Double-layer -coated modified high-nickel cobalt-free single crystal ternary positive electrode material and preparation method thereof

A double-layer coating and positive electrode material technology, applied in the direction of positive electrodes, active material electrodes, electrical components, etc., can solve the problems of poor electrochemical performance of positive electrode materials, achieve suppression of side reactions, reduce production costs, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

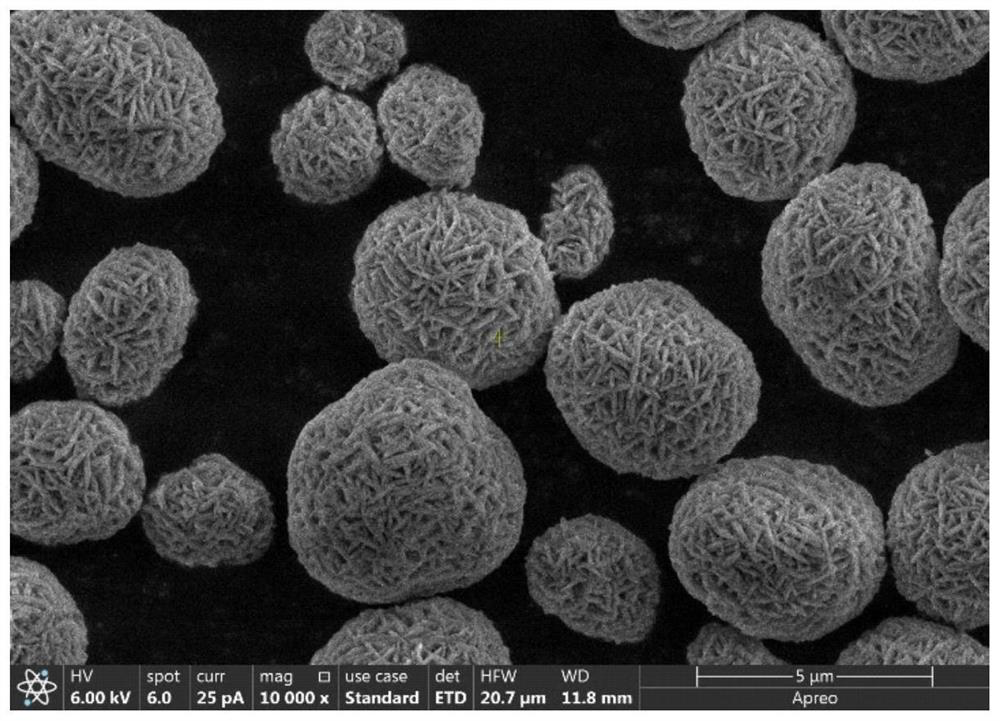

[0031] The chemical formula of the double-coated modified high-nickel cobalt-free single crystal ternary positive electrode material in this embodiment is LiNi 0.90 mn 0.07 W 0.03 o 2 @TiO 2 @C.

[0032] The preparation method of the double-layer coated modified high-nickel cobalt-free single crystal ternary positive electrode material includes the following steps:

[0033] (1) Nickel sulfate, manganese sulfate and tungsten sulfate are added in deionized water in a molar ratio of 0.90:0.07:0.03, and stirred evenly to obtain a mixed salt solution with a total metal ion concentration of 4mol / L; the mixed salt solution, 4mol / L of precipitant NaOH solution and 5mol / L of complexing agent NH 3 ·H 2 The O solution was added into the reactor together, stirring continuously, the stirring speed was 400rpm, the temperature of the reactor was controlled at 65°C, the ammonia value of the reaction solution was 8g / L, and the pH value was 12, and the co-precipitation method was reacted...

Embodiment 2

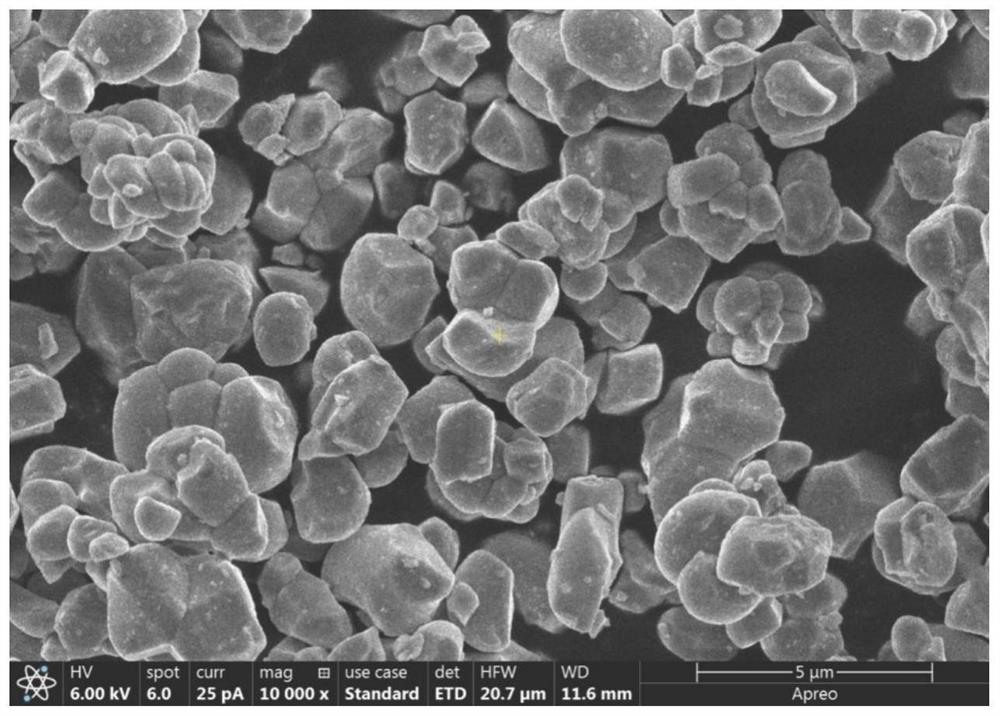

[0040] The chemical formula of the double-coated modified high-nickel cobalt-free single crystal ternary positive electrode material in this embodiment is LiNi 0.90 mn 0.05 W 0.05 o 2 @Al 2 o 3 @C.

[0041] The preparation method of the double-layer coated modified high-nickel cobalt-free single crystal ternary positive electrode material includes the following steps:

[0042] (1) Nickel sulfate, manganese sulfate and tungsten sulfate are added in deionized water in a molar ratio of 0.90:0.05:0.05, and stirred evenly to obtain a mixed salt solution with a total metal ion concentration of 4mol / L; the mixed salt solution, 5mol / L of precipitant NaOH solution and 8mol / L of complexing agent NH 3 ·H 2 Add the O solution into the reaction kettle together, stir continuously, the stirring speed is 500rpm, the temperature of the reaction kettle is controlled at 60°C, the ammonia value of the reaction solution is 9g / L, and the pH value is 11.8, and the co-precipitation method is ...

Embodiment 3

[0049] The chemical formula of the double-coated modified high-nickel cobalt-free single crystal ternary positive electrode material in this embodiment is LiNi 0.90 mn 0.03 W 0.07 o 2 @CuO@C.

[0050] The preparation method of the double-layer coated modified high-nickel cobalt-free single crystal ternary positive electrode material includes the following steps:

[0051] (1) Nickel sulfate, manganese sulfate and tungsten sulfate are added in deionized water in a molar ratio of 0.90:0.03:0.07, and stirred evenly to obtain a mixed salt solution with a total metal ion concentration of 4mol / L; the mixed salt solution, 6mol / L of precipitant NaOH solution and 10mol / L of complexing agent NH 3 ·H 2 O solution was added into the reaction kettle together, stirring continuously, the stirring speed was 400rpm, the temperature of the reaction kettle was controlled at 65°C, the ammonia value of the reaction liquid was 8g / L, and the pH value was 11.5, and the co-precipitation method wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com