Landfill reservoir area anti-seepage system capable of protecting geomembrane and construction method thereof

A geomembrane and landfill technology, applied in geotextiles, protective devices, infrastructure engineering, etc., can solve problems such as damaging mountains, not being environmentally friendly, and large landfill space, so as to increase compressive strength and save construction costs , The effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

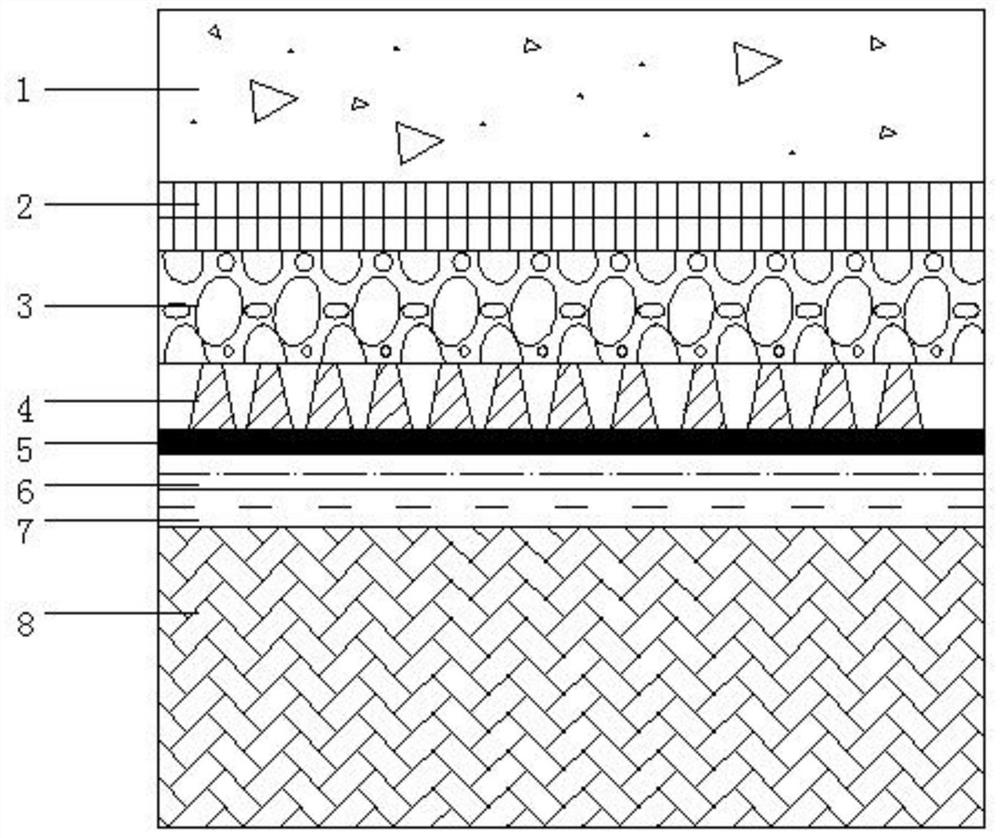

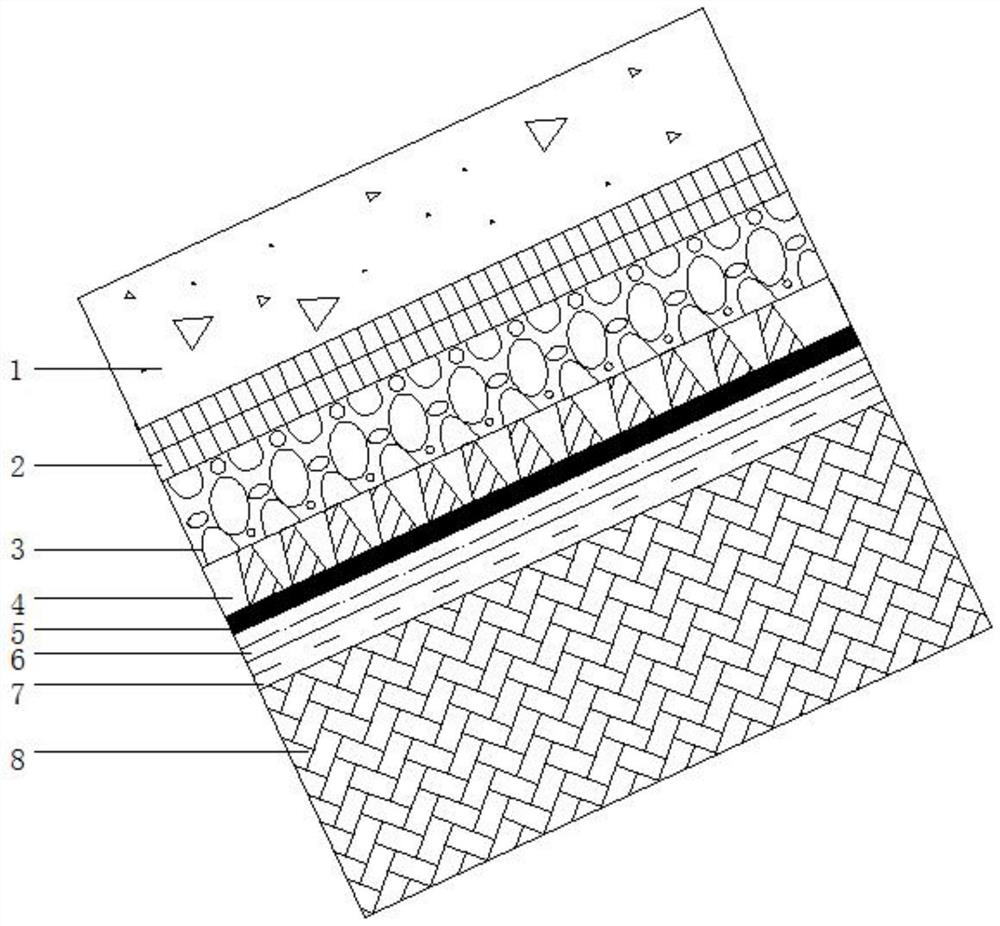

[0042] Such as figure 1 As shown, the present invention proposes a landfill reservoir area anti-seepage system that can protect geomembranes, including a reservoir bottom anti-seepage system and a slope anti-seepage system, and the reservoir bottom anti-seepage system includes vertical bottom-up The set compacted clay layer 8, bentonite waterproof blanket 7, at least one layer of geomembrane 5, gravel layer 3 and woven geotechnical filter 2; the slope anti-seepage system includes an inclined bottom-up compaction Clay layer 8, bentonite waterproof blanket 7, at least one layer of geomembrane 5, gravel layer 3 and spun geotechnical filter screen 2; the upper strata of described geomembrane 5 is laid geotextile 6, it is characterized in that: described geotextile 6 The upper layer is laid with a high-tensile filter row plate 4.

[0043] In an optional implementation of this embodiment, the anti-seepage system of a landfill reservoir area that can protect the geomembrane is a sin...

Embodiment 2

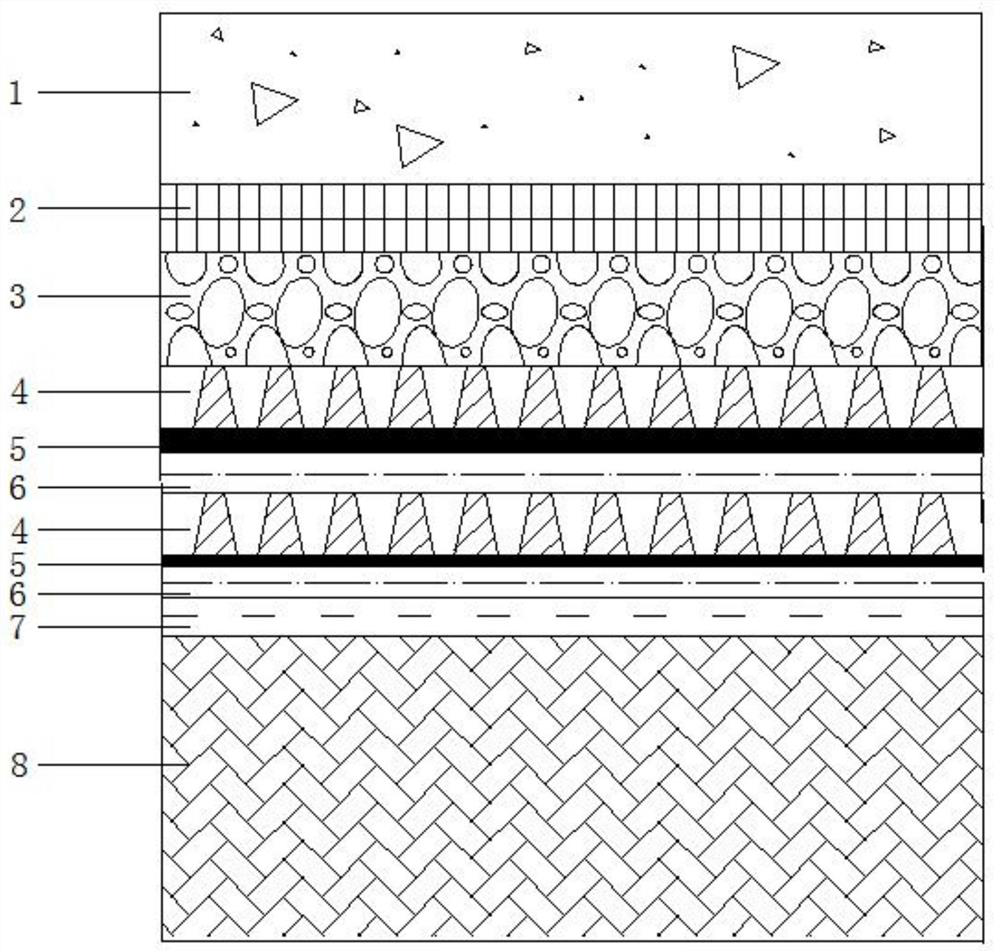

[0058] Such as Figure 3-4As shown, this embodiment proposes a landfill reservoir area anti-seepage system that can protect the geomembrane 5. The difference from Embodiment 1 is that this embodiment adopts a double-layer structure, including the reservoir bottom anti-seepage system and side Slope anti-seepage system, the anti-seepage system at the bottom of the reservoir includes a vertical compacted clay layer 8 arranged from bottom to top, a bentonite waterproof blanket 7, a first layer of geomembrane 5, a first layer of geotextile 6, a first layer of high Tensile filter panel 4, second layer of geomembrane 5, second layer of geotextile 6, second layer of high tensile filter panel 4, gravel layer 3 and woven geotechnical filter screen 2; the slope seepage prevention The system includes an inclined compacted clay layer 8 arranged from bottom to top, a bentonite waterproof blanket 7, a first layer of geomembrane 5, a first layer of geotextile 6, a first layer of high tensile ...

Embodiment 3

[0061] Such as Figure 3-4 As shown, this embodiment proposes a landfill reservoir area anti-seepage system that can protect the geomembrane 5. The difference from Embodiment 2 is that in this embodiment, the second layer of the double-layer anti-seepage system at the bottom of the reservoir The high-tensile filter plate 4 adopts a 1.5mm thick MDS-20 high-tensile filter plate 4, and the protrusions 41 of the high-tensile filter plate 4 are arranged in a ring, such as Figure 8 shown.

[0062] The principle of anti-seepage in this implementation is the same as that proposed in Embodiments 1 and 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com