Patents

Literature

150results about How to "Isolated from direct contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc negative electrode with zinc ion conductivity interface modification layer, battery and preparation method

ActiveCN111933912AImprove Interface StabilitySolve the large interface impedanceSecondary cellsChemical electrode manufacturingElectrical batteryZinc ion

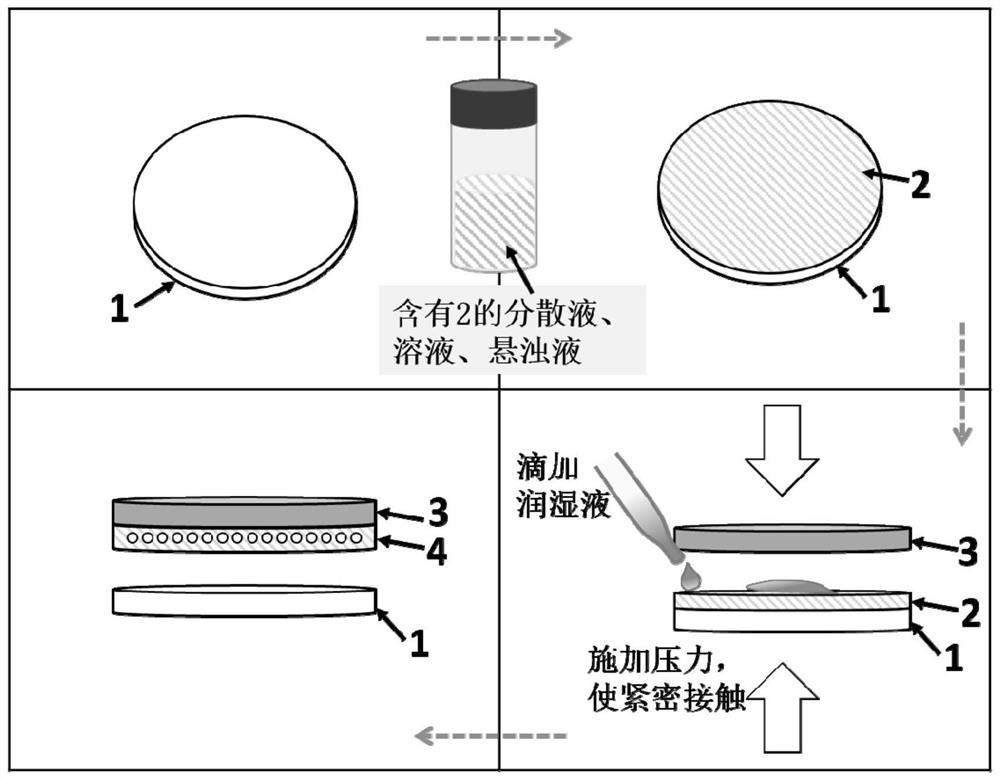

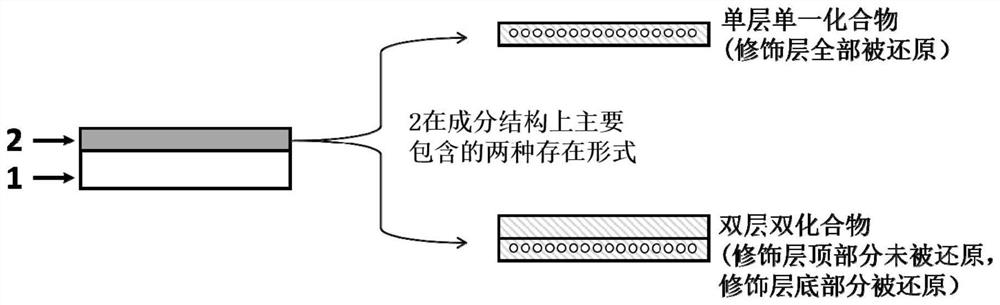

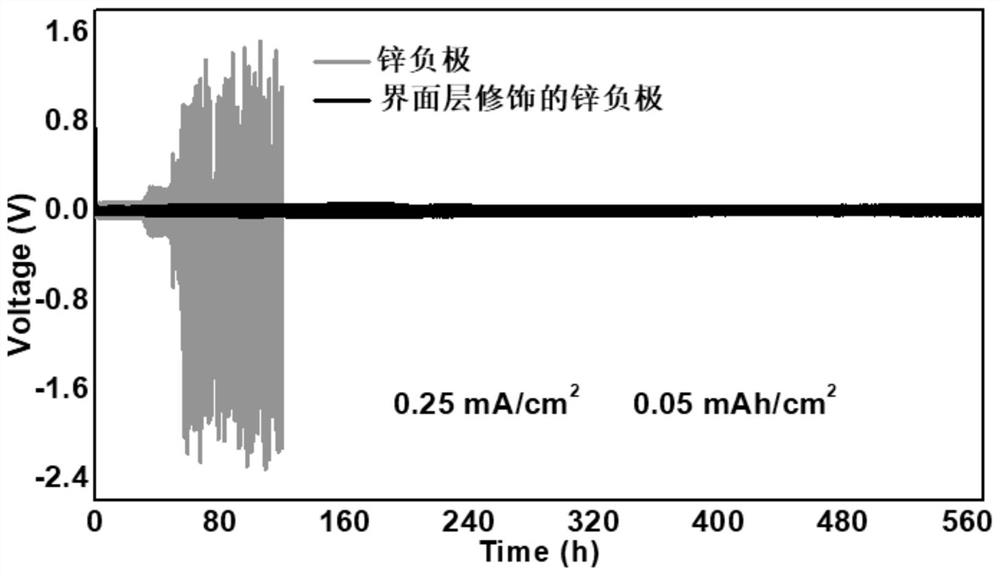

The invention provides a zinc negative electrode with a zinc ion conductivity interface modification layer, a battery and a preparation method, and belongs to the field of aqueous zinc battery metal zinc cathodes. The preparation method comprises: in air atmosphere, pre-constructing an interface modification material M on a base membrane; in a soaking environment by a wetting liquid, the interfacemodification material M layer on the base film being in close contact with the metal zinc to form the short-circuit primary battery, and the contacted interface modification material M and the metalzinc having spontaneous redox reaction, to make the interface modification material convert to ZnxM with zinc ion conductivity from M, meanwhile, transferring the interface modification material layerto the surface of the metal zinc negative electrode from the base film, and finally, obtaining the metal zinc negative electrode with the ZnxM interface modification layer with zinc ion conductivityon the surface. The ZnxM interface modification layer with the zinc ion conductivity can effectively inhibit dendritic crystal growth of a zinc negative electrode during charging and discharging of azinc battery, so that the interface stability of a metal zinc negative electrode is improved, and meanwhile, the cycling stability of a water-based zinc battery is improved. The method is simple and has a good actual effect.

Owner:HUAZHONG UNIV OF SCI & TECH

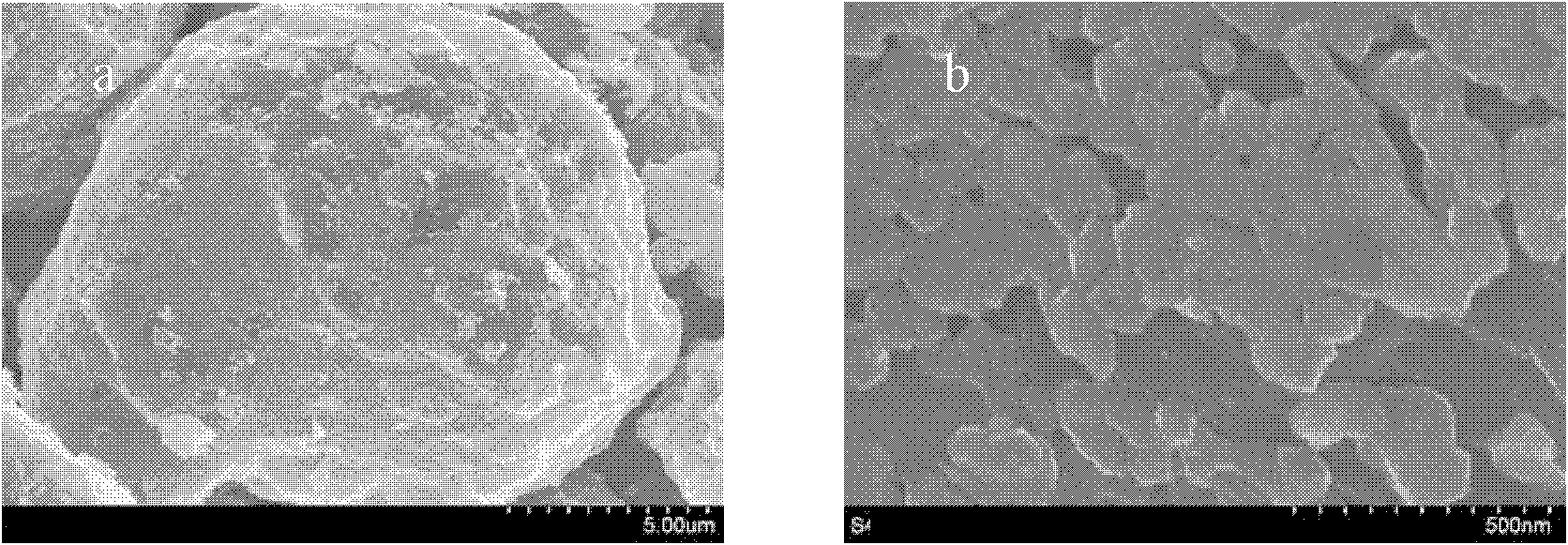

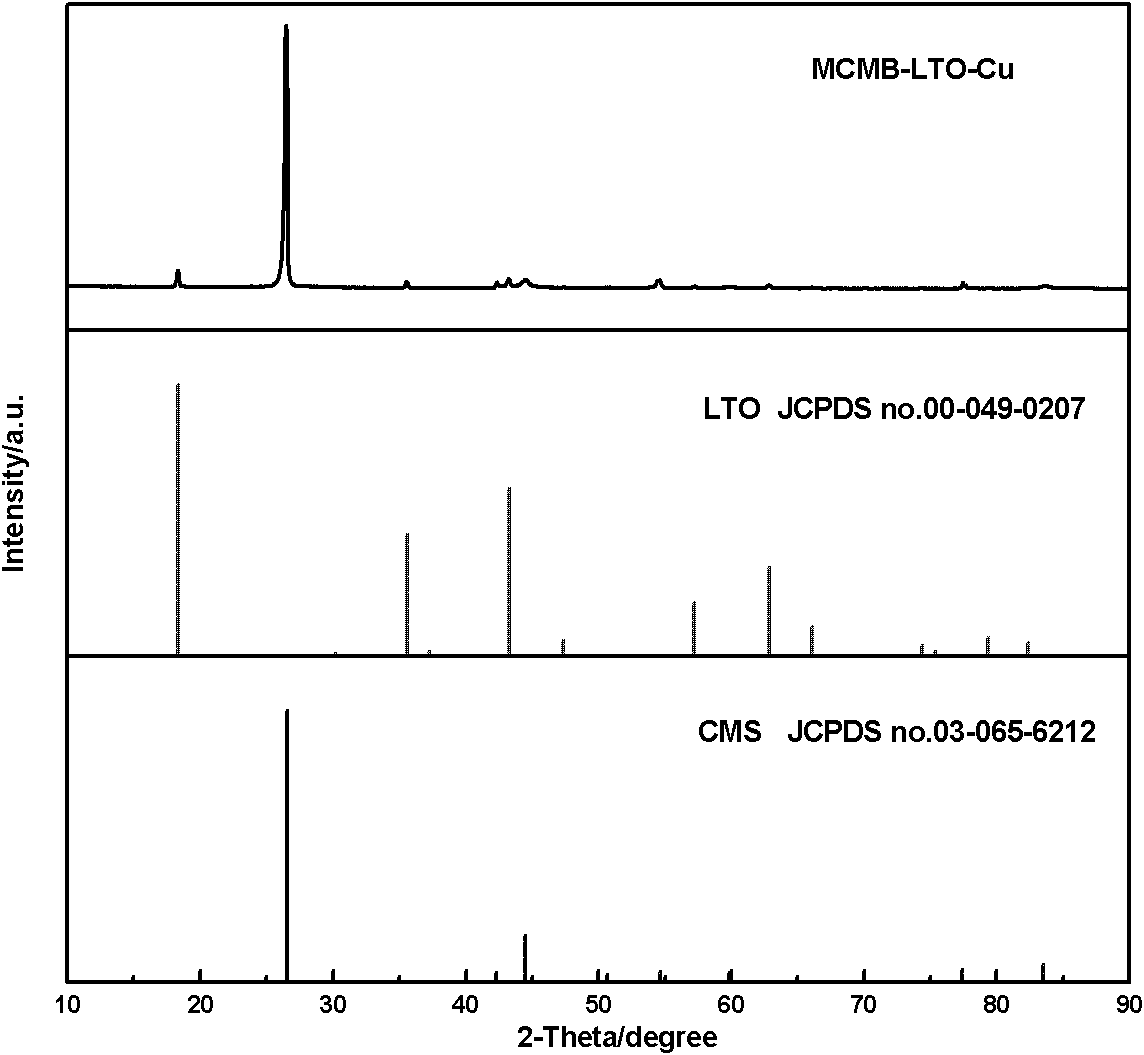

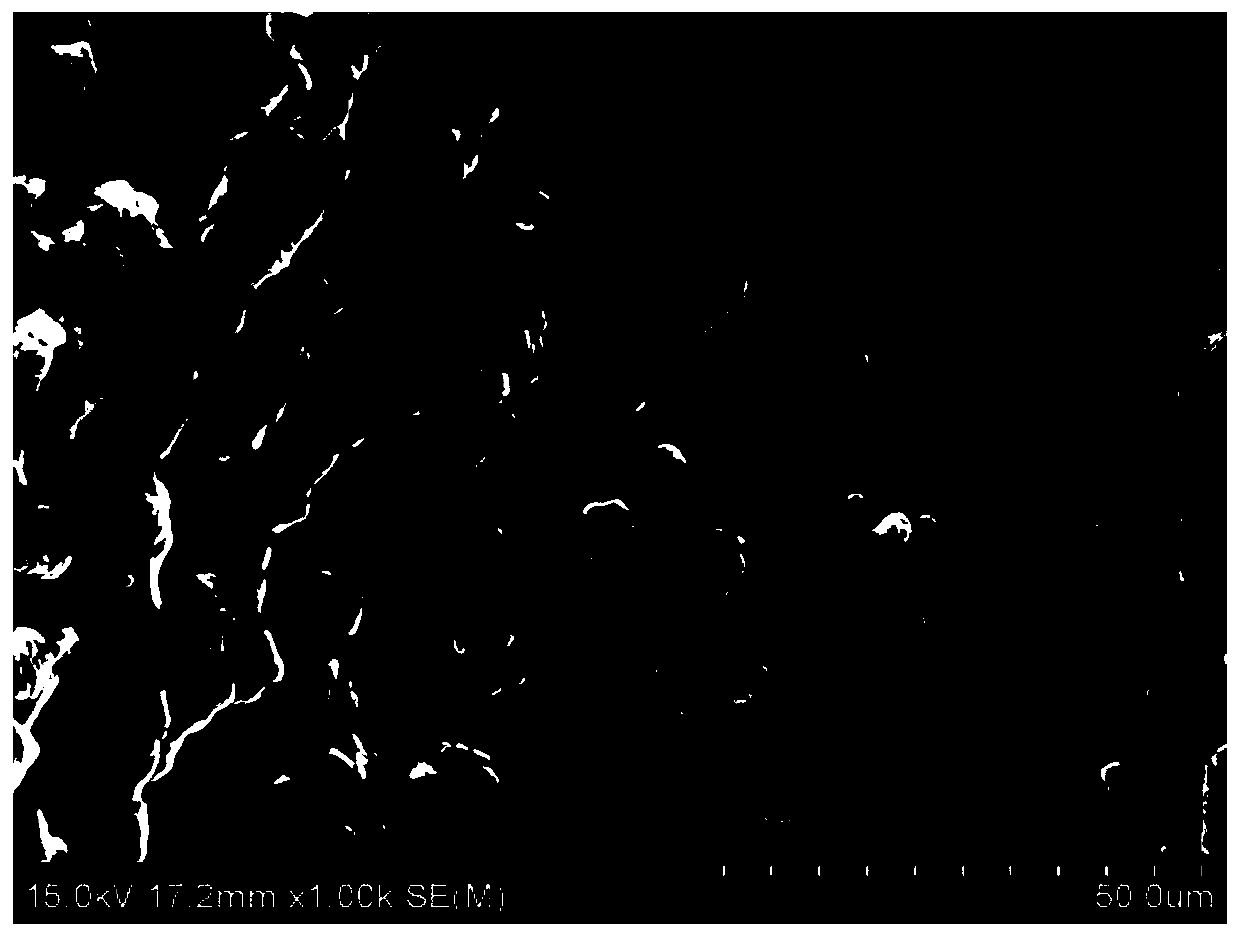

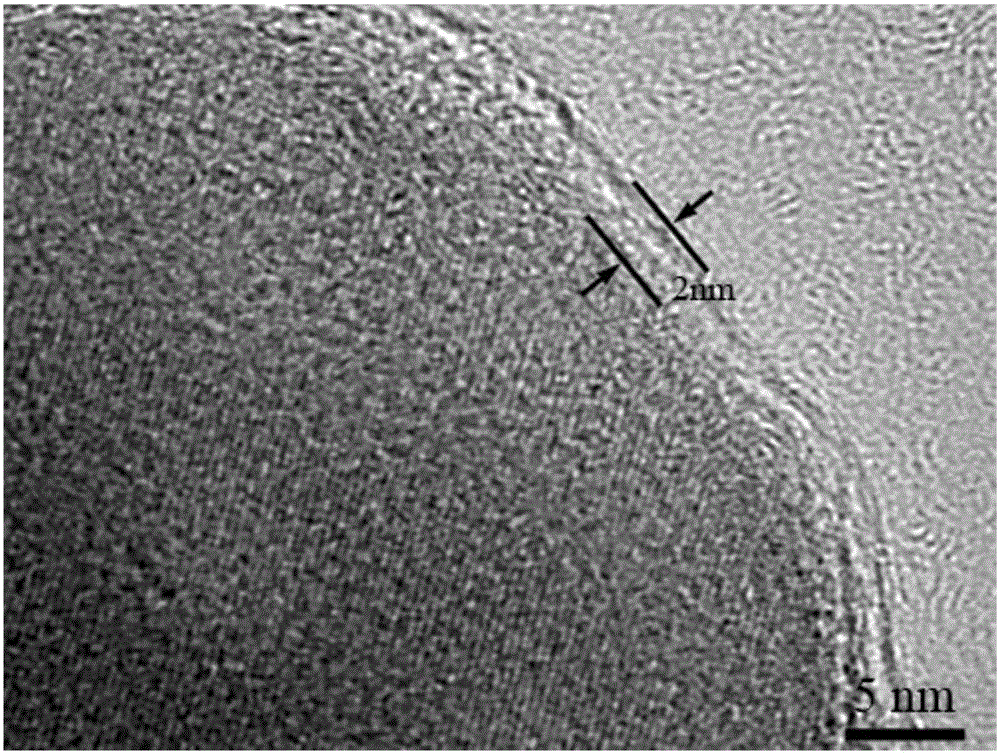

Composite carbon cathode material for lithium ion battery and preparation method thereof

InactiveCN102185142AInhibit growthImprove electrochemical performanceCell electrodesIonSpecific energy

The invention discloses a composite carbon cathode material for a lithium ion battery and a preparation method thereof, and relates to a cathode material for a lithium ion battery. The invention provides the composite carbon cathode material for the lithium ion battery and the preparation method thereof, wherein the composite carbon cathode material can reduce the influence of a solid electrolyte interface (SEI) film on the cyclical stability of the cathode material, partially prevent anode dissolved metal ions from being deposited on the surface of the cathode material to affect the cyclical performance of the cathode material and still provide high specific energy under the condition of high charging current. The composite carbon cathode material is provided with a nuclear shell layer structure of at least three layers, wherein the outer layer is a metal layer, an alloy layer or a carbon layer; the middle layer is a lithiated metal oxide layer or a metal oxide layer; and the inner layer is a carbon material layer. The preparation method comprises the following steps of: mixing and then drying a raw material for preparing a metal oxide and a carbon material; heating and sintering the dried raw materials under the protection of atmosphere to obtain a composite material of the lithiated metal oxide or metal oxide layer with nuclear shell structure and the carbon material; and plating a metal, alloy or carbon conductive layer with reversible mechanical ductility on the surface of the composite material to obtain a product.

Owner:XIAMEN UNIV

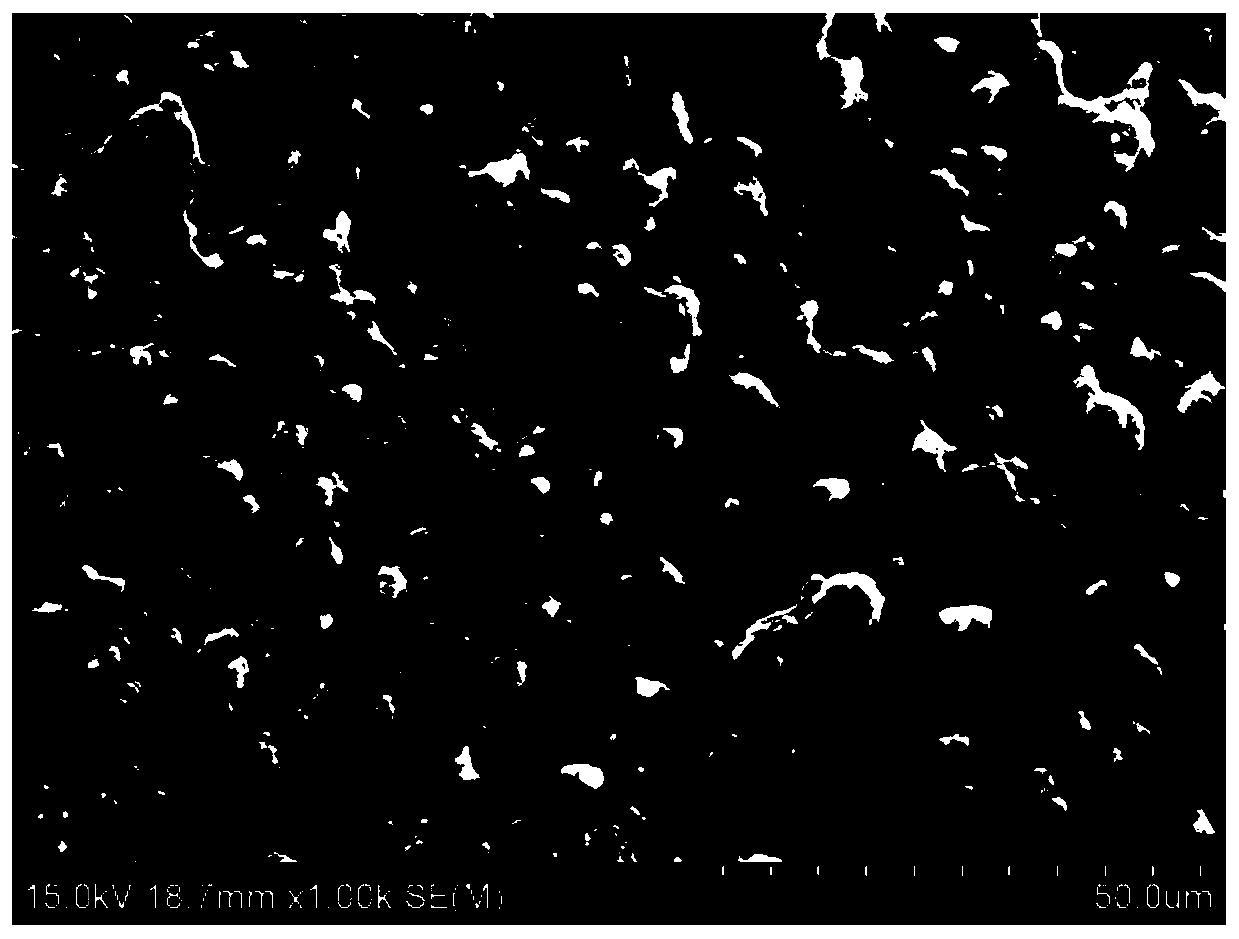

Organic/inorganic composite solid electrolyte and preparation method thereof

ActiveCN109888373AImprove ionic conductivityReduce interface resistanceSecondary cellsSolid state electrolyteComposite electrolyte

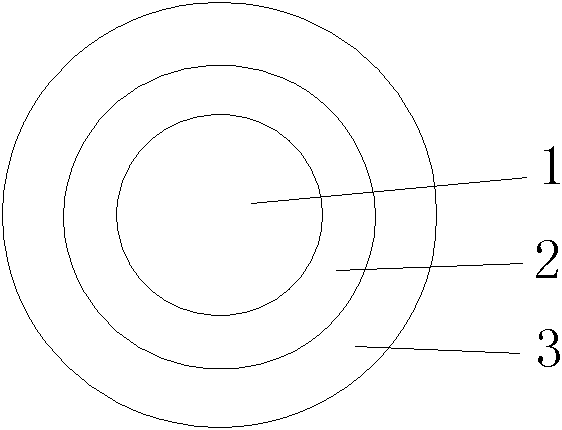

The invention relates to an organic / inorganic composite solid electrolyte and a preparation method thereof. The sulfide is pretreated, the sulfide obtained by the pretreatment is subjected to high-temperature heat treatment to obtain a sulfur-based solid electrolyte, and the sulfur-based solid electrolyte is mixed with an organic polymer and a lithium salt in an organic solvent. The organic solvent is removed and the organic / inorganic composite solid electrolyte is obtained by drying. The inner layer of the organic / inorganic composite solid electrolyte material is a sulfur-based solid electrolyte, the organic polymer is coated on the outside of the sulfur-based solid electrolyte, the sulfur-based solid electrolyte has a structure of three phases or more, or an organic / inorganic composite electrolyte is composed of a two-phase sulfide solid electrolyte and a low-decomposition-temperature polymer organic matter, so that the activity of the obtained organic / inorganic composite solid electrolyte is improved, the conductivity is improved, and the cycle performance of the lithium-sulfur battery is improved.

Owner:深圳索理德新材料科技有限公司

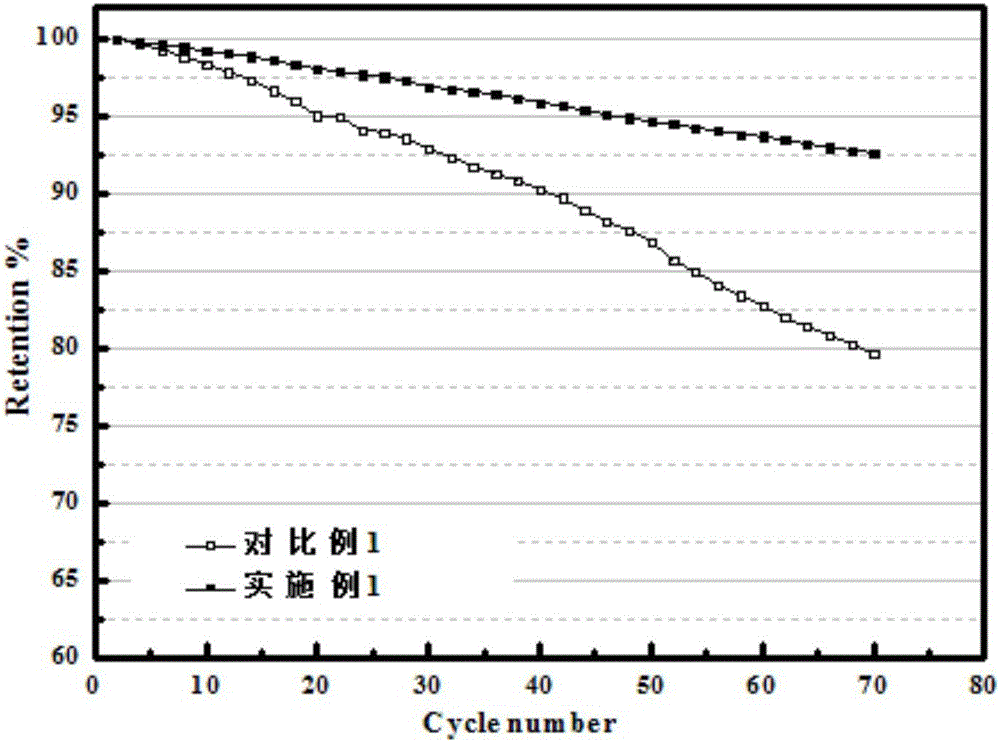

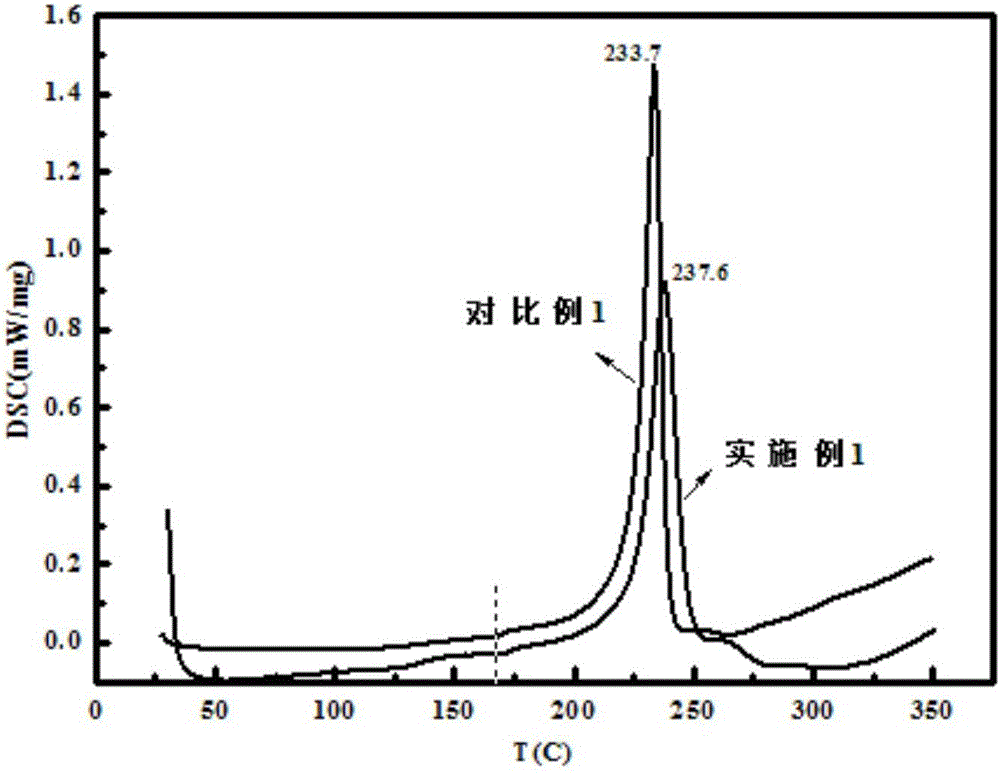

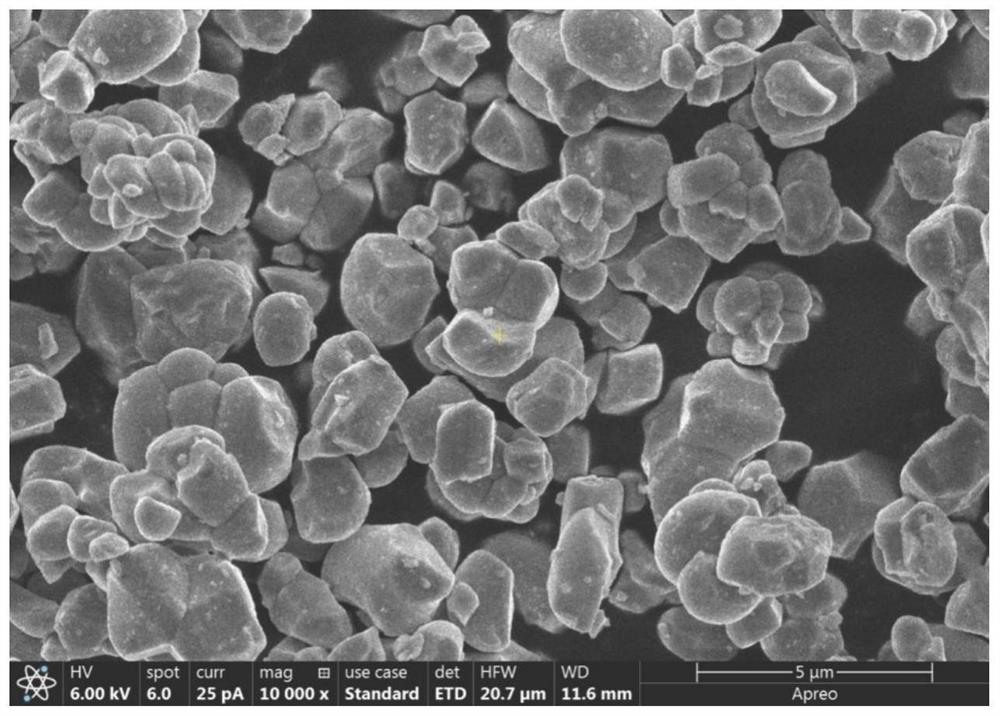

Doped lithium nickel cobalt oxide composite cathode material and preparation method thereof

InactiveCN106058205AReduce corrosionImprove cycle stabilityCell electrodesSecondary cellsCobalt oxideComposite cathode

The invention discloses a doped lithium nickel cobalt oxide composite cathode material and a preparation method thereof. The preparation method comprises the following steps: (1), dissolving manganese ion raw materials in water to prepare a solution A, and dissolving a precipitator in the water to prepare a solution B; (2), adding a doped lithium nickel cobalt oxide precursor in the solution A, and adding the solution B to the solution A while stirring; after reaction is completed, filtering the mixed solution, collecting solid matters, and cleaning and drying the solid matters, thereby obtaining solids A; and (3), putting the solids A and a lithium source in an oxygen atmosphere furnace to perform high-temperature roasting, thereby obtaining products after the roasting, namely the doped lithium nickel cobalt oxide composite cathode material existing in a core-shell structure, the surface of which is coated with a spinel lithium manganate layer. According to the preparation method, a layer of spinel lithium manganate cathode material is coated on the surface of the lithium nickel cobalt oxide, so that the efficiency and the cycle life of a battery cell in use can be improved; outmost-layer spinel isolates metallic nickel from directly contacting with electrolyte, so that the stability and the safety of the battery can be effectively improved.

Owner:TIANJIN B&M SCI & TECH

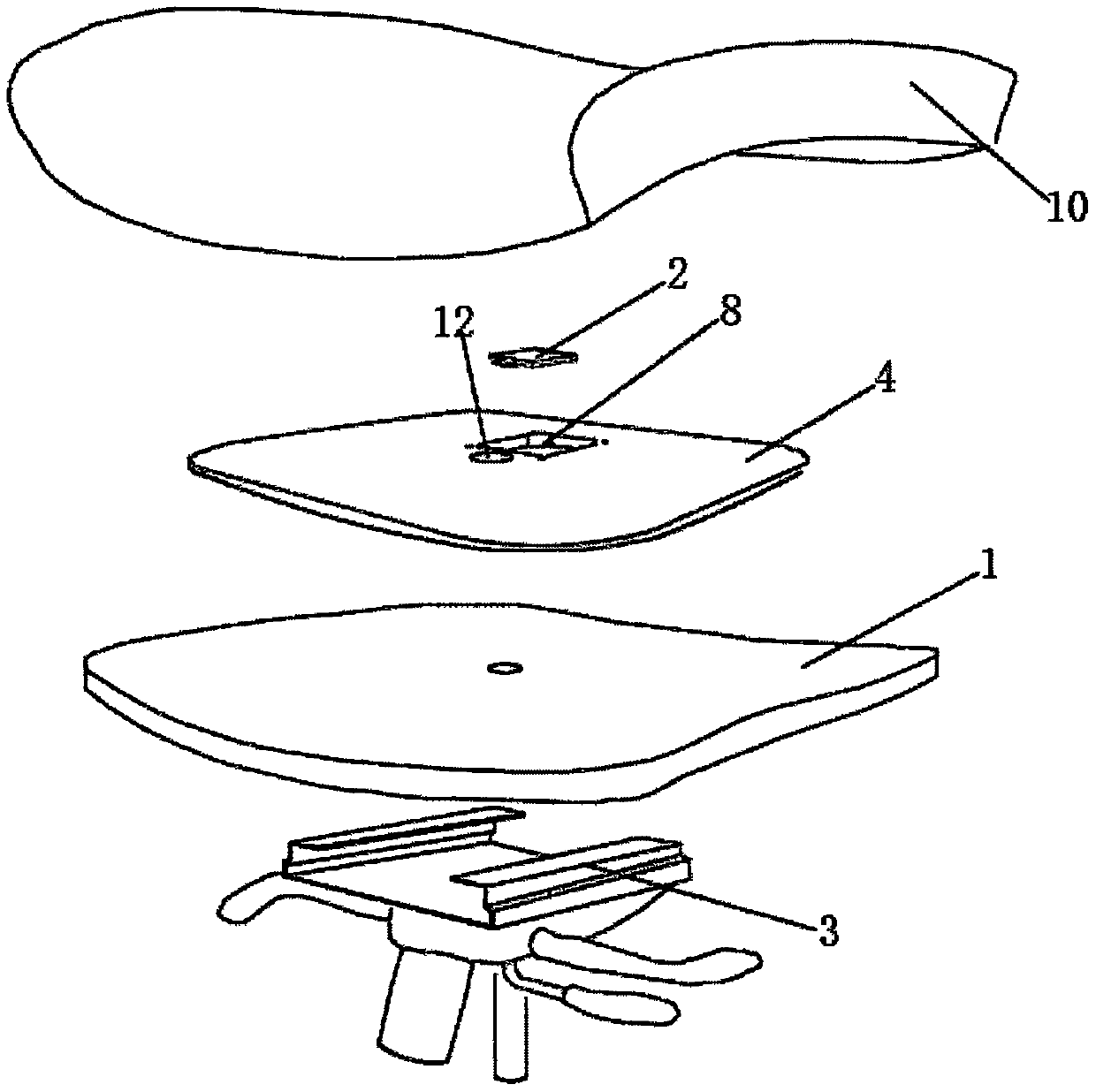

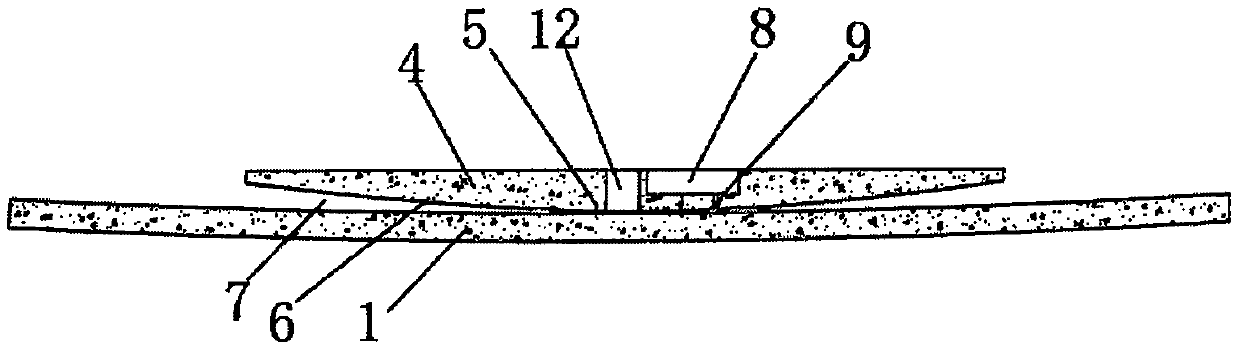

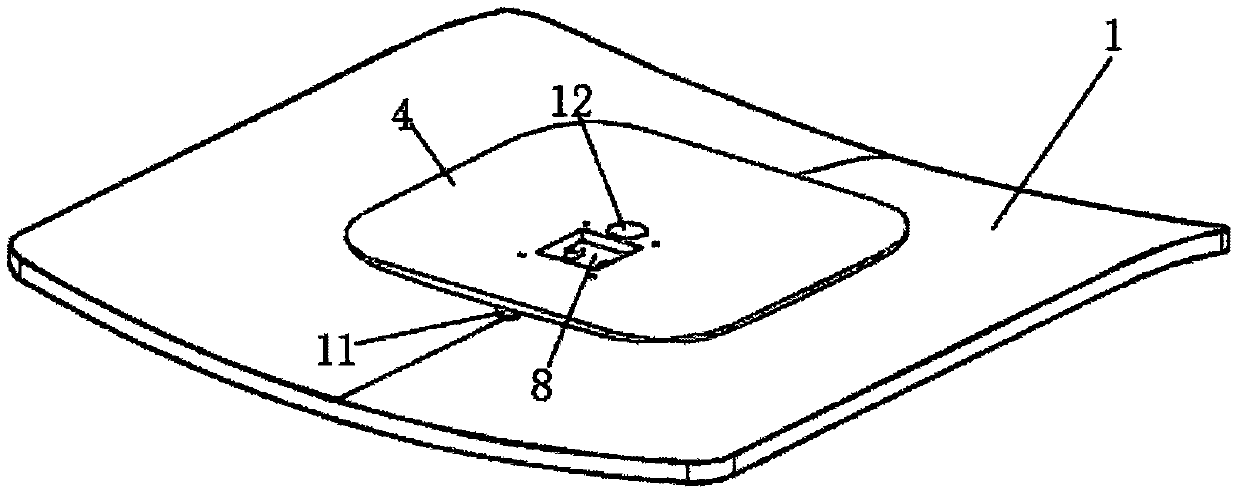

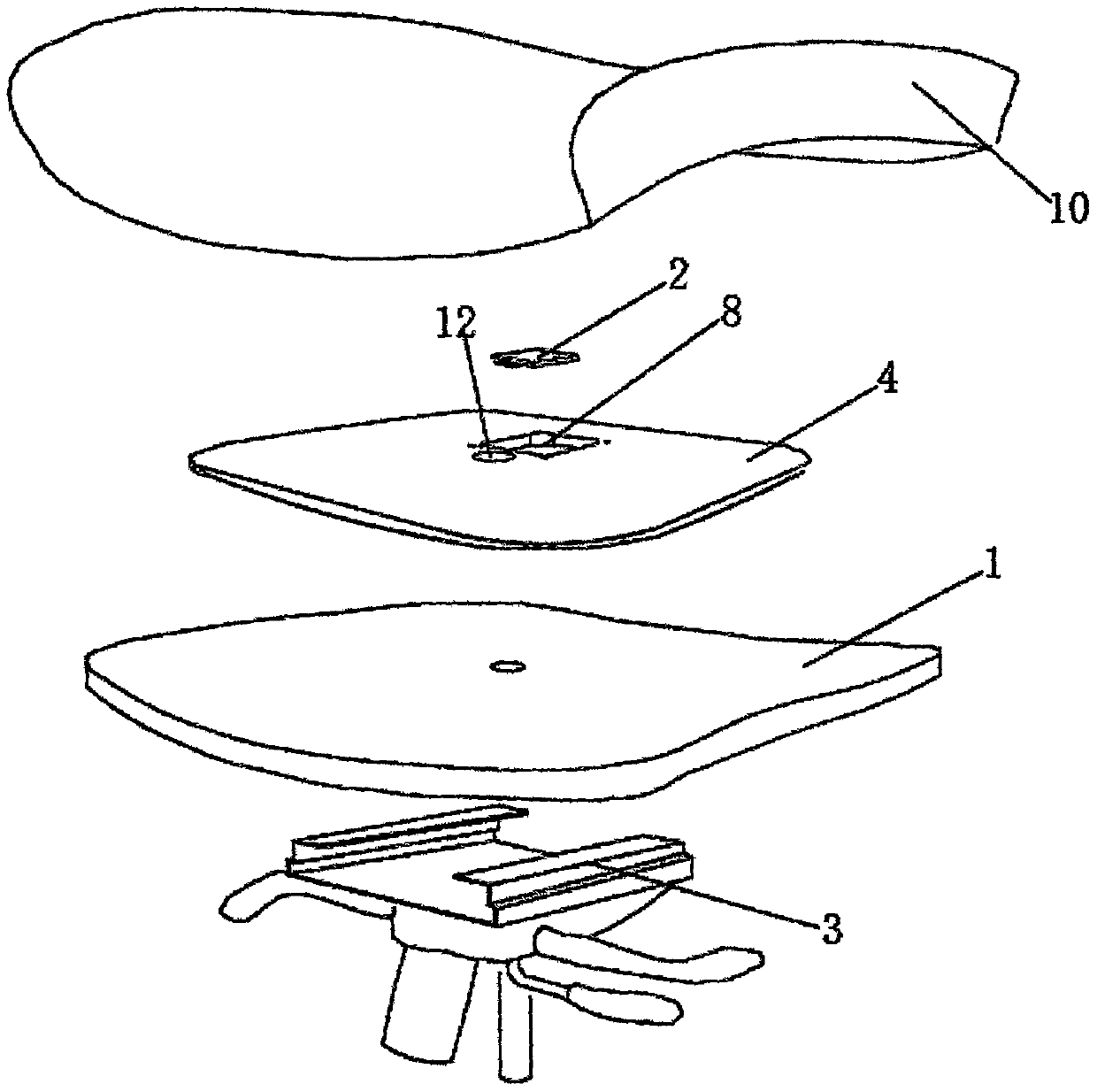

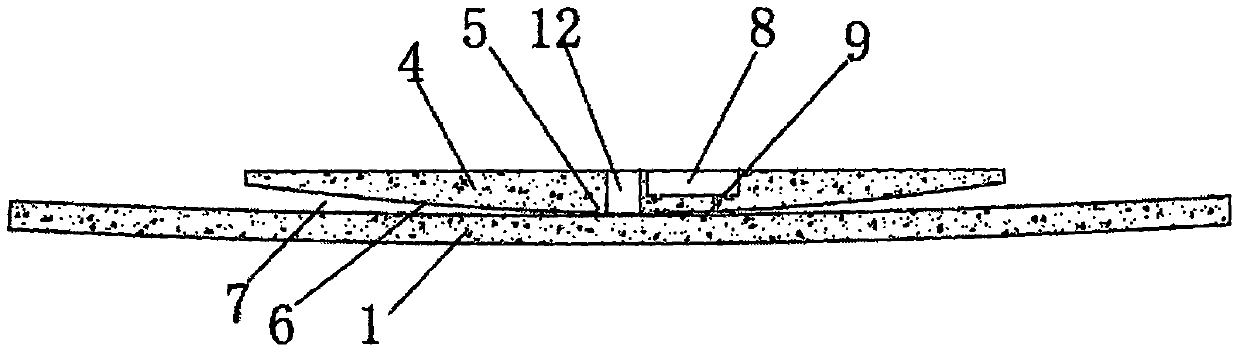

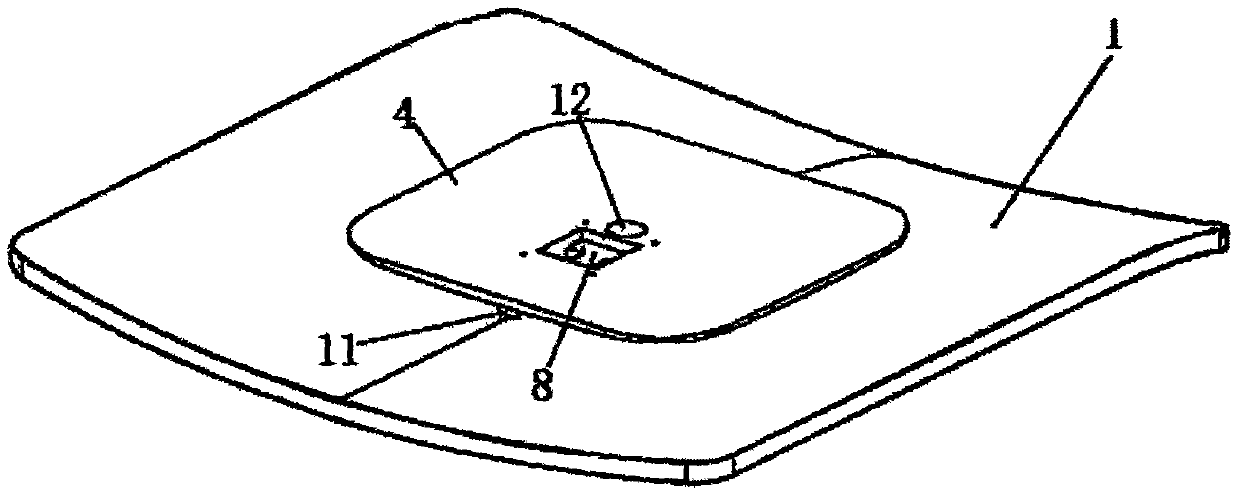

Intelligent seat based on posture recognition, intelligent interaction system and method

InactiveCN107232822AImprove recognition efficiencyComprehensive recognitionProgramme controlAngle measurementInteraction systemsAngular velocity

The invention relates to an intelligent seat based on posture recognition, and an intelligent interaction system and method. The intelligent seat comprises an intelligent hardware unit, wherein the intelligent hardware unit comprises at least one pressure sensor, at least one posture sensor, a wireless communication module, a microprocessor module and a power supply module; the pressure sensor is used for detecting pressure borne by the seat and outputting a corresponding pressure sensing signal; the posture sensor is used for sensing the posture change of the seat and outputting corresponding acceleration magnitude and angular velocity magnitude according to the corresponding posture change; the wireless communication module is used for wirelessly communicating with the outside; the microprocessor module is used for receiving corresponding values or signals outputted by the pressure sensor and the posture sensor, processing the values or signals to obtain a seat posture and outputting the same to the outside through the wireless communication module; and the power supply module is used for supplying power to all the modules. The intelligent seat provided by the invention has high recognition precision, simple structure and various functions and can solve the problems that the equipment in the prior art has single function and cannot meet the user requirement.

Owner:ZHEJIANG MARATTI FURNITURE CO LTD

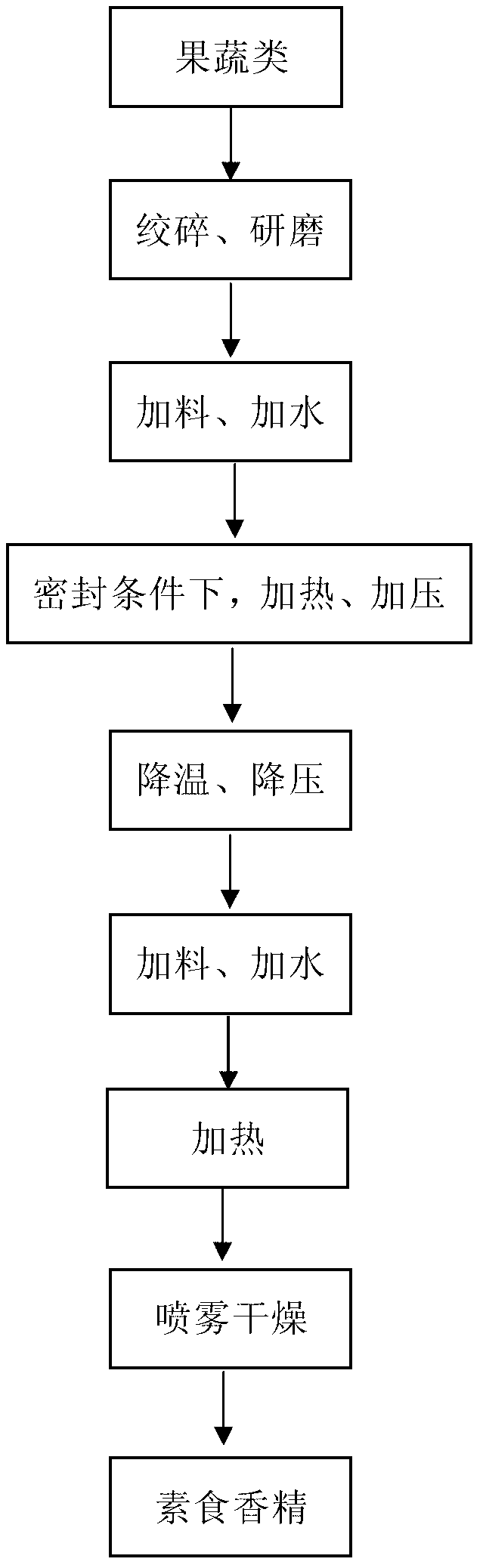

Vegetarian essence and processing method thereof

The invention discloses a vegetarian essence and a processing method thereof. The vegetarian essence is prepared by taking champignons, potatoes, onions, fermenting soy sauce and the like as the raw materials. The invention further discloses the processing method of the vegetarian essence. The vegetarian essence prepared with the processing method has an aroma and mouthfeel of natural meat, and has a lasting and dense aroma.

Owner:天津市真如果食品工业有限公司

Method for prolonging service life of amorphous alloy smelting crucible and smelting method for amorphous alloy

InactiveCN105779912AExtended service lifeIsolated from direct contactPretreated surfacesCoatingsCrucibleNitride

The invention provides a method for prolonging the service life of an amorphous alloy smelting crucible. The method comprises the steps that inorganic powder is added into a solvent to prepare suspension liquid; then, the inner wall of the crucible is sprayed and coated with the suspension liquid and subjected to short-time drying at the temperature lower than 600 DEG C, and a protective coating is formed on the inner wall of the crucible; and the inorganic powder is inorganic oxides and / or inorganic nitrides. The crucible is processed through the method provided by the invention, and the method is simple, easy to carry out, low in cost and remarkable in effect.

Owner:BYD CO LTD

A kind of preparation method of strong acid and strong alkali resistant nodular cast iron pipe

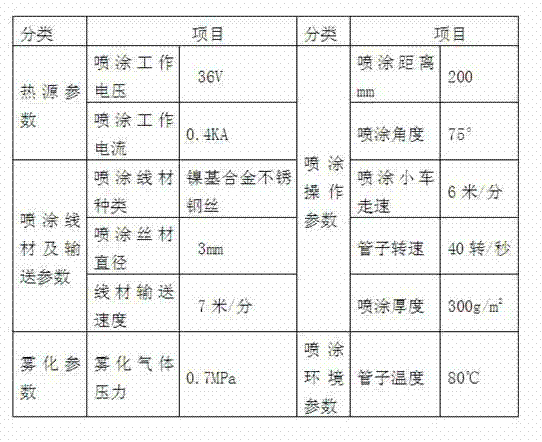

ActiveCN102266847AExtended service lifeReduce corrosion rateLiquid surface applicatorsMolten spray coatingStrong acidsAlloy

The invention discloses a method for preparing a ductile cast iron tube with strong acid and alkali resistance. The method comprises the following steps: (1) performing ball blast treatment on the surface of a ductile cast iron tube substrate; (2) spraying a stainless steel alloy bottom layer; and (3) coating an anti-corrosion coating layer on the outer surface of the ductile cast iron tube with the stainless steel alloy bottom layer. The method provided by the invention is used for reducing the uniform corrosion speed of the stainless steel alloy. on the basis of a formed synergetic anti-corrosion system of the stainless steel alloy bottom layer and the anti-corrosion coating layer, the ductile cast iron tube still has excellent anti-corrosion property under the conditions of lower pH value (PH<4) and higher PH value (PH<12), thereby greatly prolonging the service life of the ductile cast iron tube under strong acid and alkali conditions.

Owner:XINXING DUCTILE IRON PIPES CO LTD

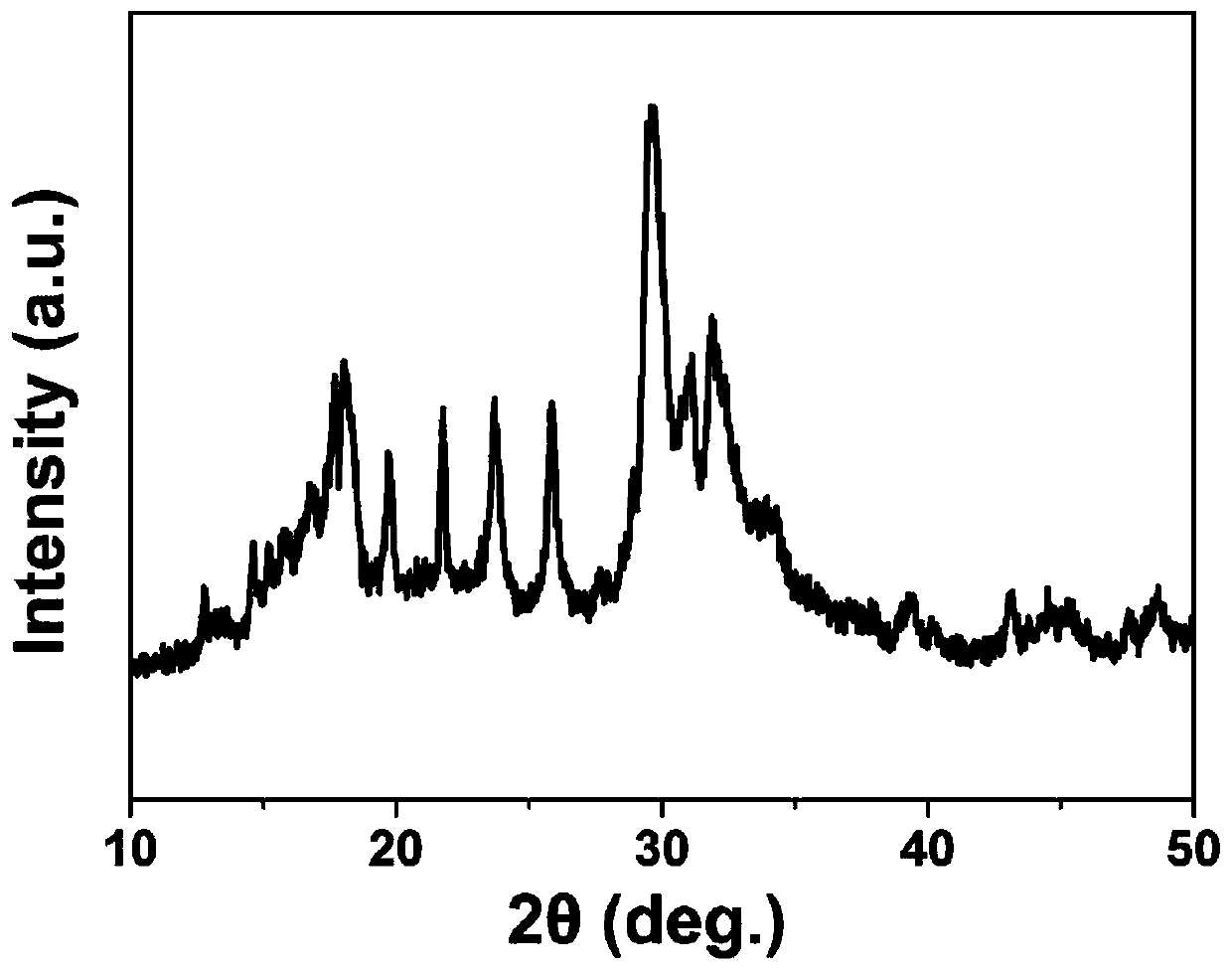

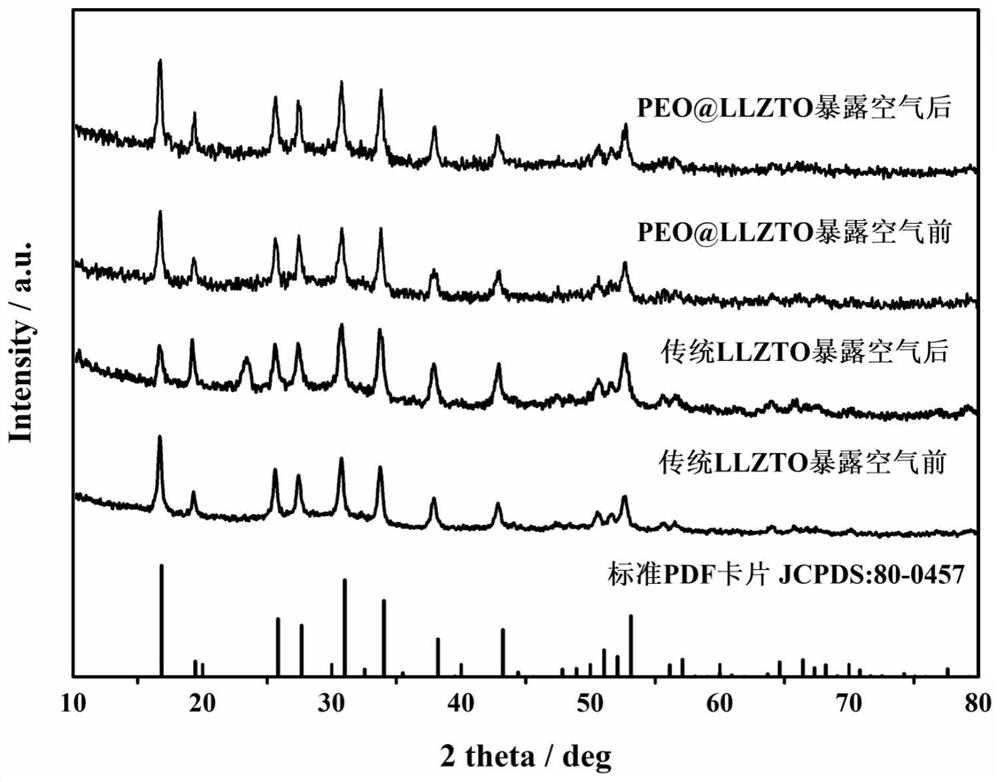

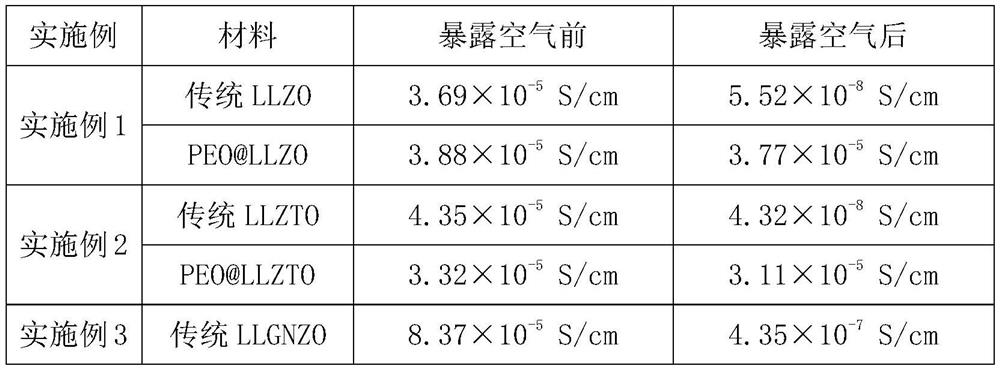

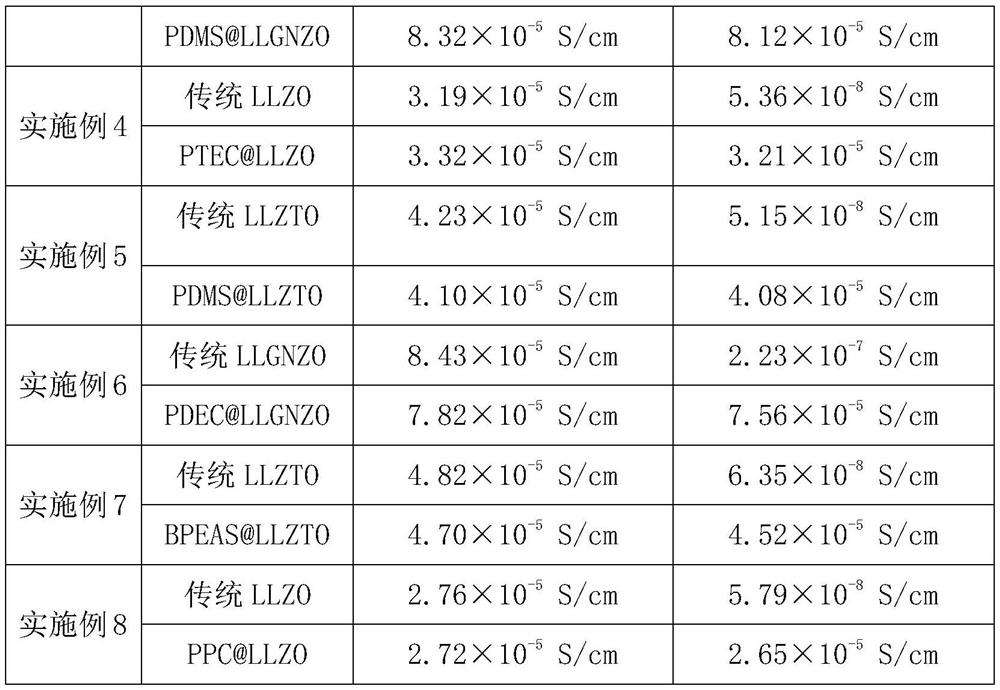

Surface treatment method for garnet type solid electrolyte

ActiveCN112290082ACoated evenlyWill not introduceElectrolytesLi-accumulatorsSolid state electrolyteConductive polymer

The invention belongs to the technical field of solid electrolyte preparation, and particularly relates to a surface treatment method for a garnet-type solid electrolyte. The method comprises the following steps: pretreating a garnet electrolyte powder material, and forming an ion conductive polymer coating layer with the thickness of 1-50 nm on the surface of the garnet electrolyte powder material by adopting a spray drying technology. According to the method disclosed by the invention, adverse reaction between the garnet solid electrolyte and air is prevented, the generation of surface impurities is inhibited, and meanwhile, the ionic conductivity of the electrolyte is not deteriorated, so that the electrolyte can keep high stability and electrochemical performance in the storage and useprocesses.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Intelligent seat, intelligent interactive system and method for controlling games based on gesture recognition

InactiveCN107233730AImprove recognition accuracySimple structureVideo gamesInput/output processes for data processingElectricityAngular velocity

The invention relates to an intelligent seat, intelligent interactive system and method for controlling games based on gesture recognition. The intelligent seat comprises an intelligent hardware unit; the intelligent hardware unit comprises at least one gesture sensor for sensing gesture change of a seat and outputting corresponding acceleration values and angular velocity values according to corresponding gesture change; a control board comprising at least two buttons which is used for sending a first game control instruction to the outside; a wireless communication module for communicating wirelessly with the outside; a microprocessor module for receiving corresponding values or signals from a pressure sensor and the gesture sensor and obtaining seat gesture after processing the values and signals and outputting through the wireless communication module; a power supply module for providing electricity for the modules. According to the invention, through adding game control buttons on the seat, through converting gesture into direction control in the game, people can change different gestures in the seat for controlling games so that they can exercise during playing games.

Owner:ZHEJIANG MARATTI FURNITURE CO LTD

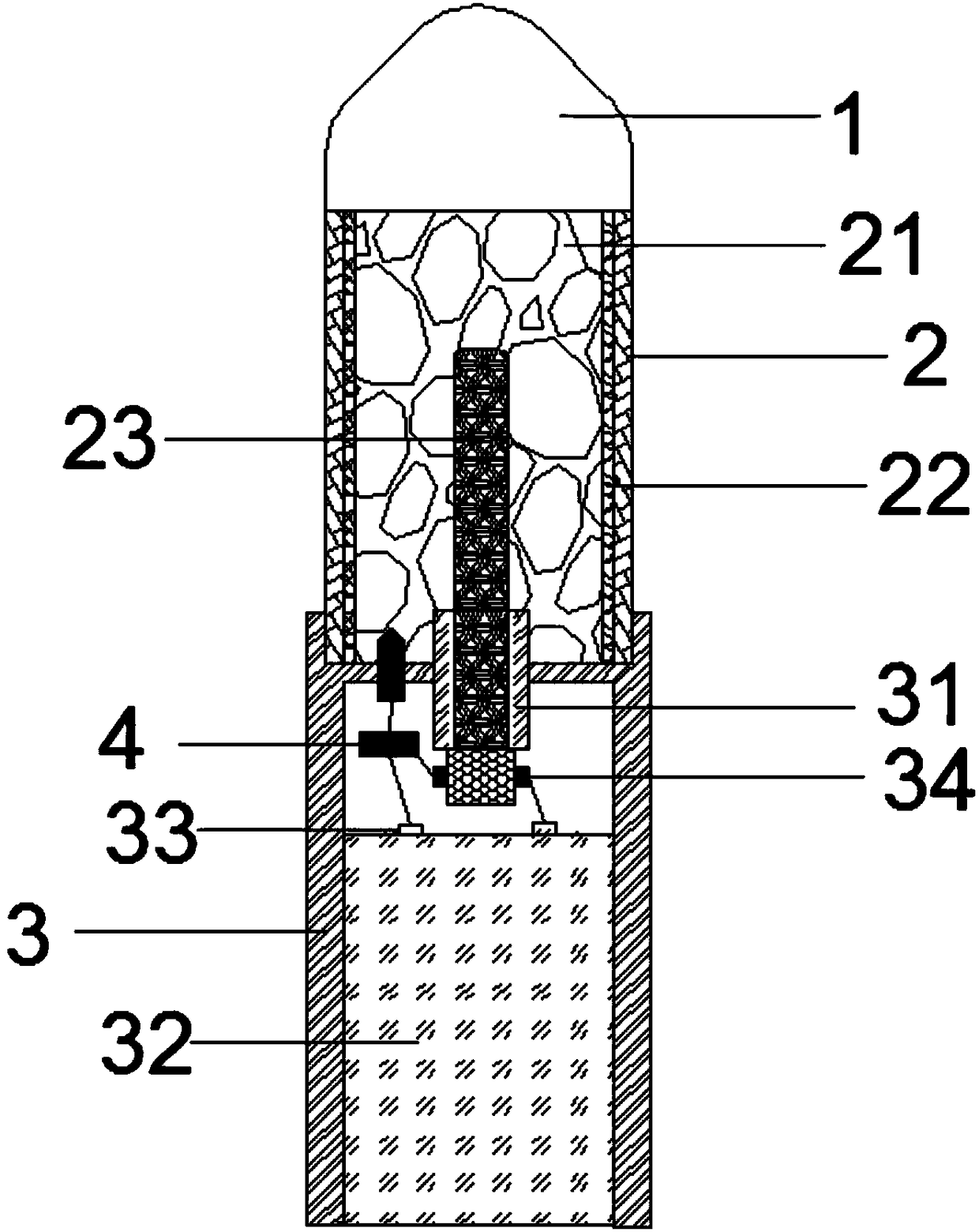

Far infrared heating electronic cigarette module

PendingCN108378426AWill not volatilize unevenlyIncrease atomization rateTobacco devicesElectricityTar

The invention provides a far infrared heating electronic cigarette module. The electronic cigarette module comprises a cigarette holder, an atomizer, a base, a far infrared heating body and a temperature regulation and control device, wherein an opening is formed in the bottom of the atomizer; a notch is formed in the top of the base; the cigarette holder is arranged on the top of the atomizer; the atomizer is mounted on the base and is filled with expanded graphite; a battery is mounted in the base; the top of the far infrared heating body extends into the atomizer; the bottom of the far infrared heating body extends into the base through the notch, and is electrically connected with the battery; one end of the temperature regulation and control device is connected with the inside of theatomizer while the other end of the temperature regulation and control device is electrically connected with the battery; and one or two far infrared reflecting layers is arranged on the inner side wall of the atomizer. The far infrared heating body is arranged in the atomizer of the electronic cigarette, far infrared rays generated by radiation can effectively penetrate through tobacco tar or a tobacco tar load, rapid and uniform heating is implemented, and meanwhile, the problem of uneven tobacco tar volatilization due to over-high local temperature can be avoided.

Owner:杭州森翼科技有限公司

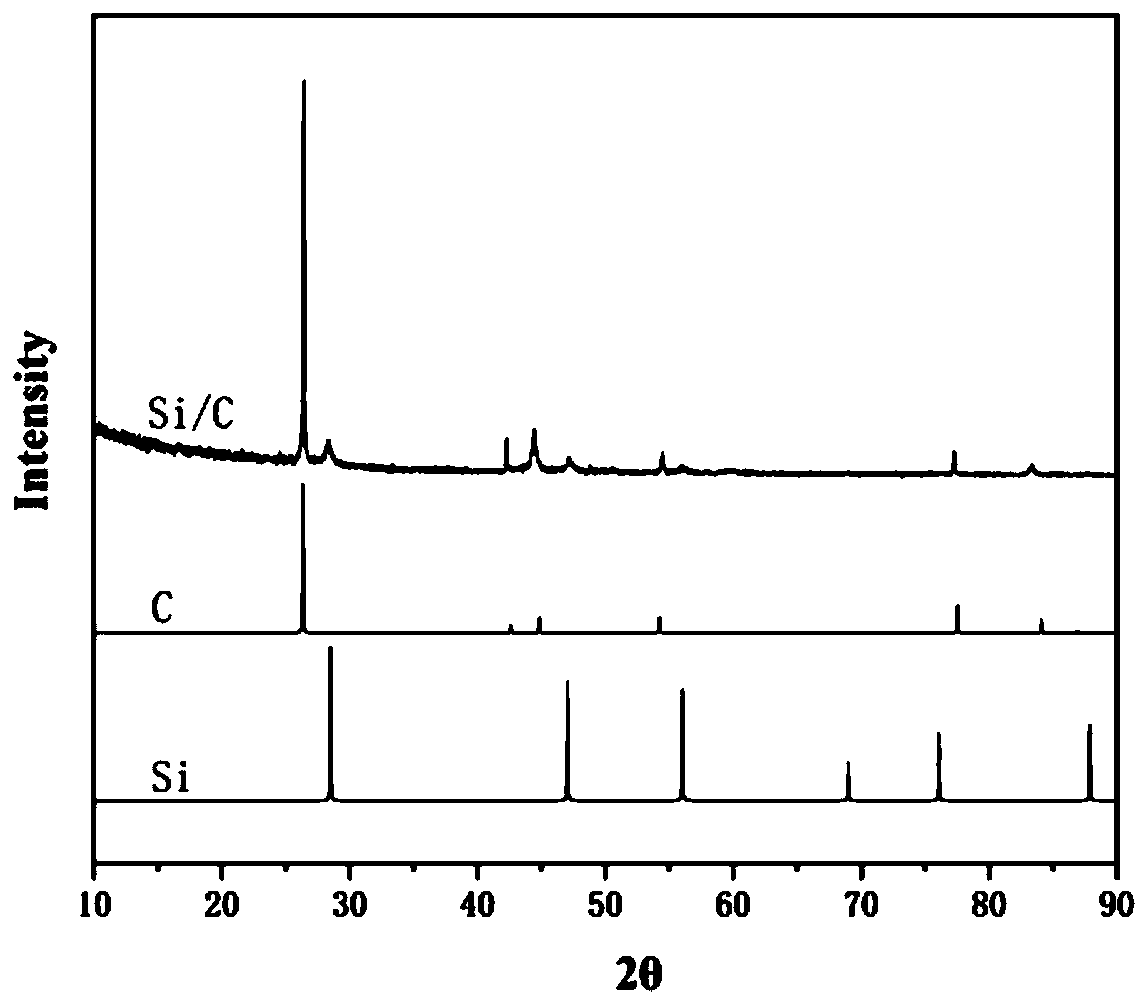

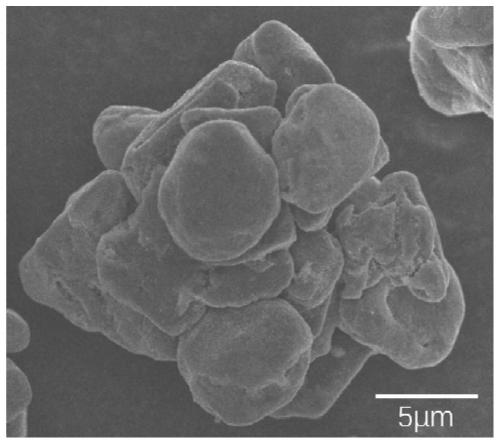

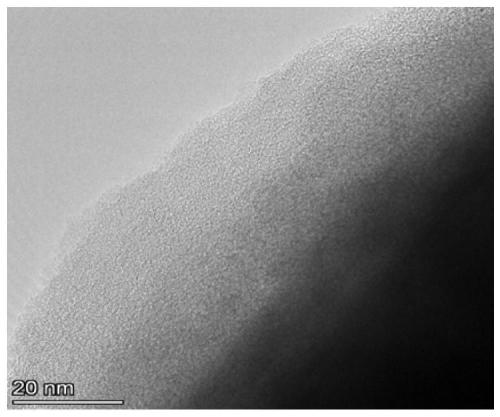

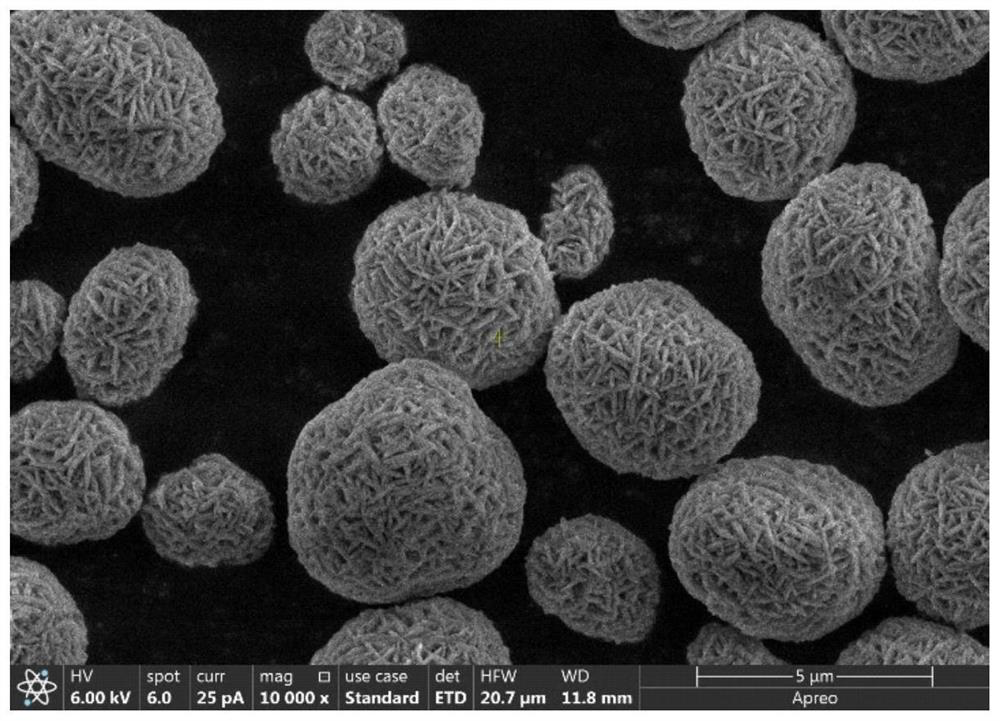

Silicon-carbon composite material with multi-layer coating structure and preparation method thereof

ActiveCN111348647AImprove Coulombic efficiencyPromote environmental protectionSiliconGraphiteCarbon compositesCarbon layer

The invention belongs to the technical field of silicon-carbon composite materials with multi-layer coating structures. The invention relates to a silicon-carbon composite material, in particular to asilicon-carbon composite material with a multi-layer coating structure. A preparation method is based on a cross-scale modification technology for a silicon-based negative electrode. Secondary particle self-assemblying and uniform dispersion of nano-silicon in gaps of graphite secondary granulation particles can be realized; through fine regulation and structural design of asphalt with differentsoftening points, multi-layer carbon layer coating can be realized; volume expansion of silicon is effectively buffered; the bonding of the secondary particles in the drying process is assisted; through fine screening and targeted regulation and control of asphalt with different softening points, distribution of nano-silicon in gaps of secondary granulation of the graphite matrix and coating modification of the surface of the graphite matrix are realized; the structure can effectively isolate direct contact between silicon and an electrolyte, reduce side reactions, effectively reduce consumption of active lithium ions and the electrolyte in a battery cycle process, and improve coulombic efficiency and cycle retention rate of the material.

Owner:西安英纳吉科技有限公司

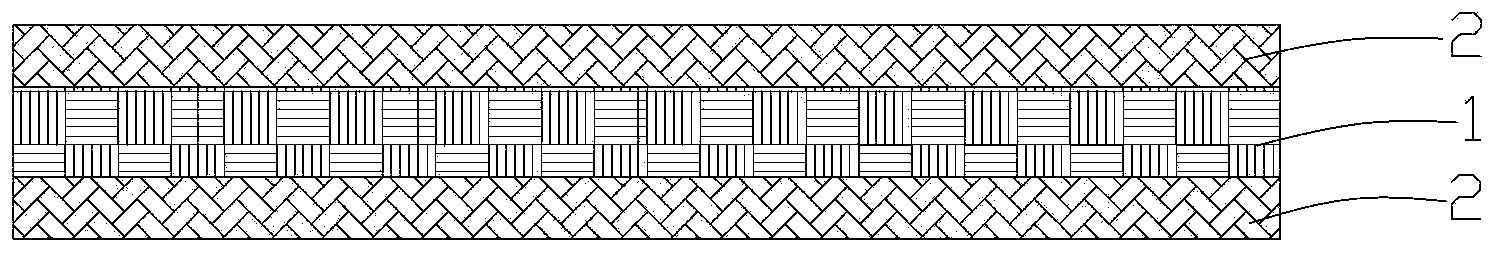

Electrochemical power-supply composite membrane and preparation method thereof

InactiveCN103579553AHigh strengthImprove flexibilitySynthetic resin layered productsCell component detailsHeat resistancePolyvinylidene difluoride

The invention provides an electrochemical power-supply composite membrane and a preparation method thereof. The electrochemical power-supply composite membrane comprises a non-woven fabrics layer and a polyvinylidene fluoride-hexafluoropropene copolymer layer combining with the surface of the non-woven fabrics layer, and the thickness of the polyvinylidene fluoride-hexafluoropropene copolymer layer is 5-10 mu m. The preparation method of the electrochemical power-supply composite membrane comprises: preparing an organic solution of polyvinylidene fluoride-hexafluoropropene copolymer, coating the non-woven fabrics layer with the organic solution of polyvinylidene fluoride-hexafluoropropene copolymer, performing drying process and the like. The electrochemical power-supply composite membrane is good in heat resistance and stable in thermal dimension, has uniformly-distributed pores capable of effectively avoiding direct contact of electrode particles, and is high in safety. The preparation method of the composite membrane is simple, the condition is easy to control, the requirements on equipment are low, the production efficiency is high, the production cost is low, and the preparation method is suitable for industrial production.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

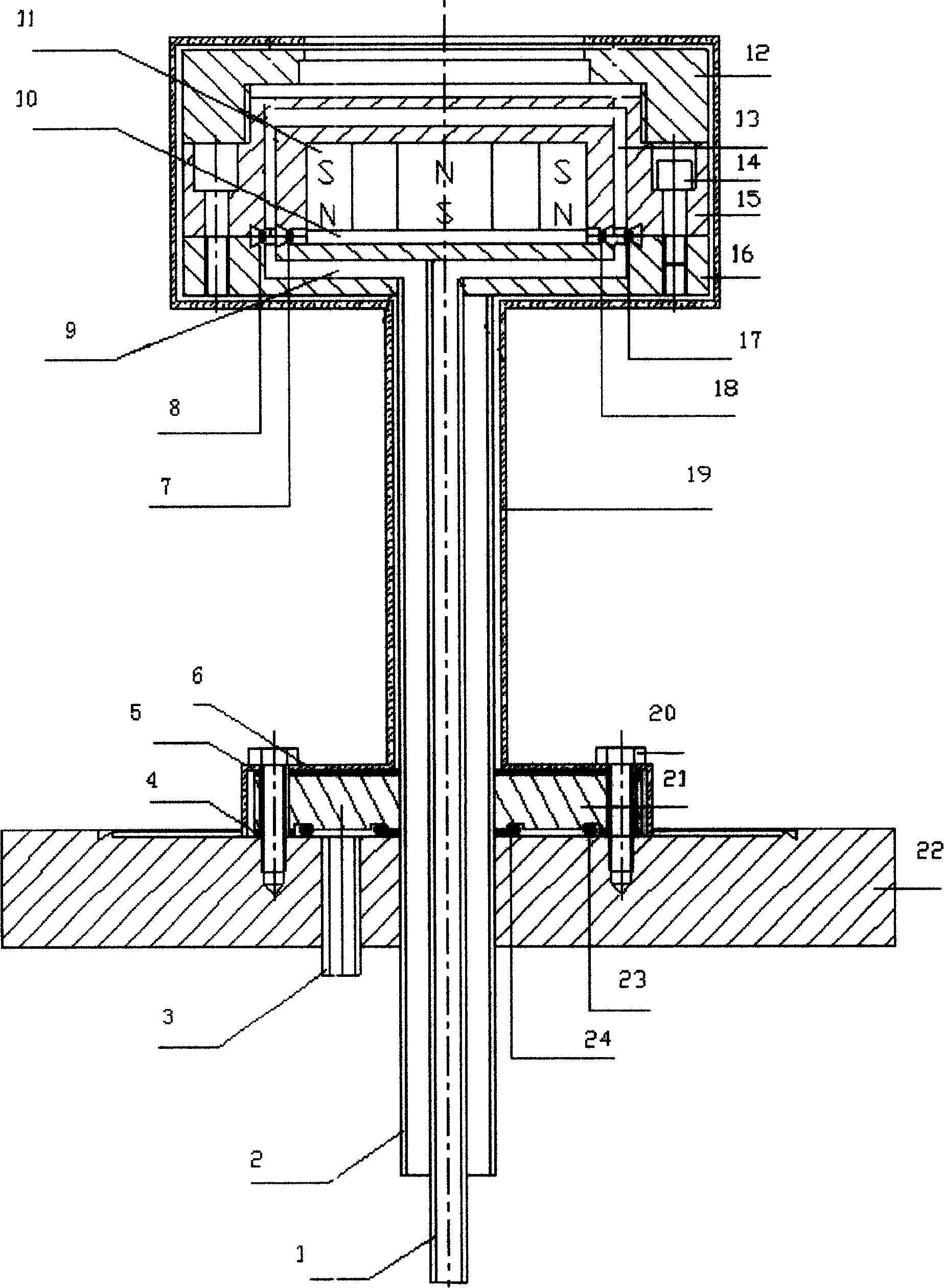

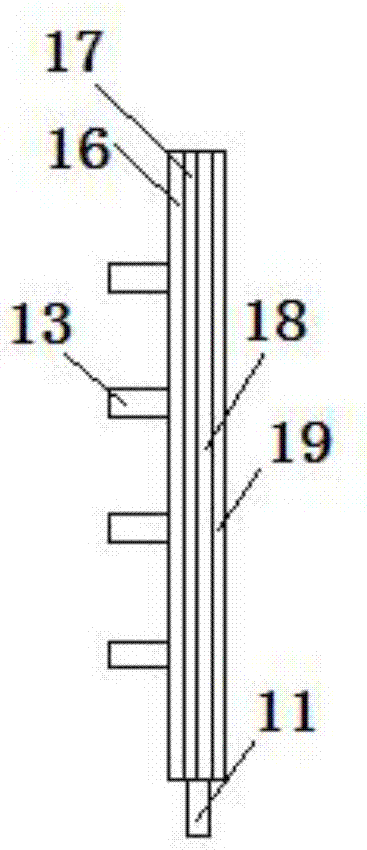

Magnetron sputtering cathode target for ultrahigh vacuum system

InactiveCN101161855AStable deliveryGuarantee normal performanceVacuum evaporation coatingSputtering coatingUltra-high vacuumEngineering

The invention discloses a magnetic control sputtering cathode target for an ultrahigh vacuum system. An upper flange and a lower flange (15 and 16) are inside provided with cooling troughs (13 and 9) which are communicated with each other, a water inlet pipe and a water outlet pipe (1 and 2) which separate from the cooling trough (9) are welded with the cooling trough (9), the upper end part of the upper flange (15) is in screw joint with a target material mounting frame (12), the chamber of the upper flange is inside provided with a magnet holder (10) and a magnet (11), metal obturating rings (17 and 18) which are positioned at an inner layer and an outer layer edges (7 and 8) are arranged between the lower end surface of the upper flange and the lower flange (16) and are fixed by a bolt (14), a small flange (21) is welded outside the water outlet pipe (2); insulation sheets (4 and 6) are arranged between the small flange (21) and a shield enclosure (19) and a base flange (22), two O-shaped cushion rubbers are arranged between the small flange and the base flange (22) which is communicated with an exhaust tube (3), the two cushion rubbers are fixed by a bolt (20) sleeved by an insulating sleeve (5). The invention has a vacuum degree up to 6x10<-8>Pa, which can realize the preparation of metal or nonmetal film with high quality and purity.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

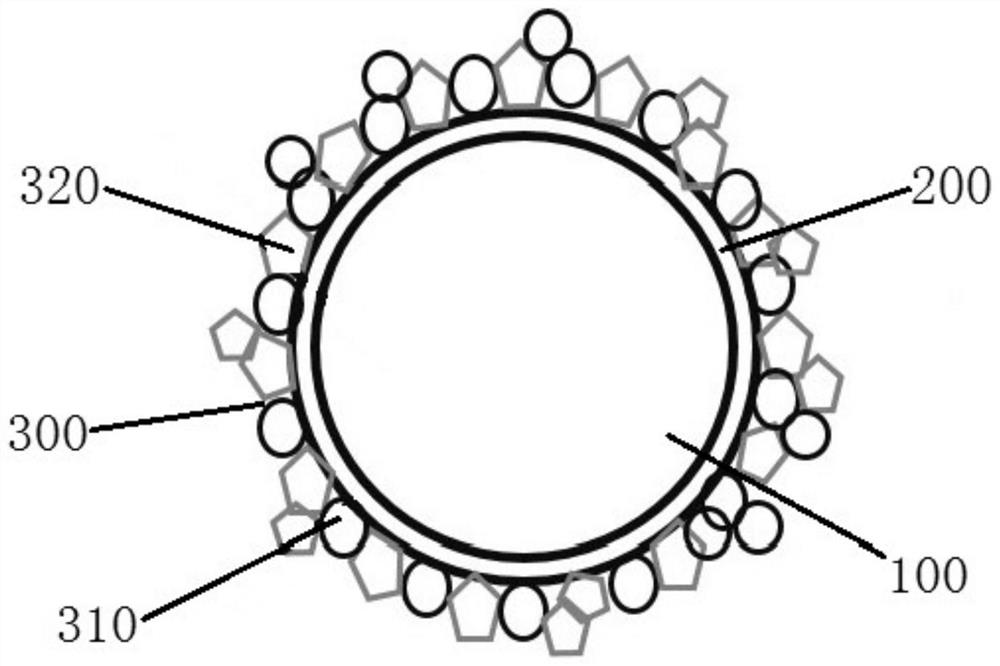

Double-layer -coated modified high-nickel cobalt-free single crystal ternary positive electrode material and preparation method thereof

ActiveCN113488634AHigh mechanical strengthGuaranteed stabilitySecondary cellsPositive electrodesLithiumPhysical chemistry

The invention discloses a double-layer-coated modified high-nickel cobalt-free single crystal ternary positive electrode material and a preparation method thereof, the chemical formula of the positive electrode material is LiNixMnyWzO2@TMO2@C, in the formula, x is greater than or equal to 0.9 and less than 1, y is greater than 0 and less than 0.06, z is greater than 0 and less than 0.04, x + y + z = 1, and TMO2 is one or more of oxides of Al, Mg, Cu and Ti. The preparation method comprises the following steps: (1) carrying out coprecipitation reaction on a nickel source, a manganese source, a tungsten source, a NaOH solution and an ammonia water solution to obtain a precursor; (2) uniformly mixing the precursor with a lithium source, and calcining to obtain a ternary positive electrode material; (3) mixing a TM source with the cobalt-free ternary positive electrode material, and calcining to obtain a single-layer coated ternary positive electrode material; and (4) mixing the single-layer coated ternary positive electrode material with a carbon source, and calcining to obtain the single-layer coated ternary positive electrode material. The double-layer -coated modified high-nickel cobalt-free single crystal ternary positive electrode material is good in electrochemical performance, the preparation method is simple, and the production cost is low.

Owner:ZHUJI PAWA NEW ENERGY

Nano conductive anti-corrosive paint for earth screen

InactiveCN101892003AImprove adhesionGood flexibilityAnti-corrosive paintsEpoxy resin coatingsEpoxyDiluent

The invention provides nano conductive anti-corrosive paint for an earth screen and a method for preparing the same. The paint comprises the following components in percentage by weight: 30 to 50 percent of hydrophilic group-containing epoxy resin film-forming matrix, 10 to 20 percent of nano magnetic ferric oxide, 10 to 30 percent of curing agent and 20 to 50 percent of inert diluent, and the total weight of all components is 100 percent. The anti-corrosive paint of the invention has quite strong adhesive force, so that the paint can be compactly adhered onto the surface of the earth screen so as to prevent the direct contact between the surface of the earth screen and soil and improve the anti-corrosive property of the earth screen; the anti-corrosive paint also has quite high surface shockproof capability; because hydroxyl groups and carboxyl groups exist in hydrophilic group-containing epoxy resin, the paint has hydrophilicity high enough for the paint to better contact surface soil, and consequently the flow-diffusion capability of the earth screen is greatly improved; in addition, the paint also has the advantages of quite high conductive capability, low cost, quite high practicability and high popularization and application value.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +1

Preparation method for anti-carbon deposition layer on the surface of steel material part of engine

InactiveCN102154625AImprove anti-carbon performanceElimination of Physicochemical AdsorptionChemical vapor deposition coatingTemperature resistanceOxidative treatment

The invention discloses a preparation method for anti-carbon deposition layer on the surface of a steel material part of an engine. The preparation method comprises the following steps of: surface leveling, cleaning treatment, chemical polishing, chemical decomposition deposition Si membrane, and oxidation treatment. Technological parameters such as temperature, pressure, flow, heat preservation time and the like are adjusted; a diffusion and penetration process of Si and O elements is controlled; compositions and structures of the surface layer of the material and the bounding force between the surface layer of the material and a substrate are changed so as to obtain a compact, adhesive, structure-controlled FeSi / Si / SiO2 coating; and a FeSi / Si / SiO2 gradient transitional composite membrane is obtained on the surface of the steel material part of the engine. The composite membrane has strong bonding force with the substrate, compact organization, small internal stress and smooth inertness, has characteristics of toughness, high-temperature resistance, corrosion resistance, bonding resistance and the like, endows the material with new surface characteristics, prevents the metal from directly contacting with organic matters, prevents the adhesion and deposition of organic colloidal materials and improves anti-carbon deposition performances.

Owner:ZHEJIANG SCI-TECH UNIV

High temperature far infrared insulated energy-saving paint and method for preparing same

ActiveCN100381516CImprove general performanceImprove energy savingCellulose coatingsSoluble glassRare earth

The invention provides a high temperature far infrared insulation energy-saving coating material and its preparing process, wherein the coating material comprises zircon sand, aluminium oxide, porcelain clay, rare-earth oxide, boron nitride, silicasol, phosphoric acid, soluble glass, cellulose methyl or cellulose glycolate. The preparing process consists of batching, immersing, agitating, mixing, filtering and loading.

Owner:娄底市华晟节能材料有限公司

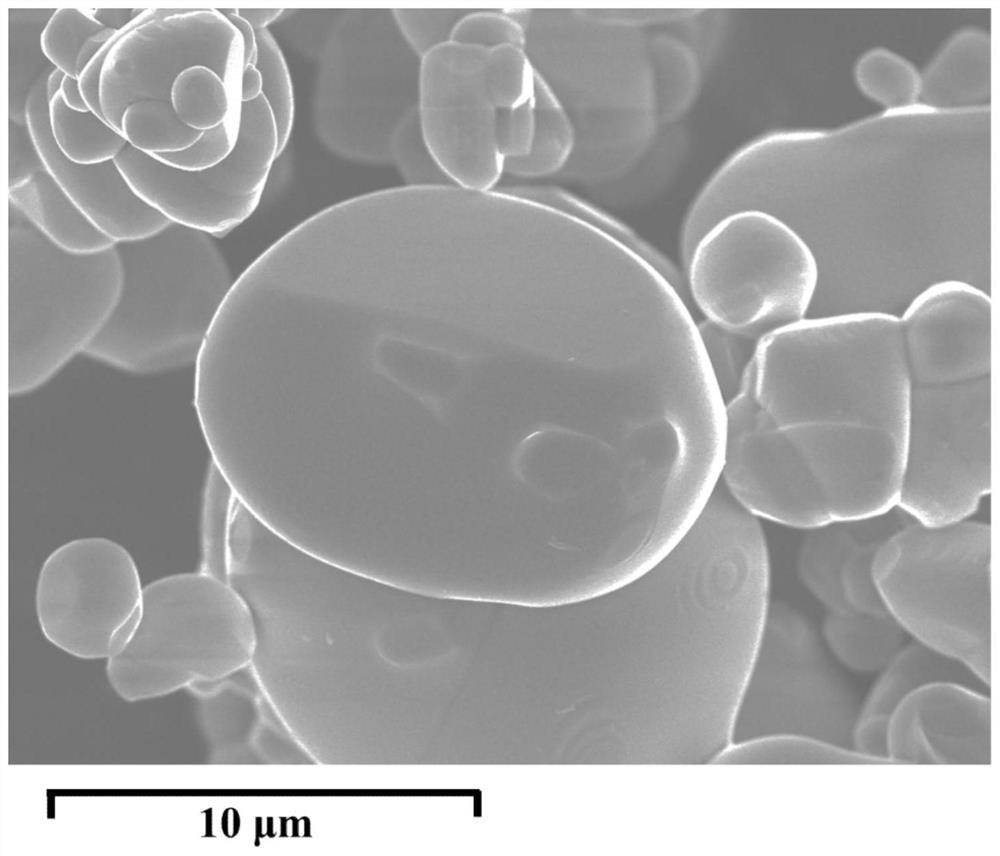

Lithium ion battery composite positive electrode material, and preparation method and application thereof

PendingCN113471414AEliminate residual lithiumImprove conductivitySecondary cellsPositive electrodesElectrical conductorLithium-ion battery

The invention discloses a lithium ion battery composite positive electrode material, and a preparation method and application thereof, and belongs to the technical field of lithium ion battery positive electrode materials. The lithium ion battery composite positive electrode material comprises a positive electrode base material, and a lithium-poor intermediate layer and a composite coating layer which sequentially coat the surface of the positive electrode base material, the lithium-poor-state intermediate layer is LixMx1Mn2-x1O4with a spinel structure, and the composite coating layer comprises an electronic conductor and an ionic conductor; and the positive electrode material is obtained by compositely coating the surface of the positive electrode base material with the composite coating layer consisting of the lithium-poor intermediate layer with a spinel structure, an electronic conductor and an ionic conductor. According to the composite positive electrode material disclosed by the invention, the positive electrode base material is coated by the lithium-poor intermediate layer and the composite coating layer, so that the rate capability and coulombic efficiency of the composite positive electrode material are effectively improved, and the cycle performance of the composite positive electrode material is improved.

Owner:BEIJING WELION NEW ENERGY TECH CO LTD

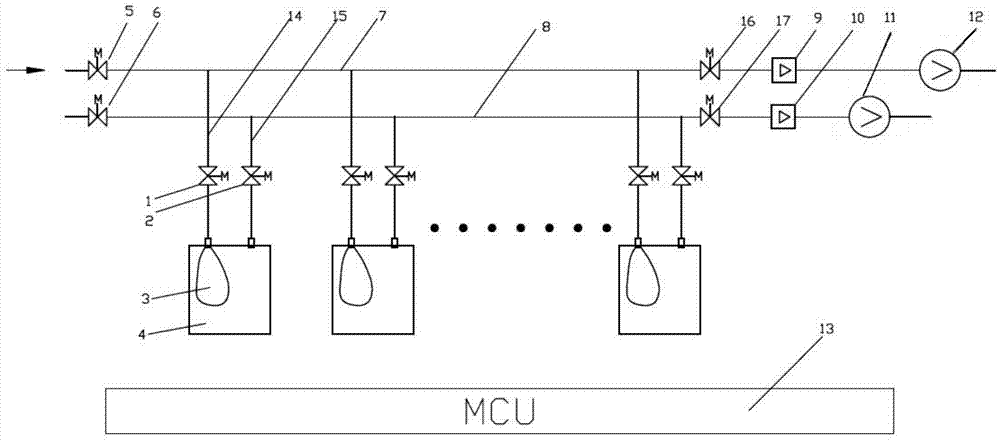

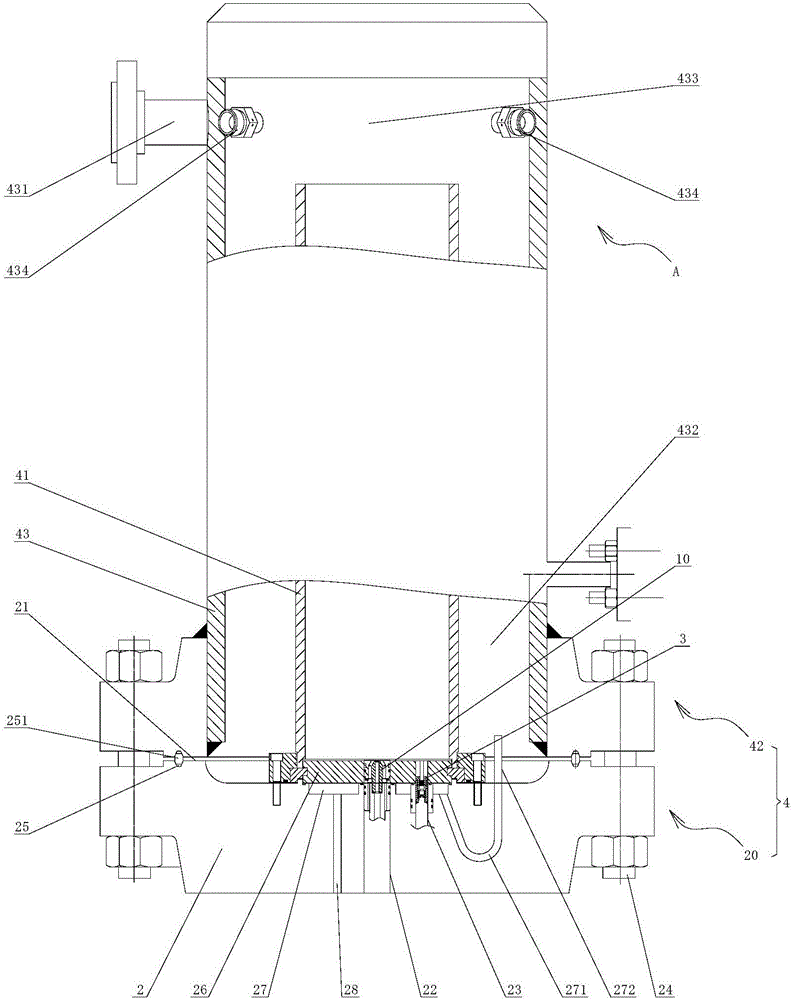

Non-contact type full-automatic gas sample retention device

ActiveCN104764632AImprove accuracyIncrease productivityWithdrawing sample devicesControl engineeringAir pump

The invention discloses a non-contact type full-automatic gas sample retention device. The non-contact type full-automatic gas sample retention device comprises a sampling pipe which is sequentially provided with a sample gas valve, an evacuation flowmeter and an air pumping pump, wherein a plurality of gas bags are connected to the sampling pipe between the sample gas valve and the evacuation flowmeter via sample gas branch pipes, and a communicating valve is arranged on each sample gas branch pipe; the non-contact type full-automatic gas sample retention device further comprises an air pipeline which is sequentially provided with an air valve, a sampling flowmeter and a sampling gas pump, a plurality of vacuum boxes which are in one-to-one correspondence with the gas bags are connected to the air pipeline between the air valve and the sampling flowmeter via evacuation branch pipes, each gas bag is hermetically arranged in the corresponding vacuum box, and a bleeder valve is arranged on each evacuation branch pipe; and the non-contact type full-automatic gas sample retention device further comprises a controller which is electrically connected with the various flowmeters, the valves and the gas pumps. The device can be used for not only realizing automatic precise sample retention of gas, improving the production efficiency and saving the labor cost, but also isolating artificial contact by the design of the non-contact type gas bags, facilitating the installation of a gas heating device and simultaneously improving the production safety; and furthermore, the device can ensure that gas has no pollution and no loss during the whole process.

Owner:苏州聚阳环保科技股份有限公司

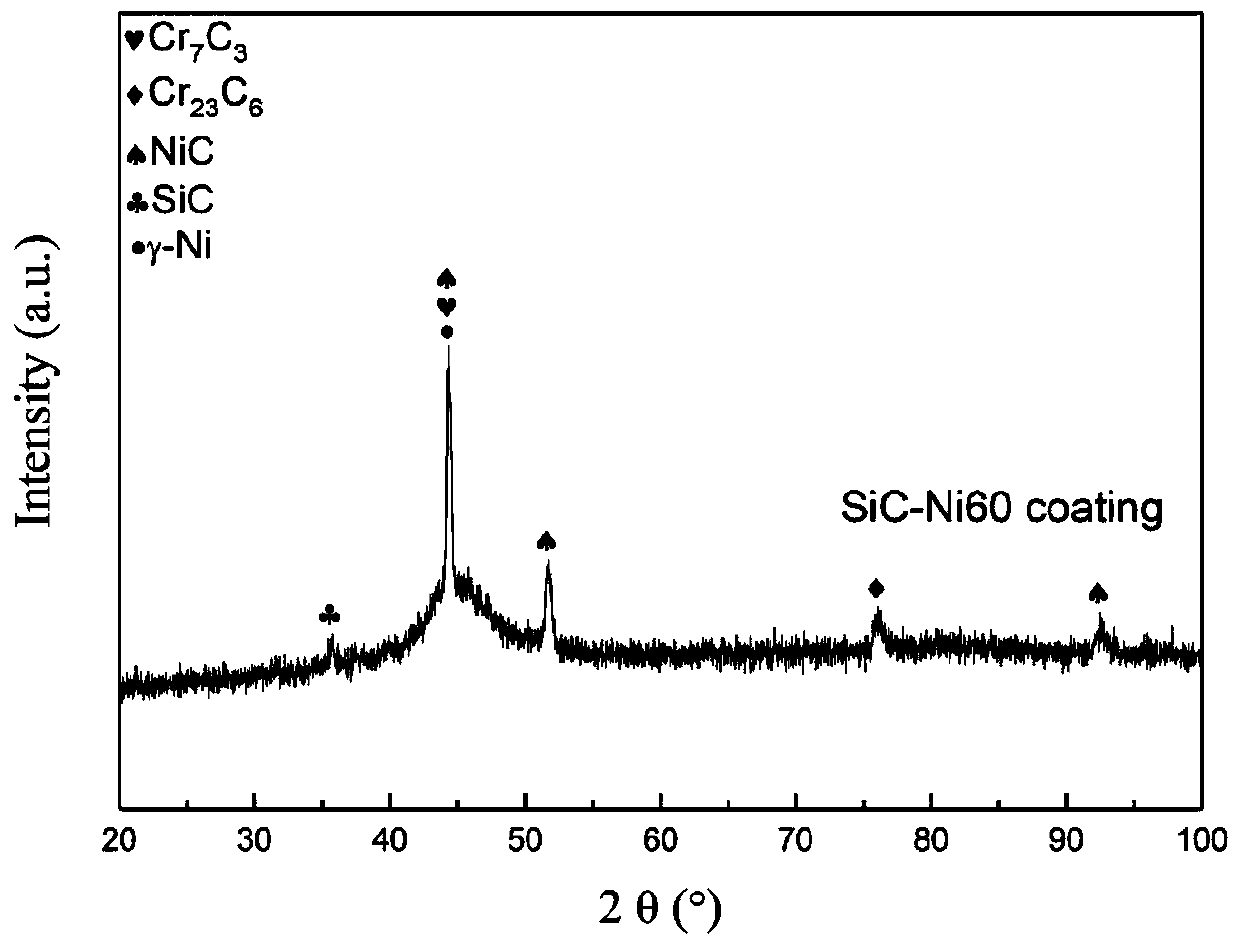

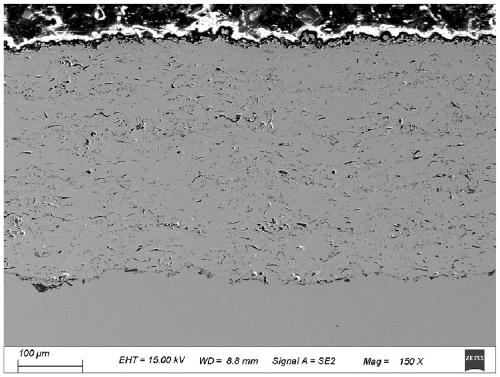

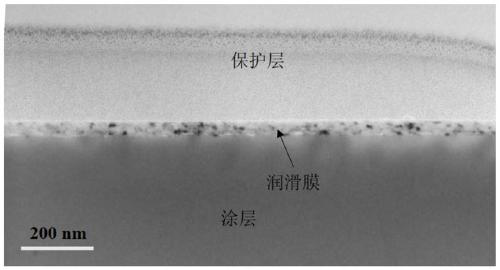

Method for enhancing tribology performance of nickel-based coating by utilizing ceramic nanoparticles

InactiveCN111041398AReduce wearIsolated from direct contactMolten spray coatingSand blastingNanoparticle

The invention relates to a method for enhancing the tribology performance of a nickel-based coating by utilizing ceramic nanoparticles. The method mainly comprises the following main steps of weighingNi60 alloy and ceramic nanoparticles according to the distribution ratio of the coating, uniformly mixing the Ni60 alloy and the ceramic nanoparticles, and then preparing a high-performance wear-resistant coating on the surface of a metal matrix after sand blasting through an atmospheric plasma spraying technology. Sprayed composite powder contains the ceramic nanoparticles, so that grain nucleation of a NiCrBSi matrix is facilitated, and surface defects such as pores and cracks during coating preparation are reduced. Under the water lubrication condition, the SiC ceramic nanoparticles undergo hydrolyzing to generate a continuous ceramic phase boundary lubricating film on a friction interface under the action of a friction pair, the direct contact between the friction pair and a nickel-based material is effectively avoided, the nickel-based material is protected, and the hardness of the interface is obvious, so that the wear resistance of a SiC-NiCrBSi composite coating can be remarkably improved.

Owner:YANGZHOU UNIV

Waterborne environment-friendly membrane and preparation method thereof

InactiveCN106221544AImprove stabilityExtended service lifePolyurea/polyurethane coatingsWear resistanceDefoaming Agents

The invention relates to a waterborne environment-friendly membrane and a preparation method thereof. The waterborne environment-friendly membrane is prepared through the steps that waterborne polyurethane resin, a defoaming agent, a dispersing agent and the like are taken as raw materials to be mixed and stirred to prepare a spraying material, then spraying is conducted, and finally a two-time curing method is adopted. The preparation method has the advantages that a preparation technology is relatively mature, and the stability is high; the prepared waterborne environment-friendly membrane has the advantages that the membrane is an elastic coating and can reduce damage of external force to a real object and isolate direct contact of the real object and the outside, environmental friendliness is achieved, wear resistance is high, skid resistance is achieved, the application range is wide, and the adhesive force is high.

Owner:镇江普优塑胶科技有限公司

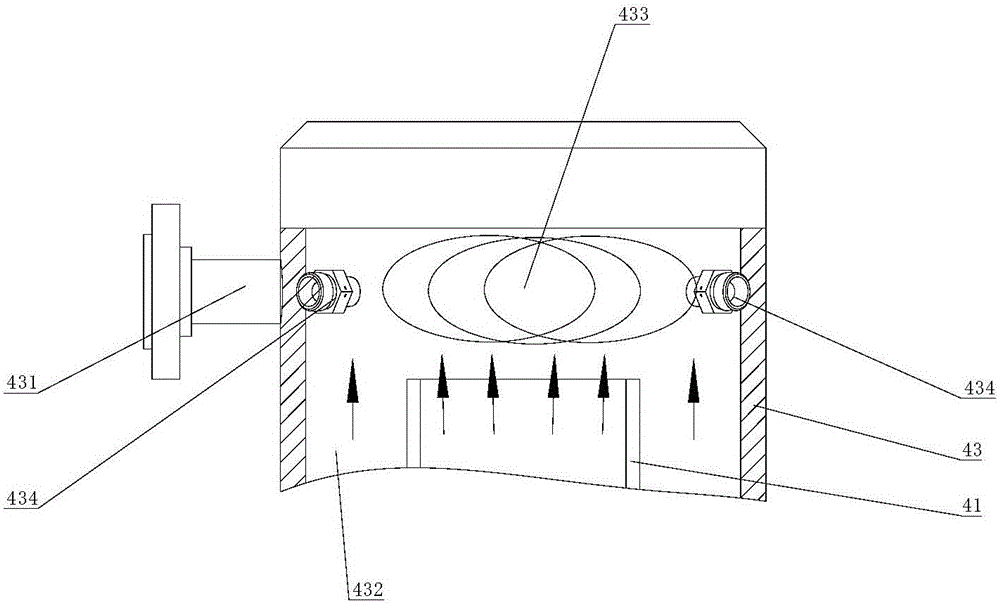

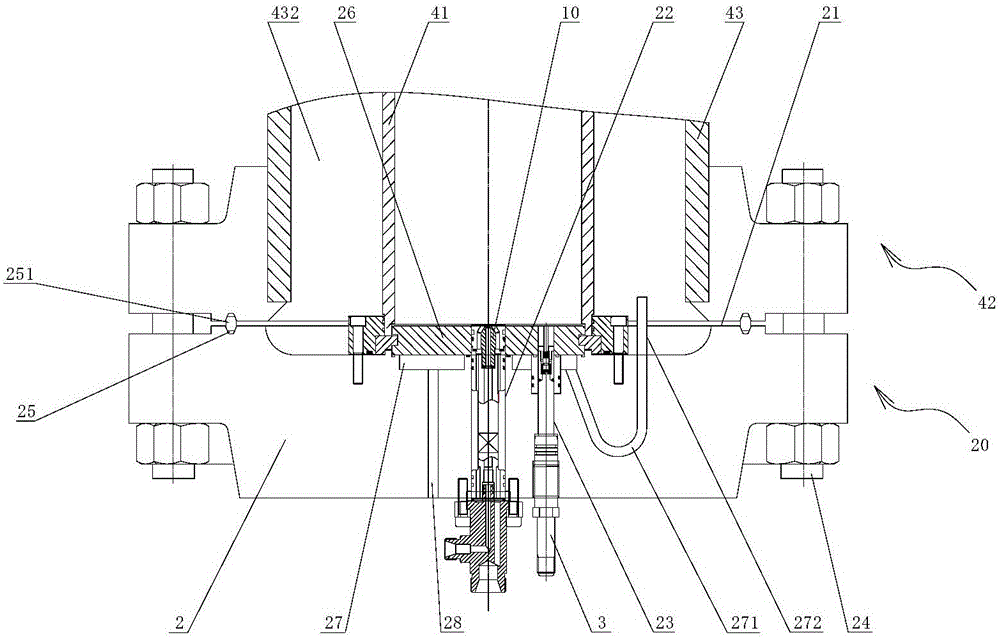

Generator for pure oxygen compound heat carrier and production method for compound heat carrier

ActiveCN105889888AReduce nitrogen contentRealize high-pressure sealed combustionFluid removalSteam generation plantsHeat carrierCombustion chamber

The invention provides a generator for a pure oxygen compound heat carrier and a production method for a compound heat carrier. The generator comprises a generator body and a generator head structure, wherein the generator body comprises a combustion chamber and a steam chamber arranged outside the combustion chamber in a sleeving manner; the generator head structure is provided with a head body, a combustion nozzle and an ignition electrode; the combustion nozzle is provided with a nozzle body, and a plurality of diaphragm outer cavities are formed on one end part of the nozzle body; a fuel channel and a pure oxygen channel are arranged in the nozzle body, the fuel channel communicates with the plurality of diaphragm outer cavities through a plurality of fuel inclined holes, and the fuel inclined holes are radially arranged outwards and slantwise along an injection direction of a fuel; and the pure oxygen channel communicates with the plurality of diaphragm outer cavities through a plurality of pure oxygen inclined holes, and the pure oxygen inclined holes are radially arranged inwards and slantwise along an injection direction of pure oxygen. The generator and the production method, which are provided by the invention, are capable of uniformly atomizing the pure oxygen and natural gas, realizing high-temperature sufficient combustion for the pure oxygen and the natural gas, and finally forming a high-temperature compound heat carrier containing carbon dioxide and steam.

Owner:CNPC GLOBAL SOLUTIONS LTD +1

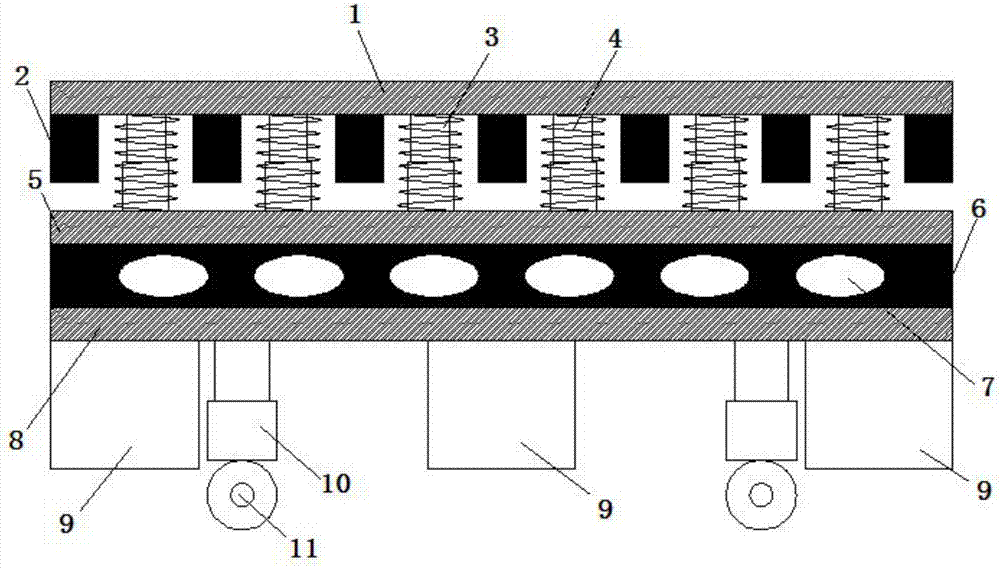

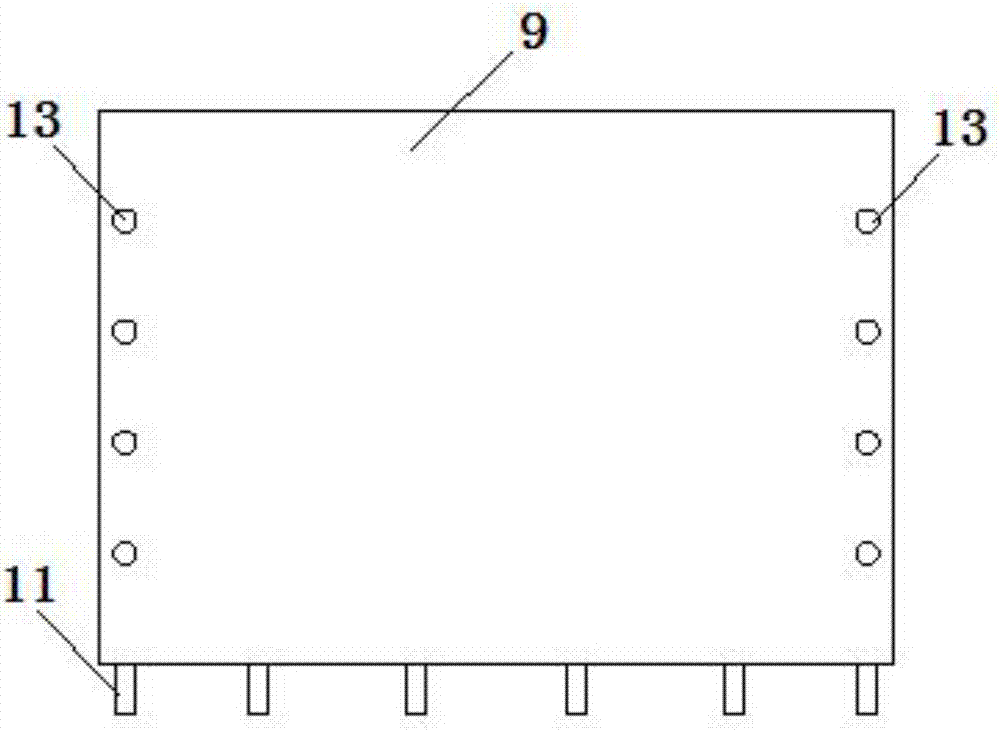

Low-noise boring machine for mold processing

InactiveCN106944869AIncrease stiffnessImprove stabilityMaintainance and safety accessoriesLow noiseEngineering

The invention relates to the field of mold processing equipment, in particular to a low-noise boring machine for mold processing, comprising a boring machine body, a shock-absorbing support seat fixed at the bottom of the boring machine body, a detachable soundproof cover installed on the shock-absorbing support, and a shock-absorbing support seat From top to bottom, it includes the upper cast steel plate, the rubber buffer plate fixed on the bottom of the upper cast steel plate, the lower cast steel plate fixed on the bottom of the rubber buffer plate, the hydraulic shock absorber fixed on the bottom of the lower cast steel plate, the sleeve The damping spring outside the hydraulic shock absorber, the support plate fixed at the bottom of the hydraulic shock absorber and the counterweight support block fixed at the bottom of the support plate; the double shock absorption of the hydraulic shock absorber through the rubber buffer plate and shock absorber spring , can effectively absorb the vibration when the boring machine is working, and reduce the noise caused by the vibration; on the one hand, the detachable sound insulation cover can further isolate the noise generated during the production of the boring machine; Splash of debris generated when

Owner:HEFEI DINGXIN MOLD

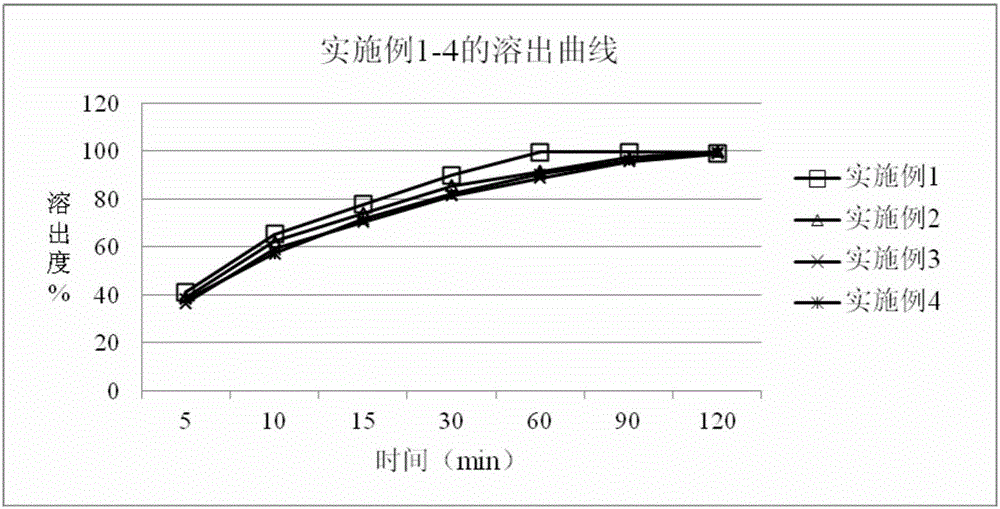

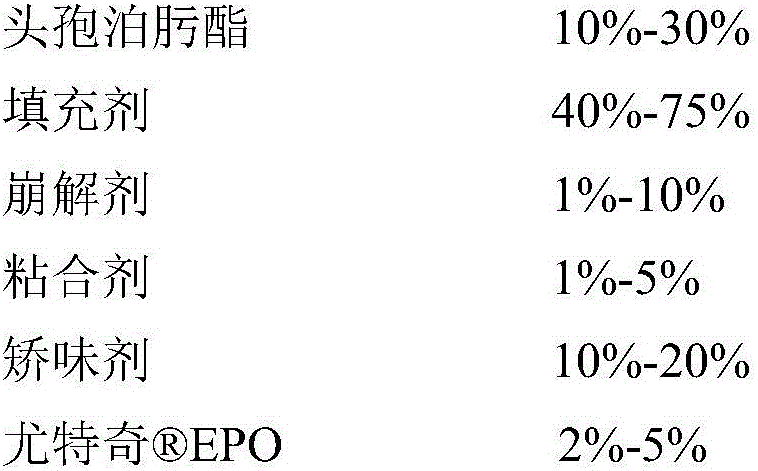

Cefpodoxime proxetil flavored chewable tablet and preparation method thereof

ActiveCN105963269AImprove stabilityIsolated from direct contactAntibacterial agentsOrganic active ingredientsFluidized bedDissolution

A cefpodoxime proxetil flavored chewable tablet is prepared from, by weight, 10%-30% of cefpodoxime proxetil, 40%-75% of filler, 1%-10% of a disintegrating agent, 1%-5% of an adhesive, 10%-20% of corrigent and 2%-5% of Eudragit EPO. The Eudragit EPO is used as a granule coating material to realize fluidized bed coating of granules containing the cefpodoxime proxetil, bitter taste is effectively removed for canines chewing the cefpodoxime proxetil flavored chewable tablet, direct contact between the cefpodoxime proxetil and the corrigent is isolated, and stability of the cefpodoxime proxetil is improved evidently. In addition, the cefpodoxime proxetil flavored chewable tablet is high in content uniformly and quick in disintegration and dissolution, and high stability is guaranteed while palatability is improved.

Owner:QILU ANIMAL HEALTH PROD

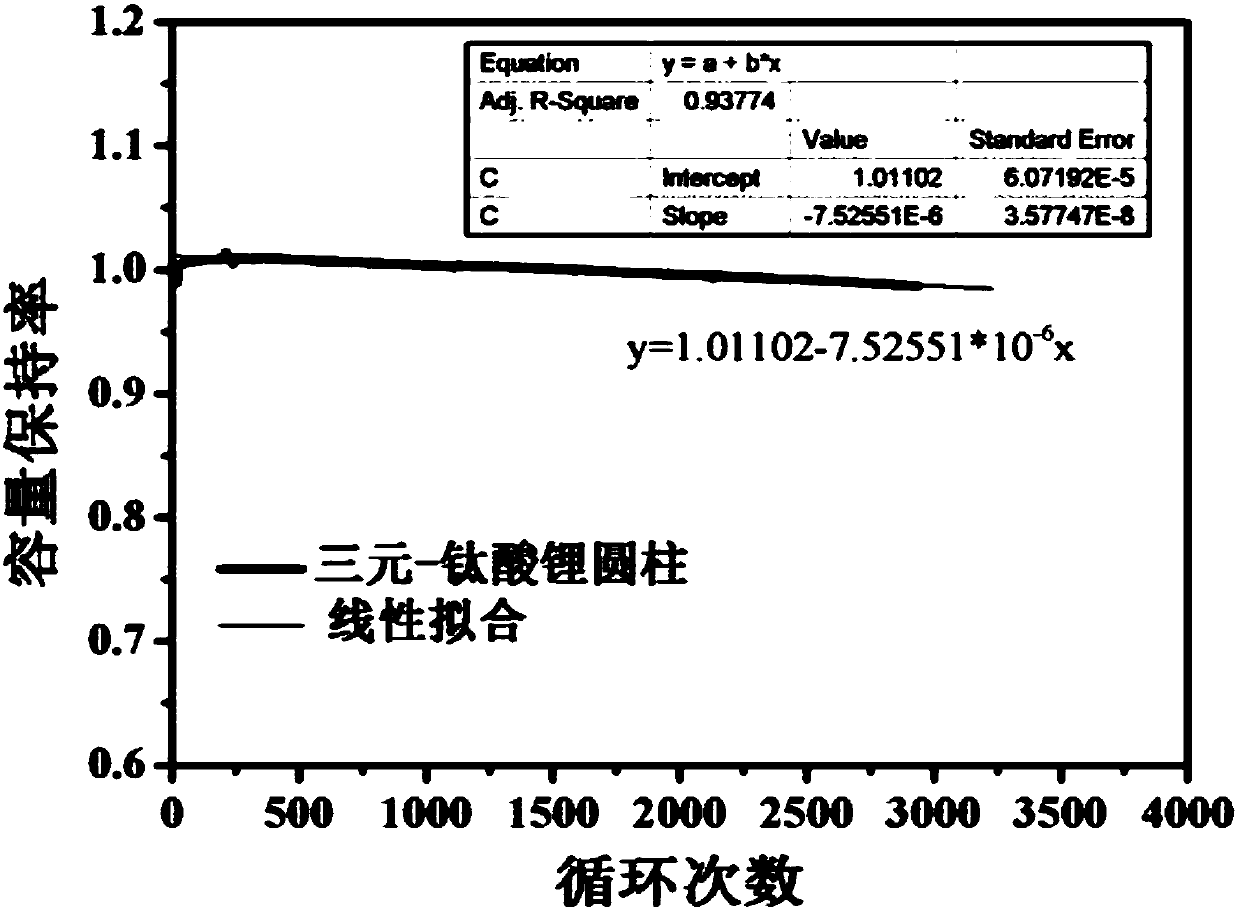

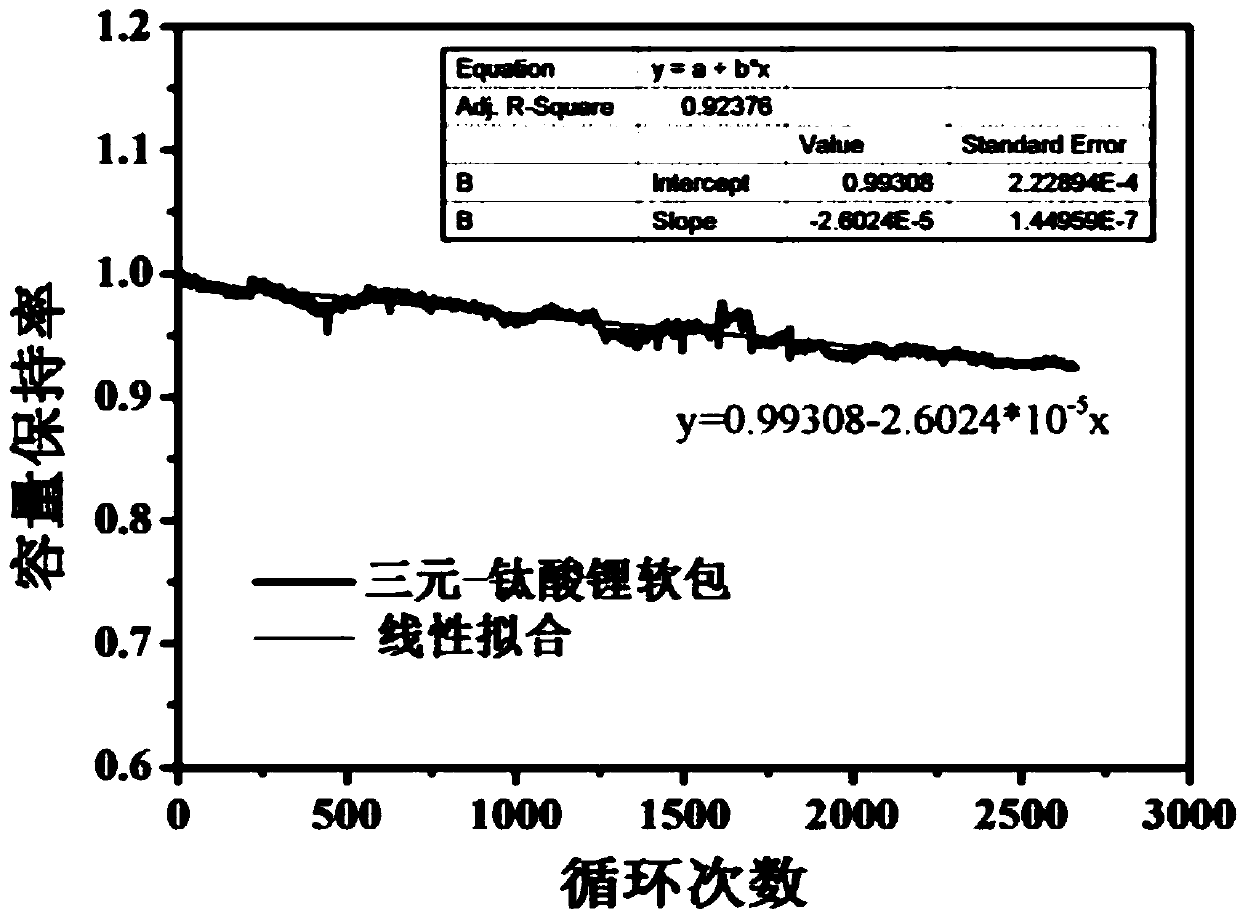

Preparation method of low moisture absorption and low gas production lithium titanate anode material

ActiveCN107808953ALower pHSmall water absorptionCell electrodesSecondary cellsLithiumPhysical chemistry

The invention discloses a preparation method of a low moisture absorption and low gas production lithium titanate anode material. The method includes the steps of: preparing a titanium source and a lithium salt into a lithium titanate precursor by hydrothermal process, performing cooling, then conducting cleaning, and then subjecting the lithium titanate precursor to high temperature calcinationstreatment to obtain lithium titanate powder; dissolving lithium titanate powder in deionized water to form a lithium titanate solution, then adding a PVP (polyvinylpyrrolidone) water solution, and conducting mixing and heating to carry out coating reaction on lithium titanate and PVP in a liquid phase; and performing vacuum drying on the reactant so as to obtain a PVP coated lithium titanate material. The lithium titanate powder material prepared by hydrothermal process lowers the pH value of lithium titanate from the raw material end, thereby weakens the material water absorption, and can effectively inhibits gas production. Then PVP is employed to perform surface film coating on lithium titanate, thus lowering the lithium titanate surface residue and weakening the catalytic effect of Ti<4+> on an electrolyte solution, and preventing the electrolyte solution from being reduced and decomposed on the lithium titanate surface to produce gas.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

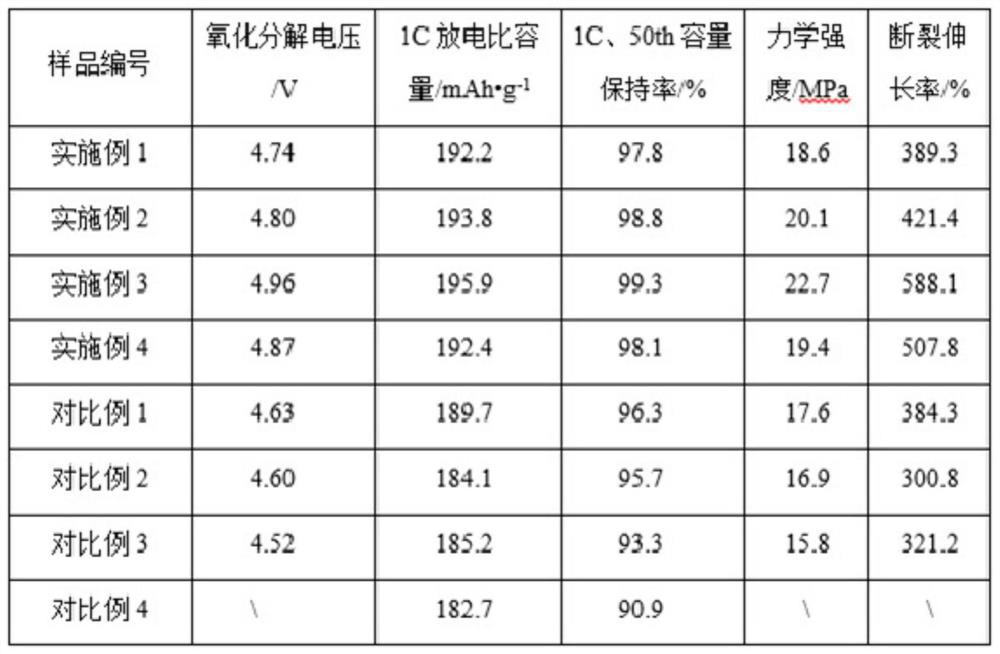

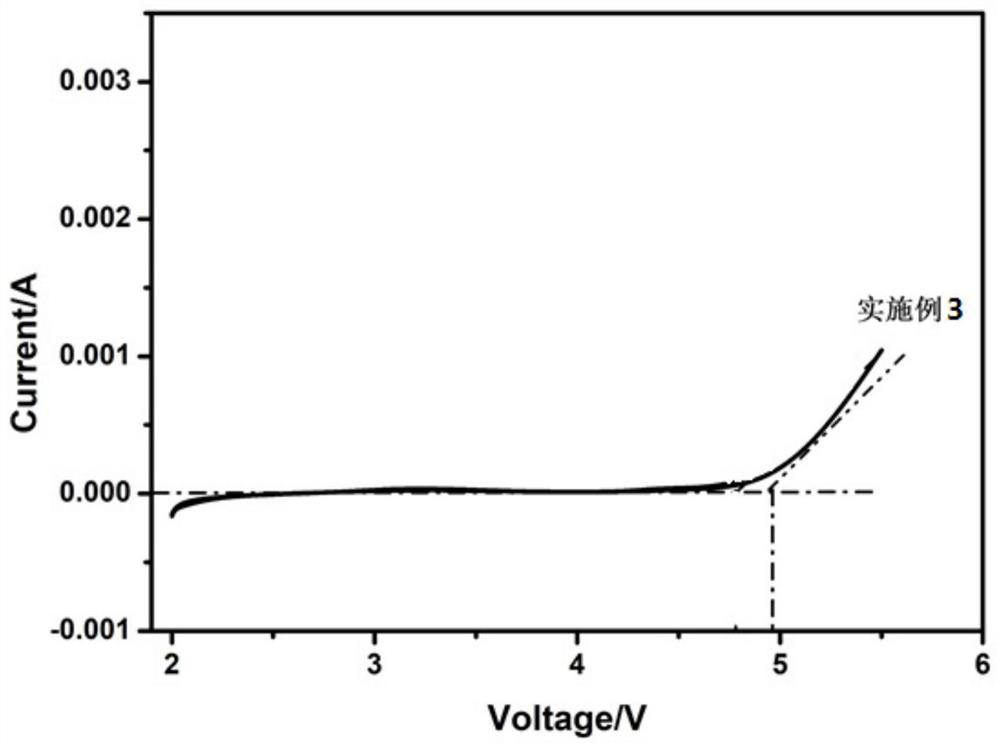

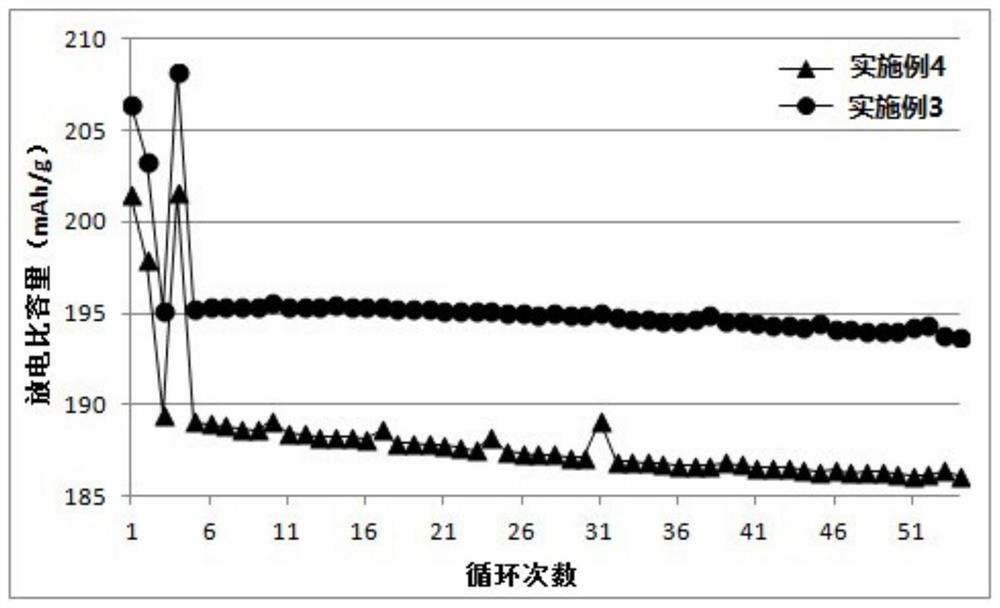

Preparation method of coated modified high-nickel ternary positive electrode material and prepared material

ActiveCN112803008AImprove mechanical propertiesInhibition of structural changesSecondary cellsPositive electrodesPolymer coatingsSpray dried

The invention discloses a preparation method of a coated modified high-nickel ternary positive electrode material, and relates to the technical field of lithium ion battery positive electrode materials. The preparation method comprises the following steps: (1) preparation of a lignin amine modified polymer emulsion: reacting diisocyanate with dihydric alcohol, adding organic amine modified lignin to replace an amine chain extender to prepare a modified polymer emulsion; and (2) adding the high-nickel ternary positive electrode material into the modified polymer emulsion obtained in the step (1), then carrying out spray drying, and curing to form a film, thereby obtaining the coated modified high-nickel ternary positive electrode material. The preparation method has the beneficial effects that spray drying and curing film forming are adopted, a polymer coating layer is continuous and uniform, good mechanical properties are provided for the material, structural changes caused by reduction of a cobalt content can be inhibited, meanwhile, a large amount of sewage brought by a wet coating process is reduced, and the manufacturing cost is decreased.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

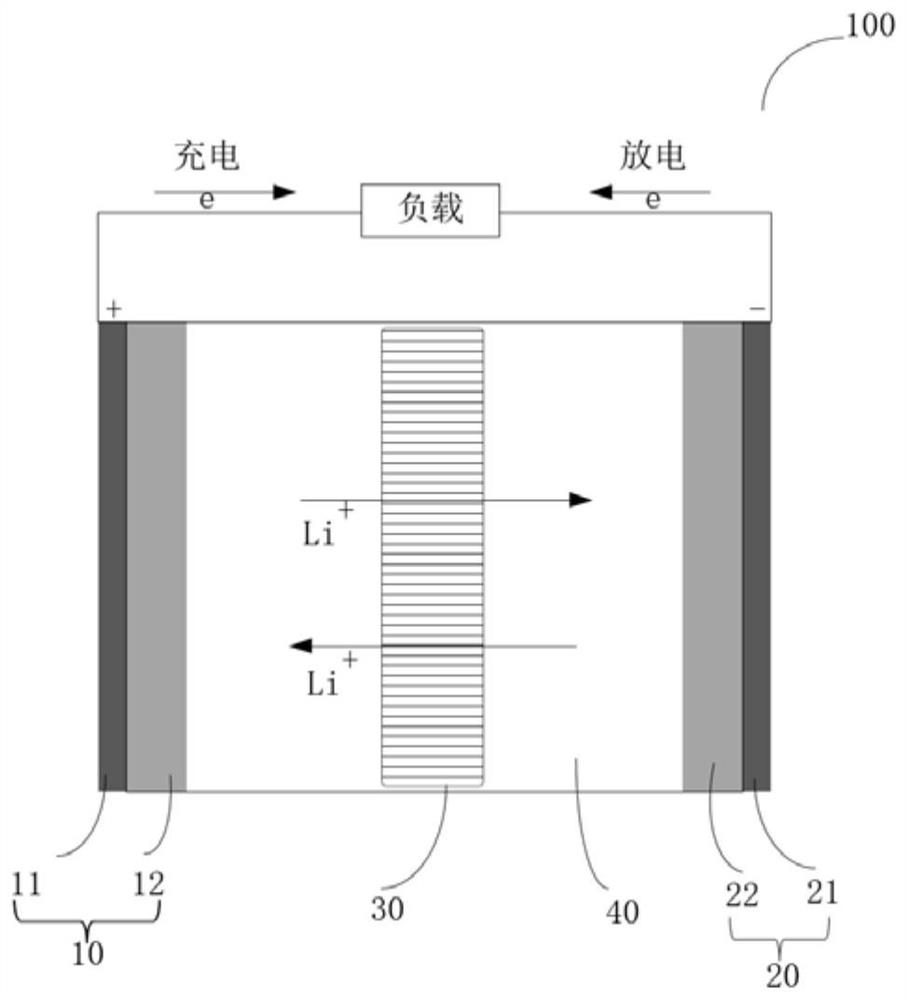

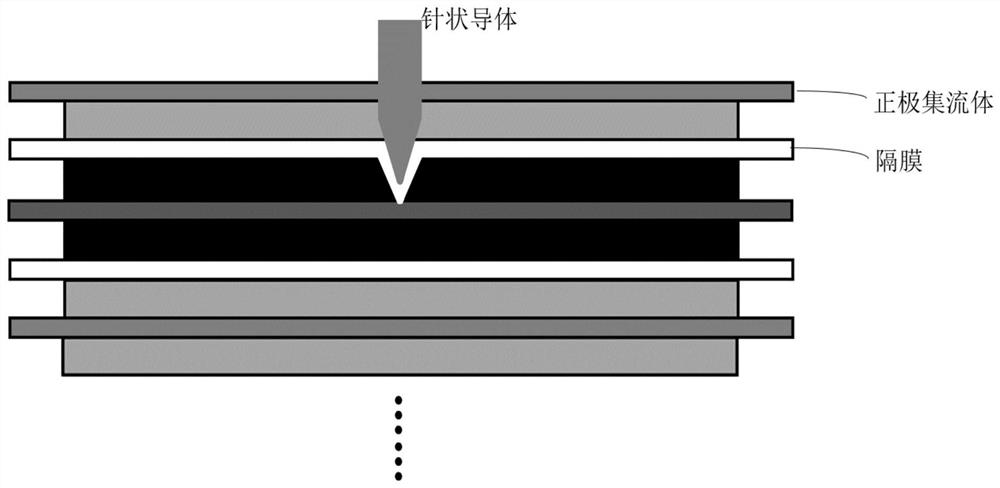

Secondary battery and terminal

PendingCN113937415AImprove securityImprove security featuresCell seperators/membranes/diaphragms/spacersFinal product manufactureHigh energyPole piece

The invention provides a secondary battery. The secondary battery comprises at least one battery unit assembly, each battery unit assembly comprises a positive pole piece, a negative pole piece and a diaphragm arranged between the positive pole piece and the negative pole piece, and each of the positive pole piece and the negative pole piece comprises a current collector and an active material layer arranged on the current collector; and the elongation rate of the diaphragm is greater than 100%, the elongation rate of the diaphragm comprises the elongation rate along the length direction and / or the elongation rate along the width direction, the ratio of the elongation rate of the diaphragm to the thickness of the active material layer of the positive pole piece and / or the negative pole piece is 3.0-8. 0 % / [mu]m, and the ratio of the elongation of the diaphragm to the elongation of the current collector of the positive pole piece and / or the negative pole piece is greater than or equal to 60. The secondary battery provided by the embodiment of the invention has high safety performance on the basis of considering high energy density. The embodiment of the invention also provides a terminal comprising the secondary battery.

Owner:HUAWEI TECH CO LTD

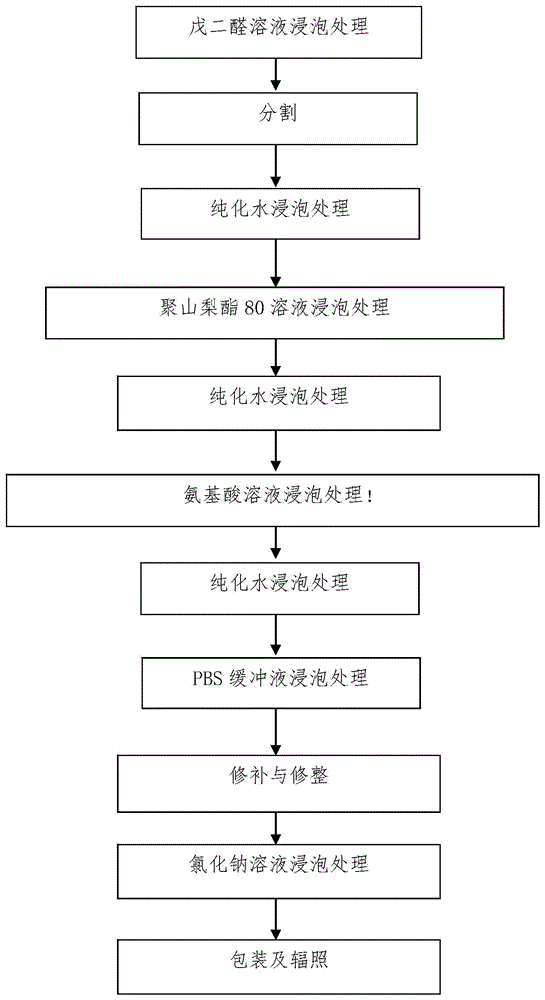

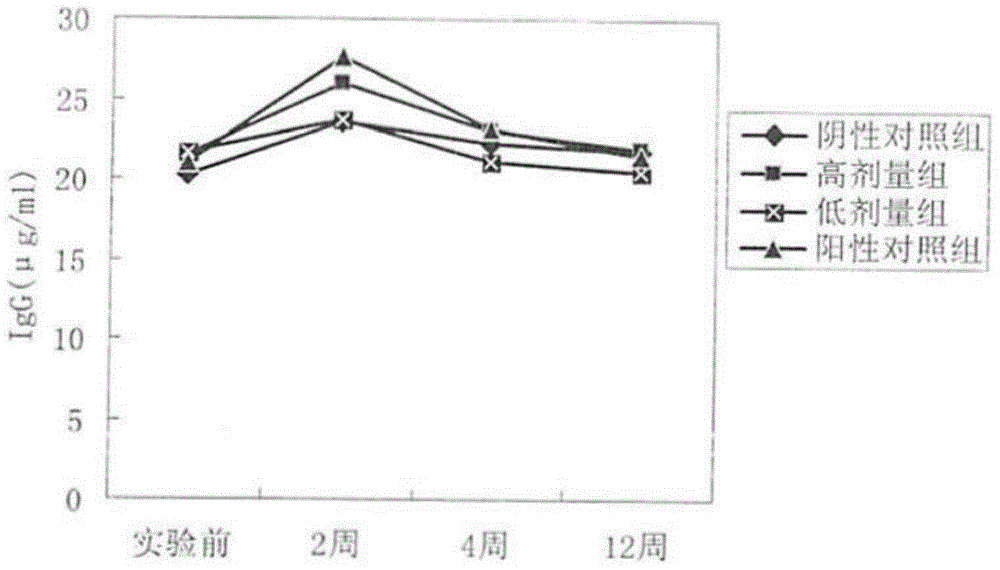

Human body biological dressing for covering burn wound surfaces and applications of dressing

ActiveCN104667336AReduce formationAvoid lossAbsorbent padsBandagesReduction treatmentBiological dressing

The invention provides a human body biological dressing for covering burn wound surfaces and applications of the dressing. Antigen removal and immunogenicity reduction treatment is performed on allograft with biological means, biochemical means and the like, dermis and epidermis are kept, and the clinical effect is far better than that of the allograft. A preparation method of the dressing sequentially comprises steps as follows: soaking treatment with a glutaraldehyde solution; segmentation; soaking treatment with purified water; soaking treatment with a polysorbate 80 solution; soaking treatment with purified water; soaking treatment with an amino acid solution; soaking treatment with purified water; soaking treatment with PBS (phosphate buffered saline); repair and trimming; soaking treatment with a sodium chloride solution; packaging and irradiation. The obtained dressing can purify and clean the wound surfaces, promote growth of granulation tissue, cover granulation wound surfaces, chronic ulcers and bedsores, shorten healing time and be applied to the field of rescue of large-area deep burns, coverage of various burn (wound) surfaces, coverage and treatment of excision surfaces, granular skin-grafting wound surfaces, the granulation surfaces, the chronic ulcers and the bedsores and the like.

Owner:BEIJING JAYYALIFE BIOTECH CO LTD

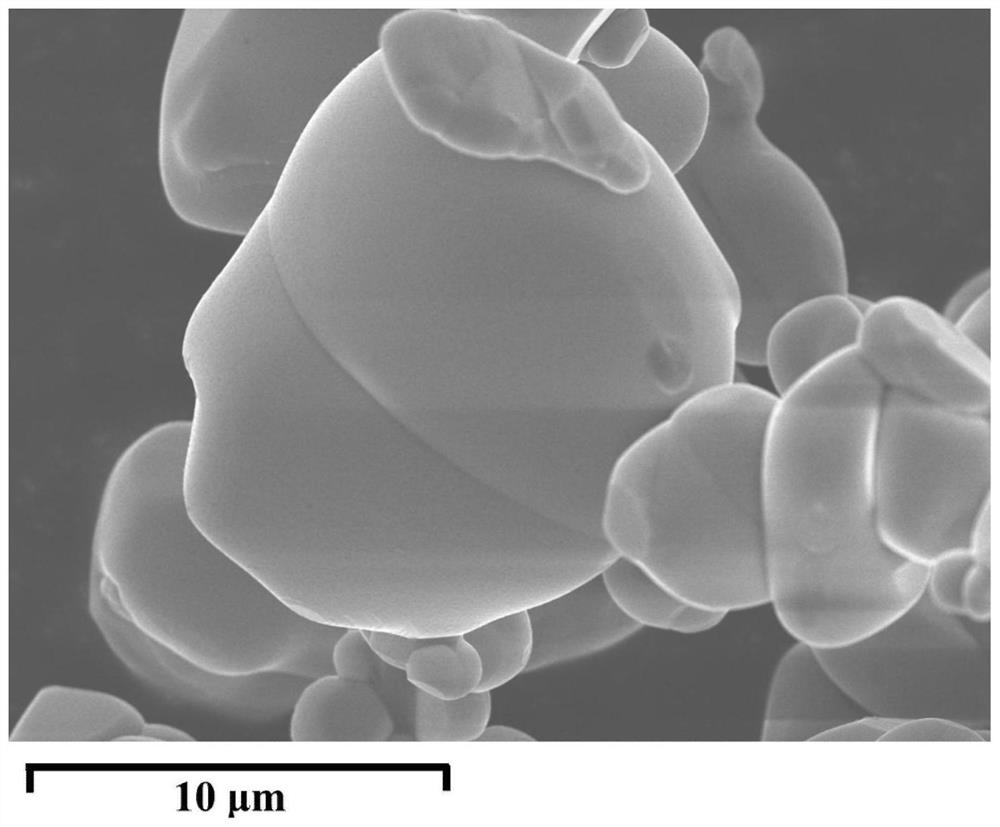

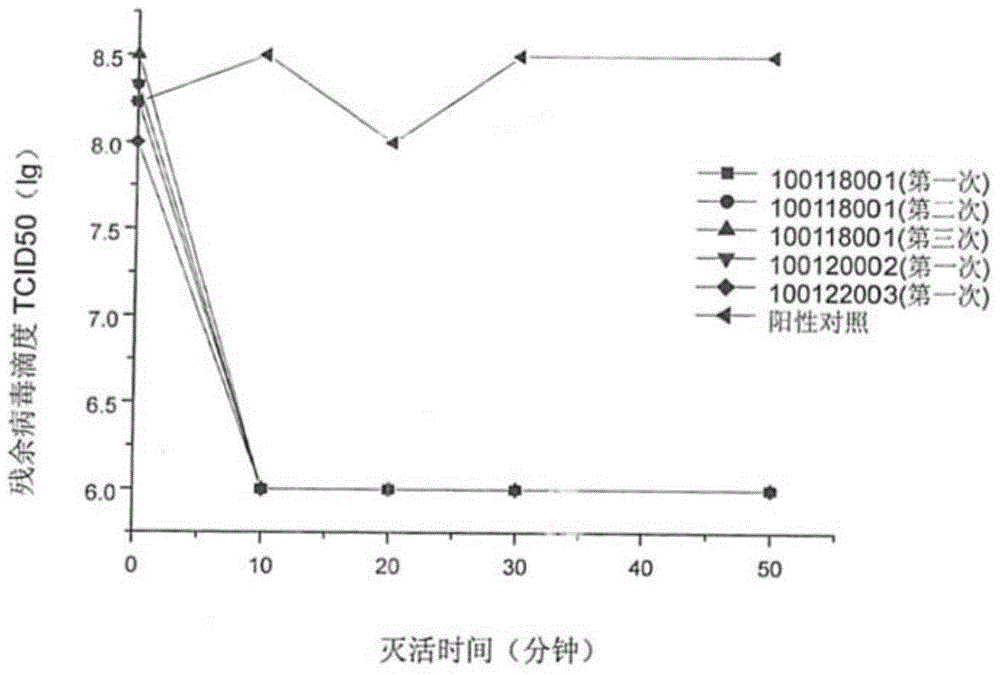

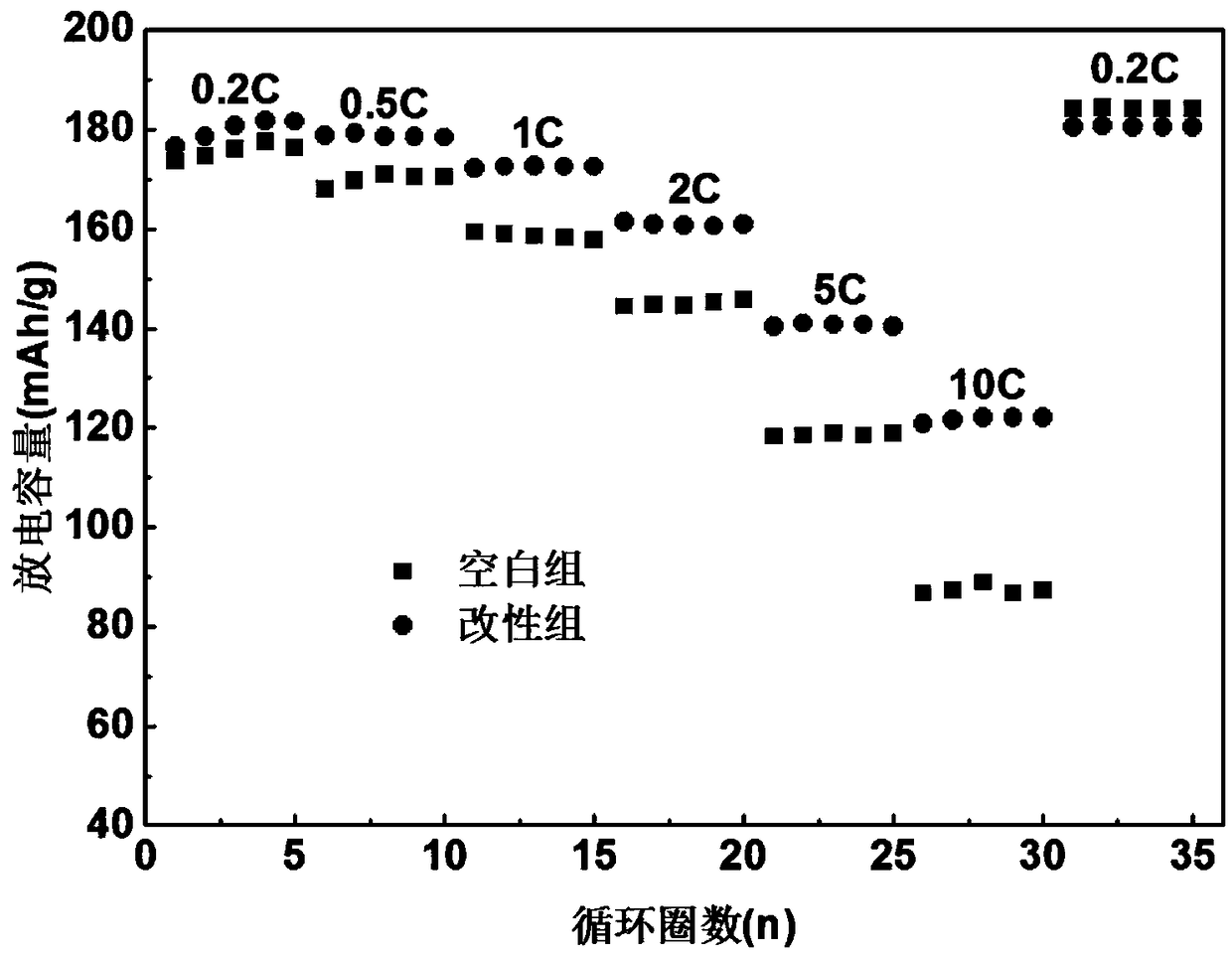

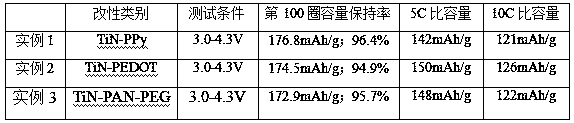

A lithium ion layered ternary cathode material modified by TiN and conductive polymer and a preparation method thereof

ActiveCN109167036AImprove cycle stabilityImproved magnification performanceCell electrodesSecondary cellsConductive polymerLithium-ion battery

The invention discloses a lithium ion layered ternary cathode material modified by TiN and a conductive polymer and a preparation method thereof. Firstly, nanometer TiN and the ternary cathode material are mixed in a liquid phase to form a ternary cathode material with TiN particles uniformly adsorbed; Then a layer of conductive polymer was polymerized on the surface of the material by liquid-phase oxidative polymerization to form a composite coating of nano-TiN particles and conductive polymer. The ternary cathode material coated with TiN and conductive polymer was obtained. As that ternary cathode material of the nickel-based lithium ion battery is coated with TiN and a conductive polymer, On the basis of effectively improving the cycling stability of the material, the magnification performance of the material is greatly improved, especially the high magnification performance, which provides a feasible improvement method for simultaneously improving the cycling stability and the highmagnification performance of the nickel-based cathode material, and has a great application prospect.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com