Waste lead-acid storage battery crushing-and-separation one-step energy-saving recycling process

A lead-acid battery, one-off technology, applied in battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of high cost, waste of resources, backward recycling process, etc., to achieve low production cost, low investment in infrastructure, Low effect of technical software

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

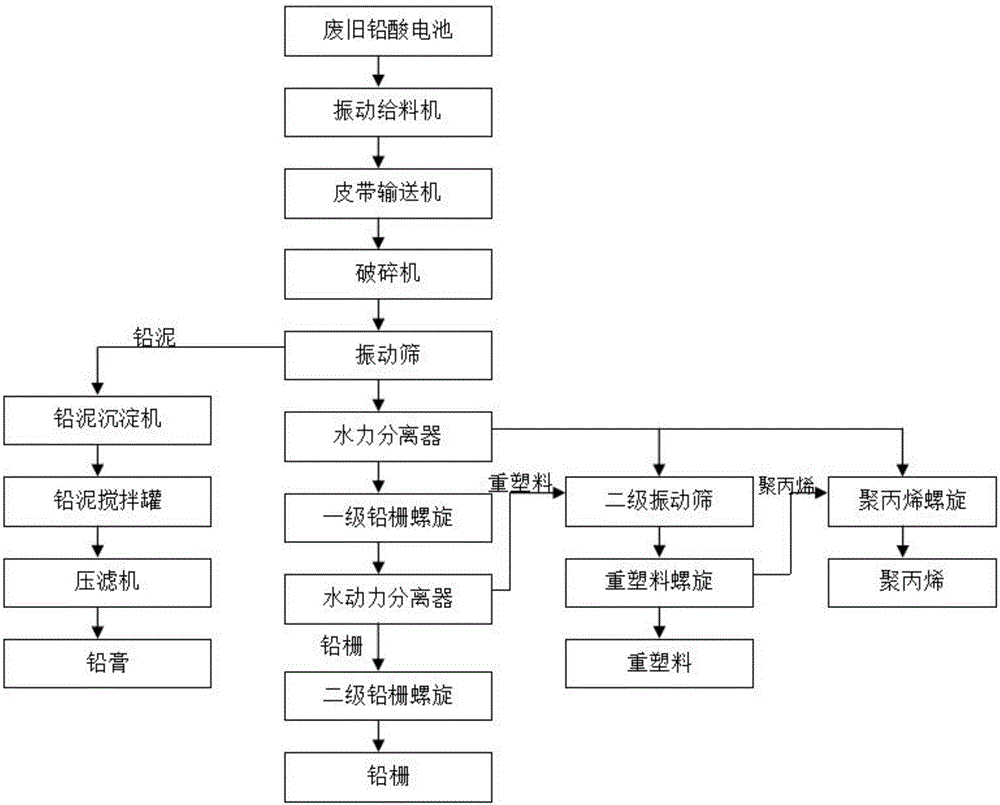

[0033] Such as figure 1 Shown, a kind of waste and old lead-acid battery crushing separation disposable energy-saving recovery process, comprises the following steps:

[0034] (1) Feeding

[0035] The waste lead-acid batteries in the raw material pit are grabbed by a six-petal hydraulic grab crane and sent to the silo above the feeder, and the vibrating feeder below the silo (the feeding speed is determined by changing the frequency of the motor to ensure uniform feeding) Feeding) The battery is transported to the belt conveyor, and an electromagnetic separator and a metal detector are installed above the conveyor belt to remove the magnetic metal mixed in the battery transportation process, so as to ensure the normal operation of the crusher and extend the life of the hammer. service life;

[0036] (2) Broken

[0037] The belt conveyor transports the waste lead-acid batteries to the crusher for crushing. There are four groups of 20 hammers in the crusher to beat and grind ...

Embodiment 2

[0060] A kind of waste lead-acid storage battery fragmentation separation disposable energy-saving recycling process, comprises the following steps:

[0061] (1) Feeding

[0062] The waste lead-acid batteries in the raw material pit are grabbed by a six-petal hydraulic grab crane and sent to the silo above the feeder, and the vibrating feeder below the silo (the feeding speed is determined by changing the frequency of the motor to ensure uniform feeding) Feeding) The battery is transported to the belt conveyor, and an electromagnetic separator and a metal detector are installed above the conveyor belt to remove the magnetic metal mixed in the battery transportation process, so as to ensure the normal operation of the crusher and extend the life of the hammer. service life;

[0063] (2) Broken

[0064] The belt conveyor transports the waste lead-acid batteries to the crusher for crushing. There are four groups of 20 hammers in the crusher to beat and grind the batteries. : 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com