Composite carbon cathode material for lithium ion battery and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor high-rate charging performance, and achieve good rate charge-discharge performance, high ion conductivity, and cheap raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

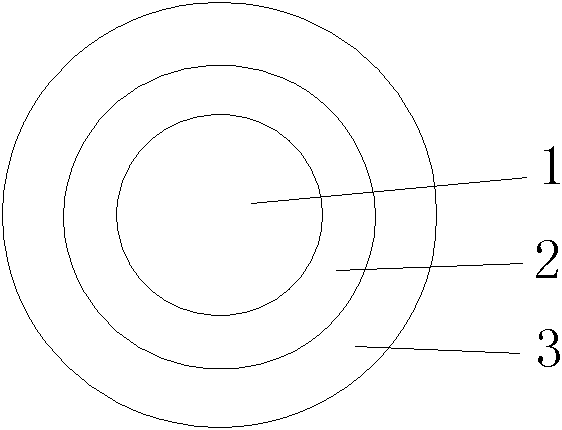

[0031] The preparation of embodiment 1MCMB / LTO core-shell structure composite material sol-gel method

[0032] Add tetrabutyl titanate and MCMB to an appropriate amount of absolute ethanol as liquid A, add lithium acetate to absolute ethanol, add a certain amount of deionized water and glacial acetic acid as liquid B, and add liquid B to liquid A , heated in a water bath at 50°C, and stirred magnetically for 3h. The homogeneously mixed material is spray dried. After drying, the material was placed in a nitrogen atmosphere protection furnace, and heated at 800 °C for 24 h to obtain a MCMB / LTO composite material with a core-shell structure.

Embodiment 2

[0033] Embodiment 2 MCMB / LTO core-shell structure composite material is prepared by solid phase sintering method

[0034] Mix lithium carbonate and anatase nano-titanium dioxide according to the stoichiometric ratio, add a certain proportion of MCMB and an appropriate amount of acetone solvent, and ball mill and mix for 3 hours at a speed of 300r / min. The homogeneously mixed material was vacuum-dried at 80 °C for 2 h, placed in a nitrogen atmosphere protection furnace, and heated at 800 °C for 24 h to prepare MCMB / LTO composites with a core-shell structure.

Embodiment 3

[0035] Embodiment 3MCMB / TiO 2 Preparation of core-shell composites

[0036] Tetrabutyl titanate and MCMB were mixed in proportion, and ball milled for 3 hours at a speed of 300 r / min. The homogeneously mixed material was dried with magnetic stirring in the air, and then moved to an oven for 24 hours at 60°C. After drying, the material was placed in a nitrogen atmosphere protection furnace and sintered at 450 °C for 5 h to obtain MCMB / TiO with a core-shell structure. 2 composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com