Zinc negative electrode with zinc ion conductivity interface modification layer, battery and preparation method

An interface modification layer and interface modification technology, which is applied in the direction of electrode manufacturing, chemical electrode manufacturing, battery electrodes, etc., can solve the problem of lack of zinc ion conductivity, the inability to fundamentally control the uniform diffusion of zinc ions, the dendrite growth trend, and ion migration. Obstacles and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

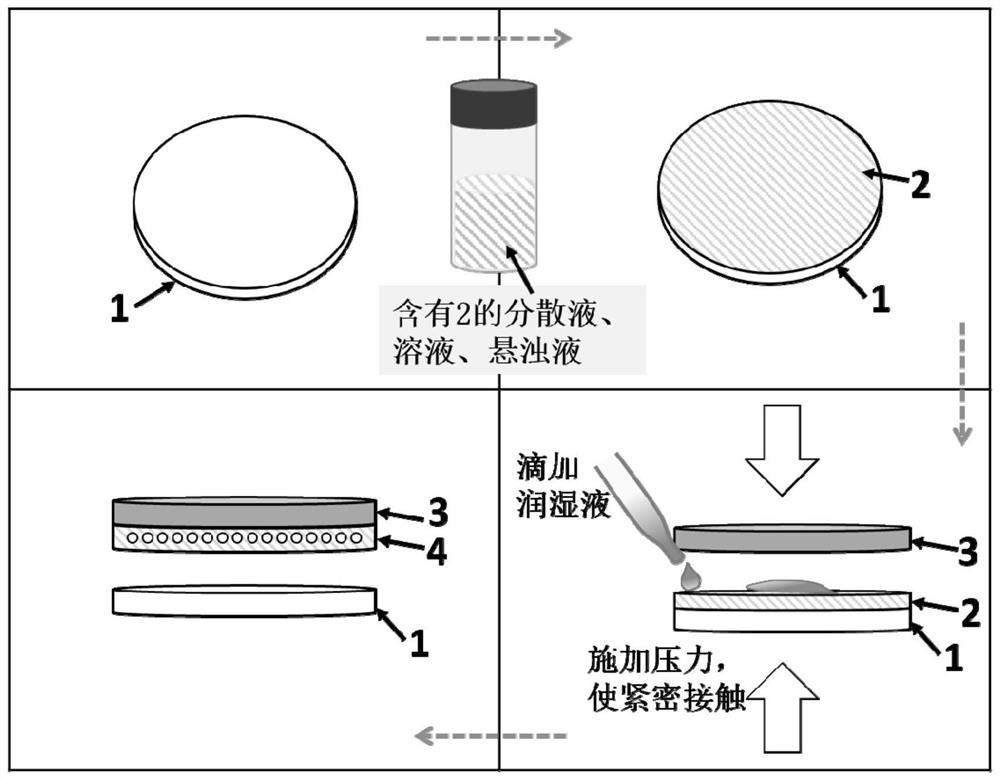

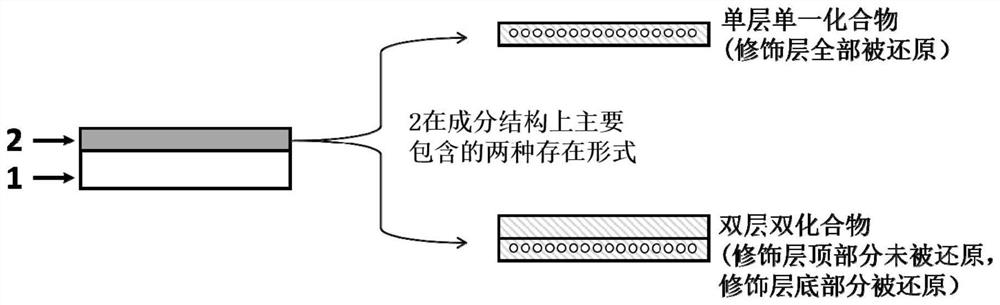

Embodiment 44

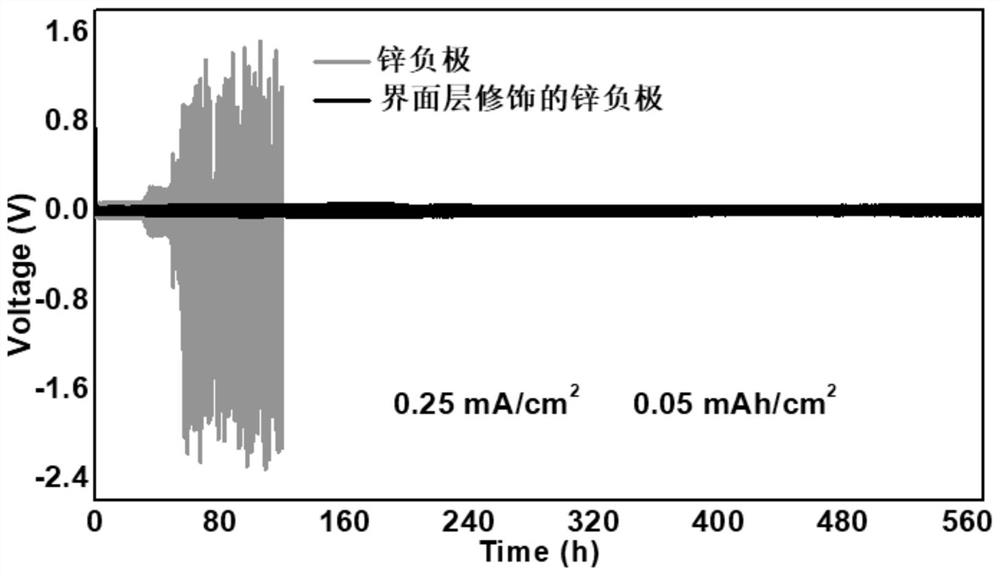

[0060] will V 2 o 5 ·nH 2 O dispersion liquid (solvent is dehydrated alcohol) obtains V by suction filtration on the nylon filter membrane by the method for vacuum suction filtration. 2 o 5 ·nH 2 O film, first with V on nylon filter 2 o 5 ·nH 2 Electrolyte (2M ZnSO 4 ), and place it directly against the metal zinc foil, and then apply a pressure of 20Mpa to the two to make them fully contact to form a short-circuit primary battery, and a redox reaction occurs. During the reaction, the metal zinc is oxidized to form zinc ions and at V 2 o 5 ·nH 2 Intercalation of O layers to form Zn x V 2 o 5 ·nH 2 O, finally peel off the nylon filter, V 2 o 5 ·nH 2 The O thin film was successfully transferred from the nylon filter membrane to the metal zinc surface, and a layer of Zn with zinc ion conductivity with a thickness of about 5 μm was formed on the zinc metal zinc surface. x V 2 o 5 ·nH 2 O interface modification layer.

[0061] image 3 is the Zn prepared in Ex...

Embodiment 45

[0064] Na 1.1 V 3 o 7.9 Dispersion liquid (solvent is isopropanol, adds the PTFE of 10% mass fraction as binding agent) by the method for spraying on glass and obtains Na 1.1 V 3 o 7.9 film, first on the glass with Na 1.1 V 3 o 7.9 Wetting solution (2M ZnSO 4 ), and place it directly against the metal zinc foil, and then apply a pressure of 10Mpa to the two to make them fully contact to form a short-circuit primary battery, a redox reaction occurs, and the metal zinc is oxidized to form zinc ions during the reaction process. 1.1 V 3 o 7.9 embedded in the material to form Zn x Na1.1 V 3 o 7.9 , and finally remove the glass, Zn x Na 1.1 V 3 o 7.9 The film was successfully transferred from the glass to the metal zinc surface, and a layer of Zn with zinc ion conductivity with a thickness of about 13 μm was formed on the zinc metal zinc surface. x Na 1.1 V 3 o 7.9 Interface modification layer. The prepared Zn x Na 1.1 V 3 o 7.9 The interface layer modificat...

Embodiment 46

[0066] Na 2 V 6 o 16 1.63H 2 The O dispersion (the solvent is acetone) is vacuum-filtered on the eggshell membrane to obtain Na 2 V 6 o 16 1.63H 2 O thin film, first with Na on the eggshell membrane 2 V 6 o 16 1.63H 2 Wetting solution (0.5M NaCl) is added to one side of the O film, and it is placed directly against the metal zinc foil, and then a pressure of 15Mpa is applied to the two to make them fully contact to form a short-circuit primary battery, and a redox reaction occurs. The reaction process The metal zinc is oxidized to form zinc ions and in Na 2 V 6 o 16 1.63H 2 O material intercalated to form Zn x Na 2 V 6 o 16 1.63H 2 O, finally remove the eggshell membrane, Zn x Na 1.1 V 3 o 7.9 The film was successfully transferred from the eggshell membrane to the metal zinc surface, and a layer of Zn with zinc ion conductivity with a thickness of about 2 μm was formed on the zinc metal surface. x Na 2 V 6 o 16 1.63H 2 O interface modification layer....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com