Bonded post-tensioned prestressed anchoring construction method for cast-in-place concrete structure

A technology of pouring concrete and post-tensioning prestressing, which is applied in the field of concrete structure rods or walls, can solve the problems that the anchoring effect cannot be guaranteed, and achieve the effects of durability guarantee, steel saving, and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

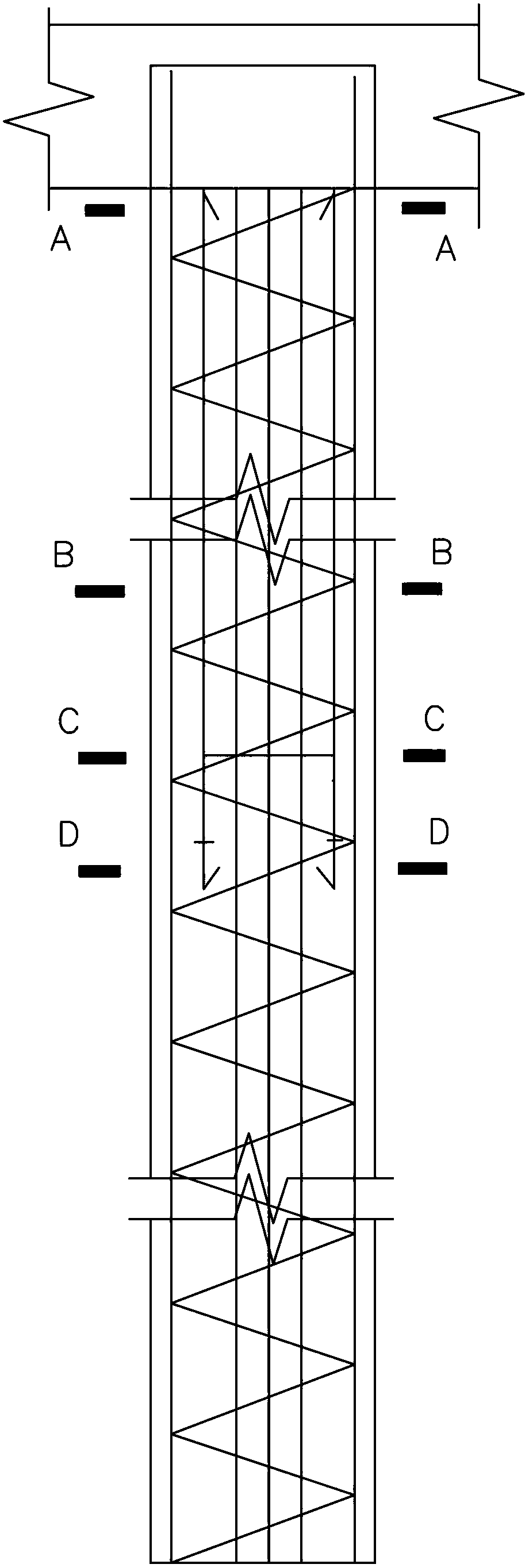

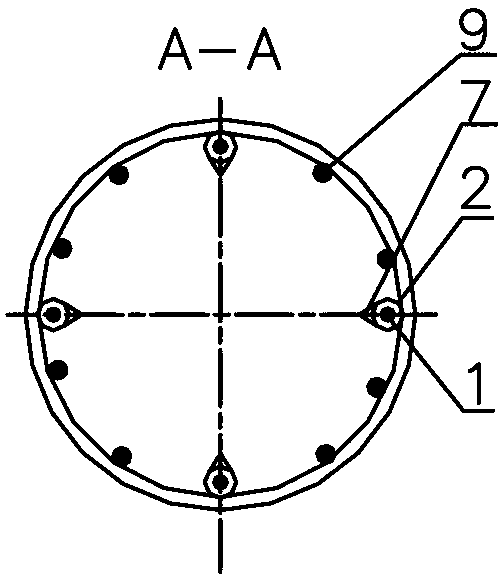

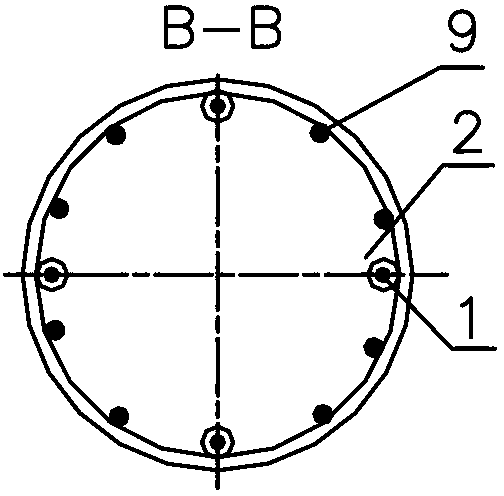

[0054] The pouring concrete structure of the present invention has bonded post-tensioning prestressed anchorage construction method, which solves the cracks caused by the buoyancy of groundwater to the tensile stress of the reinforced concrete structure of the underground building, and at the same time makes the tensioned prestressed steel strand permanently bonded with the concrete . It uses the design unit to design the reinforcement ratio of reinforced concrete structures in underground engineering, and determines the configuration of steel bars and prestressed steel strands and the design of prestressed length. The realization of prestressing is to make the steel cage of the underground structure, place the steel check valve at the bottom of the steel conduit, connect the steel cage, cast the concrete in place, insert the prestressed steel strand, build the underground structure, wait for the concrete After the structure is formed and the maintenance period is reached, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com