Tilting pendulum type float ball liquid level meter

A floating ball liquid level and floating ball technology, applied in the field of liquid level gauges, can solve the problems of inability to measure, high installation requirements, loss of magnetism, etc., and achieve the effects of rapid action response, high measurement reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

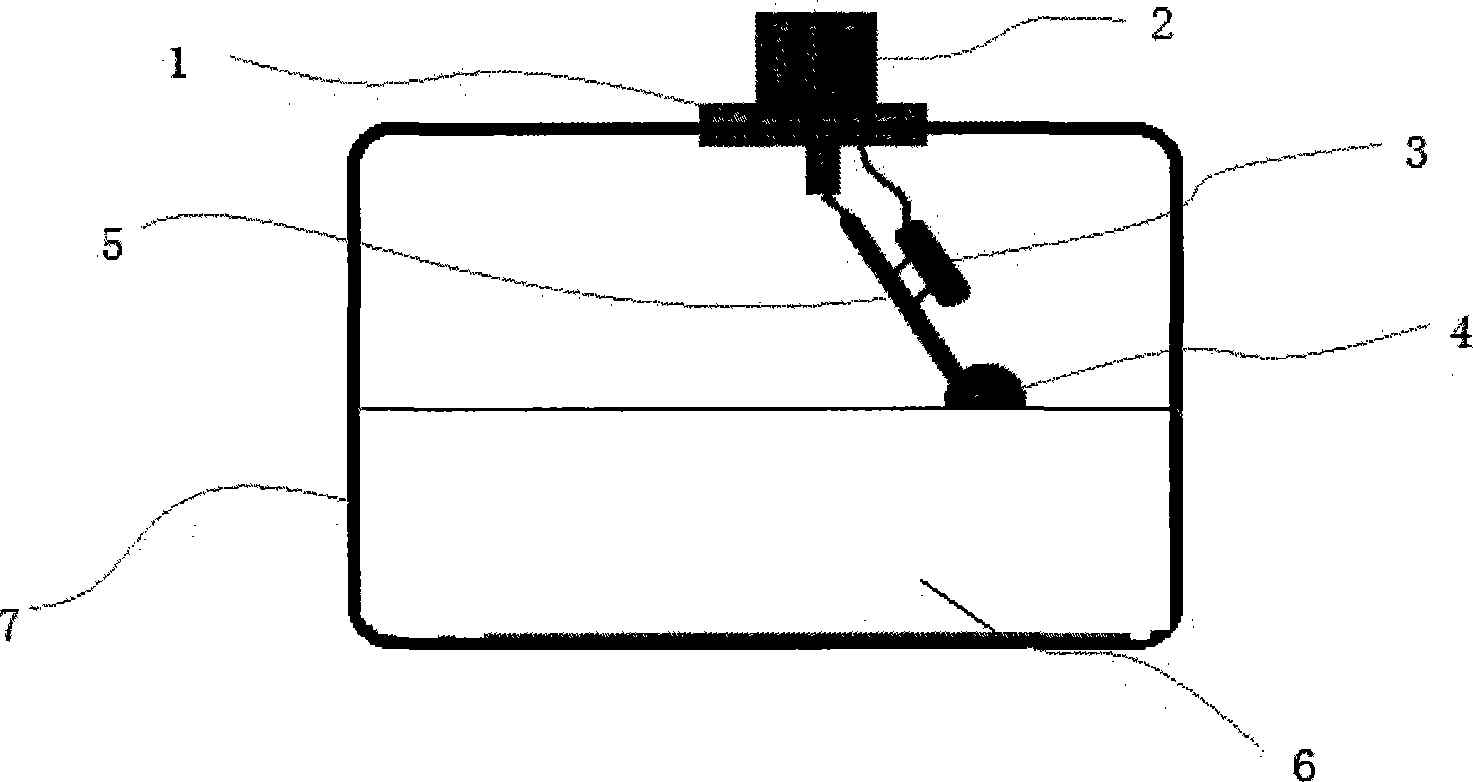

[0033] A tilting ball float level gauge, such as figure 1 As shown, the instrument is installed to the measurement position by using the installation connection part 1, and the swing rod 5 is connected with the installation connection part 1 through a hinge. The float 4 floats on the surface of the liquid 6 , and the inclination measuring element 3 is attached to the pendulum 4 . The inclination measuring element 3 transmits the angle information of the pendulum 4 to the calculation-control-display-communication-signal output part 2, and the calculation part calculates the height of the liquid surface according to the pendulum angle, pendulum length, and installation position information.

Embodiment 2

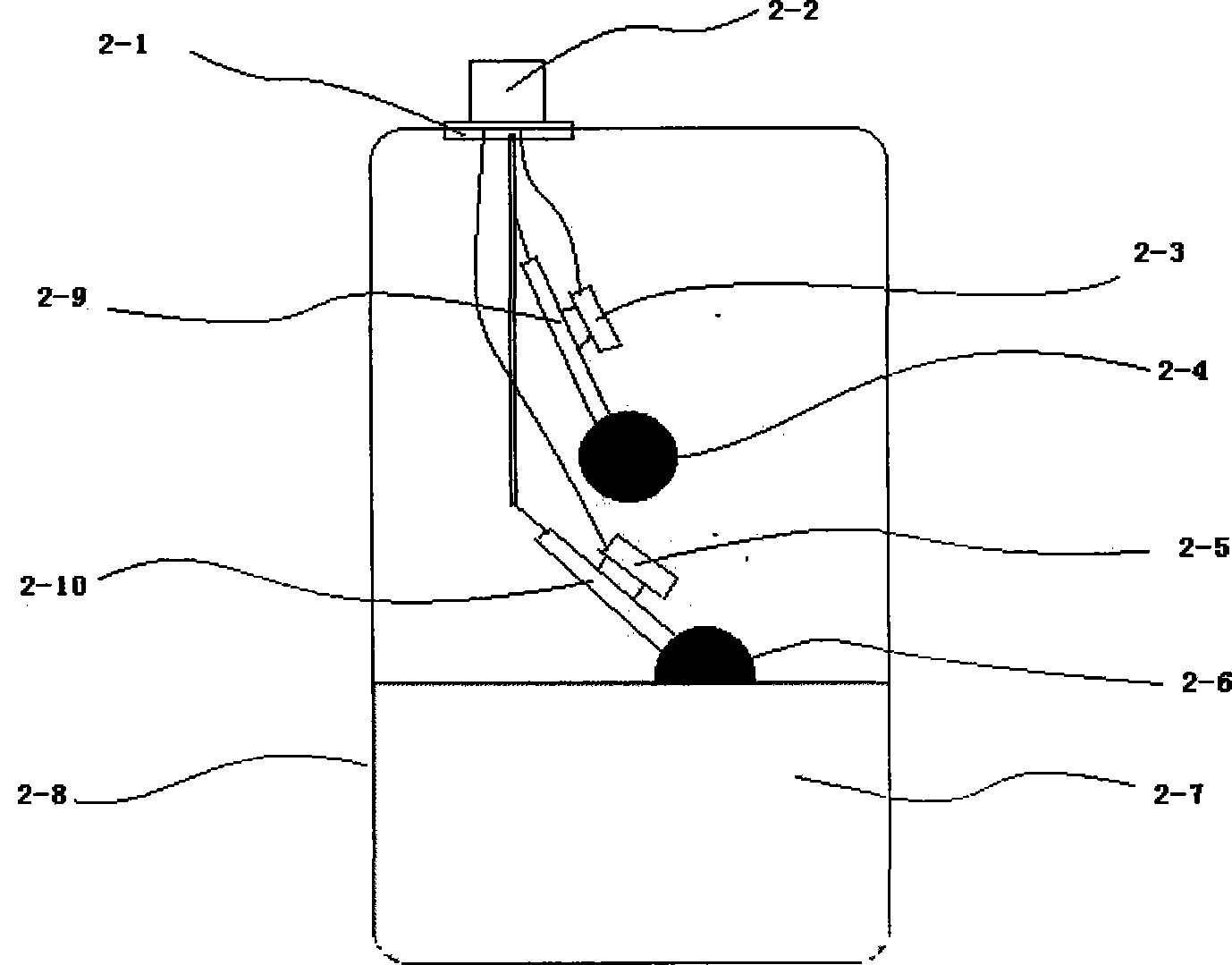

[0035] A tilting ball float level gauge, such as figure 2 As shown, the instrument is installed to the measurement position by using the installation connection part 1, and the No. 1 swing rod 9 and the No. 2 swing rod 10 are connected to the installation connection part 1 through hinges. No. 1 floating ball 5 and No. 2 floating ball 6 float on the surface of liquid 7 , and No. 1 inclination measuring element 3 and No. 2 inclination measuring element 5 are respectively attached to No. 1 pendulum 9 and No. 2 pendulum 10 . The No. 1 inclination measuring element 3 and the No. 2 inclination measuring element 5 transmit the angle information of their respective pendulums to the calculation-control-display-communication-signal output part 2, and the calculation part is based on the angle of the two pendulums, the length of the pendulum, and the installation position The information calculates the height of the liquid surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com