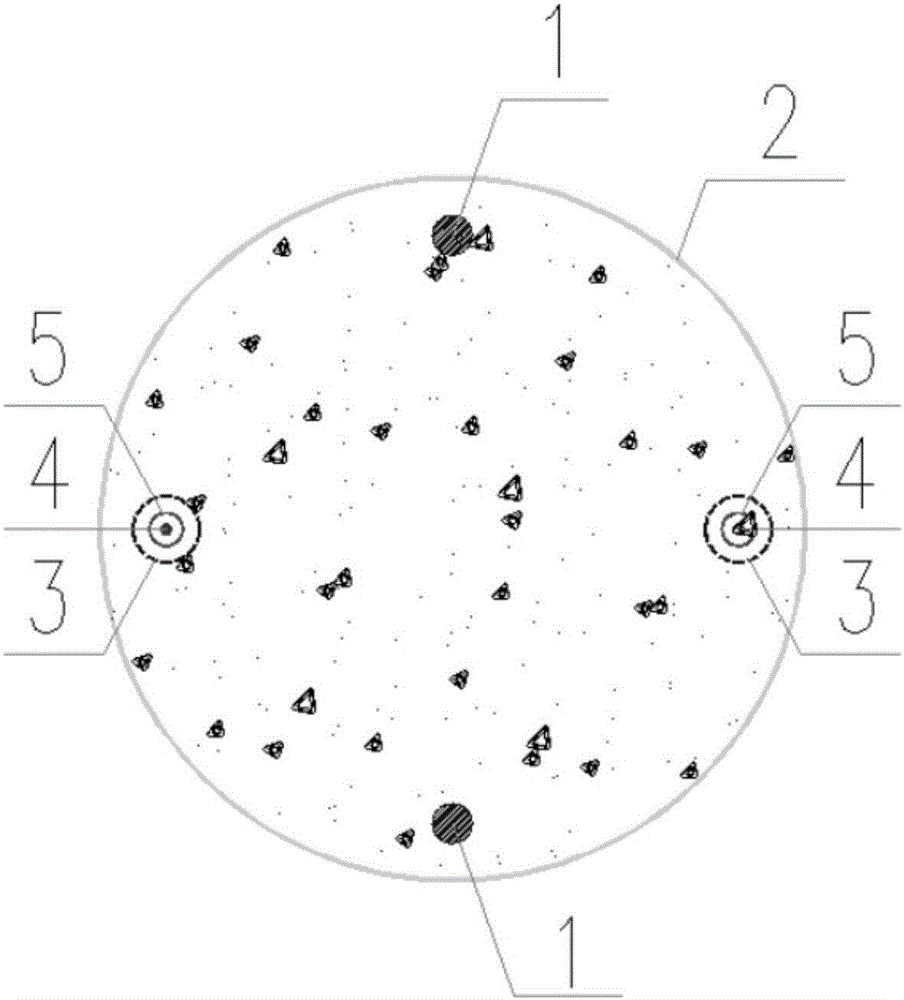

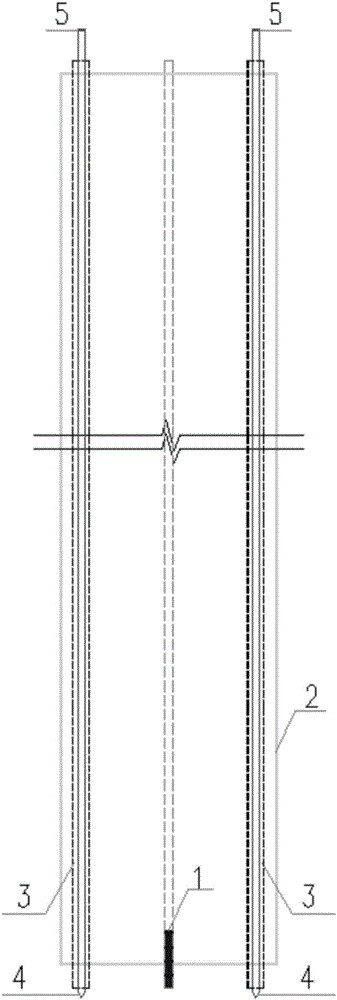

Bonded post-tensioned prestressed anchoring construction method for cast-in-place concrete structure

The invention discloses a bonded post-tensioned prestressed anchoring construction method for a cast-in-place concrete structure. The method comprises the following steps of: manufacturing and placing a steel bar cage, a steel conduit end check valve and cast-in-place concrete to form an underground structure, descending a prestressed steel strand to a design connecting part after the underground structure is molded and reaches the age, and tensioning the steel strand, anchoring and relaxing an end and grouting in a steel conduit by using special equipment, so that a prestressed steel bar is protected, and bonded connection is realized. The problem that a pile and an underground continuous wall bear buoyant force and horizontal force is solved; for the underground continuous wall which bears high bending moment, the problem that the wall on the side with higher bending moment is cracked is solved; steel is saved, the structure is easy and convenient to construct, environment is not polluted, the working surface and the construction period are not influenced, the quality guarantee rate is high, and the prestressed steel strand is inserted in a short time when the concrete is poured; and a bonded prestress applying mode is realized, the prestressed steel strand can be protected, and the durability of the underground structure is guaranteed.

Owner:TIANJIN RES INST OF BUILDING SCI

Micro-expansion super early-strength bearing grout

InactiveCN101983945AGuaranteed contactQuality assuranceBuilding repairsBridge structural detailsFlexural strengthLate stage

The invention provides a micro-expansion super early-strength bearing grout which comprises the following raw materials in parts by weight: 30-50 parts of cement, 40-60 parts of sand, 0.5-2.5 parts of water-reducing agent, 2-4 parts of expanding agent, 0.1-0.5 part of retarder and 5-10 parts of enhancer. The micro-expansion super early-strength bearing grout has the following advantages: (1) the working property is excellent, the initial fluidity reaches 320mm, and the fluidity at 30min is still above 240mm; (2) the early strength has rapid development, the strength at the late stage is not reduced, the compressive strength at 2h can be more than 20MPa, the compressive strength at 24h is more than 40MPa, the flexural strength is greater than 10MPa, and the compressive strength at 28d is greater than 50MPa; and (3) the micro-expansion super early-strength bearing grout has micro-expansion property. In view of the advantages, the micro-expansion super early-strength bearing grout can effectively improve the construction rate of a foundation bearing and other structures, and ensure the installation conformance and the construction quality of members.

Owner:WUHAN HUAXUAN HIGH TECH

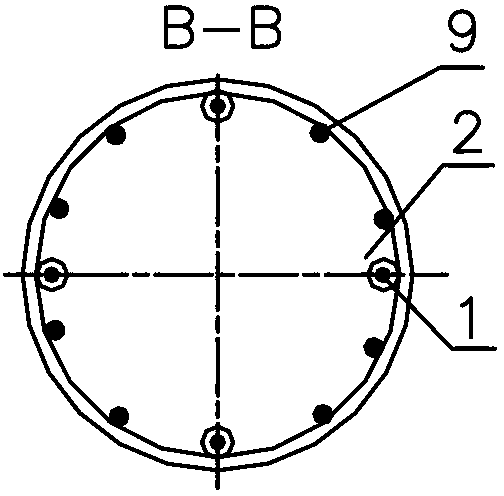

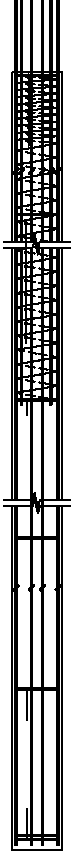

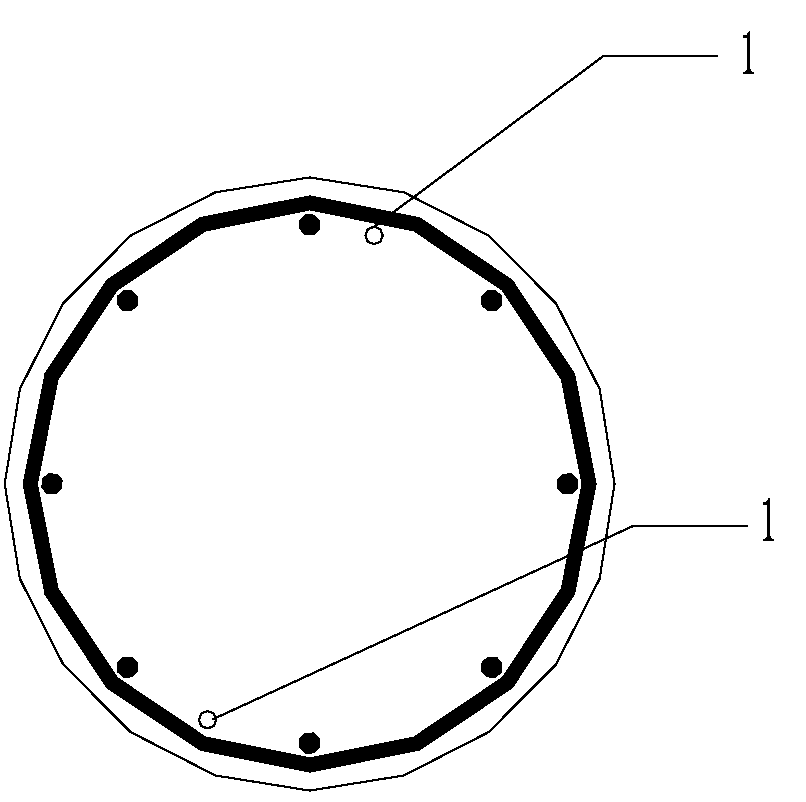

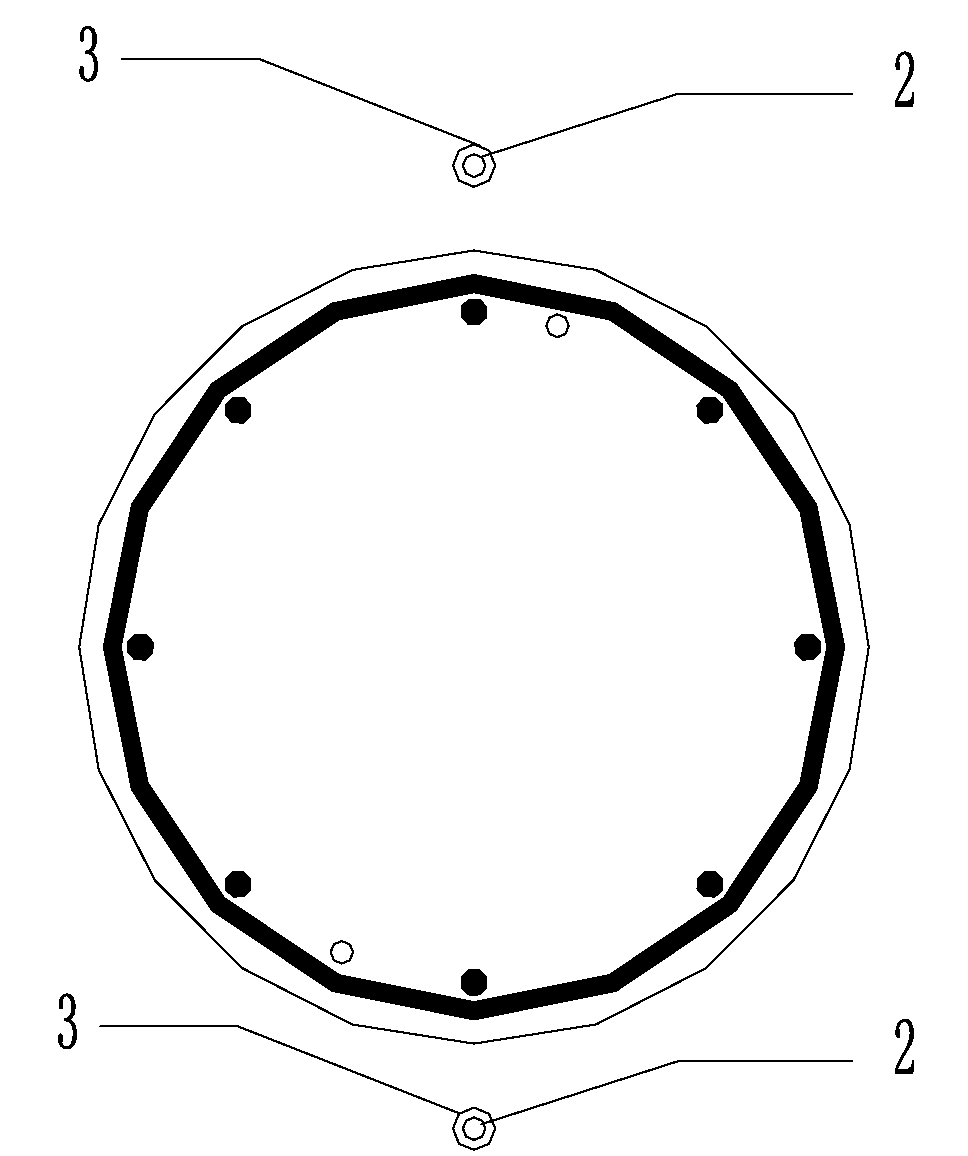

Repair method of unqualified post-grouting bored concrete pile

A repair method of an unqualified post-grouting bored concrete pile is characterized by comprising the following steps: a, drilling a plurality of lead holes at the outer side of a bored concrete pile body; b, supplementing a post-grouting pipe at the outer side of the bored concrete pile; c, conducting post-grouting construction; and d, maintaining the bored concrete pile, and inspecting and accepting the bored concrete pile, wherein the posting-grouting construction includes the following steps: (1) providing raw materials of slurry, (2) preparing the slurry, (3) conducting preparation for grouting construction, (4) conducting the first round of grouting, (5) conducting the second round of grouting, and (6) controlling over stop of the grouting. The repair method of the unqualified post-grouting bored concrete pile has the advantages of being reasonable in design of construction steps, easy and convenient to operate, safe and reliable in construction quality, free from influencing the construction period, remarkable in economic benefit, and capable of guaranteeing that a project is implemented smoothly.

Owner:MCC5 GROUP CORP SHANGHAI

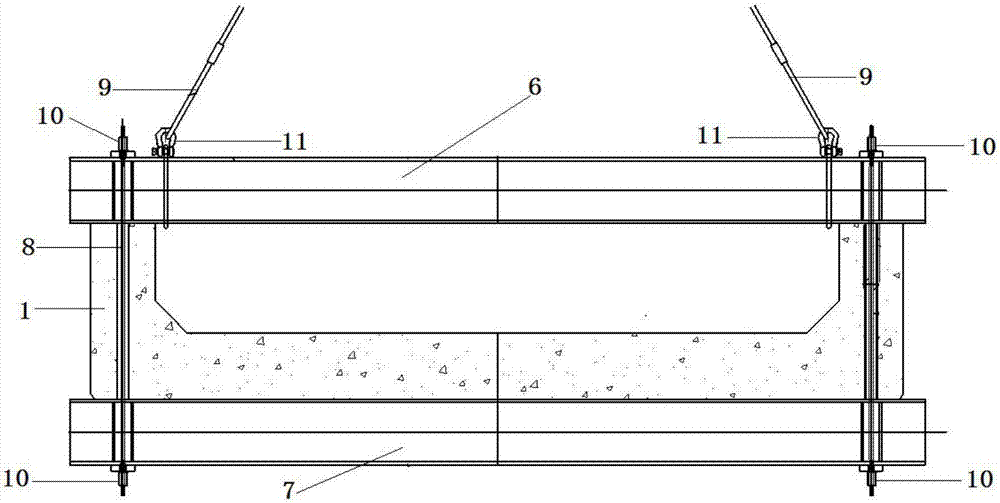

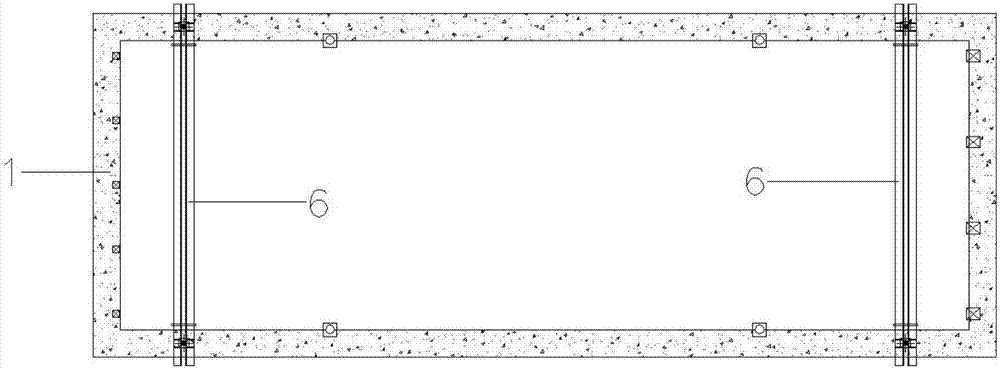

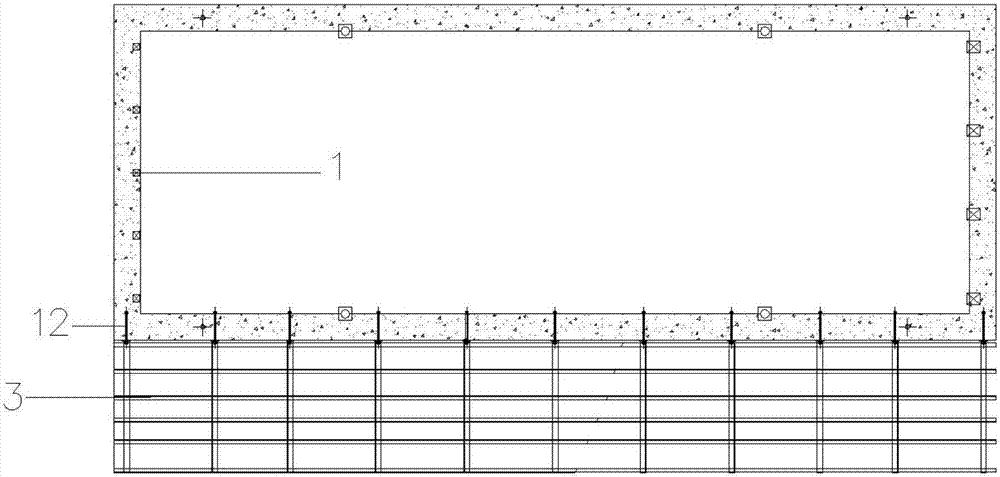

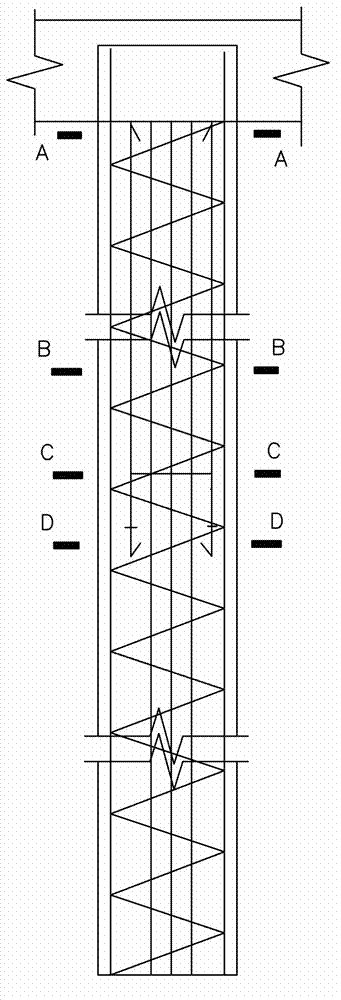

Construction method of beam body structure

InactiveCN107237270ASolve construction problemsDoes not affect the durationBridge erection/assemblyReinforced concreteMaterial consumption

The invention discloses a construction method of a beam body structure. The construction method comprises the following steps: prefabricating a U-shaped base of the beam body structure, hoisting the U-shaped base onto a bridge pier column, lapping a flange plate support and a flange plate bottom die on the left side and right side of the U-shaped base, pouring upper-part reinforced concrete of the beam body structure in a U-shaped groove of the U-shaped base based on the U-shaped base, pouring a flange plate based on the flange plate bottom die, and removing the flange plate support and the flange plate bottom die after the solidified flange plate achieves the strength requirement. According to the designed construction method, the U-shaped base is utilized as the bottom die, the support is not lapped, hoisting is conducted by utilizing a conventional crane, and the hoisting construction is easy. The on-site prefabrication can be done together with the pier column construction without the influence on the construction period of key lines, and thus the construction period is short. Auxiliary materials comprise a prefabricated pedestal and a few flange plate supports, so that the material consumption quantity is relatively small; and the installation of a beam body can be conducted by adopting a common crane, so that the hoisting cost is low. The construction method has good economy, practicability and market application values.

Owner:CCCC SECOND HARBOR ENG

Bonded post-tensioned prestressed construction method for cast-in-place reinforced concrete structure

ActiveCN102808422AReduce rustNo pollutionArtificial islandsUnderwater structuresSlurry wallHorizontal force

The invention discloses a bonded post-tensioned prestressed construction method for a cast-in-place reinforced concrete structure. The method comprises the following steps of: determining prestress applying length by using a design unit; manufacturing, placing and connecting a steel bar cage, placing a steel conduit end, an automatic locking anchoring tool and cast-in-place concrete to form an underground structure, descending a prestressed steel strand to a design connecting part after the concrete structure is molded and reaches the age, and tensioning the steel strand, anchoring and relaxing the end and post-grouting in a steel conduit by using special equipment, so that bonded connection is realized. The problem that a pile and an underground continuous wall bear buoyant force and horizontal force is solved; for the underground continuous wall which bears high bending moment, the problem that the wall on the side with higher bending moment is cracked is solved; steel is saved, the structure is easy and convenient to construct, environment is not polluted, the working surface is not influenced, the quality guarantee rate is high, and prestress applying time is not limited by construction time; and a bonded prestress applying mode is realized, the prestressed steel strand is protected, and the durability of the underground structure is guaranteed.

Owner:TIANJIN RES INST OF BUILDING SCI

Second lining grouting-with-template mechanism for full hydraulic trolley and grouting technology thereof

InactiveCN108442938AEasy constructionImprove overall mechanical propertiesUnderground chambersTunnel liningEngineeringLine defects

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Reinforced structure used for concrete displacement of shear wall and construction method of reinforced structure

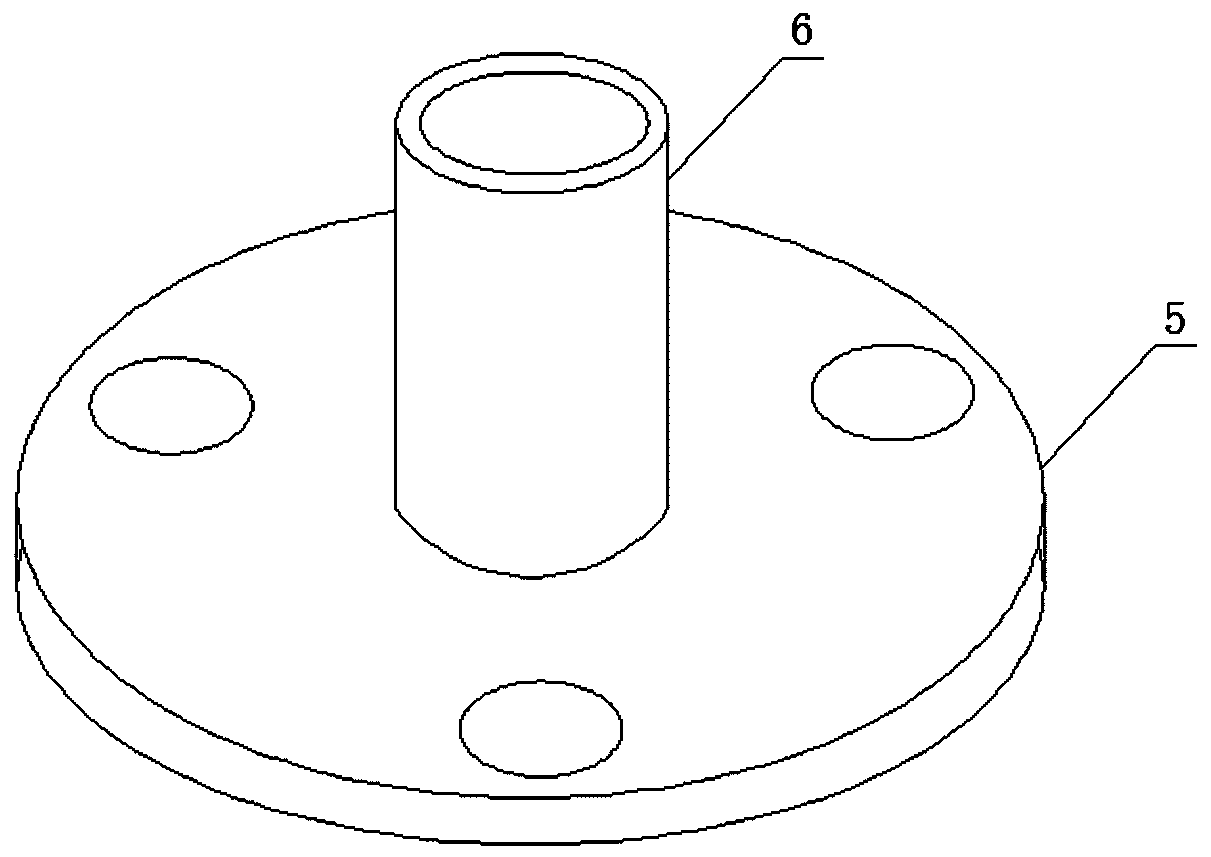

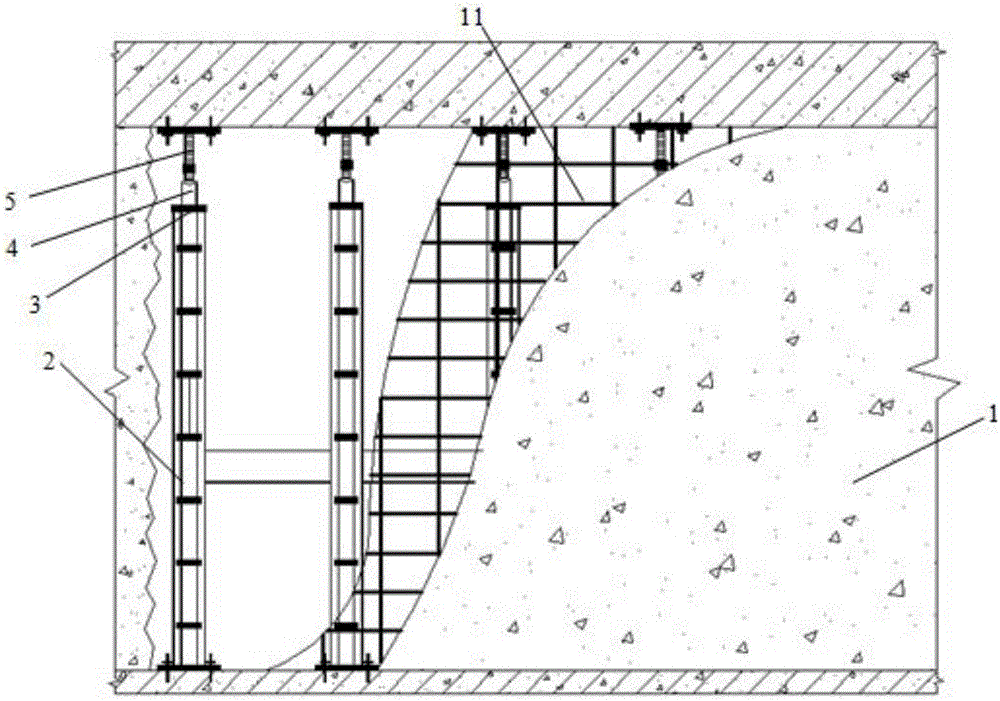

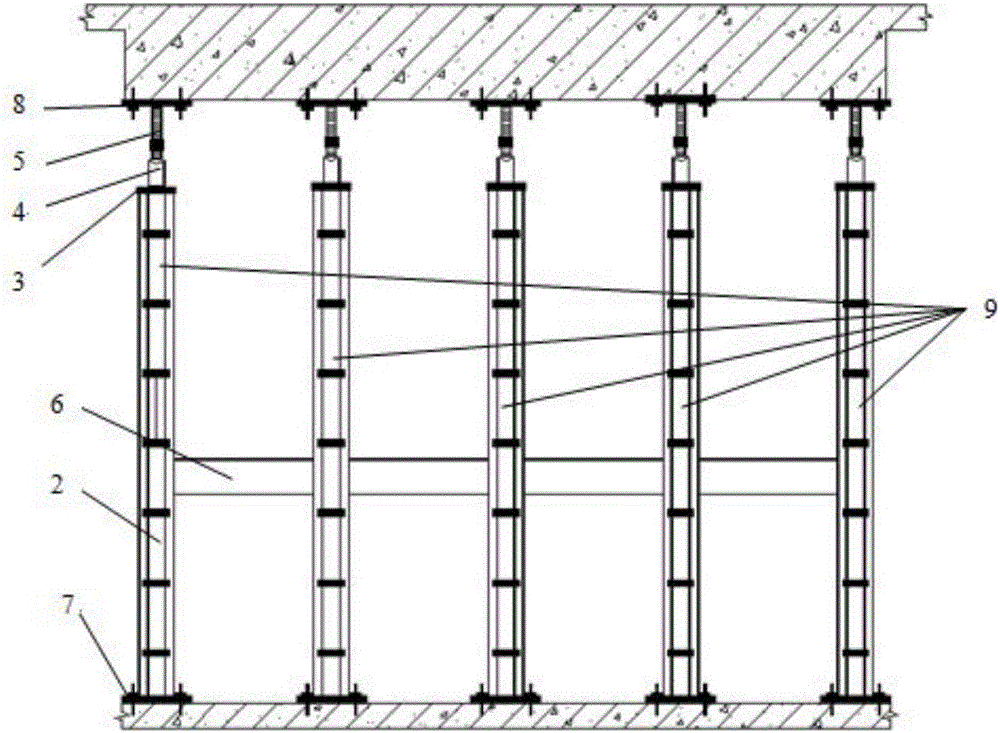

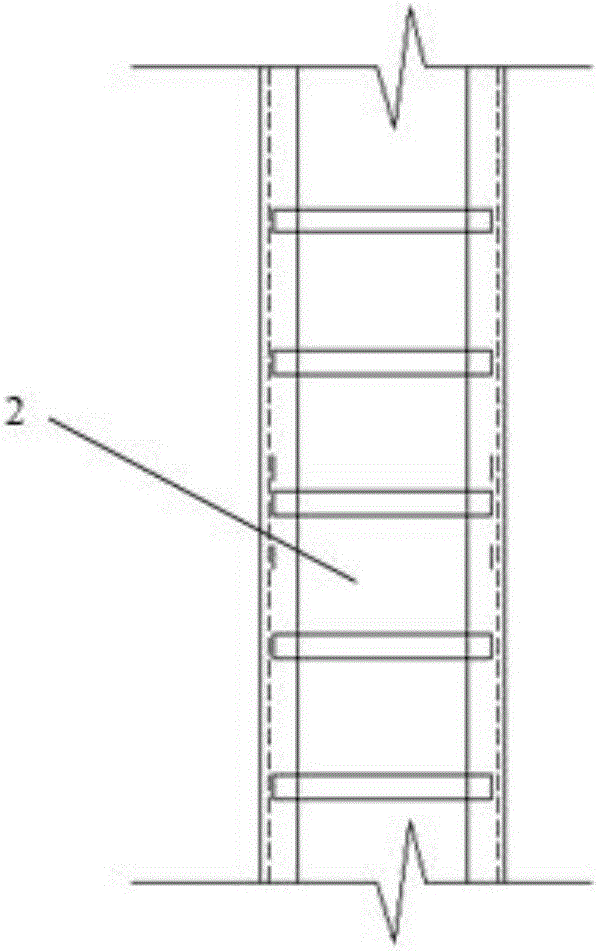

The invention provides a reinforced structure used for concrete displacement of a shear wall and a construction method of the reinforced structure. The reinforced structure includes a newly poured concrete wall surface and a number of permanent steel stand columns, wherein the permanent steel stand columns are arranged in the newly poured concrete wall surface side by side at intervals; the two sides, parallel to the wall surface, of each permanent steel stand column are provided with reinforcing steel bar nets, and each permanent steel stand column includes a center steel column, a connection steel plate located at the upper end of the center steel column, a nut located at the upper end of the connection steel plate, and a screw rod; the top ends of the screw rods on the upper portions of the permanent steel stand columns are welded with upper steel plates, the bottom portions of the steel columns are welded with lower steel plates, the upper steel plates are fixed with upper floor slabs, and the lower steel plates are fixed with ground floor slabs; a horizontal support is arranged between every two adjacent steel columns so as to increase the stabilization of the permanent steel stand columns and prevent the lateral deformation of the steel stand columns. According to the reinforced structure and the construction method of the reinforced structure, the mode in which concrete is dismantled in sections and the permanent steel stand columns are built in the concrete is adopted, the normal construction of the upper structure is not affected, that is, the shear wall displacement and the upper structure construction are conducted at the same time, the progress of the whole project is ensured, and the whole construction period is not affected.

Owner:WUHAN UNIV

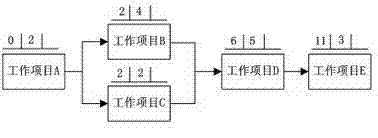

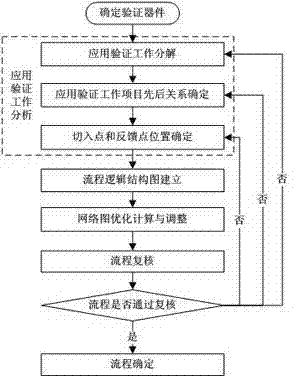

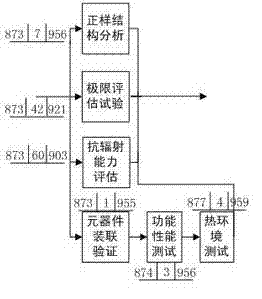

Component application validation process establishment method for space navigation

InactiveCN103699939ANot affected by app verificationDoes not affect the durationForecastingManufacturing computing systemsGuidelineProcess logic

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

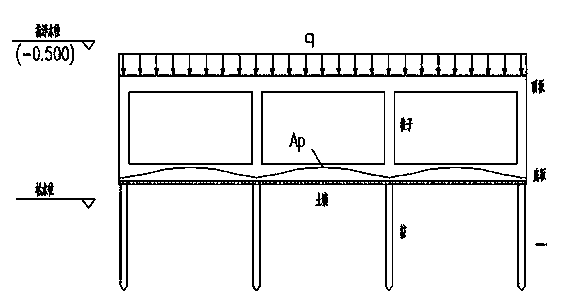

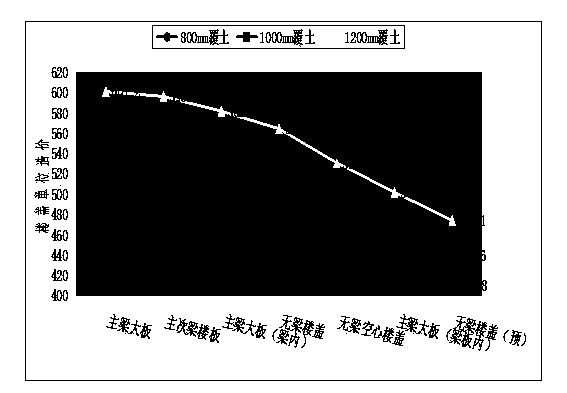

Method for designing and constructing waterproof plate for underground garage by post-tensioning bonded prestressed construction process

ActiveCN104314103ALower the altitudeLow costArtificial islandsProtective foundationPre stressArchitectural engineering

The invention relates to a method for designing and constructing a waterproof plate for an underground garage by a post-tensioning bonded prestressed construction process. The method is characterized in that the waterproof plate adopts a beamless structure comprising a bottom plate and a top plate, and is subjected to post-tensioning bonded prestressed construction; the method mainly comprises the steps of arranging bars, pouring, tensioning, grouting, and performing cutting and anchor sealing; before construction, the bar preparation scheme is determined through the lateral restraint analysis of the underground garage, and the occurrence of post-pouring belt cracks is avoided through staged tensioning and set temperature shrinkage; the tensioning end of a prestressed bar is arranged in the center of the bottom plate or a post-pouring belt region, so that the periphery can be subjected to soil covering and waterproof construction in time, and the construction period is shortened; the prestressed bar runs through the bottom of the pier cap of the pier of the bottom plate during arrangement, and a reinforcing bar does not need to be added to the pier cap, so that the cost is reduced.

Owner:江苏开来预应力工程有限公司

Cast-in-place pile end slurry supplying and grouting device and method

The invention discloses a cast-in-place pile end slurry supplying and grouting device and method. The device comprises a sounding pipe or steel pipe used for a slurry supplying and grouting channel, a probe used for breaking through the bottom of the sounding pipe or steel pipe, a probing rod used for conveying the probe to the pile end of the cast-in-place pile end and a counterforce device used for driving a static penetrometer of the probe; the sounding pipe or steel pipe embedded in the cast-in-place pile required to be subject to slurry supplying and grouting is selected to serve as the slurry supplying and grouting channel, the probe is mounted at one end of the probing rod, the other end of the probing rod is connected with the static penetrometer, the probe is conveyed to the bottom of the sounding pipe or steel pipe through the probing rod, the counterforce device of the static penetrometer is started, pressure is applied to the probe, the bottom of the sounding pipe or steel pipe is broken through, and finally a grouting pipeline system is put into the bottom of the slurry supplying and grouting channel to be subject to pile end slurry supplying and grouting construction of the cast-in-place pile.

Owner:SHANGHAI GEOTECHN INVESTIGATIONS & DESIGN INST

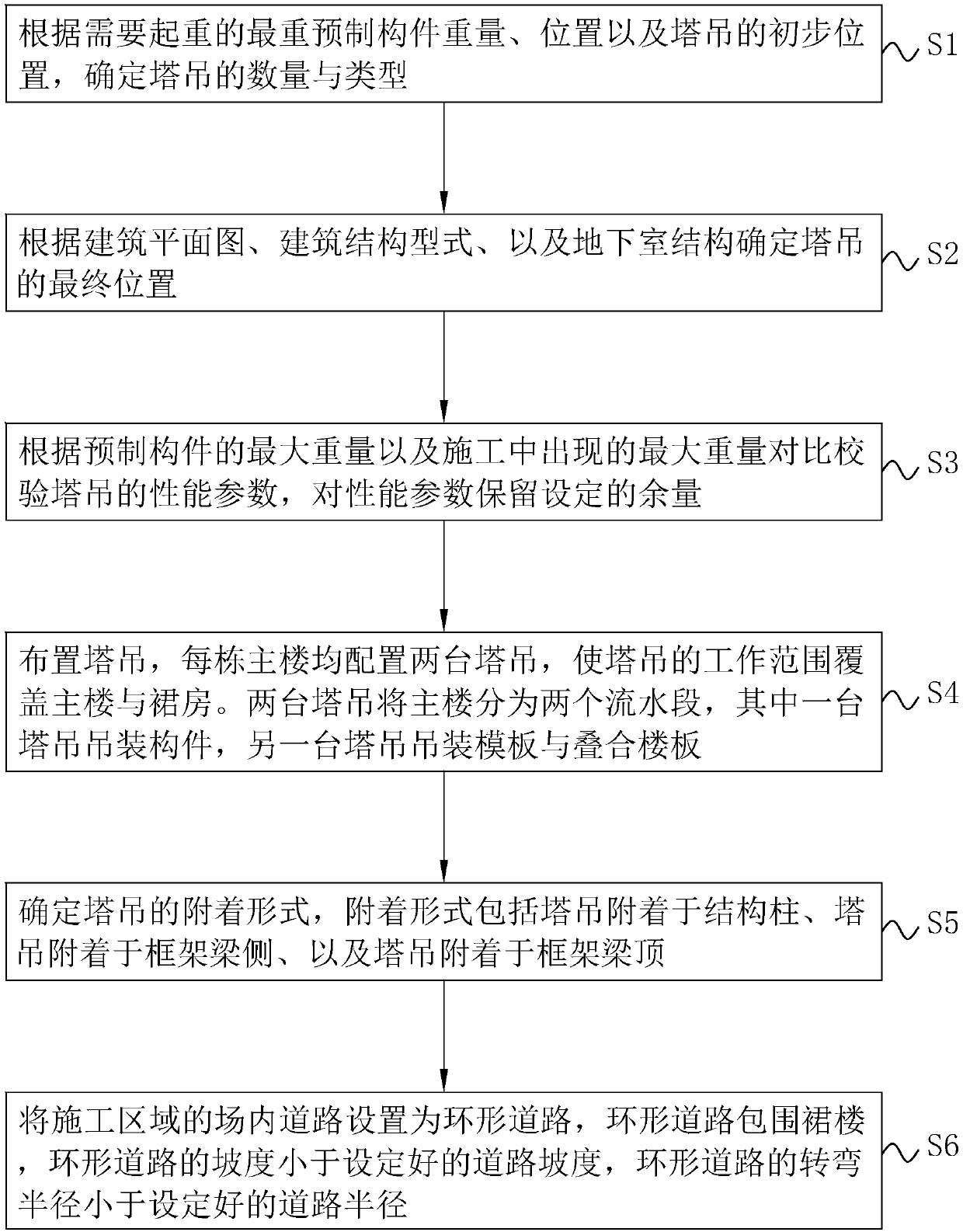

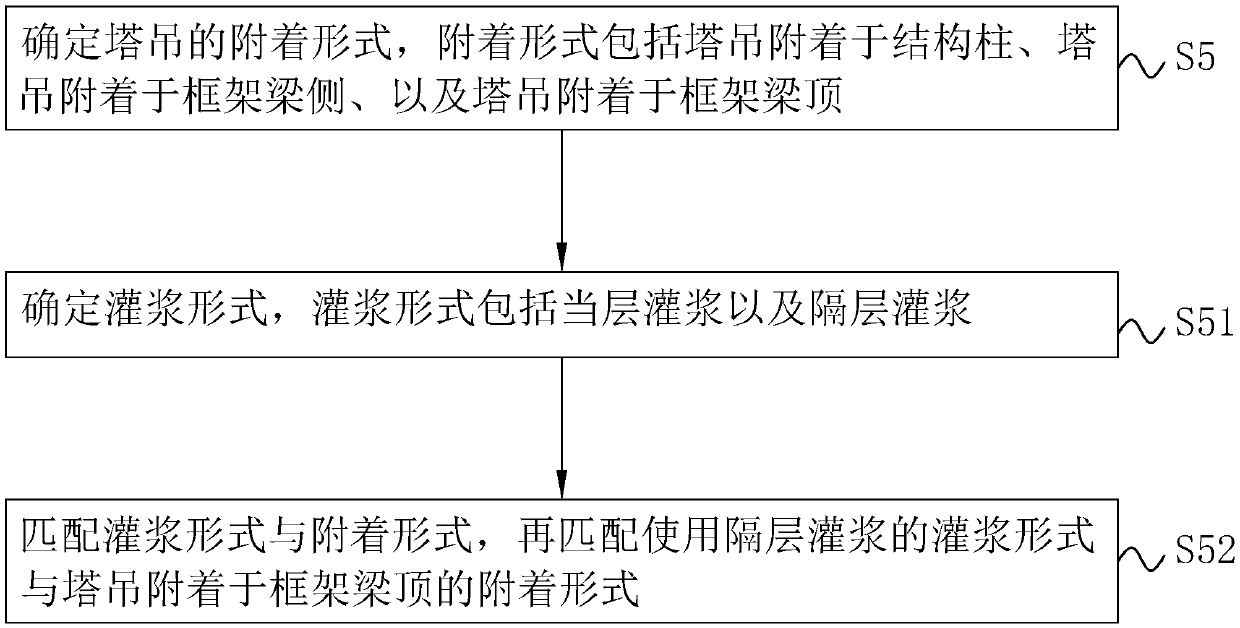

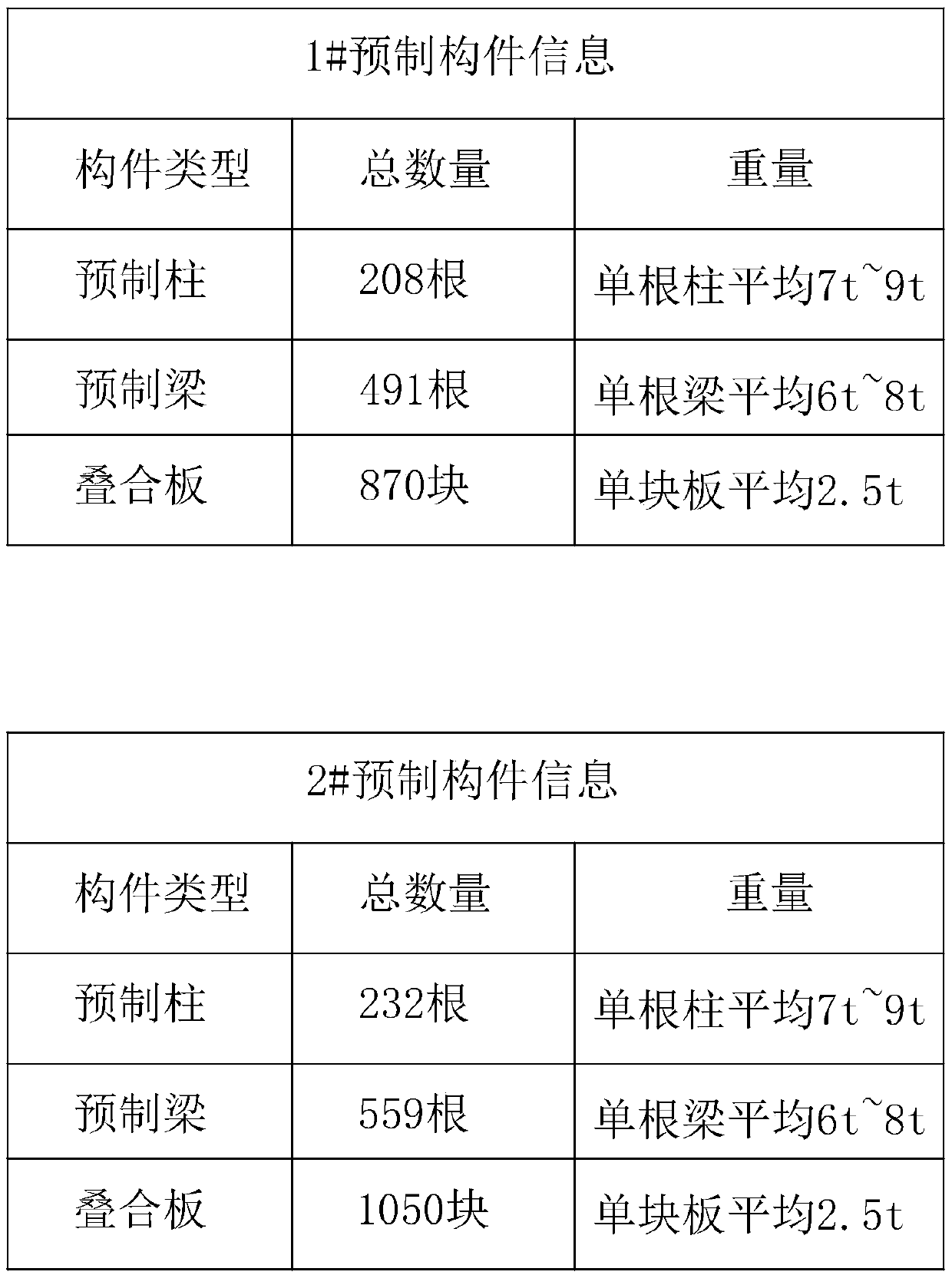

Hoisting construction method for fabricated overall framework cast-in-situ core tube structures

InactiveCN109534189AOvercome efficiencyOvercome problems such as imbalance between hoisting areasBuilding material handlingLoad-engaging elementsModel selectionEngineering

The invention relates to the technical field of construction of fabricated overall frameworks, and discloses a hoisting construction method for fabricated overall framework cast-in-situ core tube structures. The method includes the following steps that the number and types of tower cranes are determined according to the weights and positions of heaviest prefabricated parts and the preliminary positions of the tower cranes; the final positions of the tower cranes are determined according to an architectural plan, an architectural structure pattern and a cellar structure; performance parametersof the tower cranes are comparatively verified according to the maximum weights of the prefabricated parts and the maximum weight existing in construction; the tower cranes are arranged; and the attachment forms of the tower cranes are determined, wherein according to the attachment forms, the tower cranes are attached to structural columns, the tower cranes are attached to framework beam sides, and the tower cranes are attached to framework beam tops. In the model selection process, the working radius, the maximum hoisting amount of the prefabricated parts, the positions and attachment formsof the tower cranes and the like are combined for overall consideration, and the method has the beneficial effects that the efficiency of the tower cranes is high, and the balance degree between hoisting operation areas is high.

Owner:THE FIRST CONSTR CO LTD OF CHINA CONSTR FIRST GRP +1

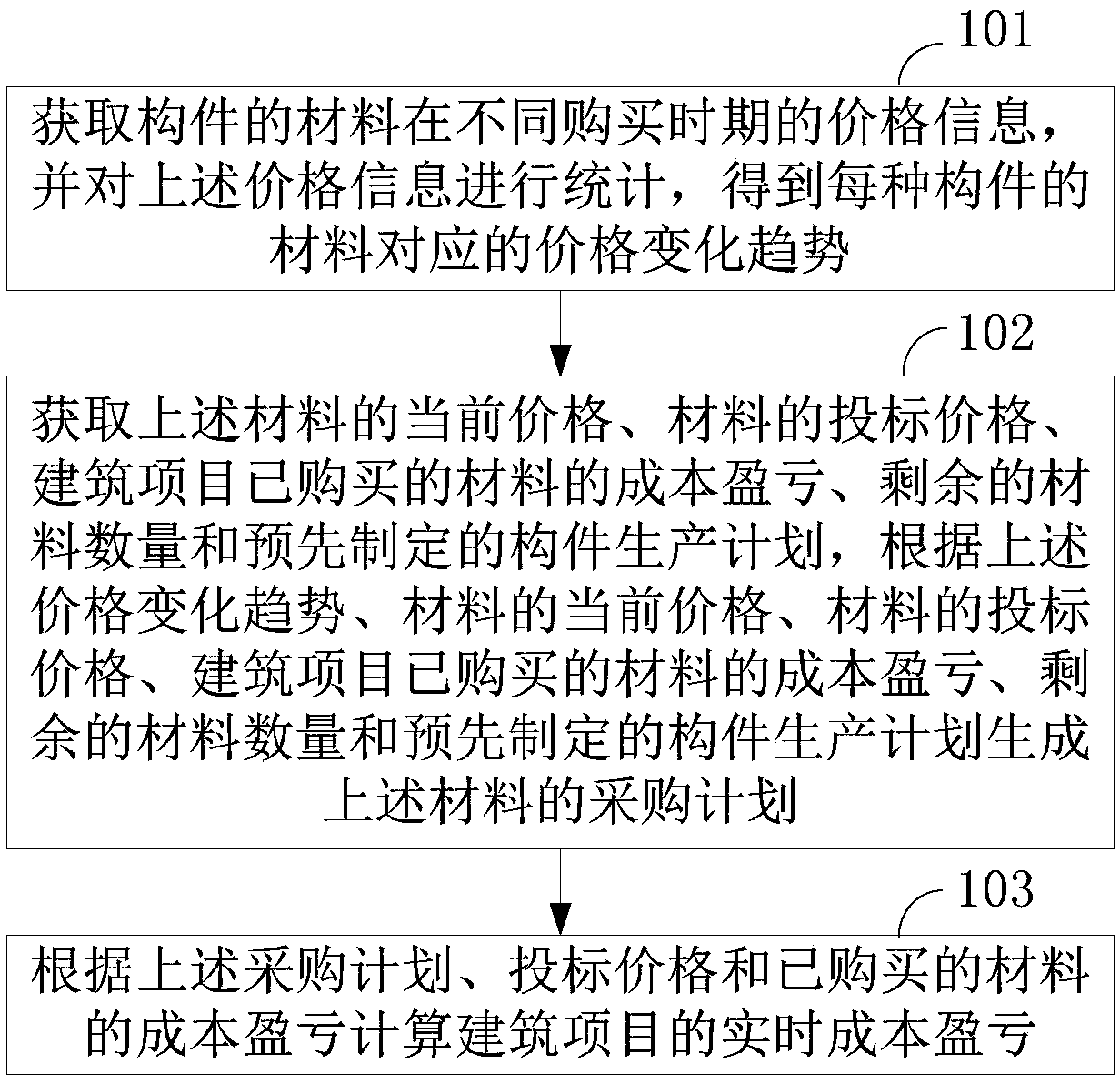

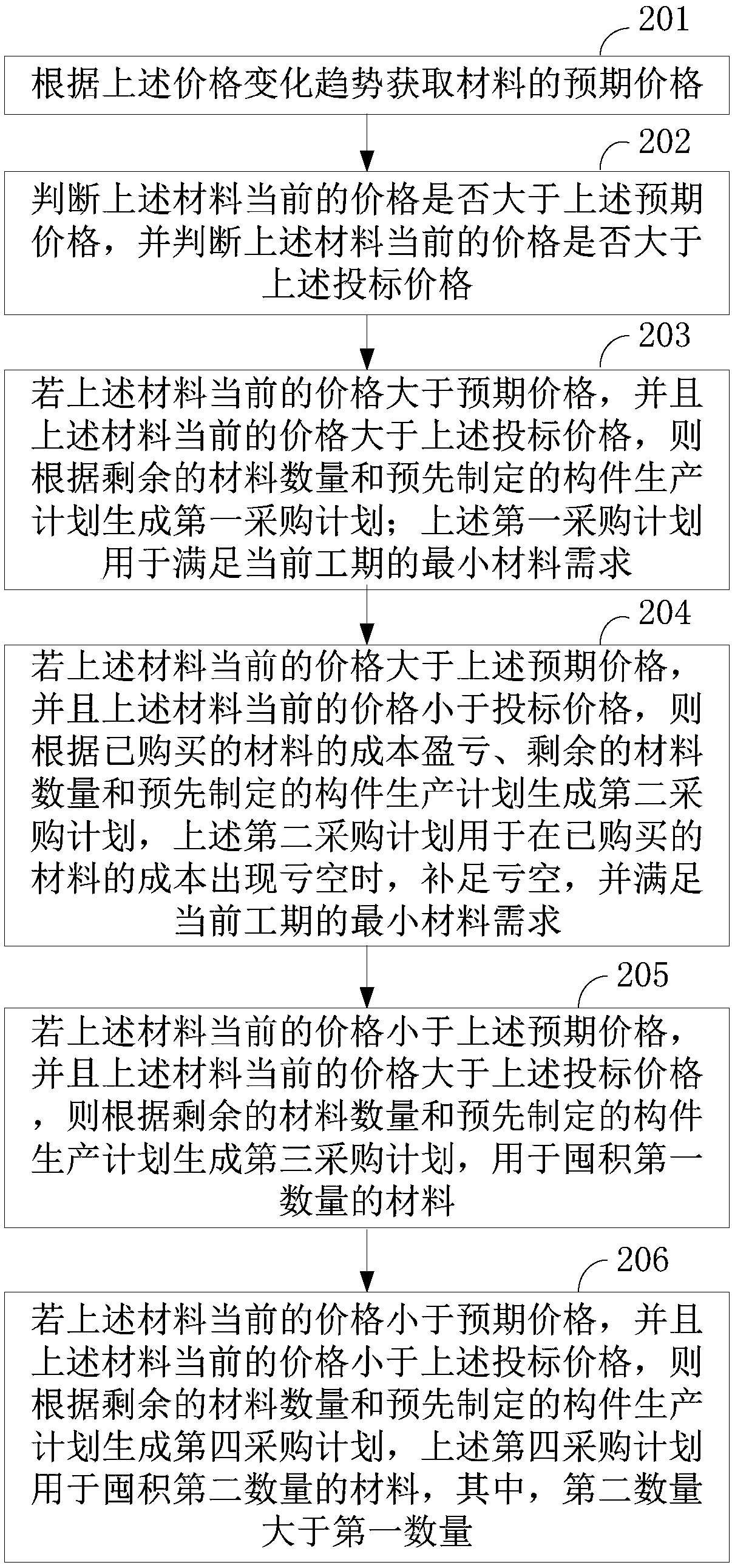

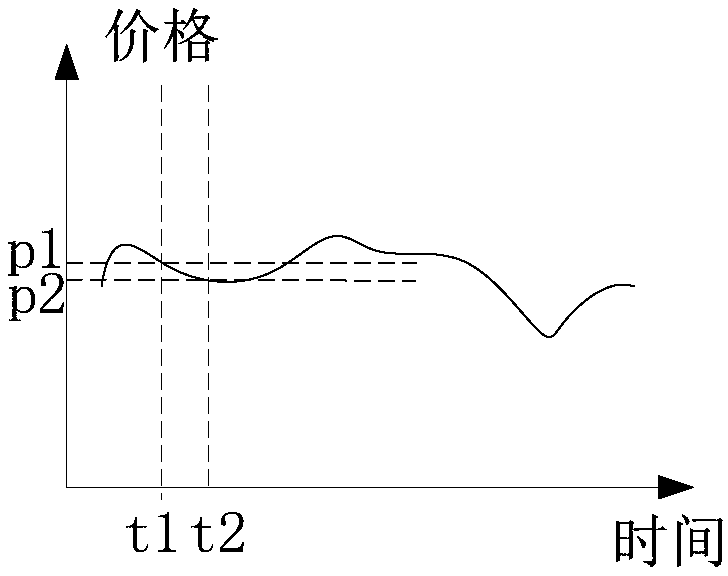

Cost early warning method and device for fabricated building

InactiveCN109559145AReduce construction costsDoes not affect the durationMarket predictionsCurrent priceMaterials science

The invention discloses a cost early warning method and device for a fabricated building. The cost early warning method for the fabricated building comprises the steps of obtaining the price information of materials of components in different purchase periods, gathering the price information, and obtaining the price change trend corresponding to the materials of all the components; acquiring the current price of the material of the component, the bidding price of the material, the cost profit and loss of the purchased material of the building project, the quantity of the remaining material anda preset component production plan; generating a purchase plan of the material according to the price change trend, the current price of the material, the bidding price of the material, the cost profit and loss of the purchased material of the building project, the quantity of the remaining material and the preset component production plan; and calculating the real-time cost profit and loss of the building project according to the purchase plan, the bidding price and the cost profit and loss of the purchased materials, so that the technical problem that the building construction cost cannot be accurately predicted due to the fact that the price of materials for producing components changes along with the market, is solved.

Owner:CHINA CONSTR SCI & TECH CO LTD

Construction method of basement roof polyvinyl chloride thorn-resistant waterproof membrane

The invention discloses a construction method of a basement roof polyvinyl chloride root thorn resistance waterproof roll. The construction method is characterized by comprising the steps of: (a) construction preparation; (b) base layer treatment of the root thorn resistance waterproof roll; (c) construction of a reinforced additional layer in a node; (d) large surface construction of the polyvinyl chloride root thorn resistance waterproof roll; (e) head shrinkage treatment of the polyvinyl chloride root thorn resistance waterproof roll; and (f) cleaning, checking and acceptance of the polyvinyl chloride root thorn resistance waterproof roll. The construction method of the basement roof polyvinyl chloride root thorn resistance waterproof roll has the advantages of reasonable design and simple operation in production of the additional layer of the polyvinyl chloride root thorn resistance waterproof roll, no influence on construction period, lower investment, safe and reliable engineering quality, improvement of once acceptance pass percent, in particular prominent improvement of root thorn and water resistant in the node and elimination of subsequent node leakage hidden danger of a basement roof, and wide promotion and application prospect.

Owner:MCC5 GROUP SHANGHAI CORPORATION LIMITED

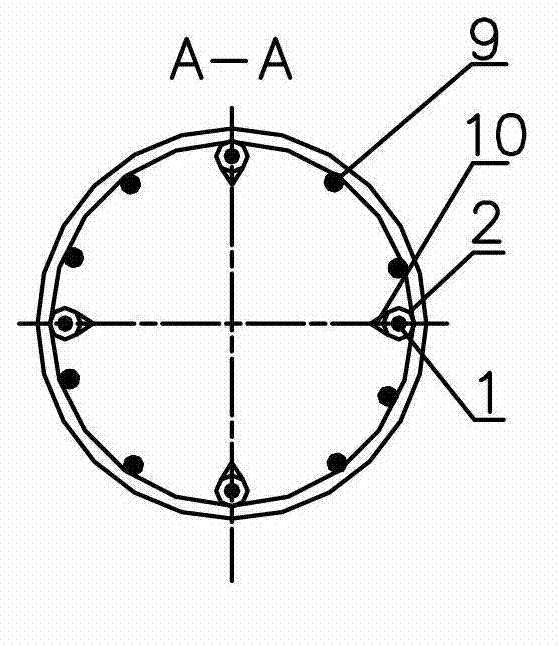

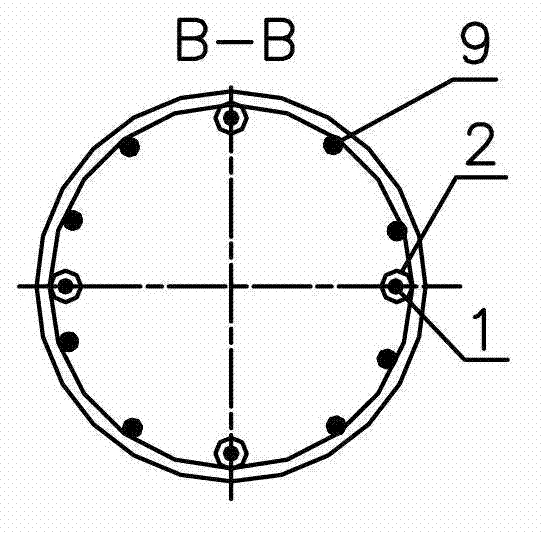

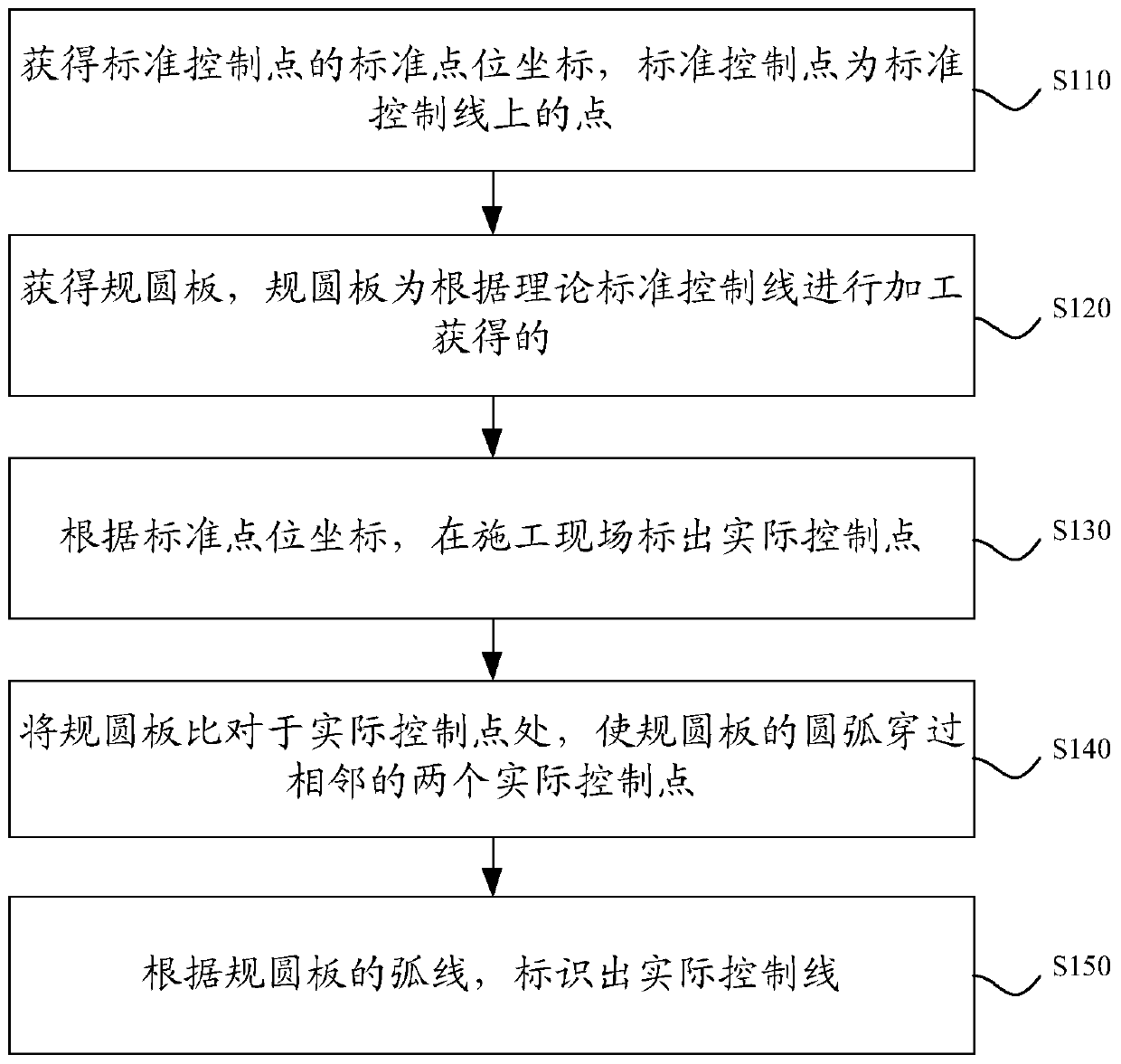

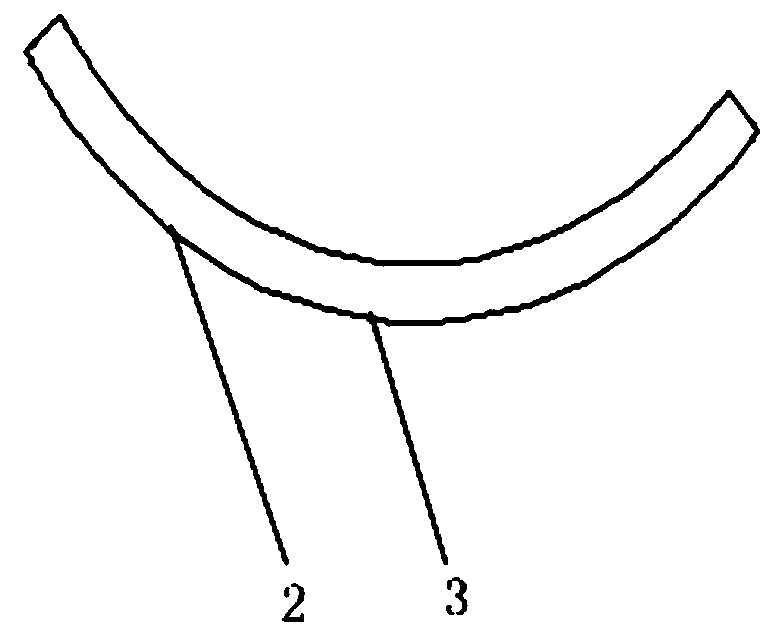

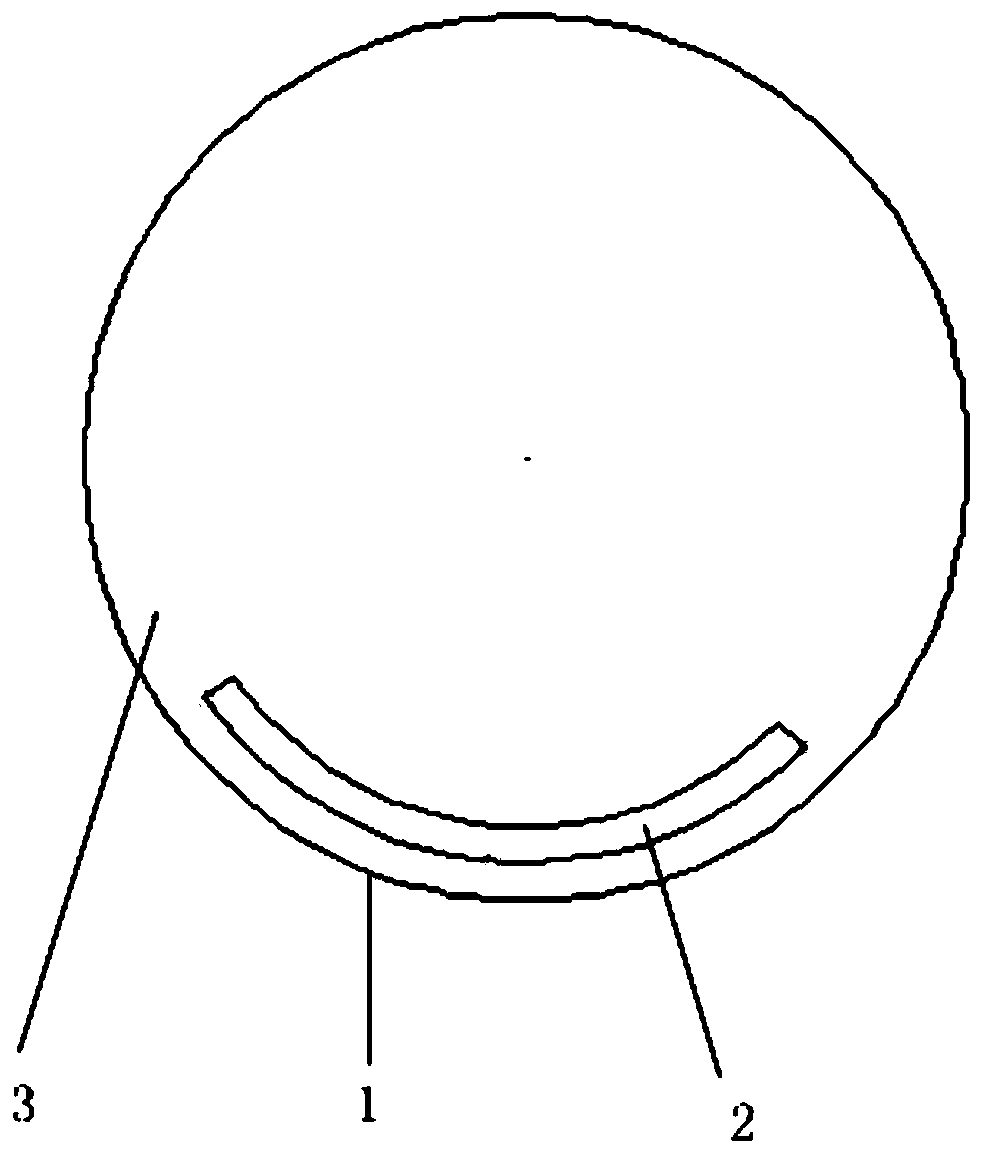

Paying-off method for arc-shaped wall control line

InactiveCN110805290AAccurate locationEnsure authenticityBuilding material handlingControl lineControl theory

The invention discloses a paying-off method for an arc-shaped wall control line. The paying-off method comprises the steps that standard point position coordinates of standard control points are obtained, and the standard control points are points on the standard control line; a gauge circular plate is obtained, and the gauge circular plate is obtained by machining according to the standard control line; actual control points are marked on a construction site according to the standard point position coordinates; the gauge circular plate is compared with the actual control points, and an arc ofthe gauge circular plate penetrates through the two adjacent actual control points; and the actual control line is marked according to the arc line of the gauge circular plate. According to the paying-off method for the arc-shaped wall control line, the accuracy of point positions is ensured, the paying-off point positions are greatly reduced, and the paying-off time is saved.

Owner:上海宝冶建筑工程有限公司 +1

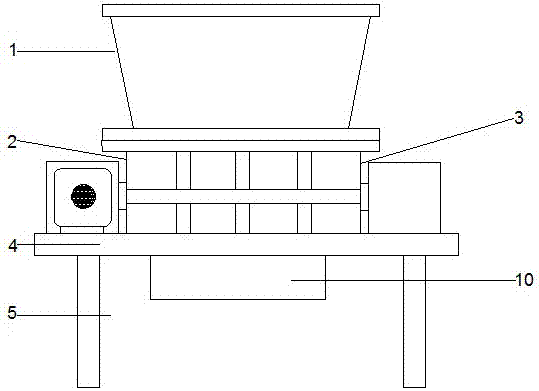

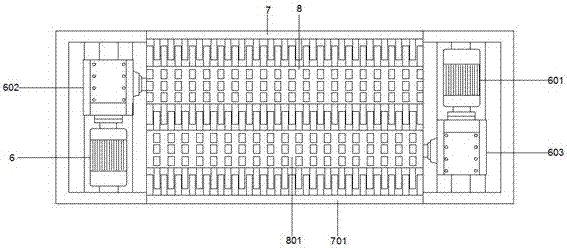

Smashing device for building and working method for smashing device

InactiveCN107537623AEvenly crushedEasy to transportGrain treatmentsElectric machineryArchitectural engineering

The invention relates to the technical field of construction waste crushing, in particular to a crushing device for construction and a working method thereof, comprising: a feeding hopper, a material box, a reinforcing rib, a base, a supporting column, a first motor, a first fixing plate, a first a toothed roller, a toothed plate, a discharge port, a second motor, a first gear box, a second gear box, a second fixed plate, and a second toothed roller; a feeding hopper is arranged above the material box, and the feeding hopper The bottom is connected with the top of the material box through bolts; the long edge of the inner side of the material box is provided with a first fixing plate, and the first fixing plate is connected with the material box by welding; the upper surface of the first fixing plate is provided with The toothed plate is connected with the first fixing plate by bolts. Through structural improvement, the invention has the advantages of small floor space, replaceable tooth plate, convenient maintenance, lower use cost of the device, strong mobility, and even crushing, etc., thereby effectively solving the problems existing in the existing device. problems and deficiencies.

Owner:陈彬

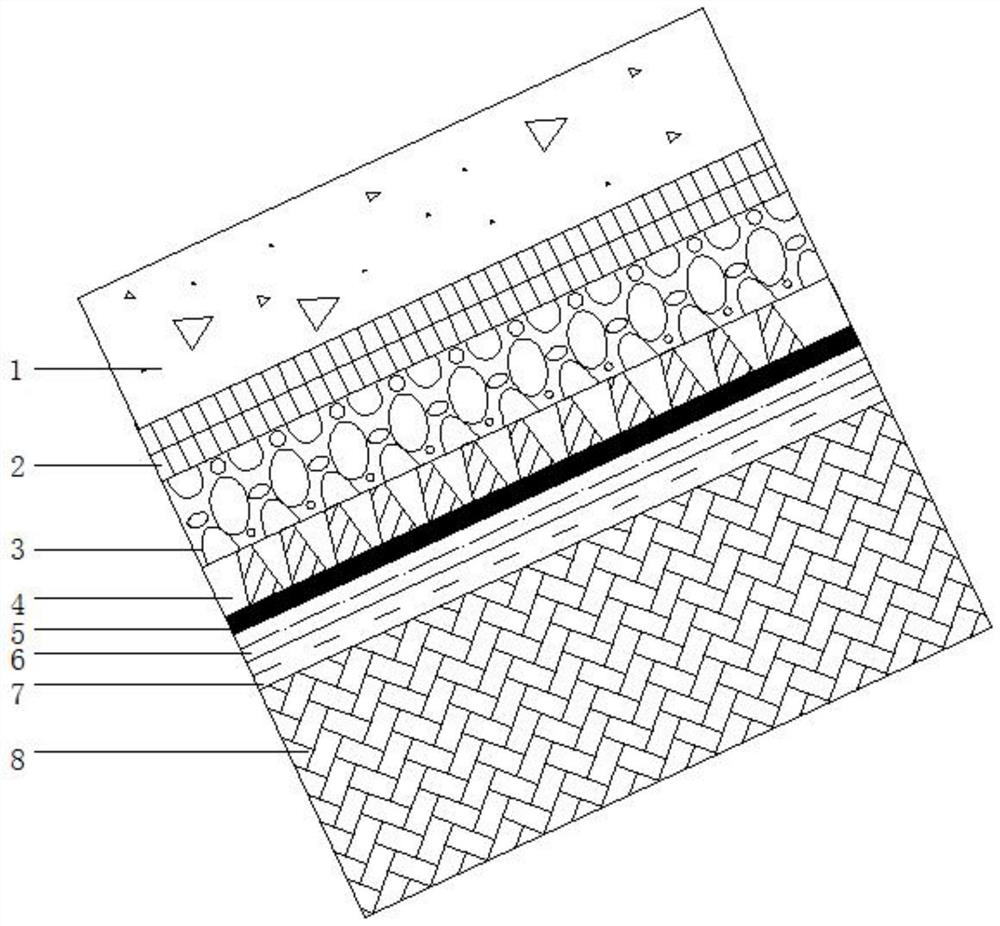

Landfill reservoir area anti-seepage system capable of protecting geomembrane and construction method thereof

InactiveCN112942443AExcellent drainage effectReduce thicknessClimate change adaptationProtective foundationSoil scienceGeomembrane

The invention relates to the technical field of landfill facilities, and particularly relates to a landfill reservoir area anti-seepage system capable of protecting a geomembrane and a construction method thereof. The landfill reservoir area anti-seepage system comprises a reservoir bottom anti-seepage system and a side slope anti-seepage system; the reservoir bottom anti-seepage system comprises a compacted clay layer, a bentonite waterproof blanket, at least one layer of geomembrane, a rubble layer and a woven geotechnical filter screen which are vertically arranged from bottom to top; the side slope anti-seepage system comprises a compacted clay layer, a bentonite waterproof blanket, at least one layer of geomembrane, a rubble layer and a woven geotechnical filter screen which are obliquely arranged from bottom to top; and geotechnical cloth is laid on the upper layer of the geomembrane, and a high-tensile filter and discharge plate is laid on the upper layer of the geotechnical cloth. The landfill reservoir area anti-seepage system is simple in structure and convenient to construct, compared with a traditional landfill anti-seepage system, resources are saved, the reservoir capacity is increased, meanwhile, the geomembrane in the anti-seepage system can be effectively prevented from being damaged, and the service life is prolonged.

Owner:山东天海新材料工程有限公司

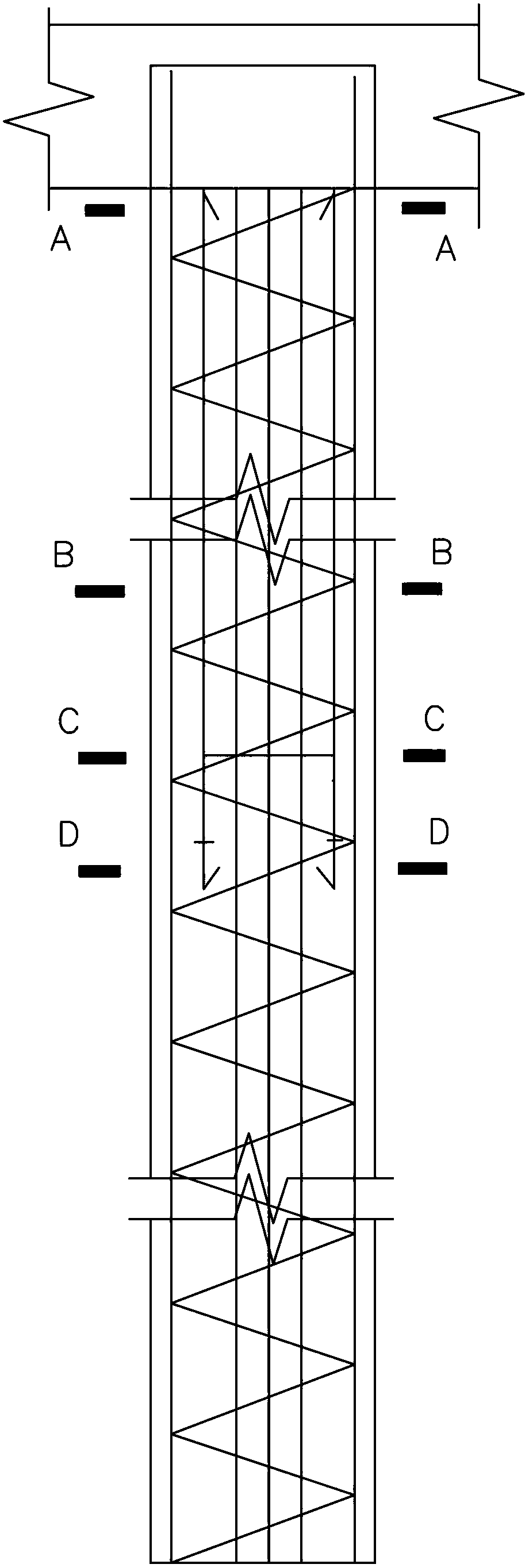

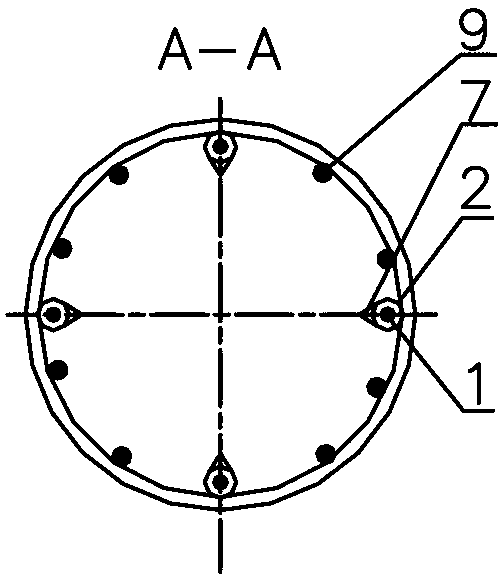

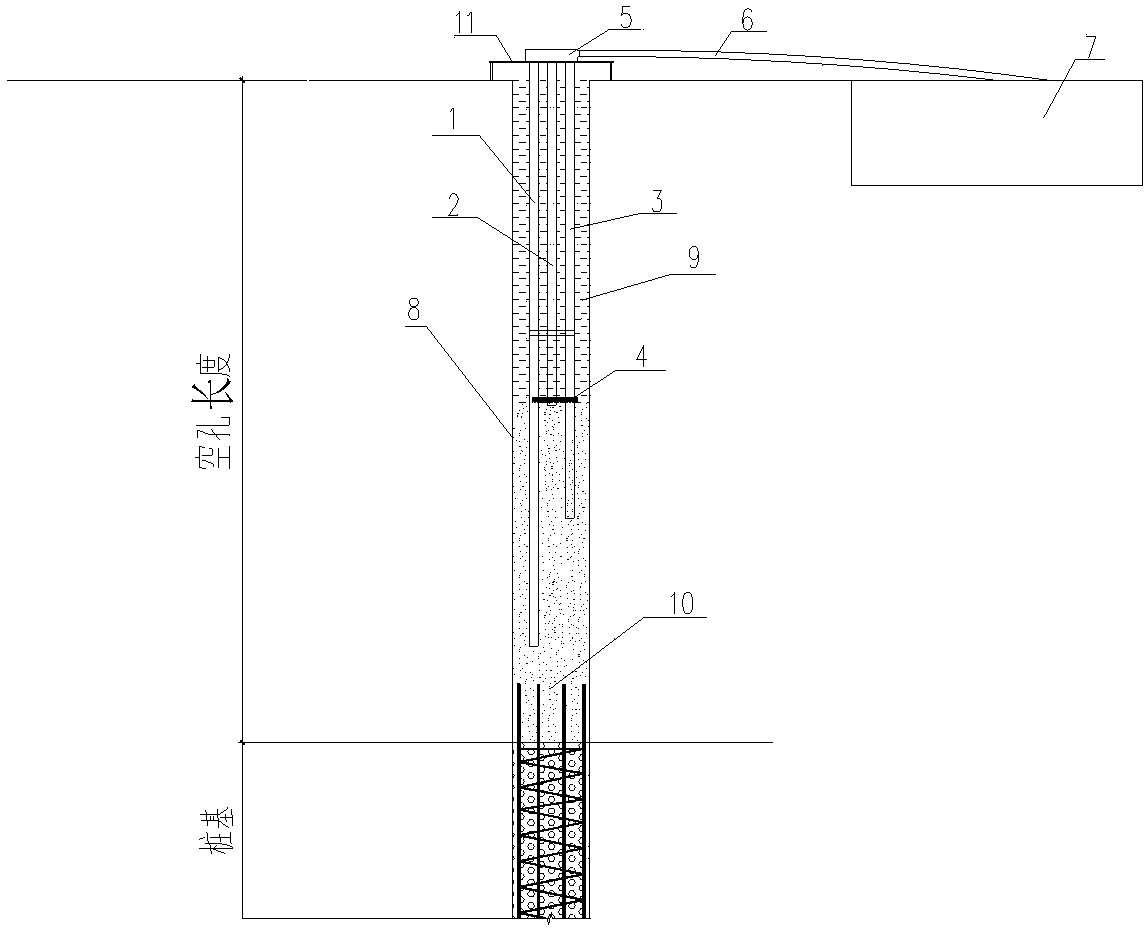

Replacement device and method for filler of empty hole part of bored pile

ActiveCN104234039AReduce back pressureEnsure safetyBulkheads/pilesEngineeringUltimate tensile strength

The invention provides a replacement device and method for a filler of an empty hole part of a bored pile. The device comprises n flow guide pipes, a flow guide trench, a bracket, a flexible pipe and a mud pit, wherein n is 1 when the length of the empty hole is 8-10 m; n is 2 when the length of the empty hole is 10-15 m; n is 3 when the length of the empty hole is 15-20 m; n is 4 when the length of the empty hole is 20-25 m; n is 5 when the length of the empty hole is 25-30 m; the bracket is used for fixing the end parts, close to the ground, of the n flow guide pipes; the end parts, close to the ground, of the n flow guide pipes are communicated with the flow guide trench; one end of the flexible pipe is connected with the flow guide trench, and the other end of the flexible pipe is connected with the mud pit. After the n flow guide pipes of different lengths are placed in the empty hole, sandy oil is used as the filler and fills the empty hole to replace mud in the hole so as to realize compact filling in the empty hole and certain strength and guarantee the quality and the safety of the subsequent construction; the device and the method have the advantages of easiness and convenience in construction, low cost, no influence on the construction period, obvious effect and energy conservation and environment protection effects.

Owner:CHINA FIRST METALLURGICAL GROUP

Dredged Soft Soil Foundation Treatment Method Simultaneously Developed by Filling and Reinforcement

ActiveCN102817354BAvoid entry problemsShorten the drainage distanceSoil preservationDrainage networkBuilding construction

The invention relates to the field of building foundations, in particular to a method for dredging a soft foundation by dredger fill and reinforcement. The method includes: a, zoning for dredger fill; b, forming a primary drainage system; and c, performing layered and zonal filling and reinforcement. The method is characterized in that in zoning for dredger fill, each filling unit (11) is 20000m<2>-50000m<2> in area; in formation of the primary drainage system, digging crisscross blind ditches (31) on the surface of the filling unit (11), and laying corrugated filter pipes (32) and drain boards (33) on the surface for the filling unit (11); and in layered zonal filling and reinforcement, filling the filling area (1) level by level, and reinforcing with all levels of drainage networks. The method is convenient in construction, short in construction period, effective in foundation treatment and low in construction cost.

Owner:BAOSTEEL ENG & TECH GRP

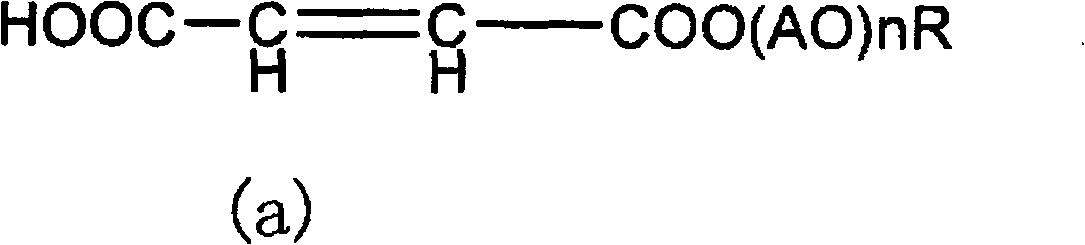

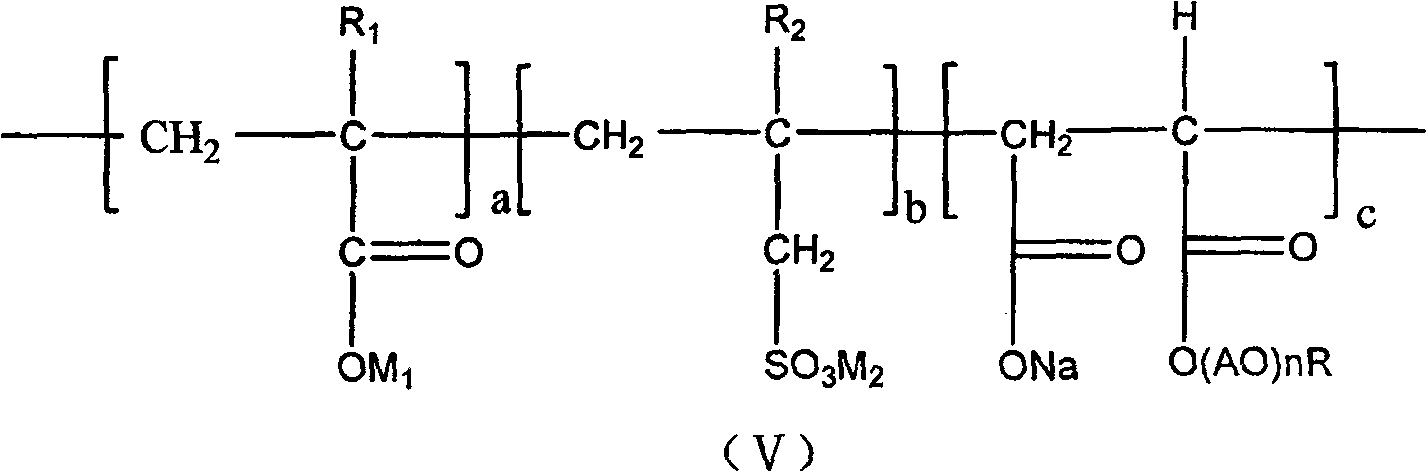

Design and preparation of coagulation time controllable high performance polycarboxylic acid water reducing agent

The invention relates to the design and synthesis of a poly carboxylic acid water reducing agent, the coagulating time of which can be controlled. The poly carboxylic acid water reducing agent is prepared by co-polymerize the following three monomers in water: the monomer a occupying 30 to 70 percent and indicated by a general expression 1, the monomer b occupying 10 to 50 percent and indicated by the general expression 2, and the monomer c occupying 10 to 40 percent and indicated by the general expression 3. The coagulating time is controlled by the monomer a which is made by condensing maleic anhydride and polyoxyethylene monoalkyl ether. The length of a polyoxyethylene monoalkyl ether chain controls the change of the coagulating time: the longer the chain, the shorter the coagulating time is; and the shorter the chain is, the longer the coagulating time is. The monomer a does not contain inhibitive substances in the process of synthesis, therefore, the water reducing agent is easy to be controlled in the coagulating process. The poly carboxylic acid water reducing agent is suitable for the construction of concrete under different temperature conditions: under higher temperature, the water reducing agent with longer coagulating time can be adopted, and under lower temperature, the water reducing agent with shorter coagulating time can be adopted. The poly carboxylic acid water reducing agent has good adaptability to cement and admixtures and has the advantages of low mixing quantity, good slump constant hold facility and water segregation resistance, and the like.

Owner:武汉格瑞林建材科技股份有限公司

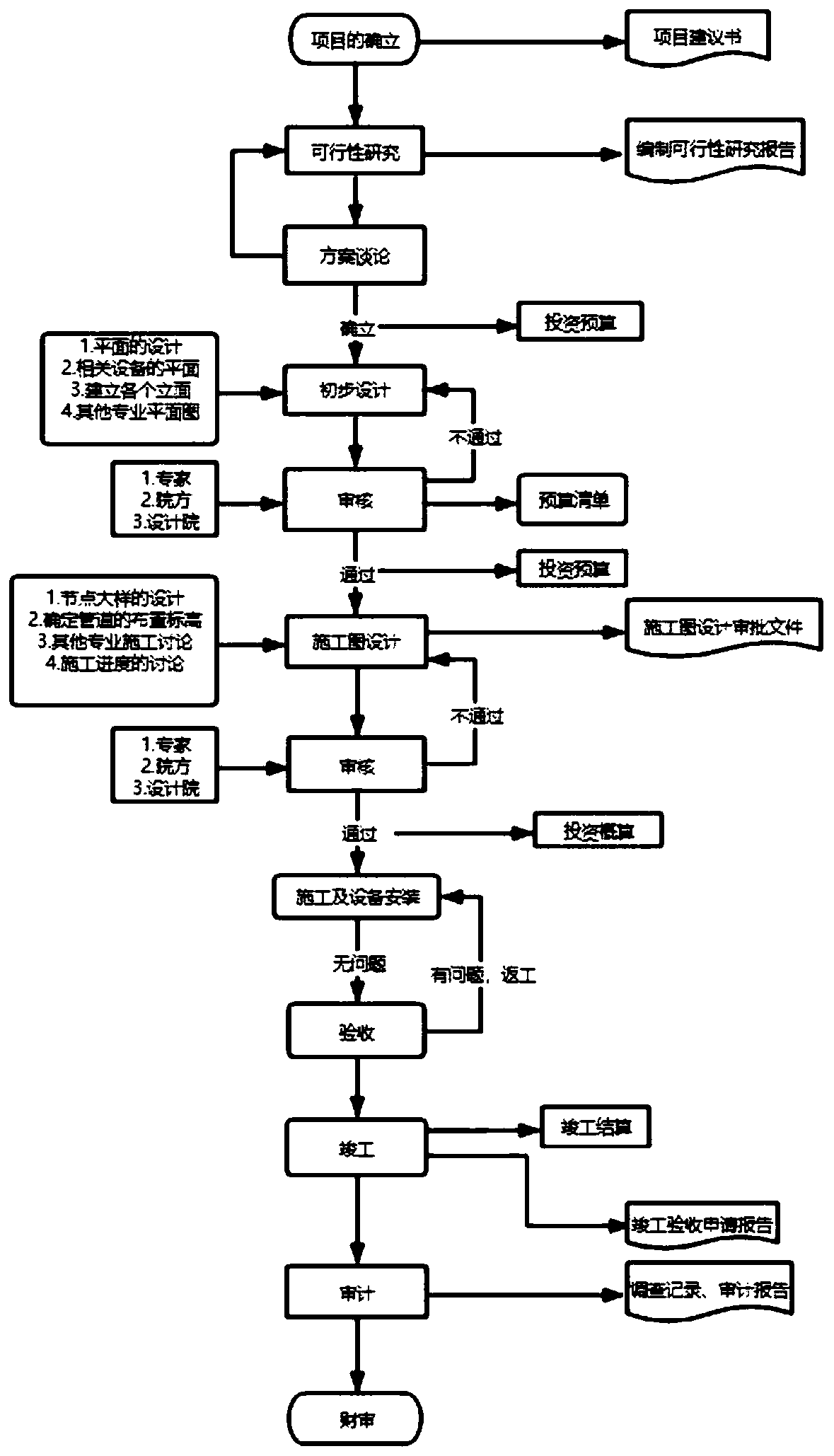

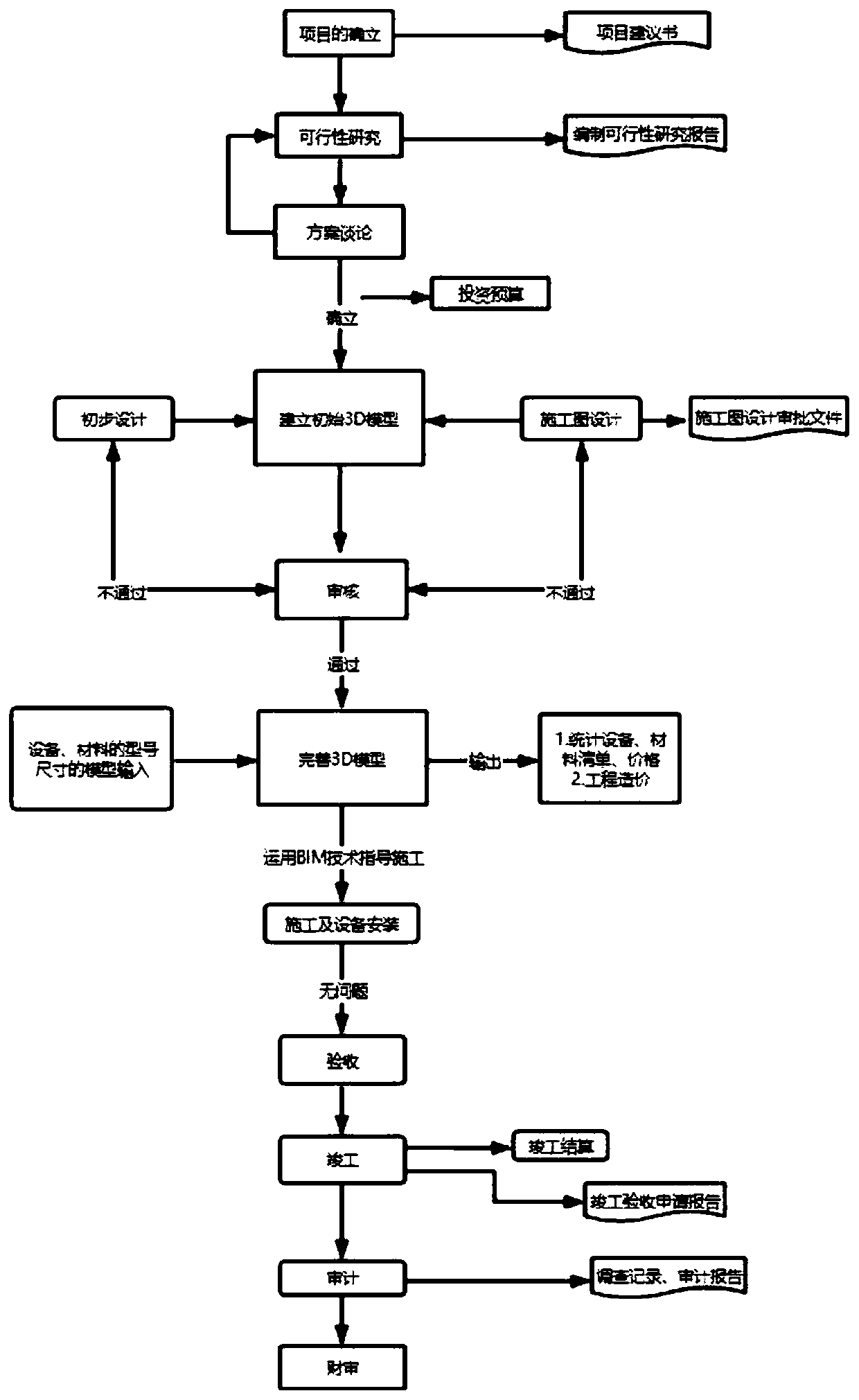

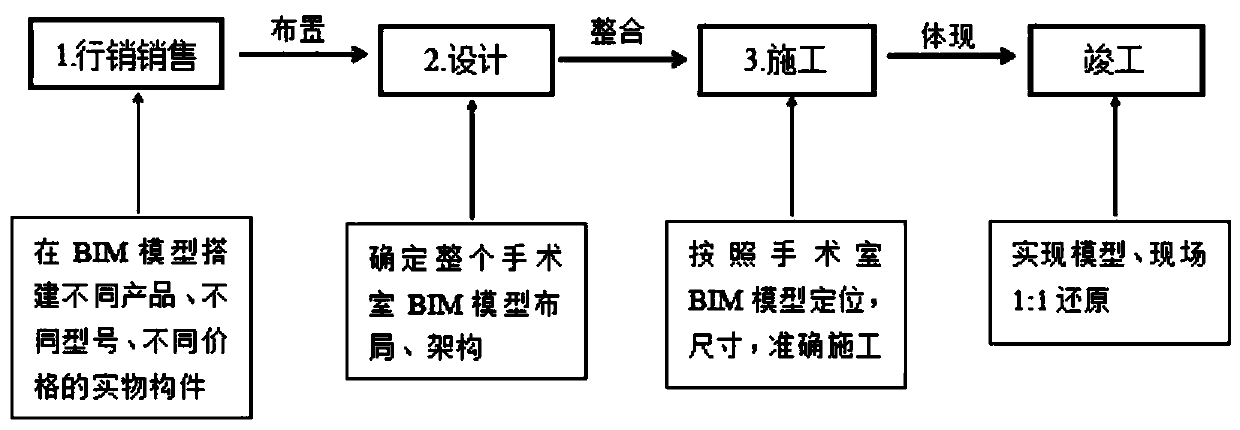

Modeling method for clean operating room based on BIM technology

PendingCN111539614AGood predictabilityGood coordinationGeometric CADOffice automationVisualizationModelSim

The invention discloses a modeling method for a clean operating room based on a BIM technology, and relates to the technical field of medical purification engineering. The method comprises the following steps: S1, establishing a project, and compiling a project proposal; S2, performing feasibility study on the project, and compiling a feasibility study report; S3, discussing a project scheme; S4,after the discussion is passed, establishing an initial 3D model; S5, checking the model; S6, perfecting the 3D model after the auditing is passed; S7, operating the BIM technology to guide project construction and equipment installation; S8, checking and accepting the project, and completing the project; and S9, auditing the project, and carrying out financial accounting. The modeling method provided by the invention has the characteristics of visualization, good coordination, predictability, simplicity and drawability.

Owner:福建阿斯兰医疗科技有限公司

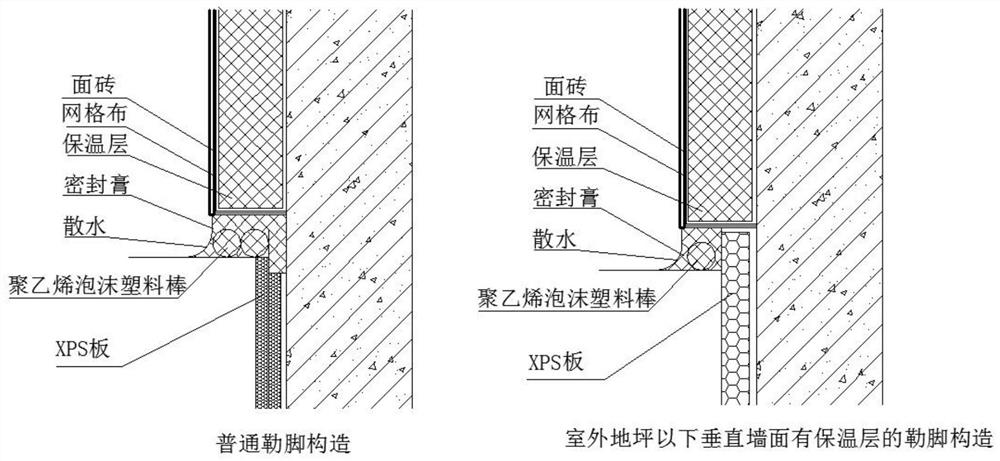

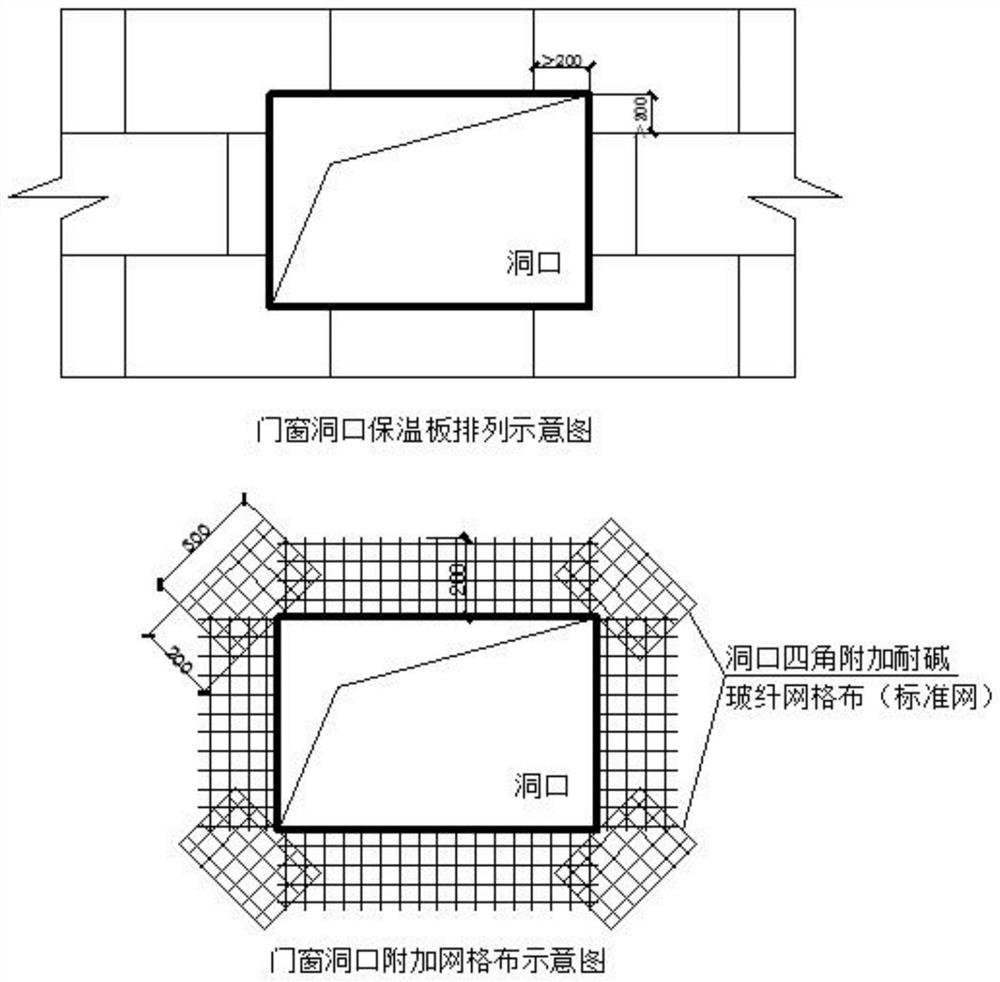

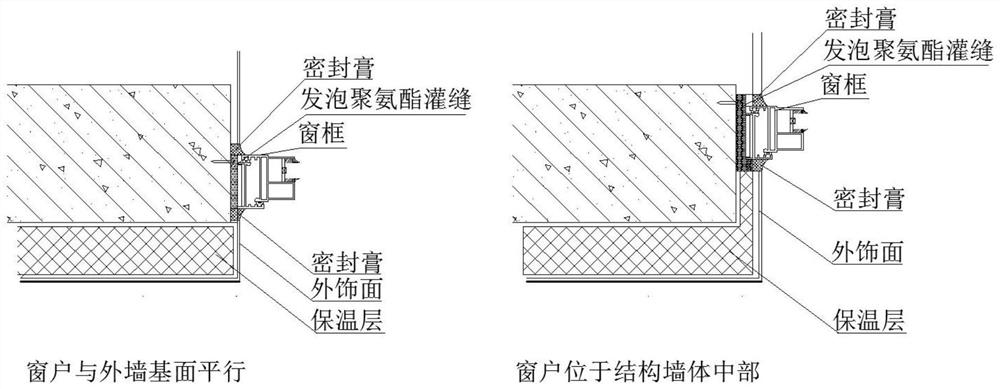

Construction method of outer wall external thermal insulation key joint

InactiveCN113235767ASimple structureClear forceWallsHeat proofingThermal bridgeArchitectural engineering

The invention discloses a construction method of an outer wall external thermal insulation key joint. The outer wall external thermal insulation key joint comprises a plinth, a door window, a balcony, a deformation joint, a roof parapet wall, an externally-hung decoration part, a fireproof isolation belt and an outer wall corner. A door and window joint comprises a door and window opening, a side opening, a window lower opening and a window upper opening. A deformation joint comprises an expansion joint flush joint, a corner joint, an anti-seismic settlement joint flush joint, a corner joint, a vertical joint and a horizontal joint. Seam joints of all thermal insulation key joints are caulked through thermal insulation materials and then plugged through sealant, gridding cloth is additionally arranged at the ends of thermal insulation plates of the key joints for reinforcement, a drainage slope is arranged on the structure to prevent water stored on the thermal insulation materials from being damaged, and dripping water is arranged for rainwater diversion to prevent the thermal insulation plates from being damaged. The problems of damage, cracking, hollowing and the like of insulation boards at key joints of a part of outer wall external insulation systems in severe cold areas are effectively solved.

Owner:CHINA MCC17 GRP

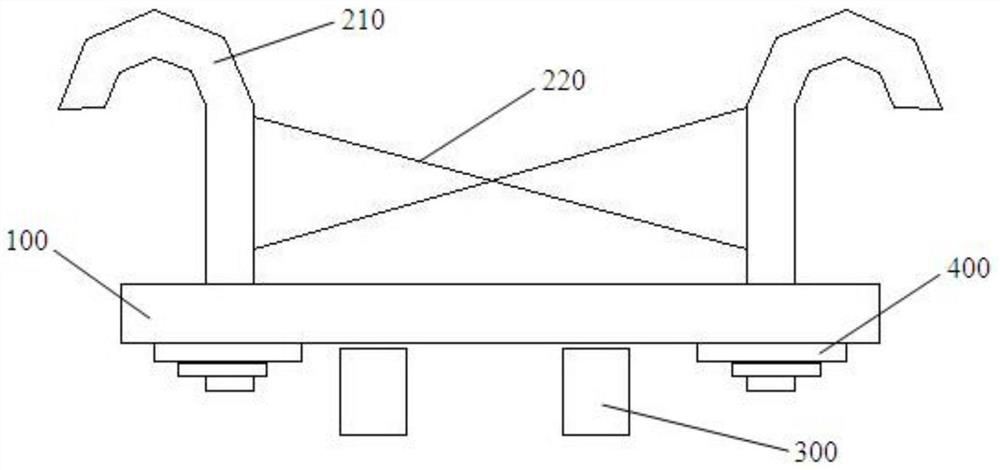

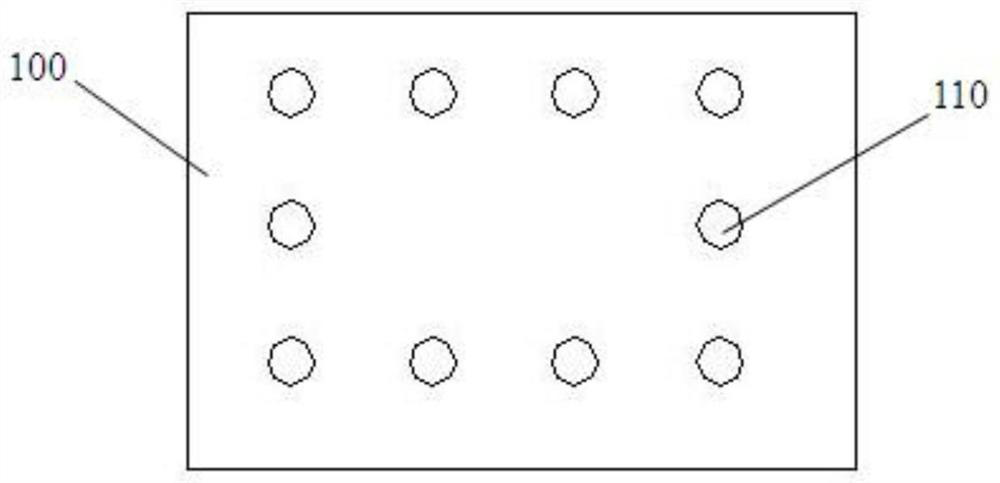

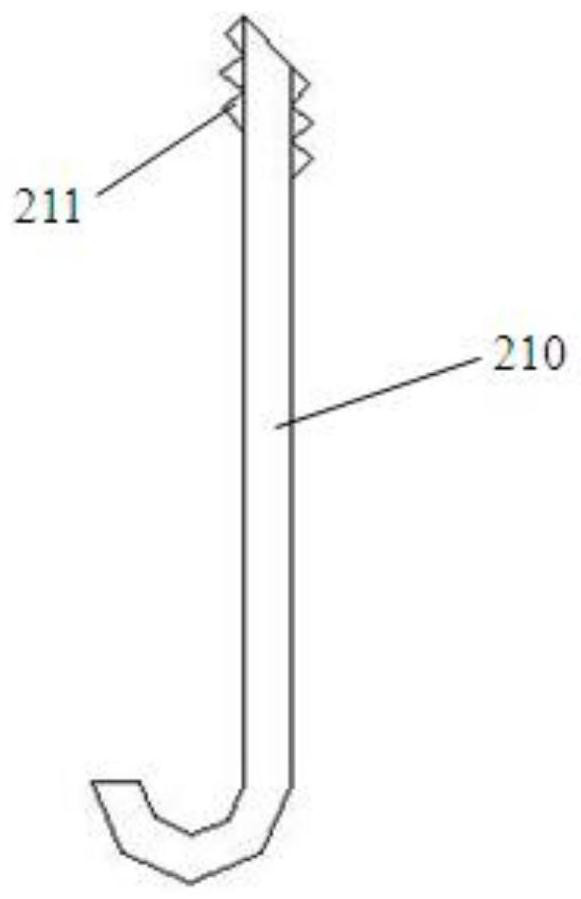

Steel structure foundation embedded bolt structure and construction method thereof

PendingCN111851754AImprove integrityFast constructionBuilding constructionsConstruction engineeringRebar

The invention discloses a steel structure foundation embedded bolt structure and a construction method thereof. The steel structure foundation embedded bolt structure comprises a positioning plate, wherein a plurality of positioning drilling holes allowing embedded parts to penetrate through are formed in the positioning plate; the embedded parts are fixedly connected on the positioning plate; a plurality of connecting steel bars are fixedly connected among the embedded parts; and the embedded parts and the connecting steel bars form an integral embedded part structure. According to the construction method, the construction manufacturing and installation of the steel structure foundation embedded bolt structure are achieved, the whole embedded part structure can be independently manufactured, the integrity is good, the processing can be carried out at any time, the construction speed is high, and the construction method cannot be limited by sites, and cannot be affected by the construction steps and the construction progress on a bearing platform. The embedded bolt structure can be quickly installed after binding with steel bars at the bottom of the bearing platform, the construction period cannot be affected, and the construction period process is favorably accelerated.

Owner:GUANGZHOU HOUSES DEV CONSTR +2

Method for repairing ground surface settlement or underground pipe deformation on outer side of foundation pit enclosure wall

PendingCN114687345AReset is highly targetedReduce consumptionExcavationsBulkheads/pilesMonitoring siteCement grout

The invention discloses a method for repairing ground surface settlement or underground pipe deformation on the outer side of a foundation pit enclosure wall, which comprises the following construction steps of: arranging a plurality of monitoring points on the ground surface on the outer side of the foundation pit enclosure wall, monitoring equipment is adopted to timely obtain a ground surface soil body settlement value on the outer side of a foundation pit enclosure wall or an underground pipe deformation settlement value or an underground pipe deformation horizontal movement value when the foundation pit is excavated; according to the height position, the transverse position and the horizontal direction or the inclined direction which are obtained according to the monitoring values and need to be repaired, the position and the direction of a construction hole in the foundation pit support wall are determined; a drilling machine is adopted for drilling holes, grouting pipes, anchor rods and a plurality of geotechnical cloth bags extending in the axial direction are placed, each geotechnical cloth bag is filled with cement grout through grouting, and the solidified grouting bodies form a set of grout bags so as to lift earth surface sinking soil bodies on the outer side of a foundation pit or reset deformed underground pipes. According to the method, construction is not conducted on the earth surface on the outer side of the foundation pit, grouting is highly targeted to lifting recovery of the earth surface or resetting of the underground pipe, and the recovery or resetting effect is good.

Owner:浙江华展研究设计院股份有限公司

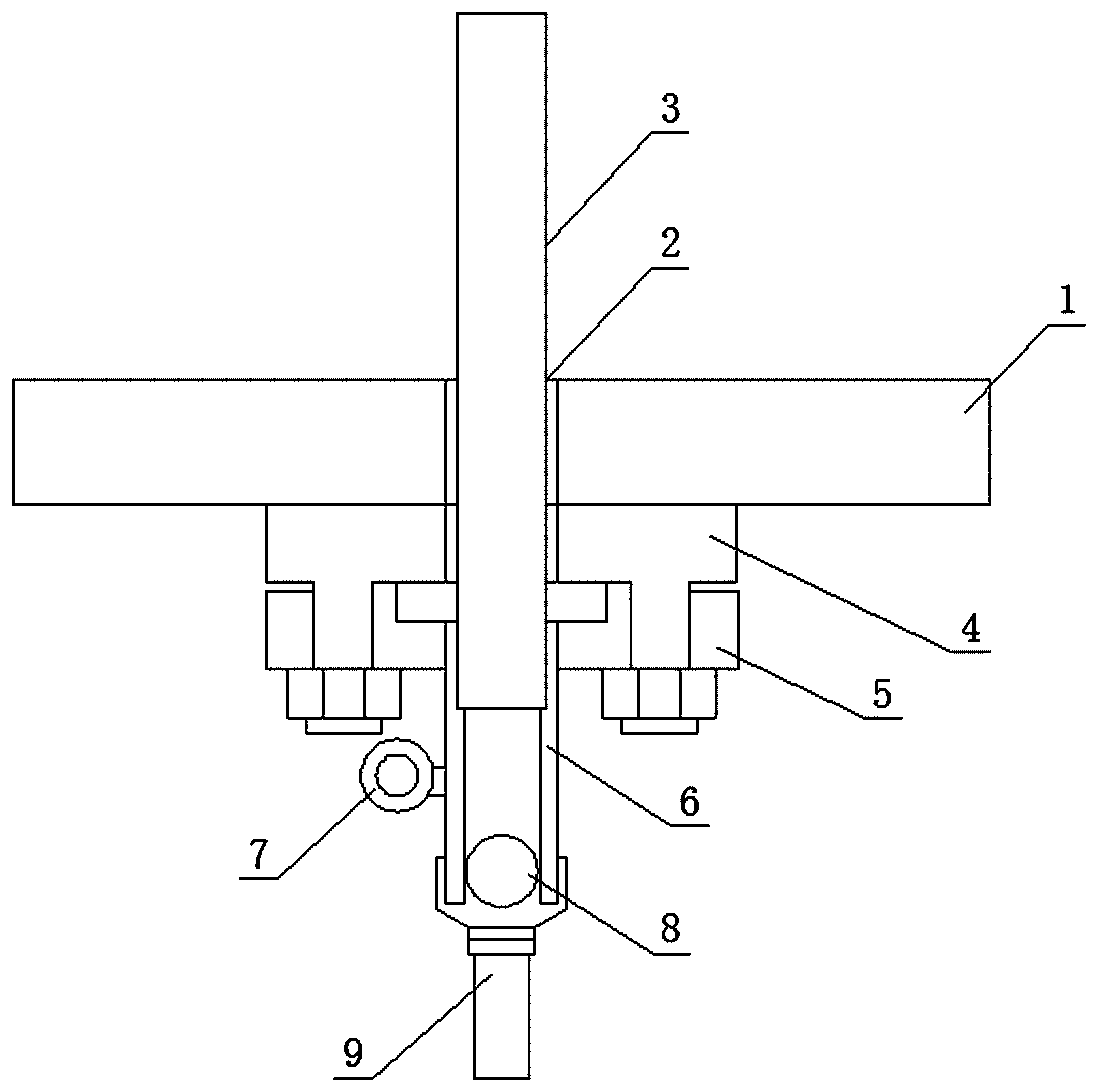

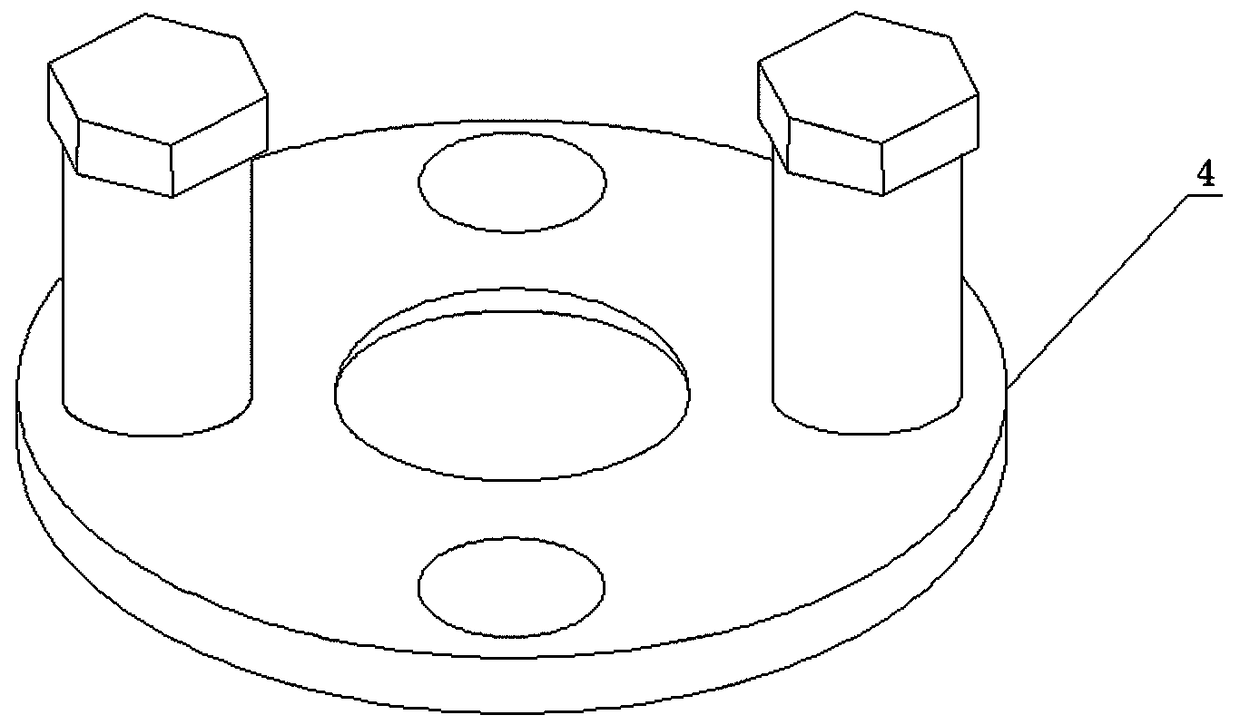

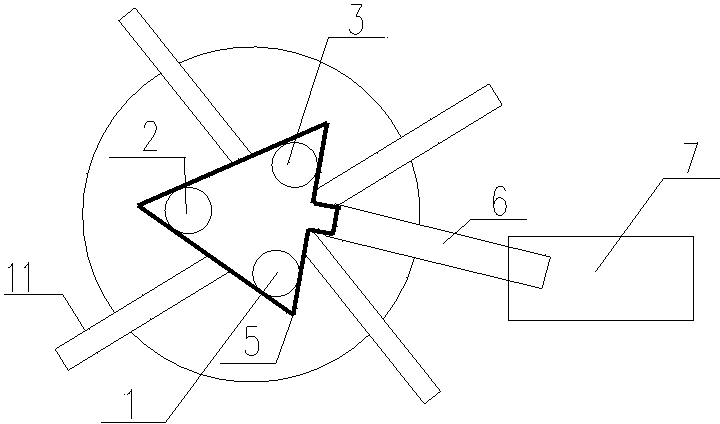

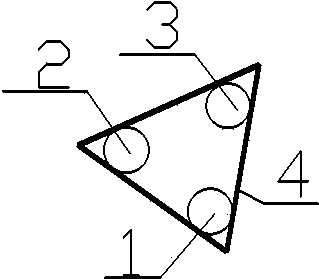

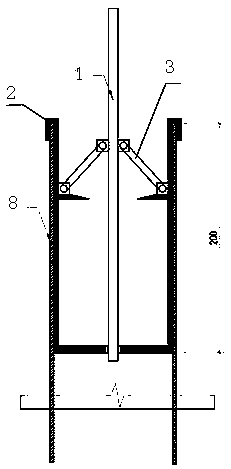

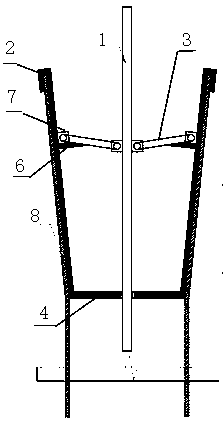

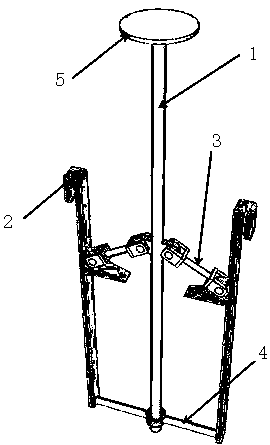

Automatic head-expanding device of side slope support water drain pipe and construction technology for increasing water facing surface

The invention discloses an automatic head-expanding device of a side slope support water drain pipe and a construction technology for increasing a water facing surface. Four symmetrical vertical openings are sawed on a pipe head of the PVC water drain pipe by an electric saw, a mechanical expander is installed, the left and right ends of a sliding fixed rod are respectively connected with a pipe wall fixed plate, the pipe wall fixed plate is connected with a vertical force-bearing rod through a lateral thrust and force transferring rod, and the vertical force-bearing rod passes through the central hole of a circular pipe of the sliding fixed rod; a limiting baffle and a hinged transmission fixed support are arranged at the 2 / 3 position of the upper end of the pipe wall fixed plate, the twoends of the lateral thrust and force transferring rod are connected with the hinged transmission fixed support of the pipe wall fixed plate and a connecting rod support of the vertical force-bearingrod; a layer of water filtering fiber net is wrapped in the range of 250 mm at the bottom of the pipe, and then the net is tied up and fixed by a ribbon around the outer wall of the pipe; by applyingpushing force to the bottom of the pipe, the mechanical expander at the bottom of the pipe can expand the pipe wall in the range of 20 cm at the pipe bottom to the two sides, the expanded pipe wall withstands the soil of the hole wall, the expanded pipe wall expands the water filter net together, the maximum expanding width is increased by 4 cm, the pipe wall is sawed to 1 cm, the area of a waterseepage port is expanded and increased, and the water drain pipe is stabilized at the same time.

Owner:贵州建工第八建设集团有限公司

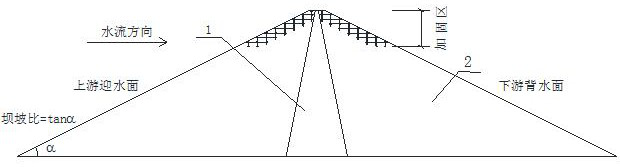

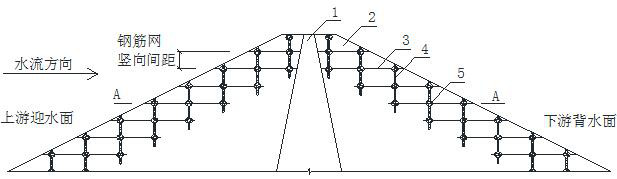

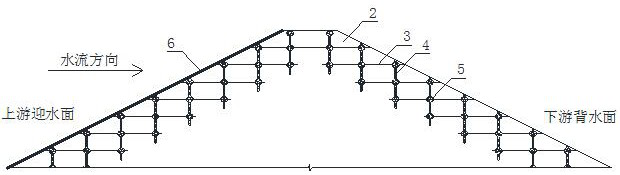

High earth-rock dam composite anti-seismic structure and construction method thereof

InactiveCN112681238AReduce loosenessReduce slipBarrages/weirsExcavationsEarthquake resistant structuresLandslide

The invention relates to a high earth-rock dam composite anti-seismic structure and a construction method thereof, and belongs to the technical field of water conservancy projects. The high earth-rock dam composite anti-seismic structure comprises a rockfill structure composed of rockfill which is filled from bottom to top, wherein the longitudinal section of the rockfill structure is trapezoidal; a reinforcing mesh is horizontally laid between every 4-6 meters of rockfill; the surface of each whole reinforcing mesh is covered with a neutral glass cement layer; a plurality of high polymer rockfill composite piles are arranged in the area from the central axis of the rockfill structure to the outer circumference of the rockfill structure; the high polymer rockfill composite piles and the rockfill are bonded into a whole; an expansion pile is arranged at the position, close to the corresponding reinforcing mesh, of each high polymer rockfill composite pile; the outer diameter of each expansion pile is larger than that of the corresponding high polymer rockfill composite pile; and the expansion piles, the high polymer rockfill composite piles and the reinforcing meshes are bonded into a whole. According to the high earth-rock dam composite anti-seismic structure and the construction method thereof, flexible three-dimensional reinforcement is adopted, the high earth-rock dam composite anti-seismic structure can well adapt to dam body deformation, loosening and sliding of the rockfill in the dam top area under the earthquake action are reduced, formation of shallow landslide is inhibited, and therefore the anti-seismic performance of a high earth-rock dam is improved.

Owner:LUDONG UNIVERSITY

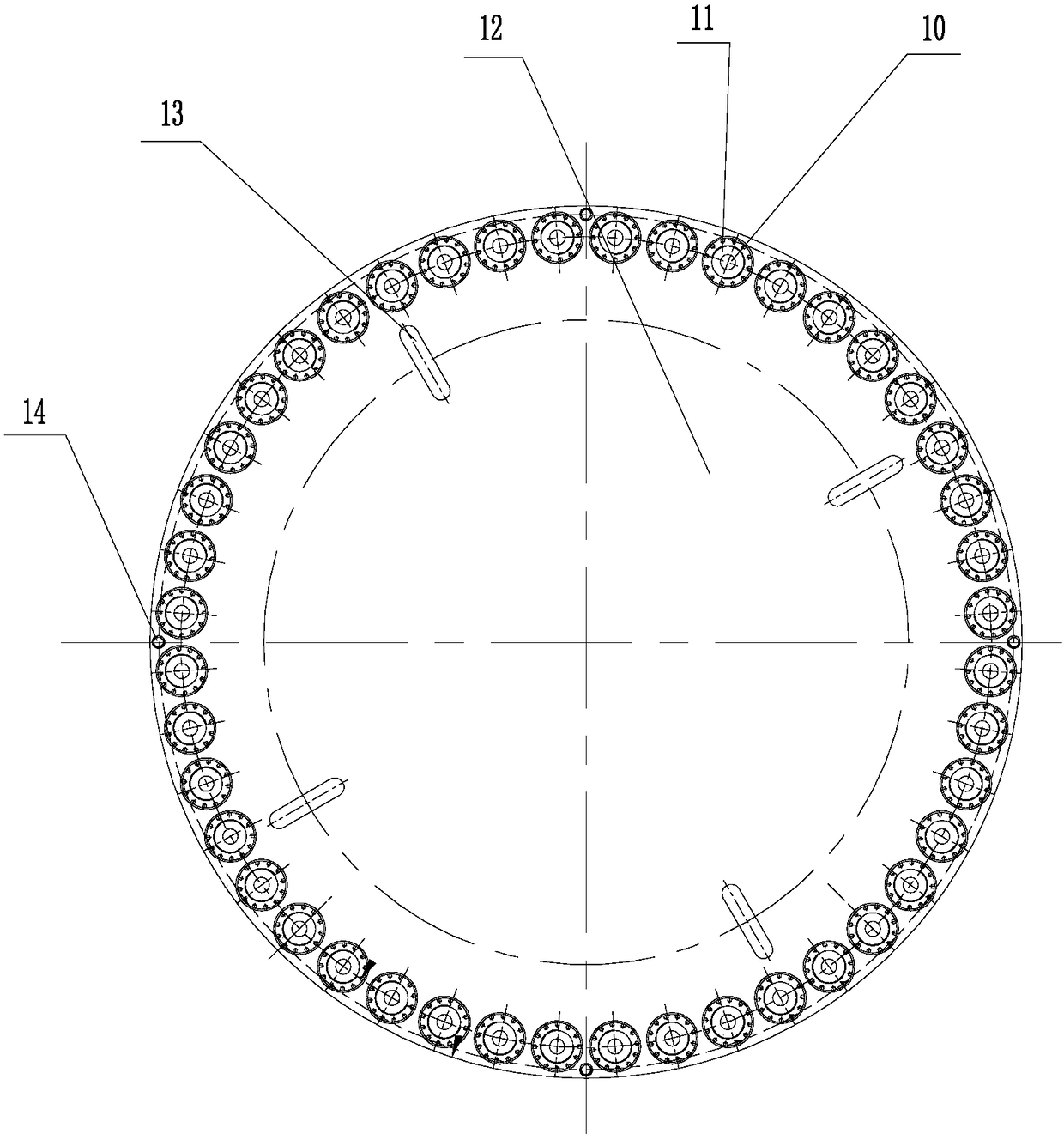

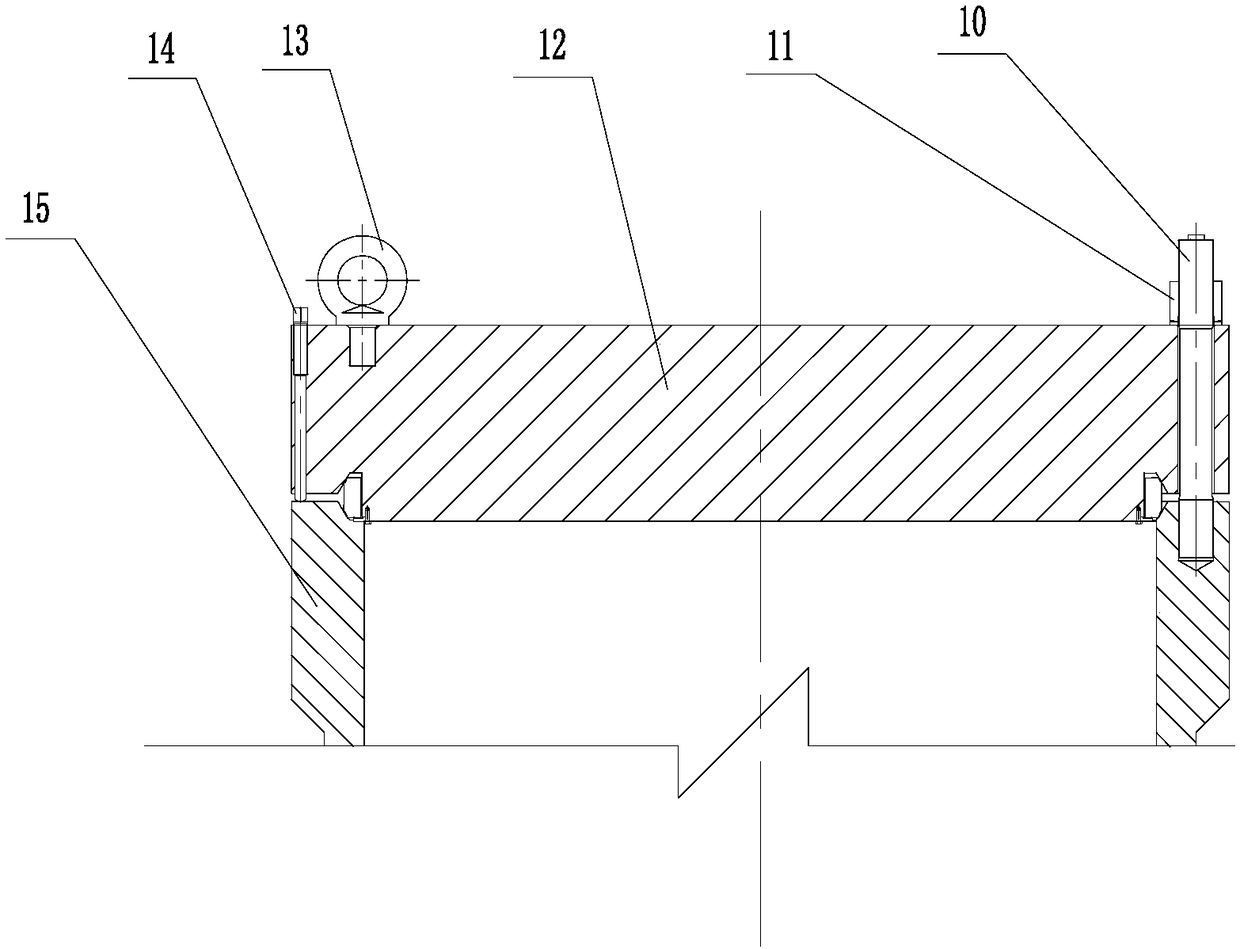

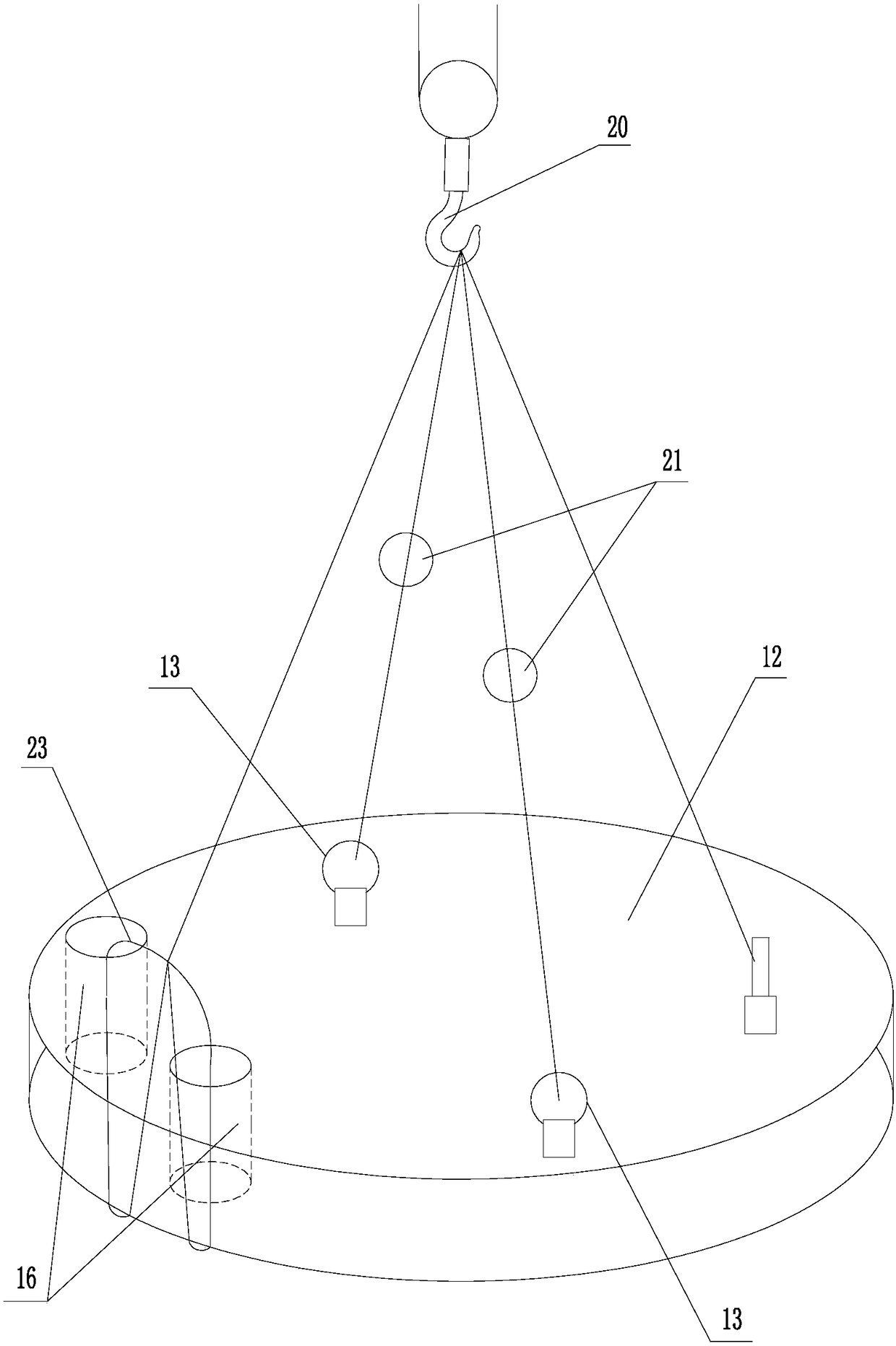

Method for hoisting heavy large covers for towers

The invention discloses a method for hoisting heavy large covers for towers by the aid of lifting rings. The method includes steps of detaching nuts; manufacturing 4 U-shaped gaskets I from steel plates with the sizes of 12 mm and manufacturing 56 U-shaped gaskets II from stainless steel plates with the thicknesses of 1mm; jacking the large covers by the aid of jackscrews; dividing the gaskets I and II into four groups; firmly bundling non-U-shaped groove ends of the corresponding gaskets I and II to form a first gasket group, a second gasket group, a third gasket group and a fourth gasket group; placing the first gasket group, the second gasket group, the third gasket group and the fourth gasket group in gaps between each large cover and a barrel; detaching connecting bolts near damaged cotter lifting rings and exposing bolt holes; symmetrically hanging two hand pulling blocks on two undamaged cotter lifting rings; allowing two ends of perforation binding steel wire rope to penetrateeach bolt hole and fastening every two corresponding tip noses with each other; folding and hanging steel wire ropes on the perforation binding steel wire ropes; hanging the hand pulling blocks and the steel wire ropes on lifting hooks and lifting the large covers; placing the large covers on ground sleepers; completely carrying out maintenance and reassembling the large covers. The method has theadvantages that the method is easy to operate and free of risks, and is safe and reliable, smooth maintenance work can be guaranteed, and influence on maintenance construction periods can be prevented.

Owner:CHINA NAT CHEM ENG THIRD CONSTR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com