Patents

Literature

455 results about "Buoyant force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The buoyant force. When an object is placed in a fluid, the fluid exerts an upward force we call the buoyant force. The buoyant force comes from the pressure exerted on the object by the fluid. Because the pressure increases as the depth increases, the pressure on the bottom of an object is always larger than the force on the top - hence...

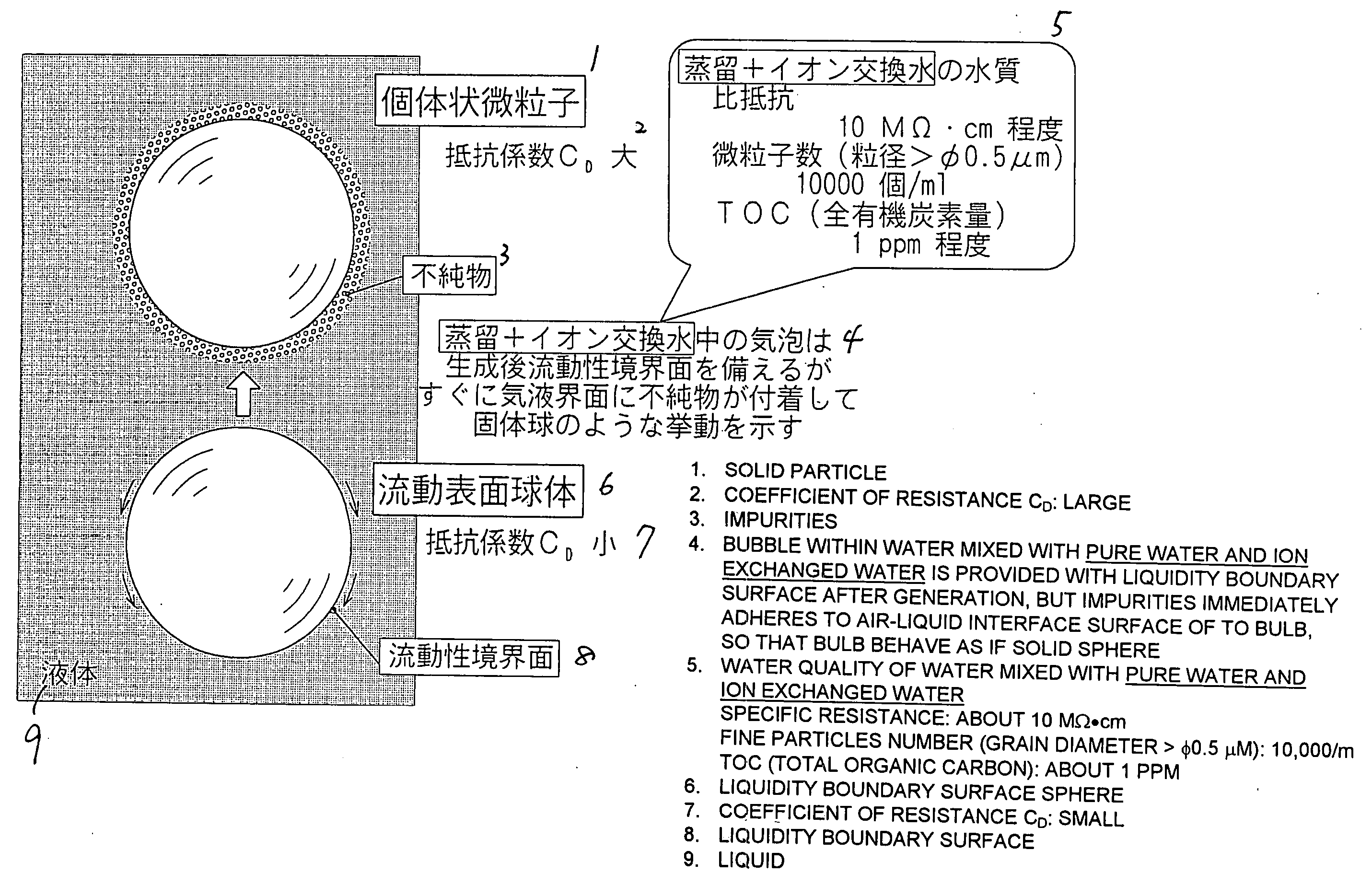

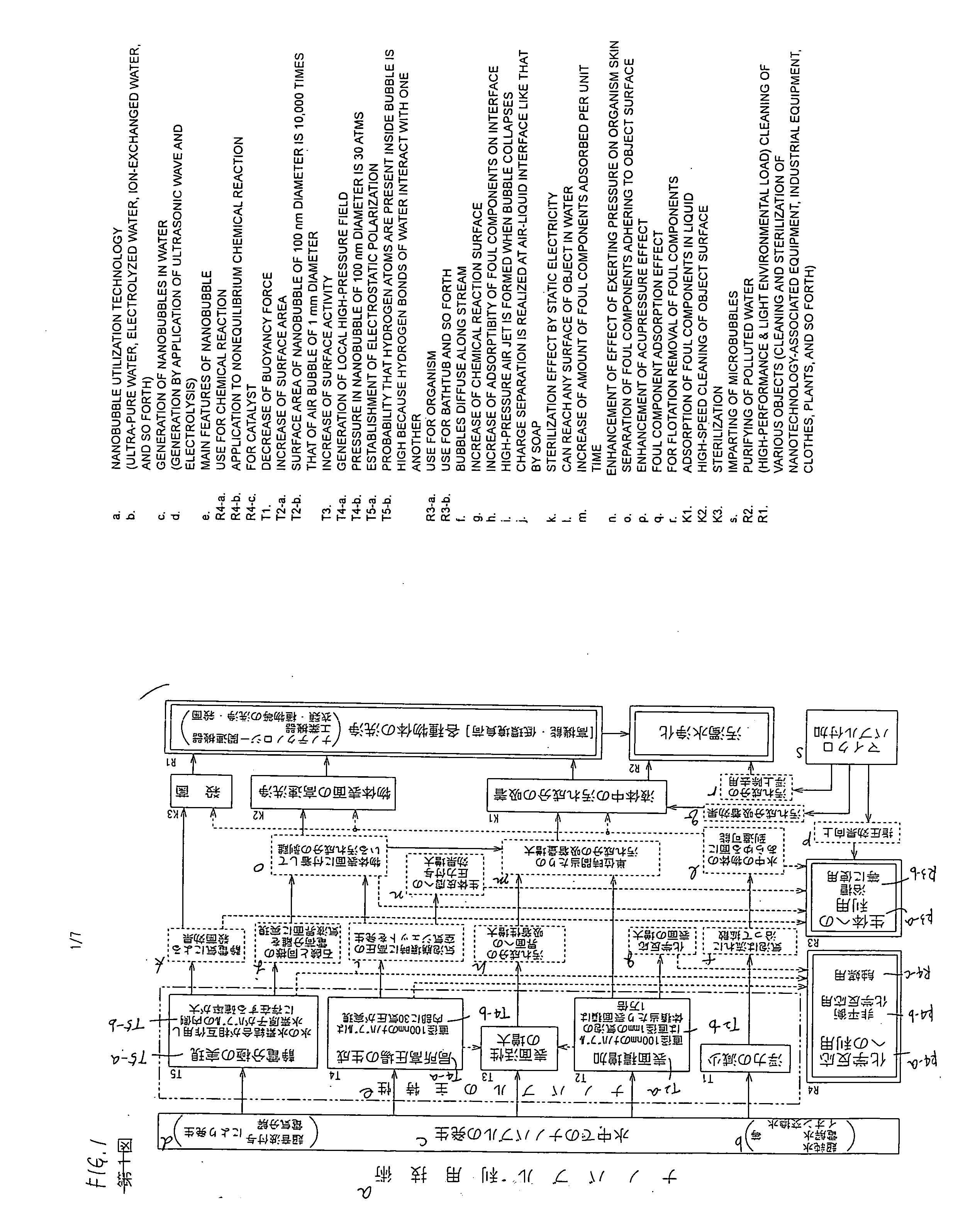

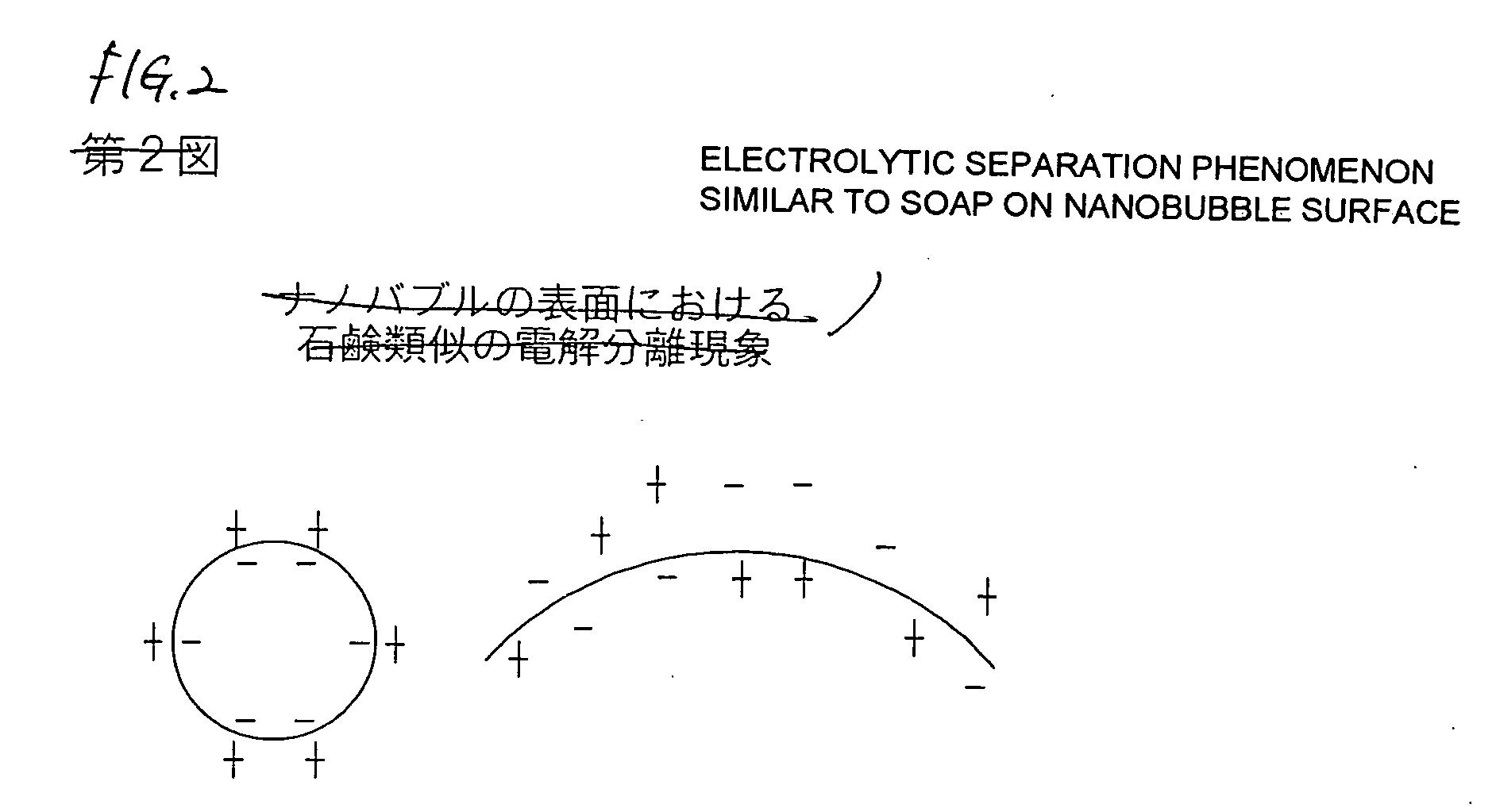

Nanobubble utilization method and device

InactiveUS20060054205A1Efficient use ofFast cleaningMaterial nanotechnologyVibration massageBiological bodyChemical reaction

The present inventors have found the presence of a nanobubble that has not been confirmed conventionally, and established a method for producing nanobubbles. The inventors have determined the theoretically expected characteristics of the produced nanobubbles, found new characteristics by analyzing data experimentally collected, and elucidated the relationship among the characters. Specifically, the inventors have found that a nanobubble has features such as decrease of the buoyant force, increase of the surface area, increase of the surface activity, generation of a local high-pressure field, interface activating action, and sterilizing action thanks to electrostatic polarization. By the association among the features, any of wide variety of objects can be cleaned with high performance and with light environmental load thanks to the function of adsorbing foul components, the function of cleaning the surface of an object quickly, and the sterilizing function, and polluted water can be purified. Nanobubbles can be applied to an organism to recover from fatigue and effectively used for chemical reactions.

Owner:NAT INST OF ADVANCED IND SCI & TECH

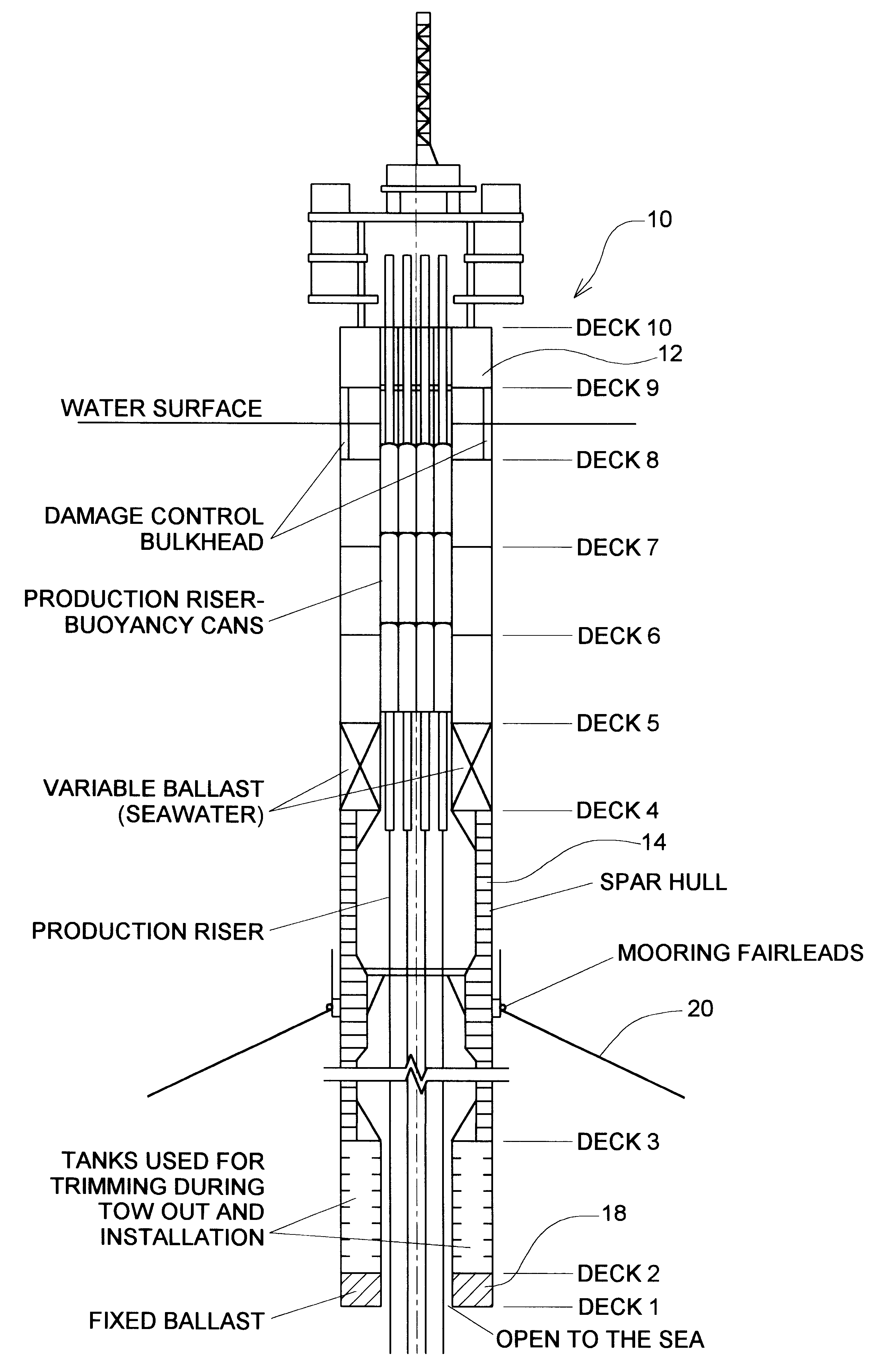

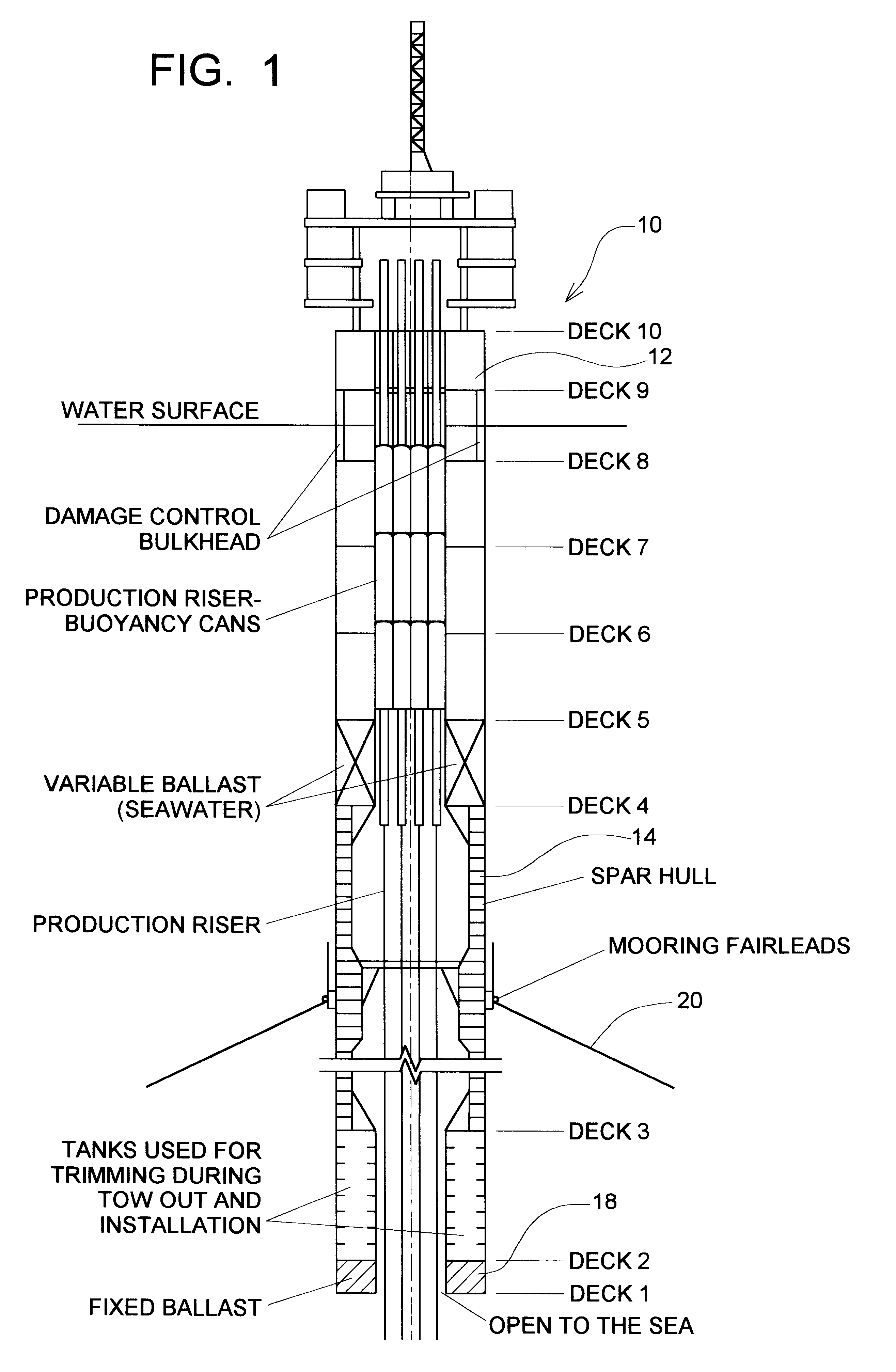

Flotation system and method for off-shore platform and the like

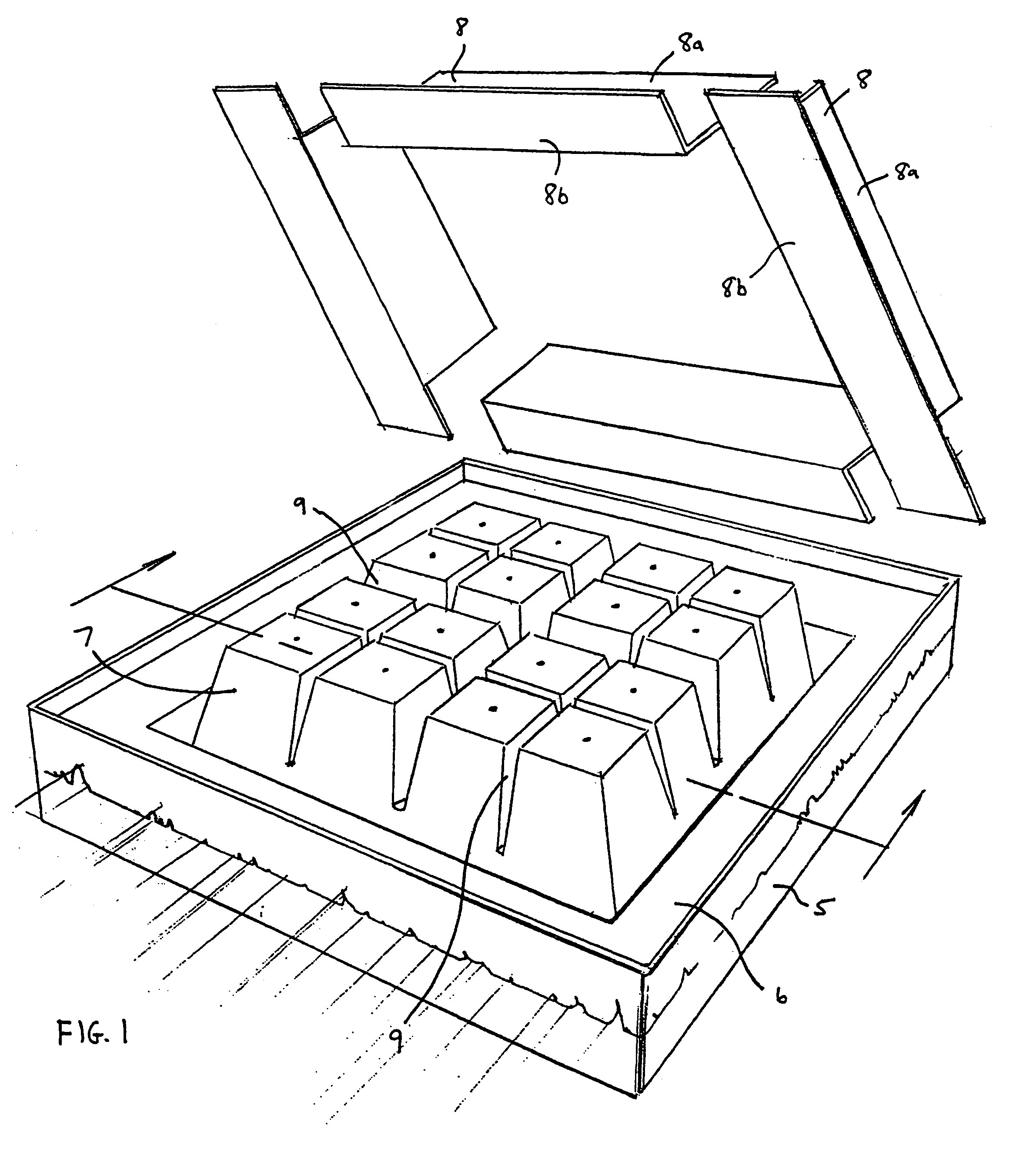

A flotation assembly made up of a load bearing structure which can be an off-shore platform, and also a flotation section comprising a plurality of flotation tubes. Each of the flotation tubes comprises a surrounding side wall defining a vertically aligned elongate pressure chamber and having an upper end closure portion that has a downwardly facing surface exposed to pressure in the chamber. The tubes are positioned at laterally spaced locations and arranged relative to the load bearing structure so as to create upwardly directed flotation forces that bear against the load bearing structure. A source of pressurized gas is transmitted to the flotation tubes to a level where the gas pressure within each tube creates a force against the side walls to alleviate compressive force of the surrounding water pressing inwardly against the side walls of the flotation tubes. There are various arrangements of the flotation tubes, and these are provided in various forms, either with closed lower ends, open lower ends exposed to ambient pressure, etc.

Owner:FIBERGLASS STRUCTURAL ENG

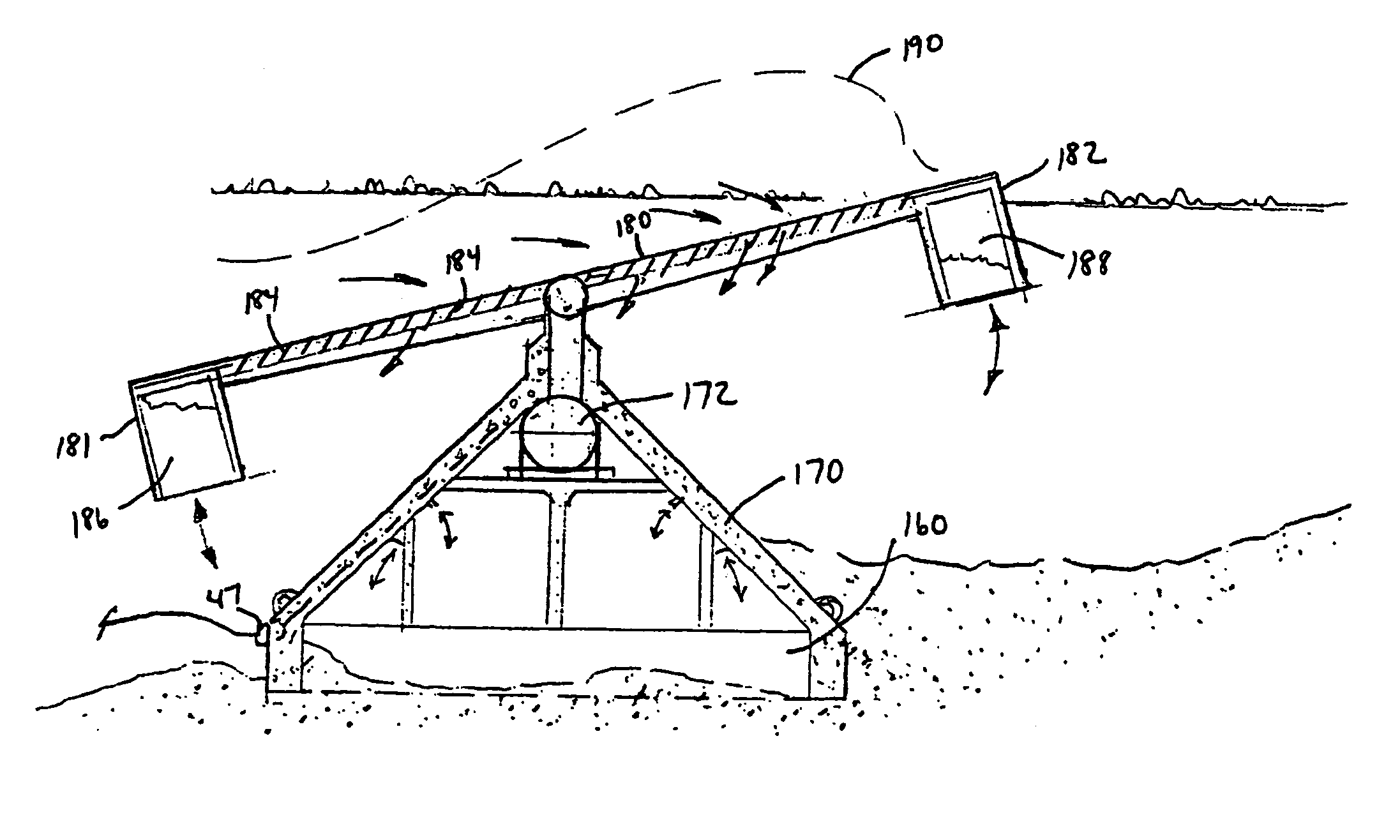

Breakwater

InactiveUS6935808B1Enhance abilityEasy and inexpensive to manufactureBreakwatersQuaysEngineeringBallast tank

Provided are static and free-floating breakwater apparatuses that utilize a rocking panel (or beach) to dissipate wave energy. At the same time, such rocking motion can in certain embodiments be used to generate electrical power. Generally speaking, the breakwater apparatuses use a buoyant element, such as an open-bottomed hollow chamber and / or a ballast tank to resist the wave's force.

Owner:DEMPSTER HARRY EDWARD

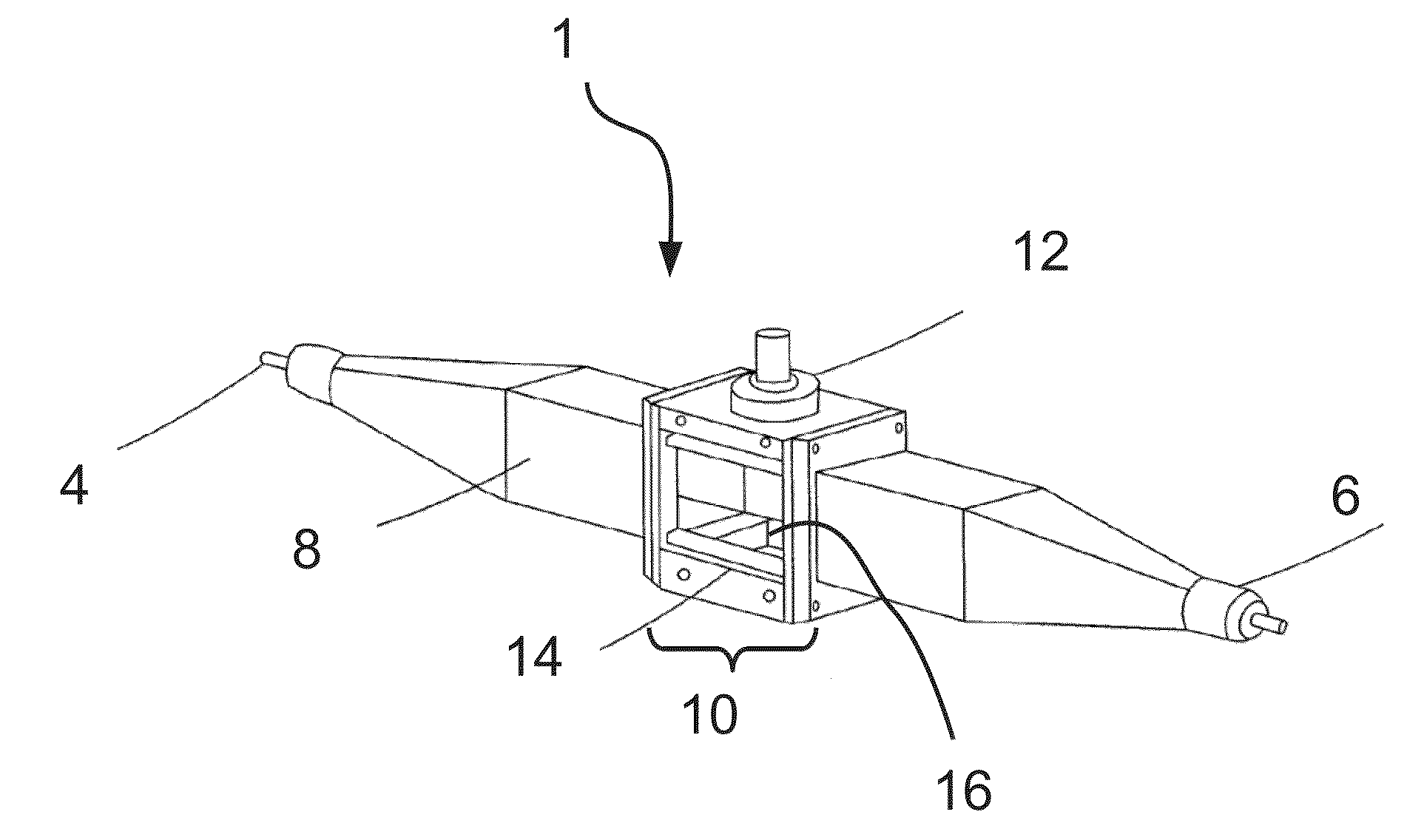

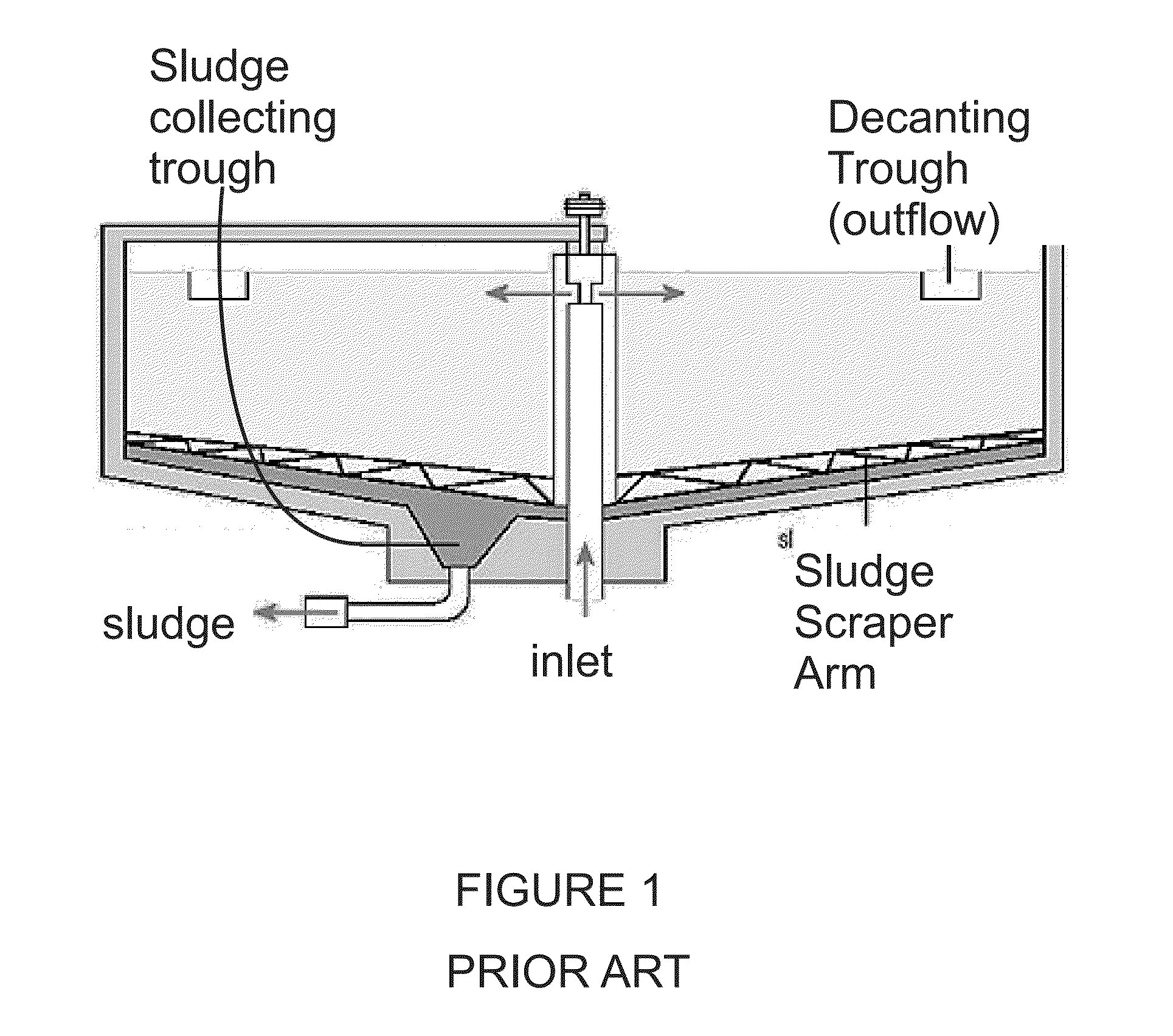

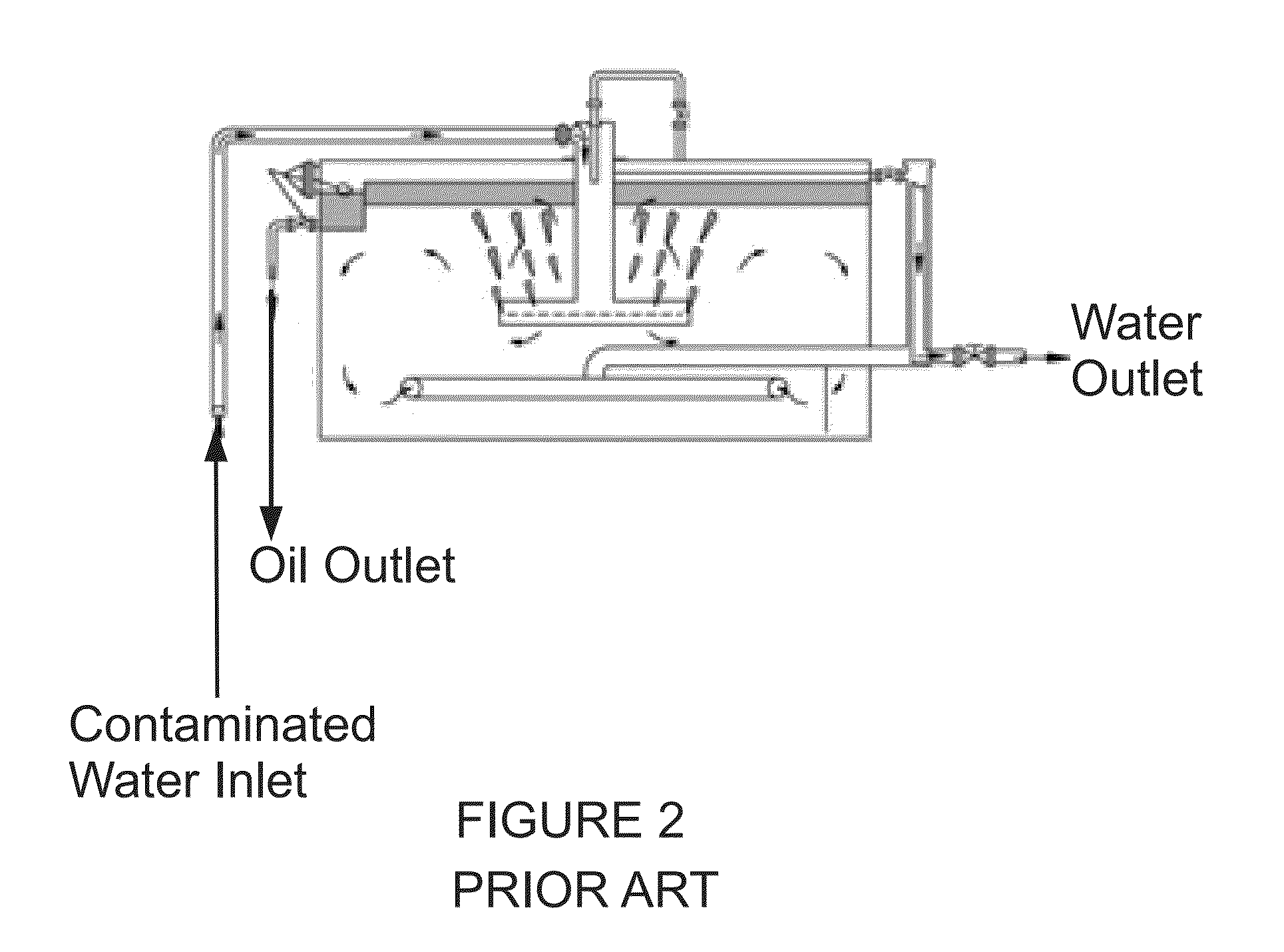

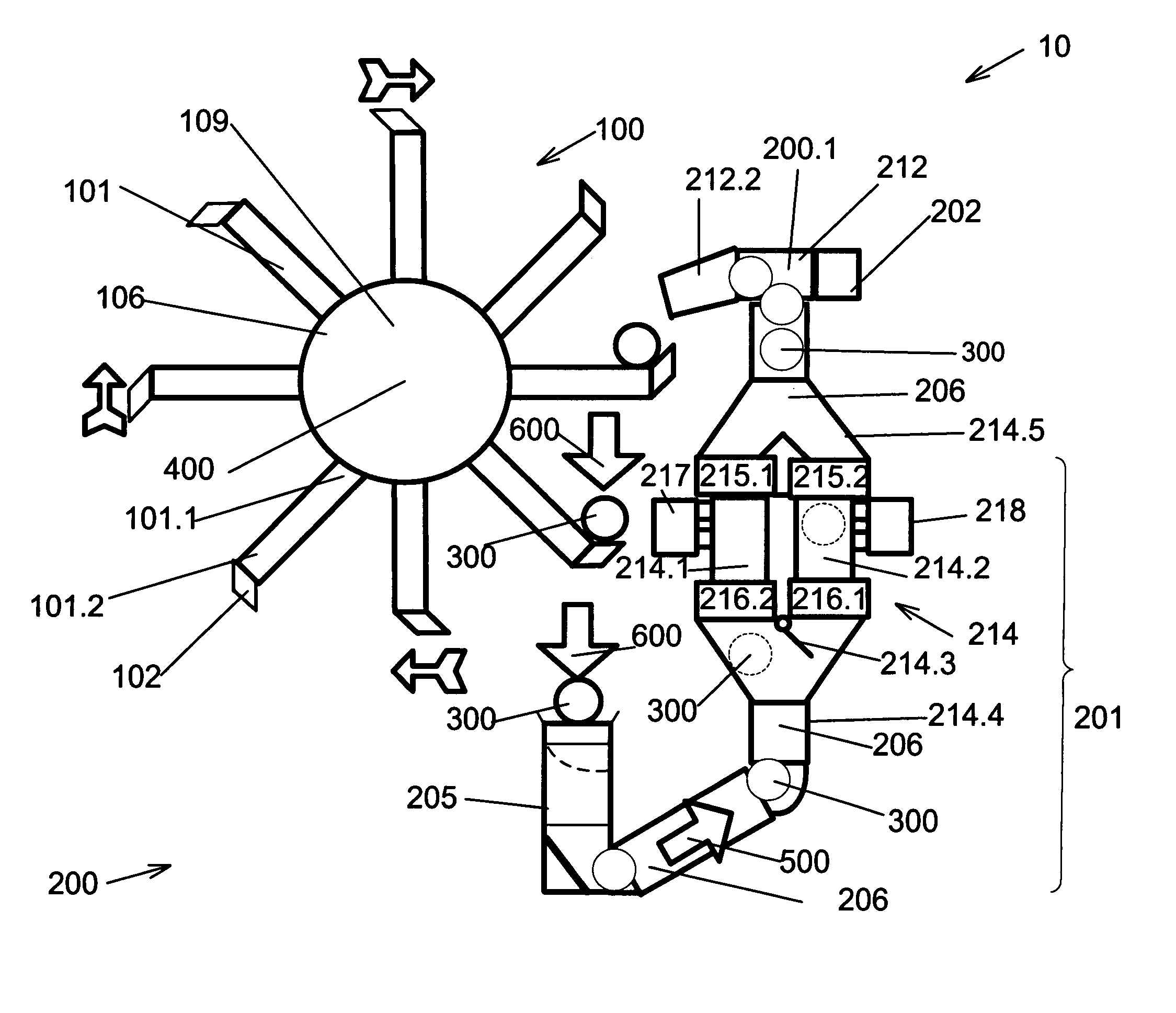

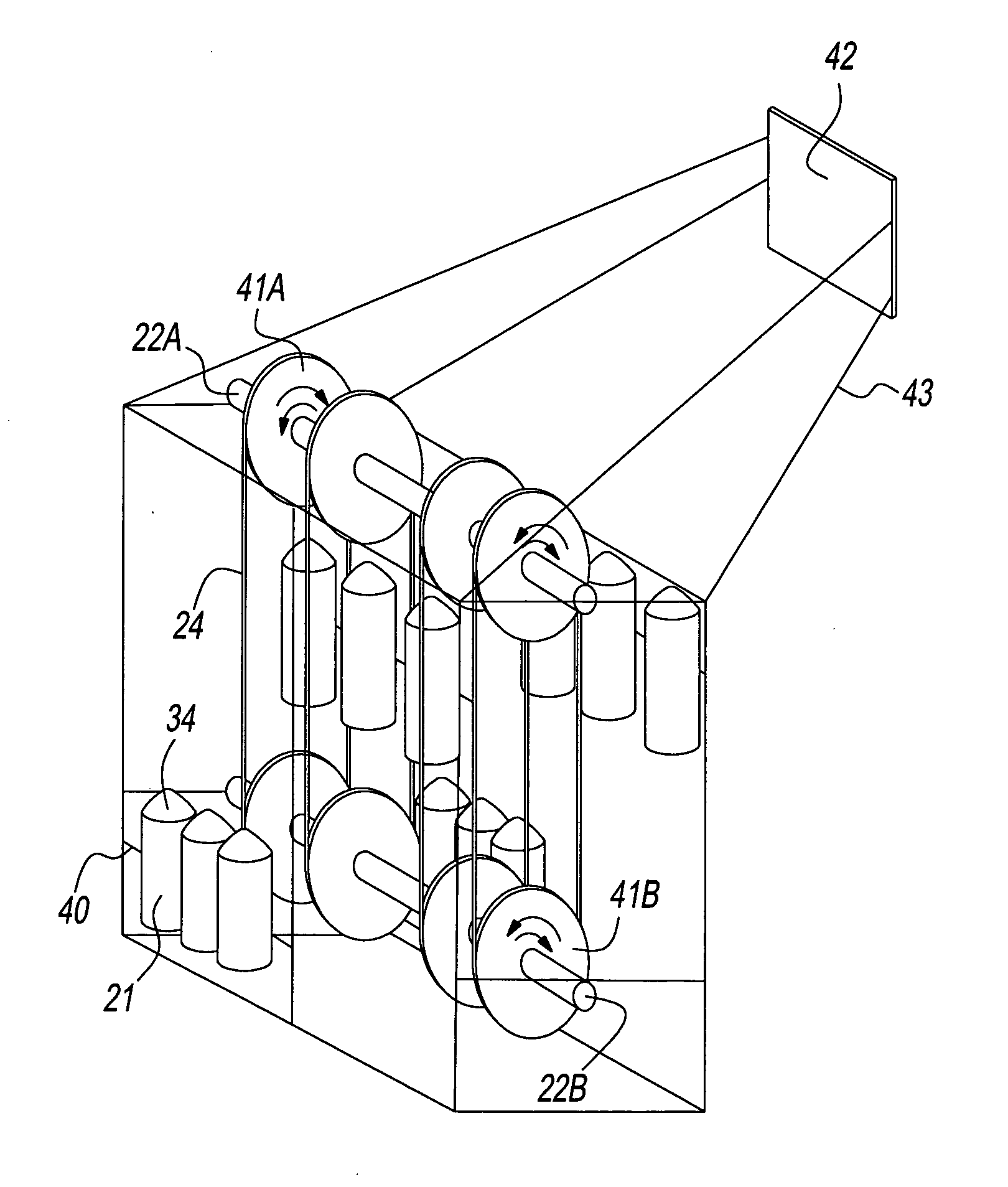

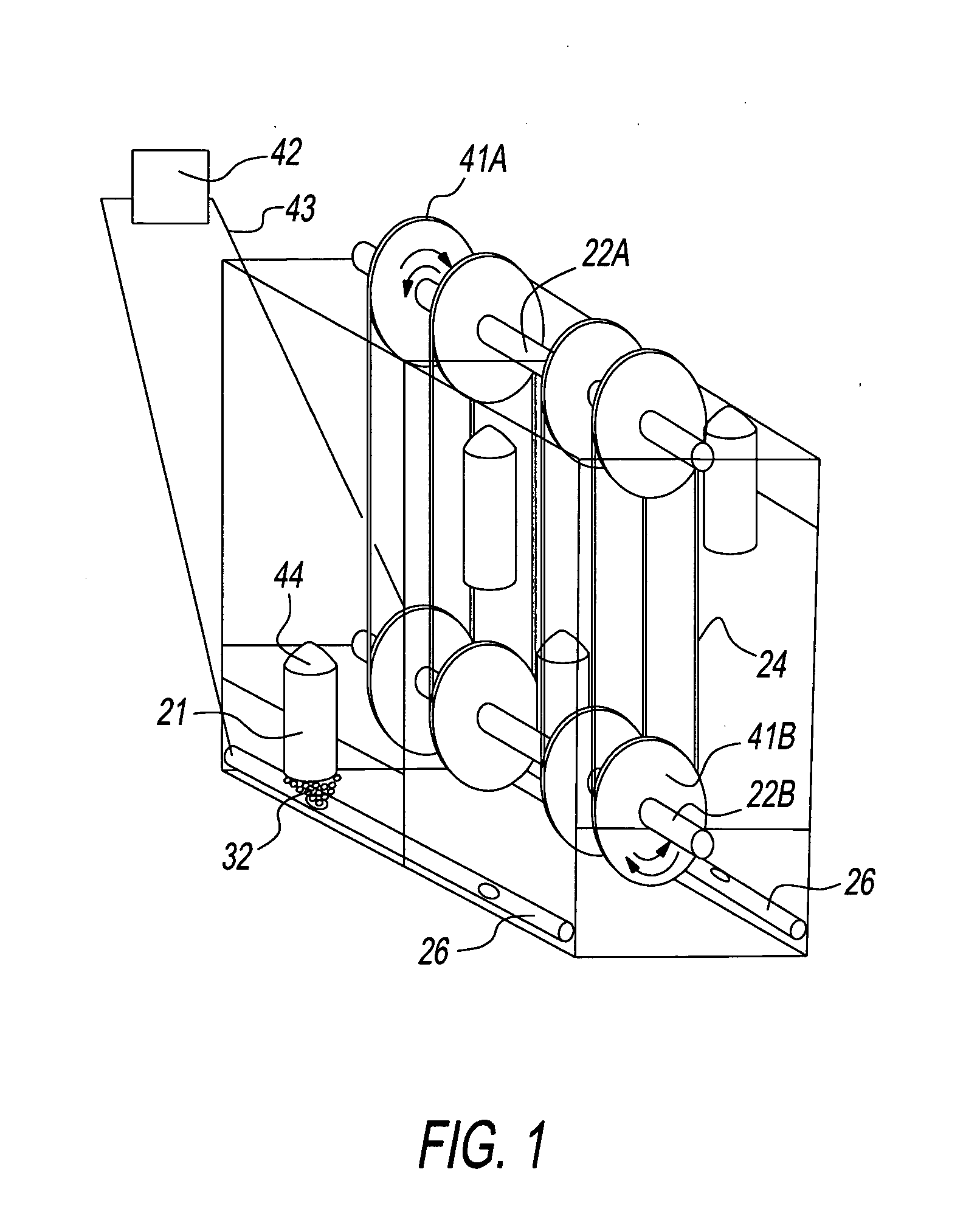

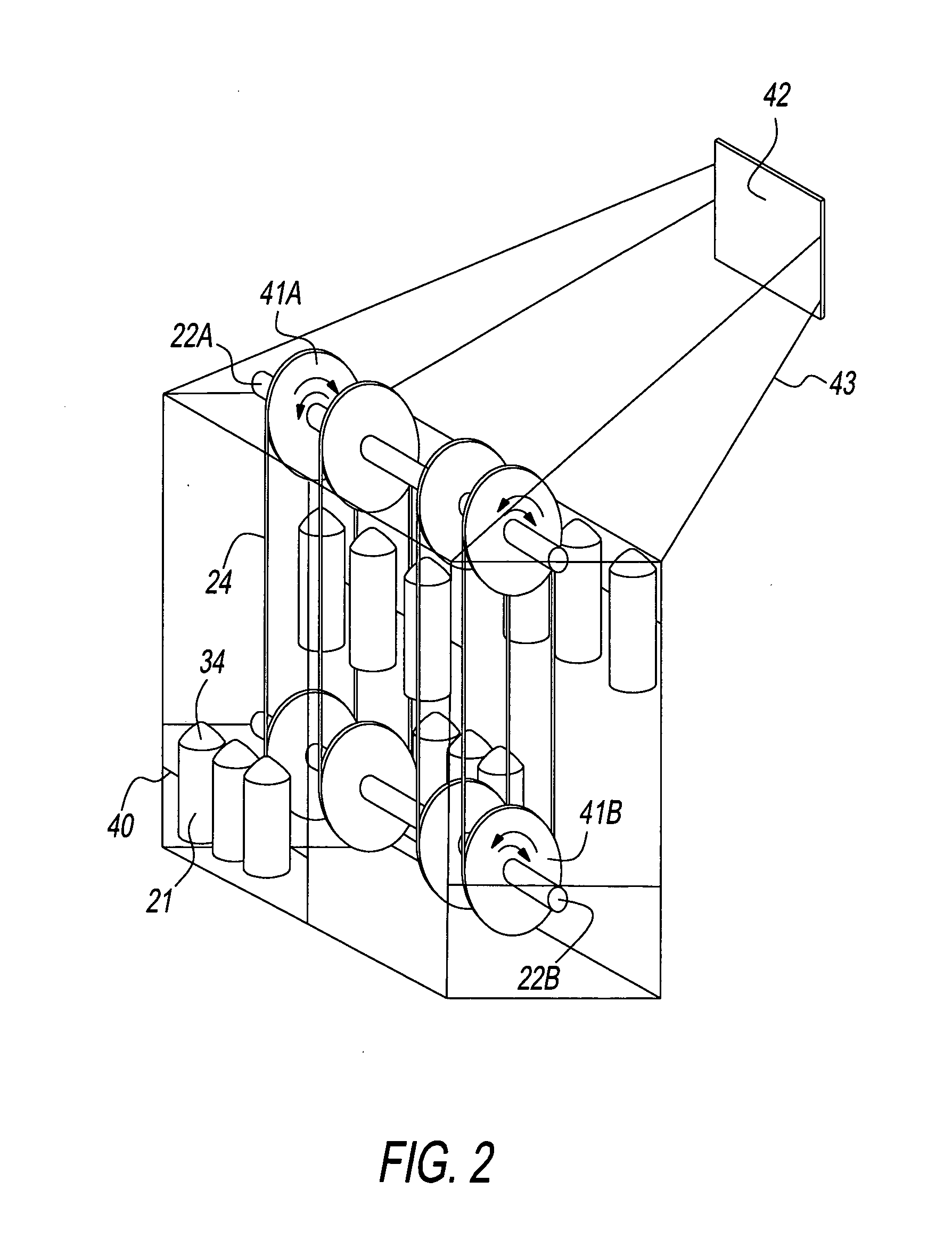

Acoustophoretic enhanced system for use in tanks

InactiveUS20130277317A1Easy to separateEasy to operateTransducer detailsWater/sewage treatment with mechanical oscillationsMechanical engineeringPetroleum engineering

A system for enhancing the separation of particles or fluids from water is disclosed. A settling tank or skim tank is provided with an open submersible acoustophoretic separator. In a skim tank, the separator captures and holds oil droplets or particles, permitting them to coalesce until they are large enough and have sufficient buoyant force to float to the top of the tank. In a settling or sediment tank, separator captures and holds particles until they are large enough that the force of gravity causes them to settle out of the water. The acoustophoretic device thus speeds up separation of the particles or droplets from the water.

Owner:FLODESIGN SONICS

Sealed shaft gravity buoyancy energy system and method of use thereof

InactiveUS7134283B2Different energyDifferent powerHydro energy generationEngine componentsEngineeringGravitational force

Owner:VILLALOBOS VICTOR

Remotely operated underwater vehicle

InactiveUS20100212574A1Solve the lack of spaceMore forceCommunication meansUnderwater vesselsWireless transceiverTransceiver

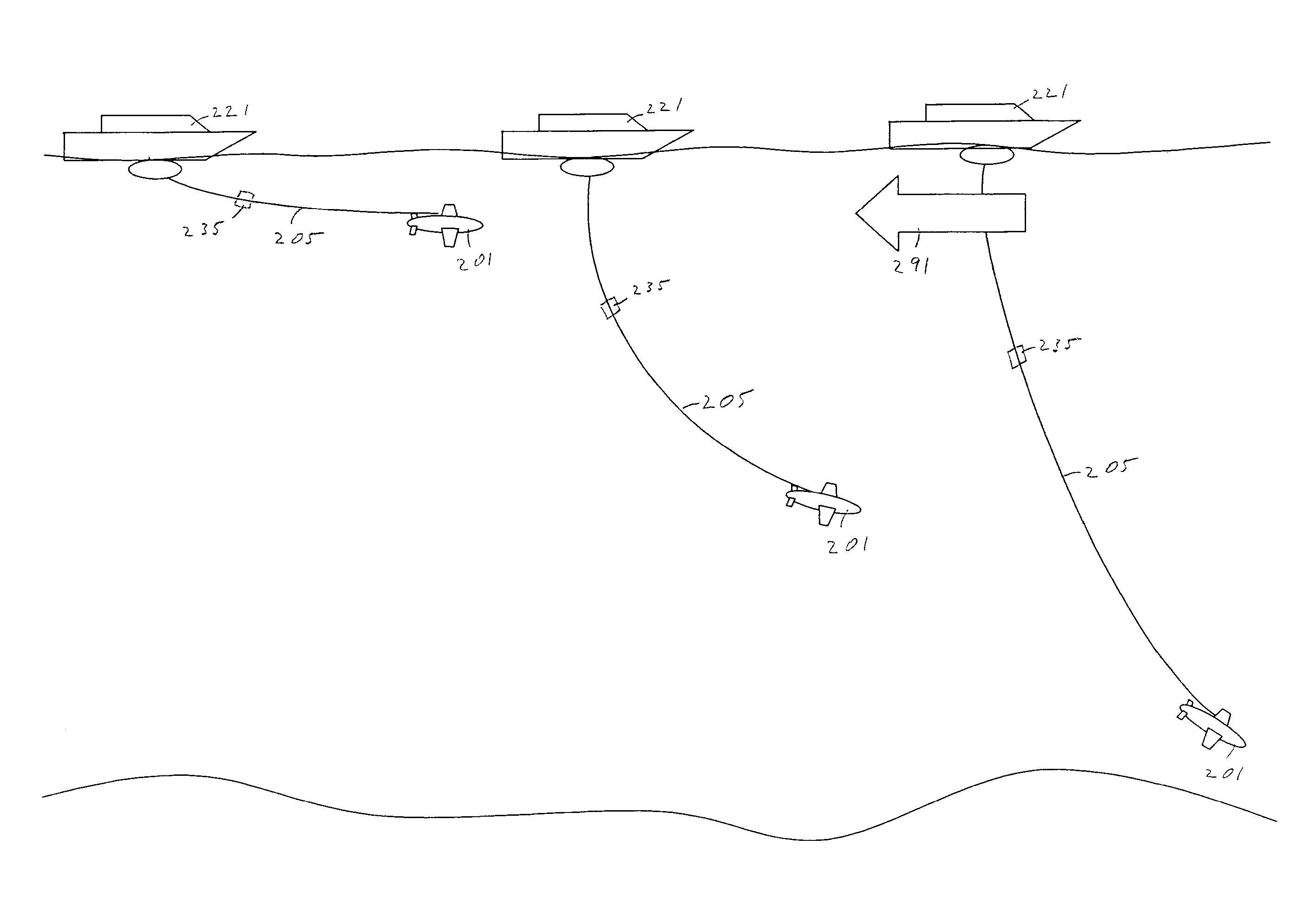

A system for communicating with a remotely operated underwater vehicle (ROV) includes a winged ROV coupled to a surface buoy by a tether. A controller on a support ship is coupled to the tether and the control signals are then transmitted through the tether to the ROV. Feedback and sensor signals are transmitted from the ROV through the wireless transceivers to the controller. The wings of the ROV produce negative lift which is greater than the buoyant force of the ROV and the vertical tension forces on the tether.

Owner:BLUEFIN ROBOTICS

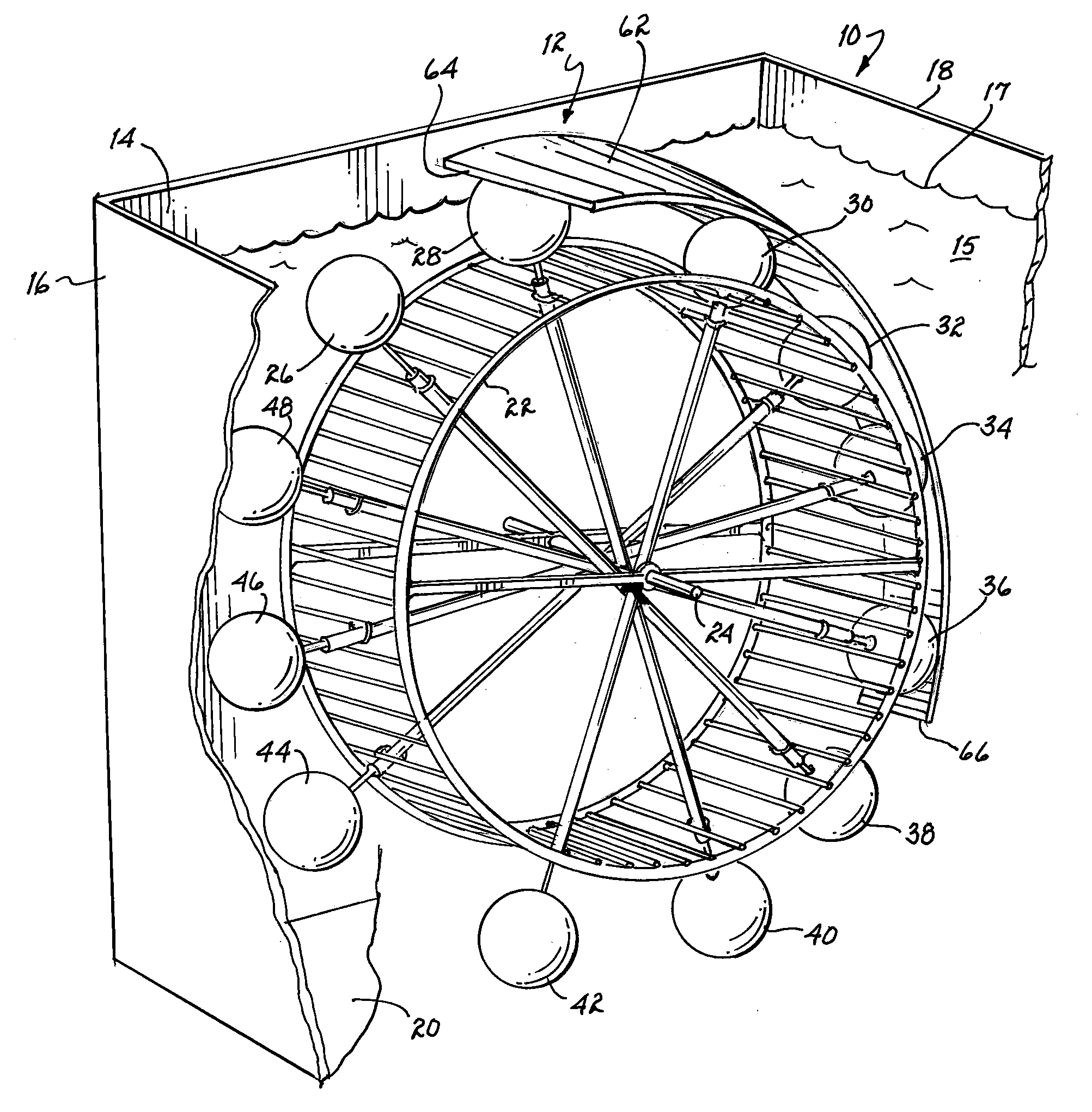

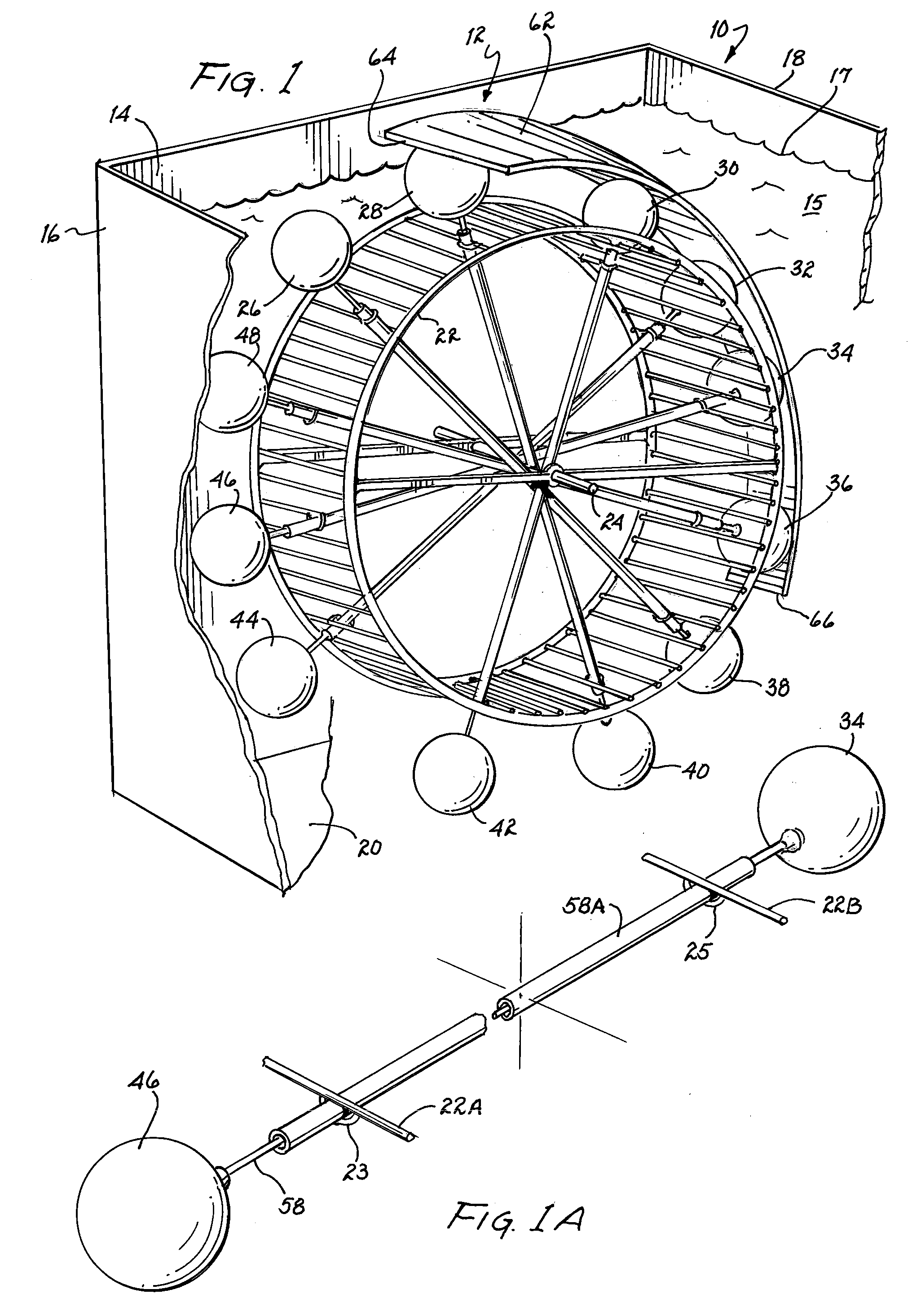

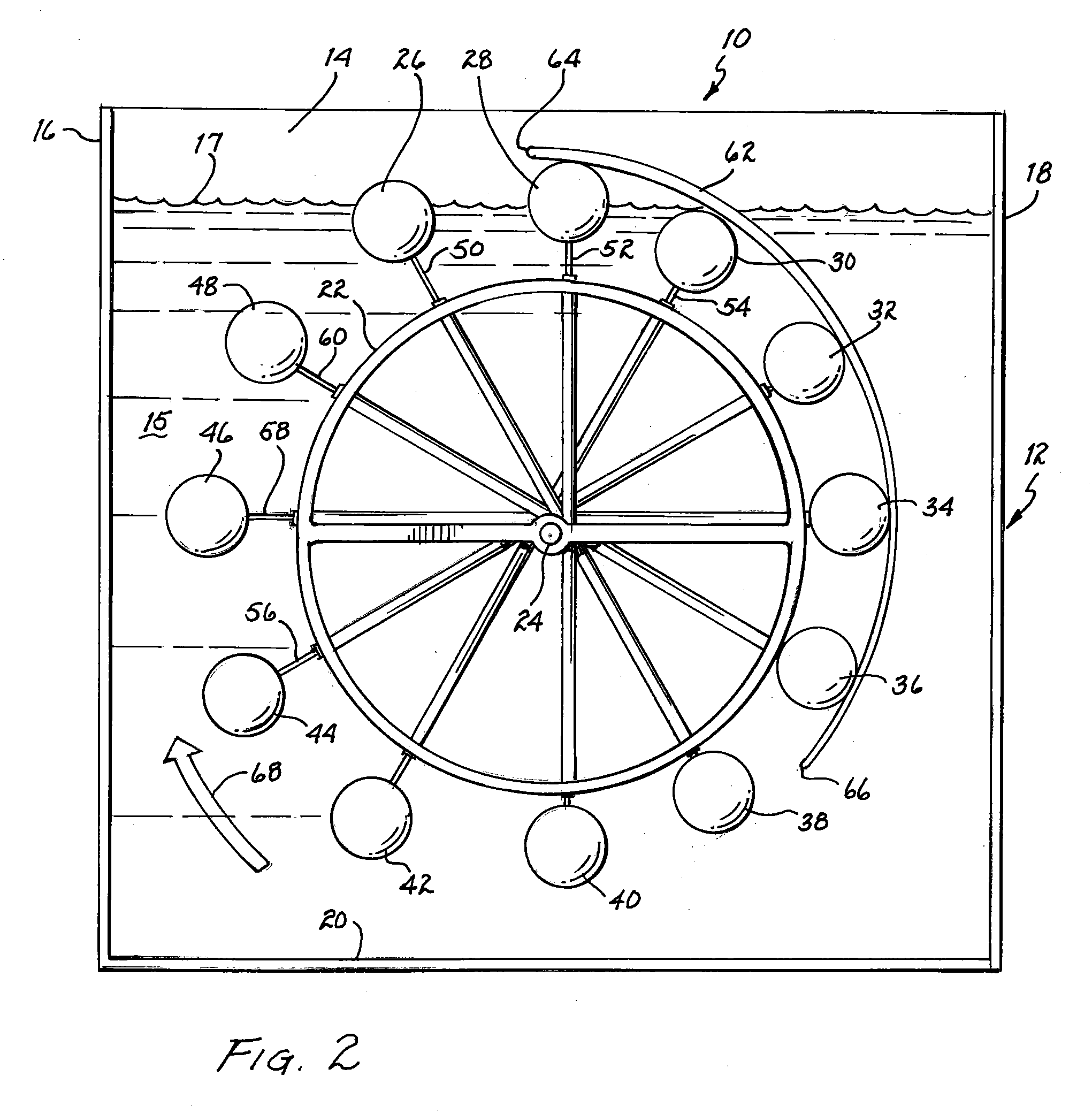

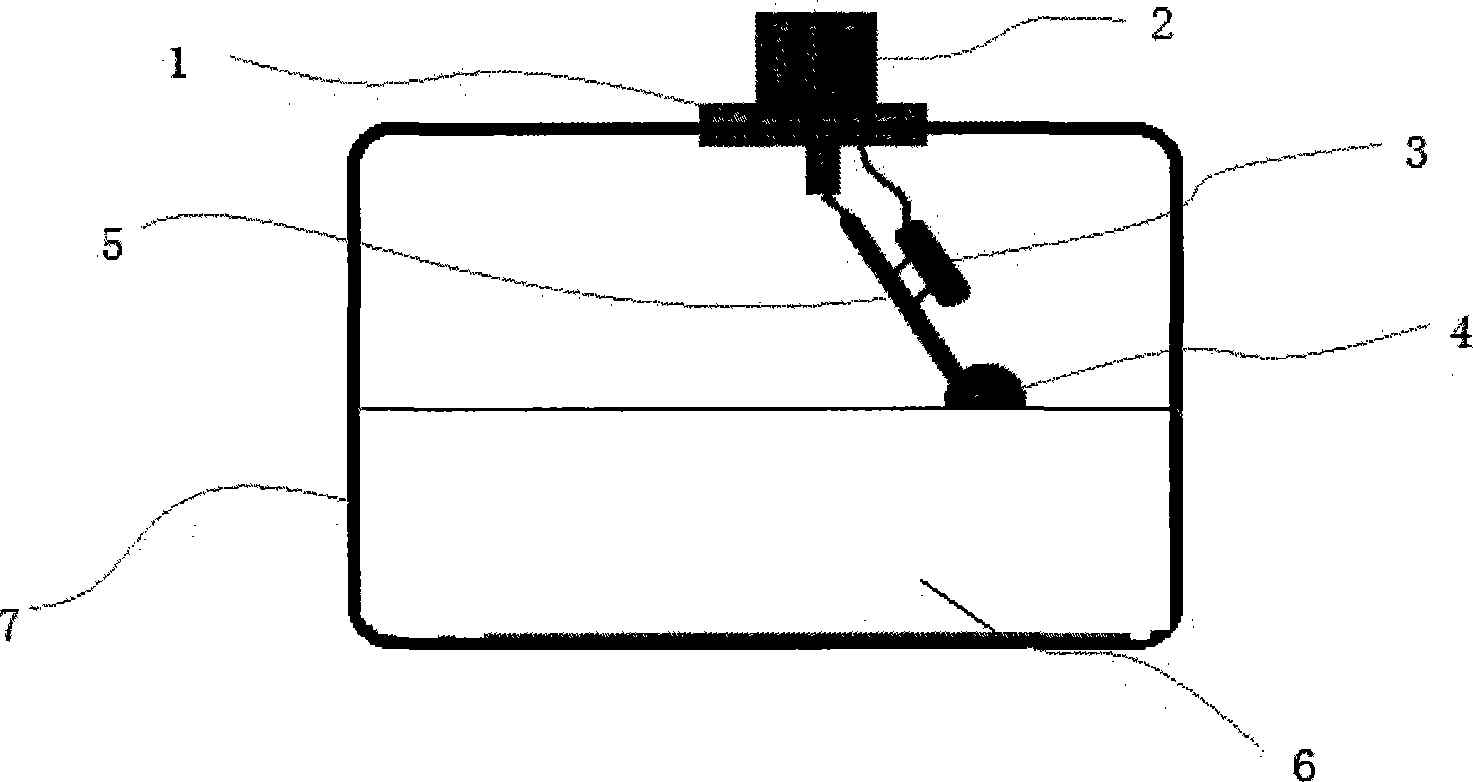

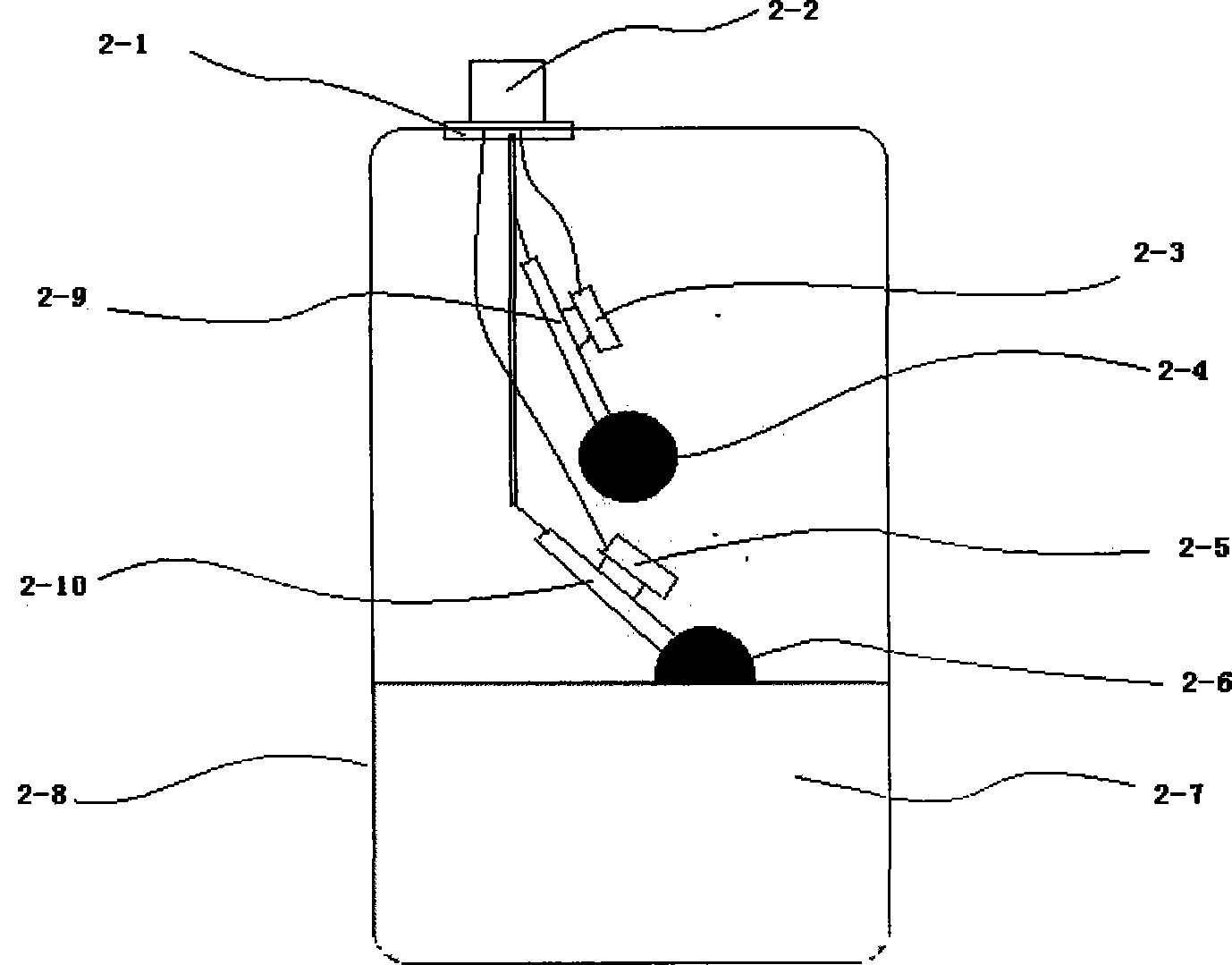

Sealed shaft gravity buoyancy energy system and method of use thereof

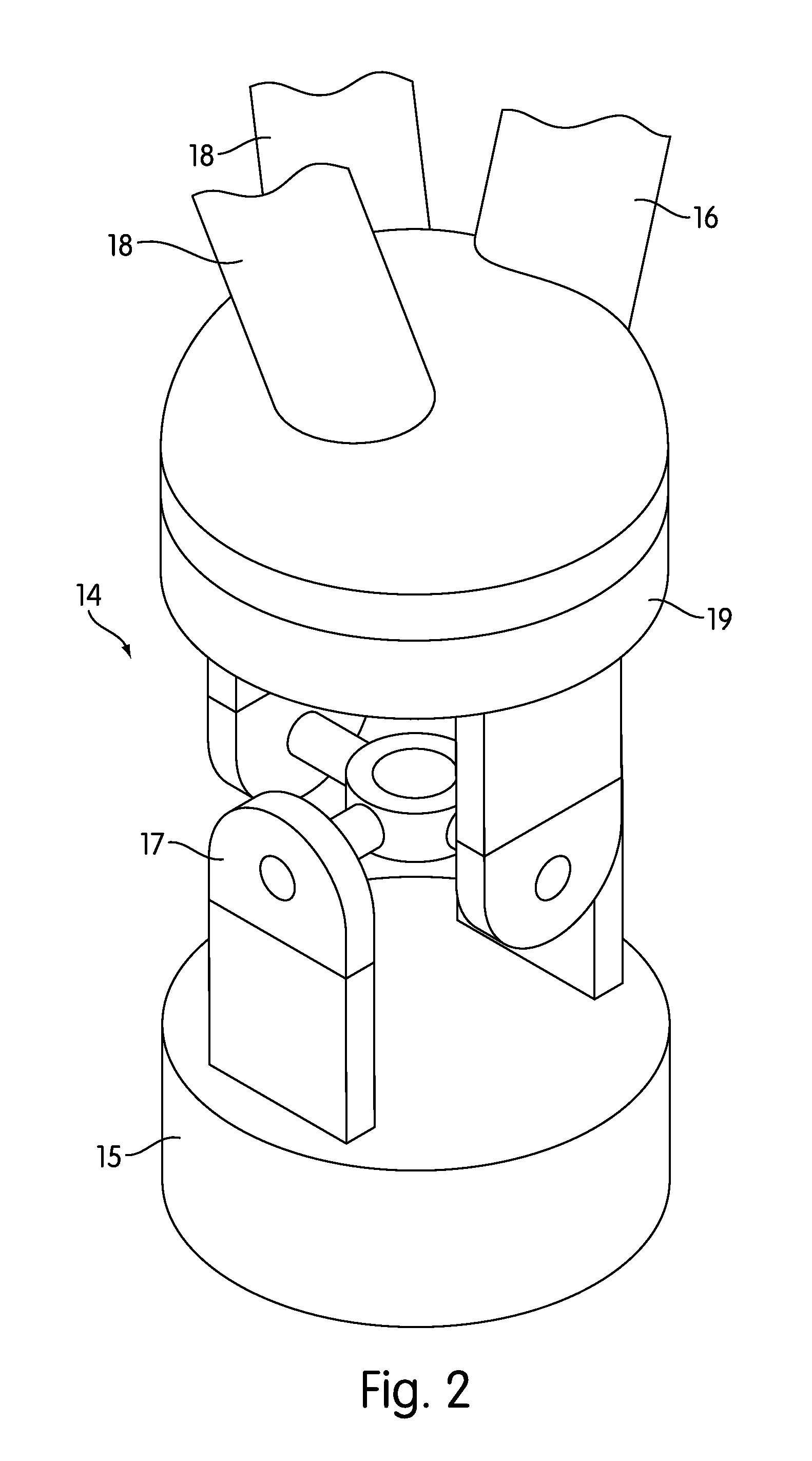

InactiveUS20060042244A1Reduce sizeReadily availableHydro energy generationEngine componentsGravitational forceVALVE PORT

A sealed-shaft gravity-buoyancy energy system and method of use thereof, wherein a wheel is powered by ball masses which fall under gravitational force, thereby causing the wheel to rotate. The ball masses are collected and inserted into a fluid shaft, wherein the fluid shaft comprises at least two separate columns having valves at the ends thereof to provide a sealing function, thereby preventing fluid loss. Buoyant force raises the ball masses to the top of the device, wherein the ball masses are deposited once again onto the wheel. A generator or other device utilizes the rotational force of the wheel to create energy.

Owner:VILLALOBOS VICTOR

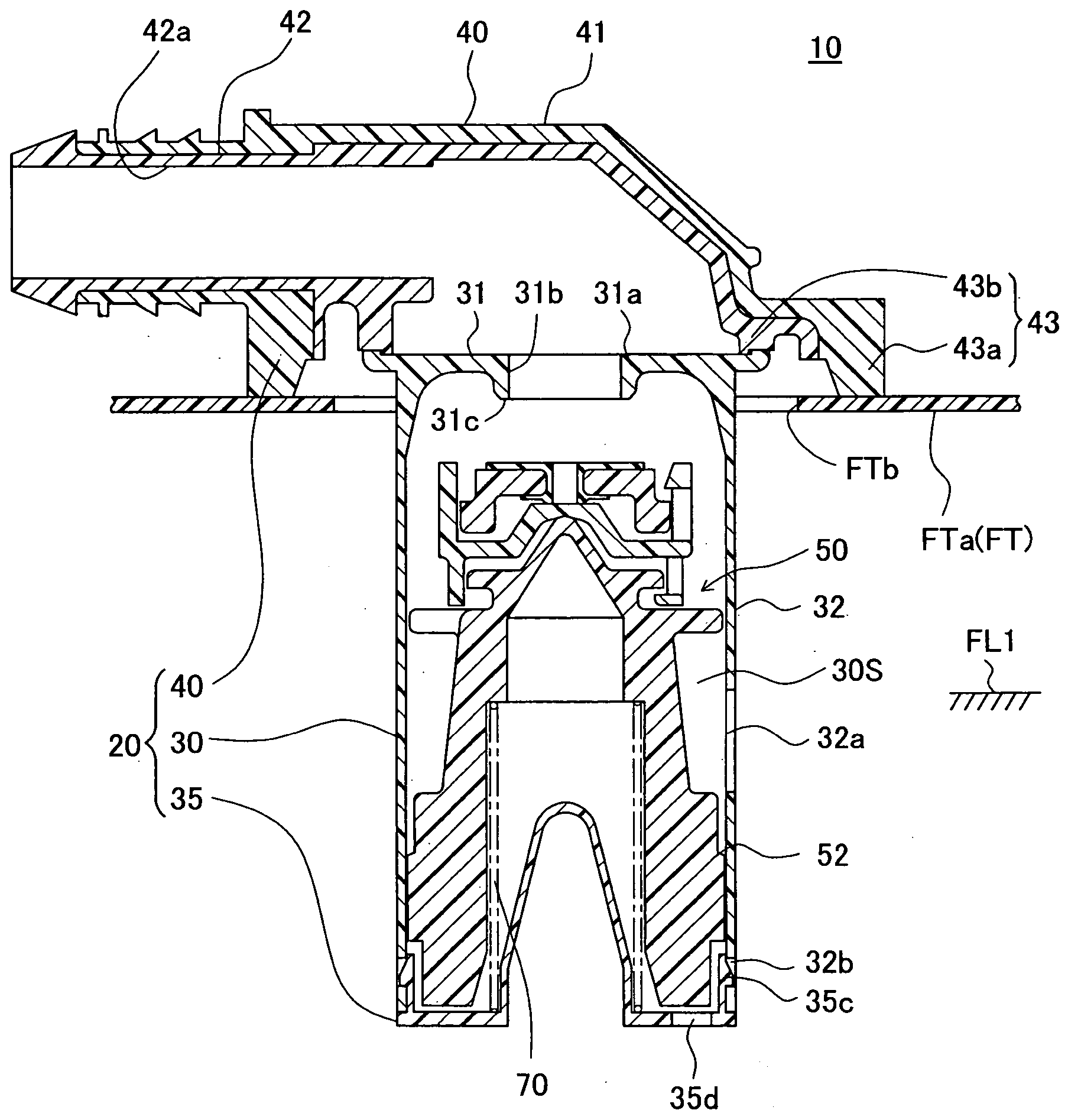

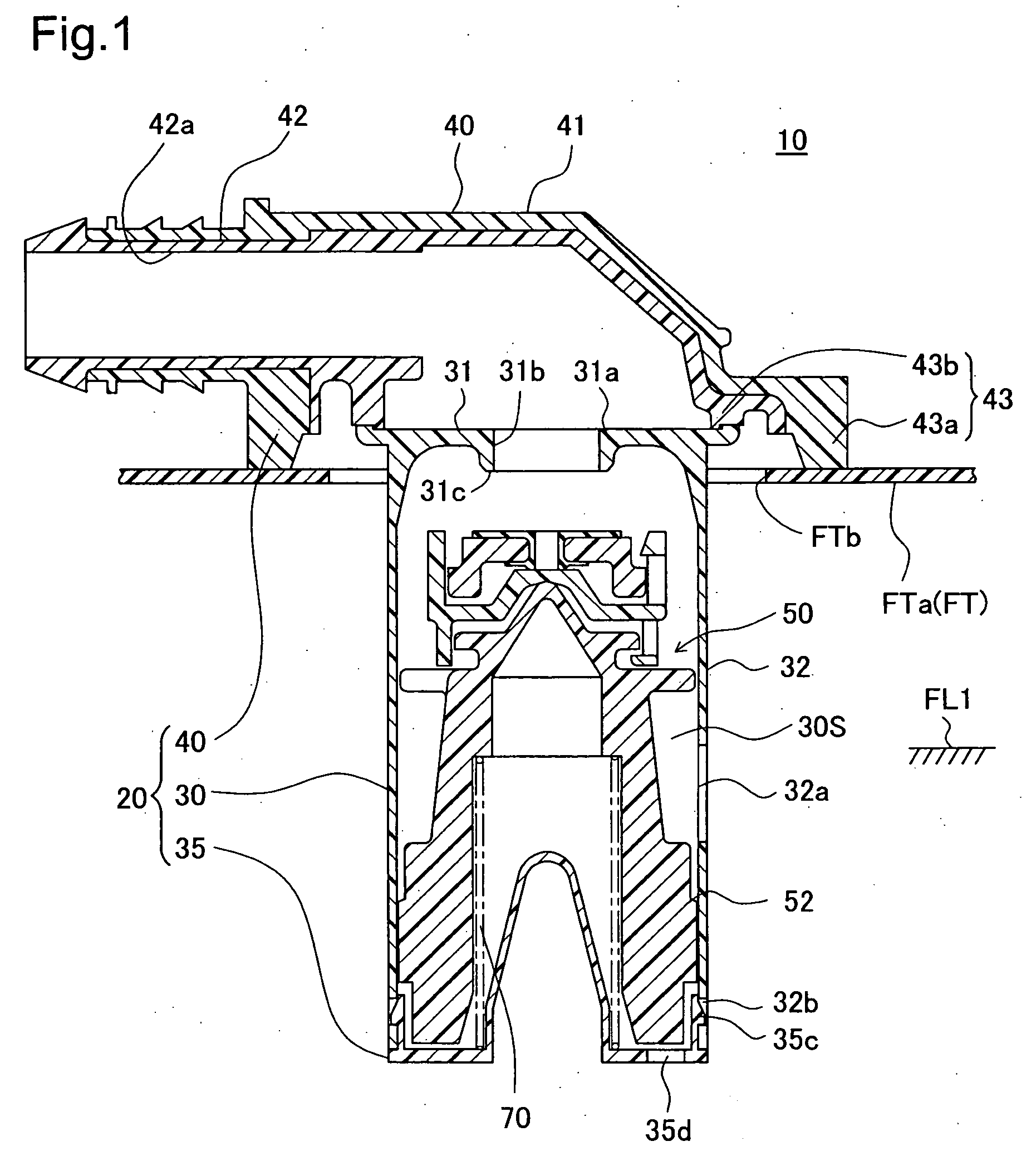

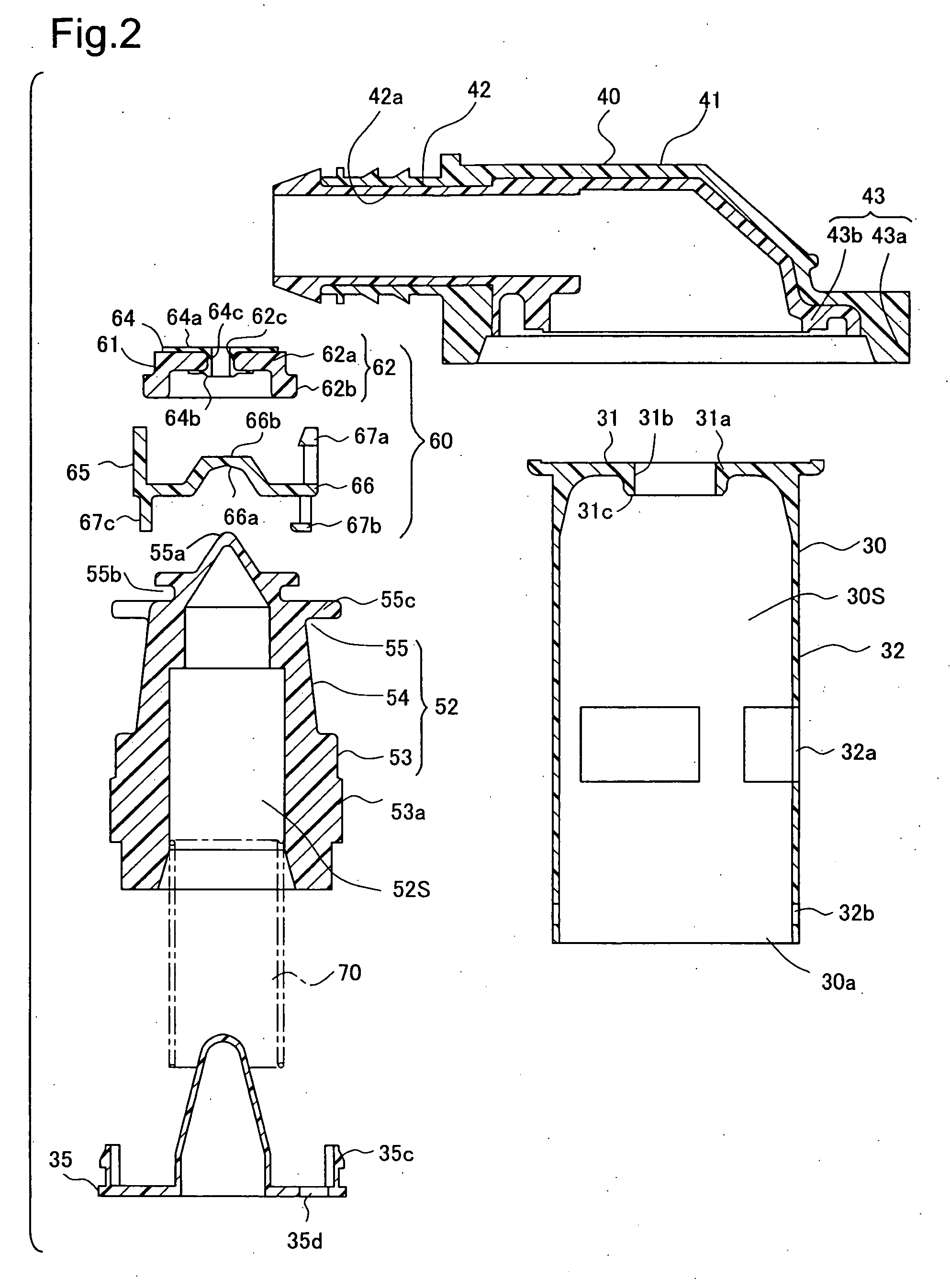

Fuel cut off valve

The fuel cut off valve comprises a casing, a float that rises and falls with increases and decreases in the buoyant force depending on the fuel liquid level within a valve chamber, and a valve mechanism that opens and closes a connecting passage through the rising or falling of the float, equipped on the upper part of the float. The valve mechanism comprises a supported part, and when the supported part is supported by a support part of the float, the center of gravity is provided below the support portion, so that the supported part is balanced on a single support portion. The fuel cut off valve can provide excellent seal performance when a vehicle is at an angle, and that can be miniaturized.

Owner:TOYODA GOSEI CO LTD

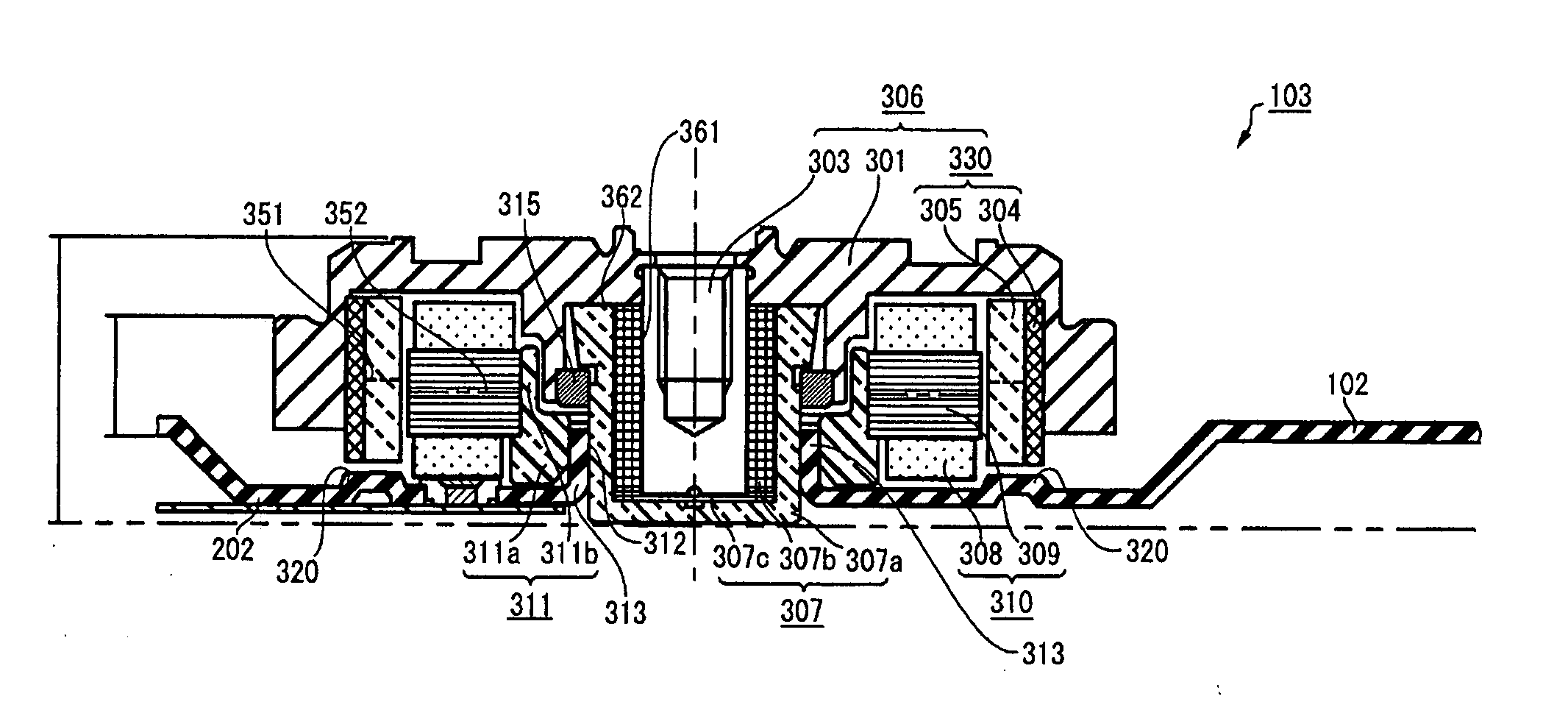

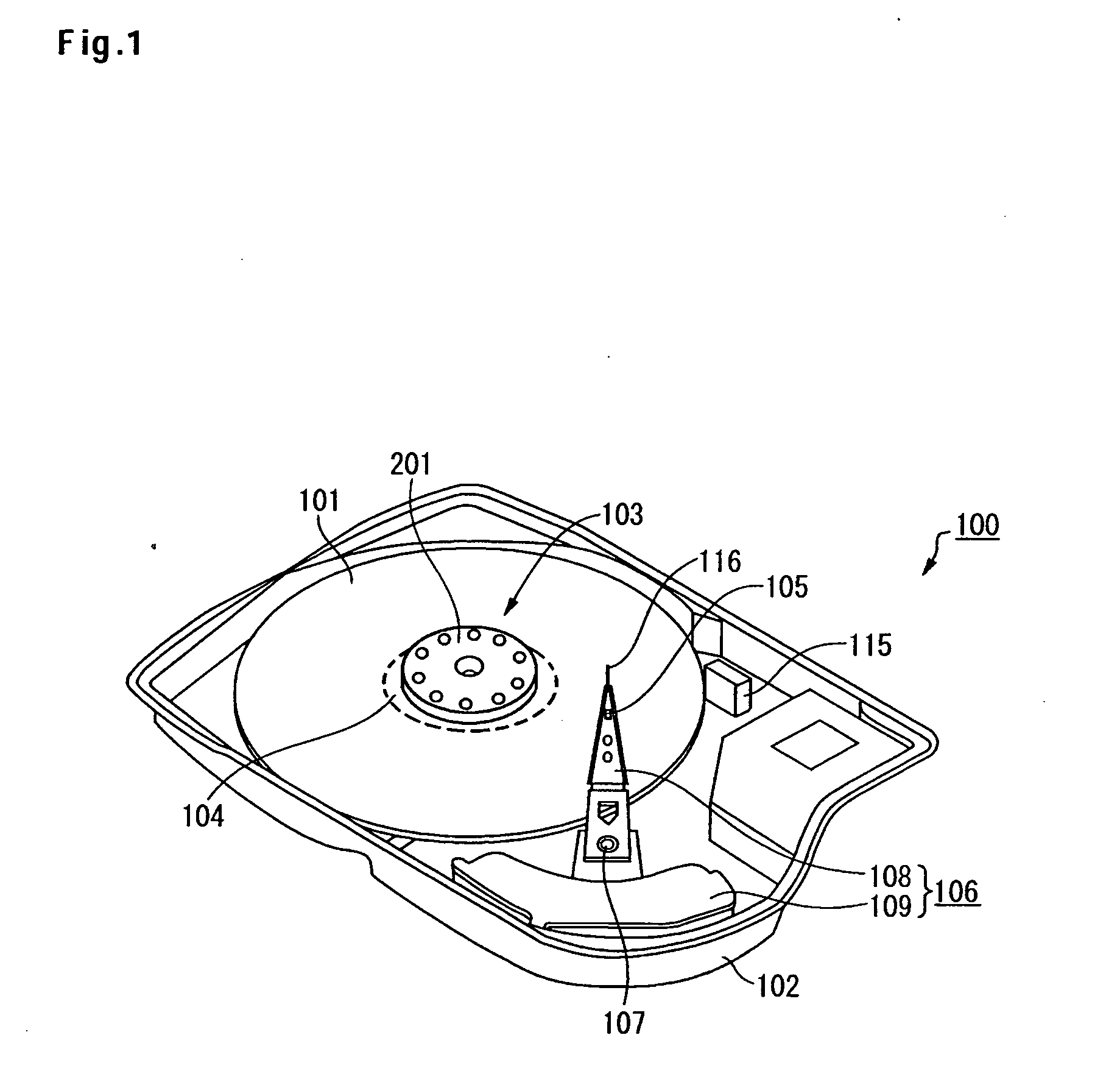

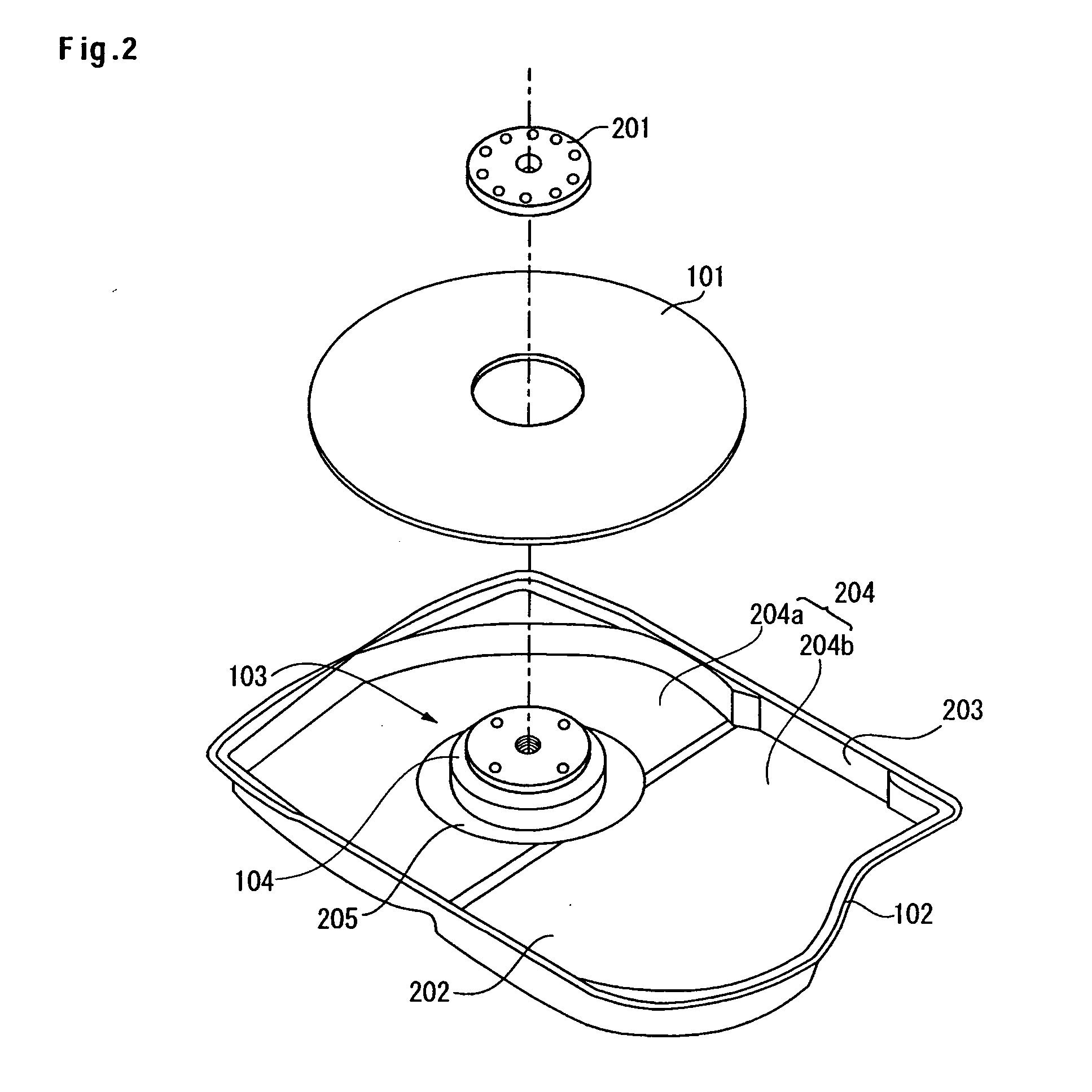

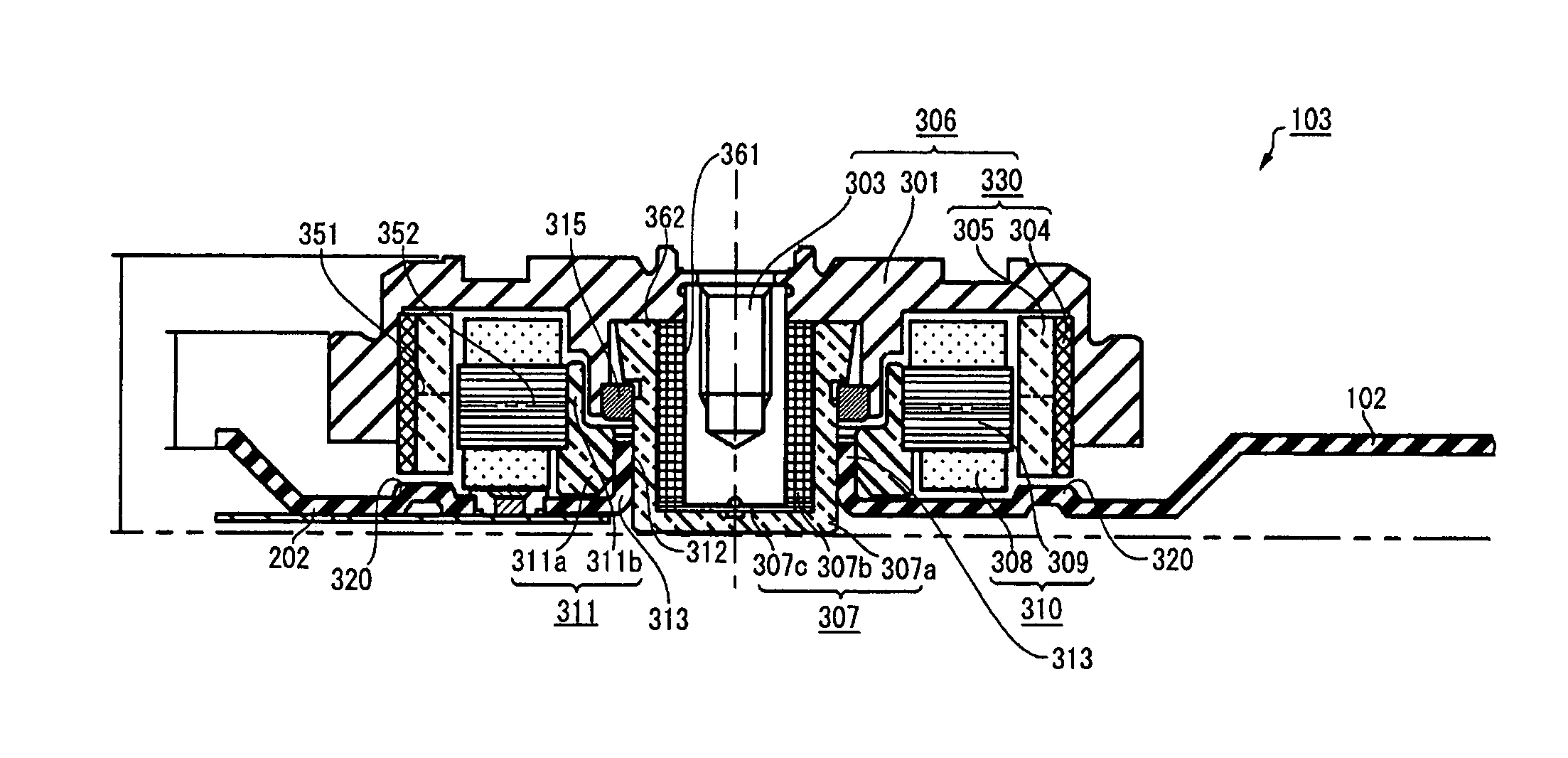

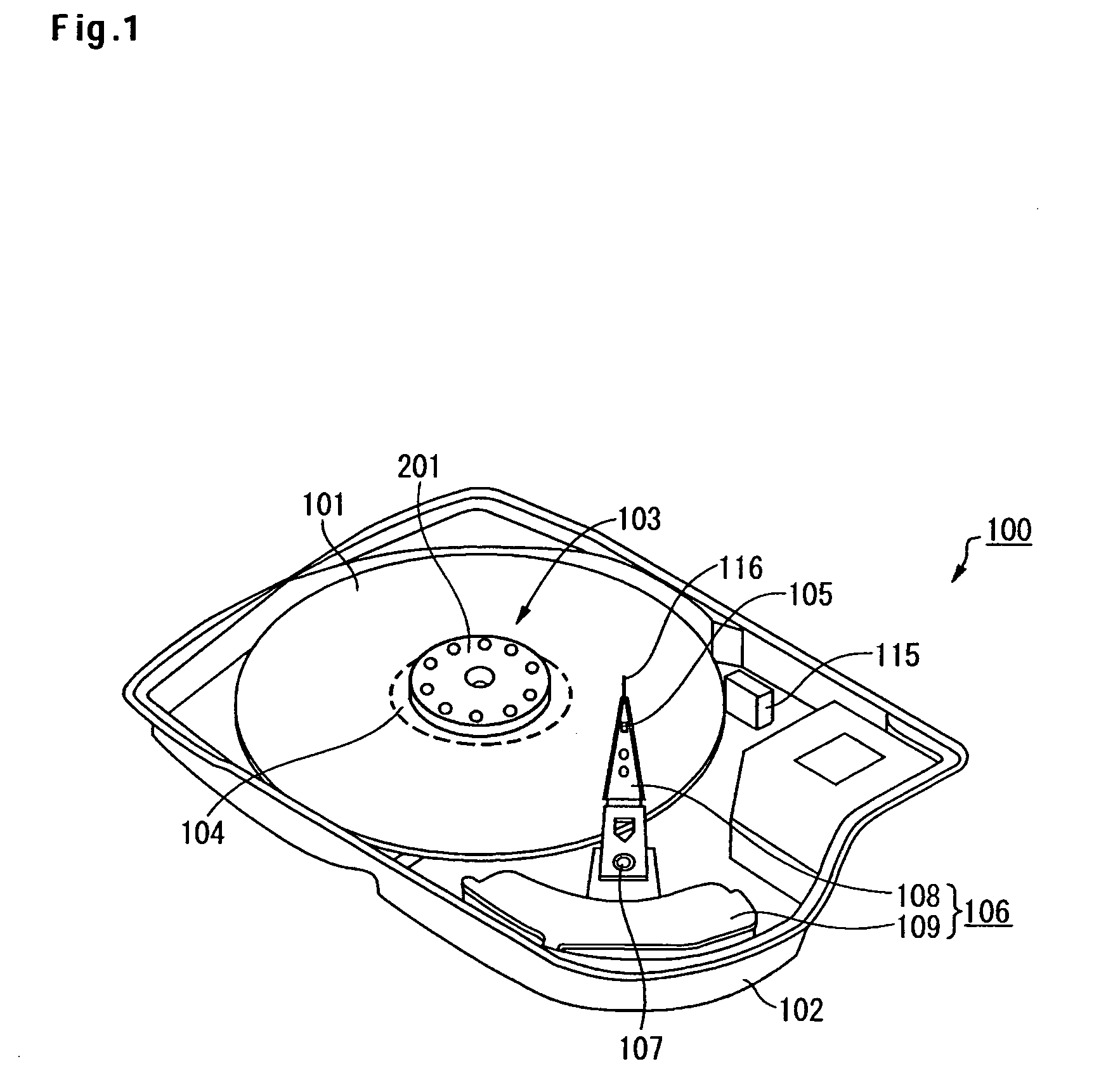

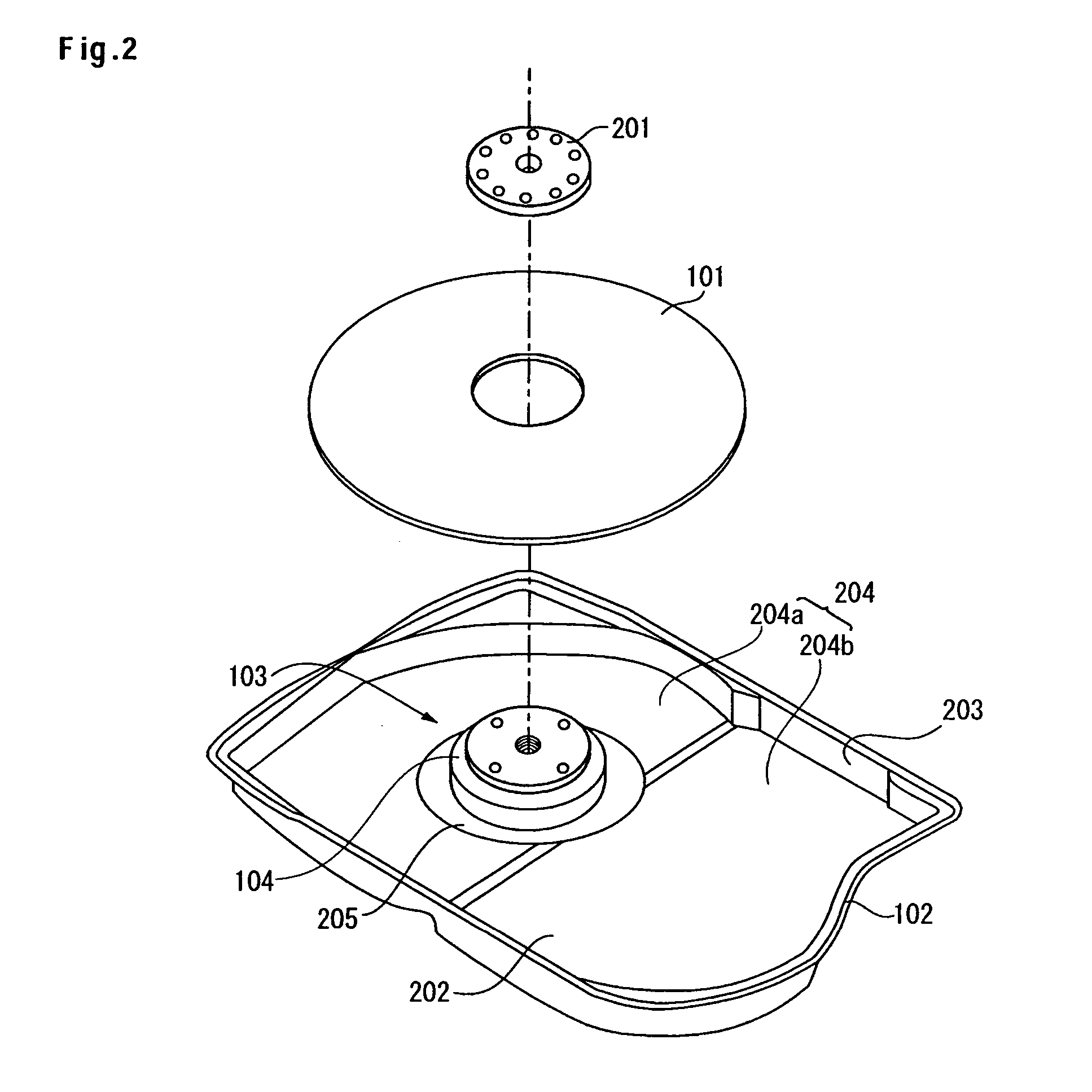

Data storage device with mechanism to control rotation of spindle motor

InactiveUS20050140220A1Effective controlSimple configurationRecord information storageManufacturing dynamo-electric machinesMagnetic tension forceHard disc drive

Embodiments of the present invention effectively control, by a simple structure, floating of a rotor of a fluid dynamic bearing motor mounted in a hard disk drive. In one embodiment, a base is formed of a magnetic material. The attractive force caused by the magnetic force acts between a bottom of the base and a magnet unit that is constituted of a rotor magnet and a back yoke. This makes it possible to attract a rotor to the base against the buoyant force produced by a thrust bearing, and thereby to effectively control the rotation of the rotor. On the bottom of the base, at a position facing the magnet unit, a convex part protruding from the inner surface of the base is formed in a ring-shape. Adjusting the height, or the width, of the convex part makes it possible to control the magnetic back pressure applied to the rotor.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

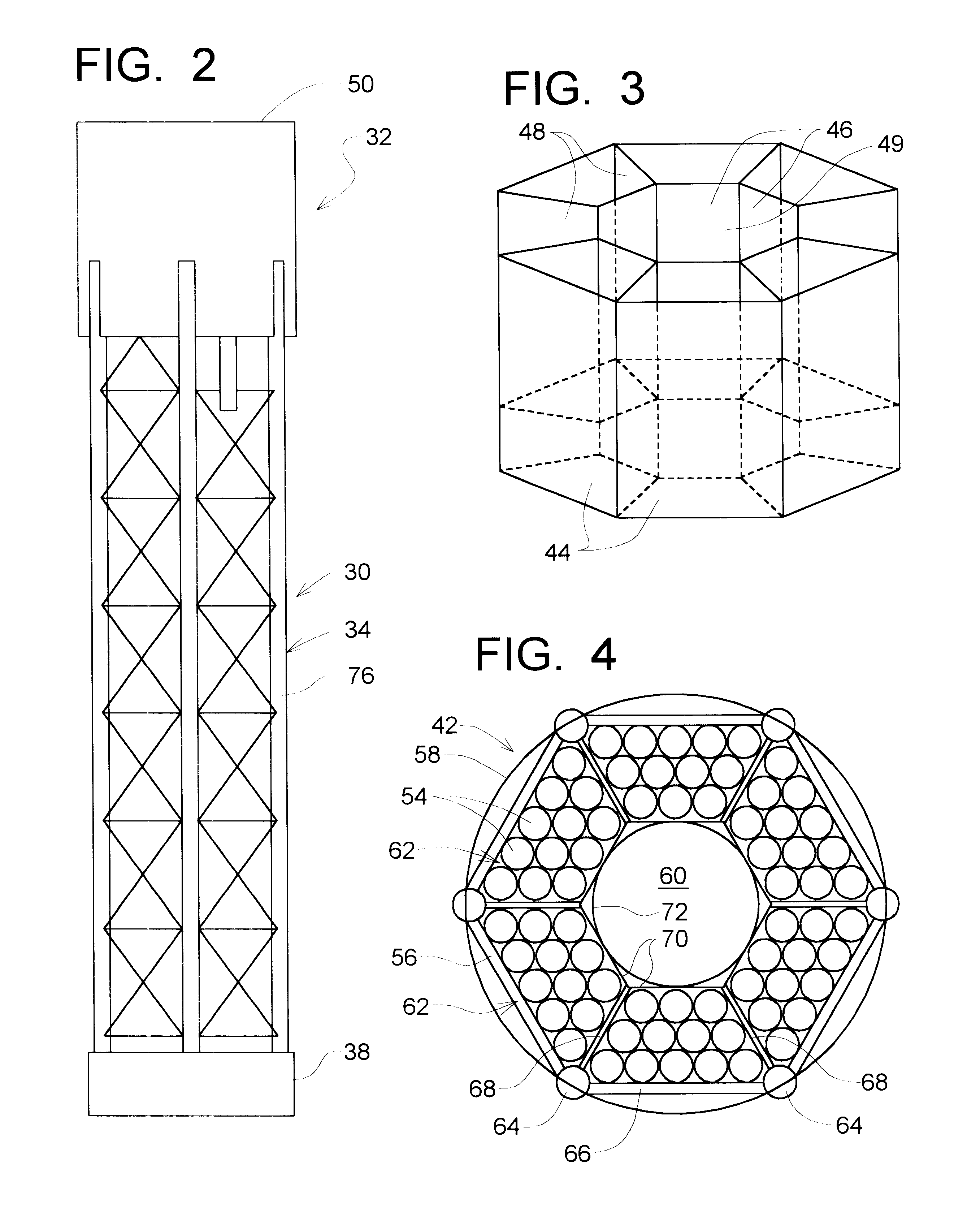

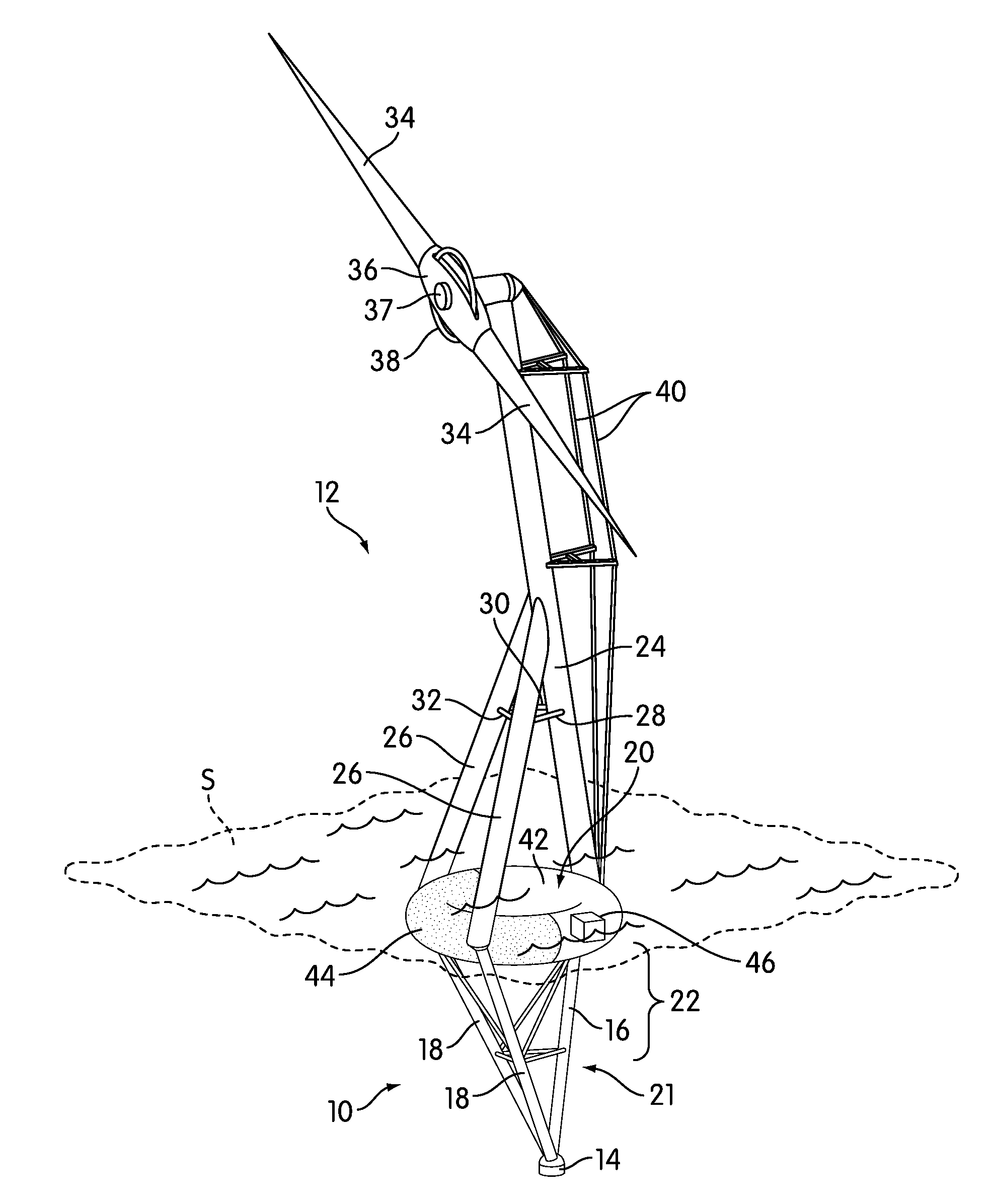

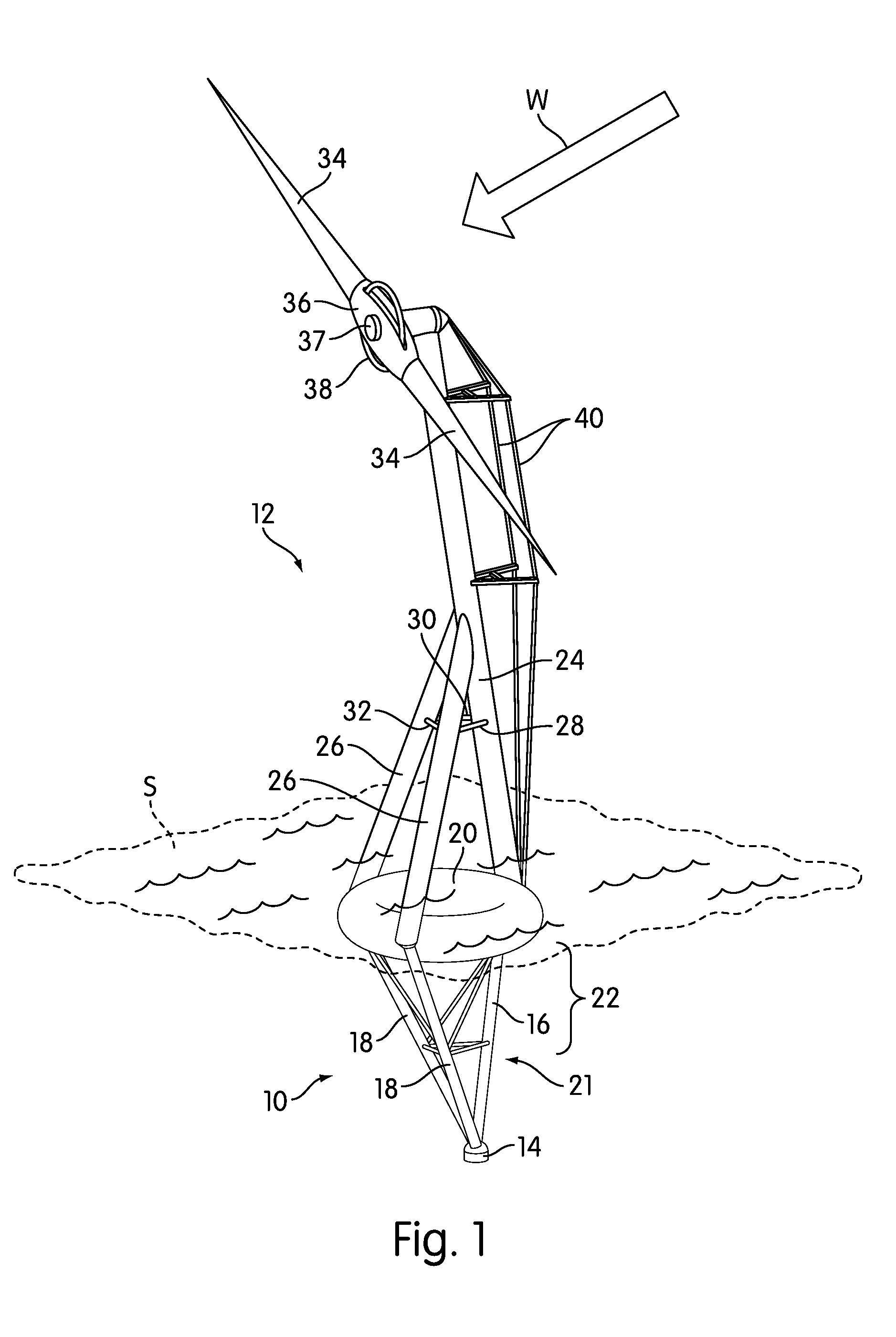

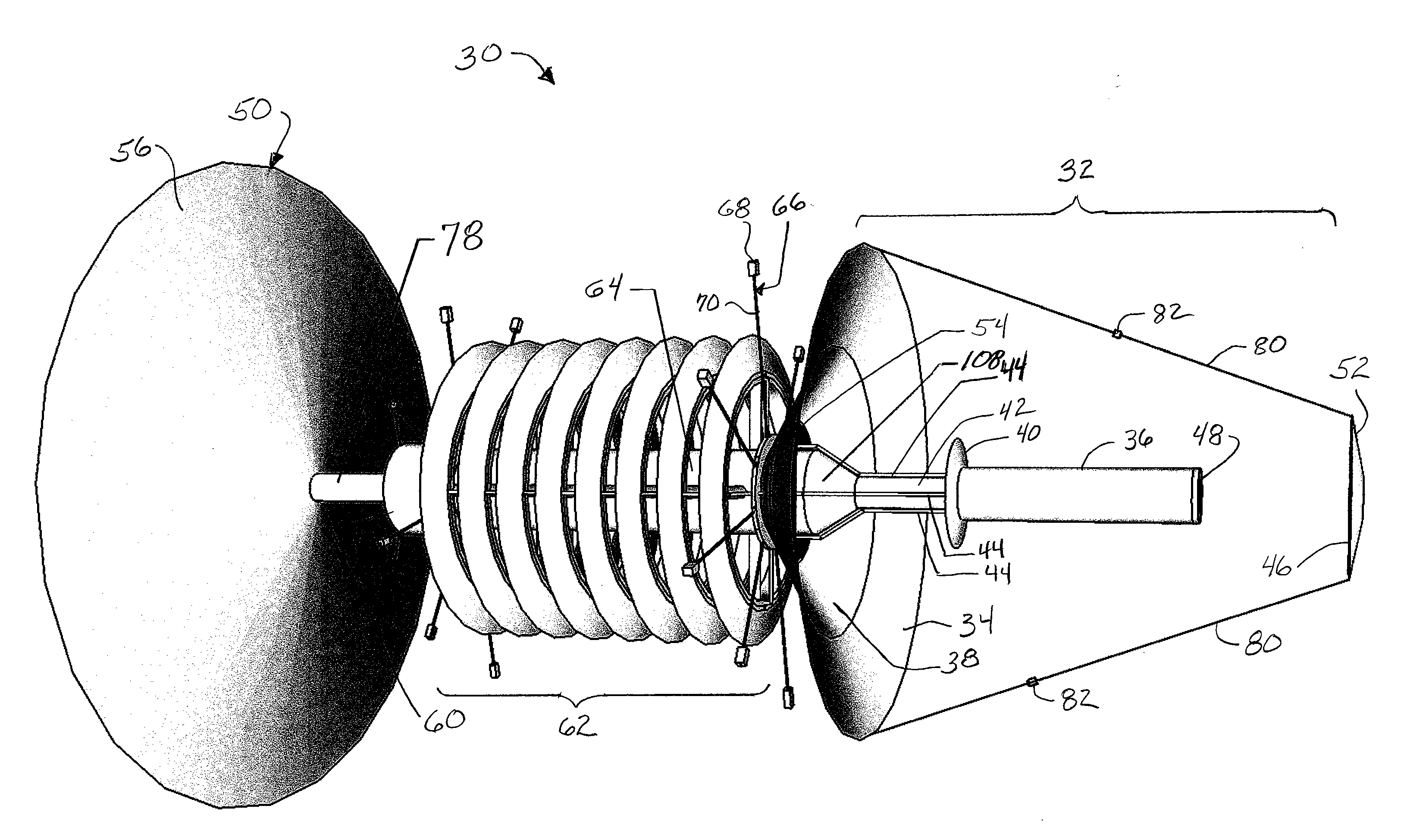

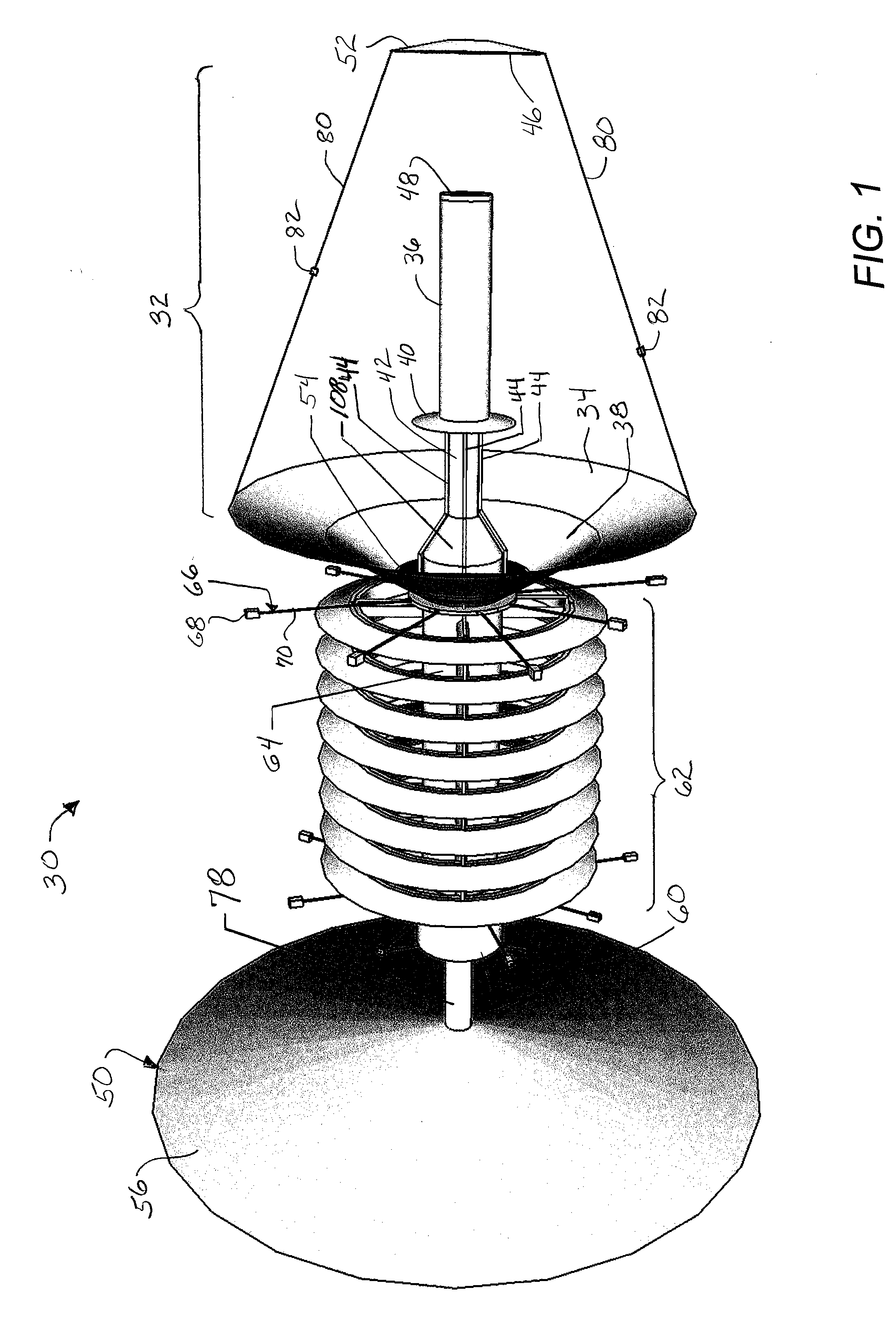

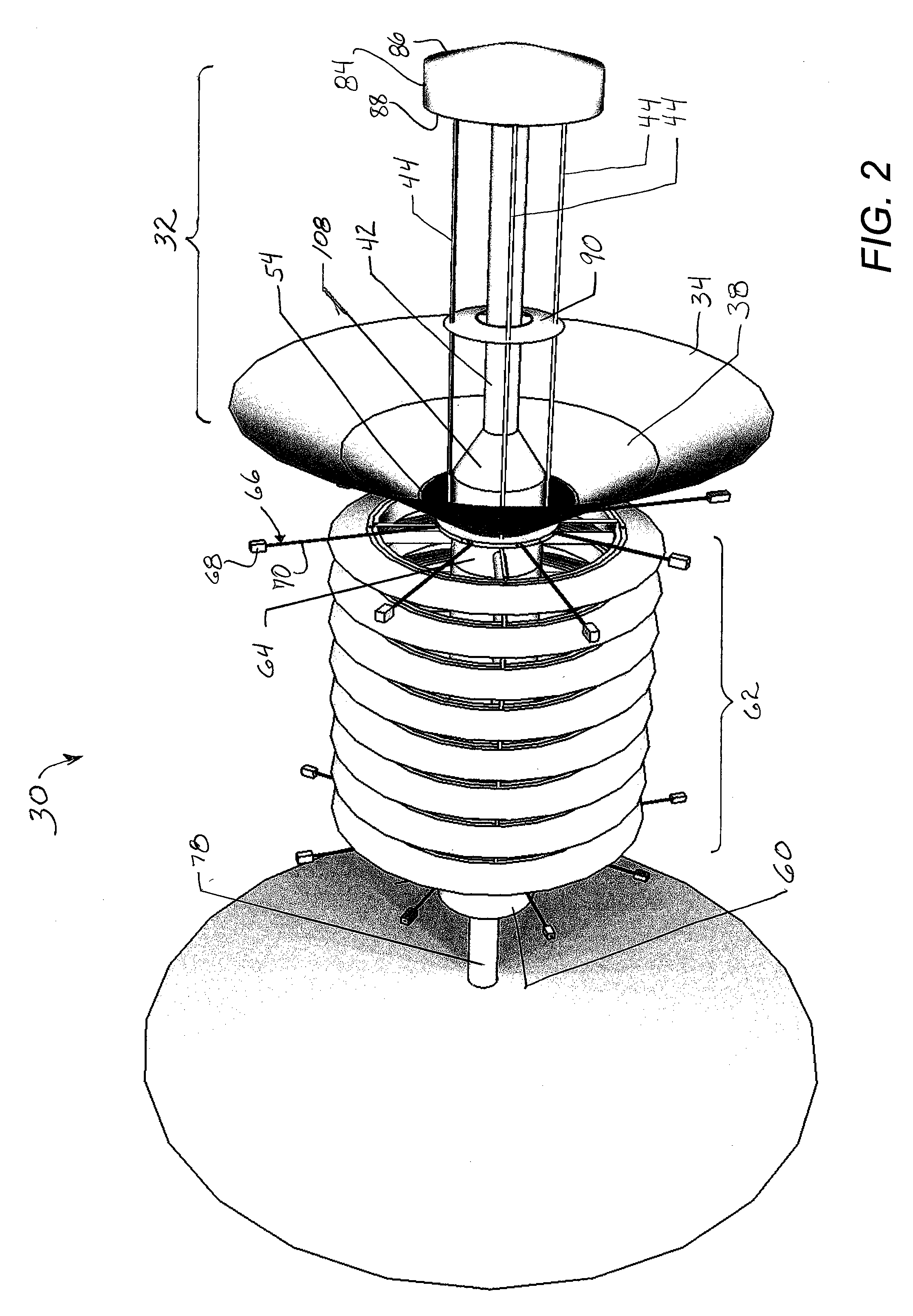

Floating underwater support structure

A floating underwater support structure is disclosed. The underwater support structure includes a joint capable of rotation and angular movement along two or three axes coupled to a truss. The truss is capable of sustaining loads in tension, compression, and bending, and comprises one or more elongate, rigid members. The elongate, rigid members are capable of sustaining loads in at least tension and compression. A buoyant member positioned between or around the members of the truss at a predetermined distance below the water provides a buoyant force that typically exceeds the weight of the entire structure. In deeper water, cross bracing may be provided between the members of the truss, and in particularly deep water, a single tendon may connect between the joint, typically anchored to the floor of the body of water, and the truss. The support structure may be used to support wind turbines and other structures.

Owner:CLEAR PATH ENERGY

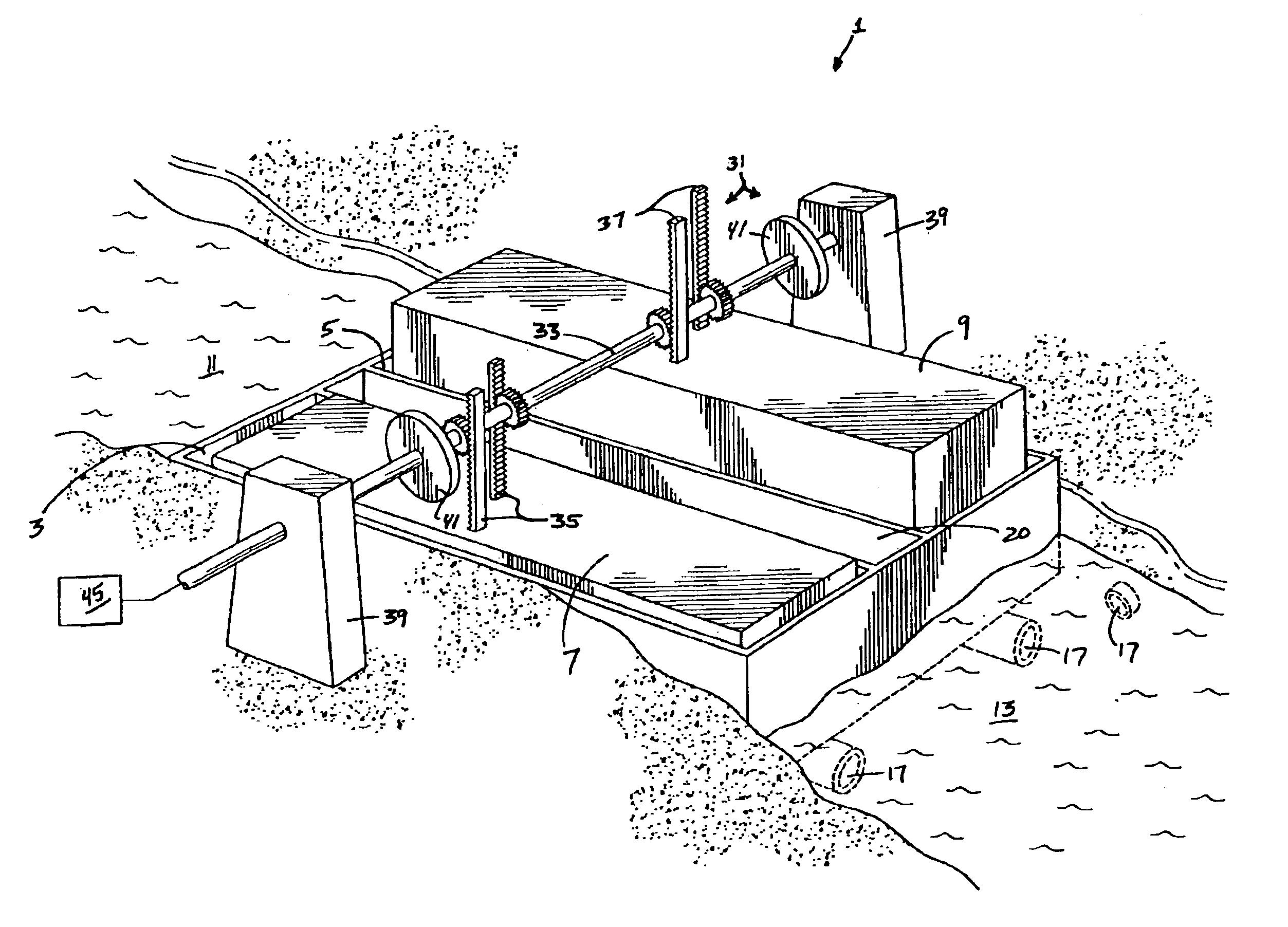

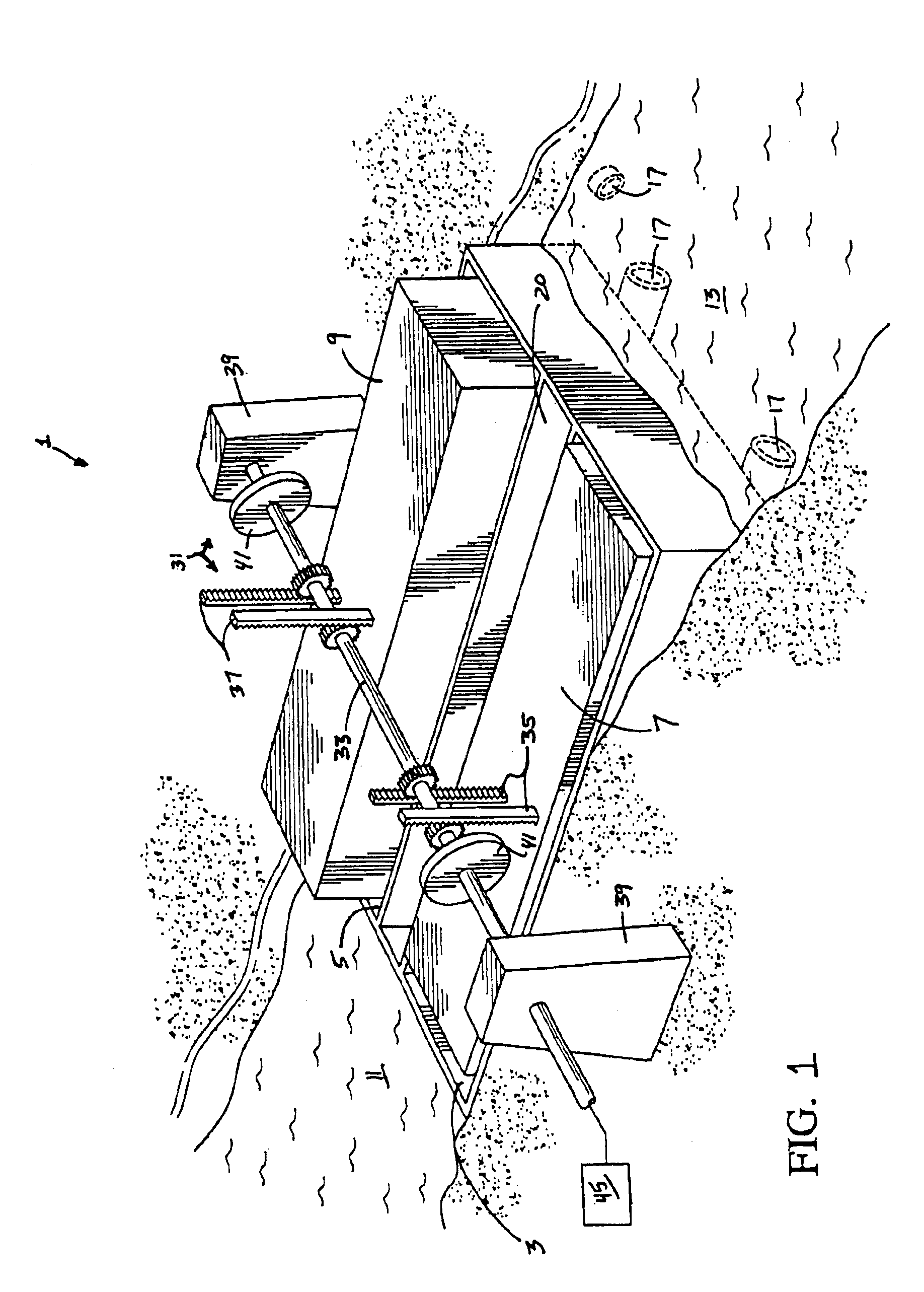

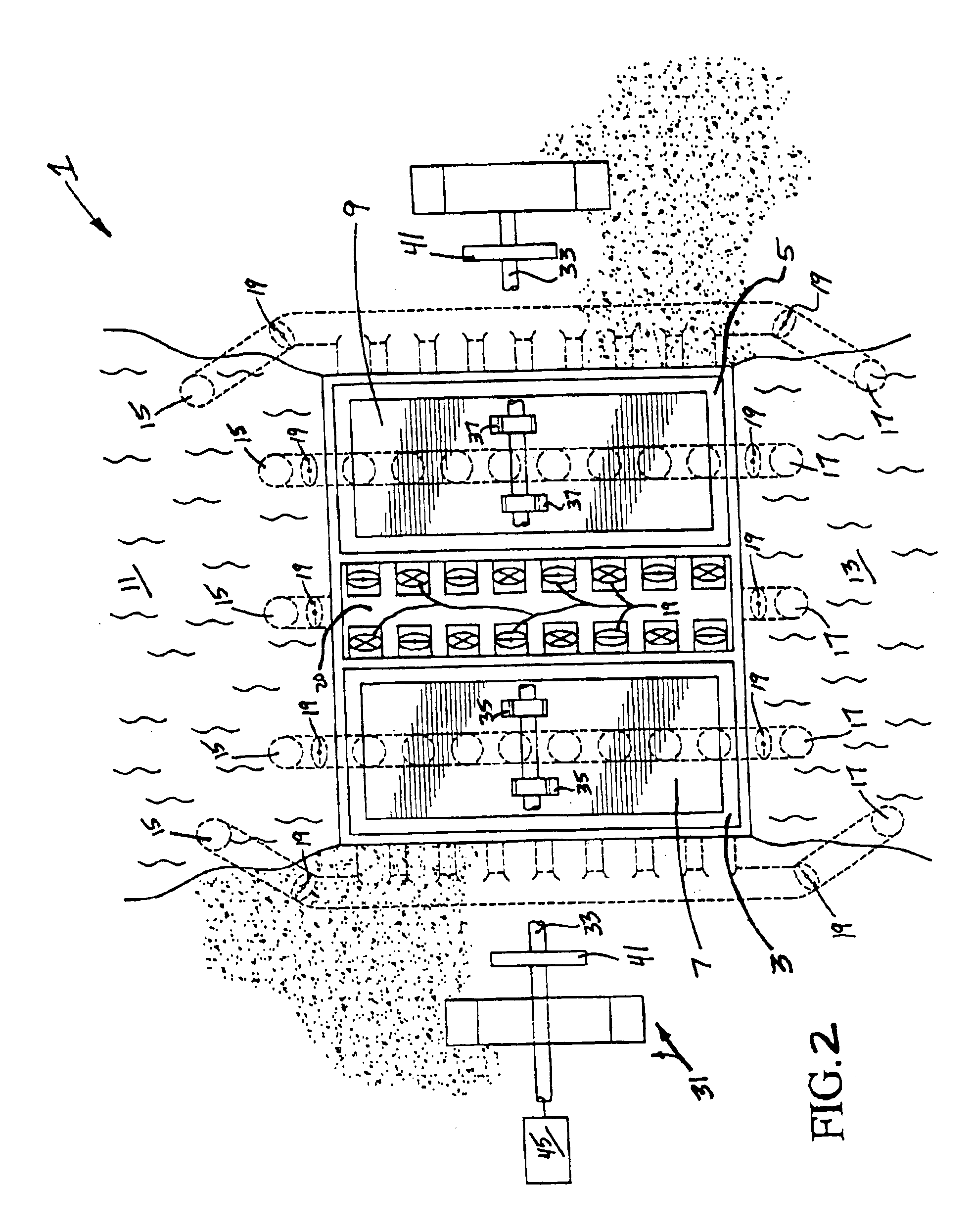

Hydropower generation apparatus and method

Apparatus and methods for generating power utilizing the flow of water from an upper water body to a lower water body in order to generate an upward buoyant force on at least one buoyant object located in a chamber. In preferred embodiments, water is recycled between at least two chambers which generate upward and downward strokes of at least two buoyant objects.

Owner:BEASTON STEVEN D

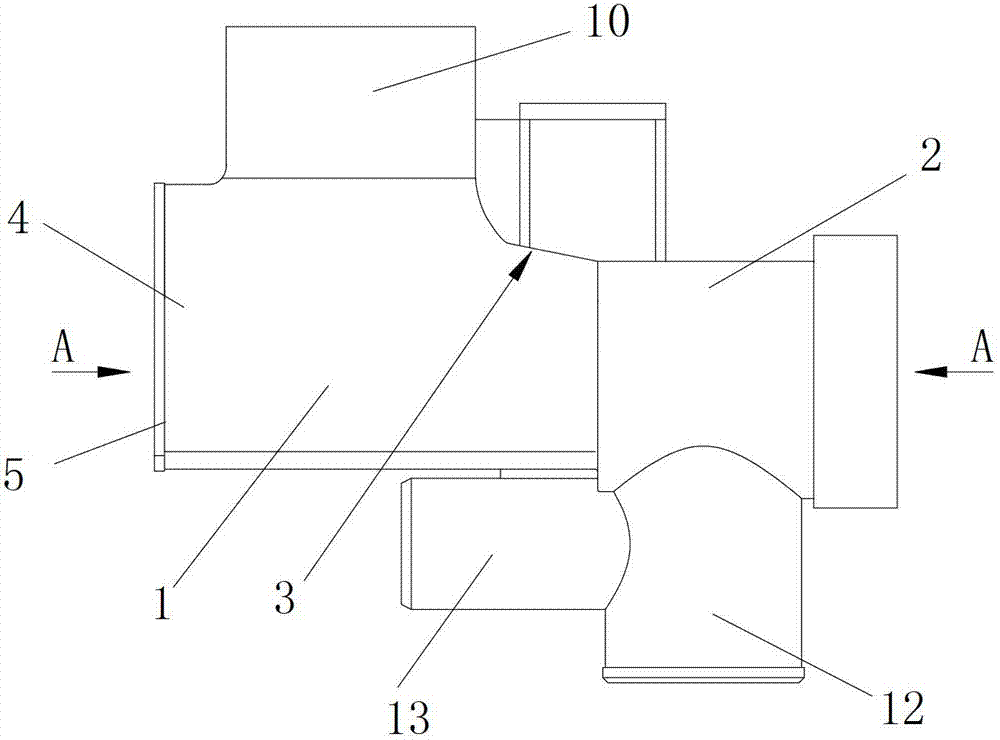

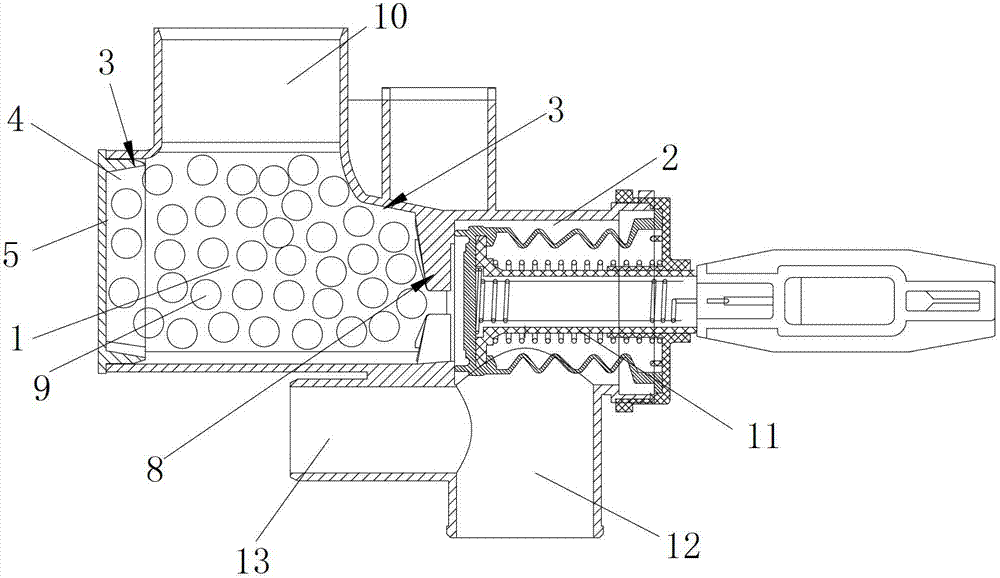

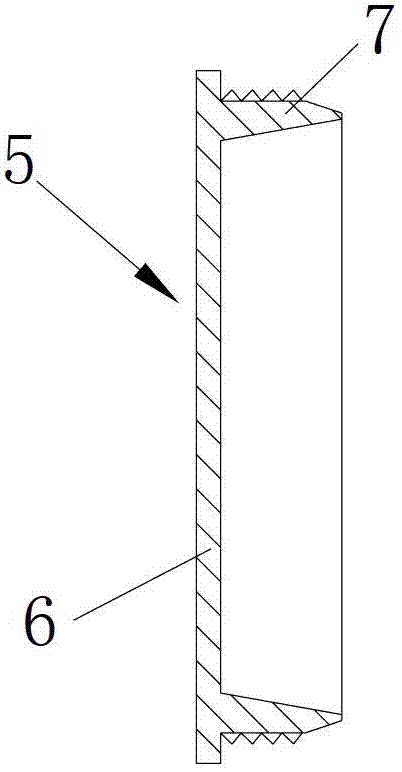

Drainage device of washing machine and washing machine

ActiveCN102733157AAvoid noiseAvoid cloggingHollow article cleaningOther washing machinesImpellerOutfall

The invention discloses a drainage device of a washing machine and the washing machine. The washing machine comprises an outer barrel, an inner barrel and an impeller, wherein cleaning particles for cleaning the walls of the barrels are arranged between the inner barrel and the outer barrel; an outfall is arranged at the bottom part of the outer barrel; the drainage device comprises a particle collecting and discharging chamber for containing the cleaning particles when dewatering and enabling the cleaning particles to float into the outer barrel to clean the wall of the barrel by buoyancy force when feeding water, and a drainage chamber; the particle collecting and discharging chamber is communicated with the outfall through an interconnection pipe; the particle collecting and discharging chamber has an inclined inner wall structure capable of enabling the cleaning particles to float along with raised water level so as to enter into the interconnection pipe along the inner wall and enter into the outer barrel via the outfall; an opening communicated with the outside is arranged at one side of the particle collecting and discharging chamber opposite to the drainage chamber; the opening is provided with a closable sealing cover; and the sealing cover is on the inner wall of the particle collecting and discharging chamber and is in an inclined structure of which the caliber gradually increases towards the internal direction of the particle collecting and discharging chamber. According to the invention, blocking caused by unfavorable flotation of the cleaning particles is avoided and the structure is simple.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Engine using bouyant elements

Owner:SILVA THOMAS A

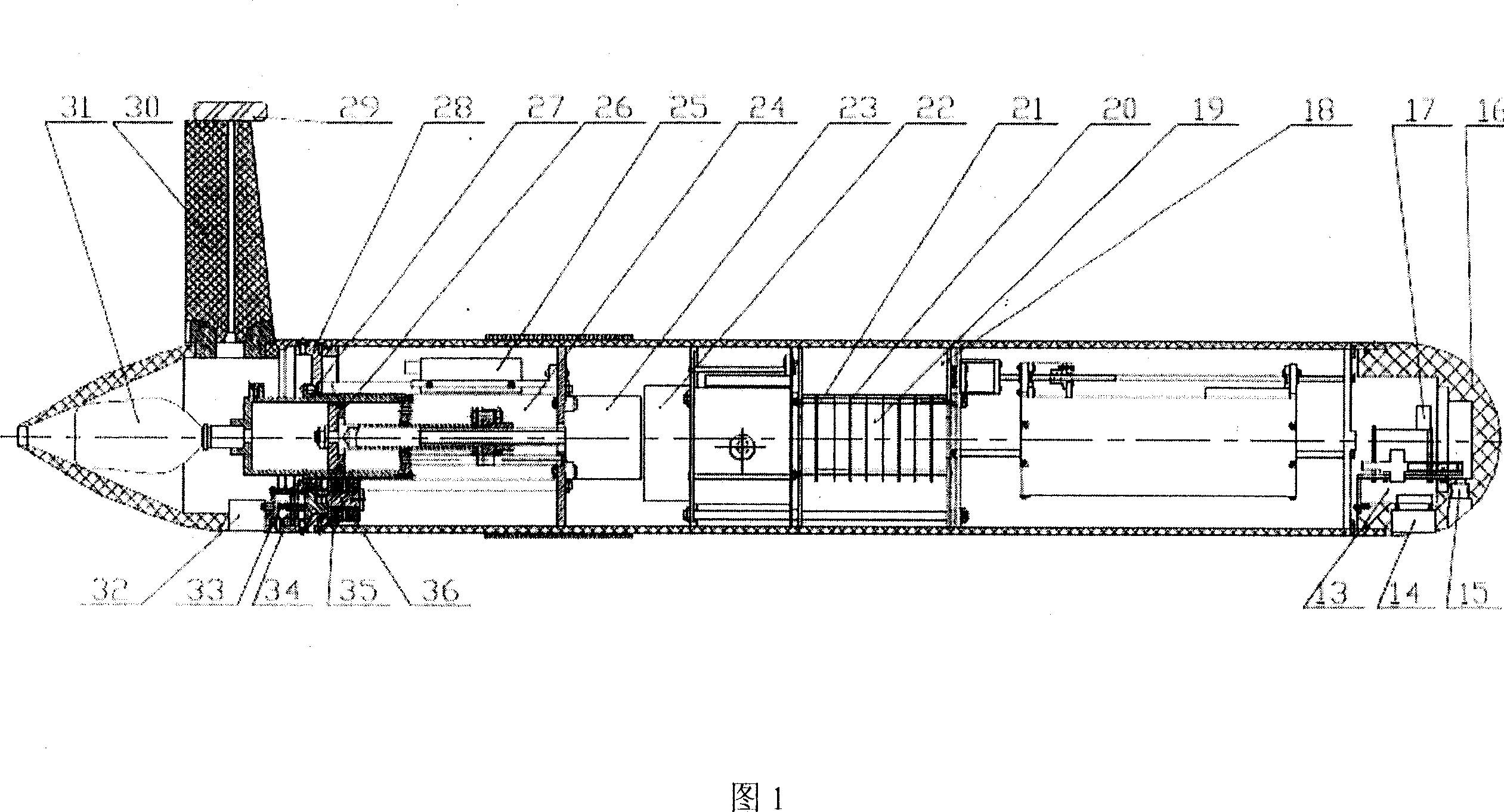

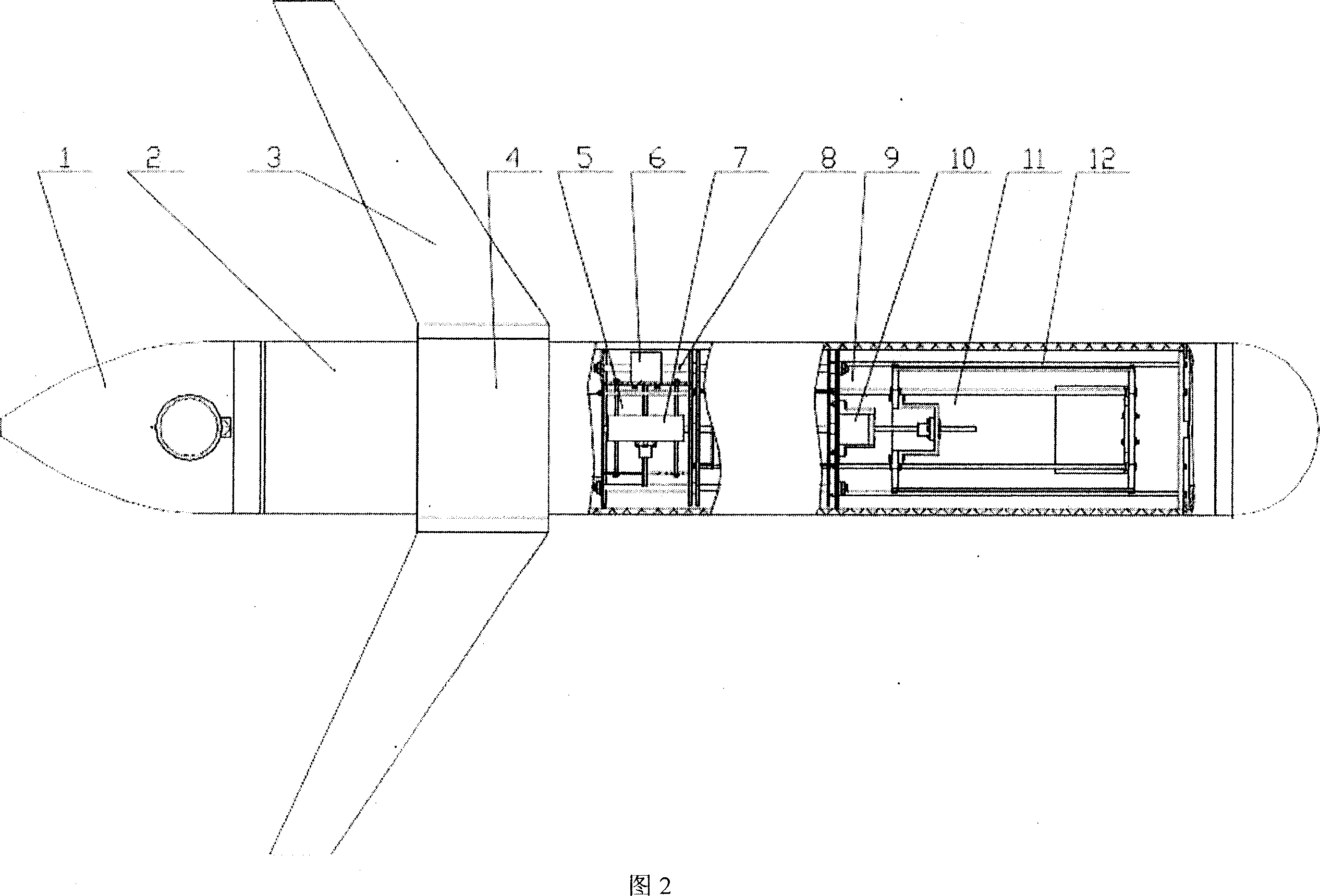

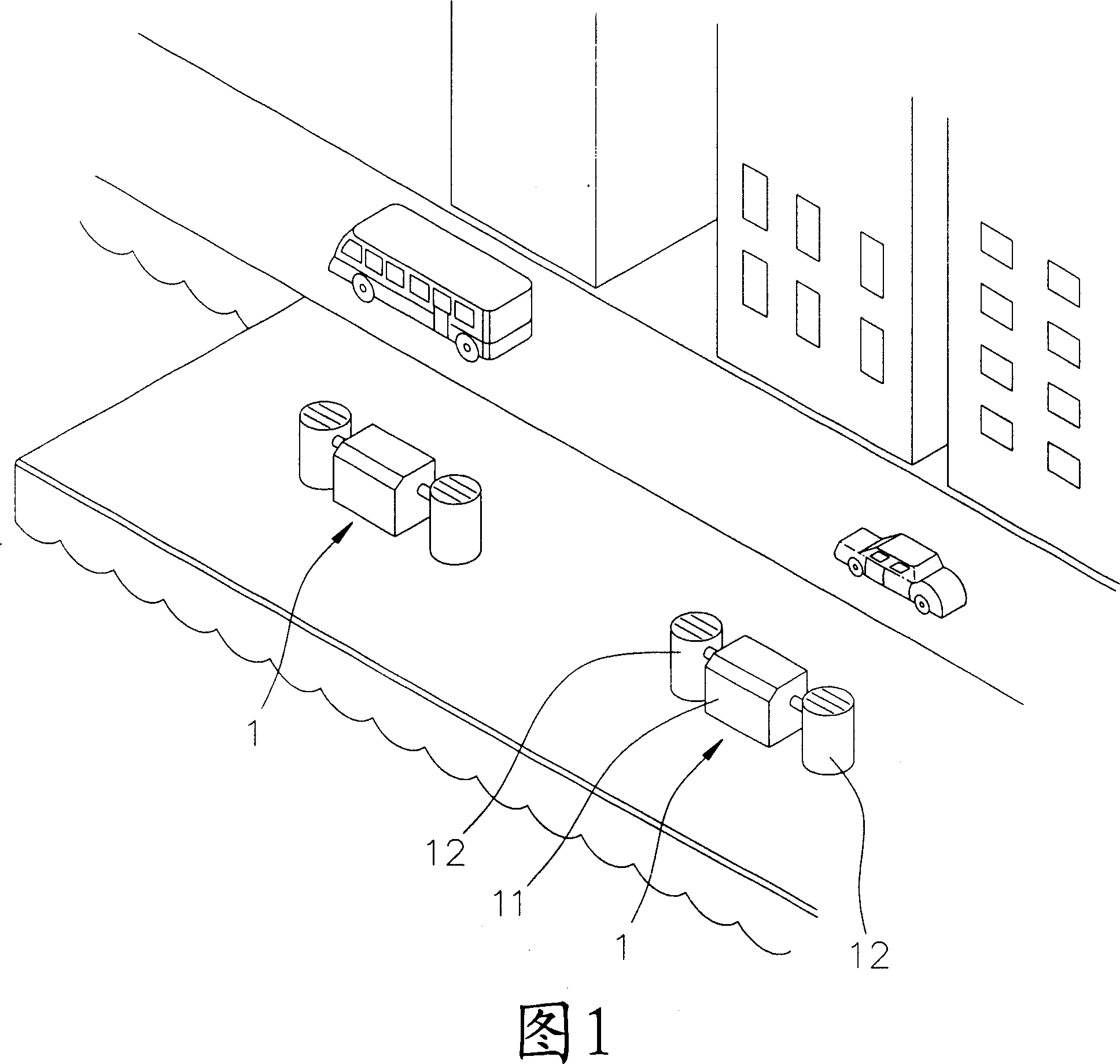

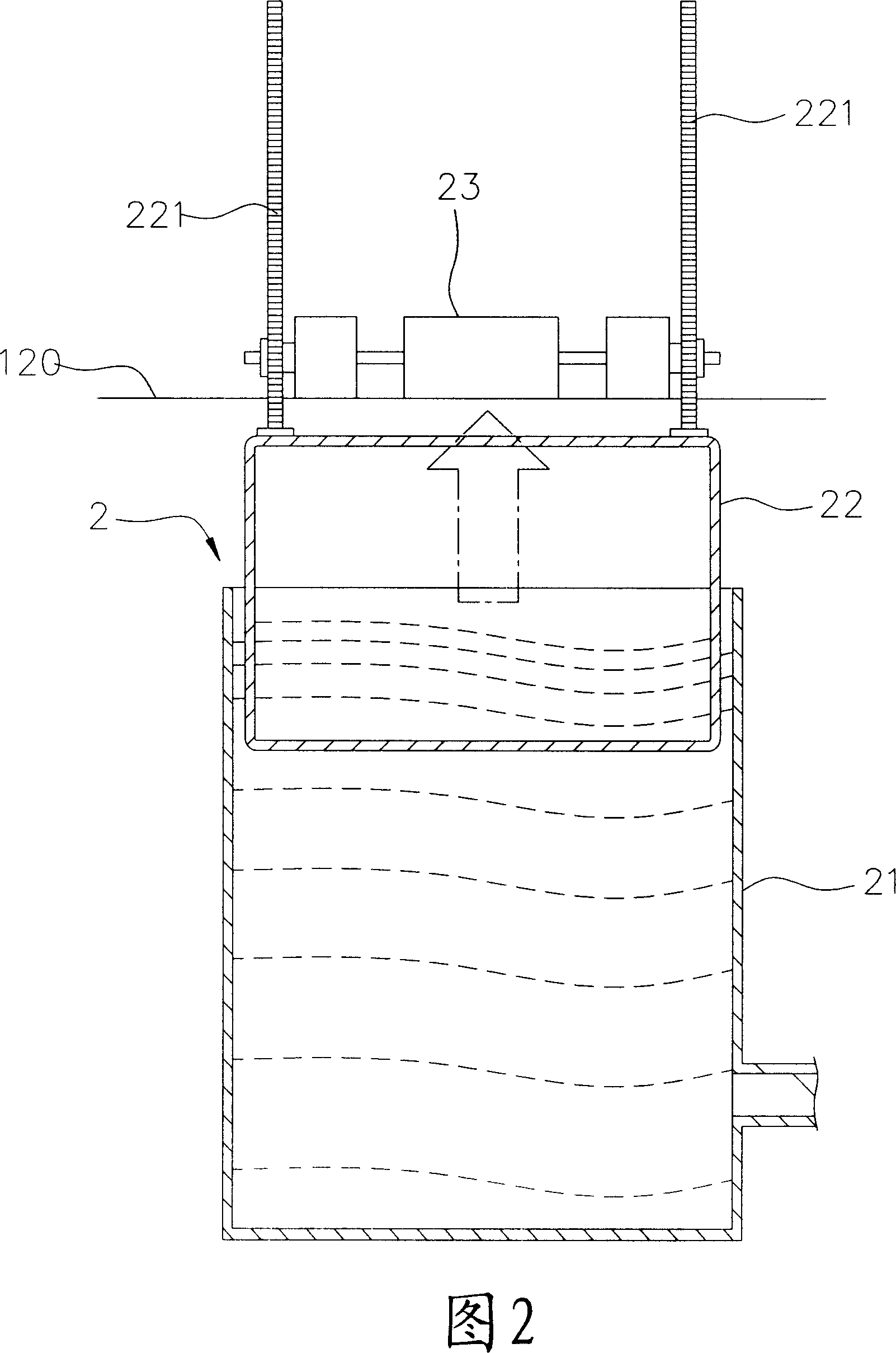

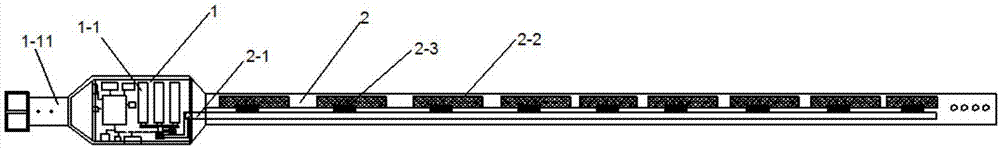

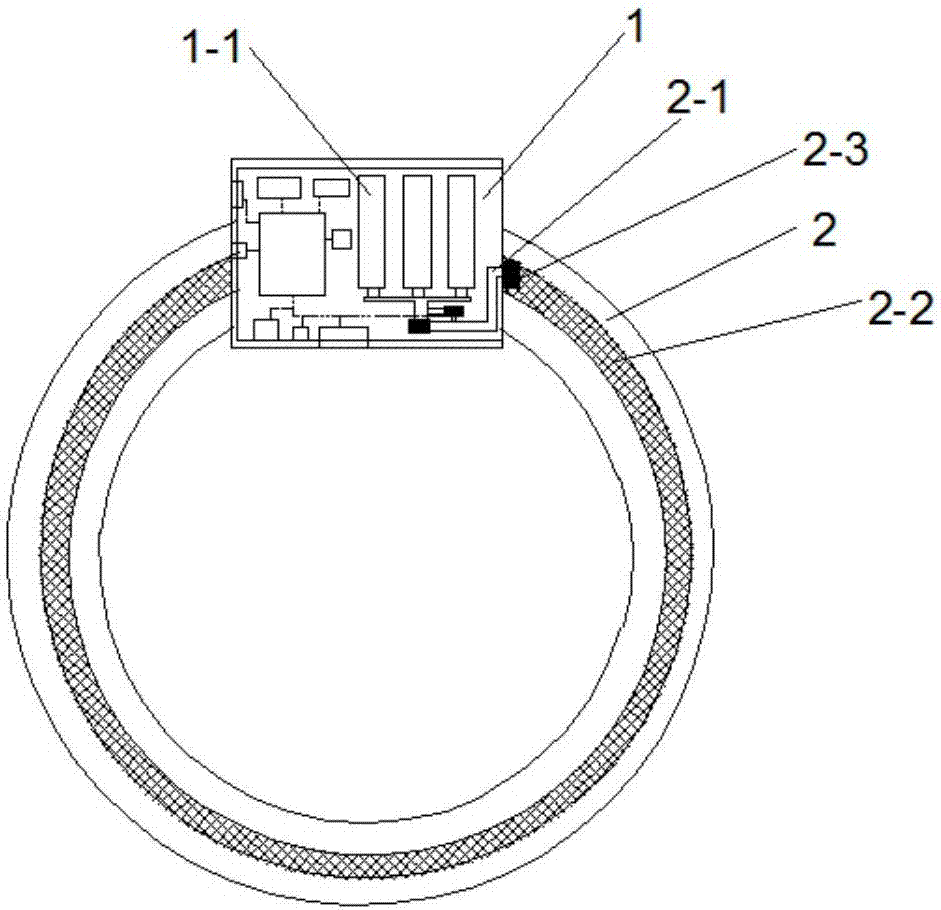

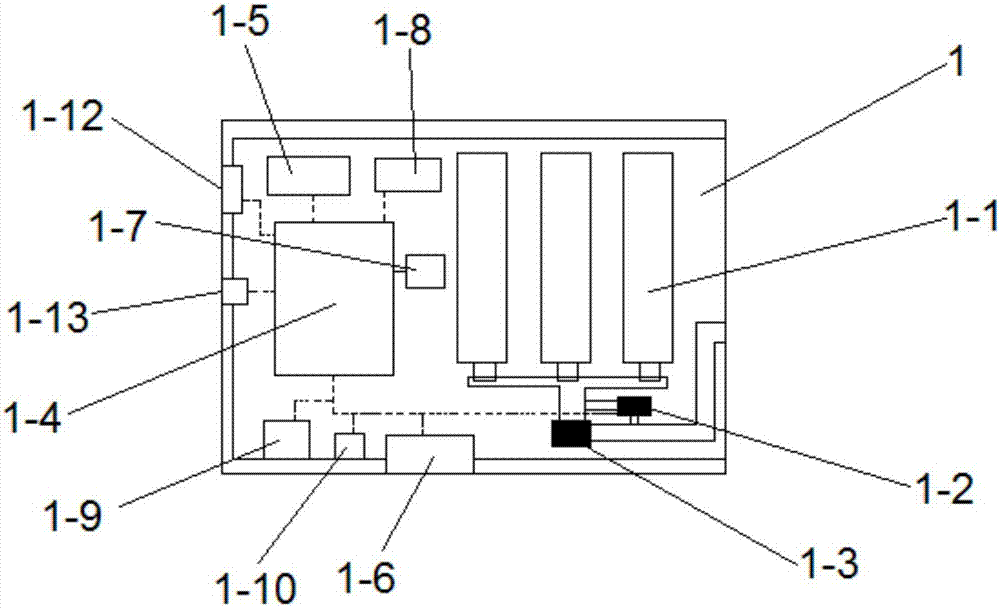

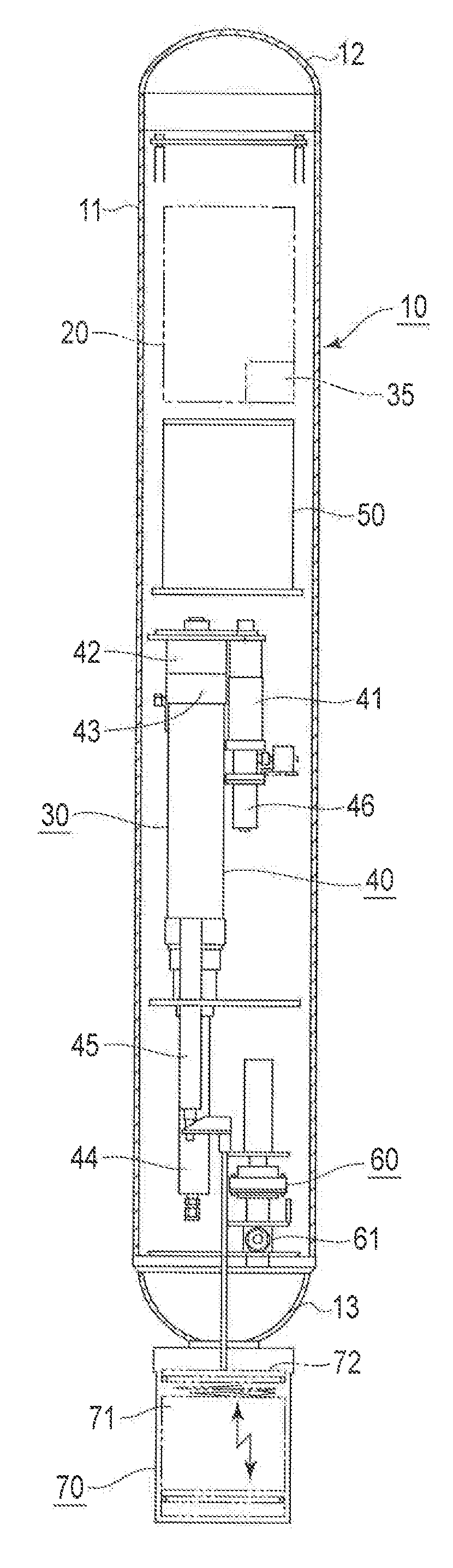

Underwater robot sliding driven by buoyant force

ActiveCN101062714AHas the ability to monitorRealize the gliding movementUnderwater vesselsUnderwater equipmentElectricityElevation angle

The invention relates to the underwater robot, comprising a tapering body, parallel middle body, electric control body, horizontal sliding fin, vertical stable fin, and all kinds of drive devices, with the vertical stable fin fixed to the tapering body, floating device fixed to the tapering and parallel middle body, radio digital transmission station installed on the fixed bracket of the floating adjusting device, horizontal sliding fin fixed to the outside and parallel middle part, pitch angle adjustment device fixed to the front and middle part, electric control part connected wit the horizontal rolling angle adjustment device and elevation angle adjusting device, motor driver installed on the fixed rack, connected with the synchronic motor, front sensor installed inside it, and the emergency treatment device fixed on the bracket with the floating adjustment device. It can effectively improve the space, time density of the ocean, with low cost, and wide application.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

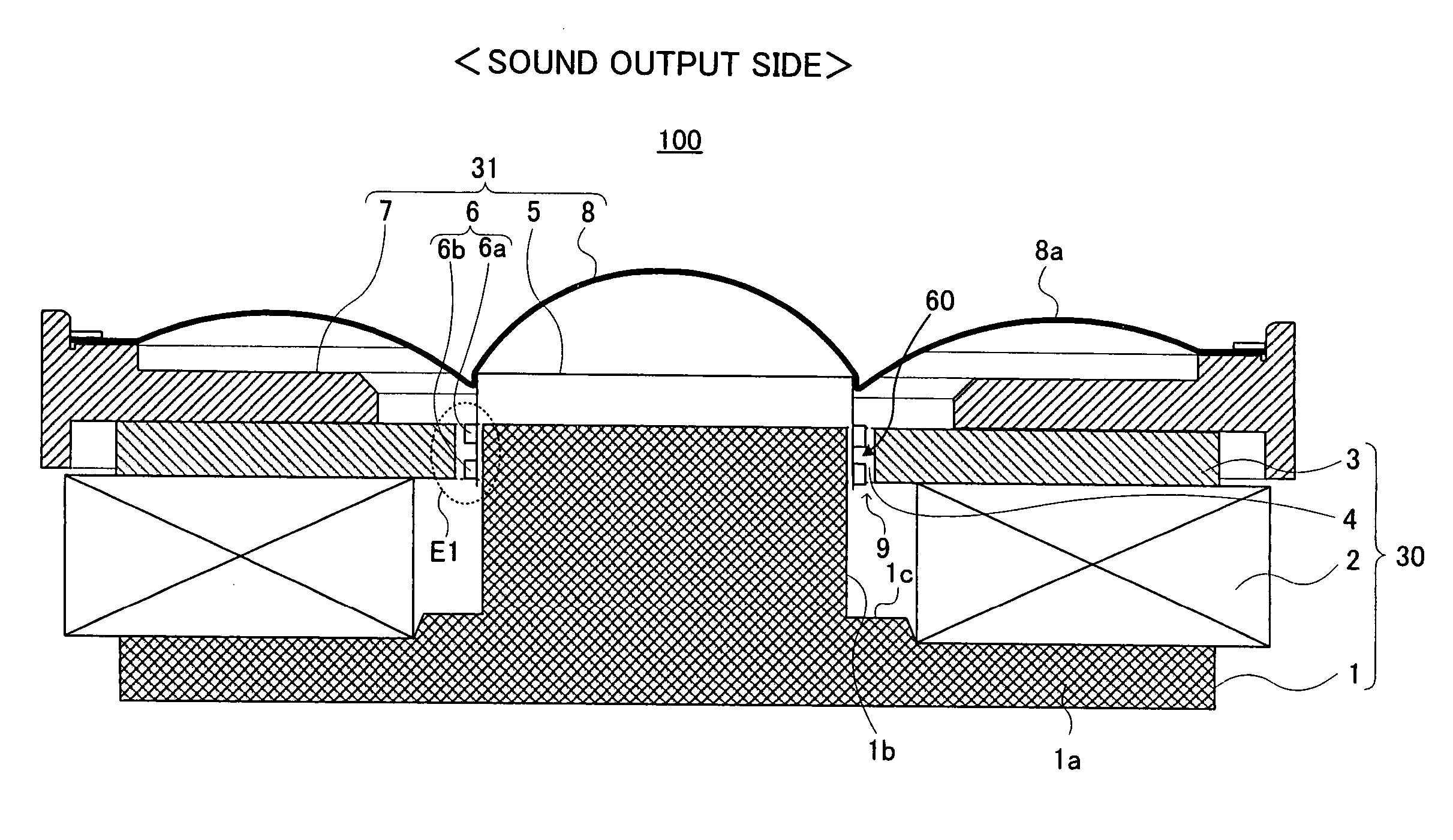

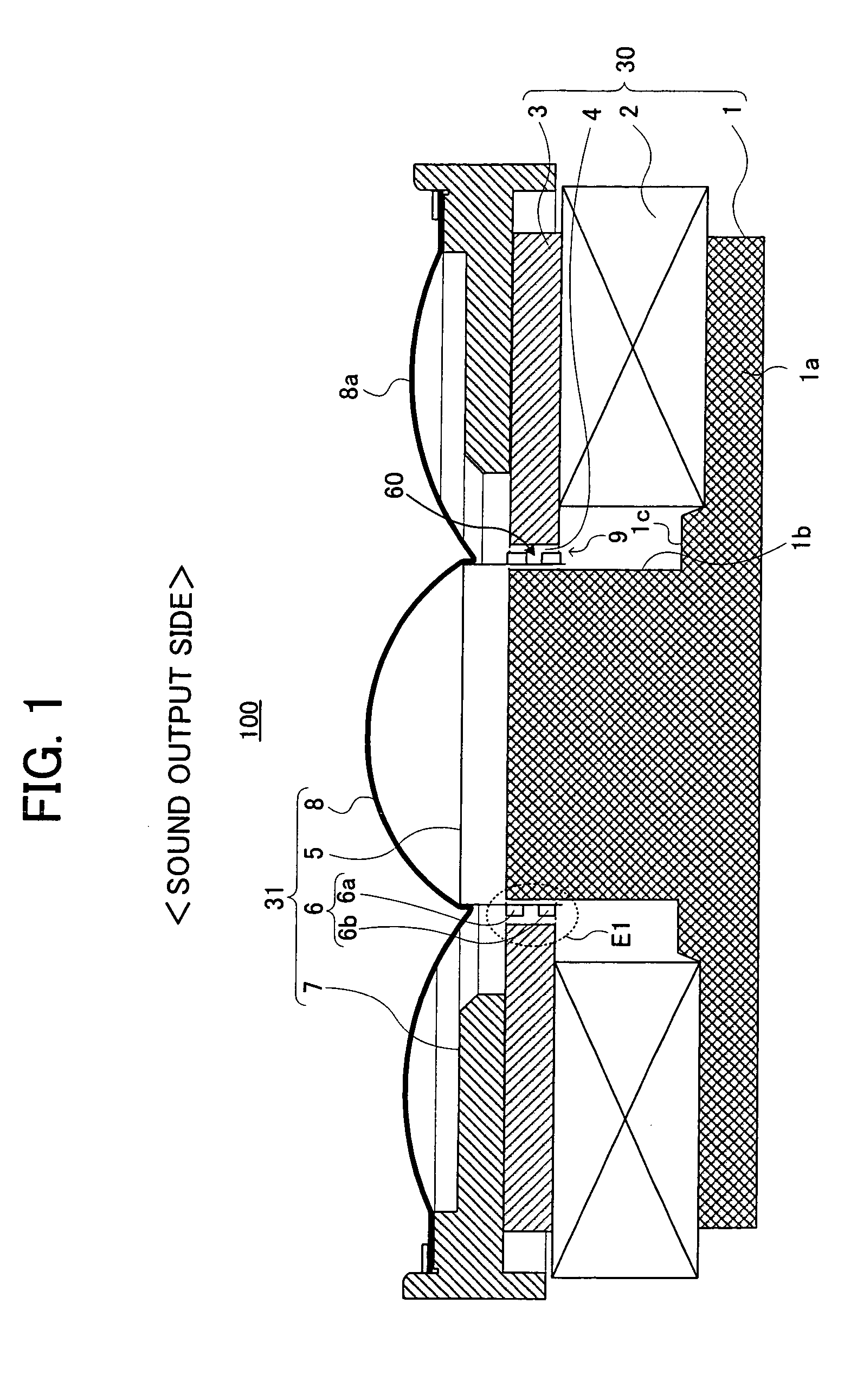

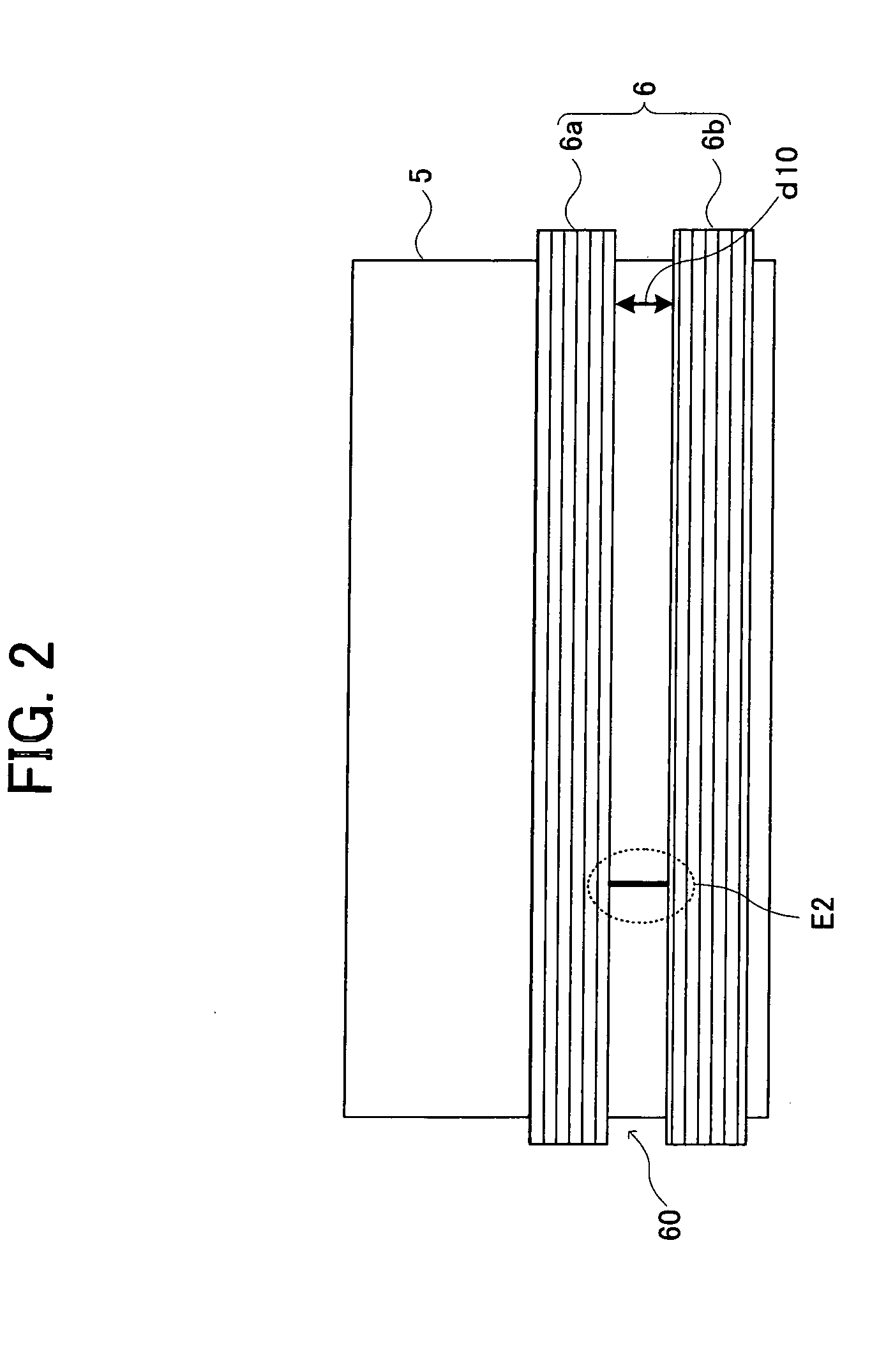

Speaker device

The speaker device includes the magnetic circuit system having an annular plate and magnetic fluid, and a vibration system having a voice coil bobbin and a voice coil. When the speaker device is not driven, the voice coil is located at a predetermined stationary position within the magnetic gap filled with the magnetic fluid. Within the magnetic gap, a recess portion into which the greater part of the magnetic fluid flows is formed in the voice coil or voice coil bobbin. When the speaker device is not driven, the greater part of the magnetic fluid enters the recess portion and forms a stable condition. Thereby, in the case where the edge is formed by soft material, the voice coil is never affected by the buoyant force of the magnetic fluid and reliably held at the predetermined stationary position within the magnetic gap.

Owner:PIONEER CORP +1

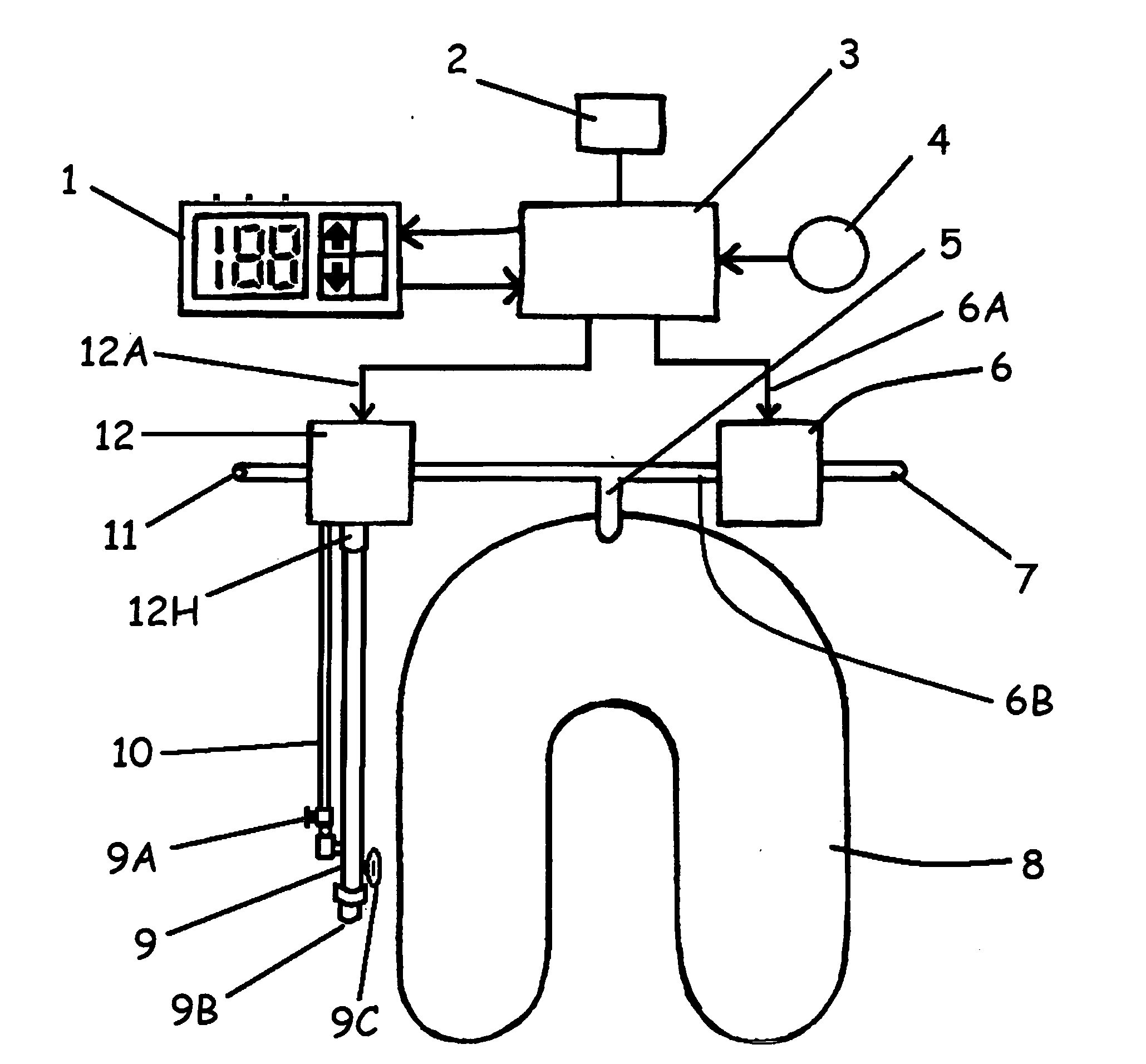

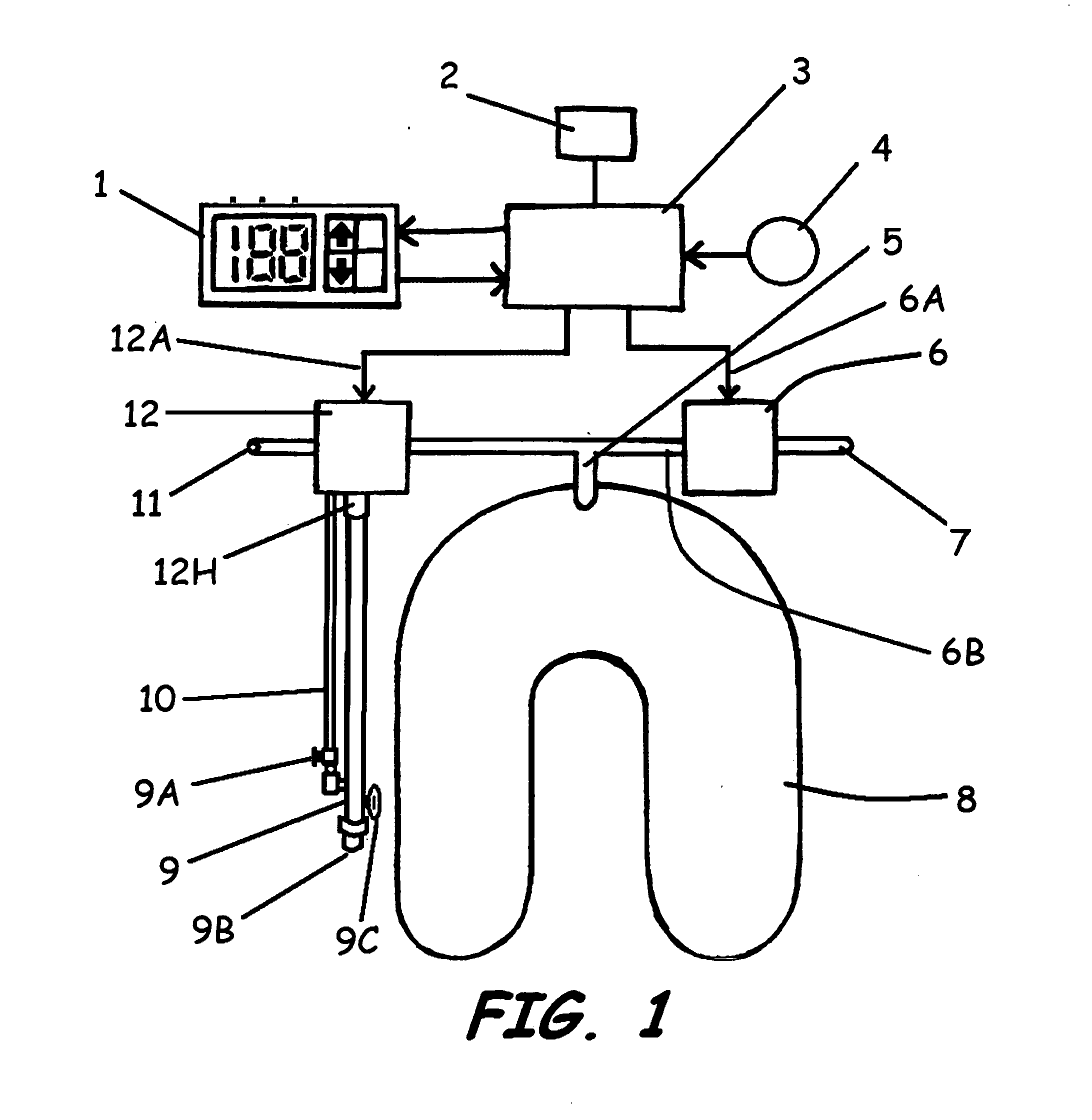

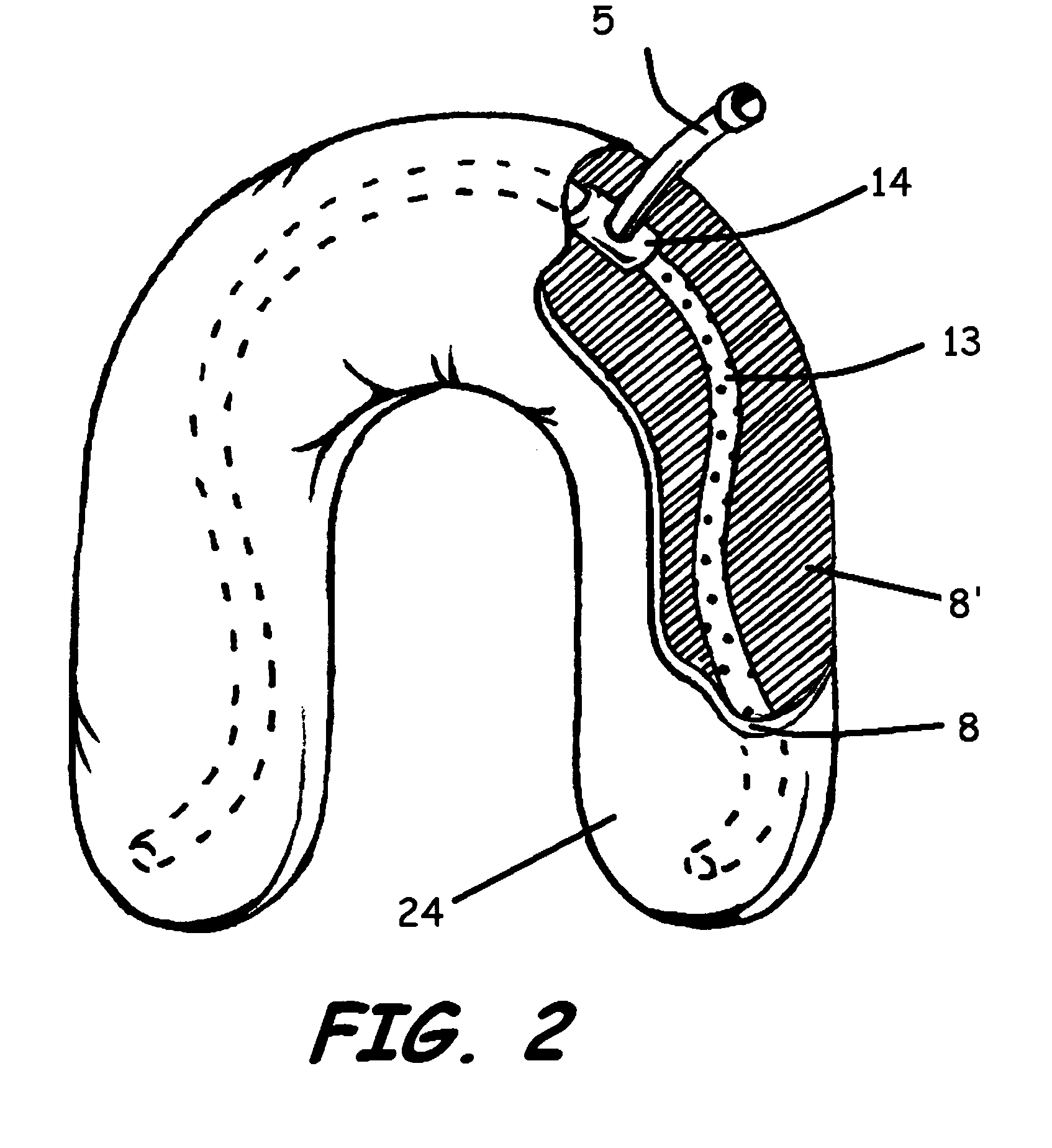

Method and device for automatic buoyancy compensation for a scuba diver or underwater device while in any orientation

InactiveUS20120128425A1Improve abilitiesSaving airUnderwater equipmentMarine engineeringUnderwater vehicle

A buoyancy compensation device and method for a scuba diver or other underwater object, which decreases buoyancy by actively pumping air from a flexible bladder while the diver or object is in any orientation, said bladder having internally a manifold assembly providing access to pockets of air anywhere within the bladder. In addition, said device and method may be adapted for automatically diving, surfacing, or maintaining a predetermined water depth while the diver or object is in any orientation and while the diver's or object's orientation changes, including a sensor for measuring water depth, one or more control inputs for selecting a depth, and a controller unit that determines descent rate, ascent rate, or maintenance of a selected depth based on monitoring the water depth, the setting of the control inputs, and the diver's or objects previous habits and behavior.

Owner:WALCK JEFFREY ALAN

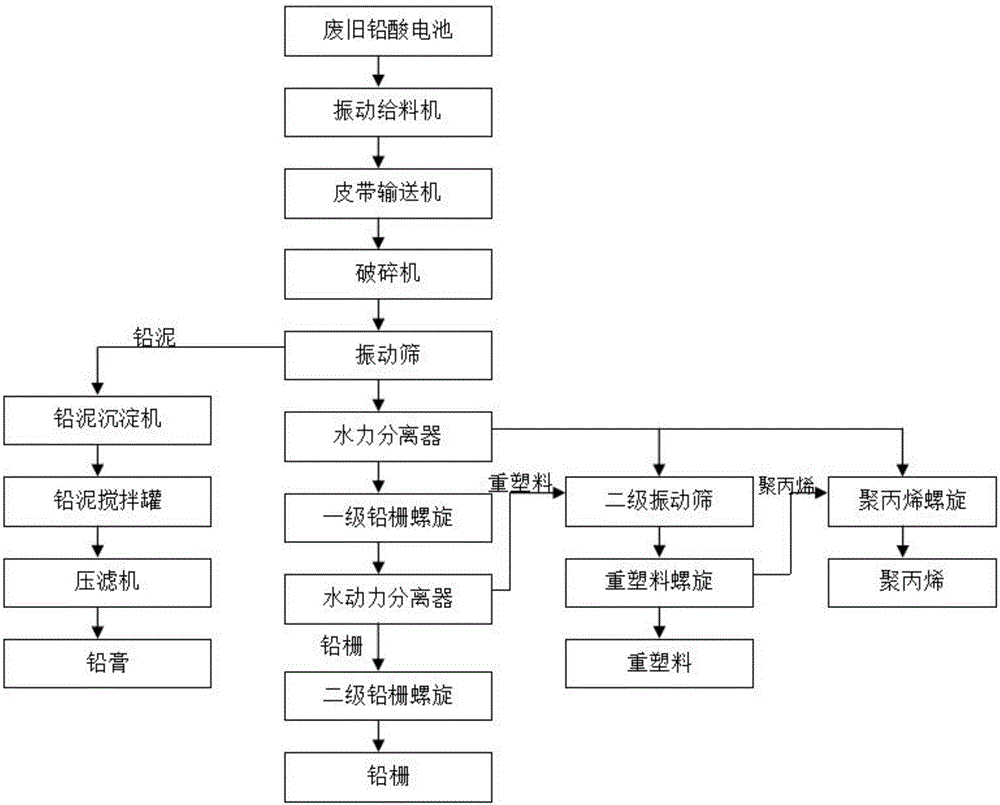

Waste lead-acid storage battery crushing-and-separation one-step energy-saving recycling process

ActiveCN105846005ALow costLess investment in infrastructureWaste accumulators reclaimingBattery recyclingCrusherScrew conveyor

A waste lead-acid storage battery crushing-and-separation one-step energy-saving recycling process. According to work principle of a system in the process, an impact hammer crusher crushes a waste storage battery, and the crushed material is cleaned and separated through a vibration sieve to obtain lead plaster, and according to the physical characters of the crushed materials of the storage battery, wherein the specific gravities of the materials are different, the materials are separated through water buoyant force and compressed air, and finally, the materials are separately conveyed into different stores for storage through a spiral conveyor.

Owner:ANHUI NARADA RENEWABLE RESOURCE TECH CO LTD

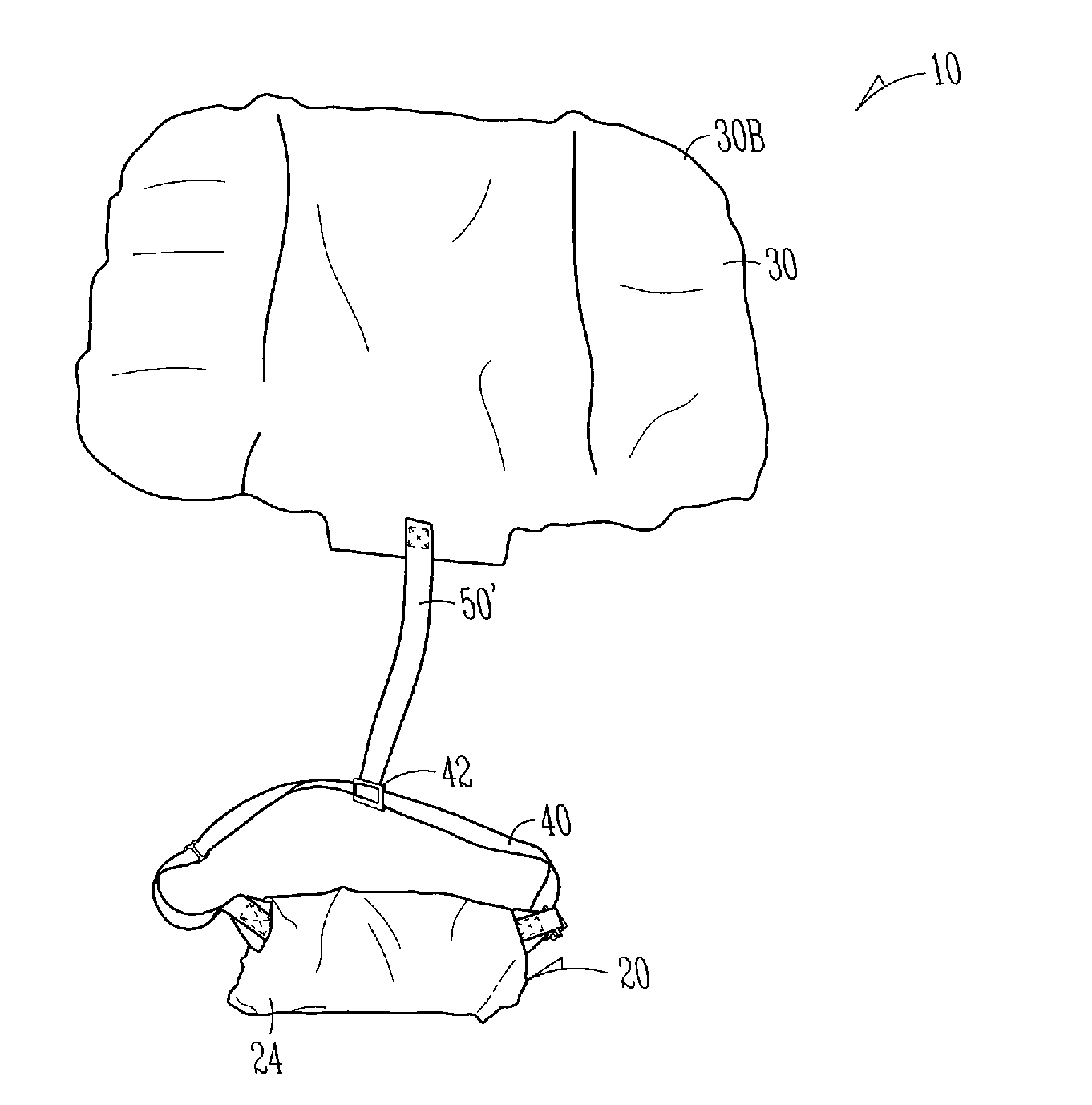

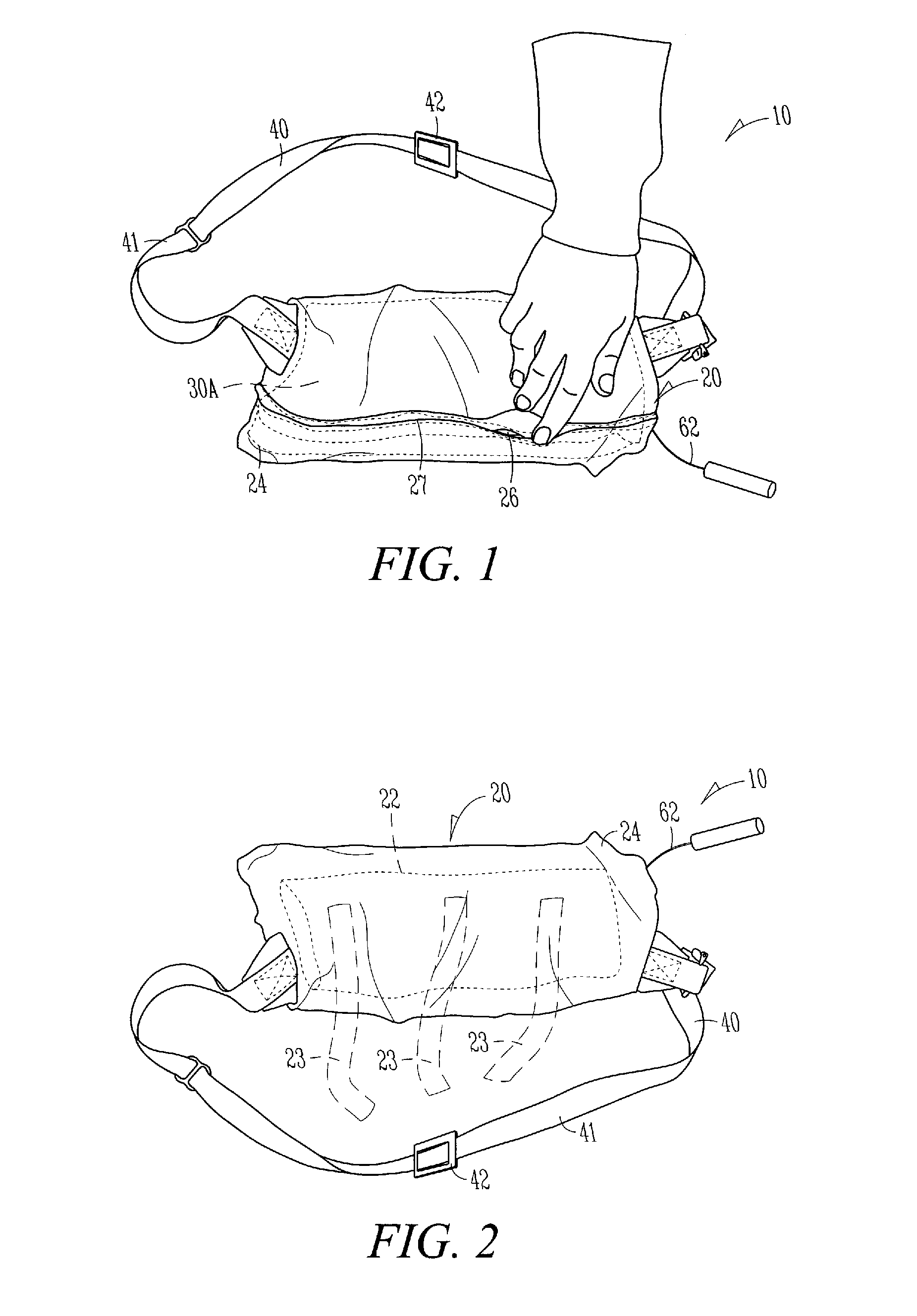

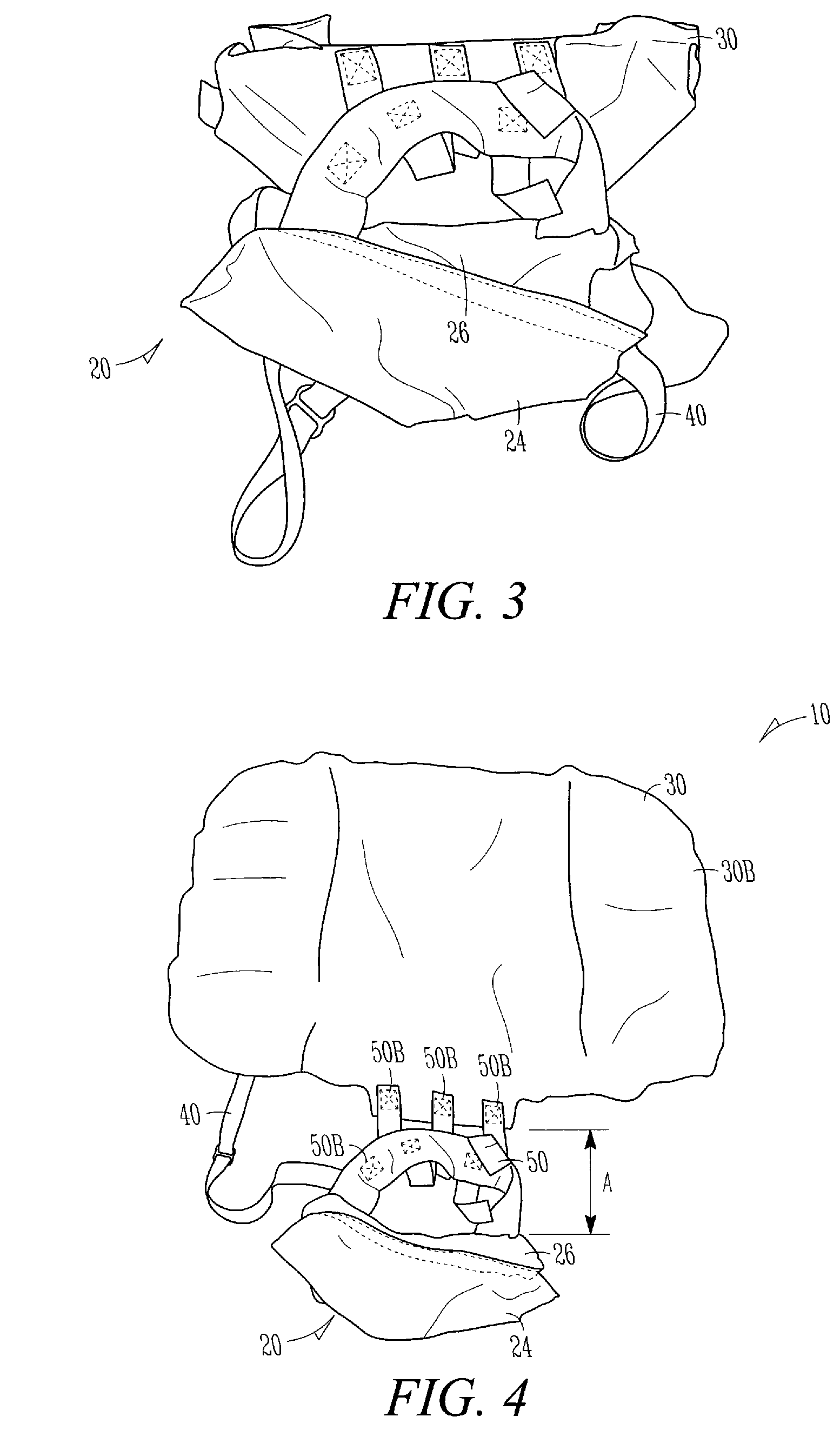

Rescue device and method therefor

A rescue device for use by a user in a material slide includes a bundle having an inflatable bladder in a storage position. Optionally, a harness is coupled to the bundle. In one example, the bundle is adapted to be selectively secured to a backpack. A tether constrains the inflatable bladder. In another example, the tether constrains the bladder to remain within a predetermined distance from a connection device. In another example, the tether constrains the inflatable bladder in a deployed position to around a head of the user. The inflatable bladder, when deployed, is generally buoyant in the material slide and pulls the user proximate to a top surface of the material slide. Optionally, the inflatable bladder, when in a deployed position, is immediately adjacent the user to aid in protecting the user against blunt force trauma from the material slide.

Owner:JTW ASSOCS

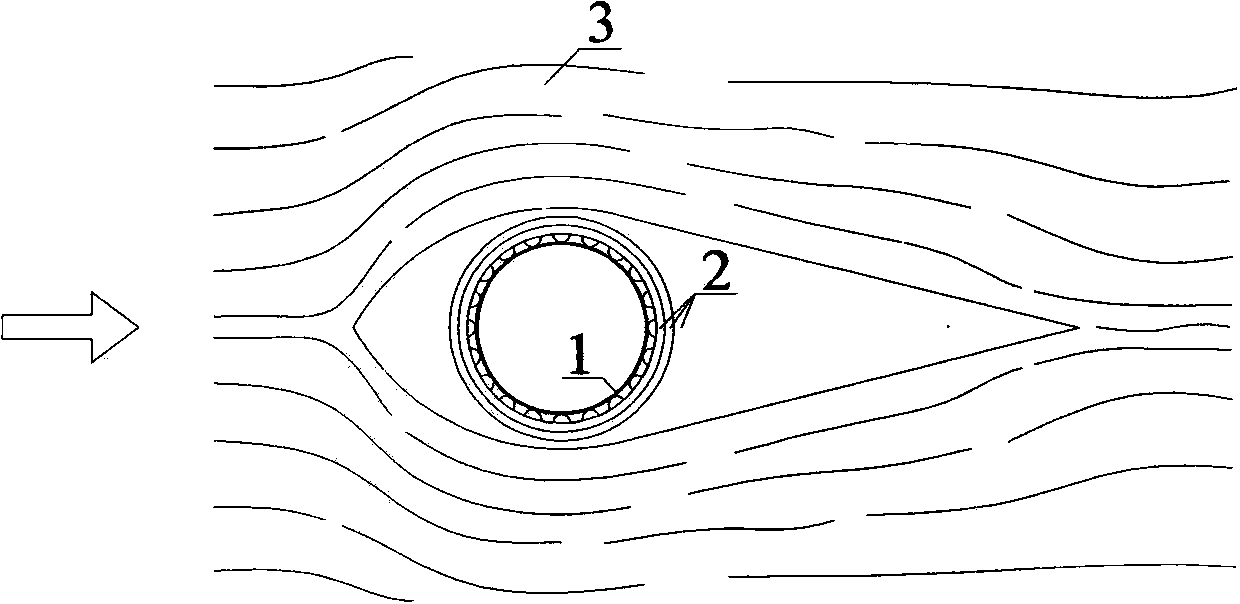

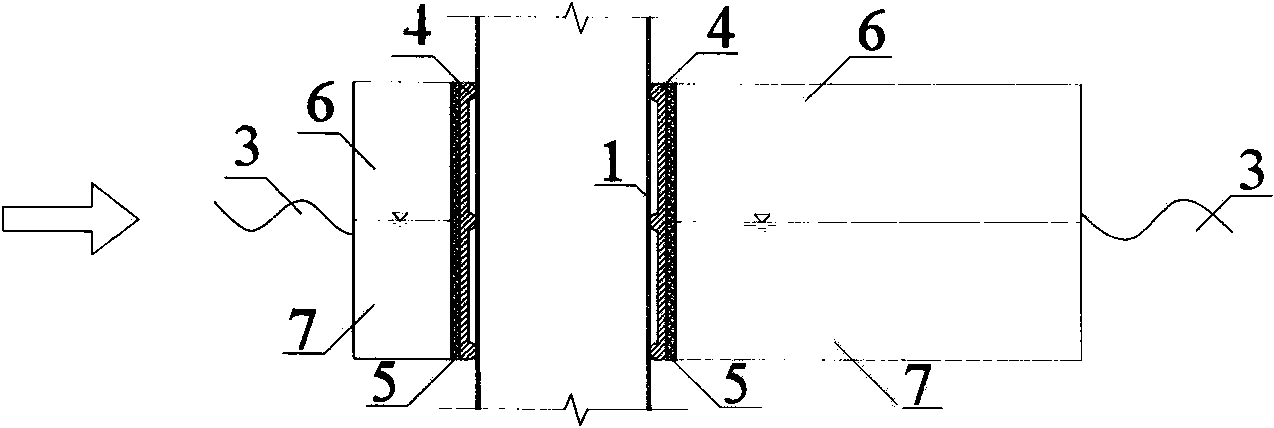

Reduction method for basic wave current vibration of offshore wind power single pile

ActiveCN103469830AReduce vibration responseAvoid fatigue damageProtective foundationViscoelastic dampingSuction force

The invention relates to a reduction method for basic wave current vibration of an offshore wind power single pile. A flexible damping device is arranged outside the basic wall surface of the single pile, wave currents are smoothed and flowing states are improved by utilizing a wing-shaped wall surface with a short head and a long tail, various water power stimulations are reduced from vibration sources, and passed loads are separated and absorbed through viscoelastic damping materials, so that the purpose of reducing pile foundation vibration is achieved. According to the reduction method for the basic wave current vibration of the offshore wind power single pile, the damping device which automatically moves up and down along water level change is always in a main stimulation area of the wave currents by changing water body weights inside a balancing water tank and adjusting relative position of a device and the water surface and under combined actions of the gravity and buoyancy force, the damping device enables the head and tail to be maintained consistent with wave current directions and plays role in damping flexibly along with change of wave current directions under combined actions of head pressure and tail suction of the wing-shaped overflowing wall surface. The reduction method for the basic wave current vibration of the offshore wind power single pile has the advantages of enabling the pile foundation vibration to be reduced by more than 70 % and being simple in structure and convenient to achieve.

Owner:NANJING HYDRAULIC RES INST

Data storage device with mechanism to control rotation of spindle motor

InactiveUS7030527B2Effective controlSimple configurationRecord information storageManufacturing dynamo-electric machinesMagnetic tension forceHard disc drive

Embodiments of the present invention effectively control, by a simple structure, floating of a rotor of a fluid dynamic bearing motor mounted in a hard disk drive. In one embodiment, a base is formed of a magnetic material. The attractive force caused by the magnetic force acts between a bottom of the base and a magnet unit that is constituted of a rotor magnet and a back yoke. This makes it possible to attract a rotor to the base against the buoyant force produced by a thrust bearing, and thereby to effectively control the rotation of the rotor. On the bottom of the base, at a position facing the magnet unit, a convex part protruding from the inner surface of the base is formed in a ring-shape. Adjusting the height, or the width, of the convex part makes it possible to control the magnetic back pressure applied to the rotor.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

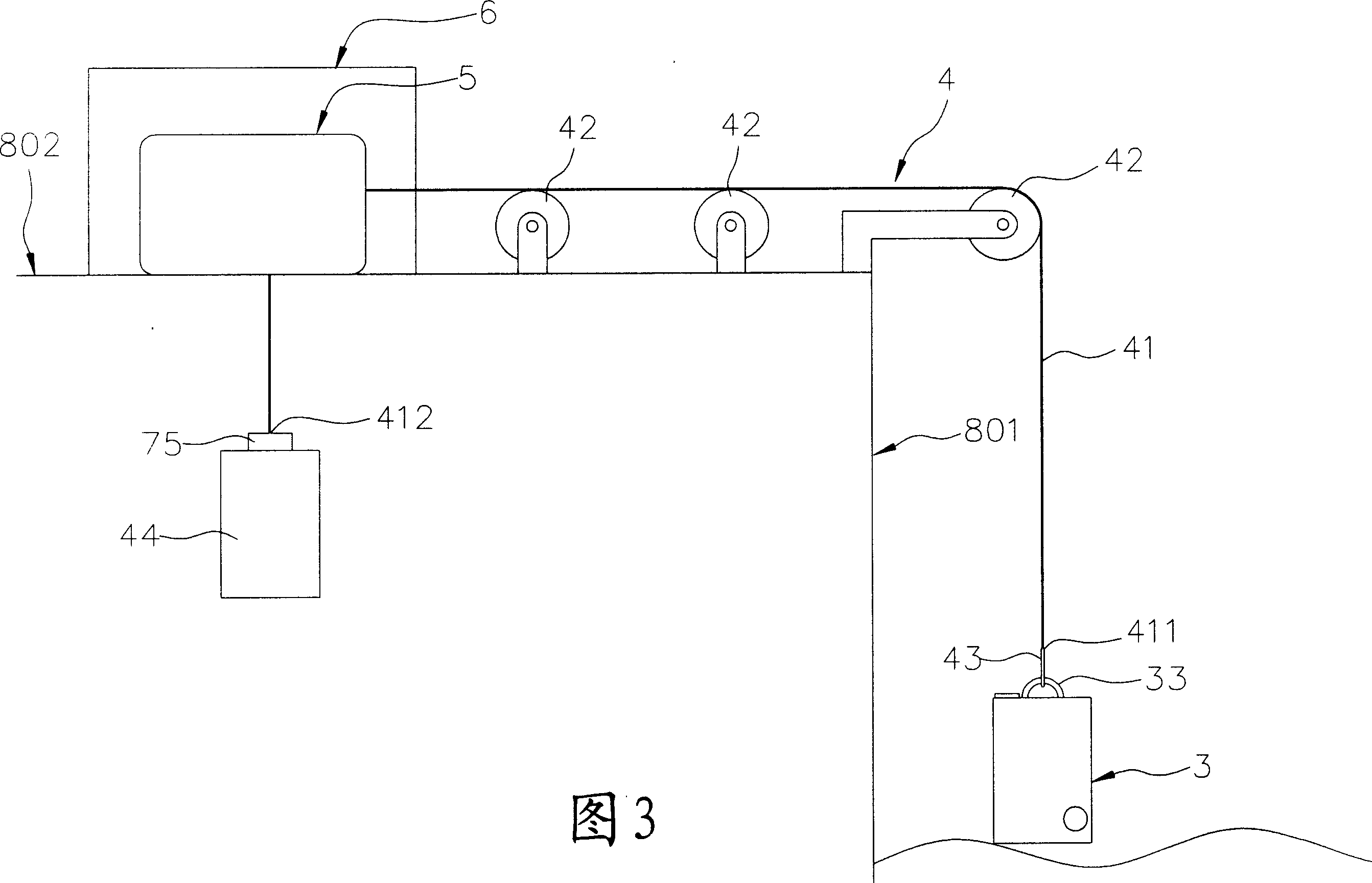

Wave generator

InactiveCN101105167AExtended service lifeLow costMachines/enginesEngine componentsElectric power systemGravitational force

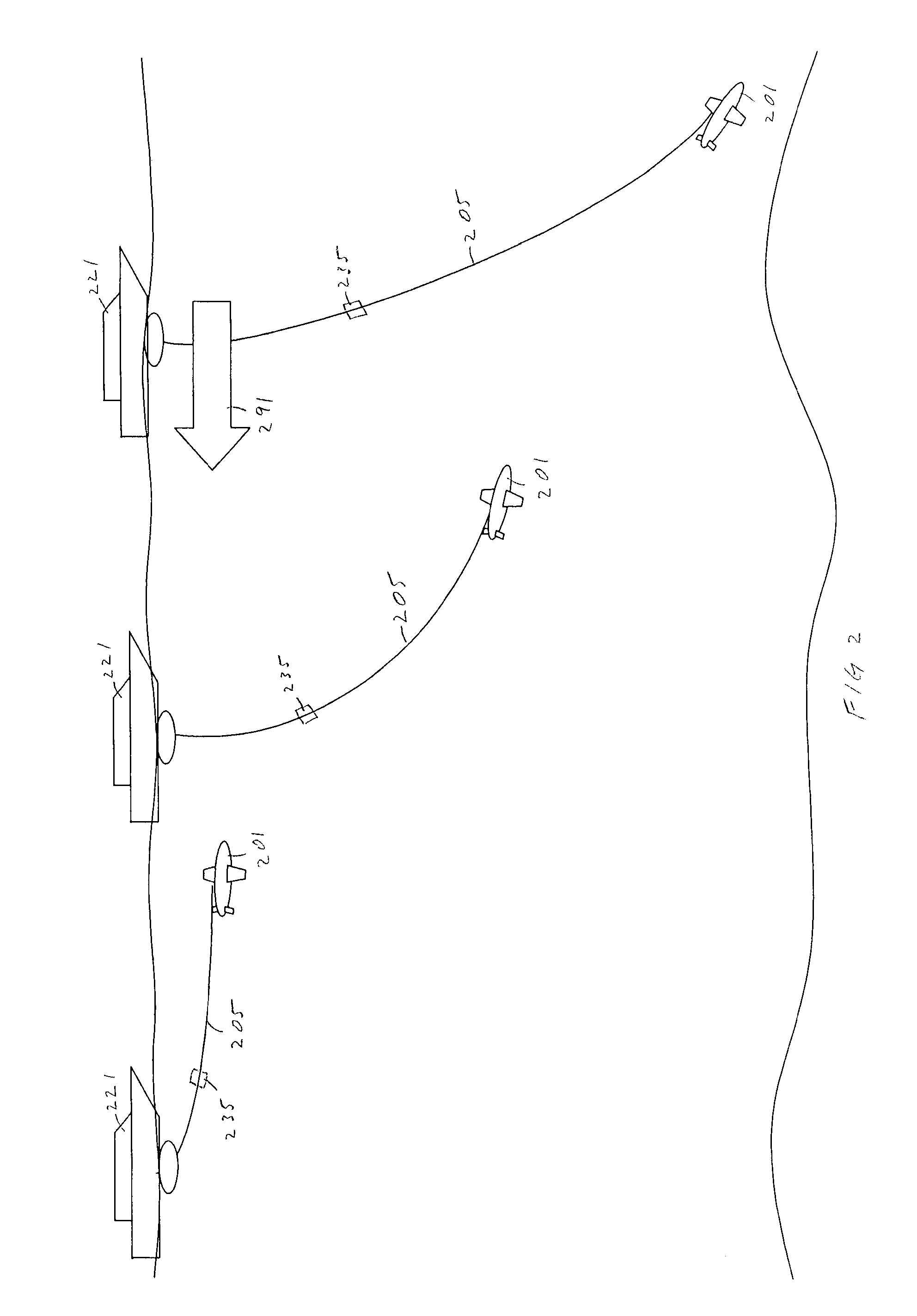

The invention relates to a wave electric power system, which comprises a floating element, a rope unit, a kinetic energy unit, and a power generation unit. The floating element has gravitational force lower than the buoyant force of seawater and can float up and down with wave. The rope unit has a rope connecting the floating element, and the rope crosses over seacoast with height of drop and in penetrated into inland far away form sea surface. The kinetic energy unit allows the rope to be coiled, and has a traction force not larger than the gravitational force of the floating element, so that the rope can carry out reciprocating movement under the action of gravitational force and traction force to generate kinetic energy. The power generation unit receives the kinetic energy from the kinetic energy unit, converts the kinetic energy to electric energy and then output. Thereby, the kinetic energy and power generation unit are far away seacoast, so as to prolong the service life thereof.

Owner:李贻萍

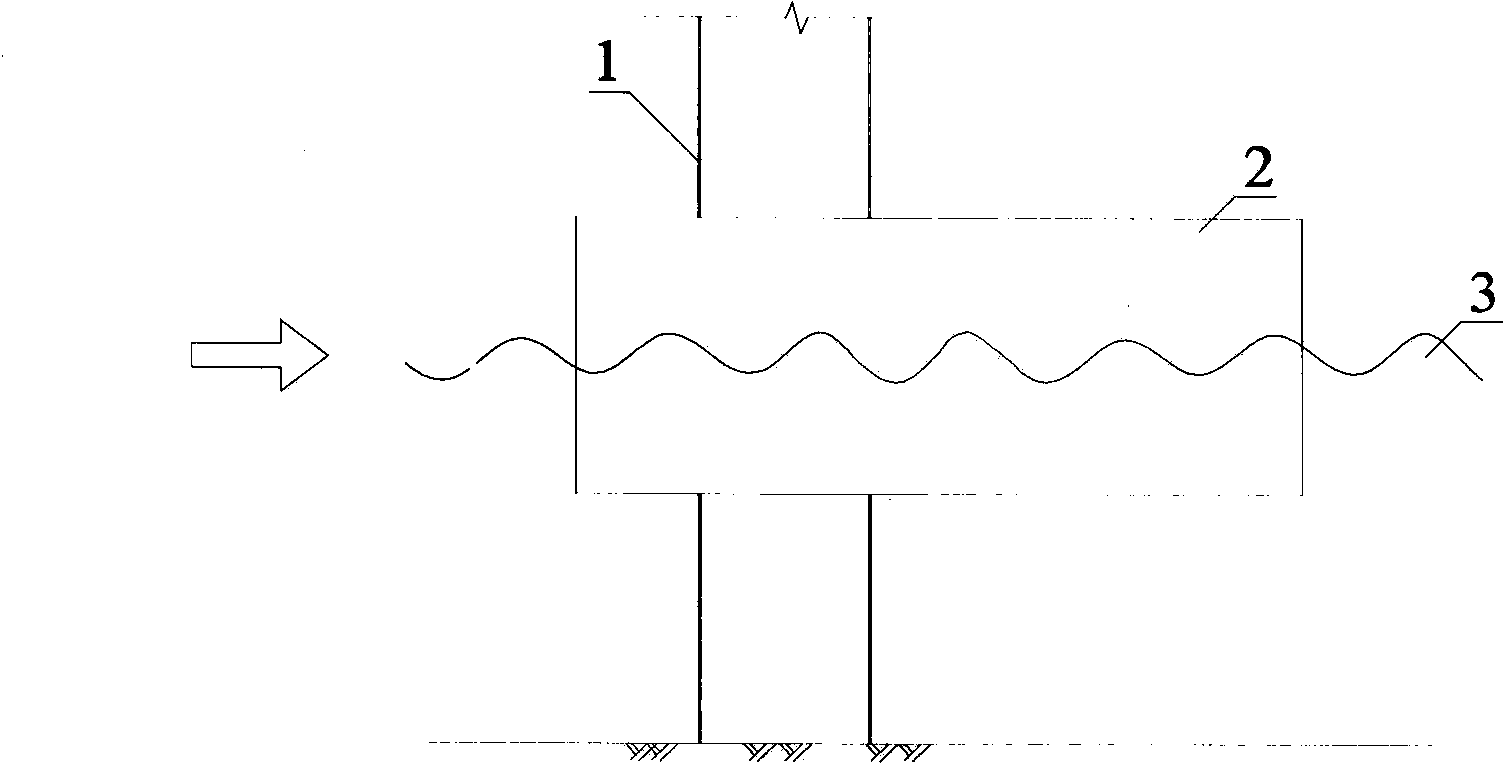

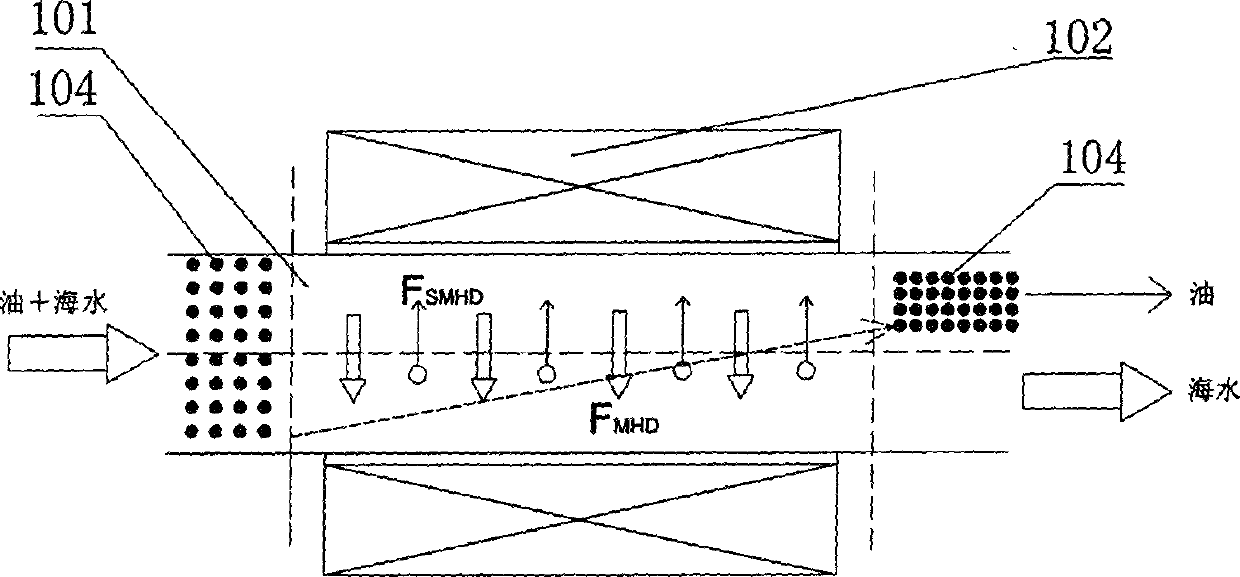

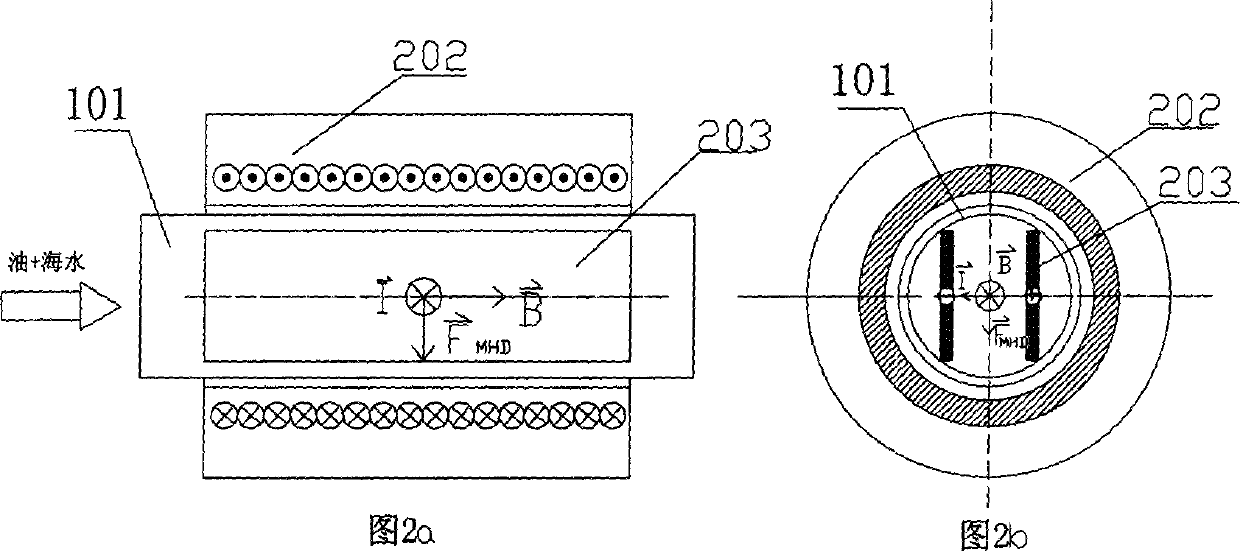

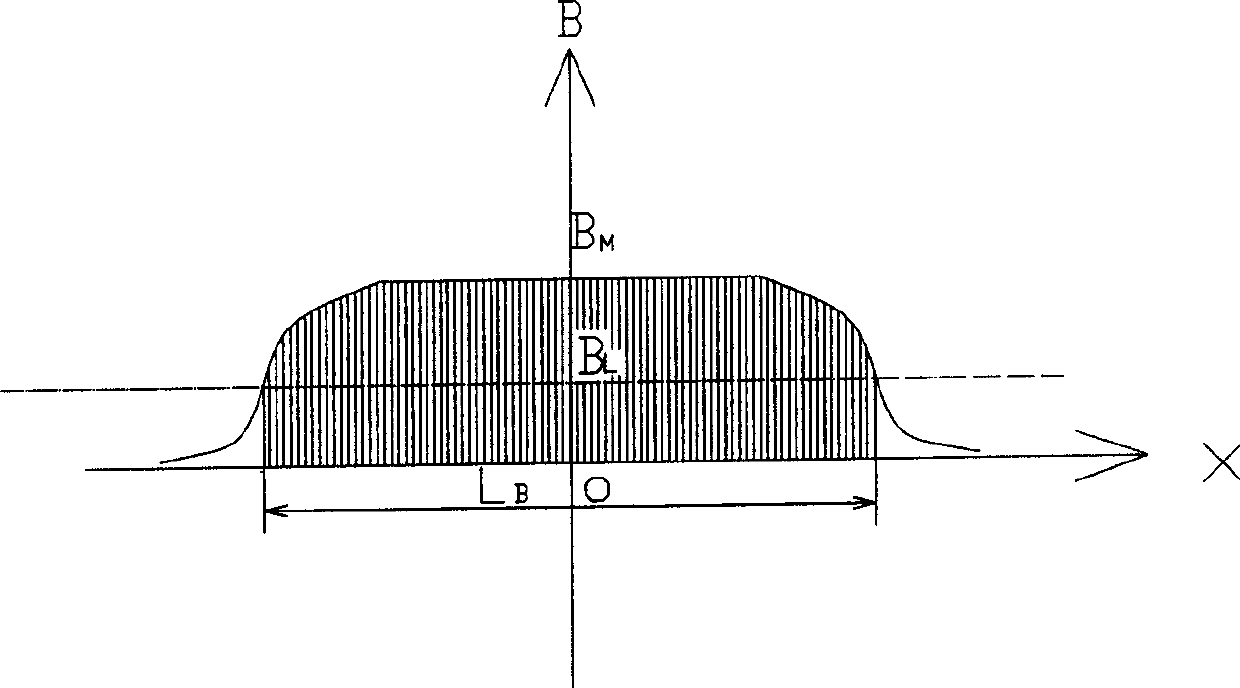

Method and equipment for oil-water separation

InactiveCN1796296AFatty/oily/floating substances removal devicesWater cleaningPerpendicular magnetic fieldOil water

This is a new method and equipment for oil-water separation. This invention is based on the fundamental principle that the magnetic force which the electrified seawater suffers from the perpendicular magnetic field is FMHD=Ií‡B. According to this principle, each of the electrified seawater micelles in the oil-seawater mixture is extruded downwards as a result of the downward magnetic force after they enter into the interaction region between the electric and magnetic fields in the electromagnetic fluid separation passage. The buoyancy of the oil droplet in the seawater is of the same magnitude but in opposite directions, so the oil droplets float upward and assemble in the upper layer of the seawater. Consequently the oil and water are separated into two layers and depart from each other at the vent of the separation passage. There are two constitutional modes for the equipment that applies this invention: (1) solenoid superconductive magnet, tubular electromagnetic fluid separation passage and built-in passage tube parallel electrode pair; (2) saddle-polar superconductive magnet, tubular electromagnetic fluid separation passage and built-in passage tube annular electrode pair. Under the effect of magnetic force in the designed working condition of this invention, the rising velocity of oil-water separation can be accelerated by 1~2 order-of-magnitude in contrast to the result of the specific gravity difference between oil and water.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

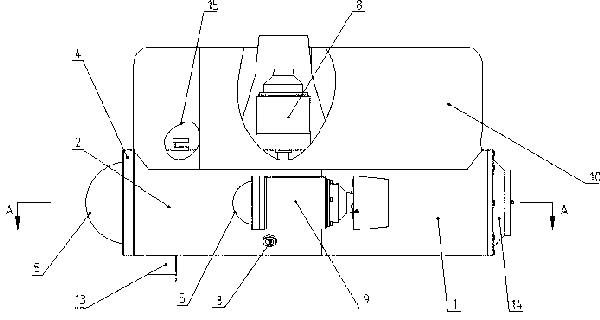

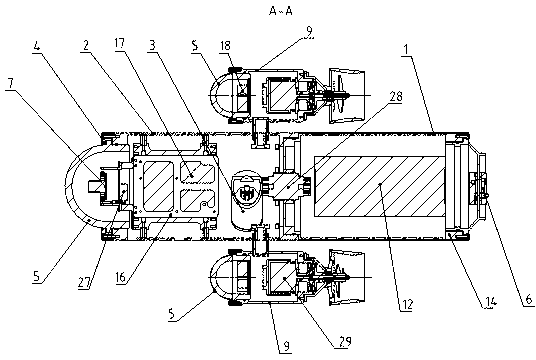

Anti-explosion submersible for mine

The invention relates to an anti-explosion submersible for a mine. The anti-explosion submersible comprises a front end part, a main cavity and a rear end part, wherein the main cavity comprises a battery box body (1), a main control box body (2), a depth sensor (3), a protective cover (5), a power supply switch device (6), a lifting thruster (8), main thrusters (9) and the like, wherein each system comprises a navigation system, an imaging system, a communication system, a power system and a control system; the rudder direction and speed of the submersible are changed through the rotating speed of propellers of the two main thruster, the anti-explosion submersible is lifted through the rotating speed of a propeller arranged in the lifting thruster, and the attitude control and regulation of the submersible are realized through a buoyancy force block device. By adopting an anti-explosion and waterproof design, the anti-explosion submersible has the advantages of simple structure, small and exquisite size, low cost and easiness in popularization, is suitable for flood detection underground a coal mine, is used for knowing underground accident conditions, and provides a correct decision basis for emergency rescue.

Owner:CITIC HIC KAICHENG INTELLIGENT EQUIP CO LTD

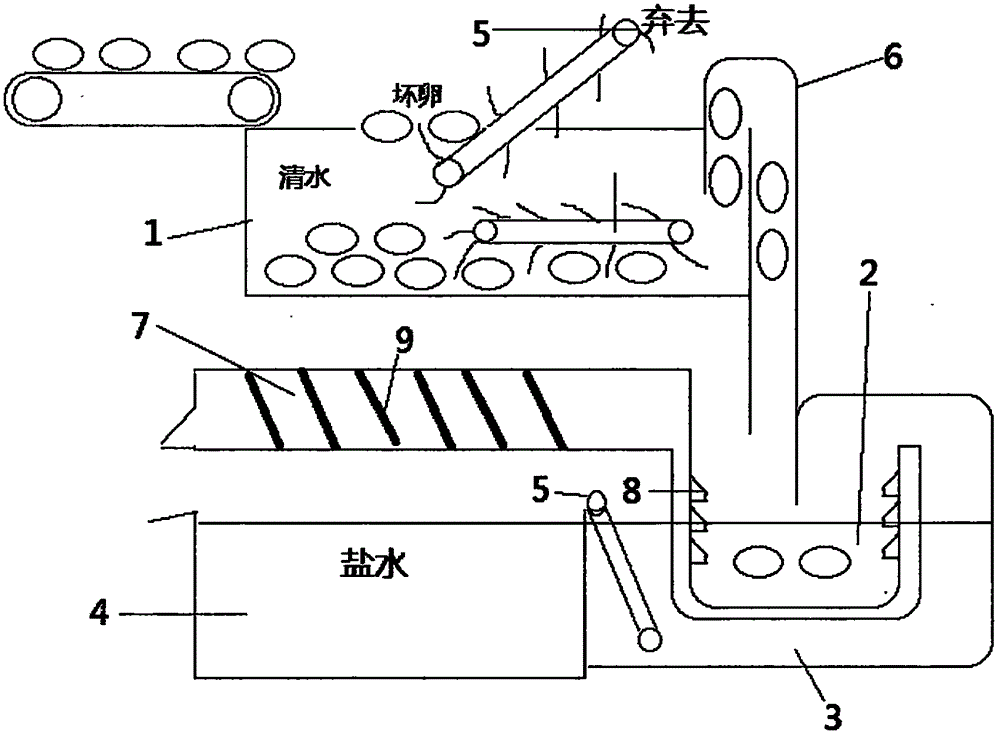

Egg product sorting production line

PendingCN105706957AKeep surfaces cleanExtended shelf lifeAvicultureProduction lineProcess engineering

The invention provides an egg product sorting production line. Aiming at the problems that a sub-packaging process of current egg products including raw eggs and the like is relatively rough and surfaces of the eggs are rarely disinfected, the invention designs sorting production line equipment capable of disinfecting the surfaces and washing to remove dirt. Meanwhile, according to the characteristics that the fresh degrees and densities of the raw eggs are different, rotten eggs are sorted and removed by buoyant force of water. The egg product sorting production line can be applied to sorting, cleaning and package of other egg products except the raw eggs. The egg product sorting production line has the advantages that a series of production line type operation process of sorting, washing and packaging the fresh eggs products is realized, the egg products are clean and the manual cost is reduced.

Owner:杨溢

Device, system and method to heat and froth milk

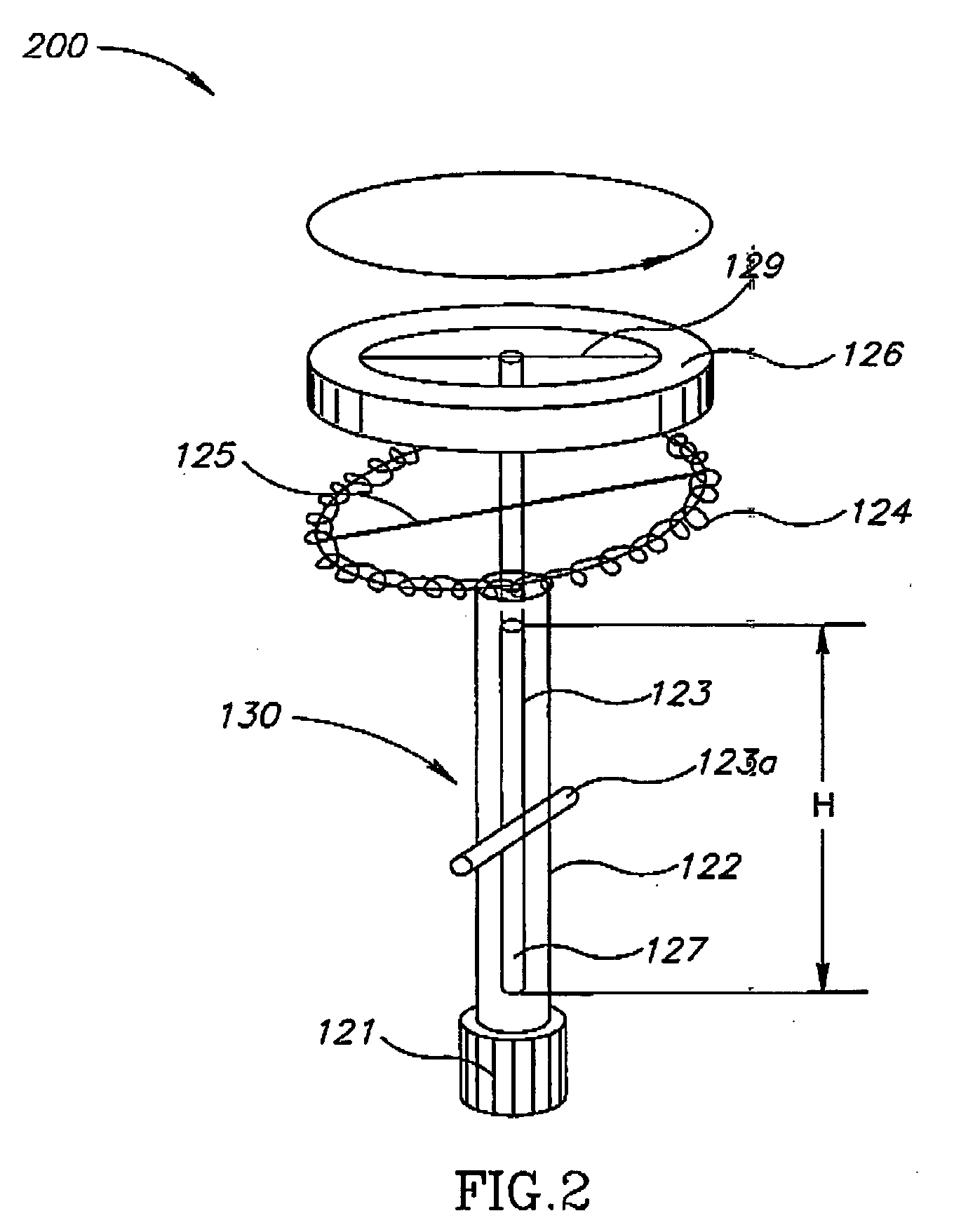

ActiveUS20070133345A1Efficient heatingEfficiently frothingTransportation and packagingRotary stirring mixersEngineeringBuoyant force

the present invention provides an agitation device, comprising a motor for supplying rotational power, an outer shaft operatively connected to the motor, an extendible inner shaft positioned within the outer shaft and operatively connected thereto, an agitator positioned on the extendible inner shaft, and a floatation device positioned on the extendible inner shaft distal to the agitator from the motor for providing a buoyant force to the extendible inner shaft and the agitator for immersing the agitator at a predetermined level in a liquid. The present invention also provides a device for agitating and heating a liquid.

Owner:ZAROM RONY

Belt type rescue device

PendingCN107472483ASimple structureEasy to carryVessel signalling devicesGPS usageSimulationHeart disease

The invention discloses a belt type rescue device which comprises a buckle head and an elastic belt. The belt type rescue device is simple in structure and convenient to carry, can be tied on the waist by being arranged in a belt form, and does not affect using of hands after being started. The belt is internally provided with a plurality of airbags, the buoyancy is sufficient, hands can conveniently grab objects for lifesaving, and a user cannot feel tired after using the device for a long time. A detection sensor is arranged and can automatically monitor the heart rate when a swimmer has a sudden heart attack, or faints by collision or has other diseases and situations, especially when a person (child) is liable to be panic in drowning, then a controller is used for automatically opening the airbags, the survival rate is increased, and the using range is expanded.

Owner:张亚彬

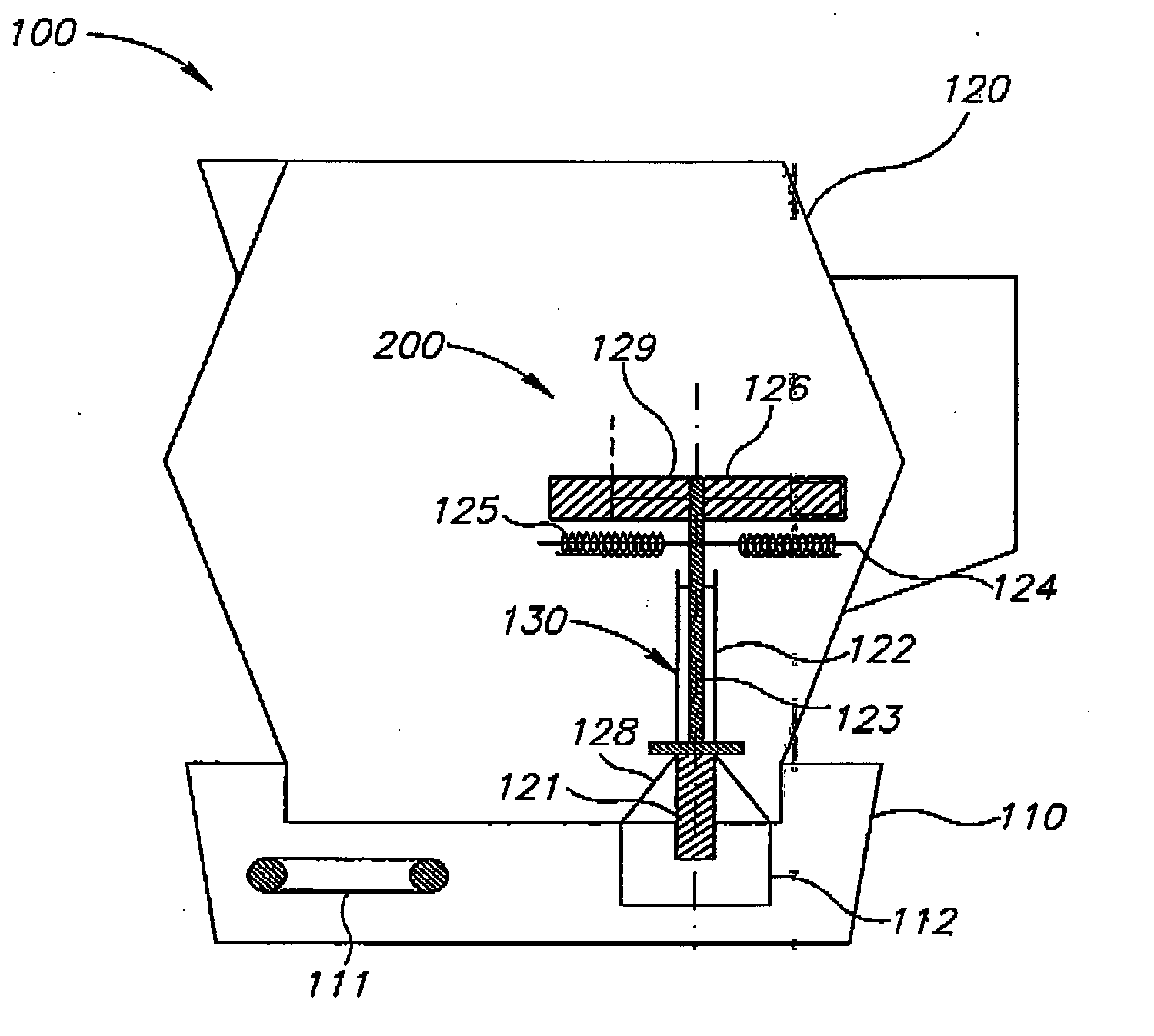

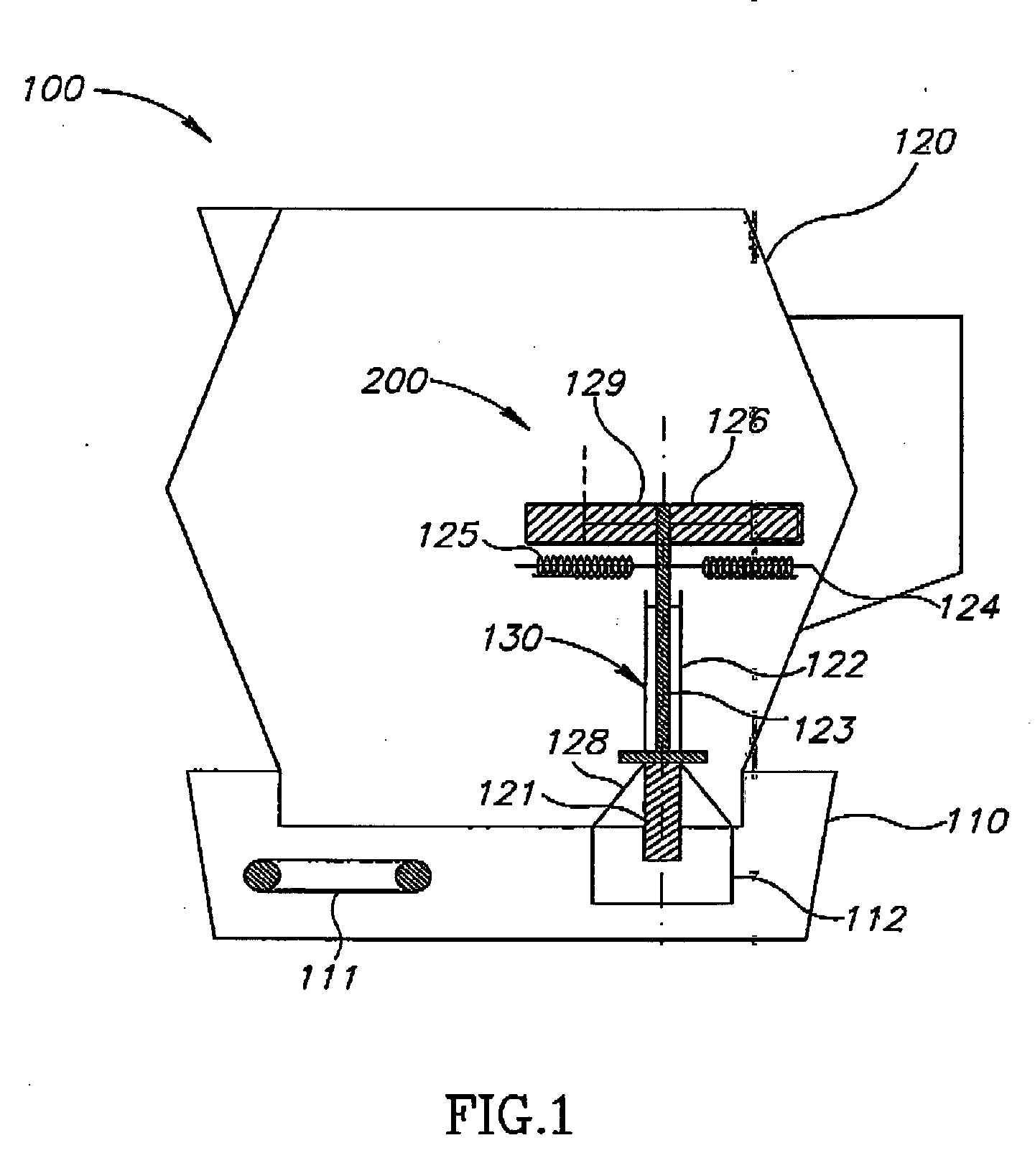

Vertical gravity/buoyancy power generator

InactiveUS20110179784A1Broaden applicationIncreasing potential useWorking fluid for enginesHydro energy generationLiquid mediumVertical plane

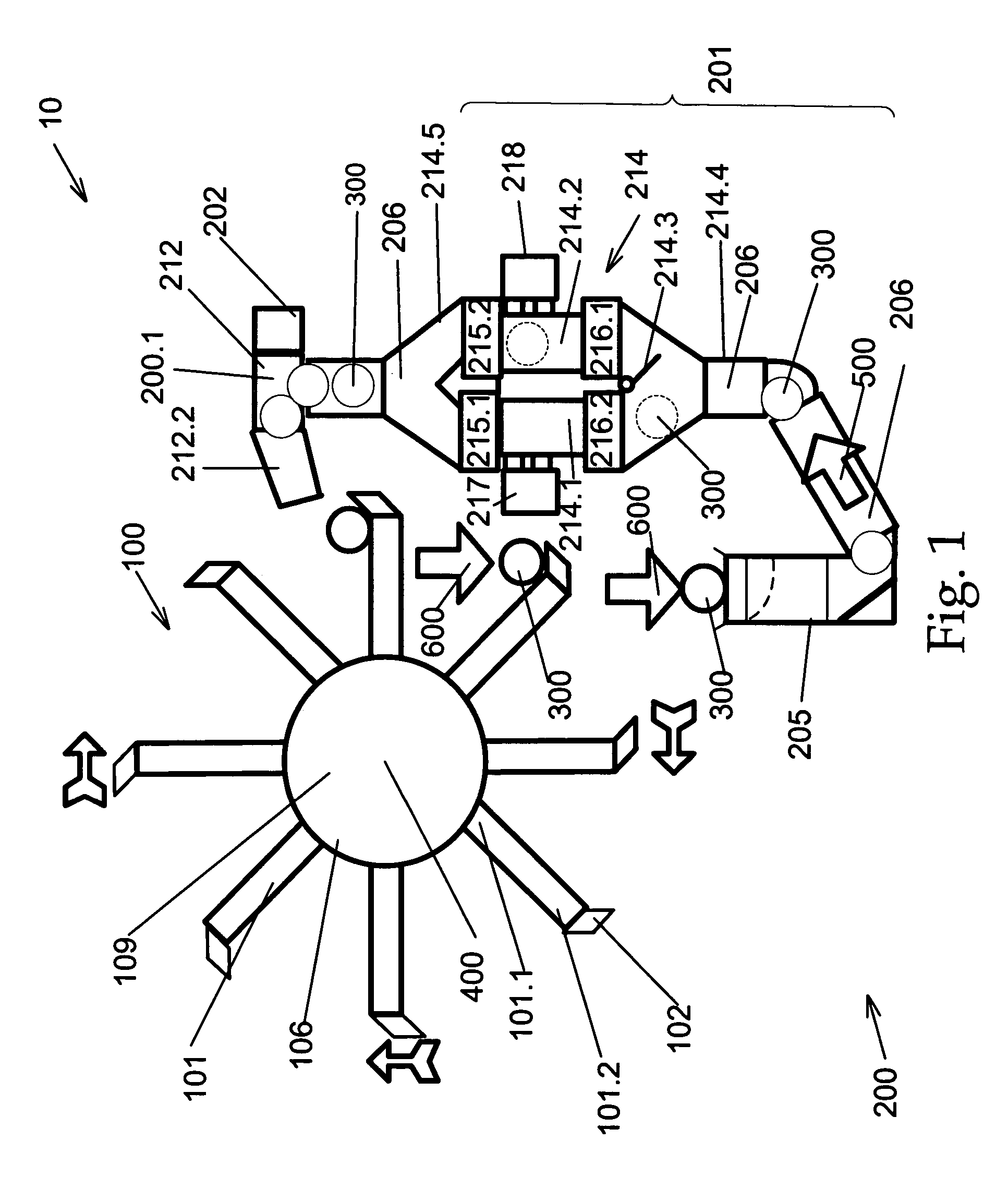

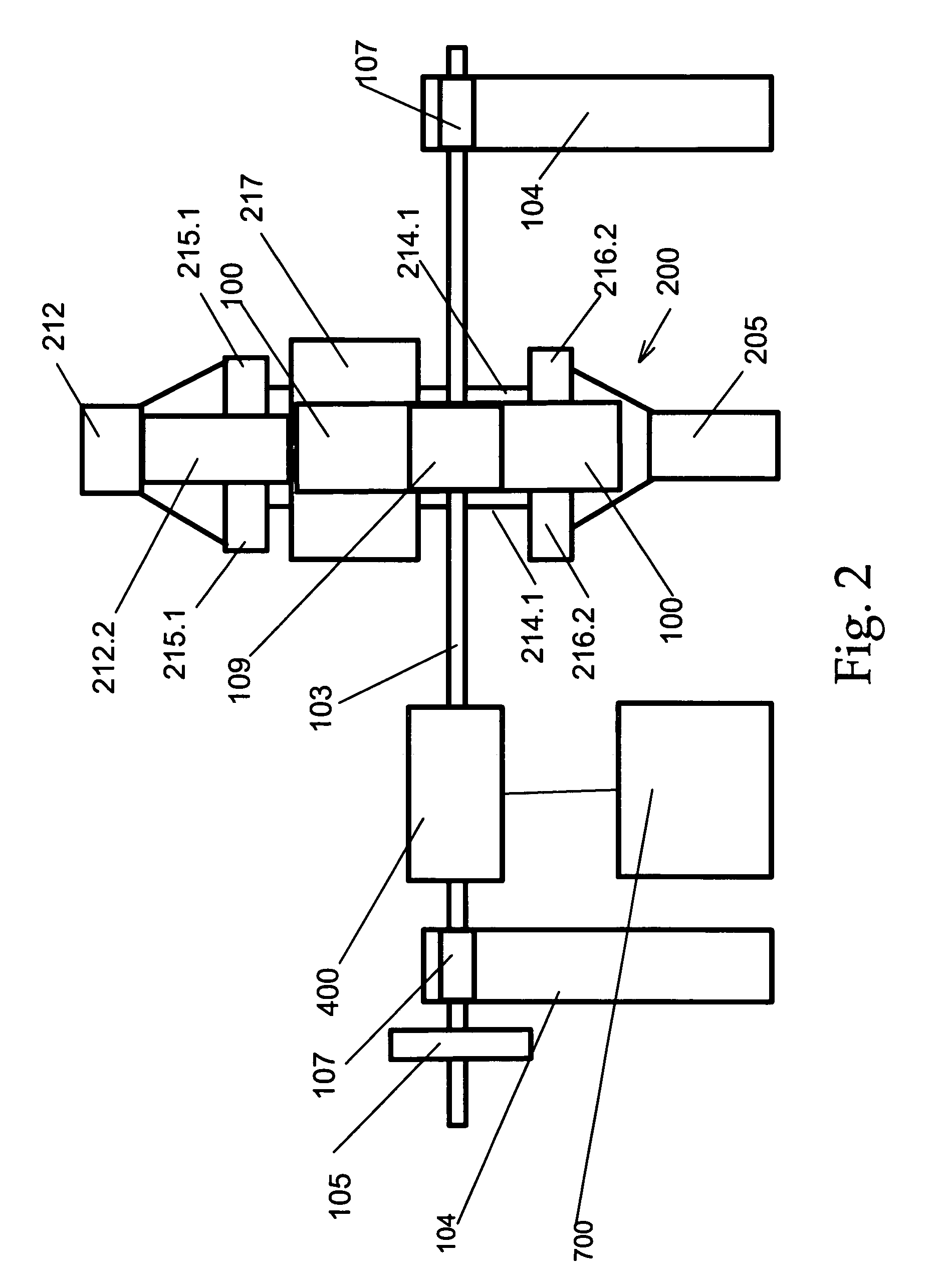

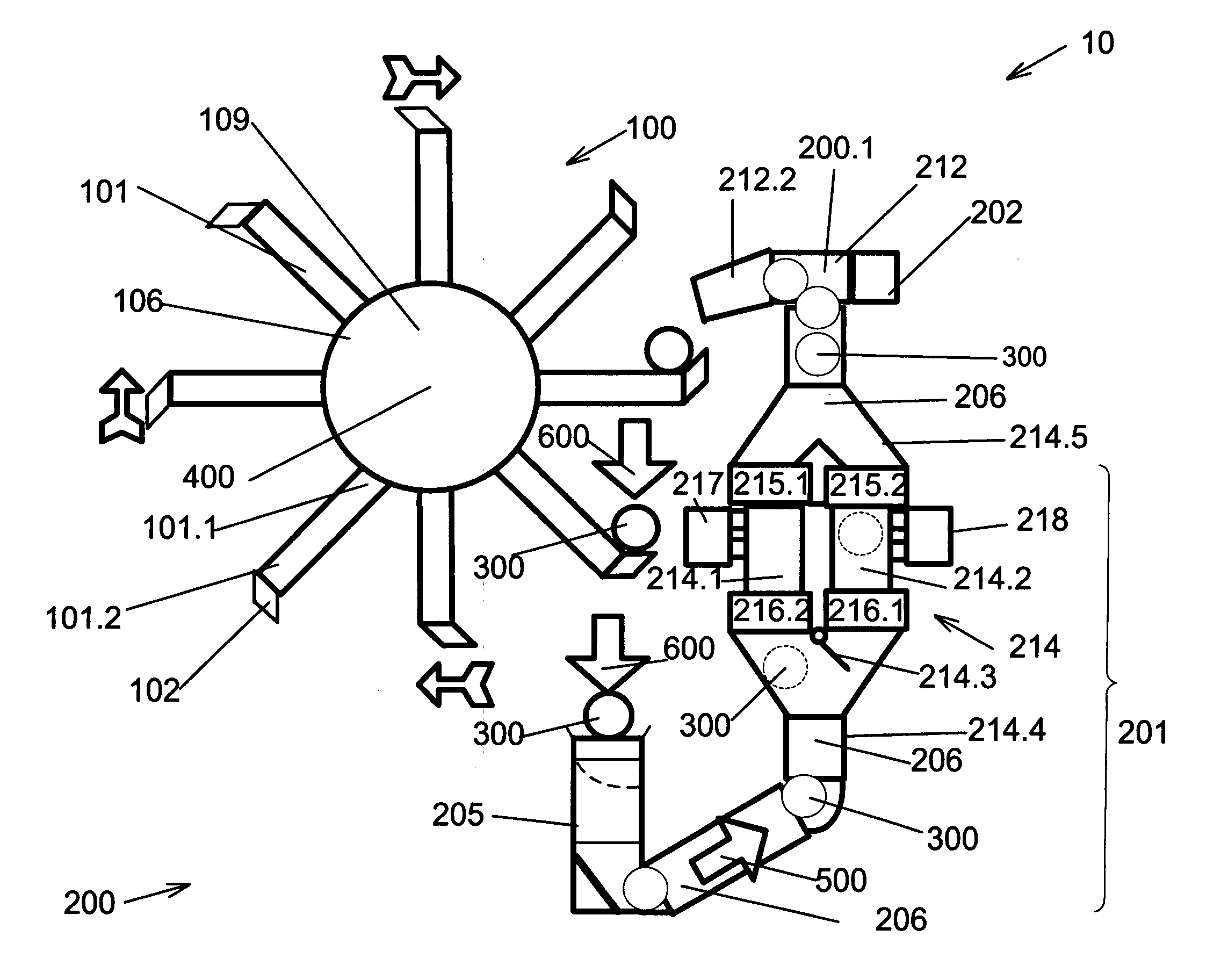

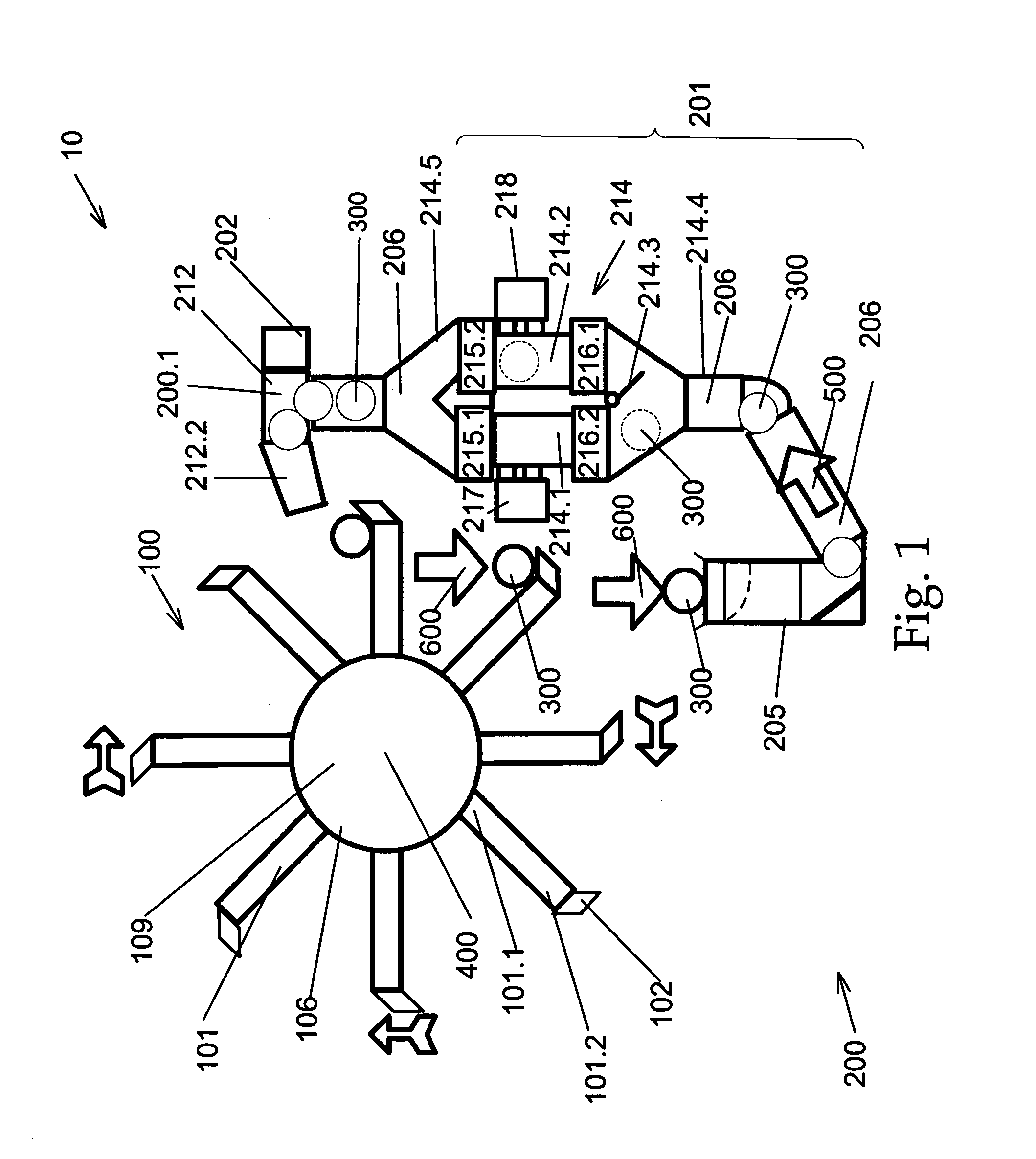

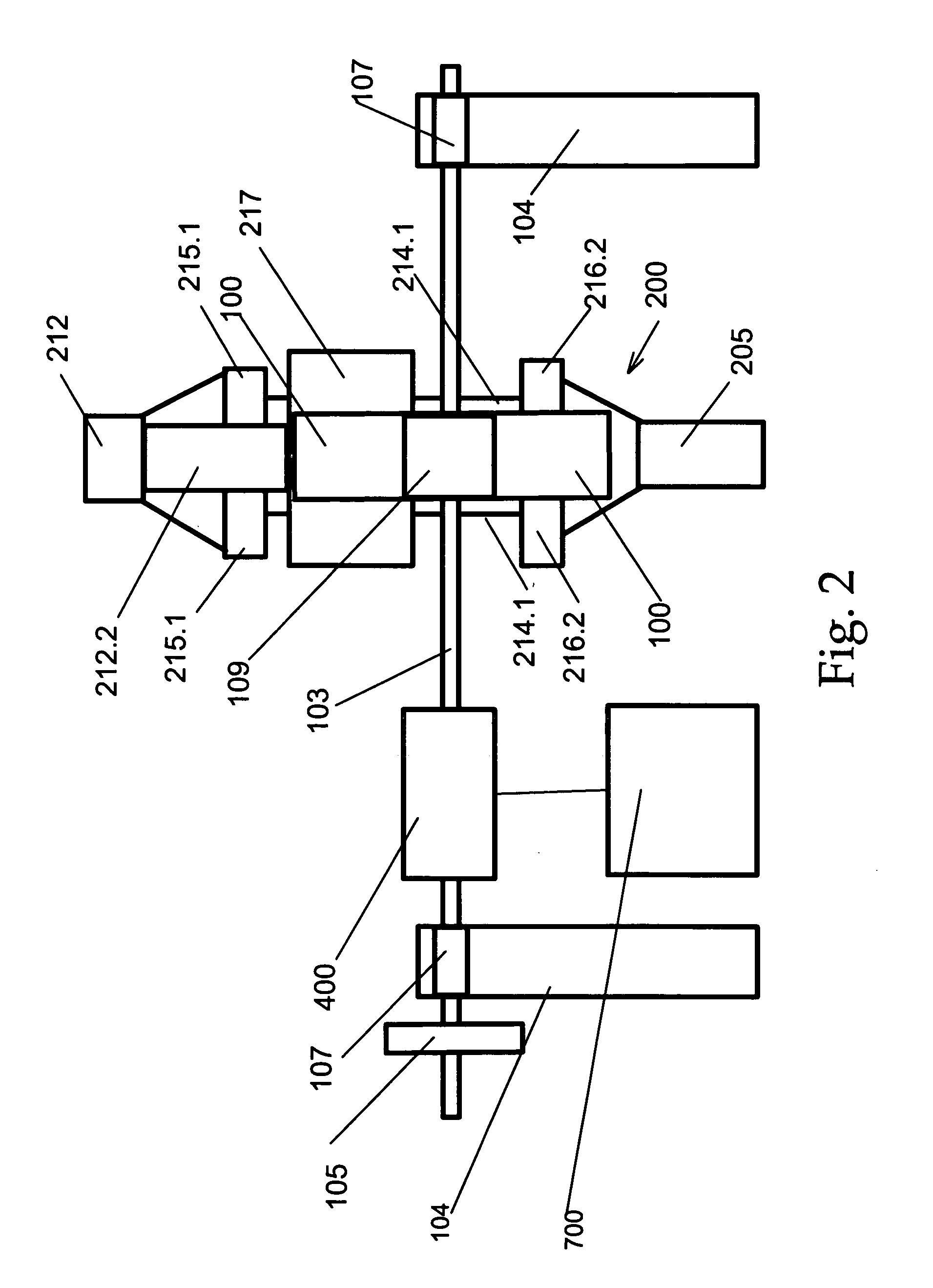

The vertical gravity / buoyancy power generator relates to the generation of power by harnessing the gravitational and buoyant forces which act on an apparatus in a natural or man-made liquid medium and convert such forces into mechanical energy. More specifically, the vertical gravity / buoyancy power generator improves on operably different, fluid medium power generators by efficiently utilizing the gravitational force as efficiently as the buoyant force is harnessed. The vertical gravity / buoyancy power generator includes methods, systems and devices for a plurality of weighted containers which ascend and descend in a primarily vertical plane and which drive one or more chains, belts or conveyances with rotating sprockets or pulleys on horizontally aligned shafts in primarily a vertical arrangement upon such apparatus. In the descent phase the containers are open on both ends (FIG. 1) and have greater density than the volume of liquid they displace causing them to rapidly descend through the liquid medium due to the gravitational force. In the ascent phase the containers are filled by bladders (FIG. 5), have both ends closed, or are closed on their upper end when, in any embodiment, a volume of gas is introduced such that the overall volume of the containers have a lesser density than the liquid displaced causing the containers to rise through the liquid medium due to the buoyant force. The chains, belts or conveyances driven by the containers rotate the sprockets or pulleys (FIG. 1) and their associated shafts creating mechanical power. Such power can be used to turn electrical generators or other mechanical machines which necessitate such power input.

Owner:HASTINGS DOUGLAS REYNOLDS

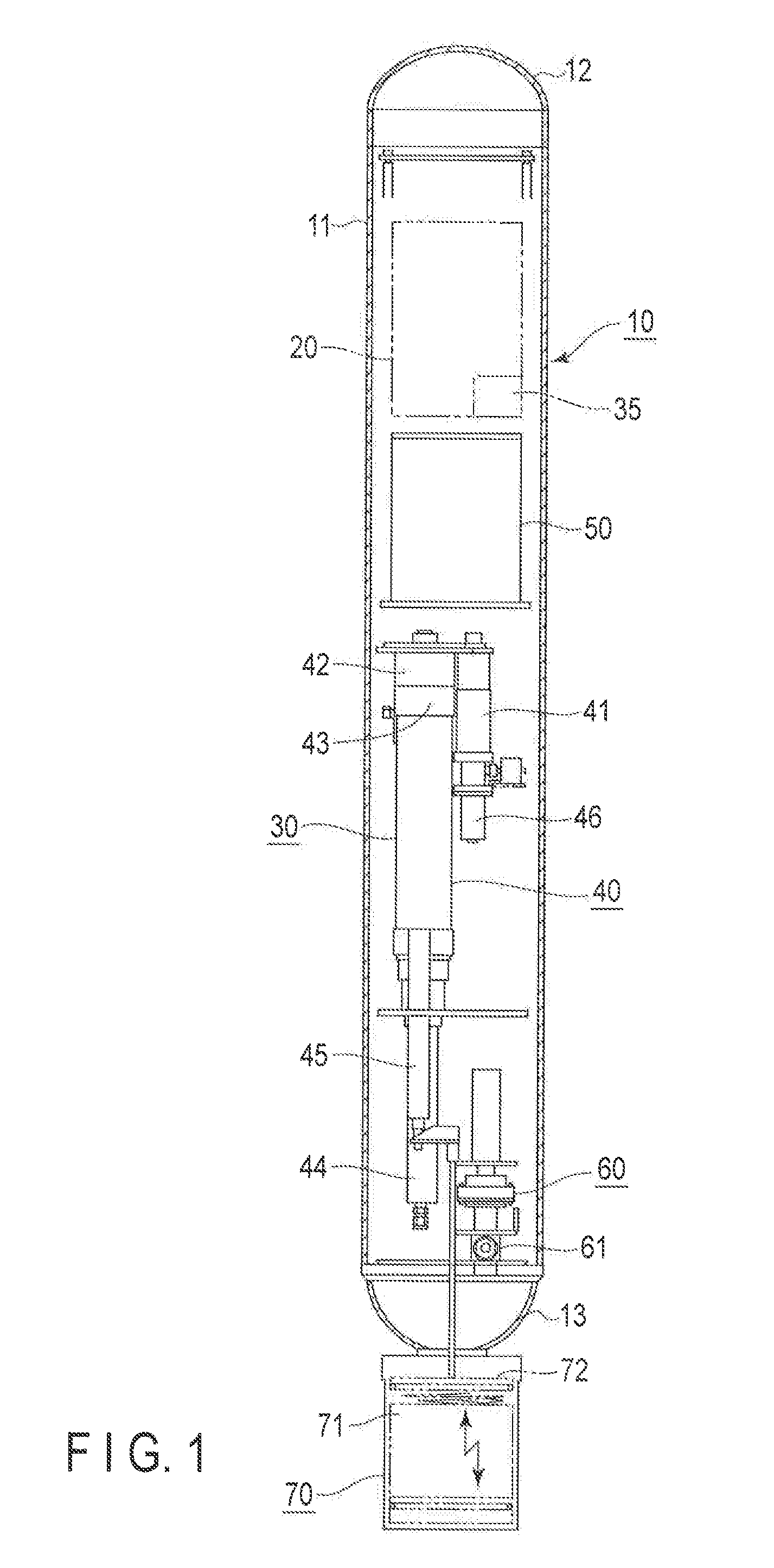

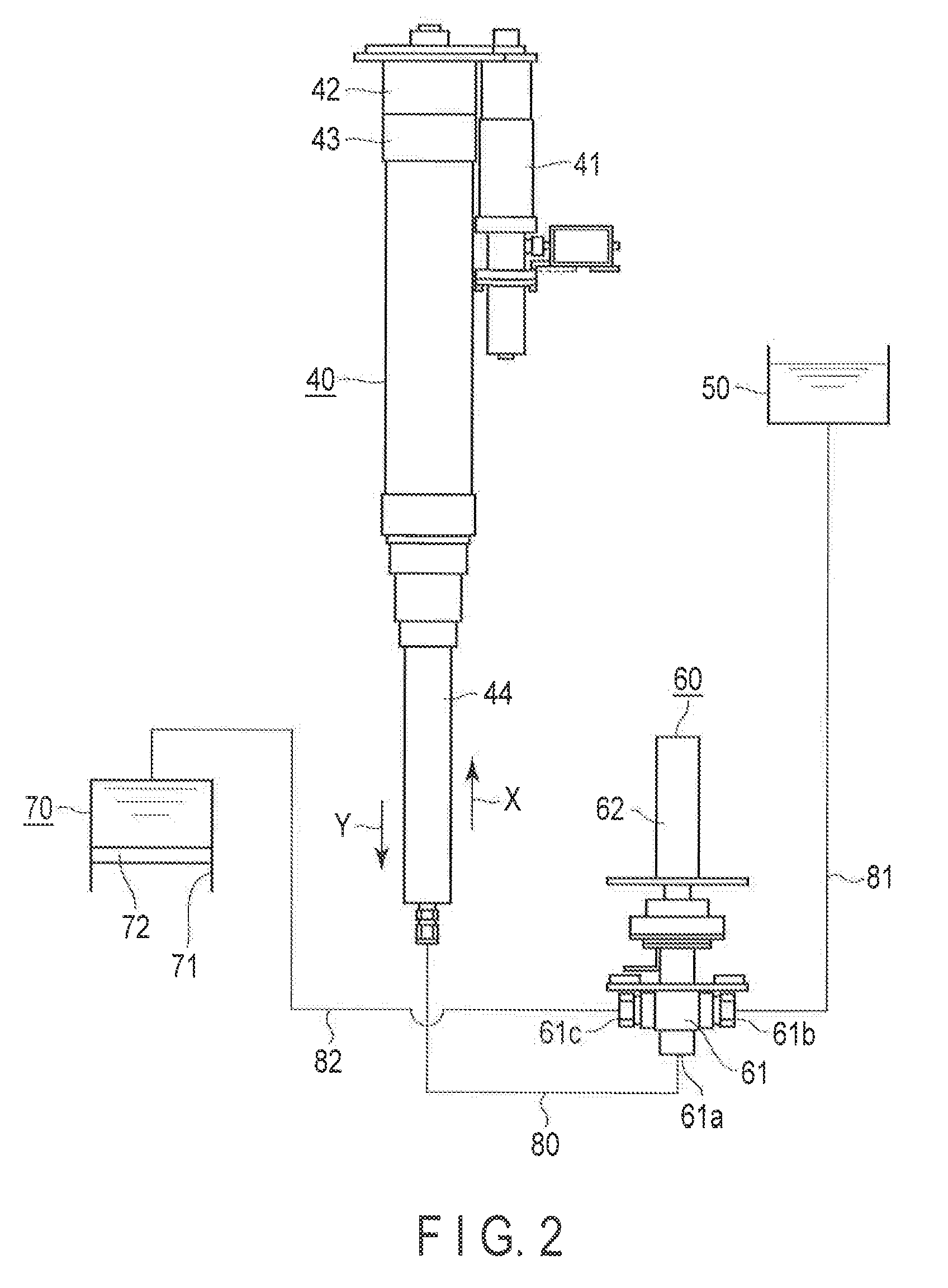

Float device

ActiveUS20120204775A1Reduce in quantityImprove accuracyVolume/mass flow measurementAcceleration measurementReciprocating motionDrive motor

A float device includes a drive motor provided inside a float hull, a plunger reciprocating along with rotation of the drive motor, an internal oil reservoir for housing an hydraulic oil therein, an externally-opened cylinder attached to the float bull, a buoyant force adjustment piston reciprocating in the cylinder along with exit / entry of the hydraulic oil, and a three-way valve having a first connection port connected to the plunger, a second connection port connected to the internal oil reservoir, and a third connection per connected to the cylinder, for switching the flow between the first connection port and the second connection ports and the flow between the first connection port and the third connection port.

Owner:TSURUMI SEIKI +1

Orbiting power plant

InactiveUS20100264656A1Characteristic can be alteredFrom solar energyCosmonautic power supply systemsWorking fluidSuperheated steam

Owner:FLOOD KERRY A

Tilting pendulum type float ball liquid level meter

InactiveCN104061983AReliable measurementSimple structureLevel indicators by floatsWired communicationPendulum

The invention discloses a tilting pendulum type float ball liquid level meter which comprises a mounting and connecting part, a computing-controlling-displaying-communication-signal outputting part, a tilting angle measuring element, a float ball and a pendulum rod. The mounting and connecting part is used for mounting and connecting a pendulum part to a measuring position. The computing-controlling-displaying-communication-signal outputting part is mainly used for completing signal collecting, data computing, signal displaying, wireless and wired communication work of a communication device and other equipment terminals, and signal outputting work. The tilting angle measuring element is mainly used for measuring the tilting angle of the pendulum part and the horizontal or vertical direction. The float ball floats on a liquid surface, provides buoyant force and transmits liquid surface change information. The pendulum rod is fixedly connected with the float ball, provides a fixed length, and provides a determined computing parameter.

Owner:胡桂标

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com