Drainage device of washing machine and washing machine

A technology for a drainage device and a washing machine, applied in the field of washing machines, can solve the problems of affecting the life of the washing machine, loud noise, increasing the energy consumption of the washing machine, etc., and achieve the effects of simple structure, avoidance of blockage, and low production and installation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

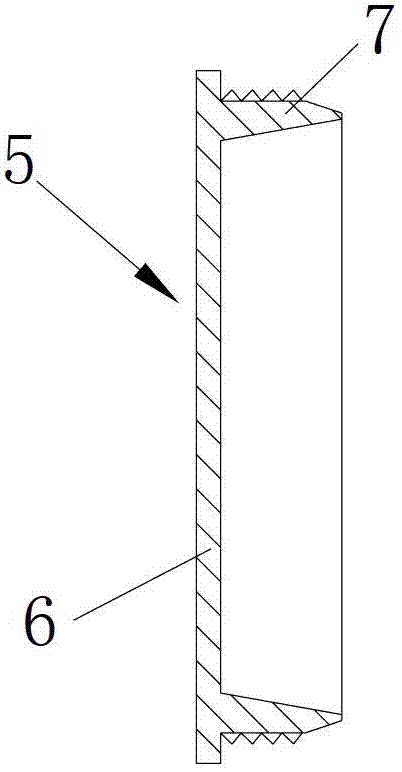

[0037] Such as image 3 As shown, the sealing cover 5 described in this embodiment includes an outer cover 6 and a fixed connection end 7 inserted into the particle storage chamber. The inner wall 70 of the connection end 7 is inclined to form a bell mouth structure. The caliber of one side of the drainage chamber 2 is the largest, and the caliber of the direction 6 of the outer cover is reduced.

[0038] The sealing cover 5 is detachably connected to the particle storage chamber 1 by threads, the connecting end 7 is a tubular structure with external threads, and the opening of the particle storage chamber is provided with a matching internal thread.

Embodiment 2

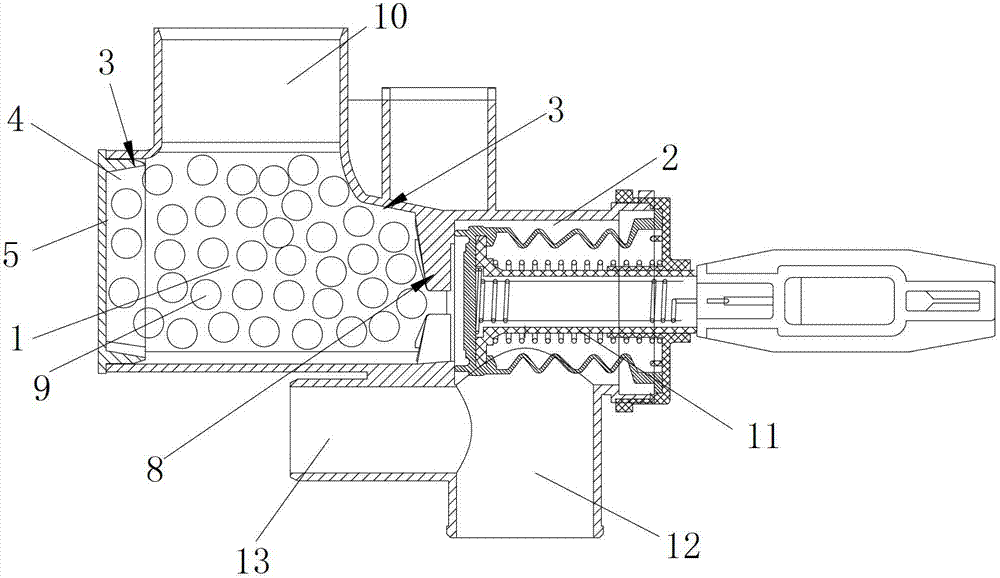

[0040] Such as figure 2 As shown, the connection between the connecting pipe 10 and the particle storage chamber 1 described in this embodiment is an inverted bell-mouth structure, and the circular arc transitions from bottom to top with a reduced diameter.

Embodiment 3

[0042] Such as figure 2 As shown, a filter structure 8 is provided between the particle storage chamber and the drainage chamber of the present invention to block the discharge of the cleaning particles 9 and to allow the passage of lint and flakes.

[0043] The filter structure is composed of a plurality of retaining ribs 80 to form a grille, and between the retaining ribs 80 is a thread waste passage port, and the retaining ribs are inclined from the edge to the center along the water outlet direction, forming a structure that is concave toward the drainage chamber in the middle (see figure 2 , Figure 4 with Figure 5 ), the retaining rib is inclined to cooperate with the inclined side wall of the adjacent particle storage chamber to form an inclined inner wall structure, and the middle recess of the filter structure 8 is provided with a long strip-shaped opening 81 for the sheet to pass through.

[0044] Filtration structure 8 inclined structure projection of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com