Patents

Literature

373results about "Chemical electrode manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

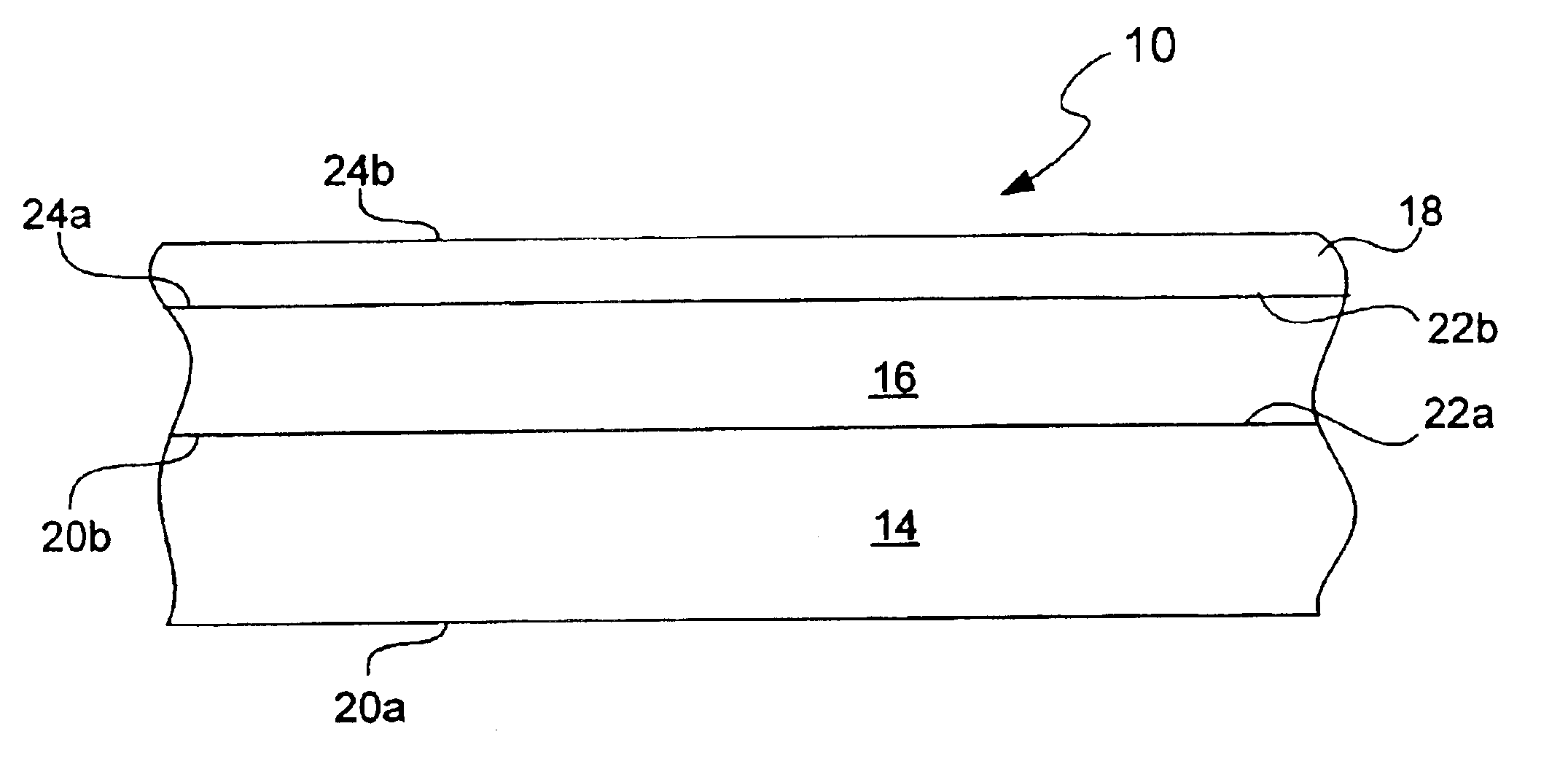

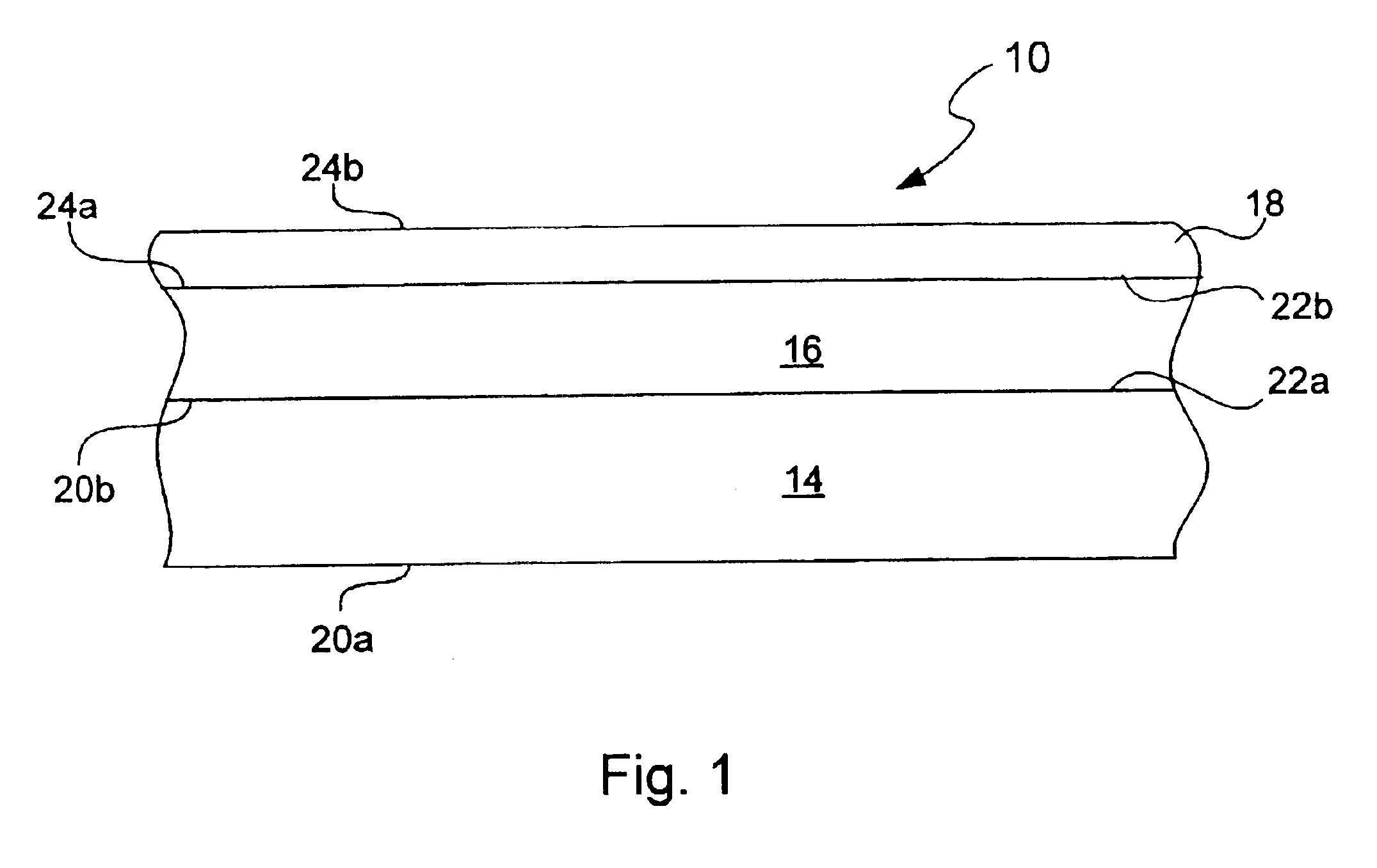

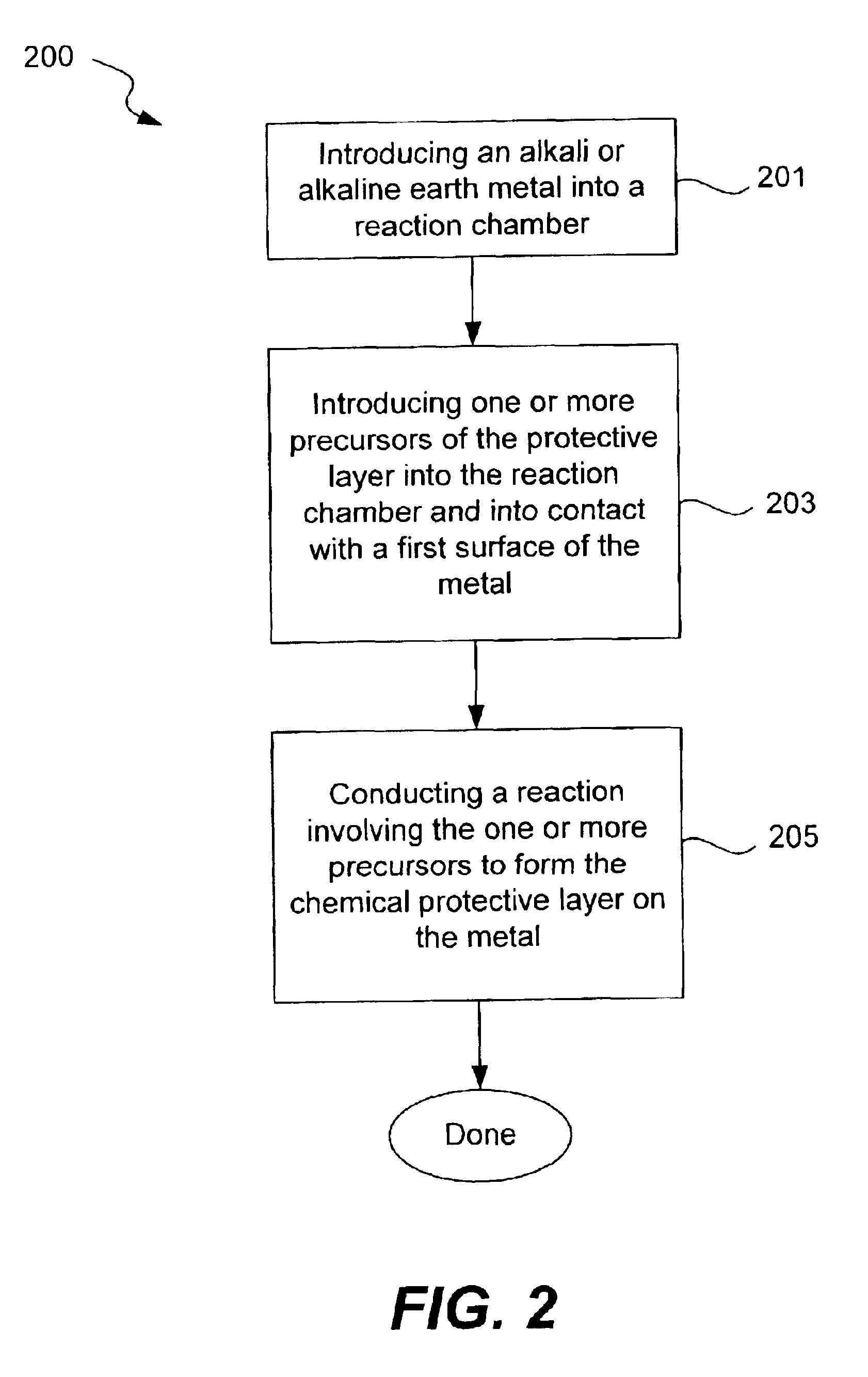

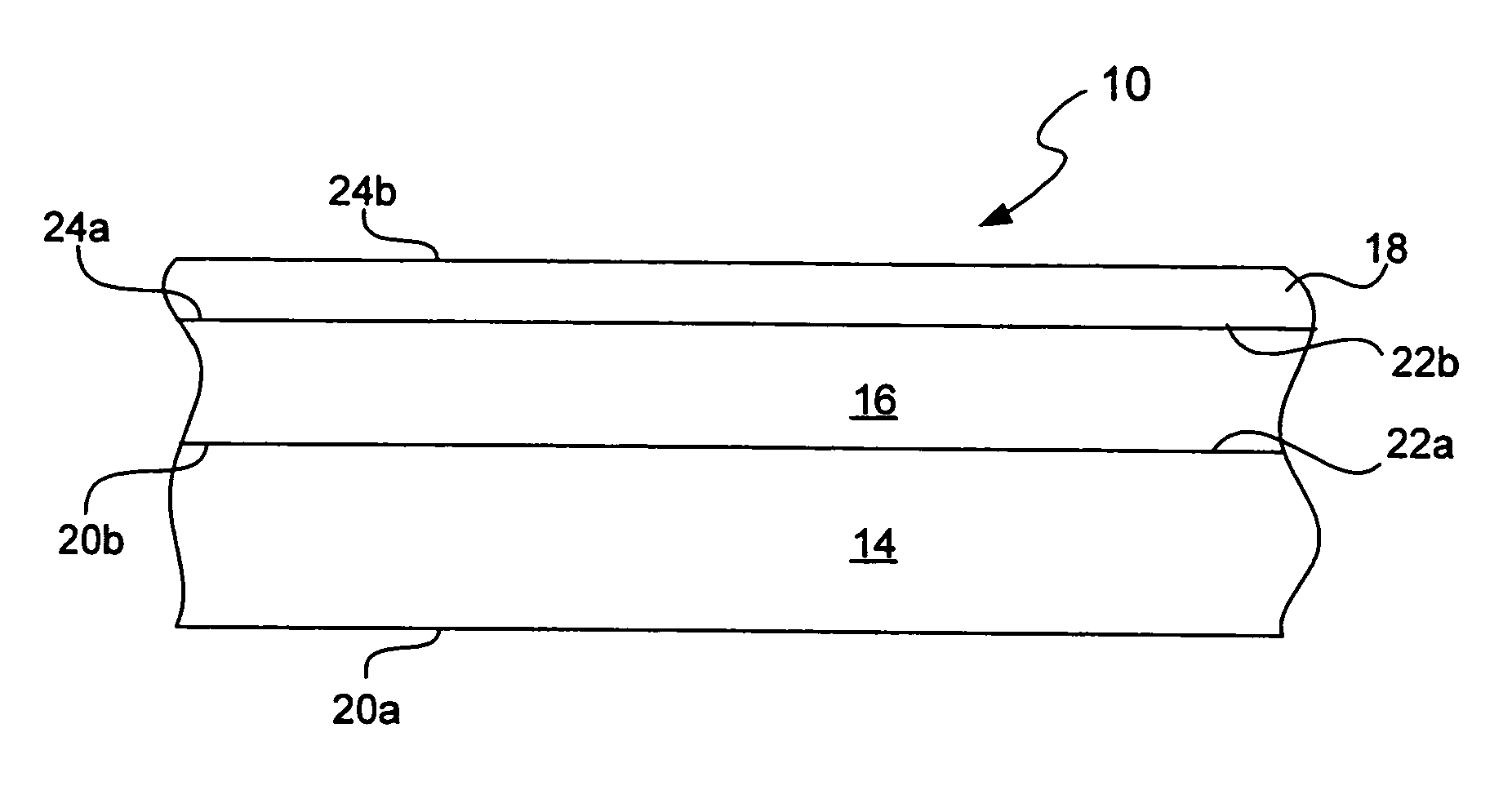

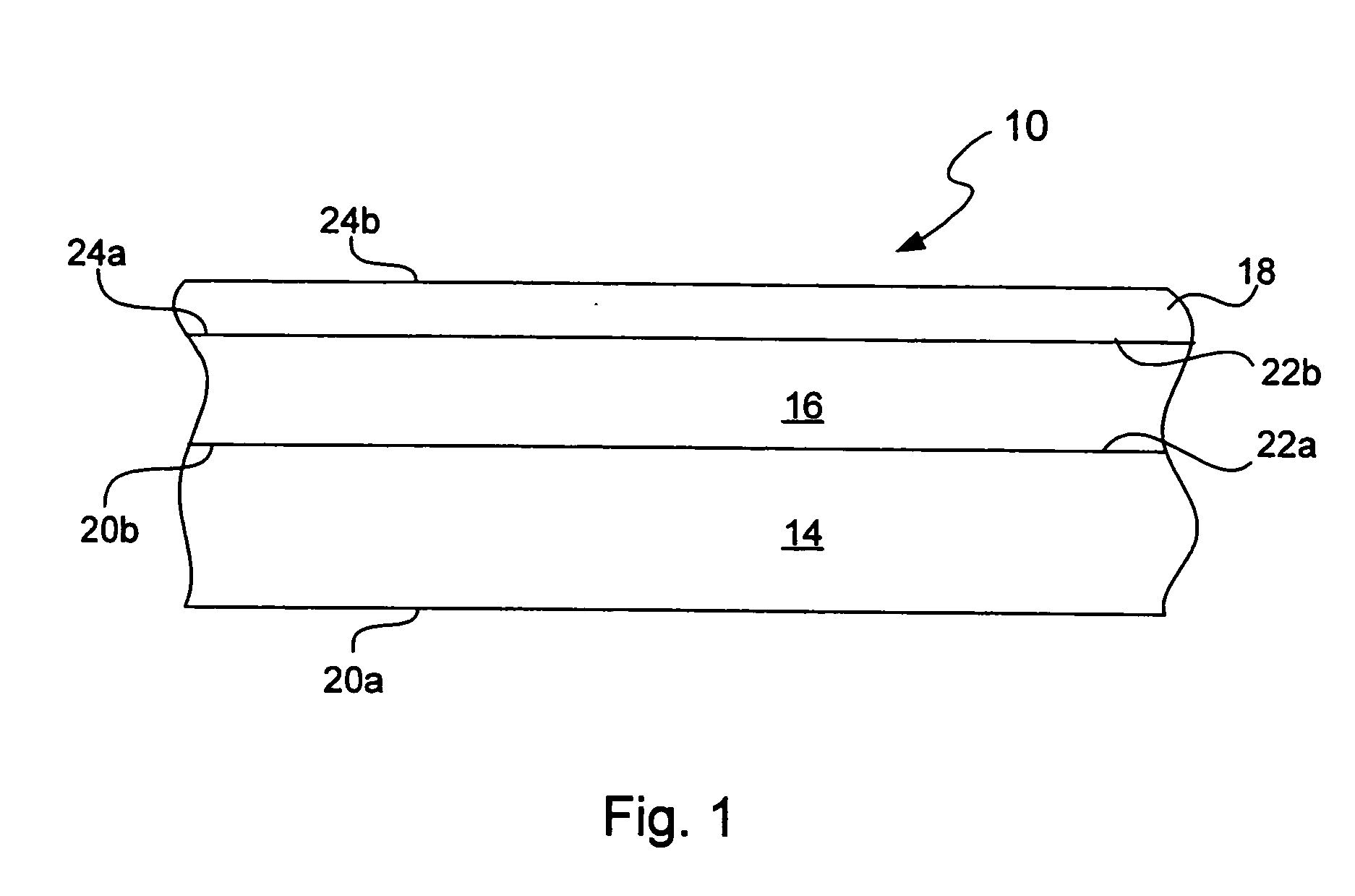

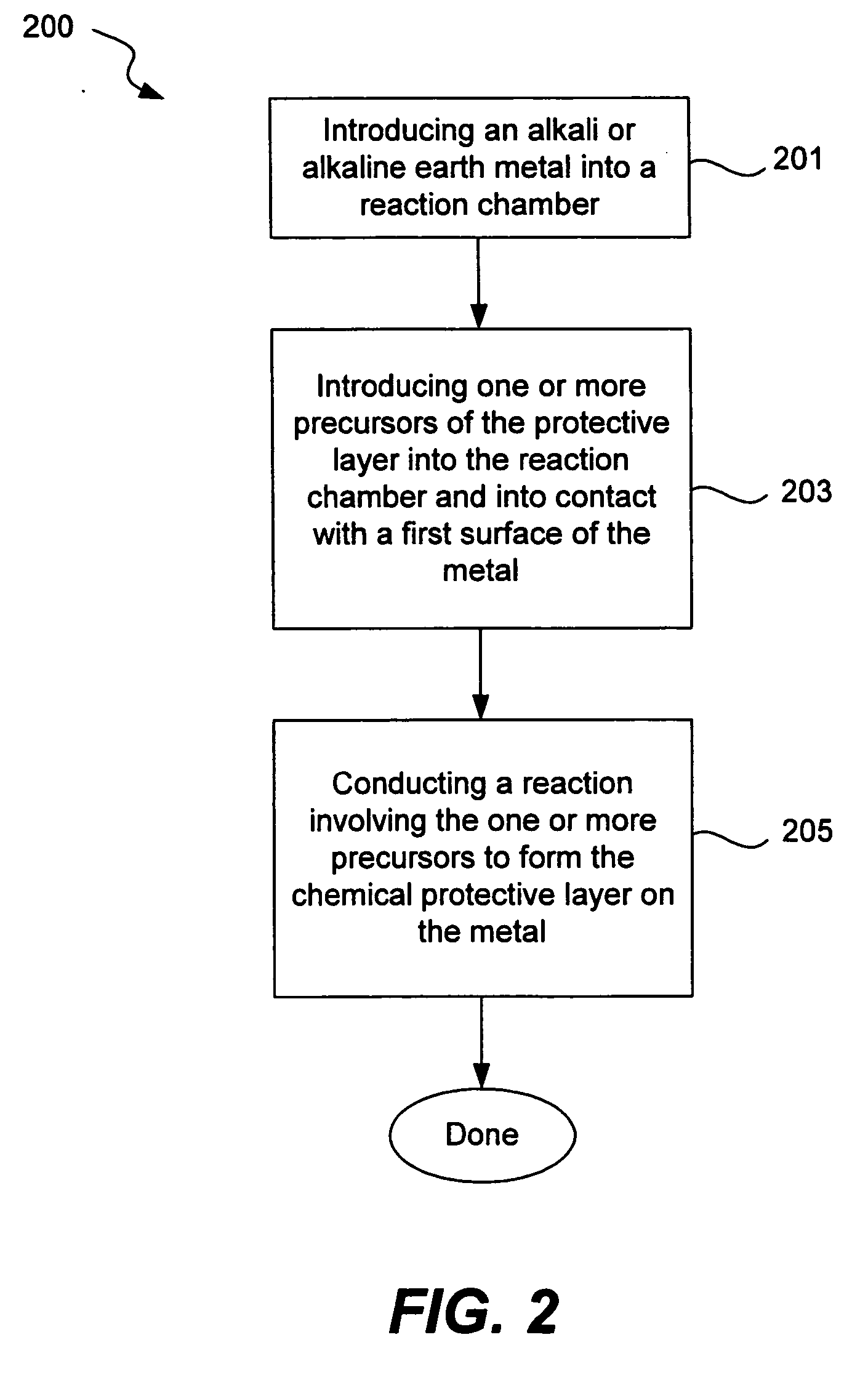

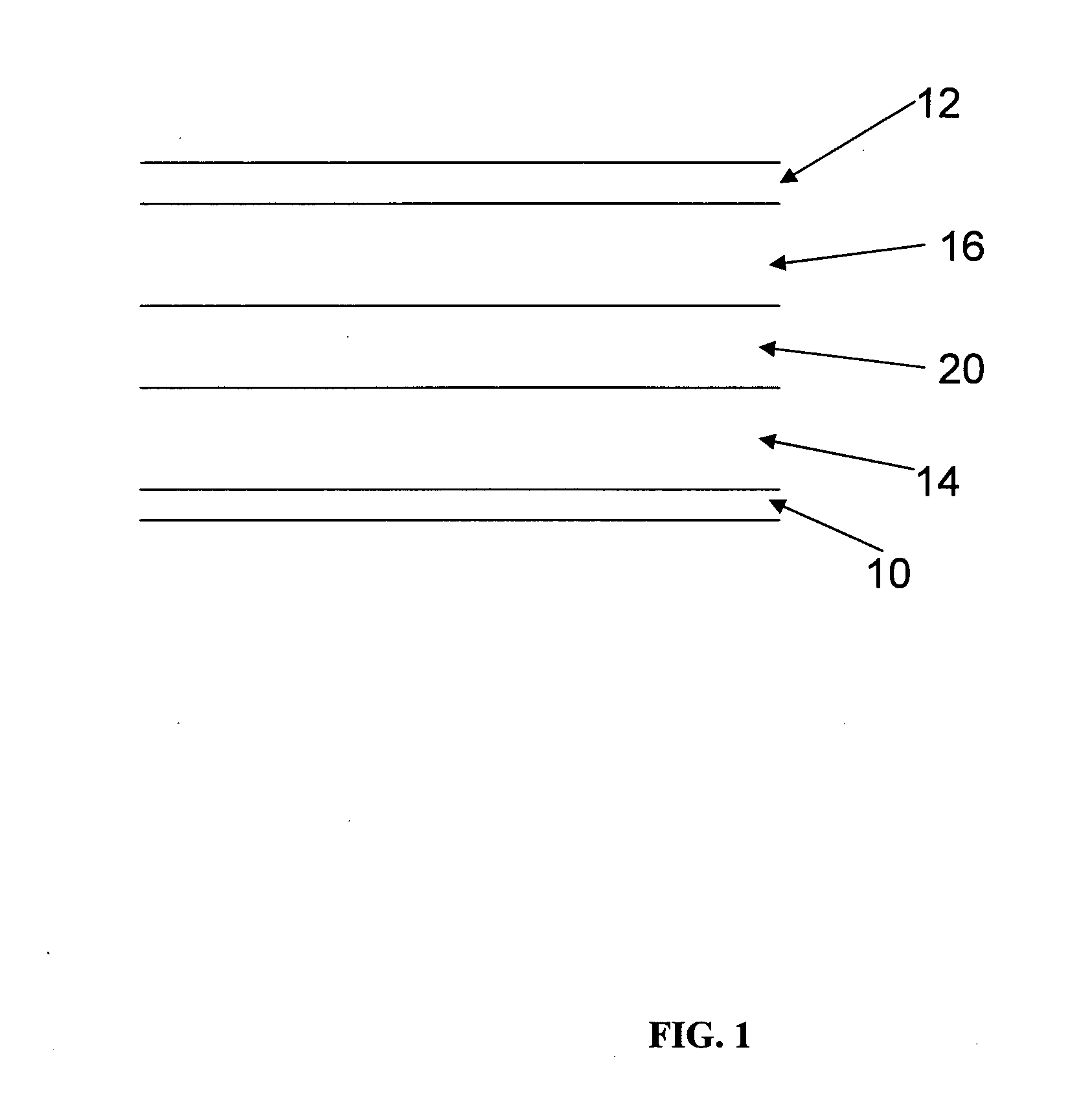

Chemical protection of a lithium surface

InactiveUS6911280B1Easy to produceSimple processElectrochemical processing of electrodesFinal product manufactureAlkaline earth metalLithium metal

Disclosed are compositions and methods for alleviating the problem of reaction of lithium or other alkali or alkaline earth metals with incompatible processing and operating environments by creating a ionically conductive chemical protective layer on the lithium or other reactive metal surface. Such a chemically produced surface layer can protect lithium metal from reacting with oxygen, nitrogen or moisture in ambient atmosphere thereby allowing the lithium material to be handled outside of a controlled atmosphere, such as a dry room. Production processes involving lithium are thereby very considerably simplified. One example of such a process in the processing of lithium to form negative electrodes for lithium metal batteries.

Owner:POLYPLUS BATTERY CO INC

Chemical protection of a lithium surface

InactiveUS20050186469A1Easy to produceEasy to processElectrochemical processing of electrodesFinal product manufactureAlkaline earth metalLithium metal

Disclosed are compositions and methods for alleviating the problem of reaction of lithium or other alkali or alkaline earth metals with incompatible processing and operating environments by creating a ionically conductive chemical protective layer on the lithium or other reactive metal surface. Such a chemically produced surface layer can protect lithium metal from reacting with oxygen, nitrogen or moisture in ambient atmosphere thereby allowing the lithium material to be handled outside of a controlled atmosphere, such as a dry room. Production processes involving lithium are thereby very considerably simplified. One example of such a process is the processing of lithium to form negative electrodes for lithium metal batteries.

Owner:POLYPLUS BATTERY CO INC

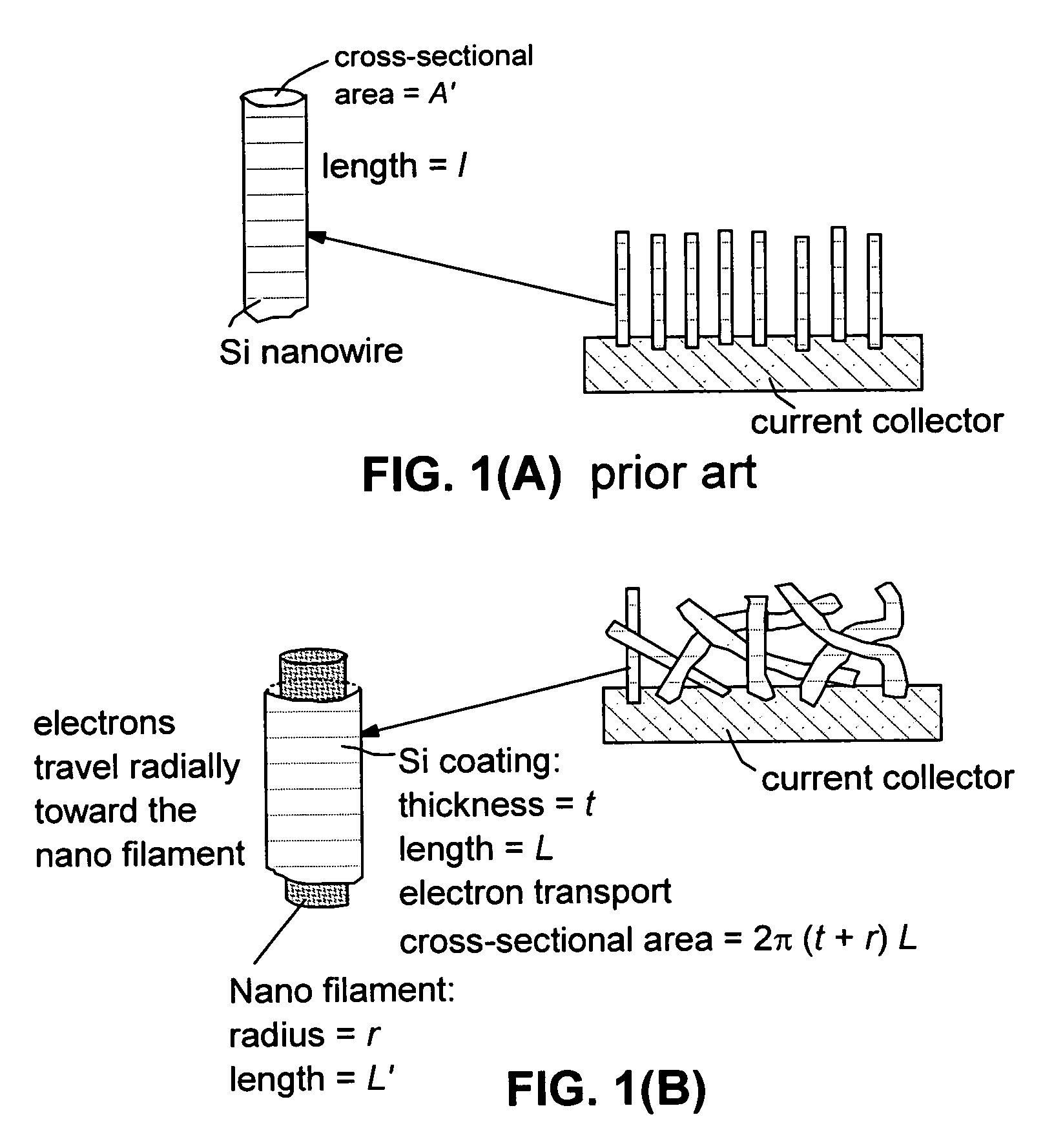

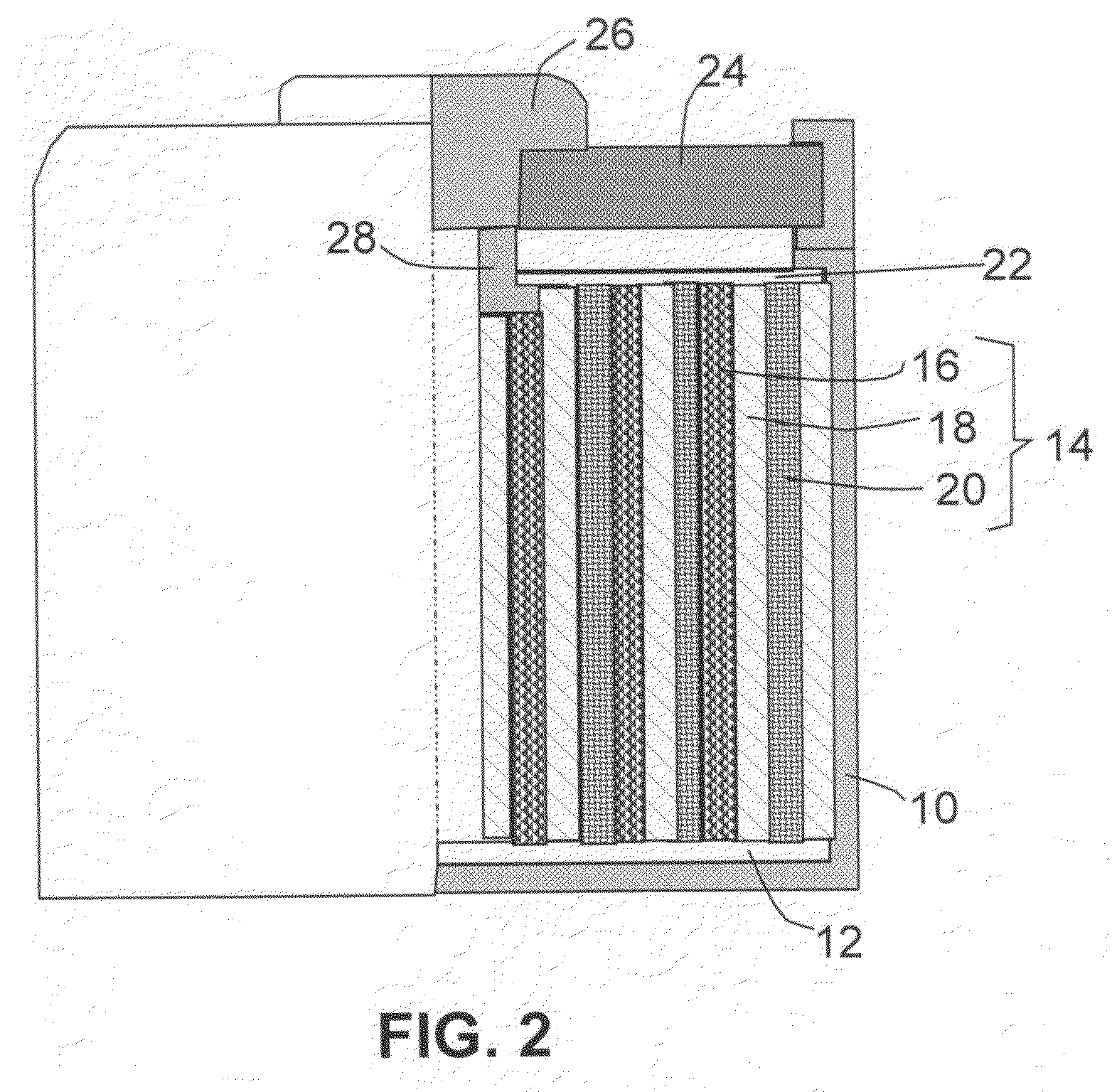

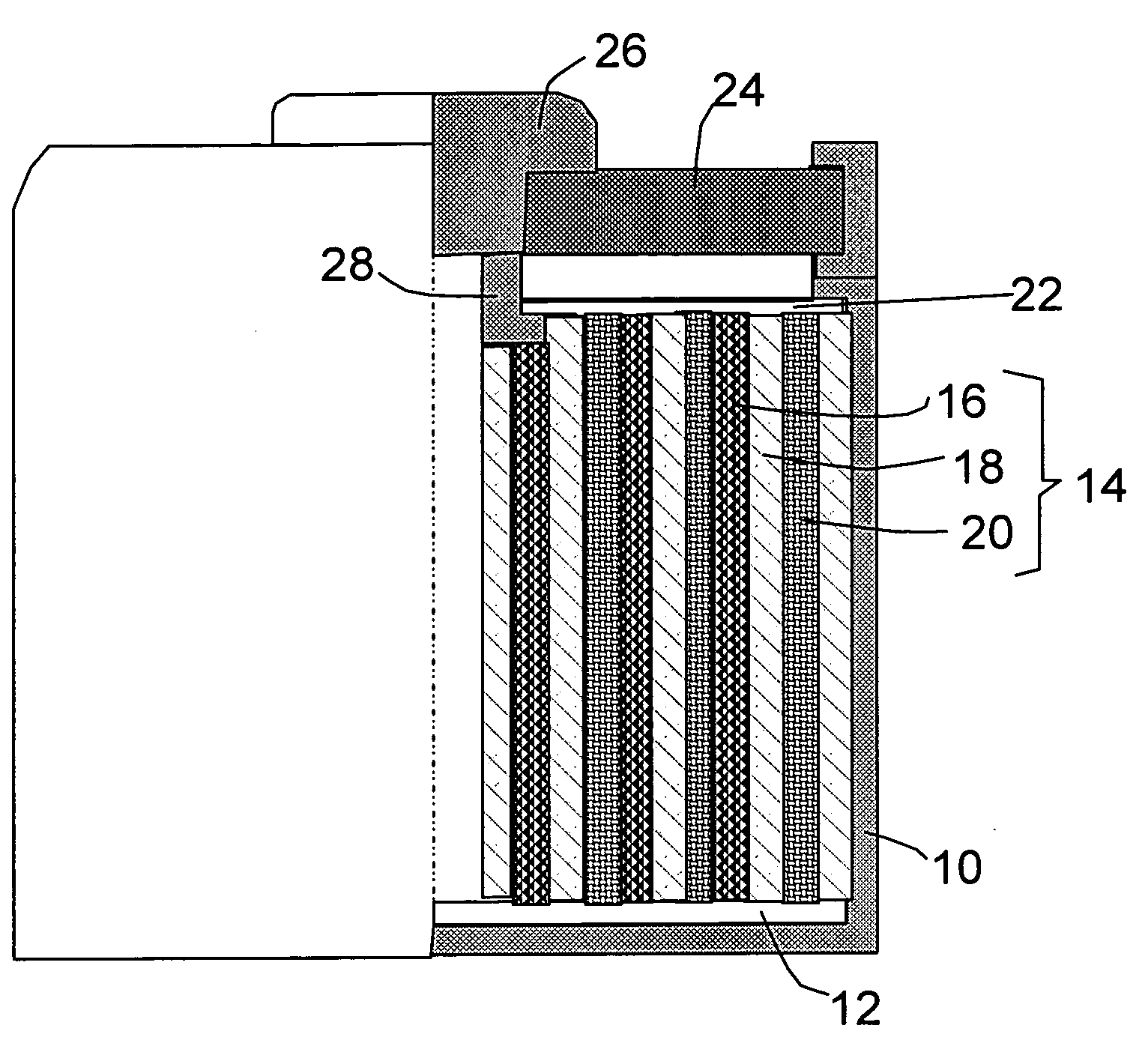

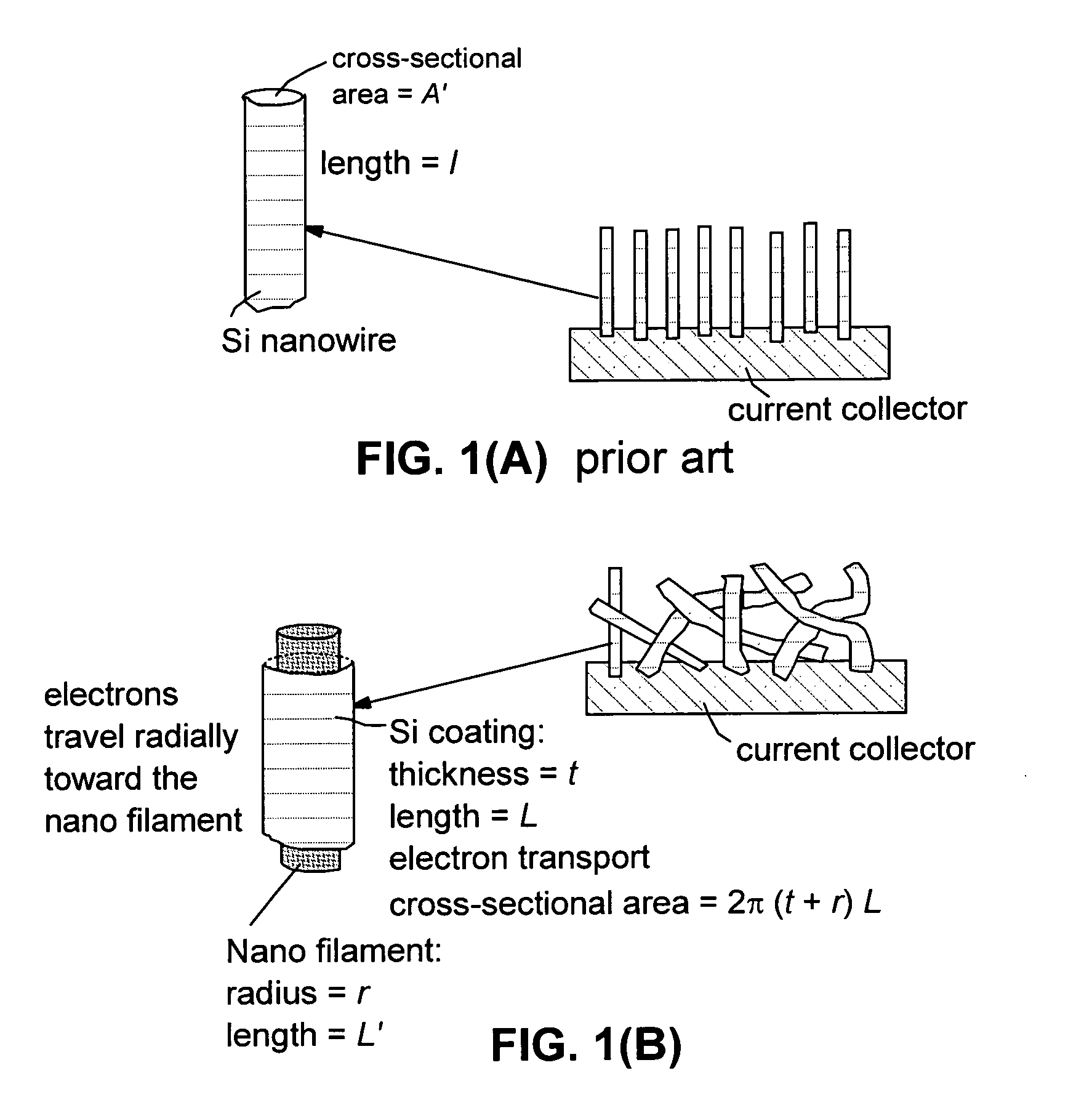

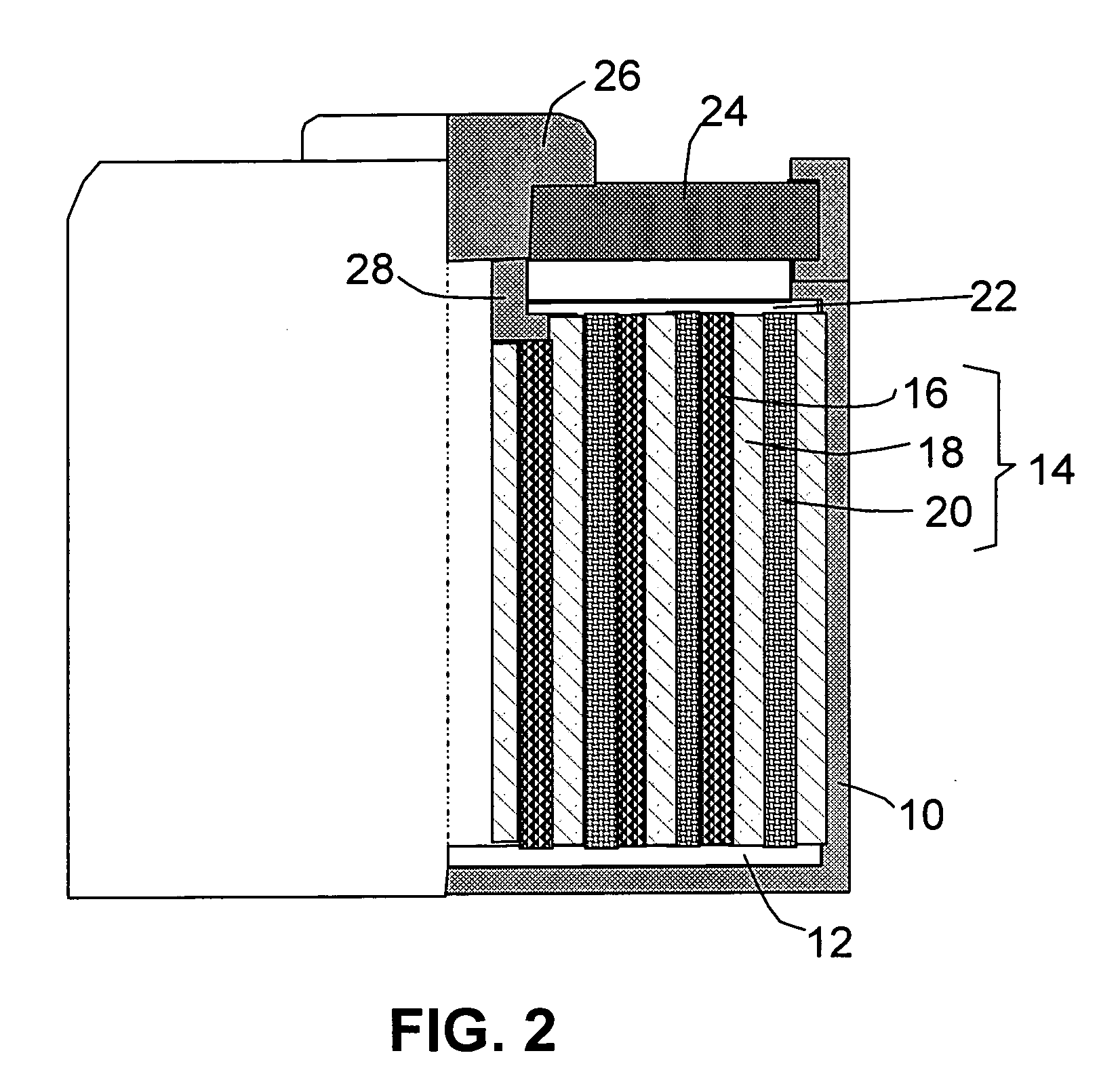

Hybrid nano-filament anode compositions for lithium ion batteries

ActiveUS20090169996A1Superior multiple-cycle behaviorImprove cycle lifeElectrochemical processing of electrodesElectrode thermal treatmentLithium-ion batteryNanometre

This invention provides a hybrid nano-filament composition for use as an electrochemical cell electrode. The composition comprises: (a) an aggregate of nanometer-scaled, electrically conductive filaments that are substantially interconnected, intersected, or percolated to form a porous, electrically conductive filament network comprising substantially interconnected pores, wherein the filaments have an elongate dimension and a first transverse dimension with the first transverse dimension being less than 500 nm (preferably less than 100 nm) and an aspect ratio of the elongate dimension to the first transverse dimension greater than 10; and (b) micron- or nanometer-scaled coating that is deposited on a surface of the filaments, wherein the coating comprises an anode active material capable of absorbing and desorbing lithium ions and the coating has a thickness less than 20 μm (preferably less than 1 μm). Also provided is a lithium ion battery comprising such an electrode as an anode. The battery exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

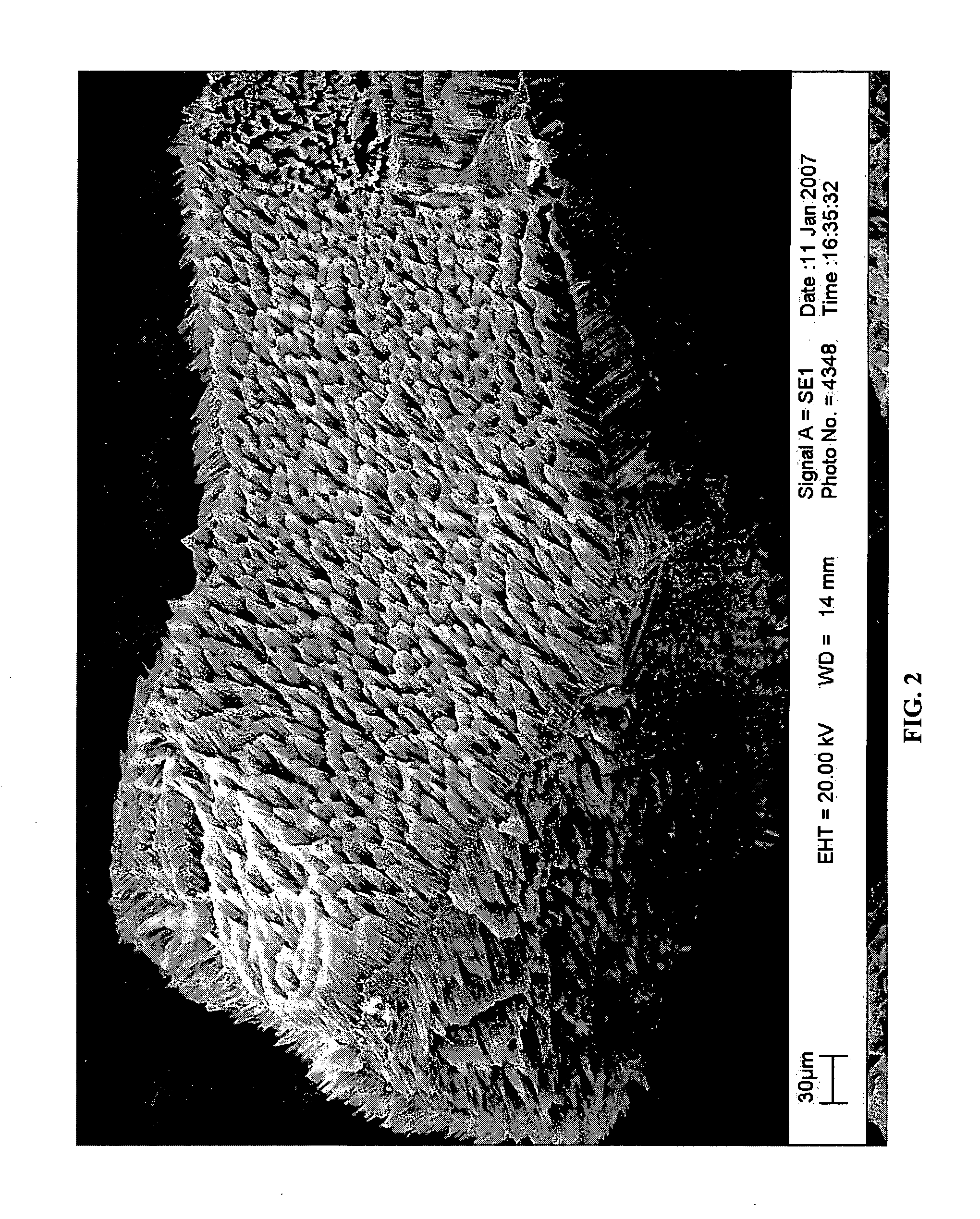

Method of producing hybrid nano-filament electrodes for lithium metal or lithium ion batteries

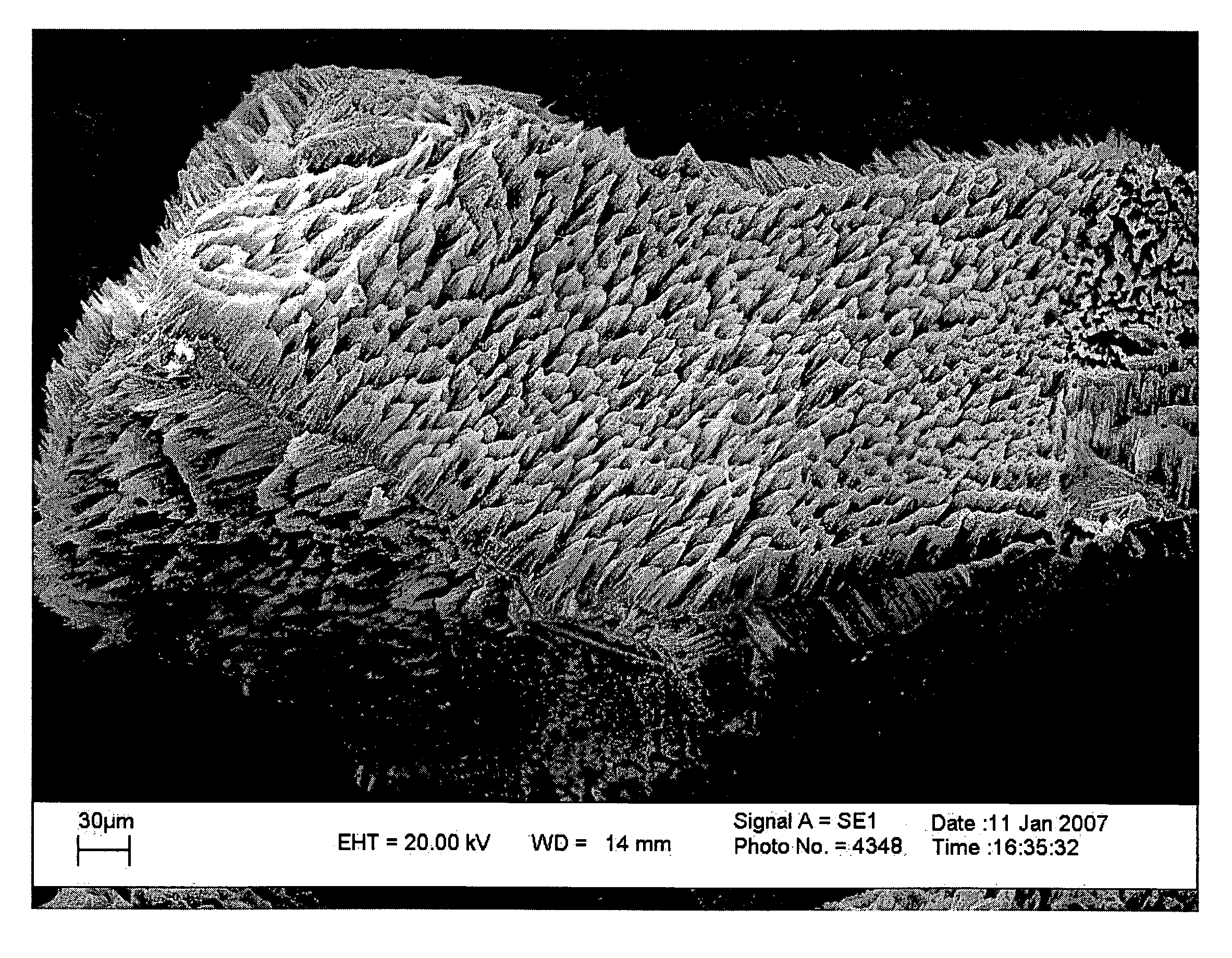

ActiveUS20090169725A1High reversible capacityLower internal resistanceElectrochemical processing of electrodesElectrode thermal treatmentChemical LinkageFiber

Disclosed is a method of producing a hybrid nano-filament composition for use in a lithium battery electrode. The method comprises: (a) providing an aggregate of nanometer-scaled, electrically conductive filaments that are substantially interconnected, intersected, physically contacted, or chemically bonded to form a porous network of electrically conductive filaments, wherein the filaments comprise electro-spun nano-fibers that have a diameter less than 500 nm (preferably less than 100 nm); and (b) depositing micron- or nanometer-scaled coating onto a surface of the electro-spun nano-fibers, wherein the coating comprises an electro-active material capable of absorbing and desorbing lithium ions and the coating has a thickness less than 10 μm (preferably less than 1 μm). The same method can be followed to produce an anode or a cathode. The battery featuring an anode or cathode made with this method exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Negative active material for lithium secondary battery and method for preparating same

ActiveUS20070190413A1Reduce the amount of solutionImprove charge and discharge cycle lifeElectrode thermal treatmentActive material electrodesLithiumDischarge efficiency

Provided are an anode active material for a lithium secondary battery having high reversible capacity and excellent charge / discharge efficiency, comprising a complex composed of ultra-fine Si phase particles and an oxide surrounding the ultra-fine Si phase particles, and a carbon material; and a method for preparing the same. The present invention also provides a method for preparing an anode active material for a lithium secondary battery comprising producing a complex composed of ultra-fine Si particles and an oxide surrounding the ultra-fine Si particles by mixing a silicon oxide and a material having an absolute value of oxide formation enthalpy (ΔHfor) greater than that of the silicon oxide and negative oxide formation enthalpy by a mechanochemical process or subjecting them to a thermochemical reaction to reduce the silicon oxide; and mixing the Si phase-containing oxide complex and carbon material.

Owner:LG ENERGY SOLUTION LTD

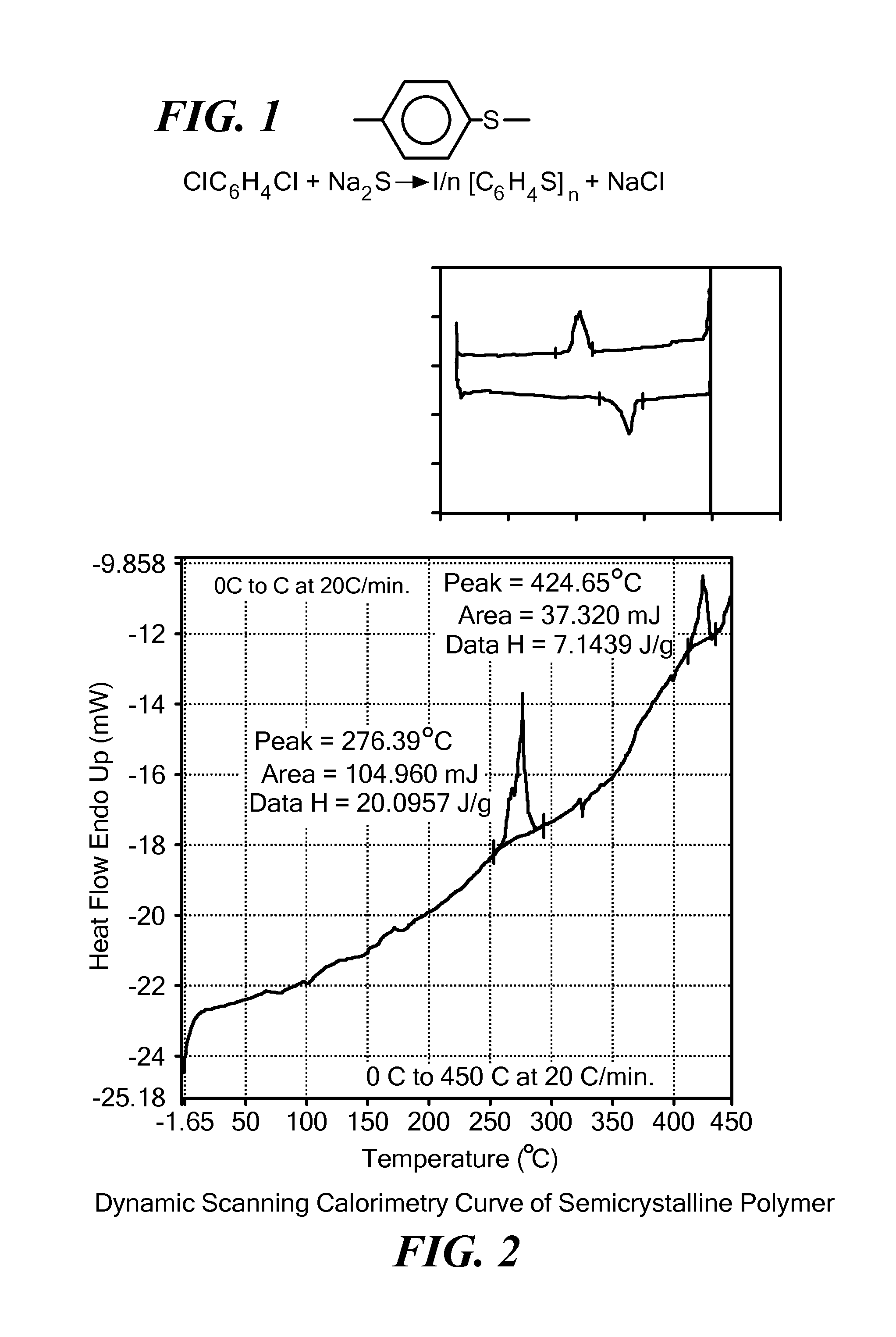

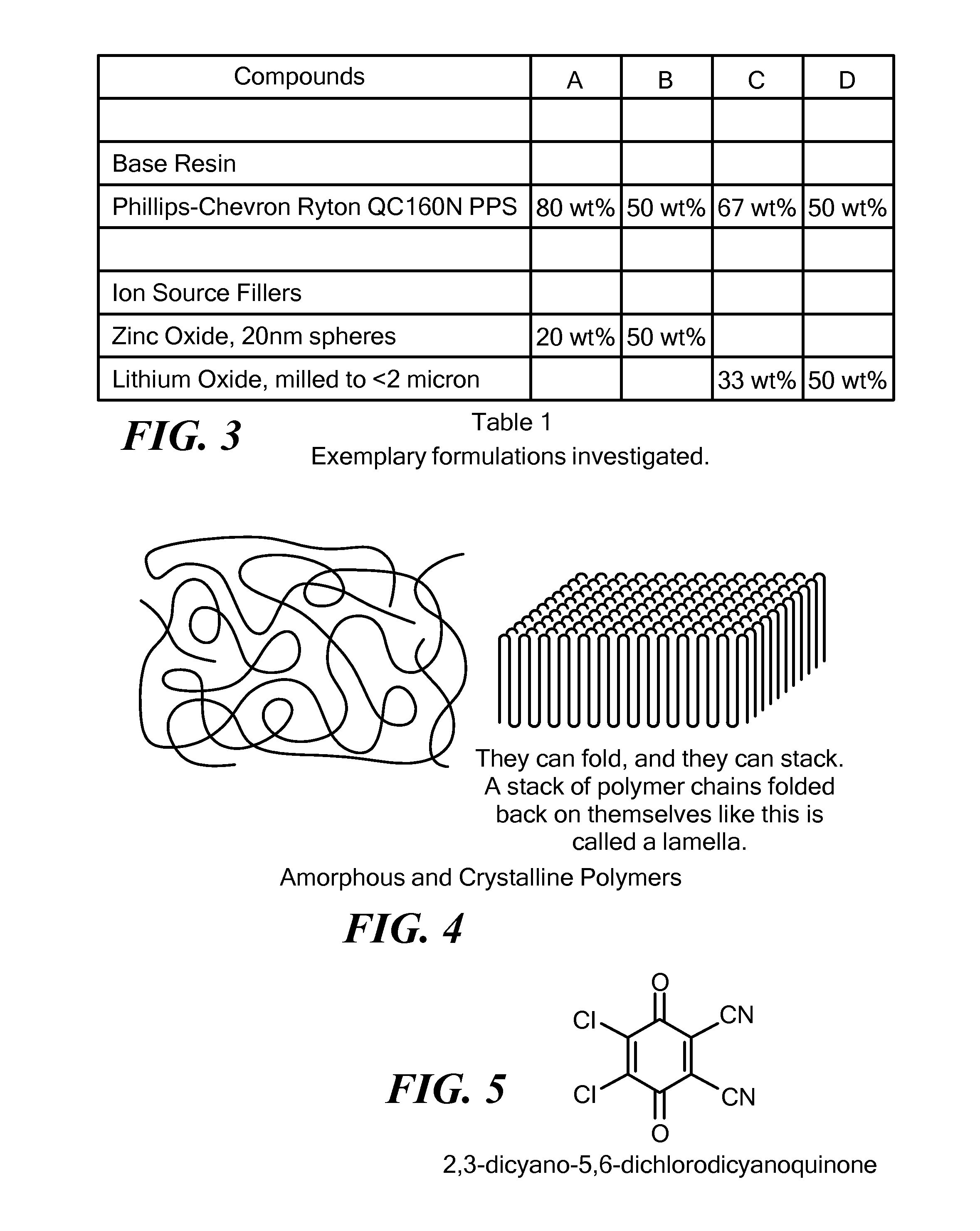

Solid, ionically conducting polymer material, and methods and applications for same

ActiveUS20150155559A1Low effective aqueous porosityLarge specific surface areaSolid electrolytesAlkaline accumulatorsPolymer sciencePolymer

The invention features a rechargeable alkaline battery comprising an anode; a cathode; and an electrolyte; wherein at least one of anode, the cathode and the electrolyte includes a solid, ionically conducting polymer material, and methods for the manufacture of same.

Owner:IONIC MATERIALS INC

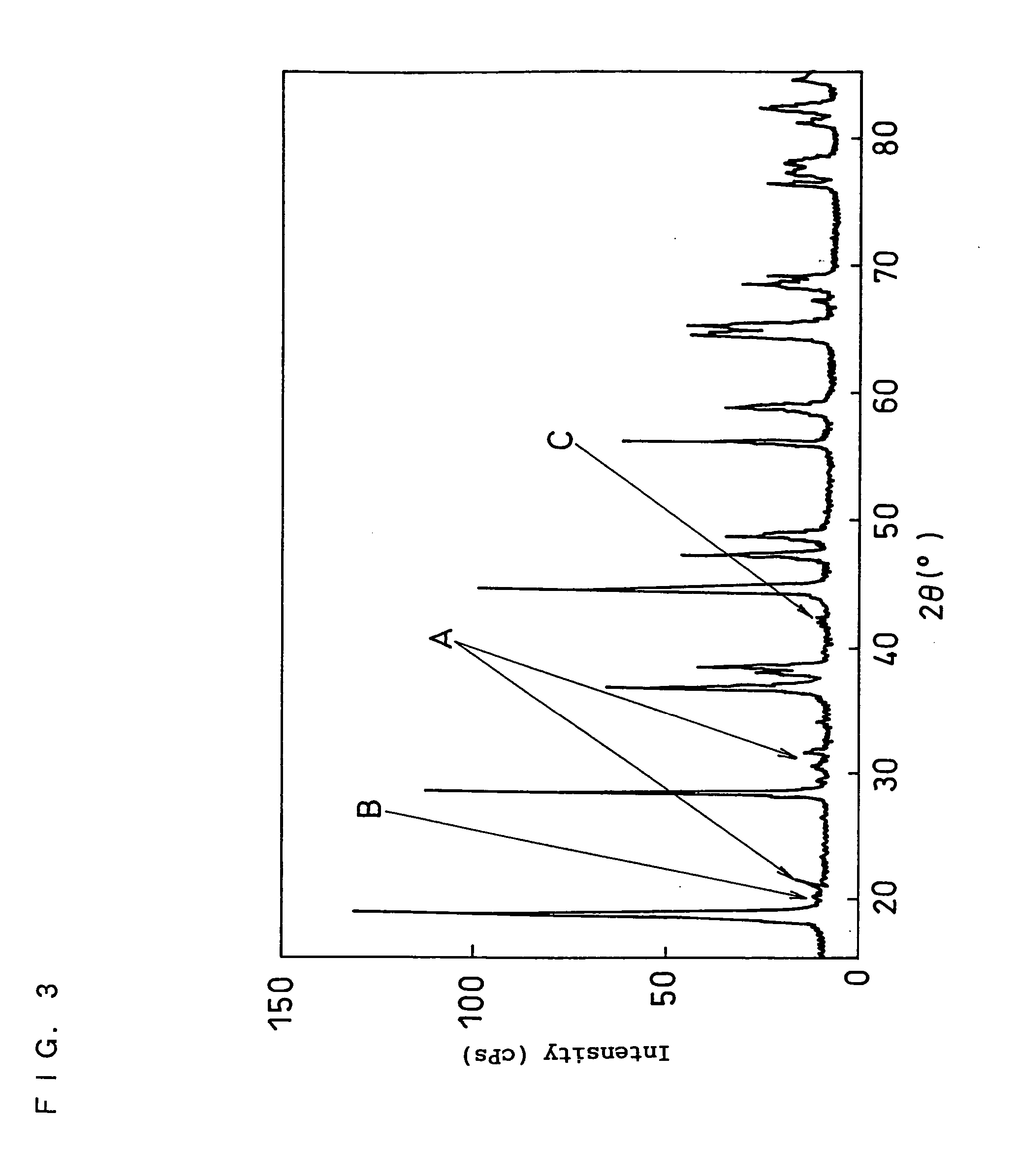

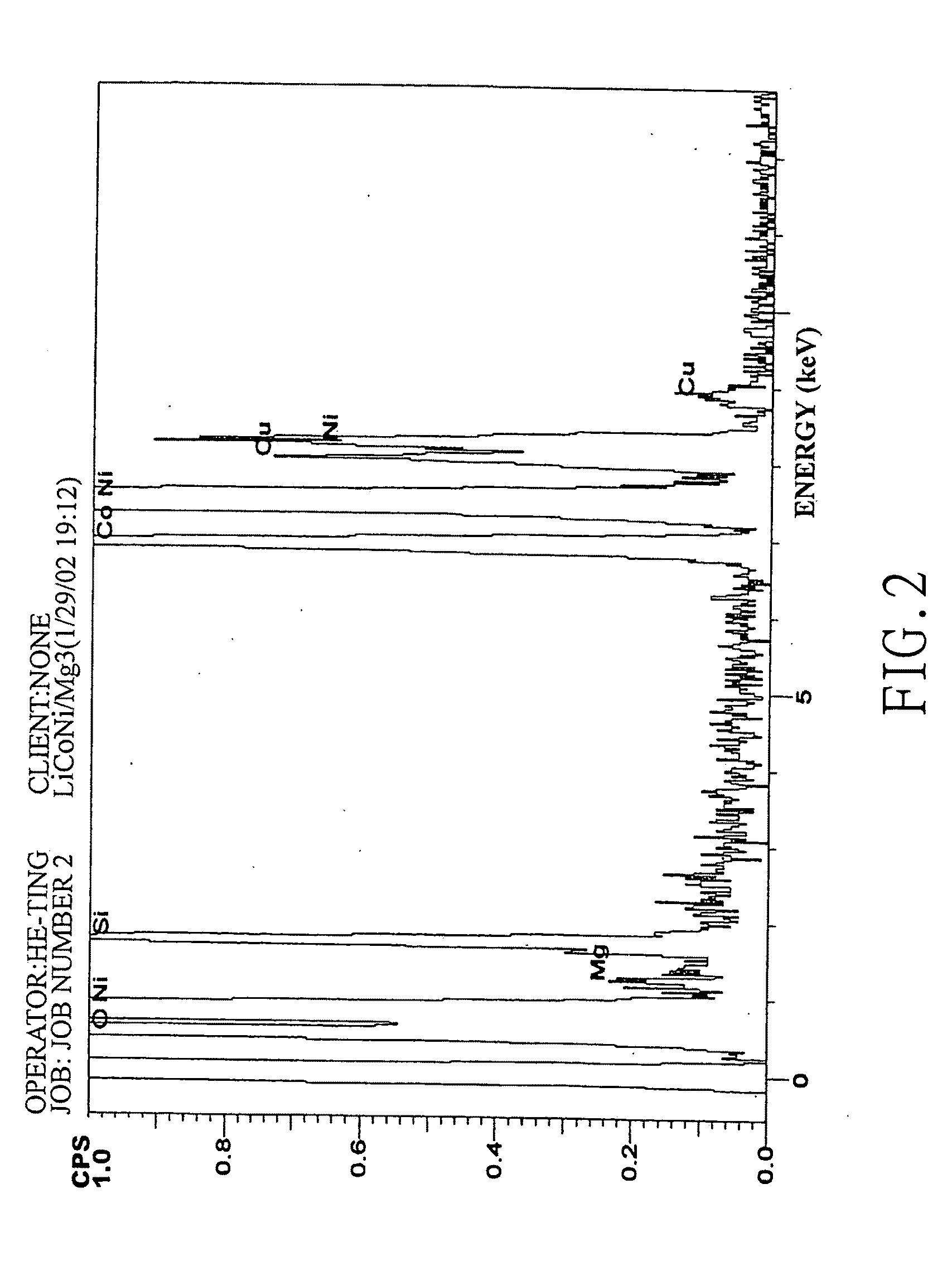

Positive electrode active material for non-aqueous electrolyte secondary battery, production method thereof, and non-aqueous electrolyte secondary battery using the same

A positive electrode active material for a non-aqueous electrolyte secondary battery of this invention includes: a lithium nickel composite oxide containing lithium, nickel, and at least one metal element other than lithium and nickel; and a layer containing lithium carbonate, aluminum hydroxide, and aluminum oxide, the layer being carried on the surface of the lithium nickel composite oxide. The lithium nickel composite oxide is composed such that the ratio of the nickel to the total of the nickel and the at least one metal element is 30 mol % or more. The layer is composed such that the amount of the lithium carbonate is 0.5 to 5 mol per 100 mol of the lithium nickel composite oxide. The total of aluminum atoms contained in the aluminum hydroxide and the aluminum oxide is 0.5 to 5 mol per 100 mol of the lithium nickel composite oxide.

Owner:PANASONIC CORP

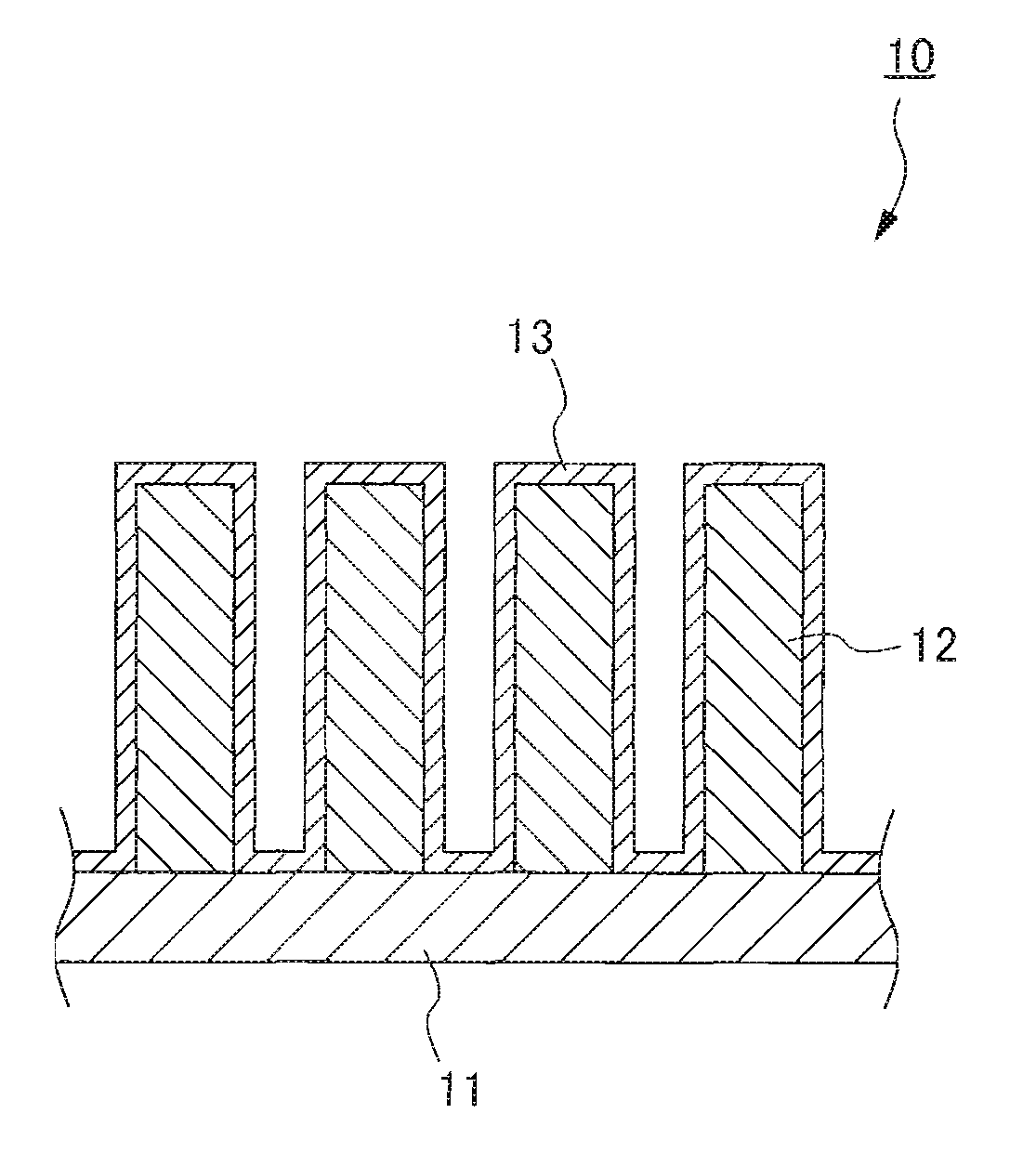

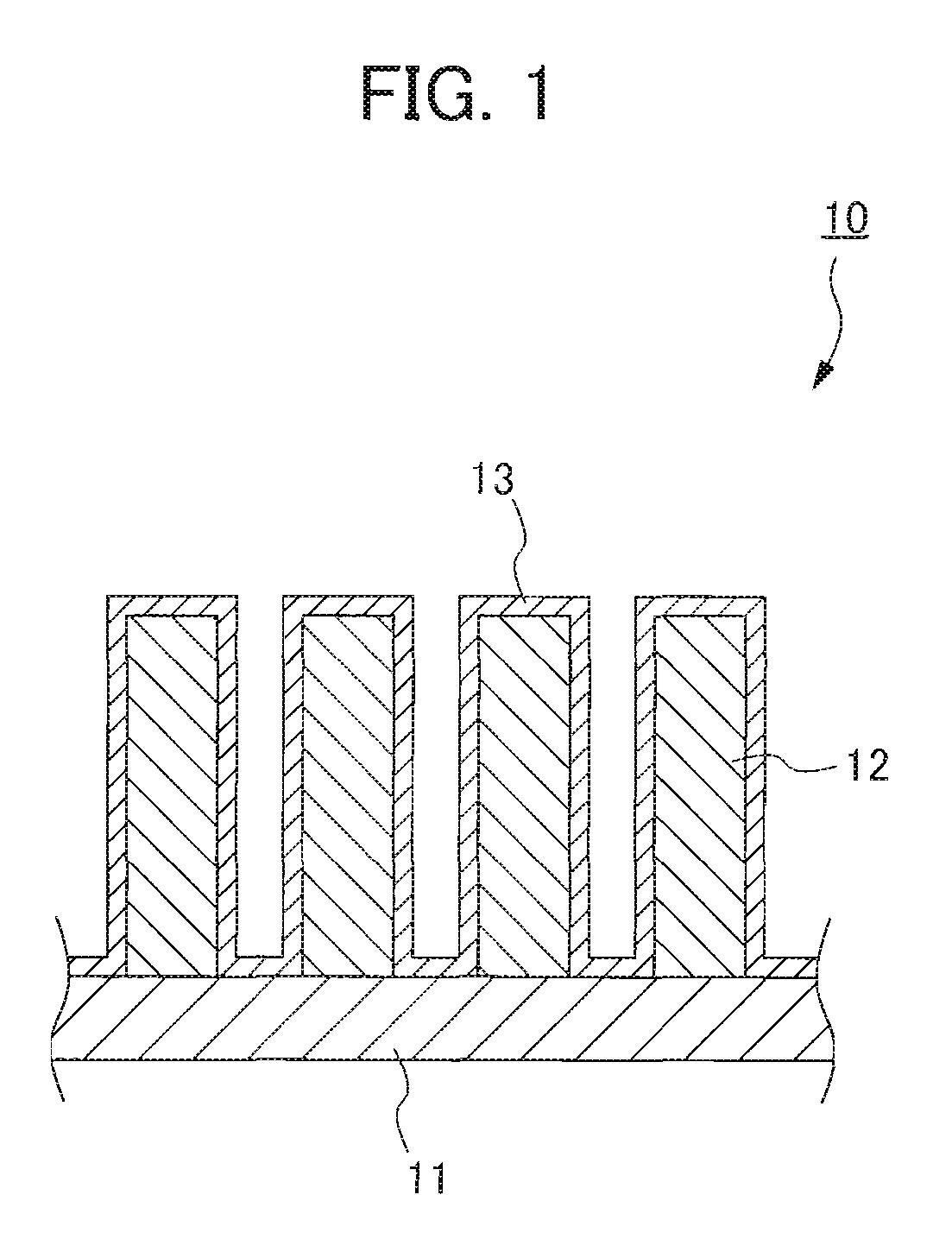

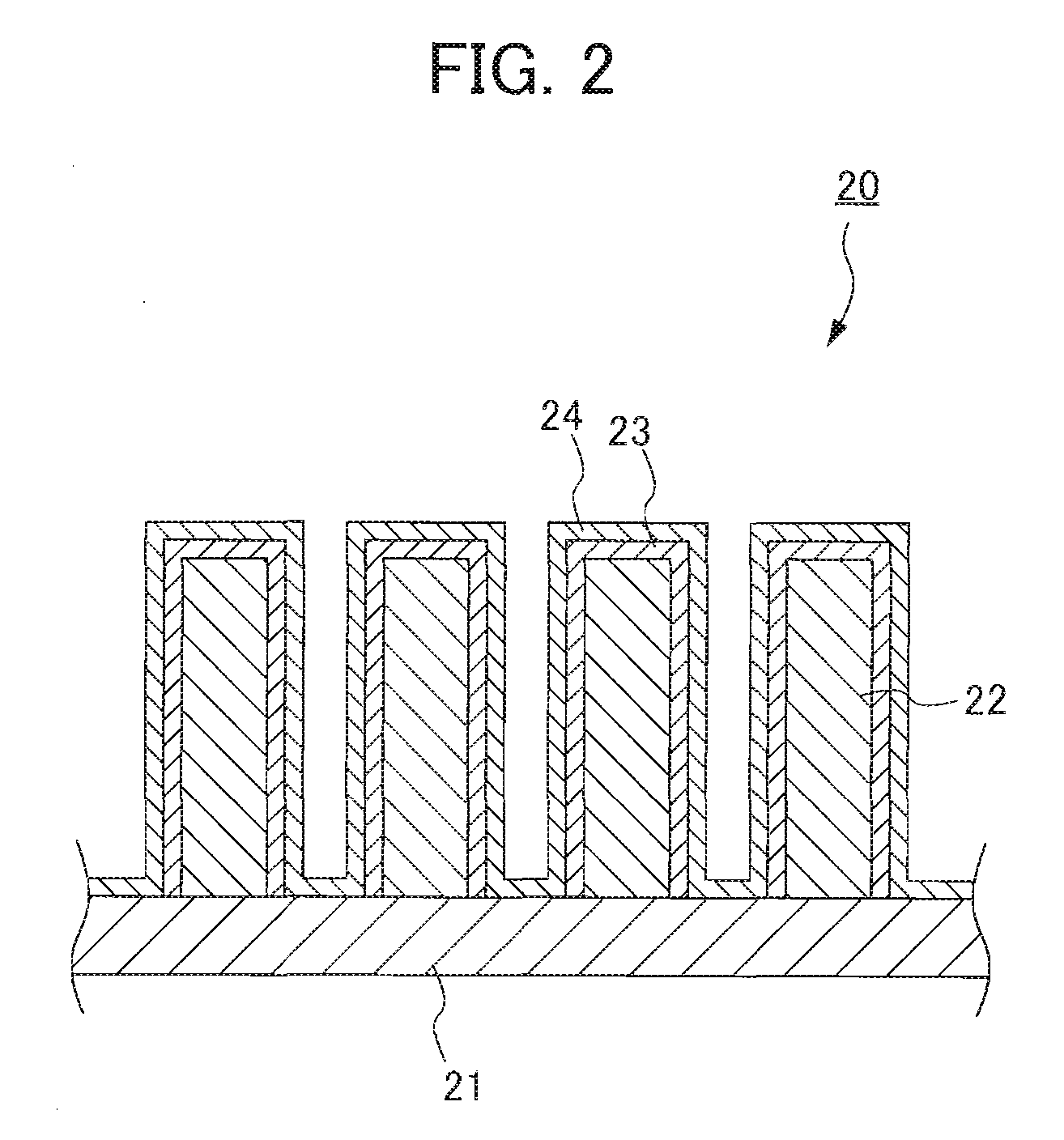

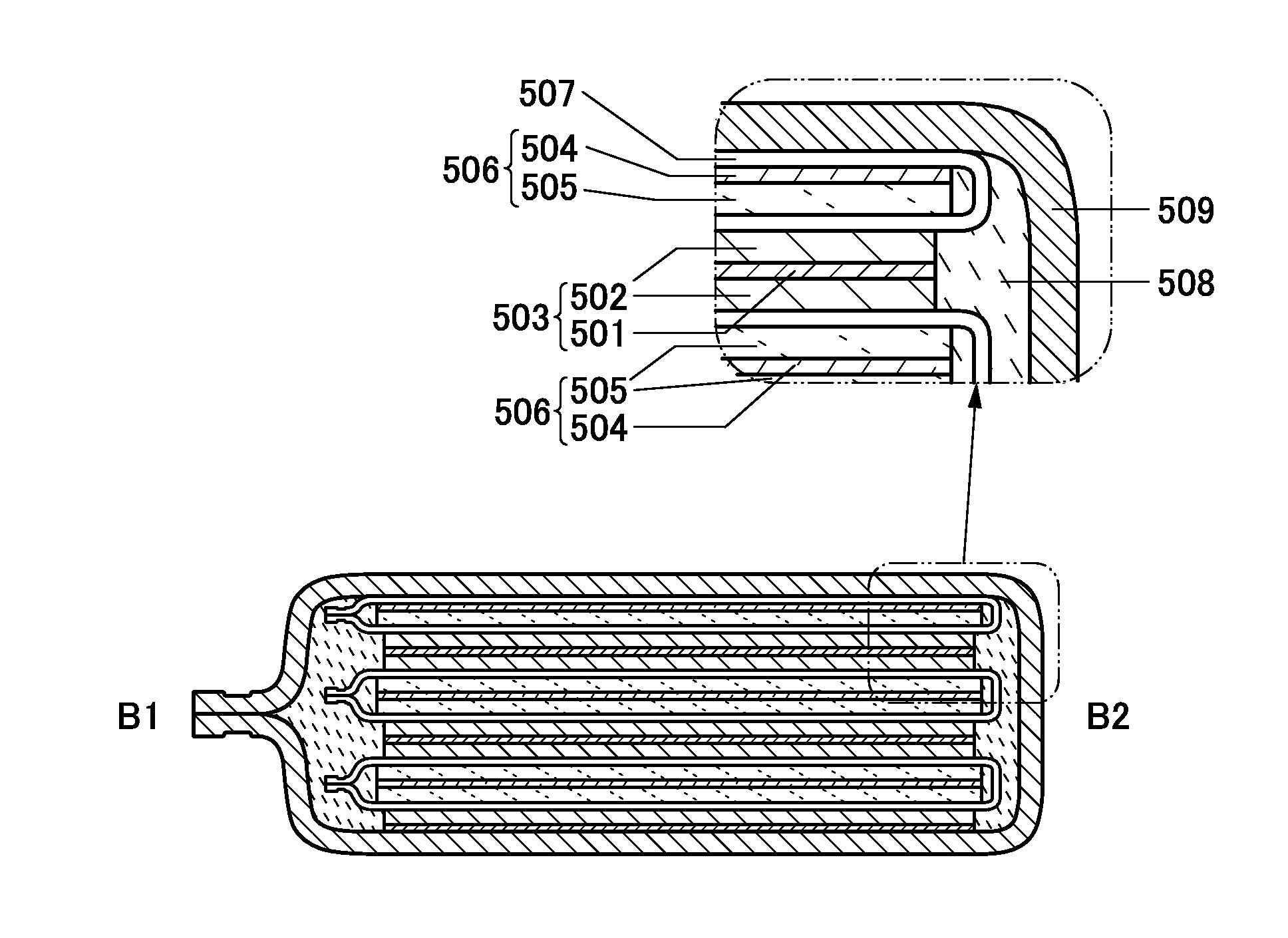

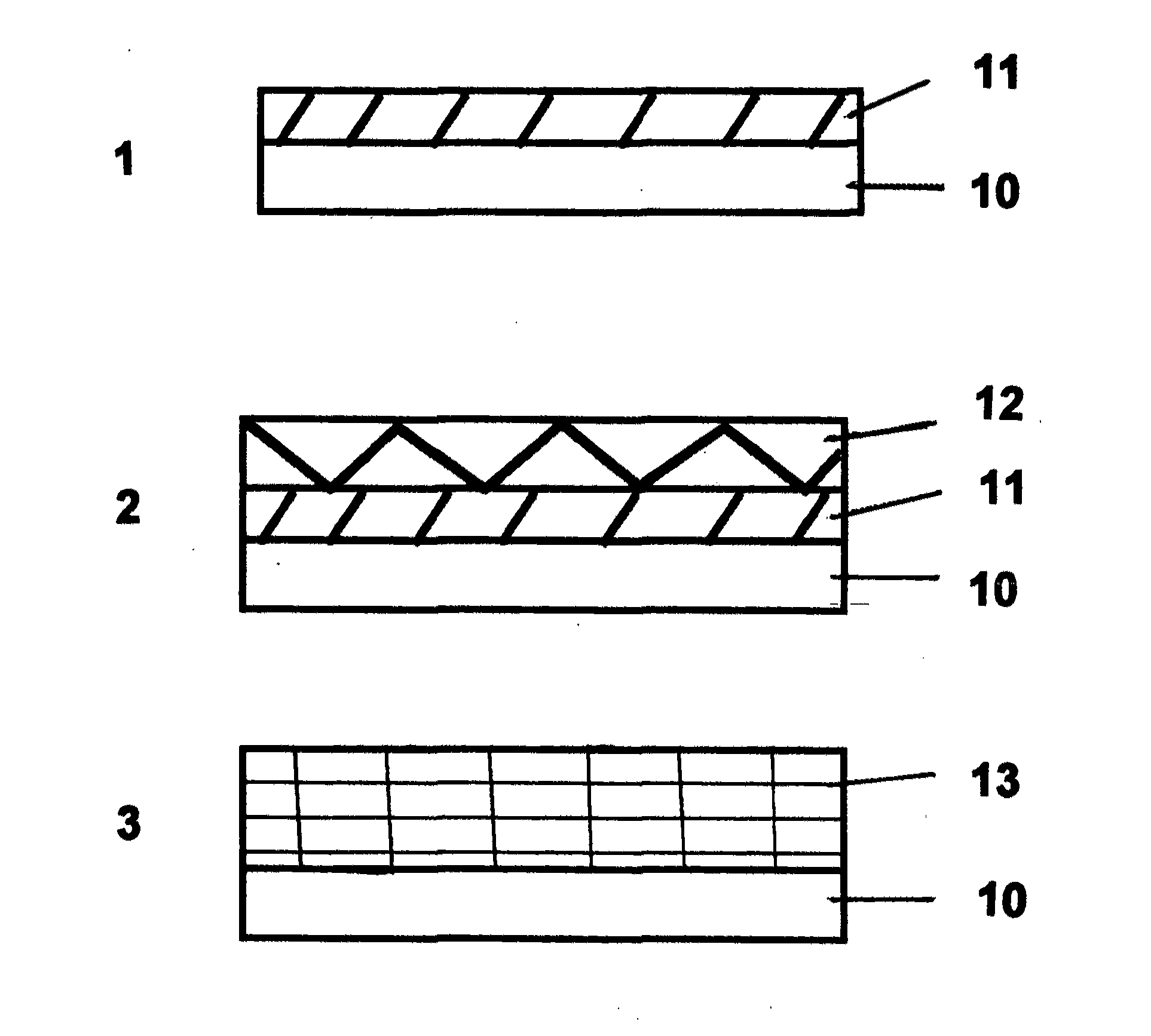

Negative electrode base member

ActiveUS20100119939A1Increase energy densitySuperior in discharge cycle characteristicElectrochemical processing of electrodesFinal product manufactureOrganic filmComposite film

The present invention aims to realize a battery having high output voltage, high energy density and excellent charge and discharge cycle characteristics through a constitution different from those of conventional batteries. Specifically, one of the following negative electrode base members is used as a negative electrode base member for lithium ion secondary batteries: a negative electrode base member wherein a metal film is formed on a support having an organic film; such a negative electrode base member wherein the surface layer of the organic film is covered with a metal oxide film; a negative electrode base member wherein a metal film is formed on a support having a composite film formed from a composite film-forming material containing an organic component and an inorganic component; and a negative electrode base member wherein a silica coating is formed, on a support having a photoresist pattern, from a silica film-forming coating liquid and a metal film is formed on the support after removing the photoresist pattern.

Owner:TOKYO OHKA KOGYO CO LTD +1

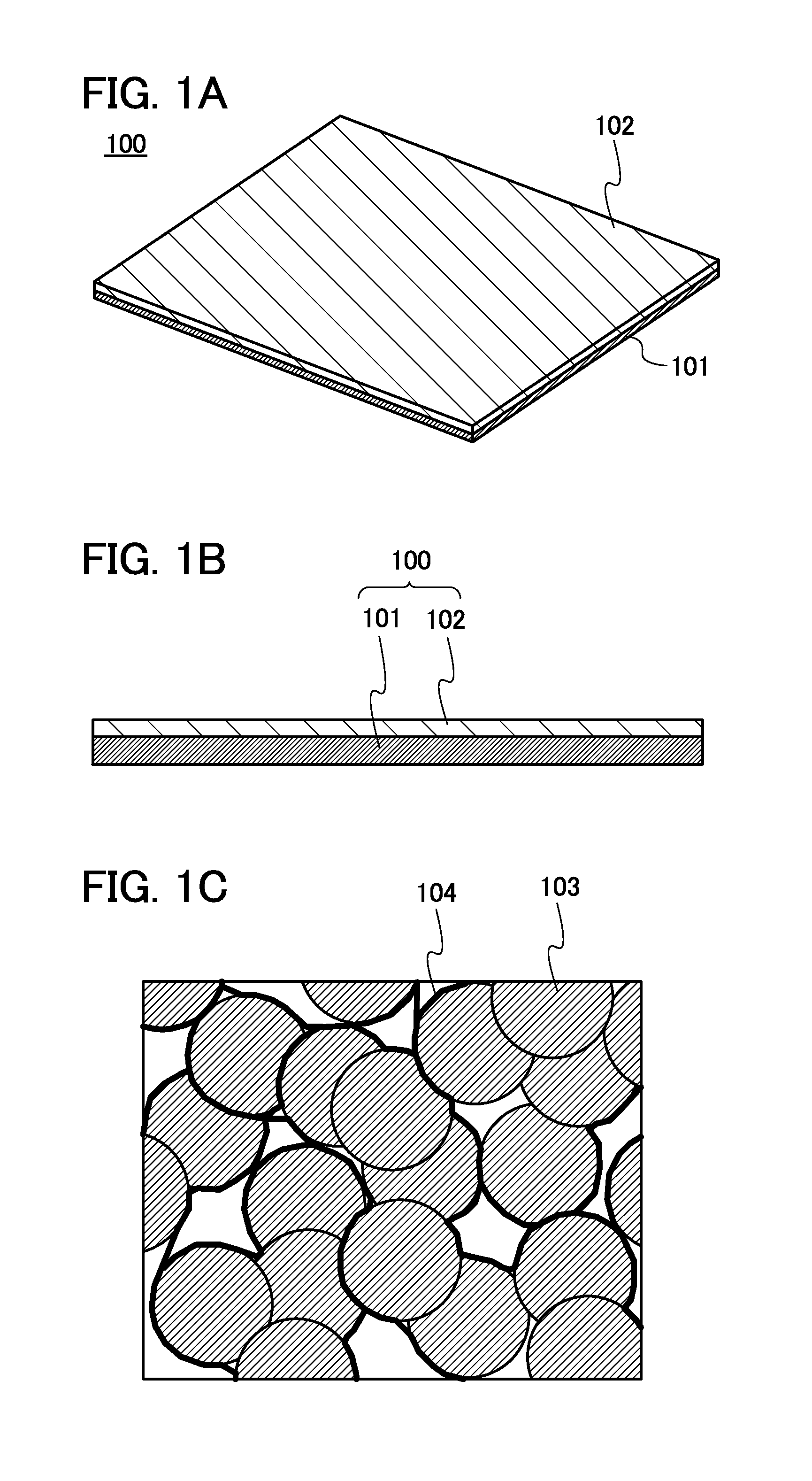

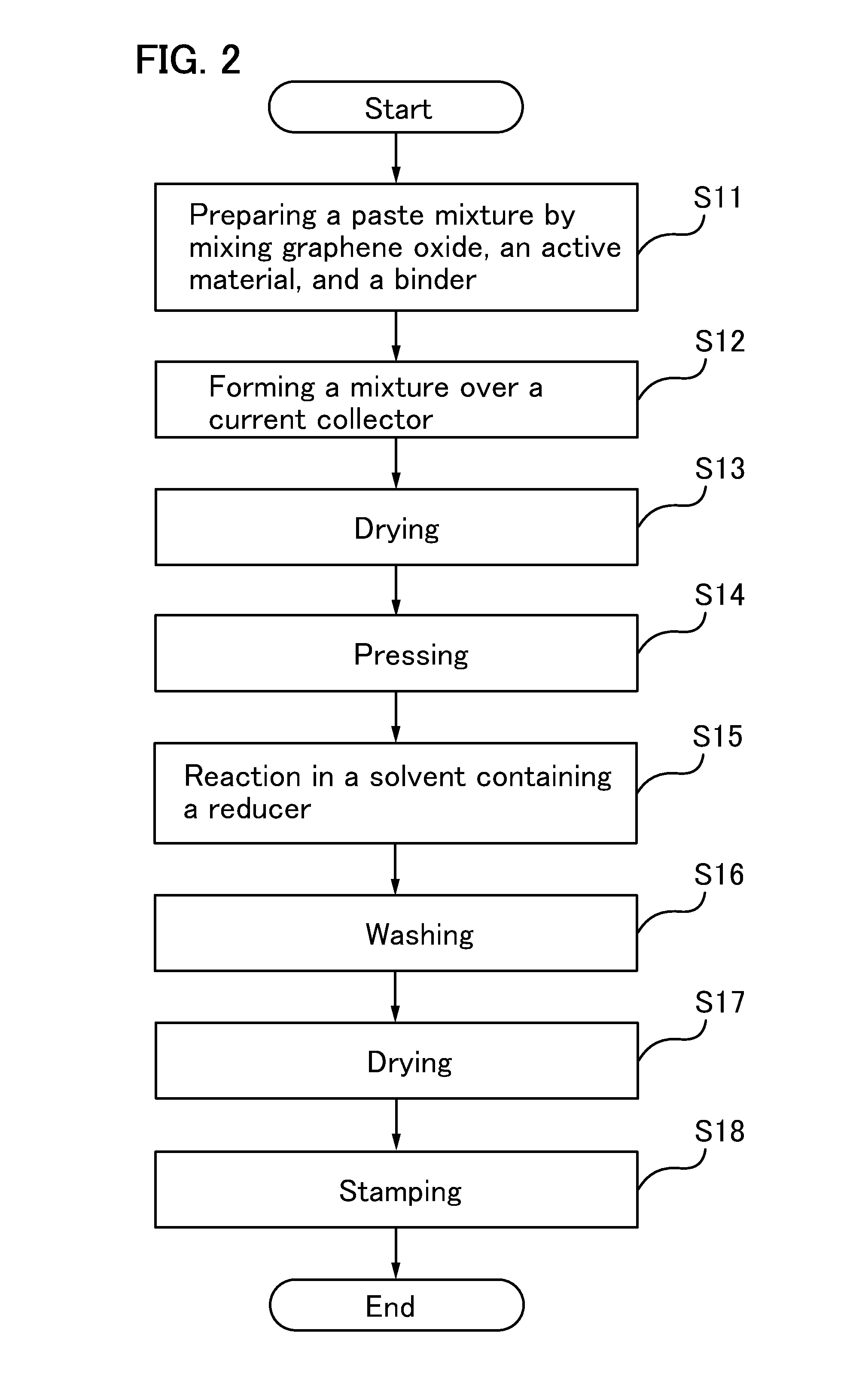

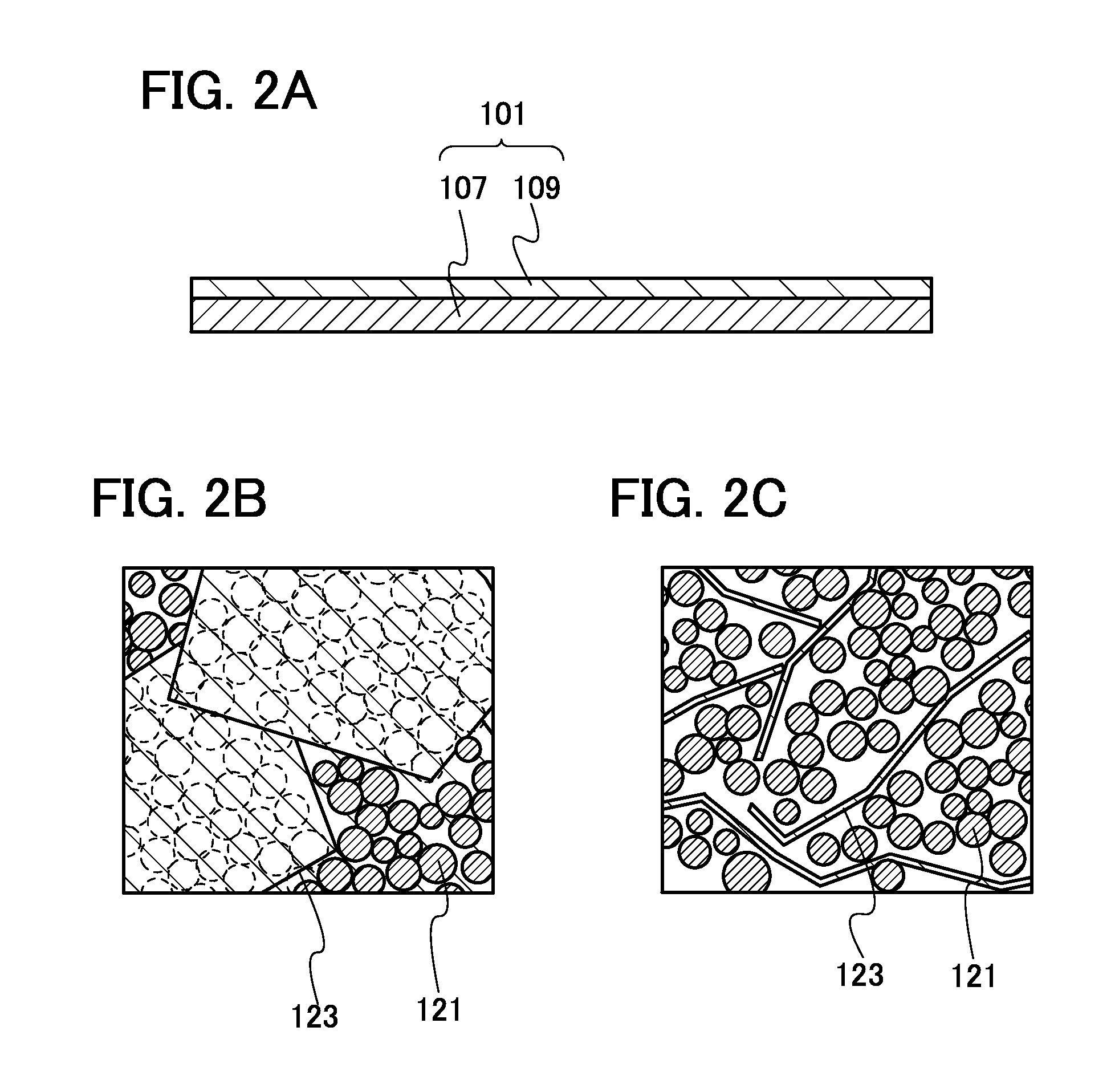

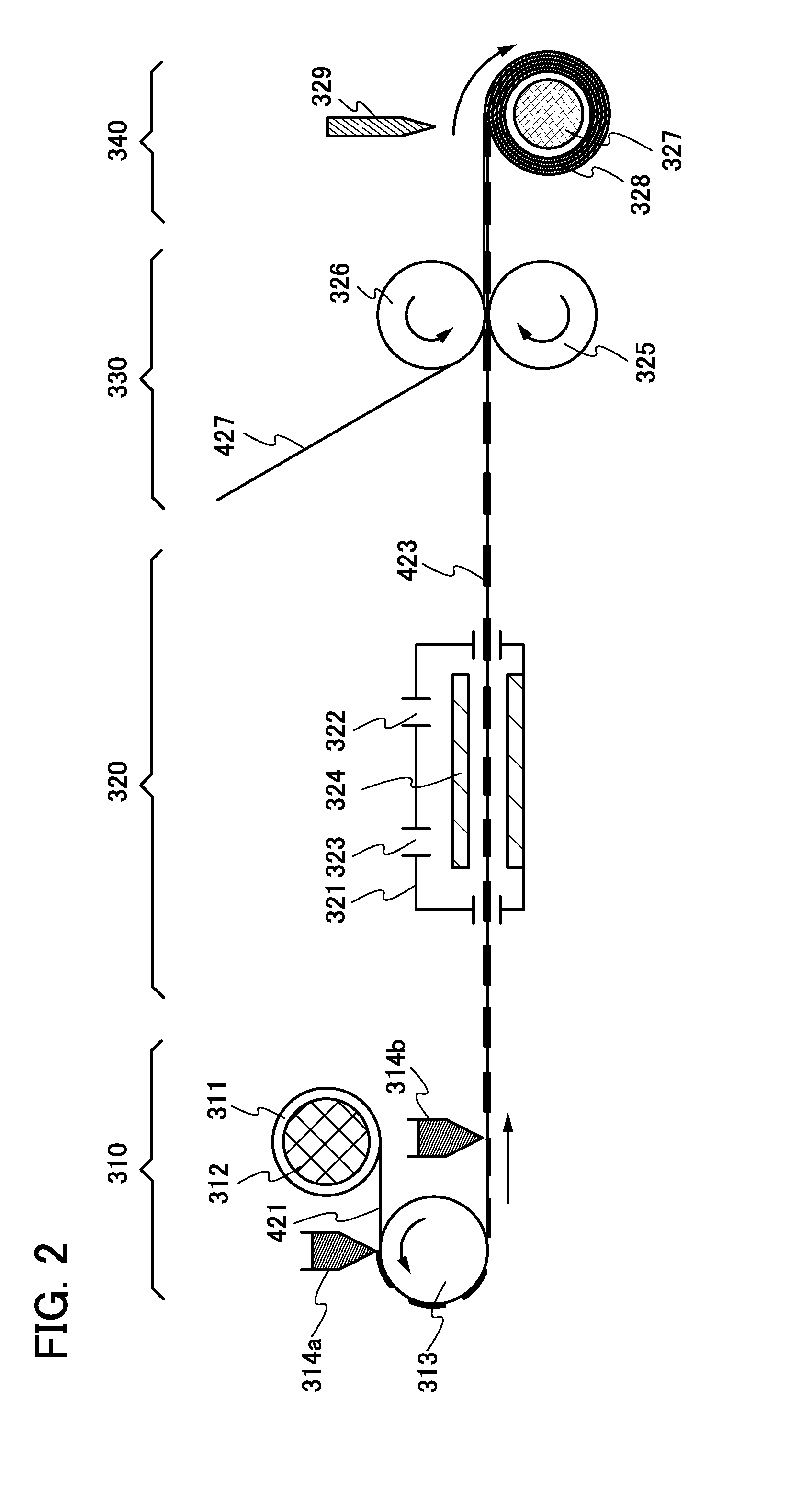

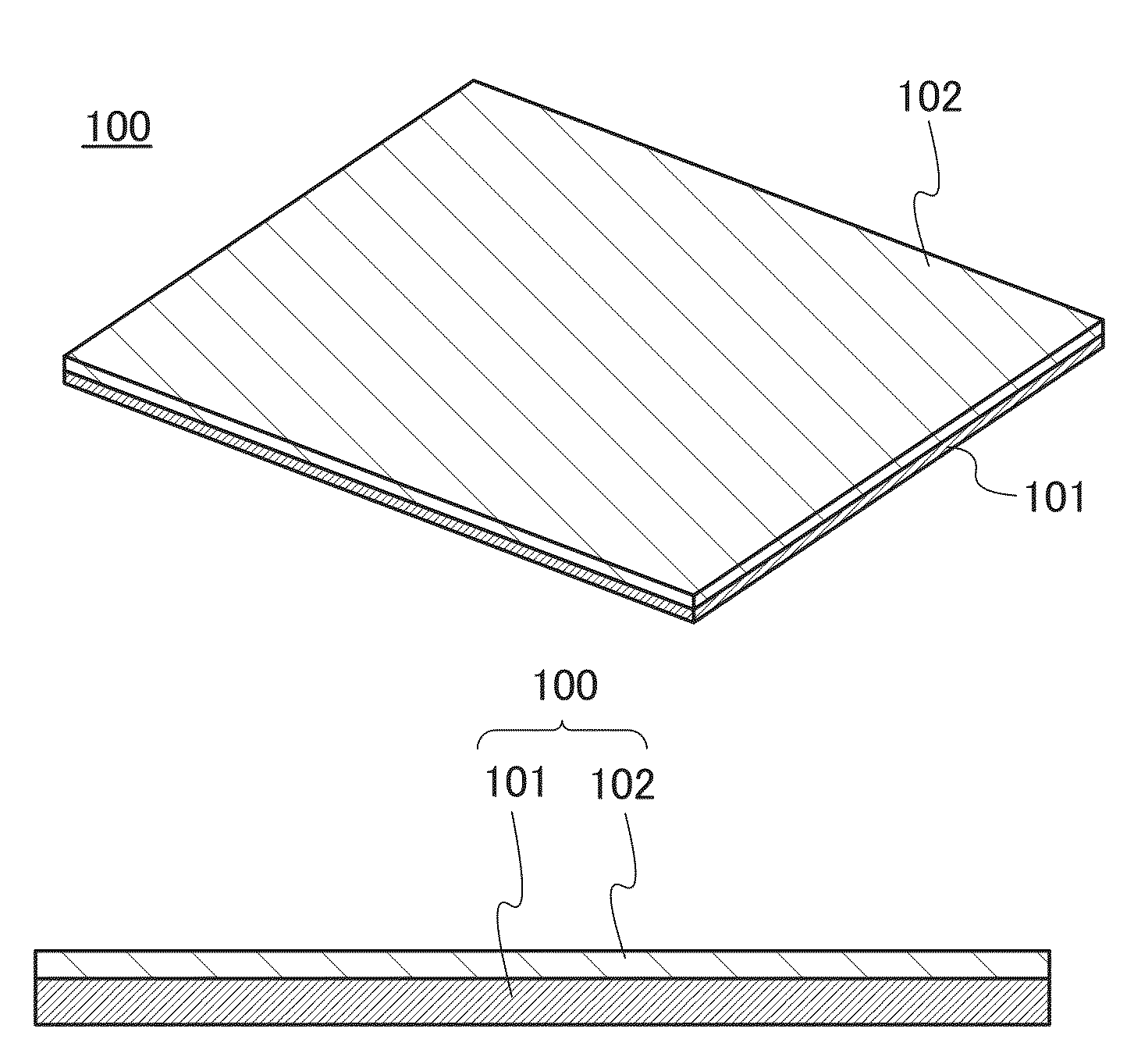

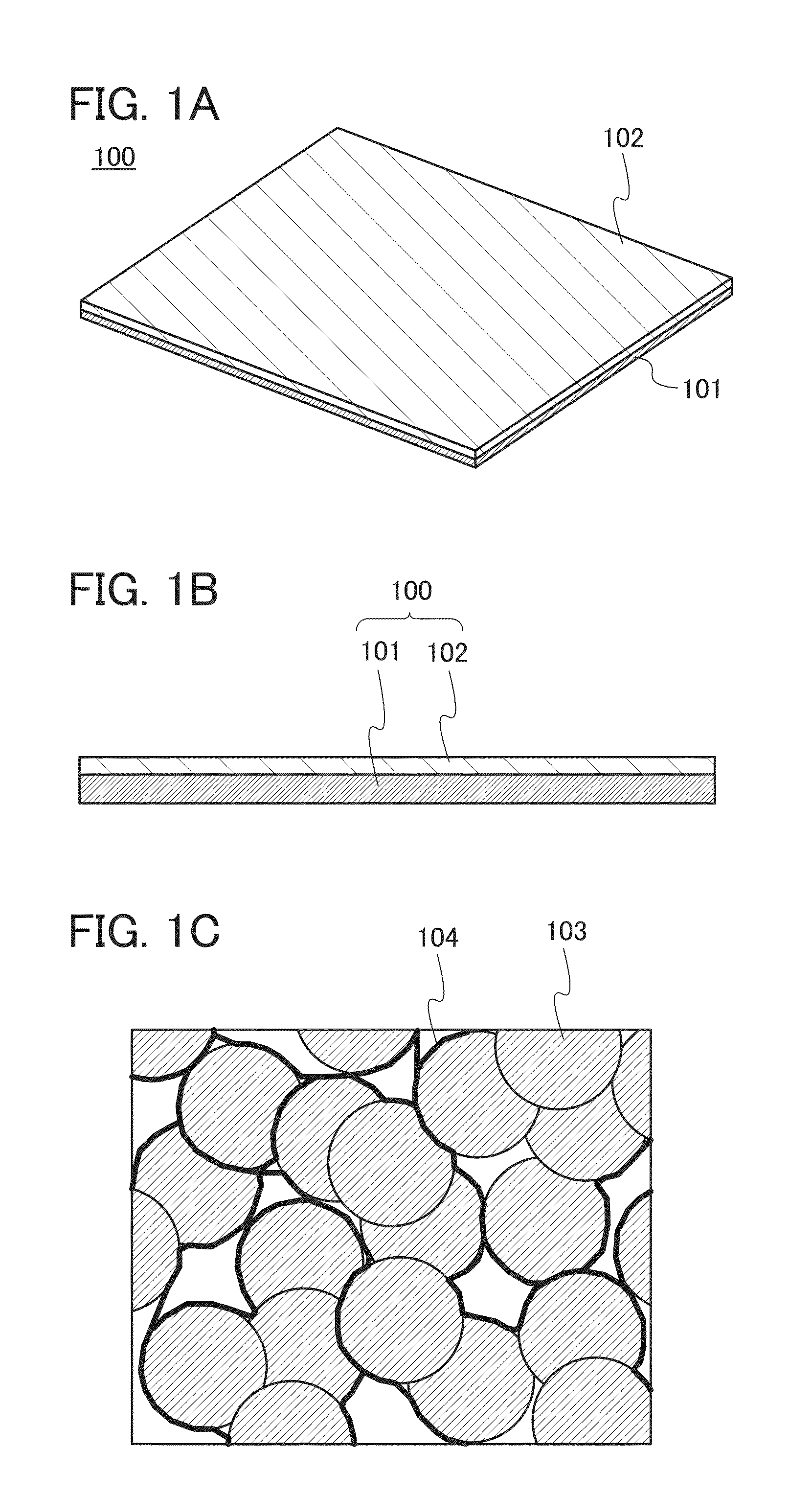

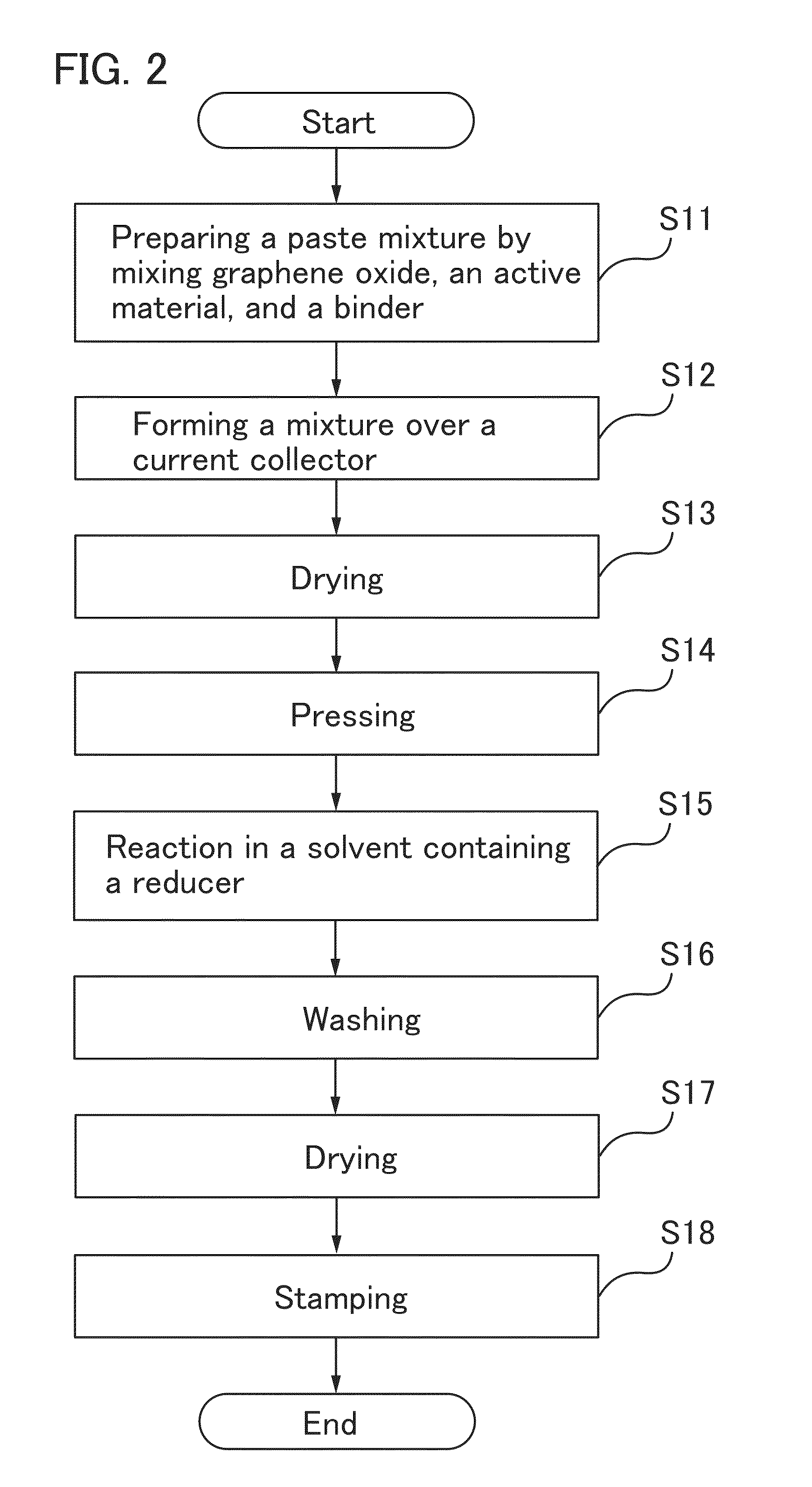

Method for manufacturing storage battery electrode, storage battery electrode, storage battery, and electronic device

ActiveUS20130337320A1High densityReduce electrical conductivityElectrode rolling/calenderingElectrode thermal treatmentSolventElectron

To provide a method for forming a storage battery electrode including an active material layer with high density in which the proportion of conductive additive is low and the proportion of the active material is high. To provide a storage battery having a higher capacity per unit volume of an electrode with the use of a storage battery electrode formed by the formation method. A method for forming a storage battery electrode includes the steps of forming a mixture including an active material, graphene oxide, and a binder; providing a mixture over a current collector; and immersing the mixture provided over the current collector in a polar solvent containing a reducer, so that the graphene oxide is reduced.

Owner:SEMICON ENERGY LAB CO LTD

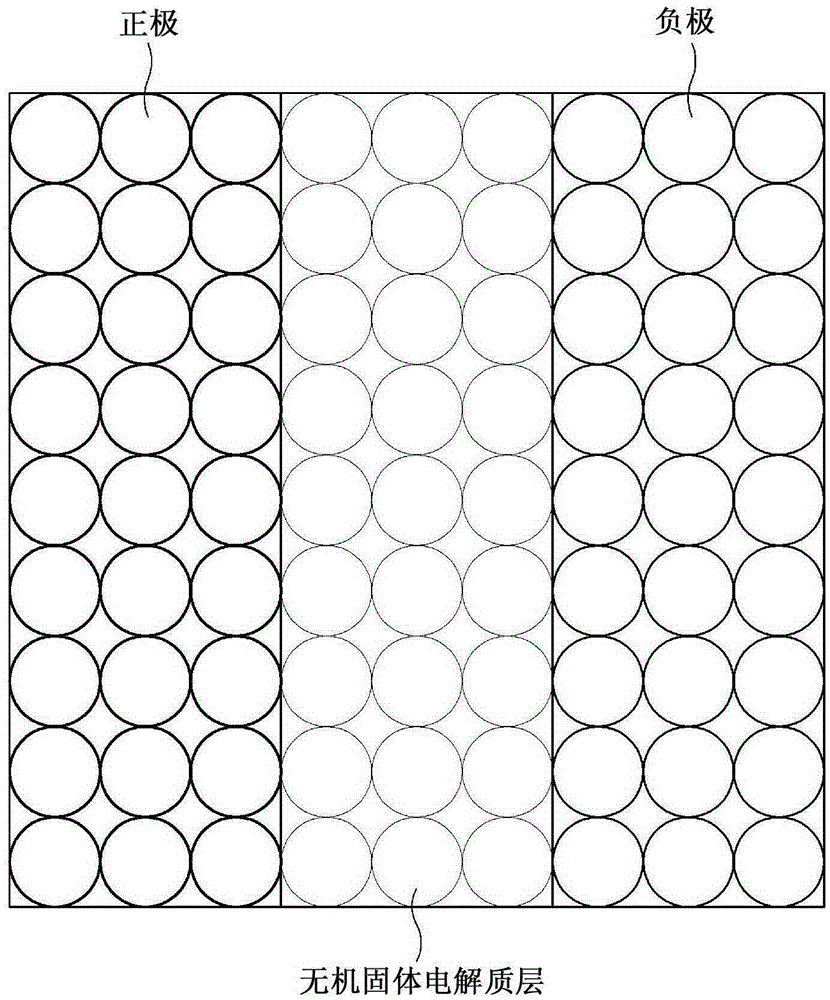

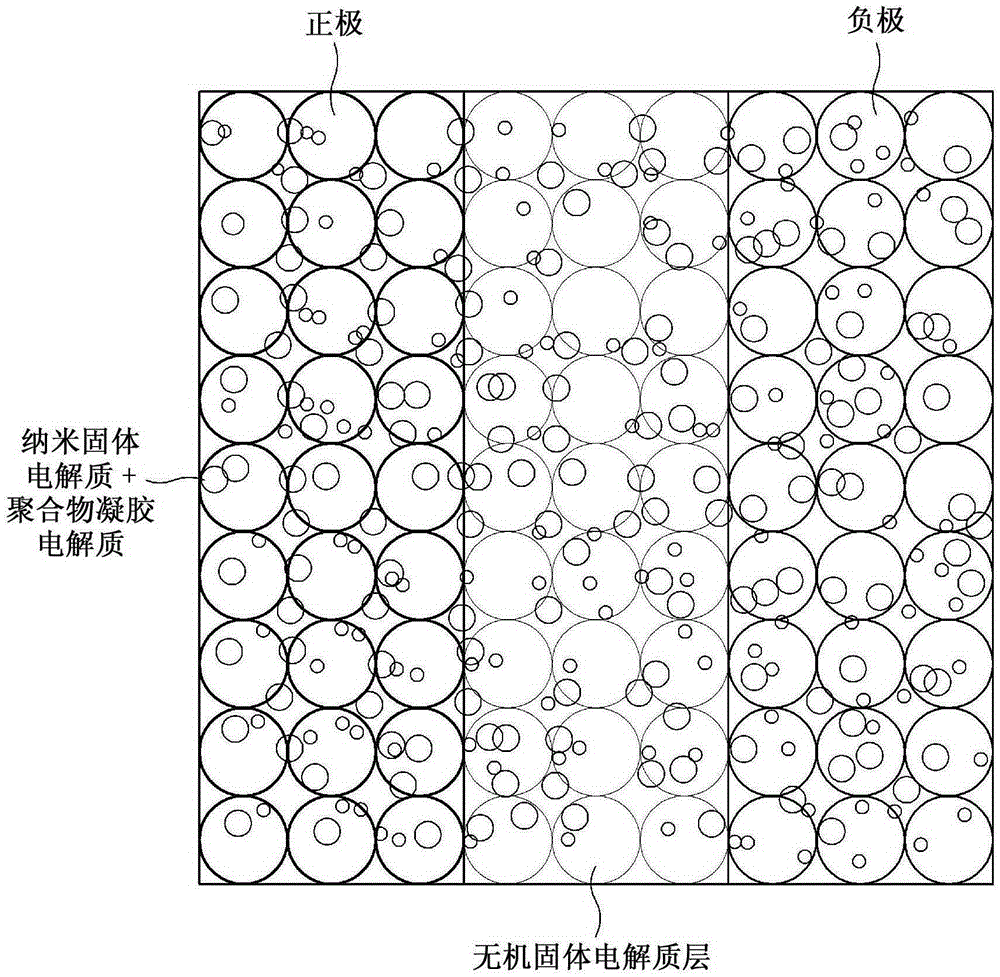

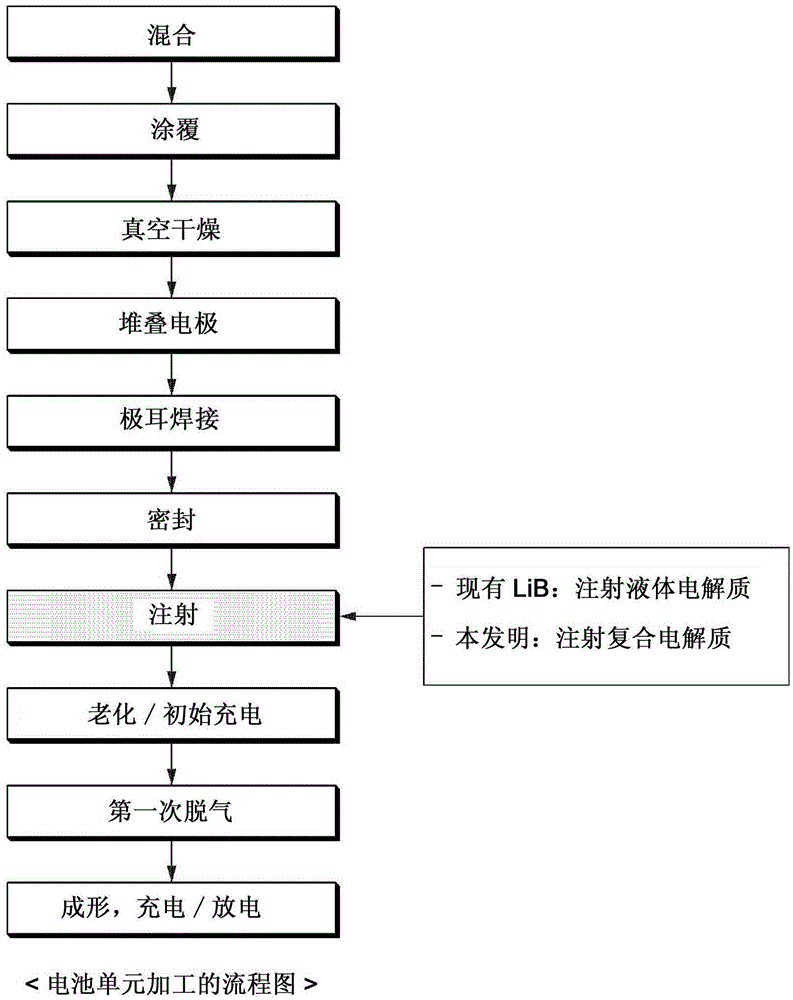

All-solid-state battery containing nano-solid electrolyte and method of manufacturing the same

Provided is an all-solid-state battery containing a nano-solid electrolyte which has excellent stability and enhanced battery performance and can be manufactured without changing an existing process, and a method of manufacturing the same. Due to substantially improved battery performance, as well as having excellent safety, the all-solid-state battery containing a nano-solid electrolyte may be widely used and further contribute to industrial development such as electric vehicles in which medium and large lithium ion rechargeable batteries are used.

Owner:HYUNDAI MOTOR CO LTD

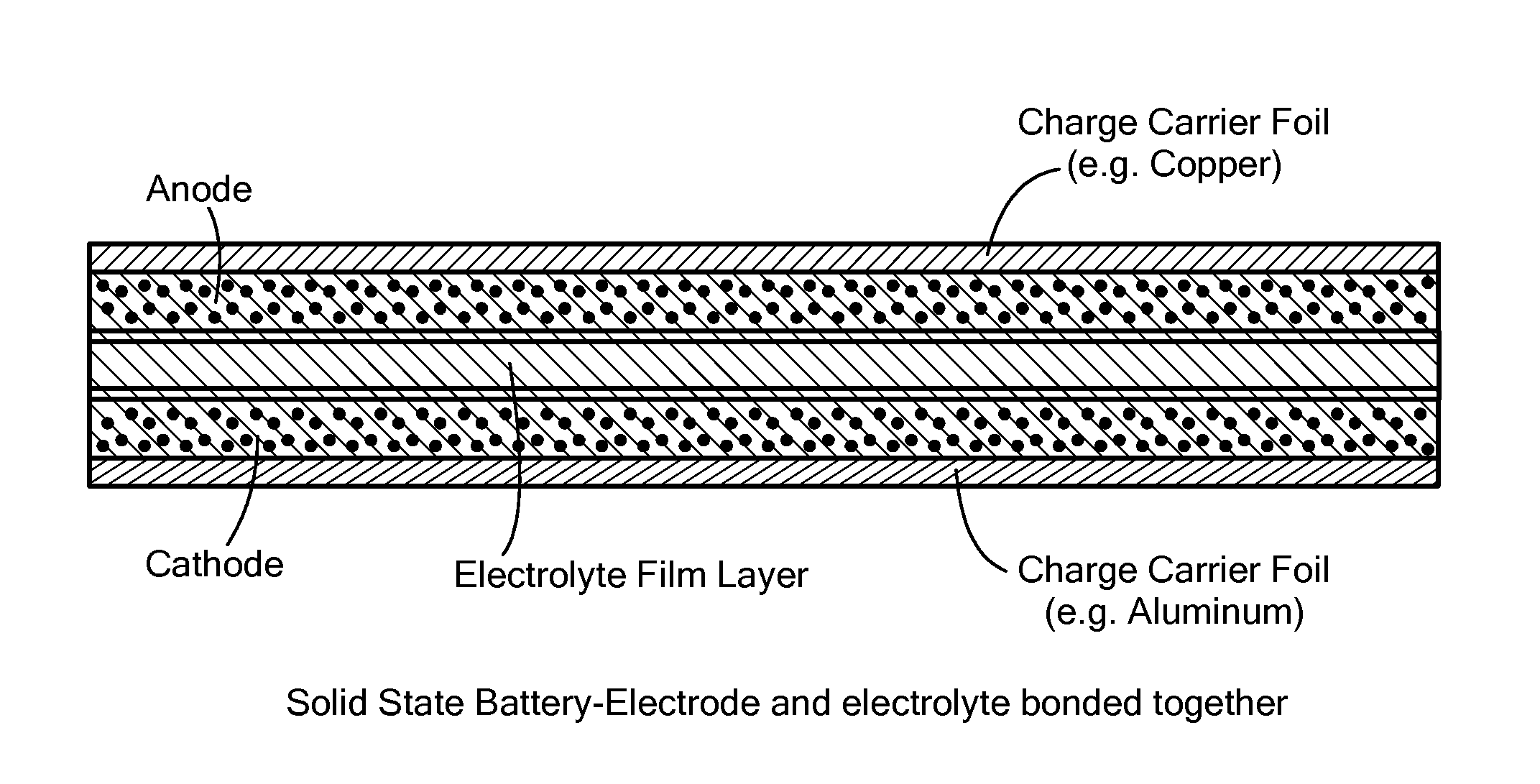

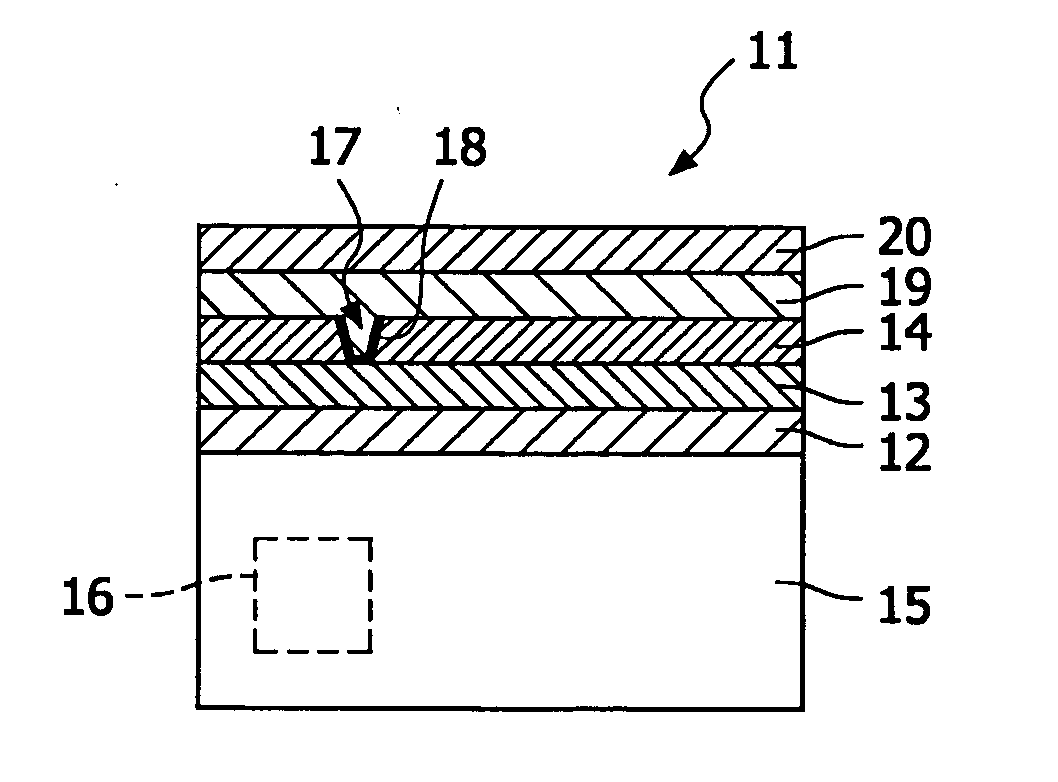

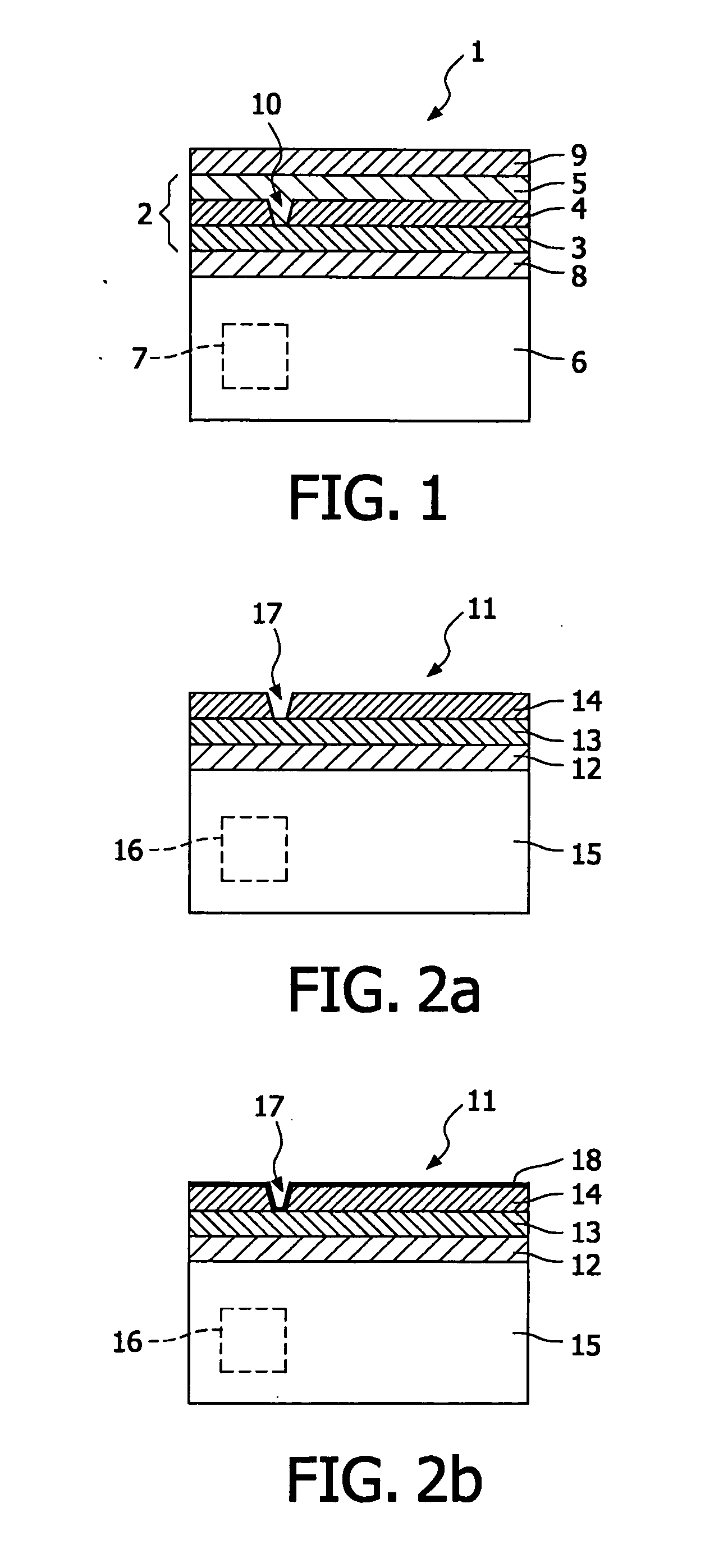

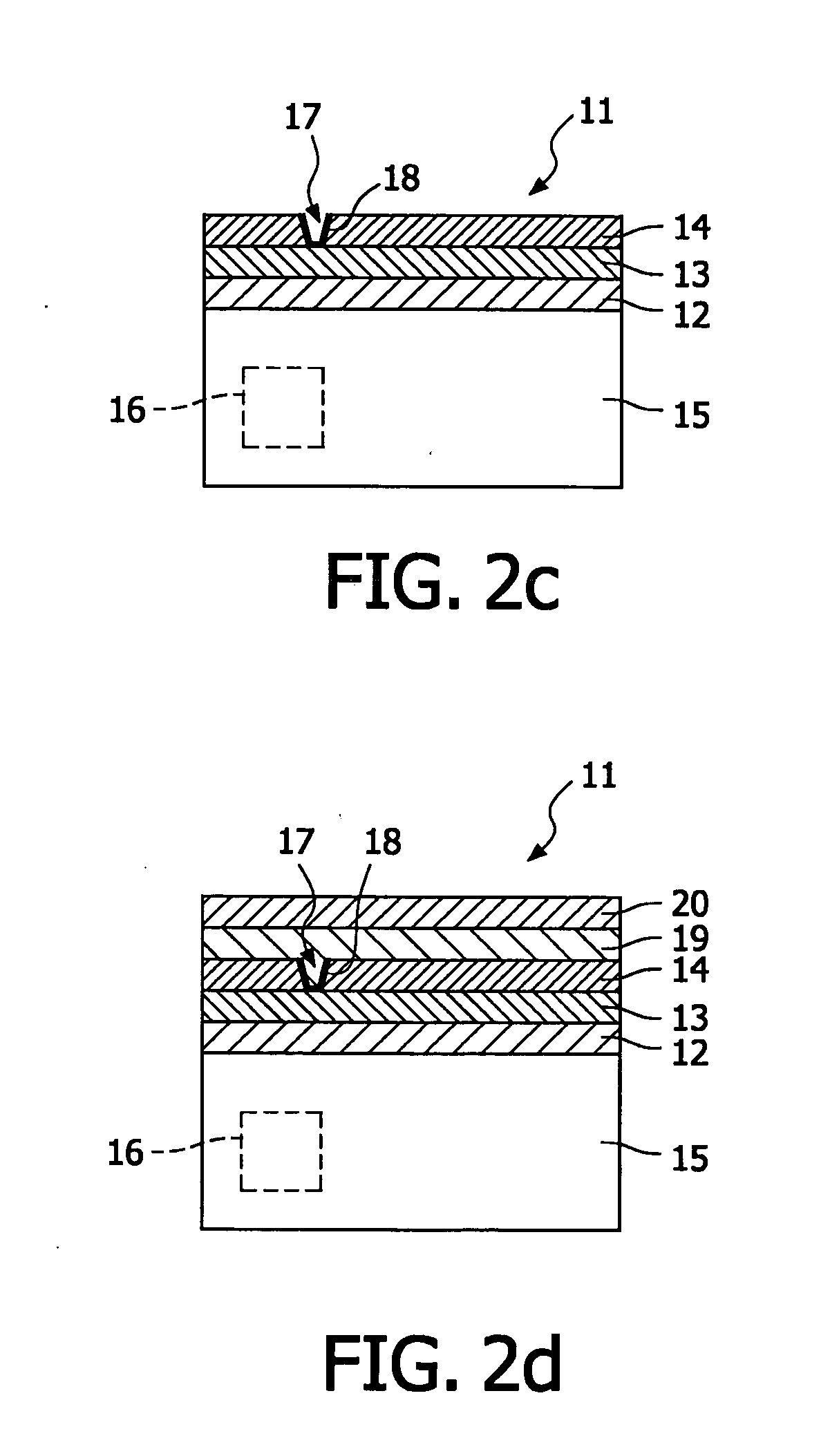

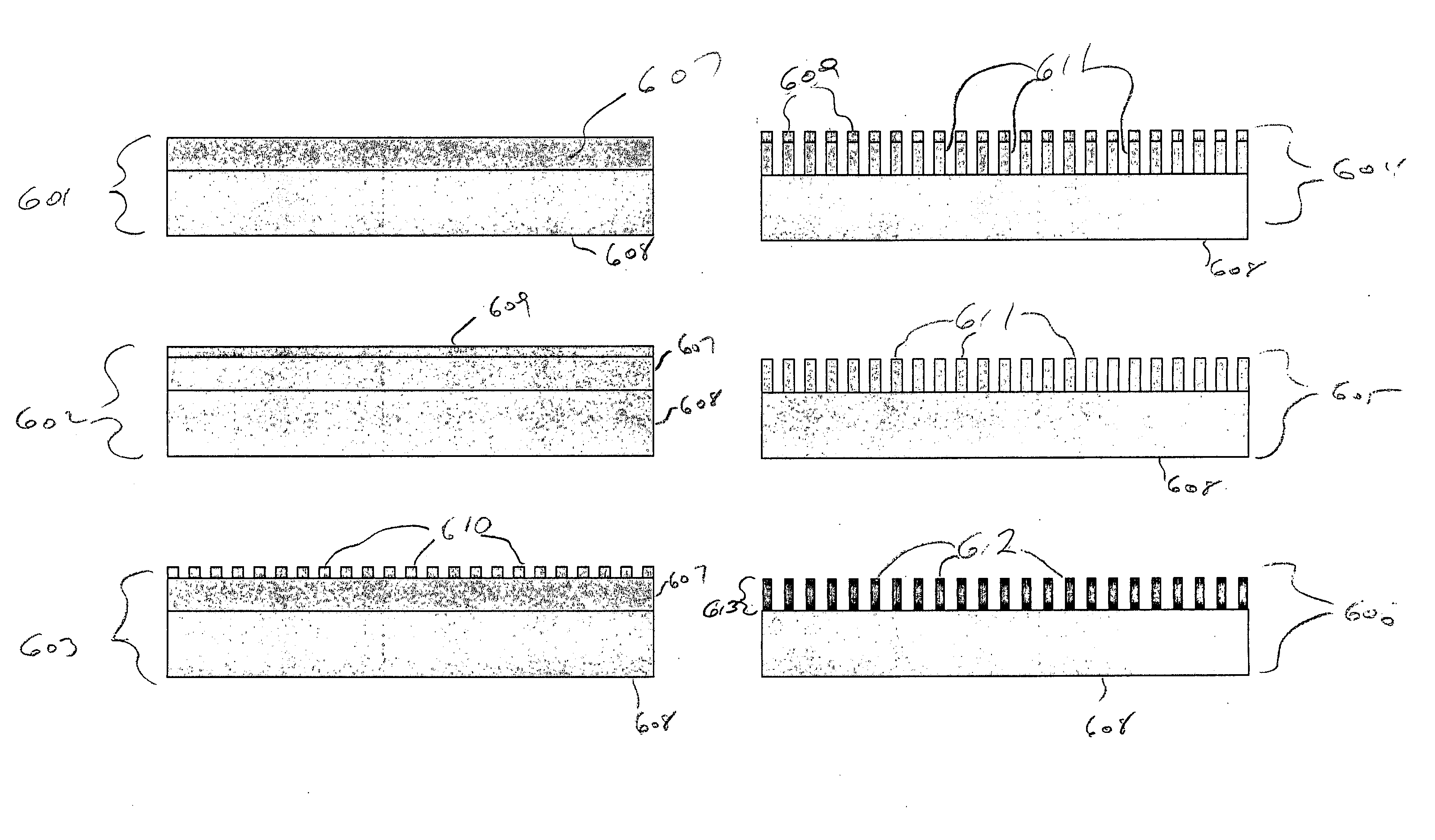

Solid-state battery and method for manufacturing of such a solid-state battery

InactiveUS20100233548A1Lower impedanceImprove battery performanceFinal product manufactureElectrode carriers/collectorsSolid state electrolyteElectricity

Batteries based on solid-state electrolytes are known in the art. These (planar) energy sources, or solid-state batteries, efficiently convert chemical energy into electrical energy and can be used as the power sources for portable electronics. The invention relates to a method for manufacturing of a solid-state battery in which the pinholes in a solid electrolyte are at least partially filled by the deposition of an electrically insulating layers. The invention also relates to a battery obtained by performing such a method. The invention further relates to an electronic device provided with such a battery.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

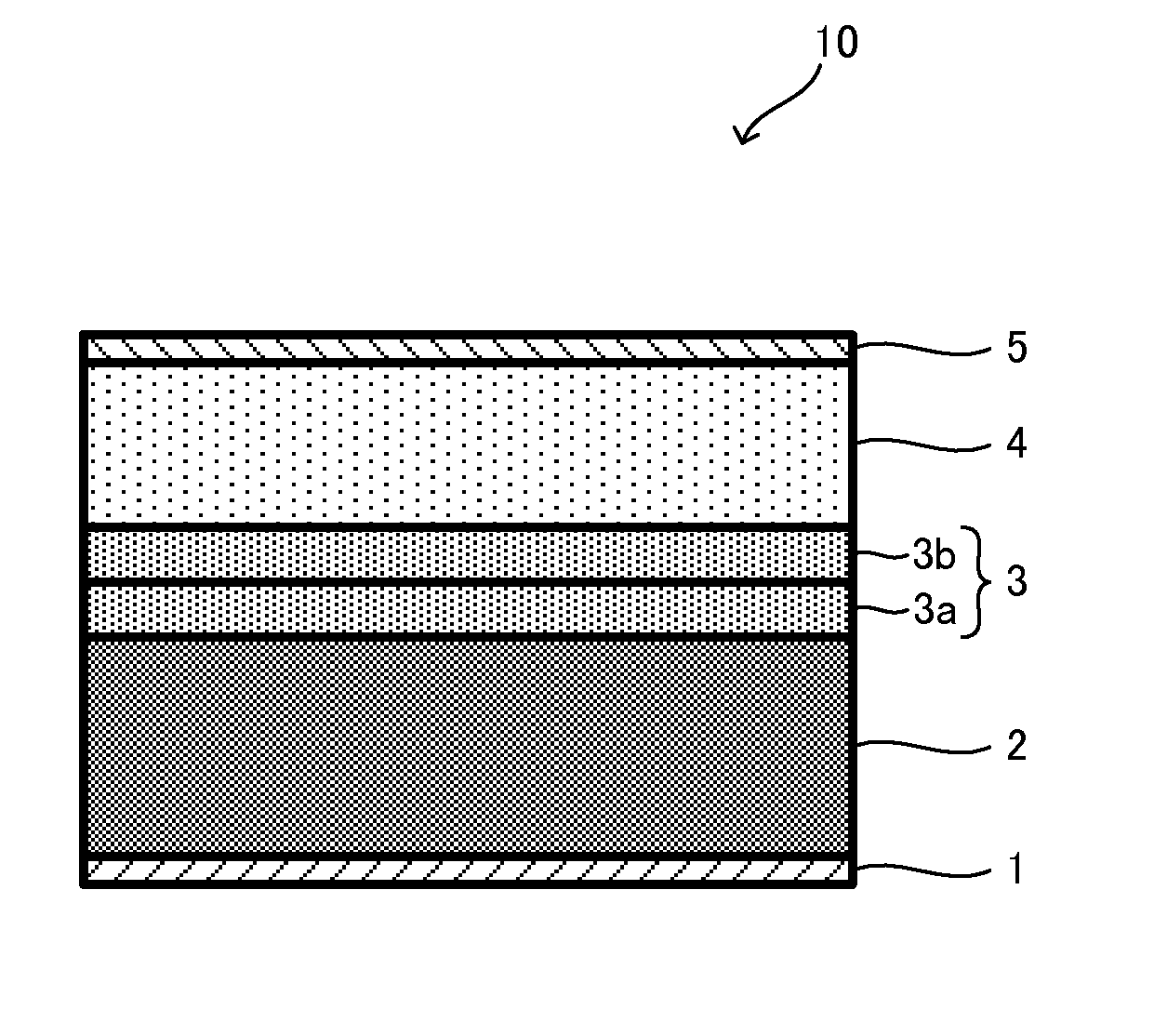

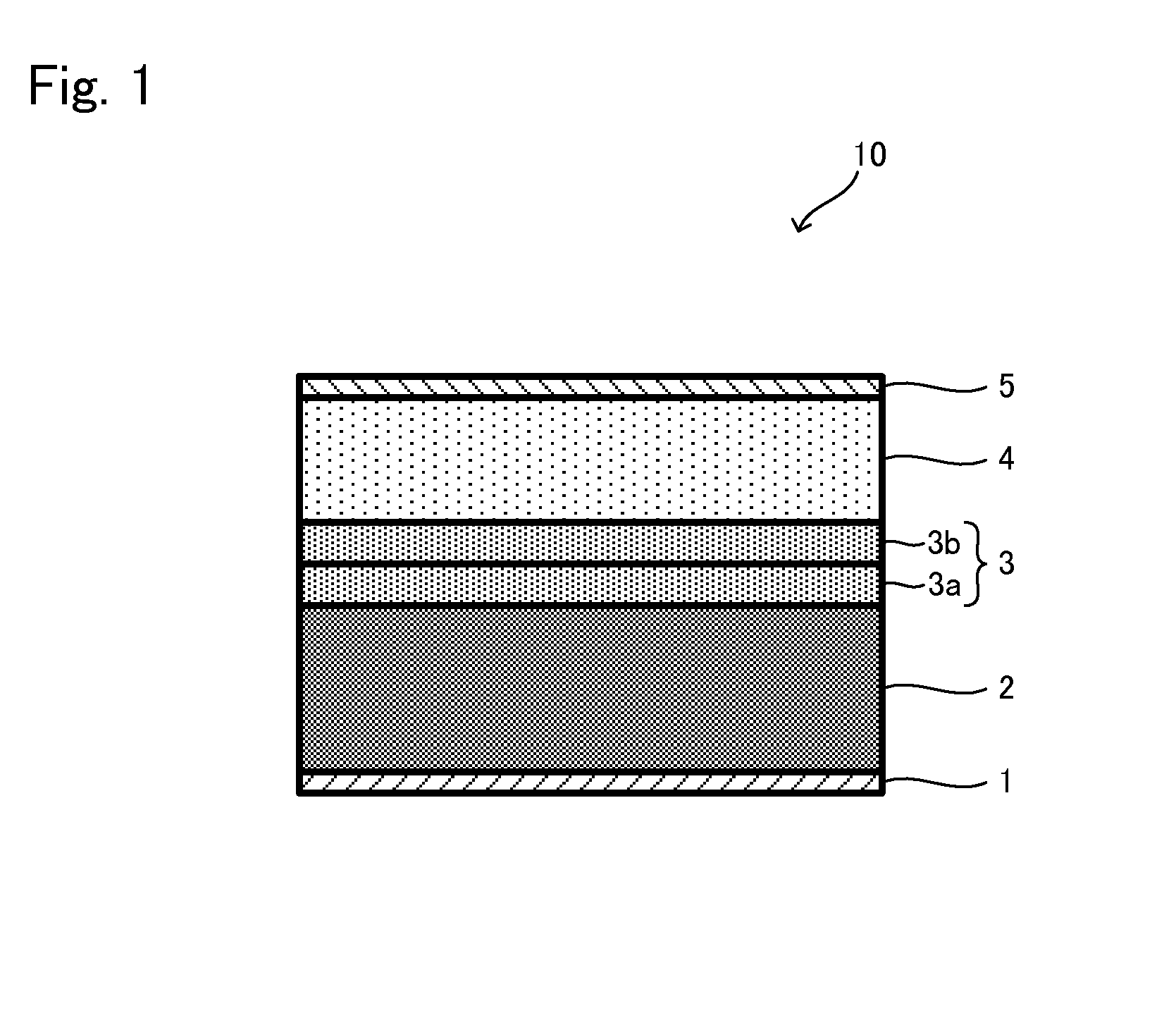

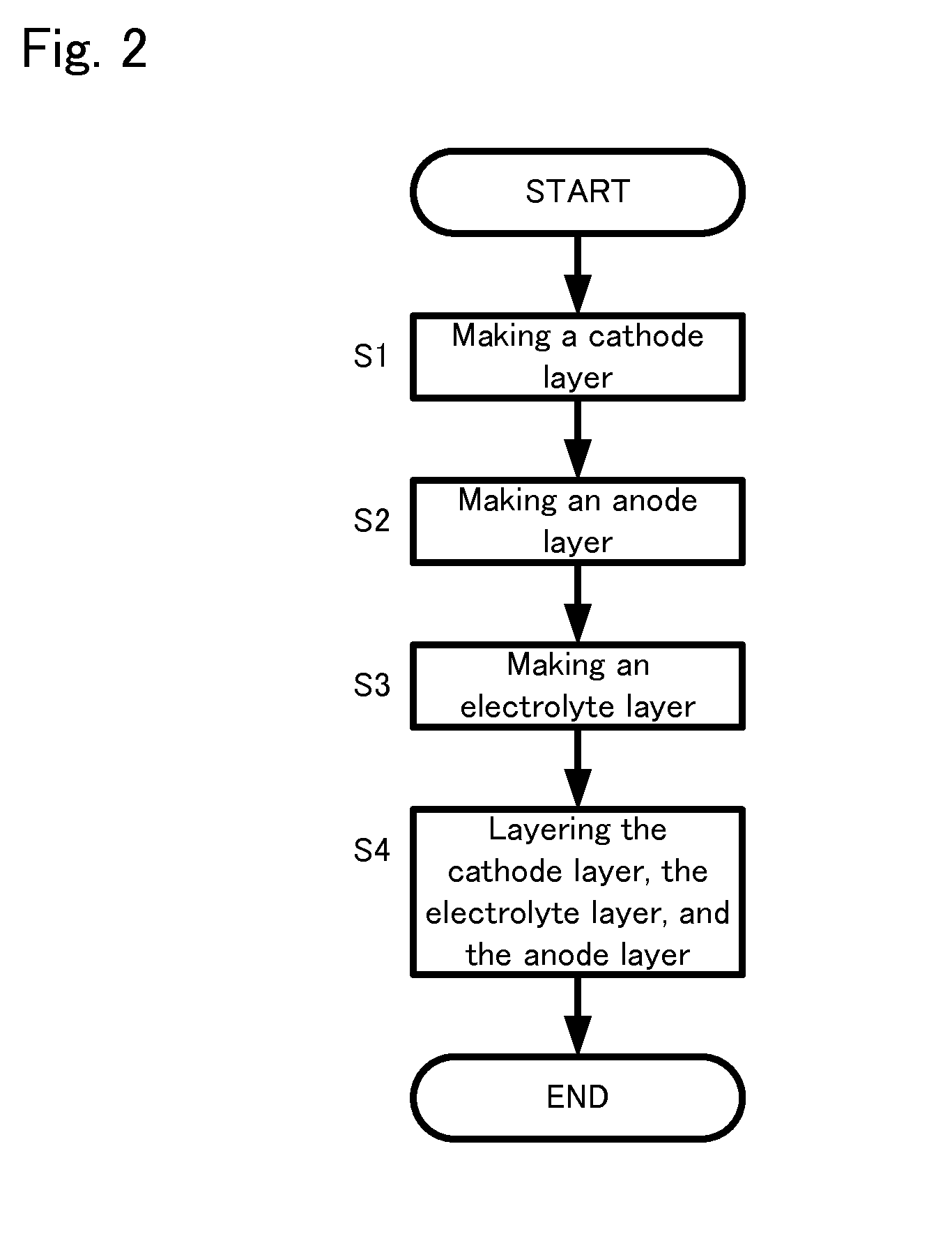

All-solid-state battery and method for manufacturing the same

An all-solid-state battery including a cathode layer, an anode layer, and an electrolyte layer arranged between the cathode layer and the anode layer, the electrolyte layer including a first solid electrolyte layer including a sulfide solid electrolyte, and a second solid electrolyte layer other than the first solid electrolyte layer, the electrolyte layer including the sulfide solid electrolyte. Also provided is a method for manufacturing an all-solid-state battery including the steps of (a) making a cathode layer, (b) making an anode layer, (c) making an electrolyte layer including a first solid electrolyte layer including a sulfide solid electrolyte and a second solid electrolyte including the sulfide solid electrolyte, and (d) layering the cathode layer, the electrolyte layer, and the anode layer, such that the electrolyte layer is arranged between the cathode layer and the anode layer.

Owner:TOYOTA JIDOSHA KK

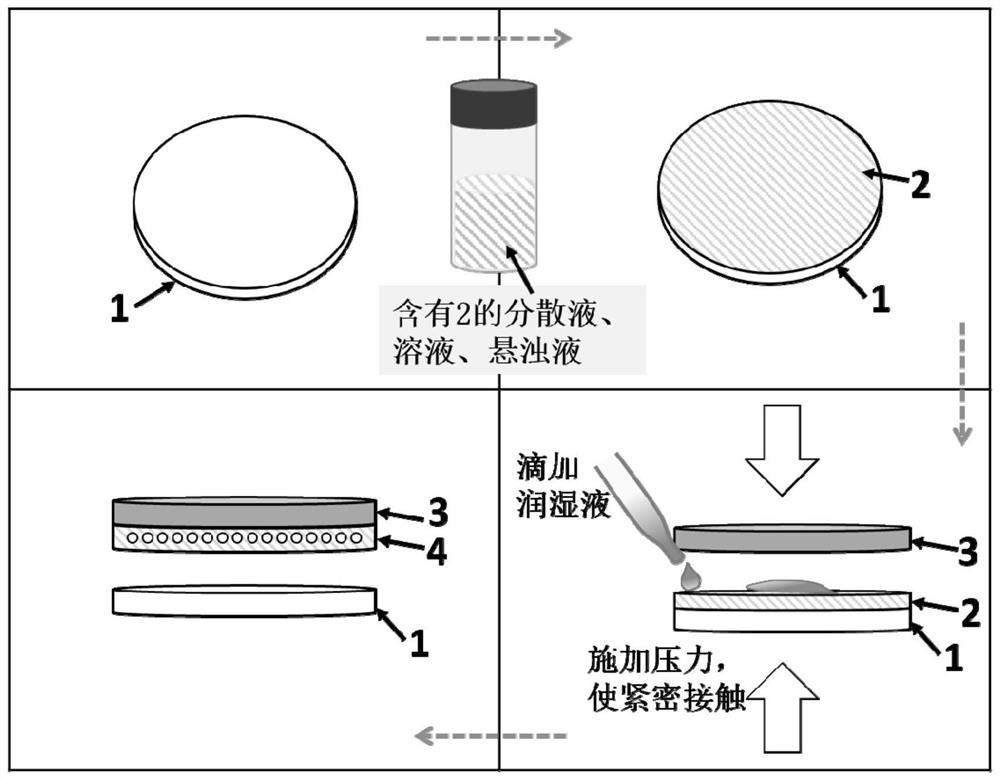

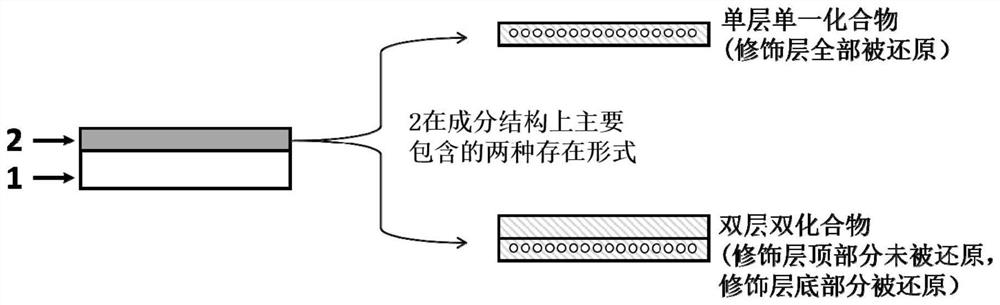

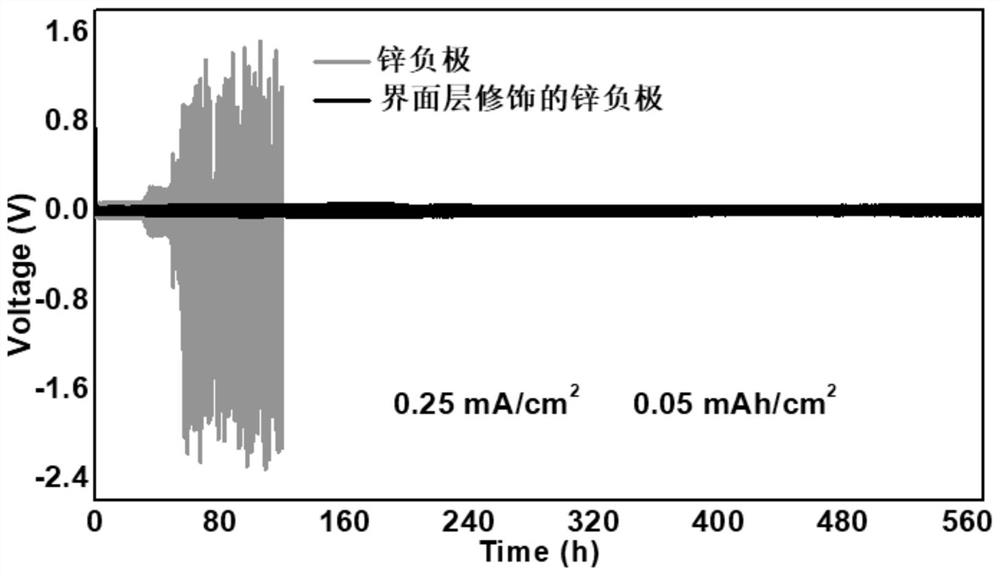

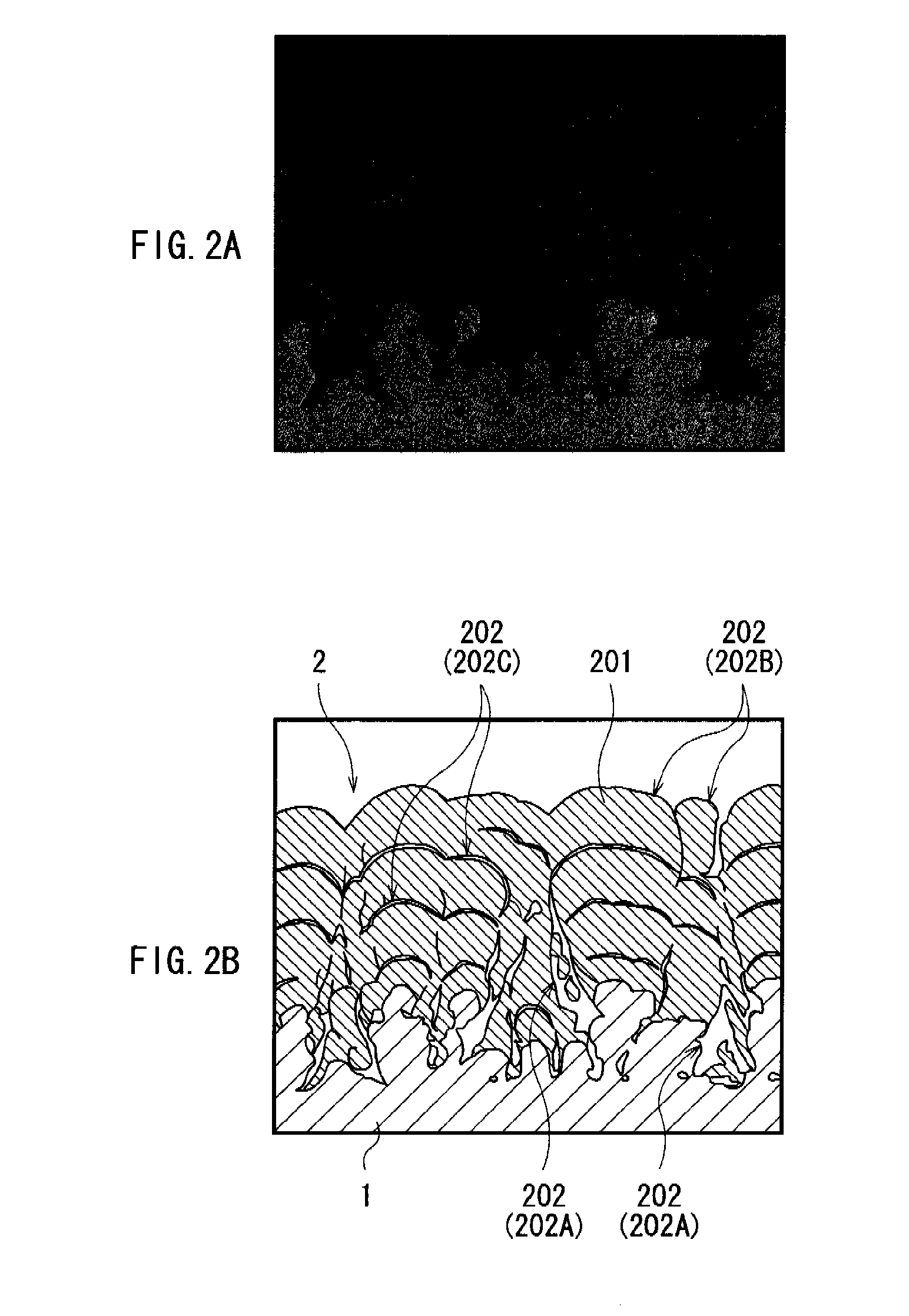

Zinc negative electrode with zinc ion conductivity interface modification layer, battery and preparation method

ActiveCN111933912AImprove Interface StabilitySolve the large interface impedanceSecondary cellsChemical electrode manufacturingElectrical batteryZinc ion

The invention provides a zinc negative electrode with a zinc ion conductivity interface modification layer, a battery and a preparation method, and belongs to the field of aqueous zinc battery metal zinc cathodes. The preparation method comprises: in air atmosphere, pre-constructing an interface modification material M on a base membrane; in a soaking environment by a wetting liquid, the interfacemodification material M layer on the base film being in close contact with the metal zinc to form the short-circuit primary battery, and the contacted interface modification material M and the metalzinc having spontaneous redox reaction, to make the interface modification material convert to ZnxM with zinc ion conductivity from M, meanwhile, transferring the interface modification material layerto the surface of the metal zinc negative electrode from the base film, and finally, obtaining the metal zinc negative electrode with the ZnxM interface modification layer with zinc ion conductivityon the surface. The ZnxM interface modification layer with the zinc ion conductivity can effectively inhibit dendritic crystal growth of a zinc negative electrode during charging and discharging of azinc battery, so that the interface stability of a metal zinc negative electrode is improved, and meanwhile, the cycling stability of a water-based zinc battery is improved. The method is simple and has a good actual effect.

Owner:HUAZHONG UNIV OF SCI & TECH

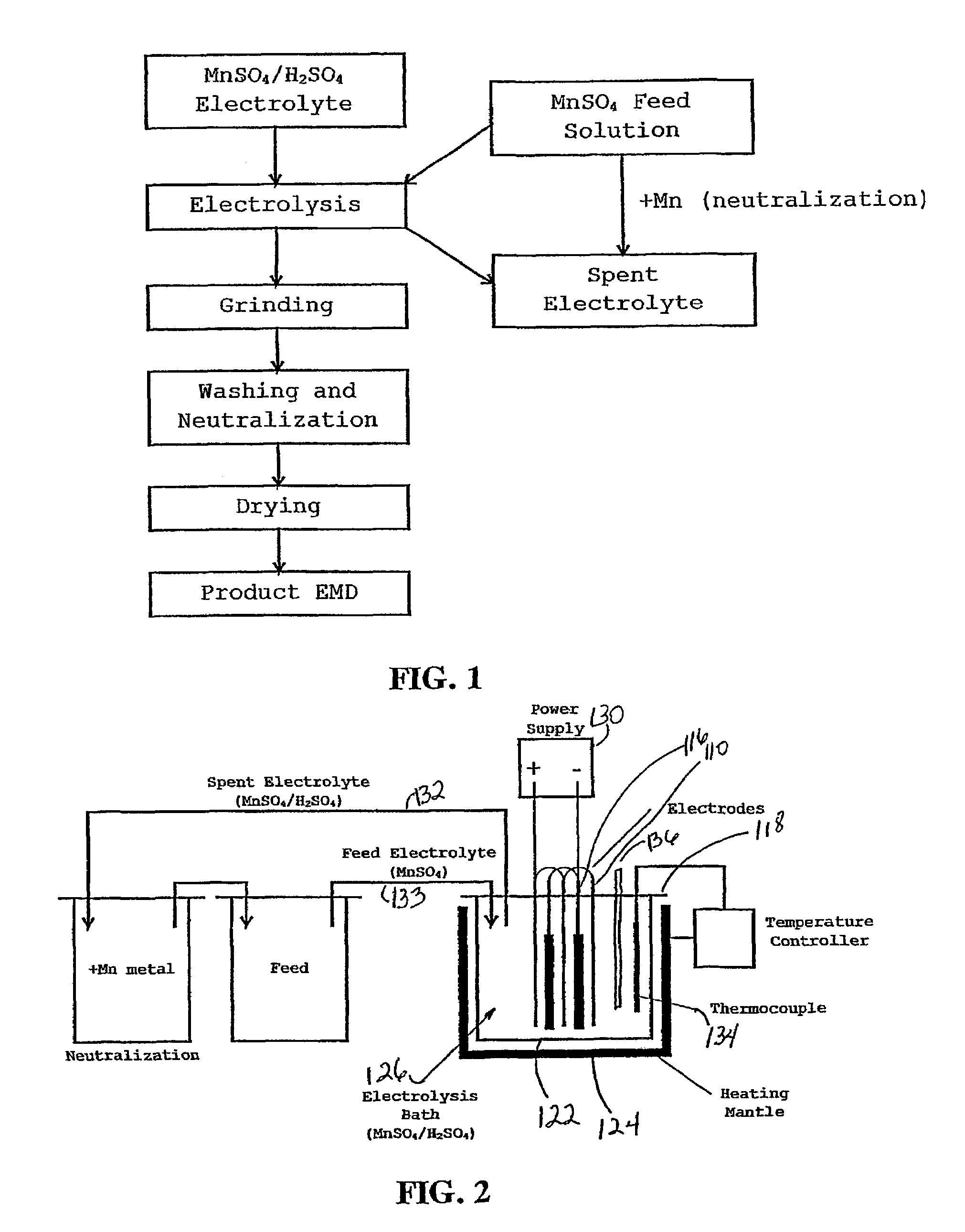

Doped manganese dioxides

InactiveUS7501208B2Improve electrochemical performanceAlkaline accumulatorsElectrochemical processing of electrodesDopantSulfate

An active manganese dioxide electrode material that exhibits improved electrochemical performances compared with conventional manganese dioxide materials includes at least one dopant. The doped manganese dioxide electrode materials may be produced by a wet chemical method (CMD) or may be prepared electrolytically (EMD) using a solution containing manganese sulfate, sulfuric acid, and a dopant, wherein the dopant is present in an amount of at least about 25 ppm.

Owner:ENERGIZER BRANDS

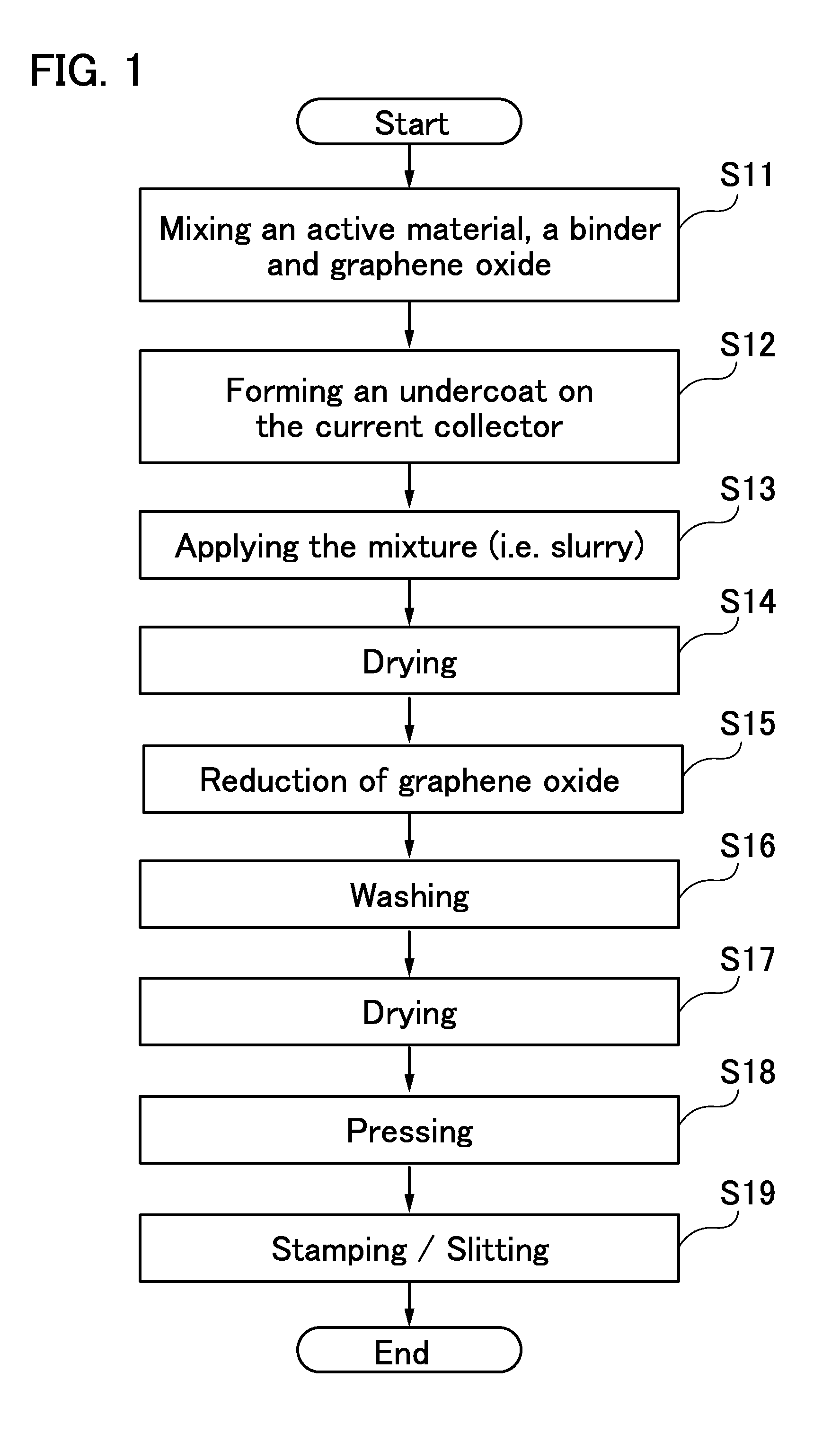

Method for forming negative electrode and method for manufacturing lithium secondary battery

ActiveUS20130212879A1Improve electrical characteristicsReduce the number of stepsContact member manufacturingElectrode thermal treatmentLithiumSlurry

The number of steps is reduced in the formation process of an electrode. Deterioration of the electrode is suppressed. A highly reliable lithium secondary battery is provided by suppressing the deterioration of the electrode. A method for forming a negative electrode and a method for manufacturing a lithium secondary battery including the negative electrode are provided. In the method for forming the negative electrode, graphene oxide, a plurality of particulate negative electrode active materials, and a precursor of polyimide are mixed to form slurry; the slurry is applied over a negative electrode current collector; and the slurry applied over the negative electrode current collector is heated at a temperature higher than or equal to 200° C. and lower than or equal to 400° C. so that the precursor of the polyimide is imidized. The graphene oxide is reduced in heating the slurry to imidize the precursor of the polyimide.

Owner:SEMICON ENERGY LAB CO LTD

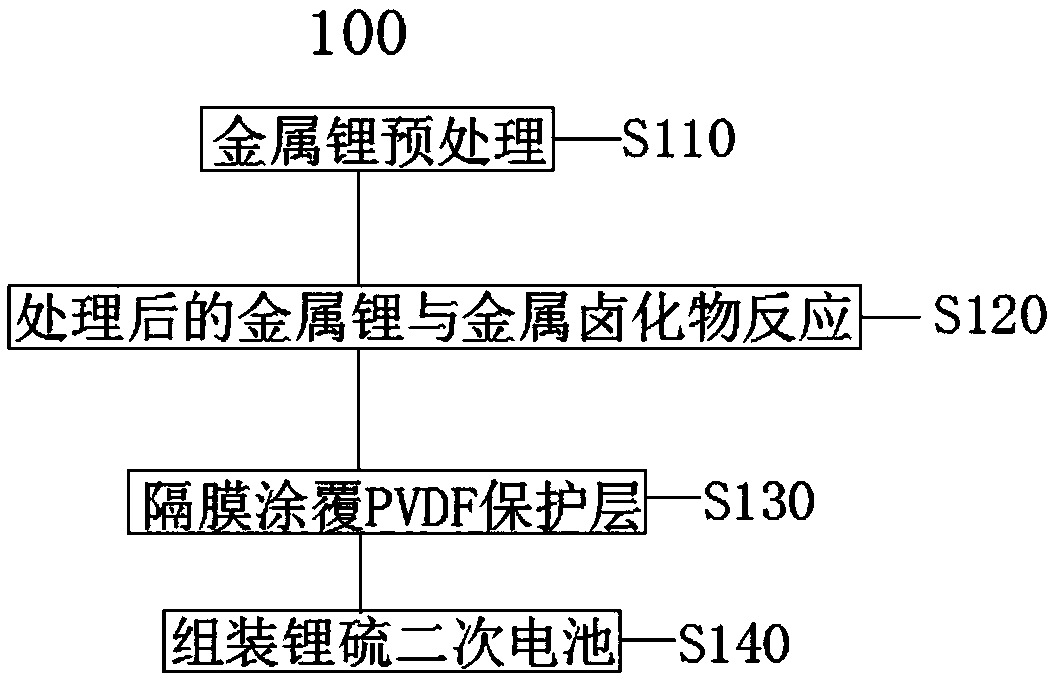

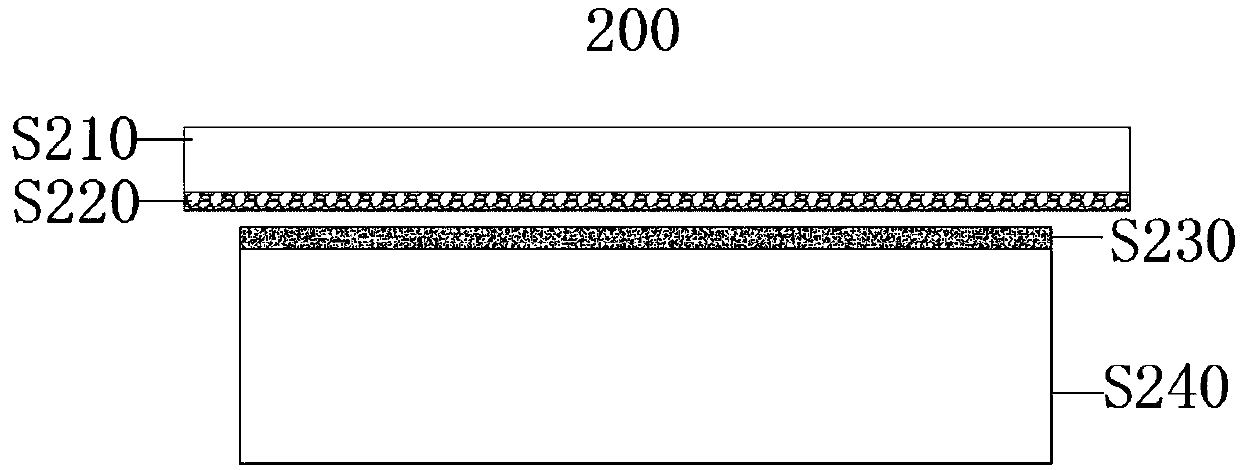

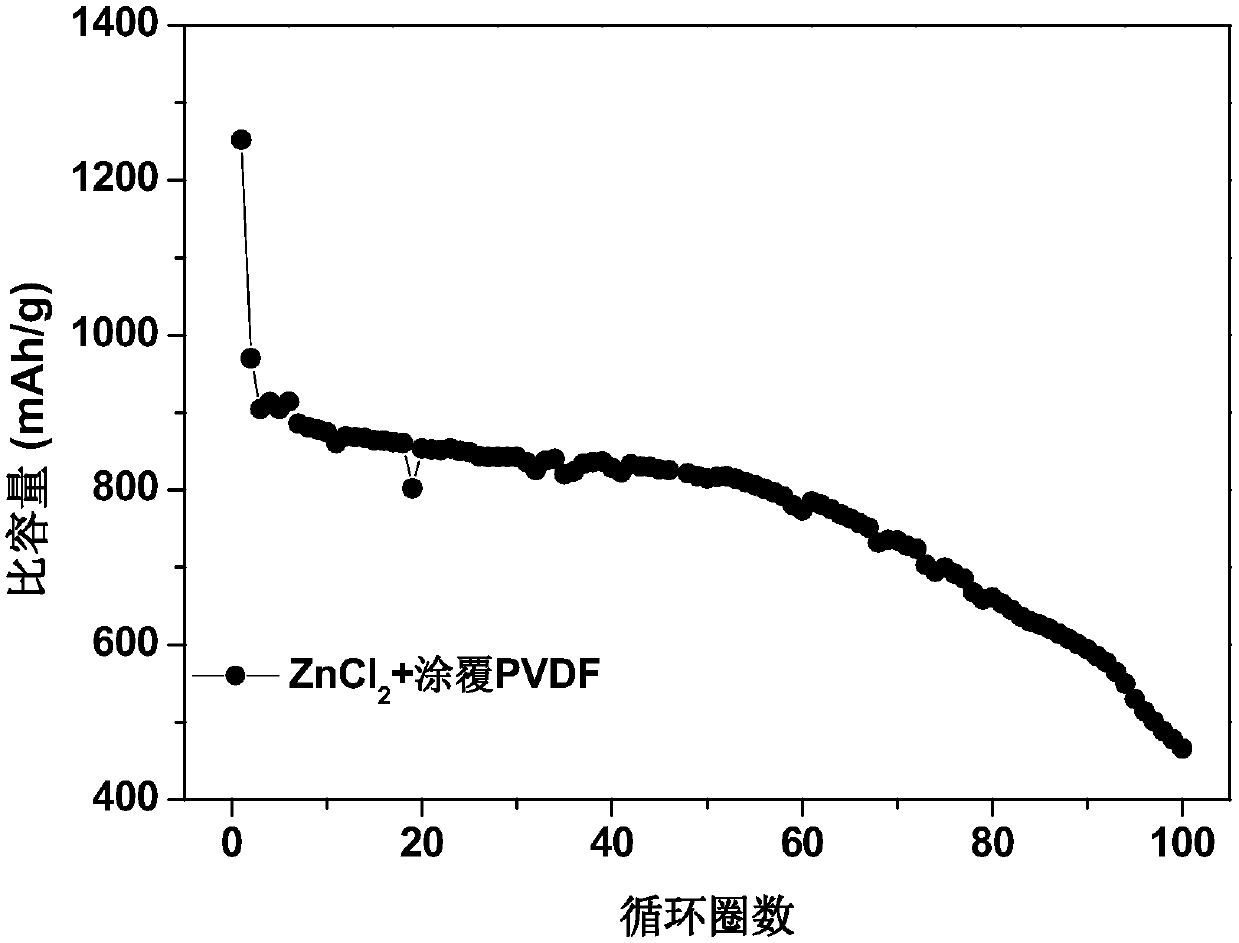

Lithium metal negative electrode dual protection method and application

ActiveCN109585947AImprove controllabilityImprove ionic conductivityCell seperators/membranes/diaphragms/spacersChemical electrode manufacturingAlloyDendrite

The invention discloses a lithium metal negative electrode dual protection method and application. The method comprises the steps of: infiltrating a lithium metal negative electrode in a mixture of ametal halide and an additive, and forming a composite protective layer in situ on the surface of the lithium metal negative electrode, wherein the composite protective layer comprises combination of an alloy and an inorganic salt; and coating the surface of a membrane with an organic polymer solution to obtain a membrane having an inner surface coated with an elastic organic modifying layer. The lithium metal negative electrode dual protection method and application are simple to operate, high in controllability, low in raw material cost, easy to obtain the raw materials and low in cost, and can form a layer of stable composite protective layer at the surface of the lithium metal negative electrode. The protective layer can effectively inhibit the growth of the lithium dendrites and can reduce the side reaction generated by contact of the lithium metal negative electrode and the electrolyte, and the obtained modified lithium metal negative electrode is stable in cycle performance to effectively inhibit the generation of the dendrites of the lithium metal negative electrode and can be widely applied to the novel high specific energy electrochemical energy storage device, such as a lithium ion battery and a lithium-sulfur battery.

Owner:安徽盟维新能源科技有限公司

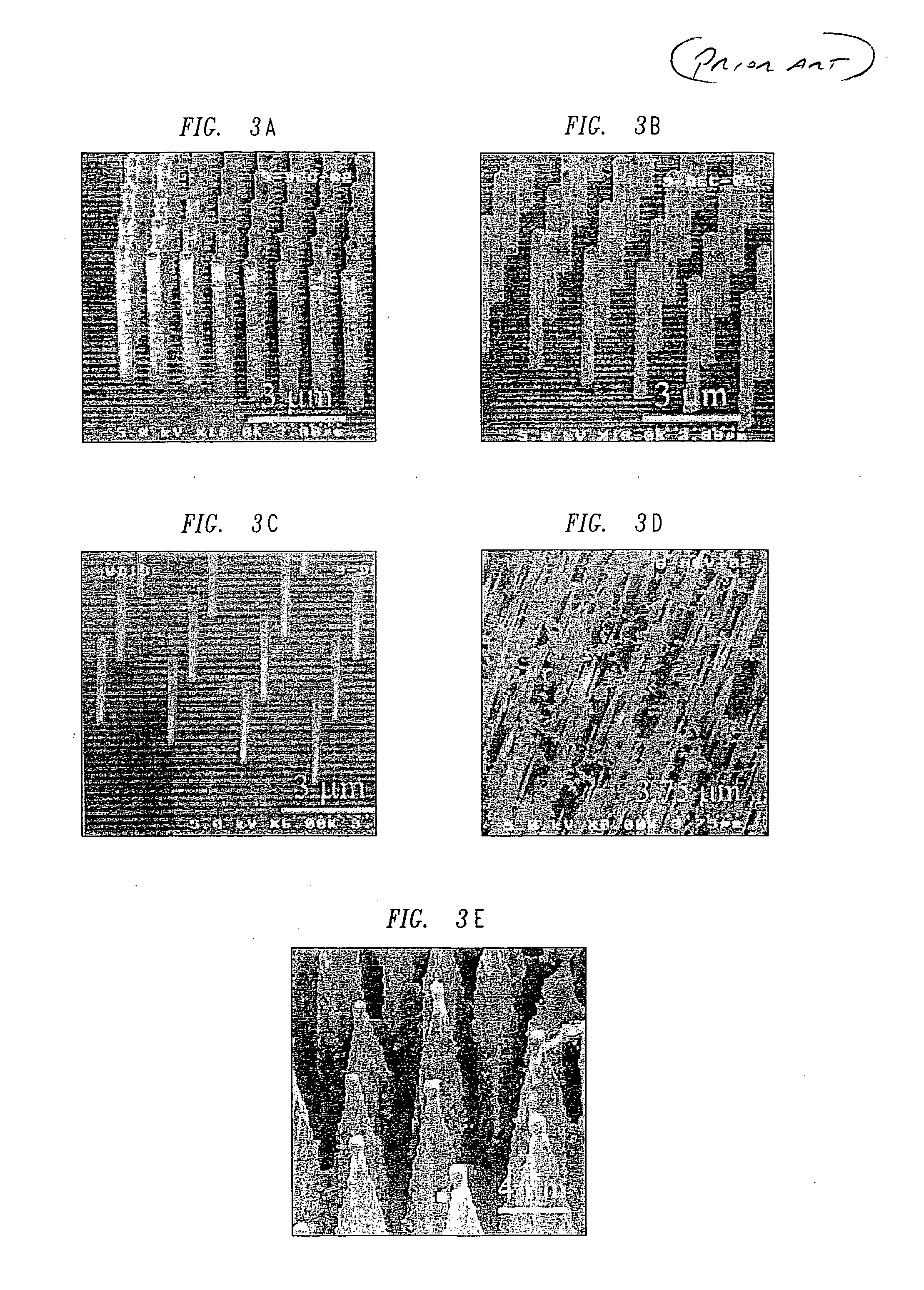

A method of fabricating structured particles composed of silicon or a silicon-based material and their use in lithium rechargeable batteries

InactiveUS20110269019A1Easy to operateReduce operating costsDecorative surface effectsSemiconductor/solid-state device manufacturingElectrical batteryLithium-ion battery

A process for etching silicon to form silicon pillars on the etched surfaces, includes treating silicon with an etching solution that includes 5 to 10M HF 0.01 to 0.1M Ag+ ions and 0.02 to 0.2M NO3− ions. Further, NO3− ions in the form of alkali metal, nitric acid or ammonium nitrate salt is added to maintain the concentration of nitrate ions within the above range. The etched silicon is separated from the solution. The process provides pillars, especially for use as the active anode material in lithium ion batteries. The process is advantageous because it uses an etching bath containing only a small number of ingredients whose concentration needs to be controlled and it can be less expensive to operate than previous processes.

Owner:NEXEON LTD

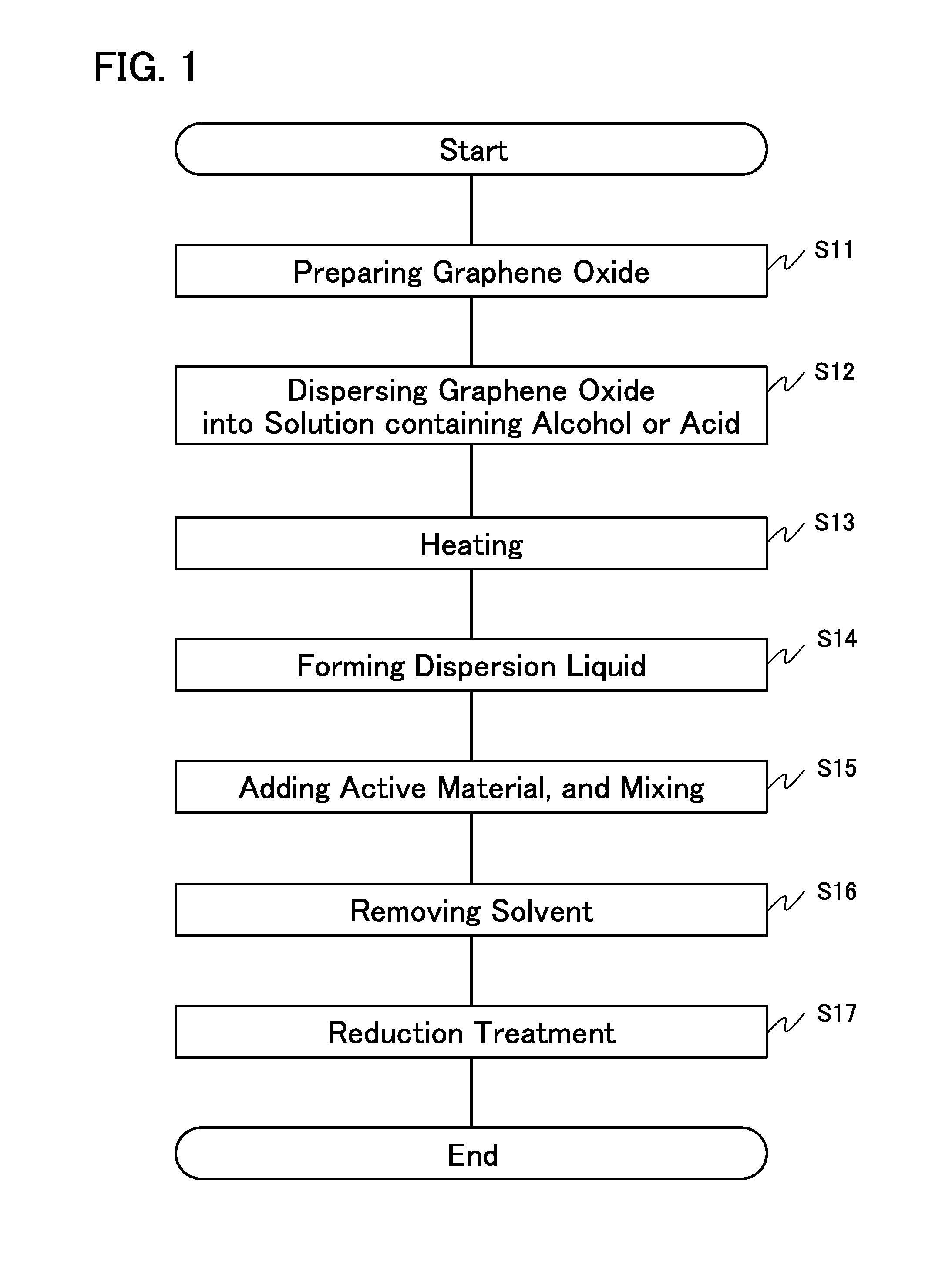

Storage battery electrode, manufacturing method thereof, storage battery, electronic device, and graphene

ActiveUS20160064726A1Good dispersionImprove electronic conductivityOrganic chemistryElectrode thermal treatmentAlcoholHigh electron

To provide graphene oxide that has high dispersibility and is easily reduced. To provide graphene with high electron conductivity. To provide a storage battery electrode including an active material layer with high electric conductivity and a manufacturing method thereof. To provide a storage battery with increased discharge capacity. A method for manufacturing a storage battery electrode that is to be provided includes a step of dispersing graphene oxide into a solution containing alcohol or acid, a step of heating the graphene oxide dispersed into the solution, and a step or reducing the graphene oxide.

Owner:SEMICON ENERGY LAB CO LTD

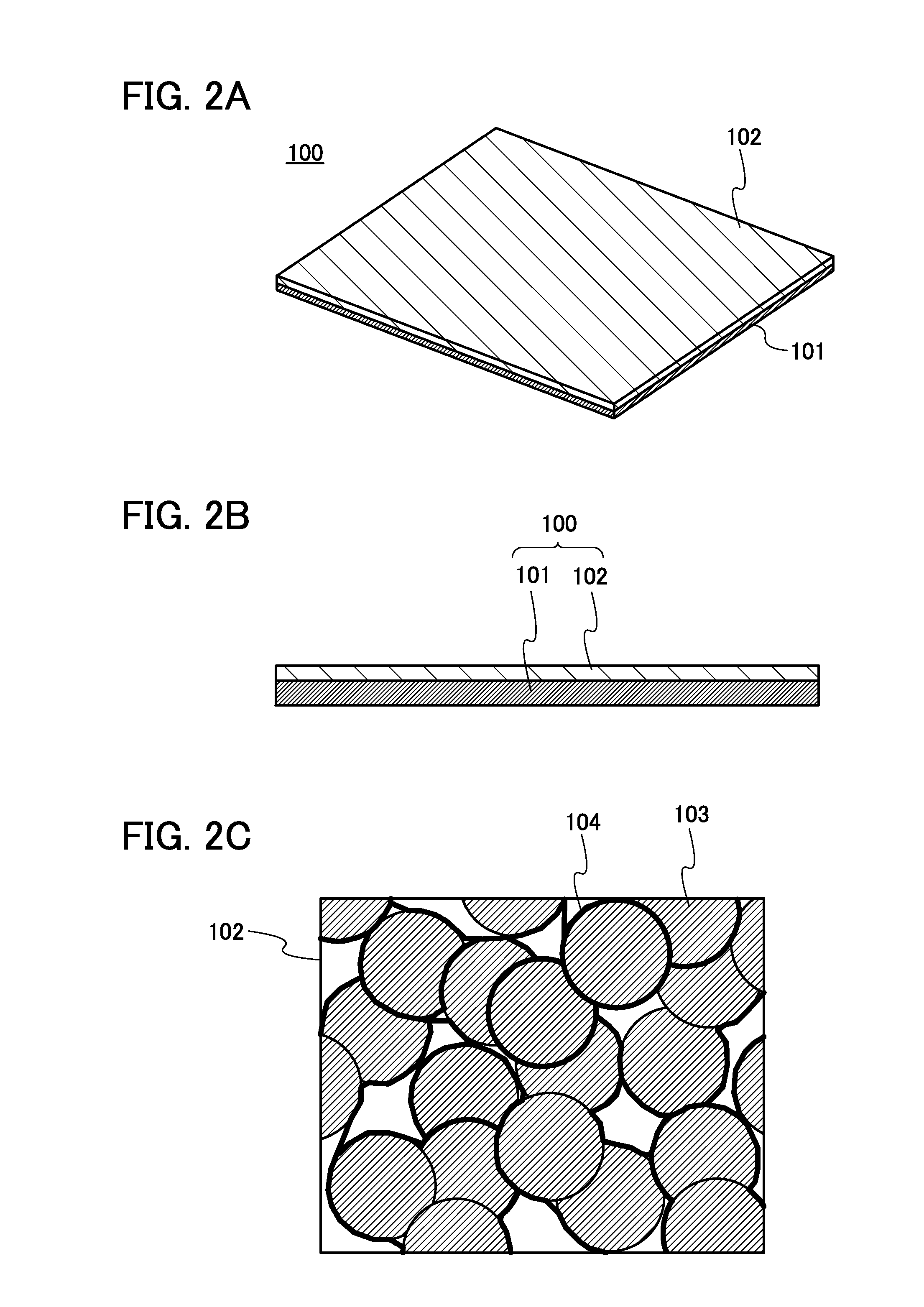

Method for manufacturing electrode for storage battery

ActiveUS20140295068A1High densityLarge capacityElectrode rolling/calenderingElectrode thermal treatmentHigh densitySlurry

To provide a storage battery electrode including an active material layer with high density that contains a smaller percentage of conductive additive. To provide a storage battery having a higher capacity per unit volume of an electrode with the use of the electrode for a storage battery. A slurry that contains an active material and graphene oxide is applied to a current collector and dried to form an active material layer over the current collector, the active material layer over the current collector is rolled up together with a spacer, and a rolled electrode which includes the spacer are immersed in a reducing solution so that graphene oxide is reduced.

Owner:SEMICON ENERGY LAB CO LTD

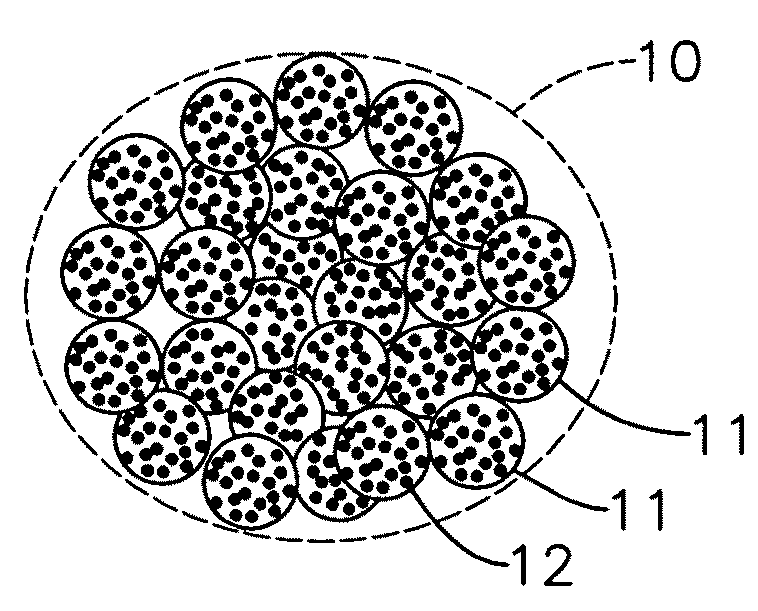

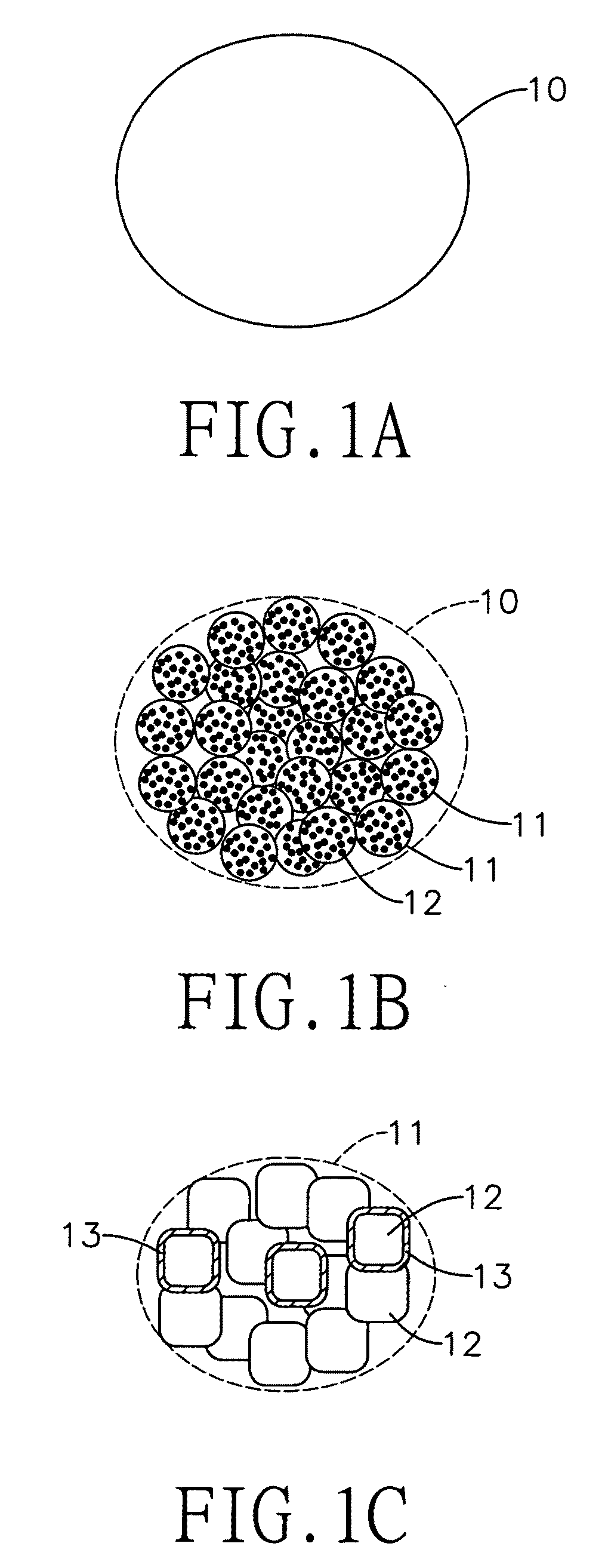

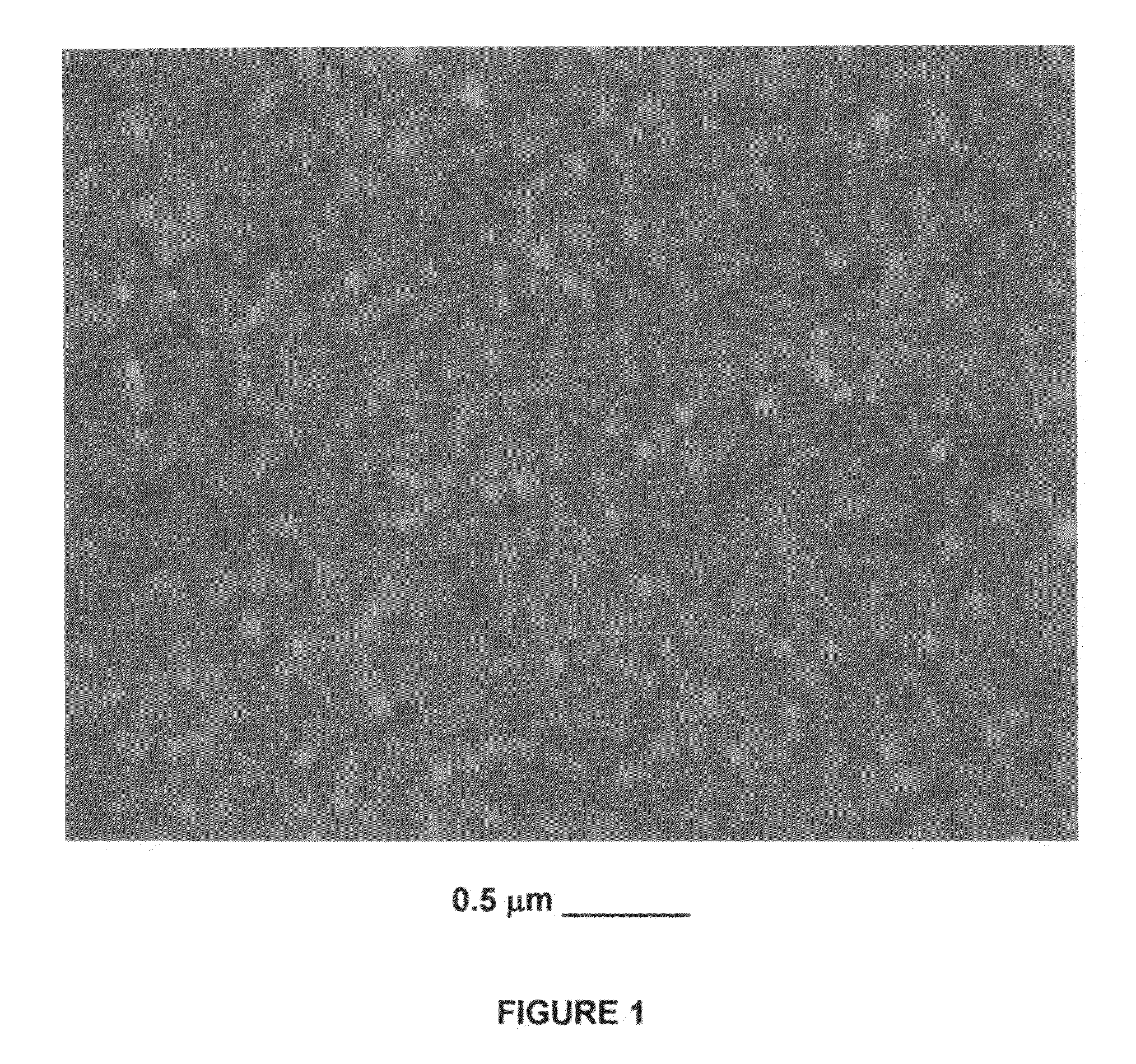

Cathode material particle

ActiveUS20090050859A1Improve securityConductive materialChemical electrode manufacturingHigh rateThermal stability

A cathode material particle comprising a plurality of cathode material cores and each cathode material core having plurality of grains and each grain being uniformly covered with a nano-metal oxide layer, wherein a thickness of the nano-metal oxide layer is 1 nm to 100 nm. The cathode material has excellent safety (good thermal stability), high-capacity, good cycleability and-high-rate charging or discharging capability.

Owner:IND TECH RES INST

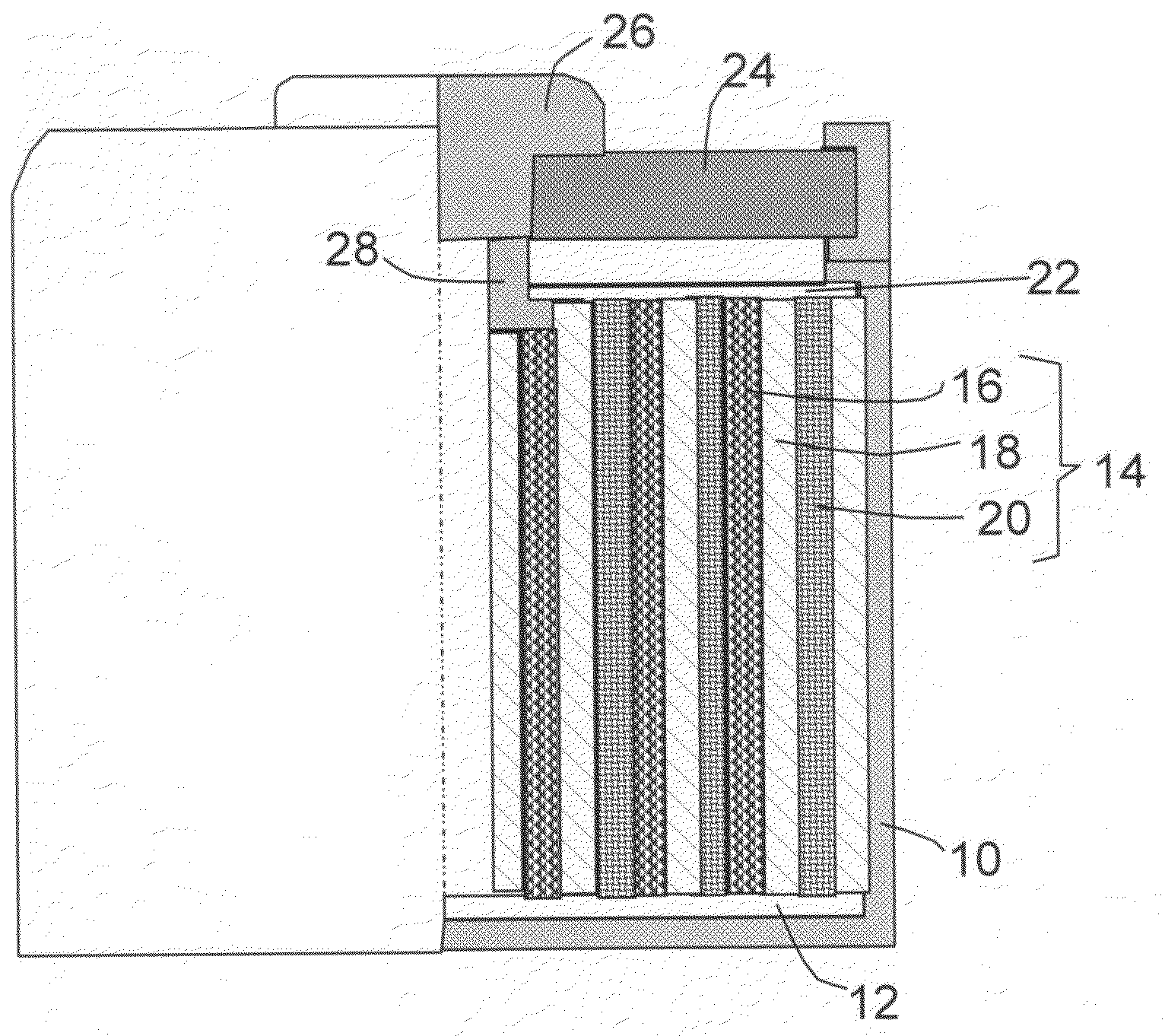

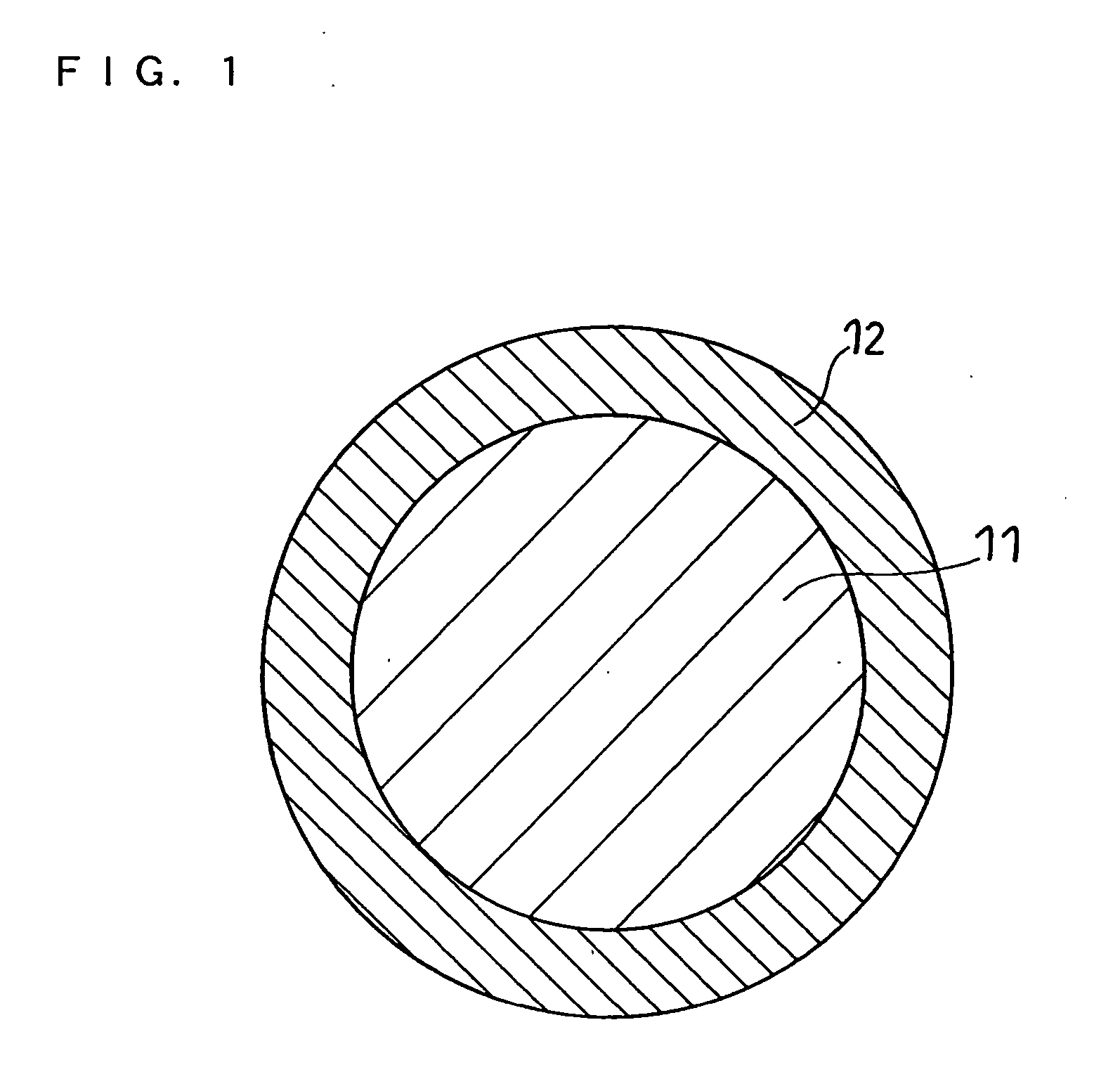

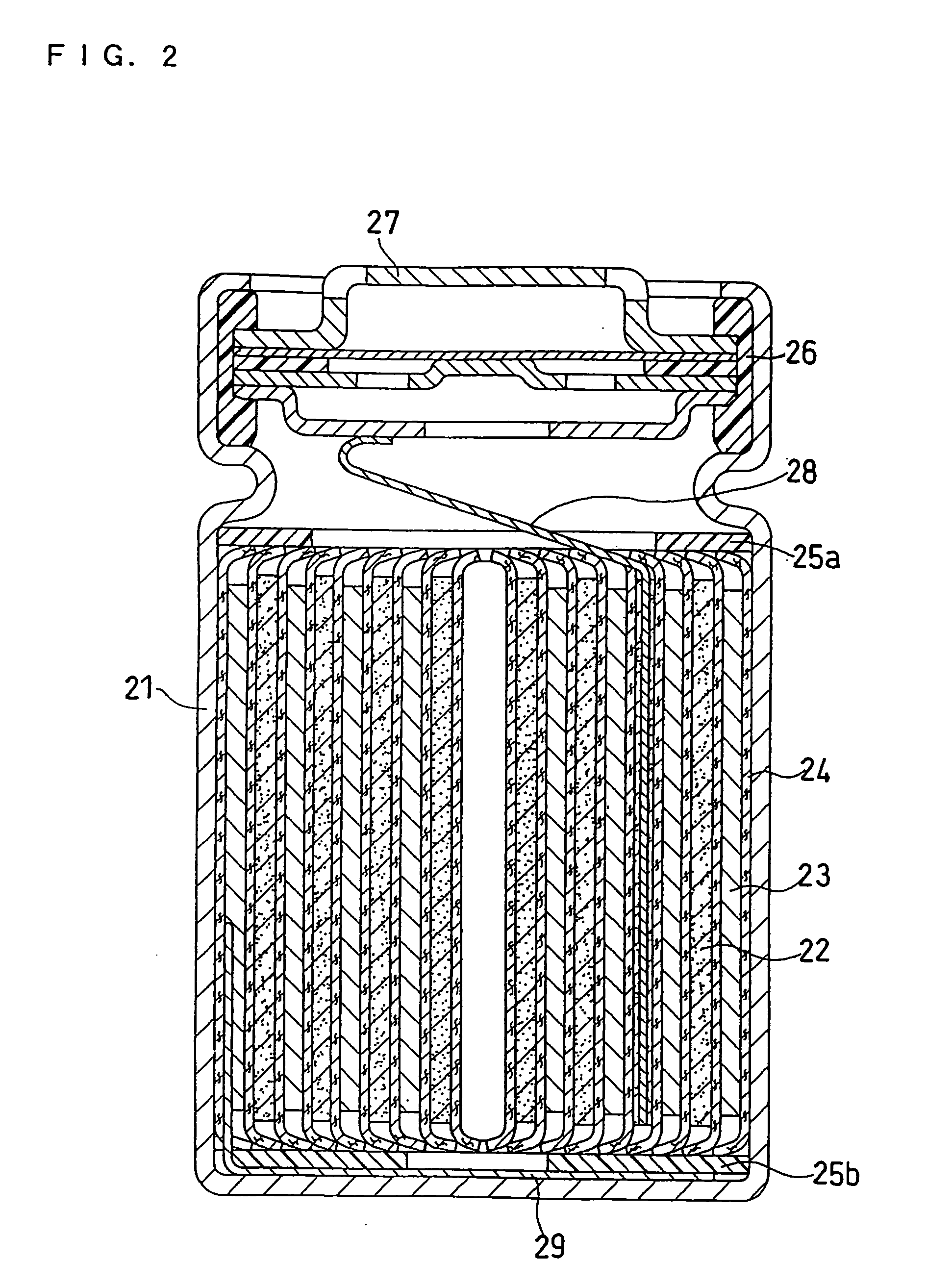

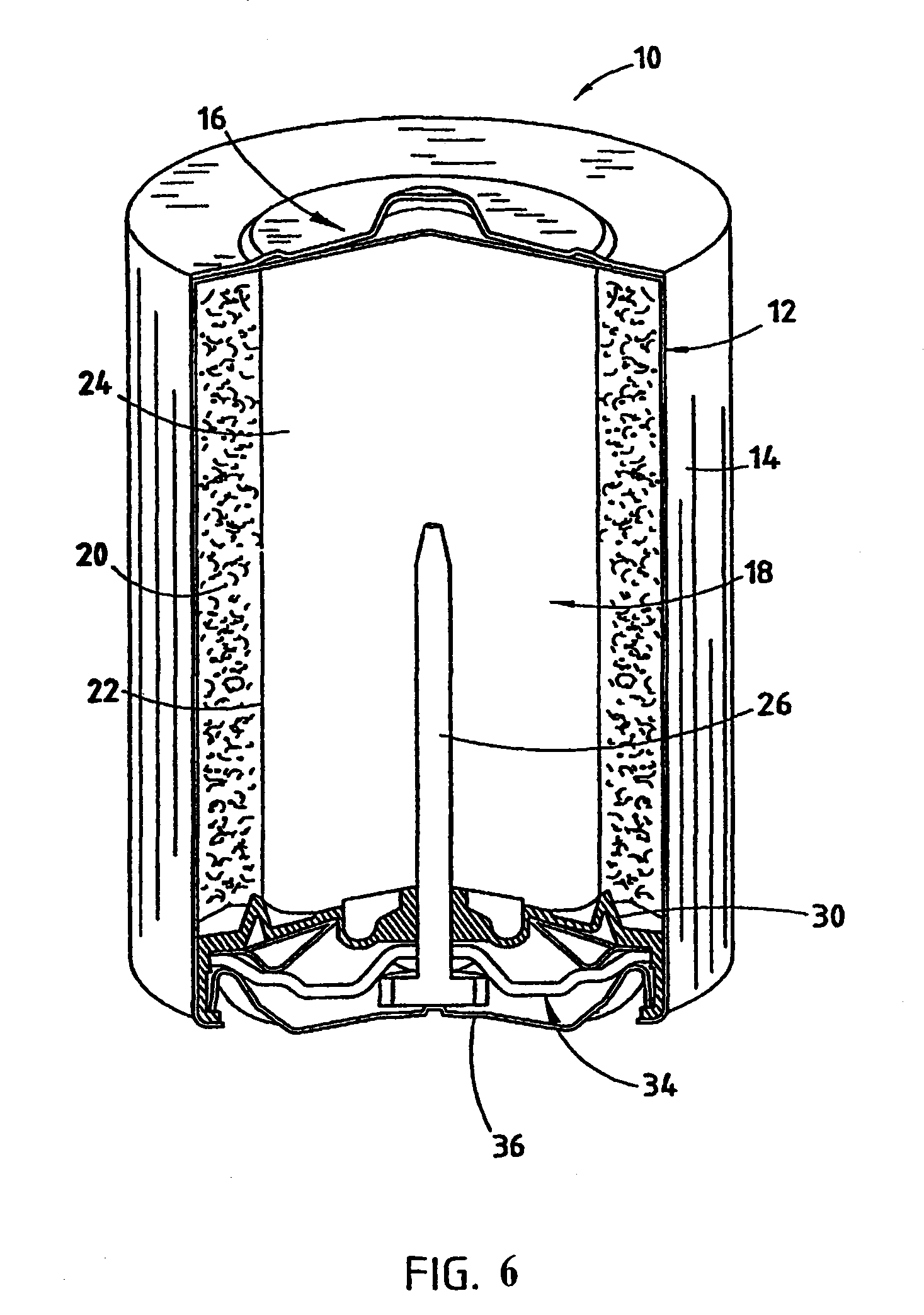

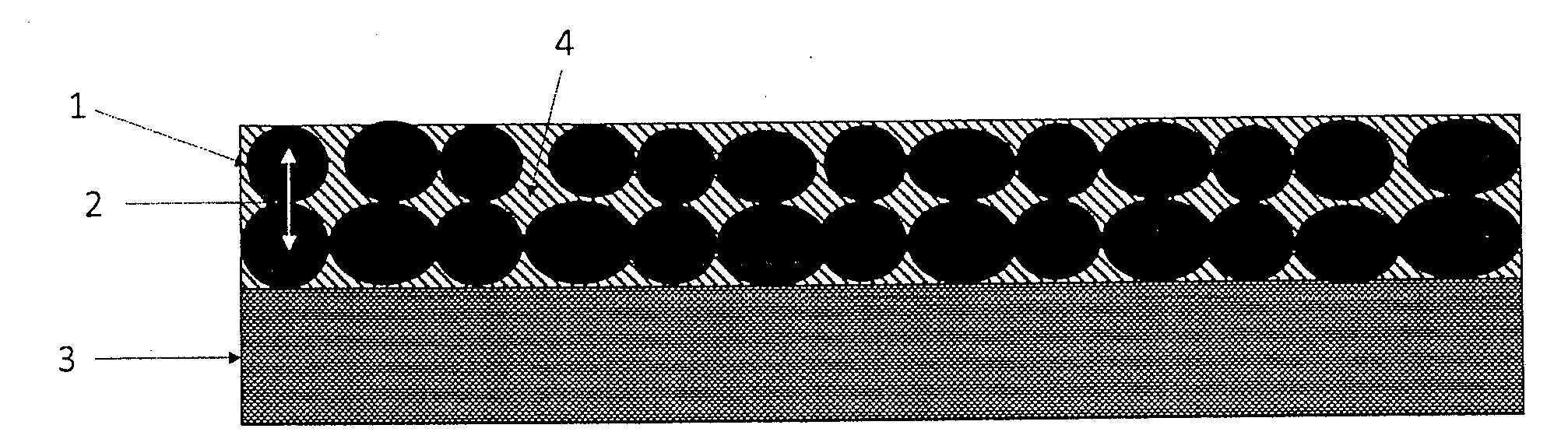

Anode and secondary battery

InactiveUS20080305395A1Small sizeImprove performanceElectrochemical processing of electrodesSmall-sized cells cases/jacketsSiliconPorosimetry

A battery capable of improving cycle characteristics is provided. An anode includes: an anode current collector, and an anode active material layer arranged on the anode current collector, in which the anode active material layer includes an anode active material including silicon (Si), and including a pore group with a diameter ranging from 3 nm to 50 nm both inclusive, and the volumetric capacity per unit weight of silicon of the pore group with a diameter ranging from 3 nm to 50 nm both inclusive is 0.2 cm3 / g or less, the volumetric capacity being measured by mercury porosimetry using a mercury porosimeter.

Owner:SONY CORP

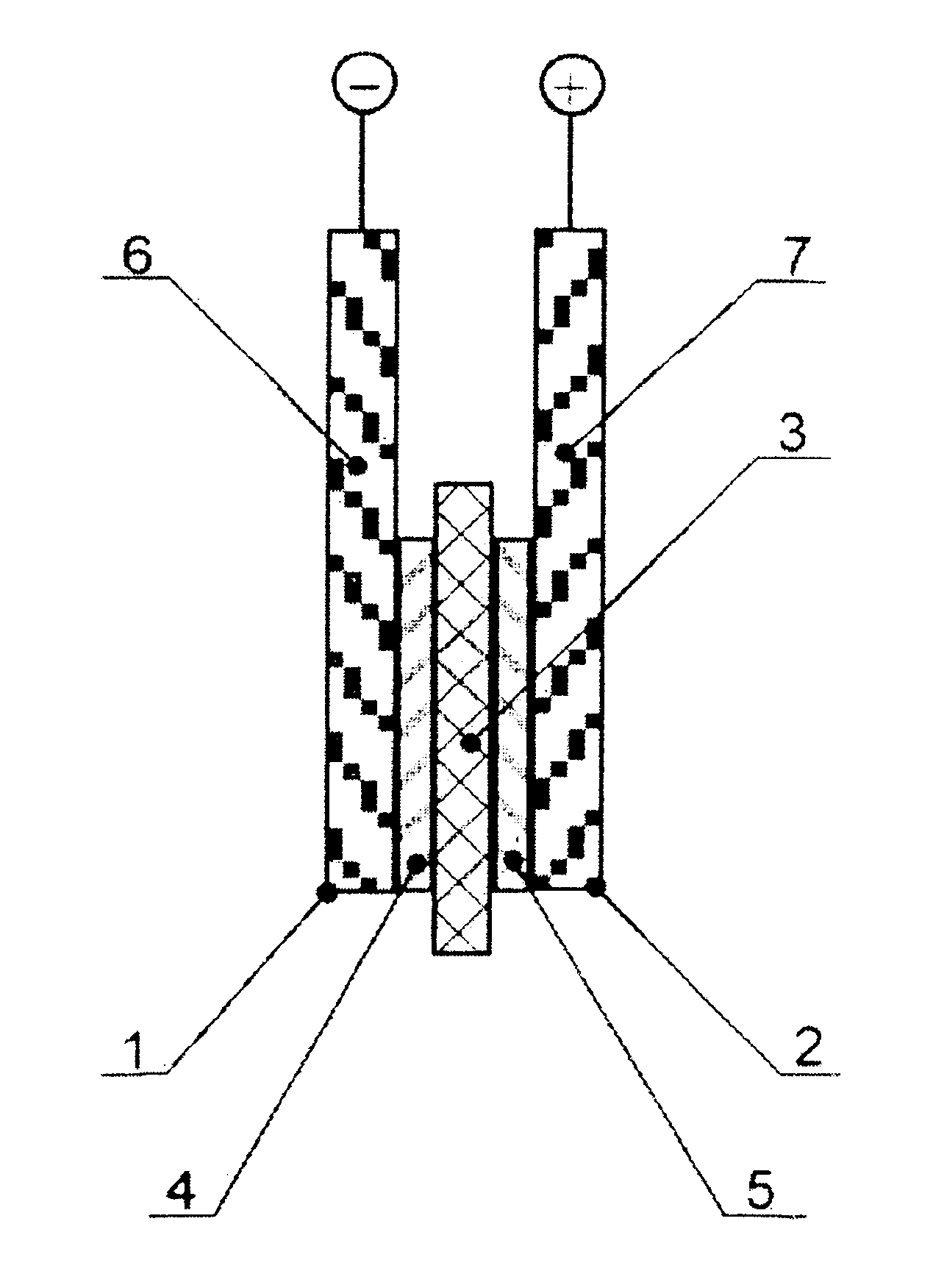

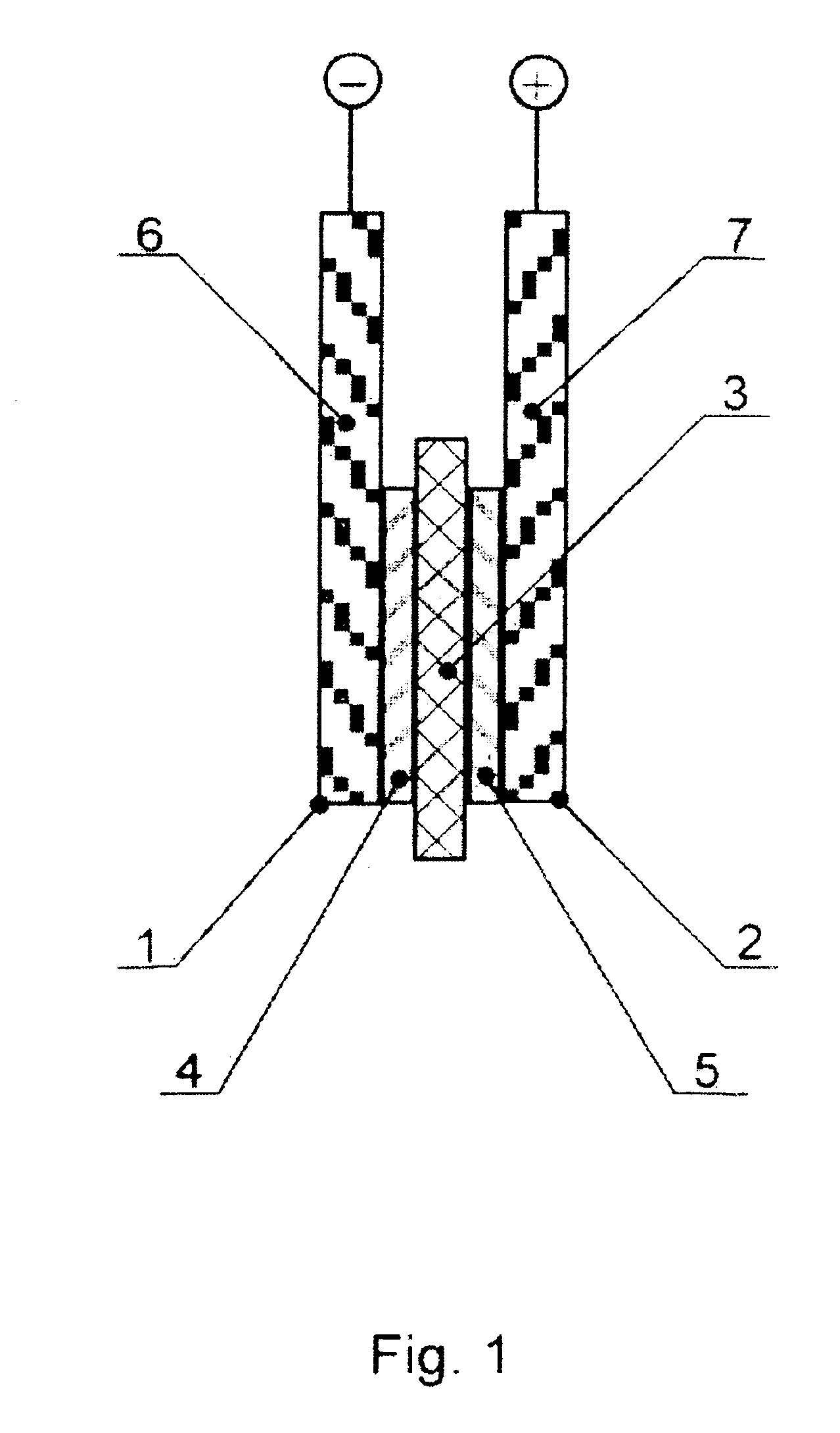

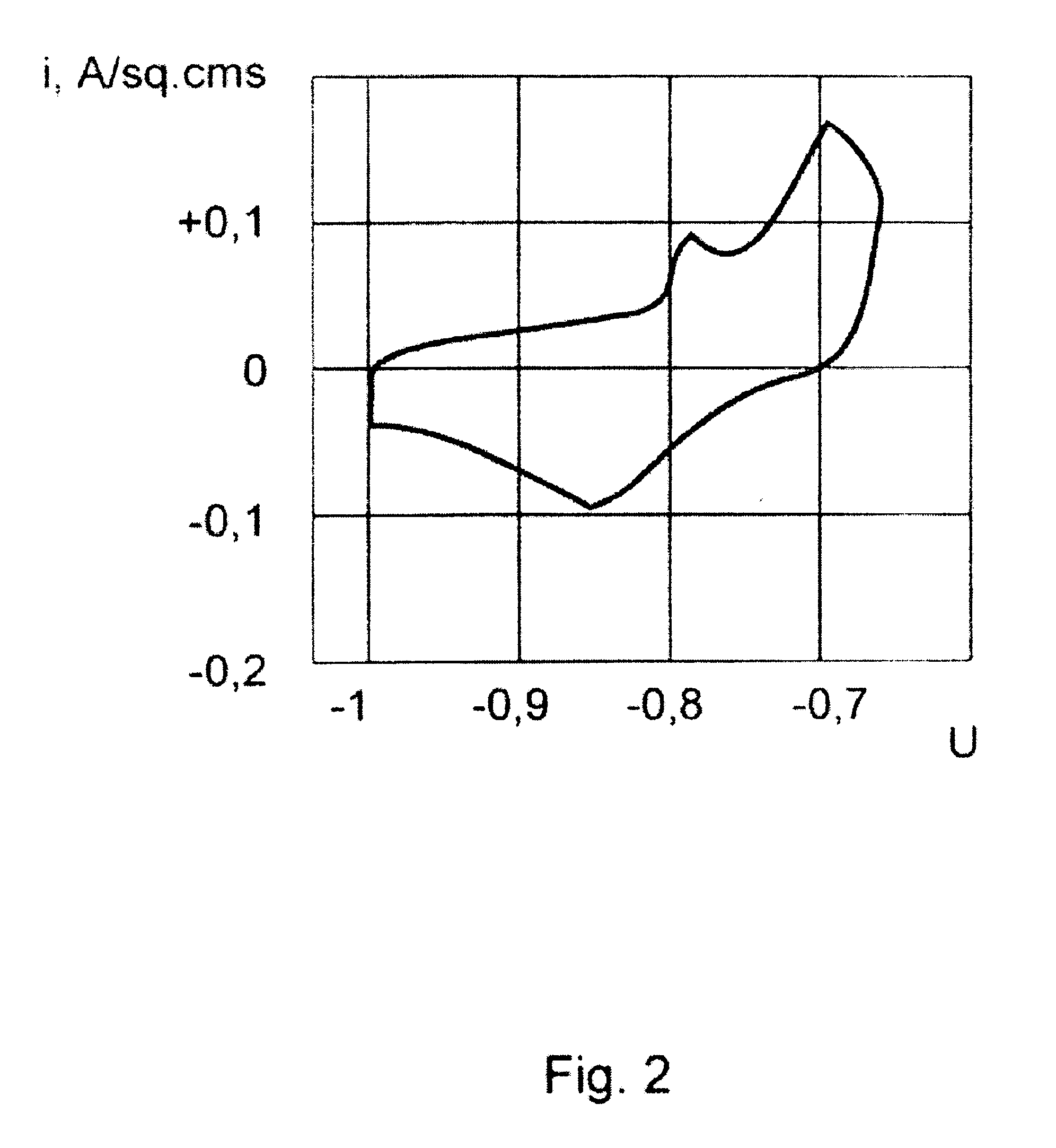

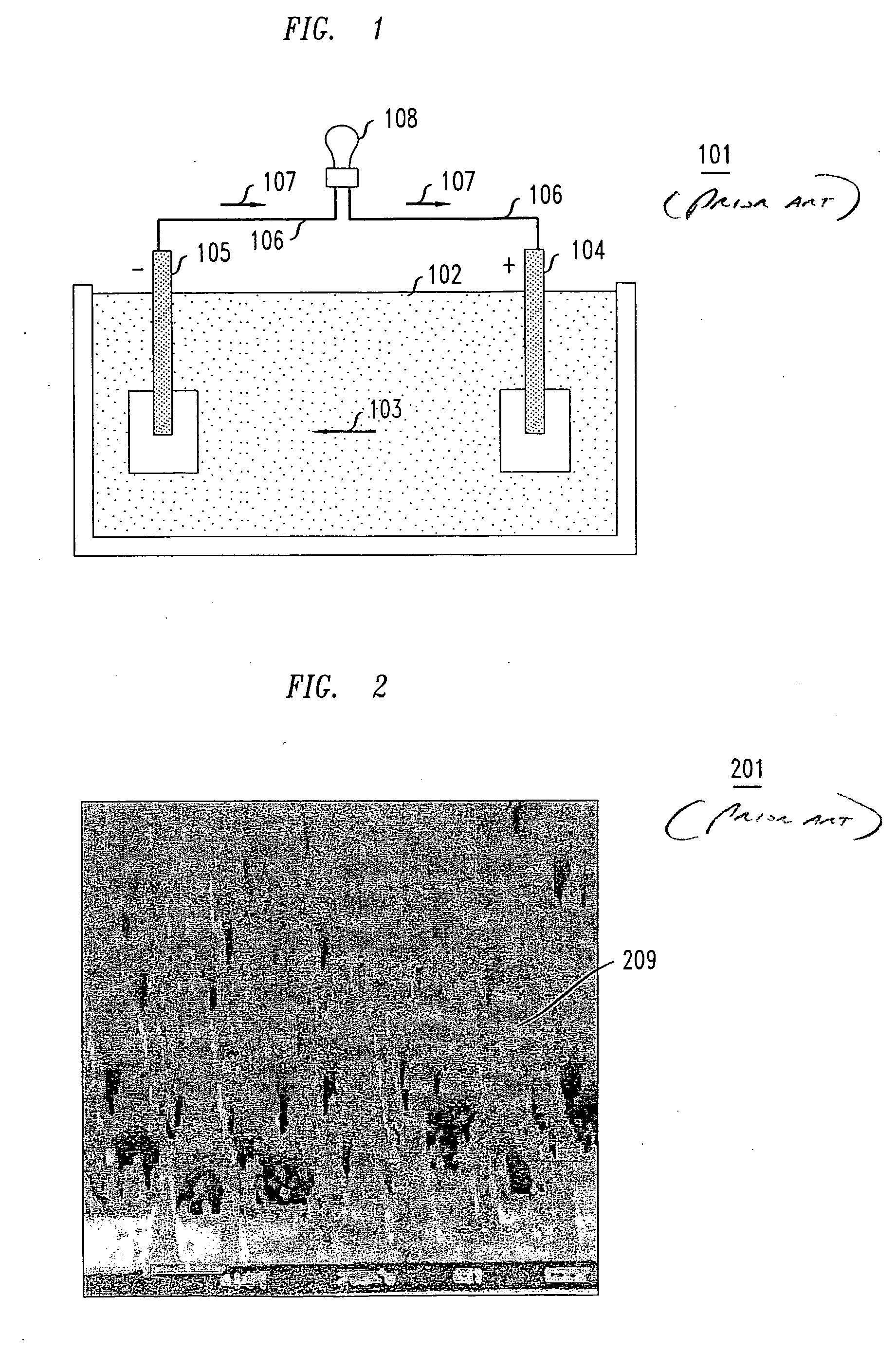

Electrochemical energy storage device of high specific power and electrodes for said device

InactiveUS6844111B2Extended service lifeIncrease the number ofAlkaline accumulatorsElectrochemical processing of electrodesElectrolysisAlloy

The claimed invention relates to electrical engineering, and in particular to production of rechargeable electrochemical energy storage devices of high specific power. Positive and negative electrodes for electrochemical energy storage device of high specific power according to the invention comprise active element interacting with aqueous alkaline electrolyte in the process of redox charge-discharge reactions made of electron-conductive electrolytic alloy having composition M(l-x-y)OxHy, where M for positive electrode is nickel or nickel-based alloy, M for negative electrode—a metal out of the group: iron, nickel, cobalt or an alloy on the basis of a metal out of this group, x is atomic fraction of absorbed oxygen in the electrolytic alloy being within the limits of 0.01≦x≦0.4, for positive electrode preferably in the limits of 0.05≦x≦0.4, y is atomic fraction of absorbed hydrogen in the electrolytic alloy being within the limits of 0.01≦y≦0.4, for negative electrode preferably in the limits of 0.05≦y≦0.4, the said electrolytic alloy functioning simultaneously as current-carrying collector and as active material.Electrochemical energy storage devices of high specific power according to three embodiments of the invention comprise at least one negative and one positive electrodes submerged in aqueous alkaline electrolyte and divided by a separator—a layer of ion-conductive but non electron-conductive material.Enhancement of service life owing to increase in number of recharge cycles under conditions of elimination of ecological harmful cadmium is the technical result achieved by the invention.

Owner:MIRZOEV RUSTAM AMINOVICH +3

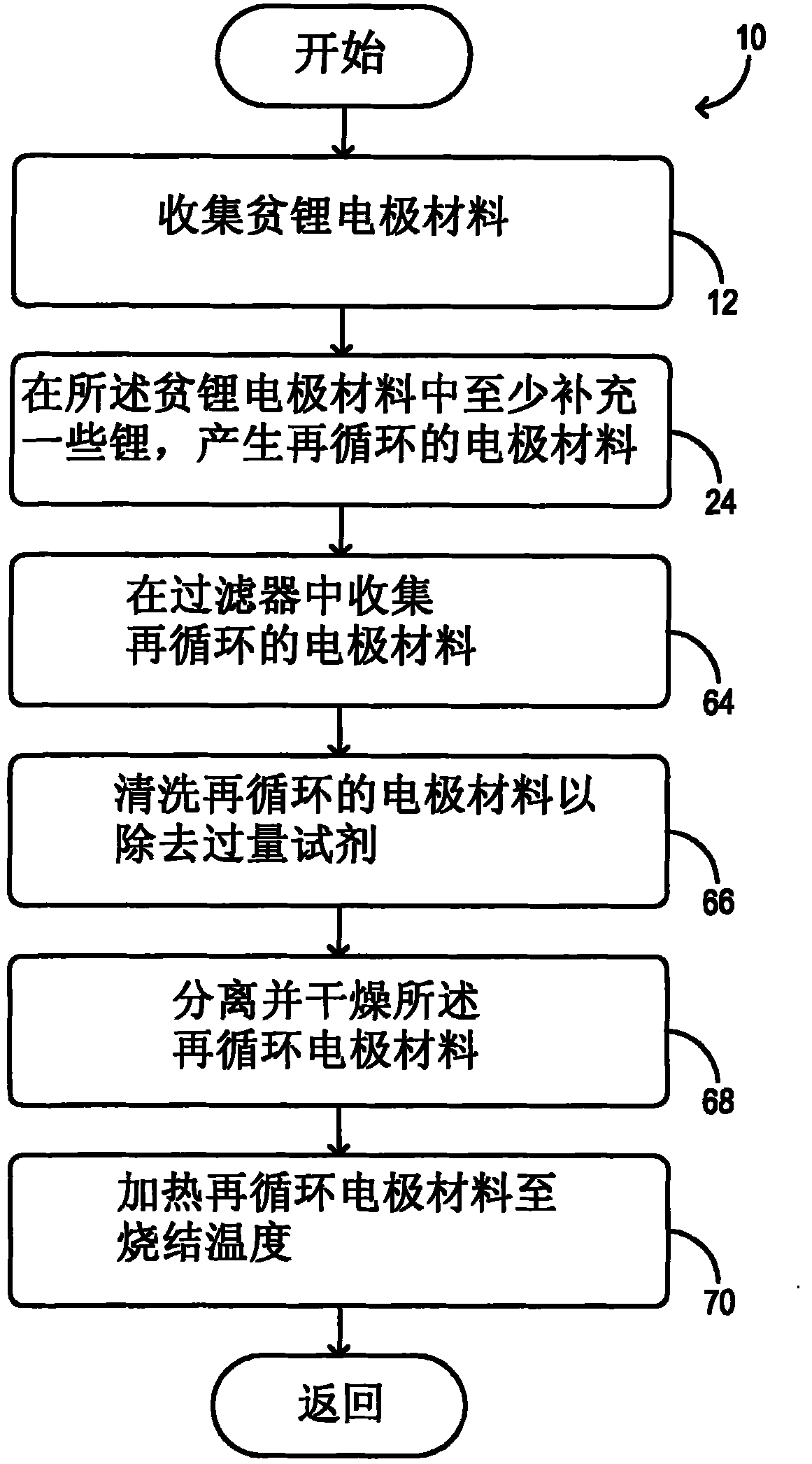

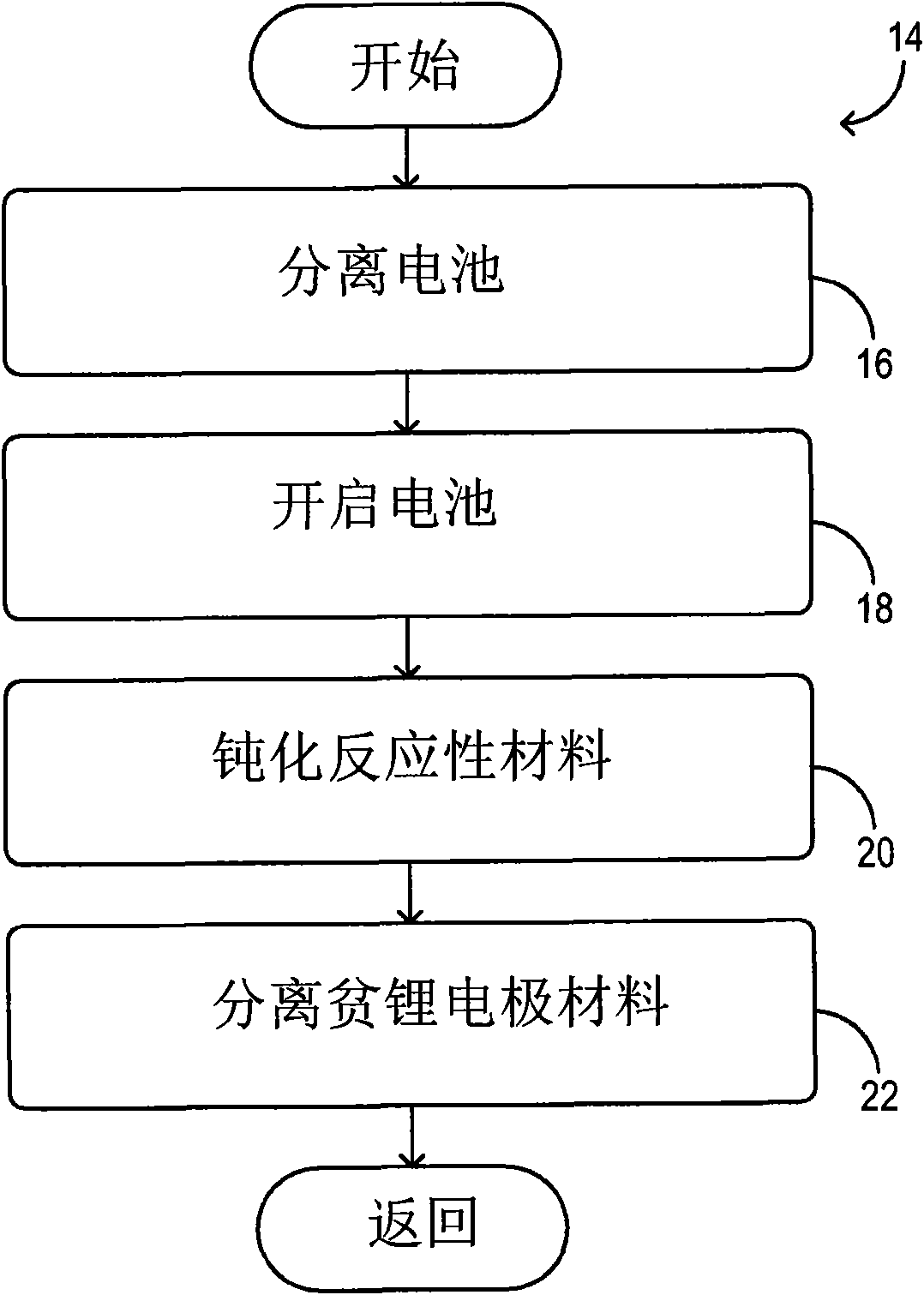

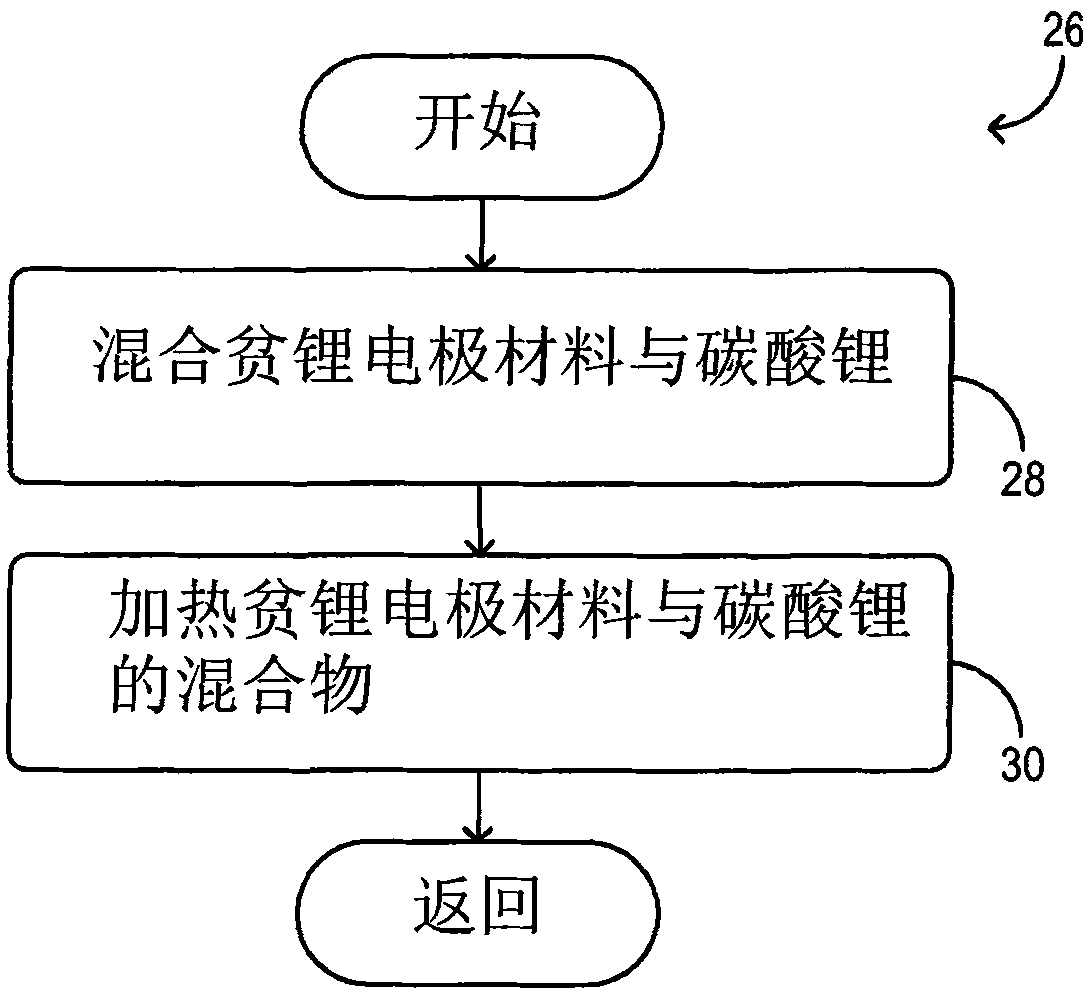

Reintroduction of lithium into recycled battery materials

Methods for making a recycled or refurbished electrode material for an energy-storage device are provided. One example method comprises harvesting a lithium-deficient electrode material from a recycling or waste stream, and replenishing at least some lithium in the lithium-deficient electrode material. A second example method comprises breeching an enclosure of a cell of an energy storage device, replenishing at least some lithium in a lithium- deficient electrode material of the cell, and sealing the enclosure of the cell.

Owner:S·E·斯鲁普

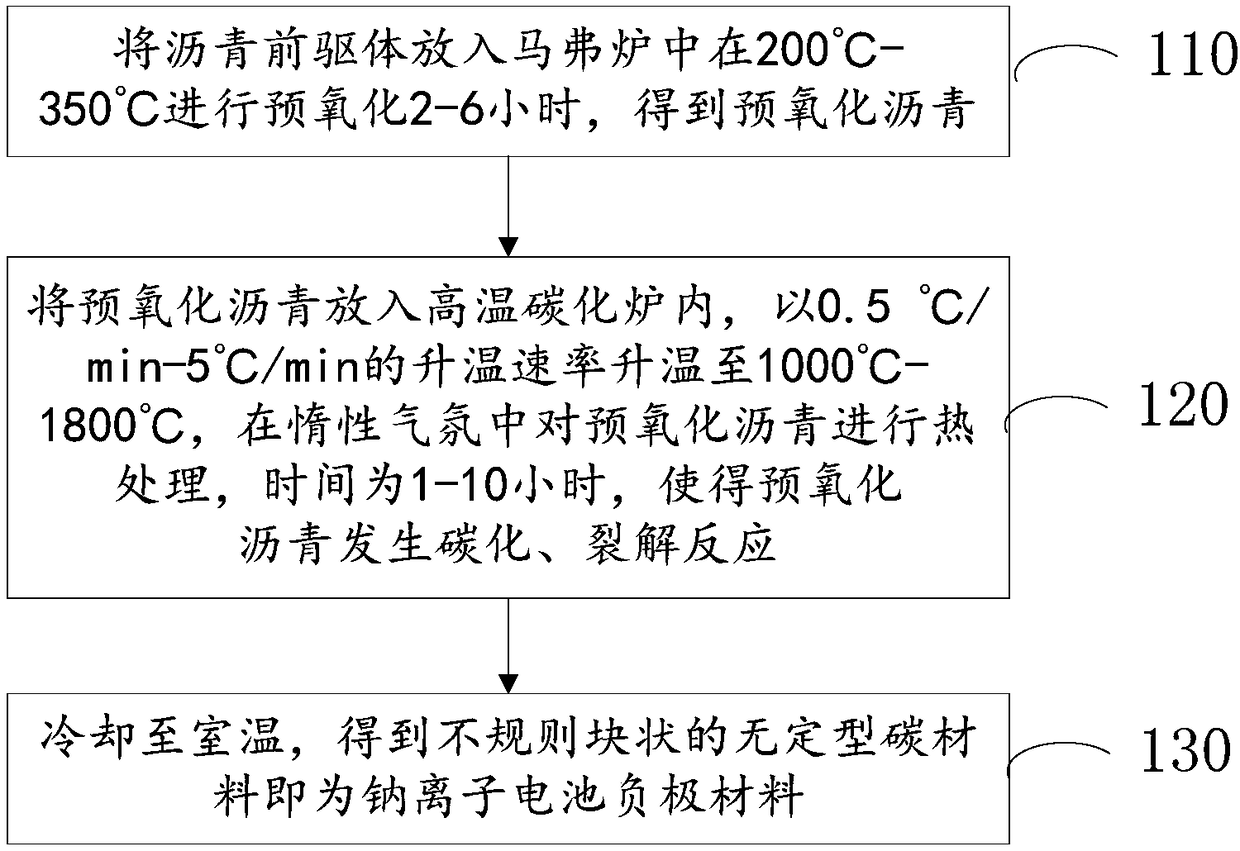

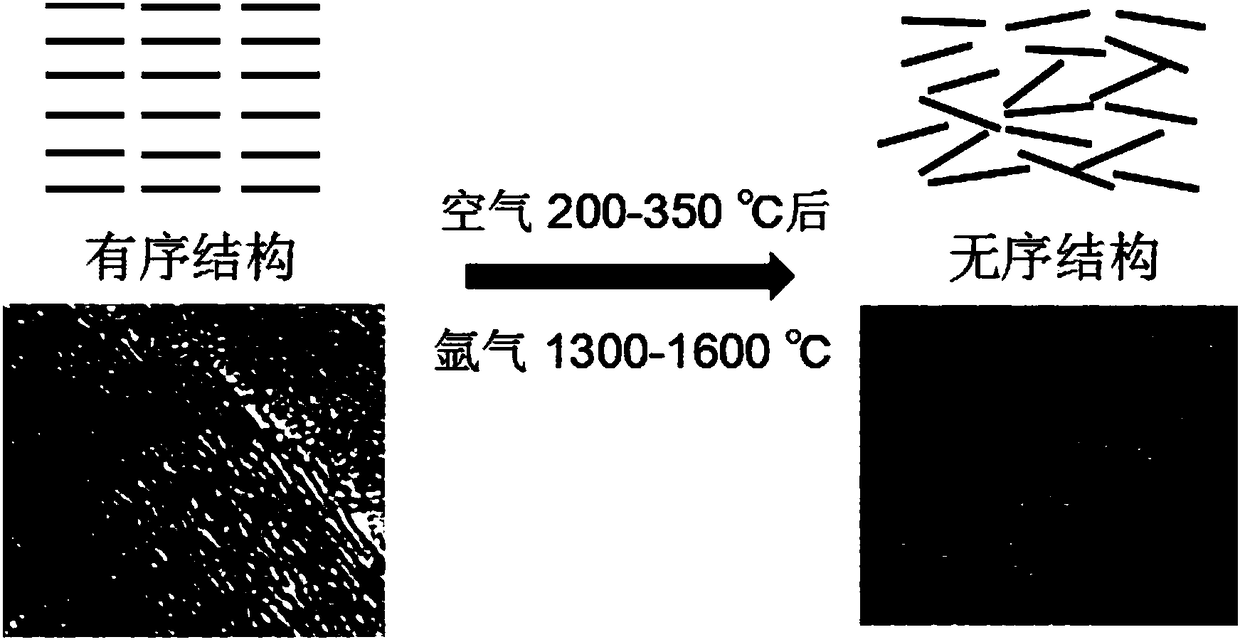

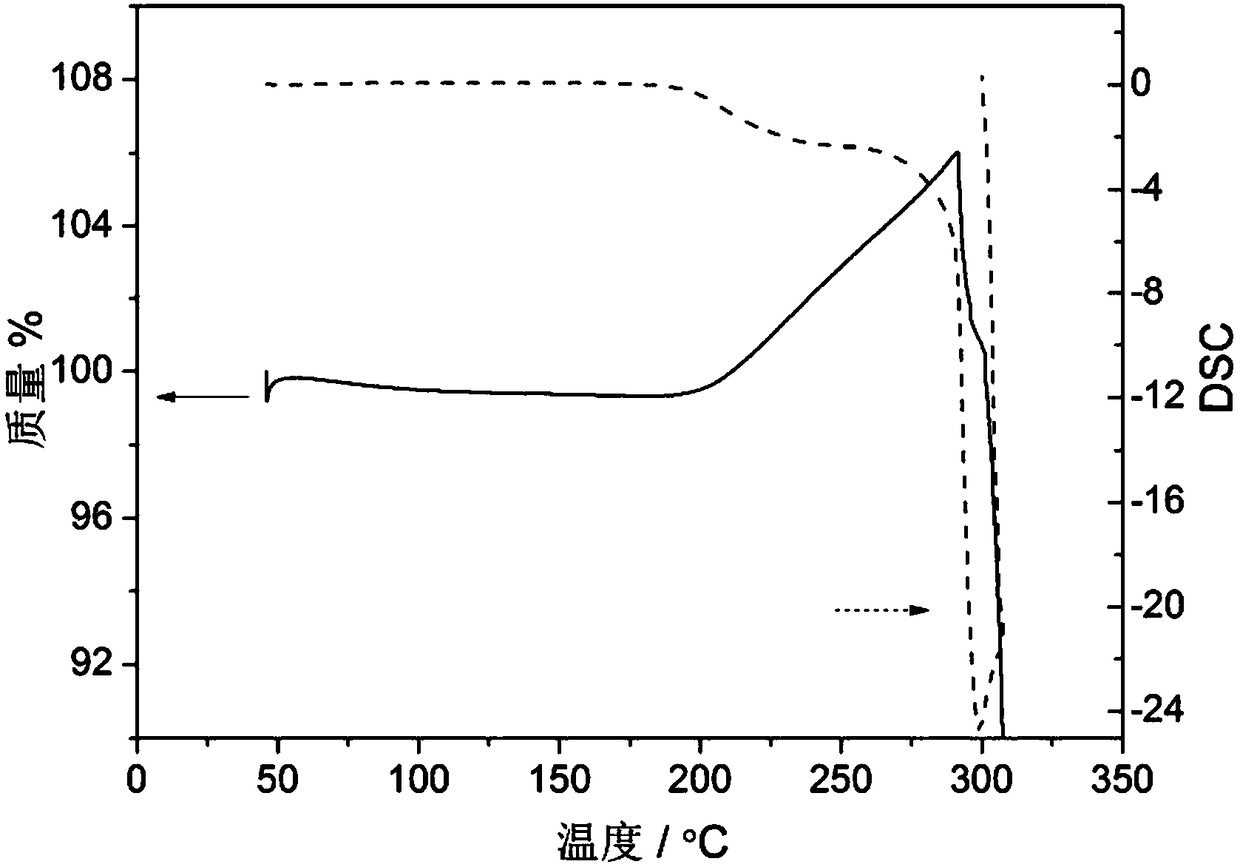

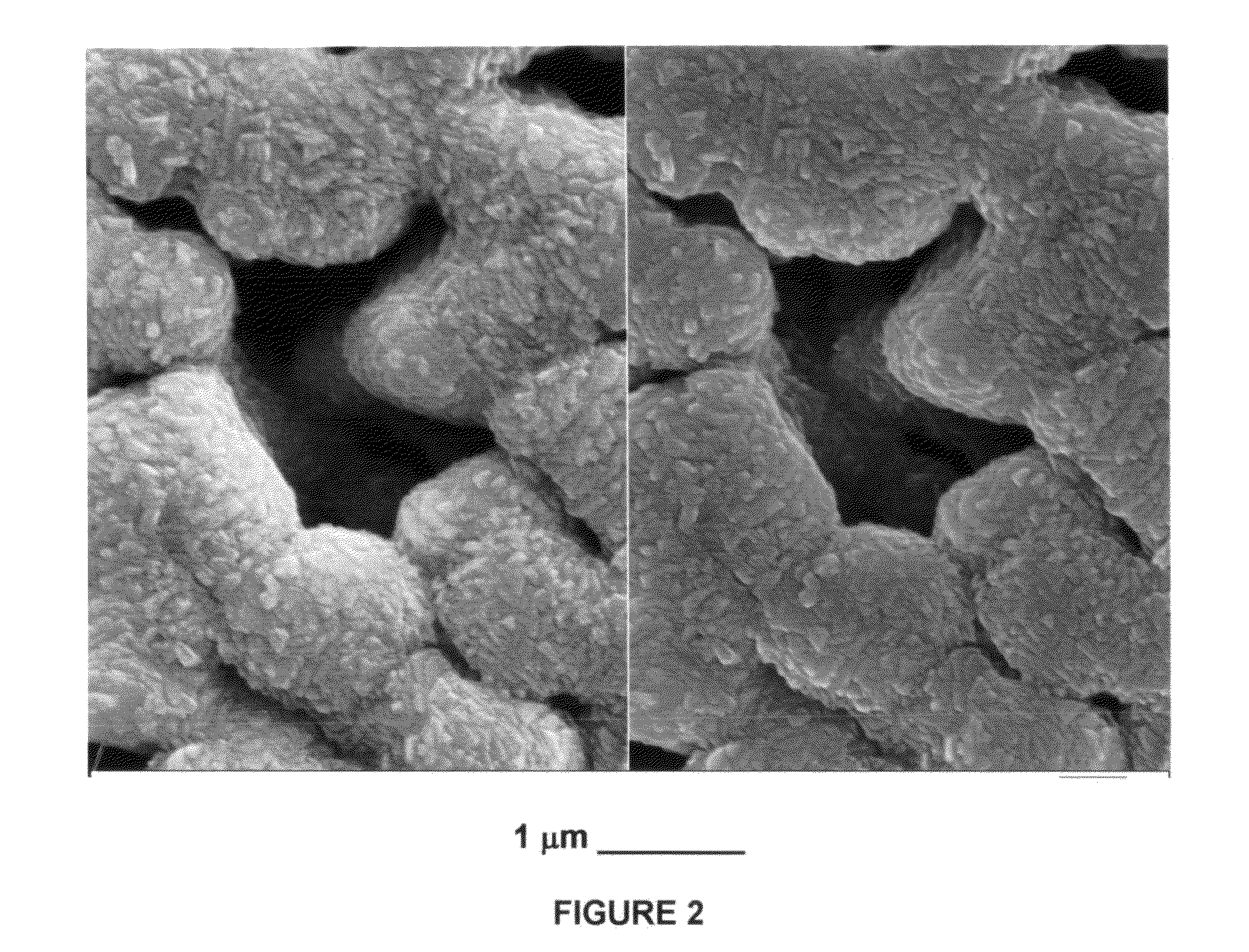

Asphalt-based negative electrode material for sodium ion battery and preparation method and application thereof

InactiveCN109148883AImproved magnification performanceLow costElectrode thermal treatmentSecondary cellsElectrical batteryPhysical chemistry

The embodiment of the invention relates to an asphalt-based negative electrode material for a sodium ion battery and a preparation method and application thereof. The method comprises the following steps: putting an asphalt precursor into a muffle furnace at 200 DEG C to 350 DEG C for preoxidation for 2 to 6 hours to obtain preoxidized asphalt; putting the preoxidized asphalt into a high-temperature carbonization furnace, and the temperature of the preoxidized asphalt rising to 1300 DEG C to 1600 DEG C at a heating rate of 0.5 DEG C / min to 5 DEG C / min, performing heat treatment on the preoxidized asphalt in an inert atmosphere for 1 to 10 hours to cause carbonization and cracking reaction of that preoxidized asphalt; wherein oxygen in the preoxidized asphalt is used for breaking the ordered structure of the asphalt in the carbonization process of the preoxidized asphalt to form a disordered structure with wedge-shaped cracks, and the carbon yield is improved and the cost is further reduced; and cooling is performed to reach room temperature to obtain an irregular lumpy amorphous carbon material, that is the negative electrode material for the sodium ion battery.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI +1

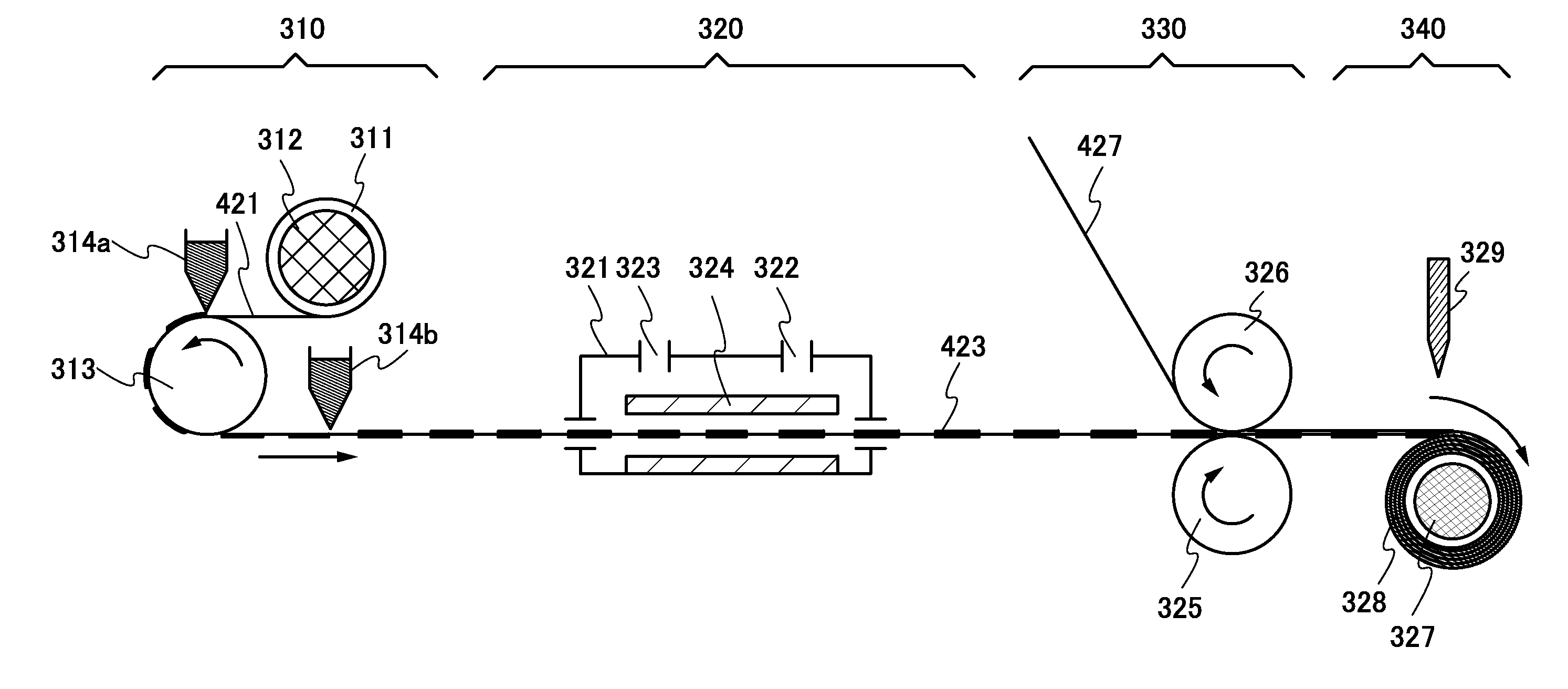

Method for manufacturing storage battery electrode, storage battery electrode, storage battery, and electronic device

ActiveUS9225003B2Reduce capacityContact resistanceElectrode rolling/calenderingElectrode thermal treatmentEngineeringSolvent

To provide a method for forming a storage battery electrode including an active material layer with high density in which the proportion of conductive additive is low and the proportion of the active material is high. To provide a storage battery having a higher capacity per unit volume of an electrode with the use of a storage battery electrode formed by the formation method. A method for forming a storage battery electrode includes the steps of forming a mixture including an active material, graphene oxide, and a binder; providing a mixture over a current collector; and immersing the mixture provided over the current collector in a polar solvent containing a reducer, so that the graphene oxide is reduced.

Owner:SEMICON ENERGY LAB CO LTD

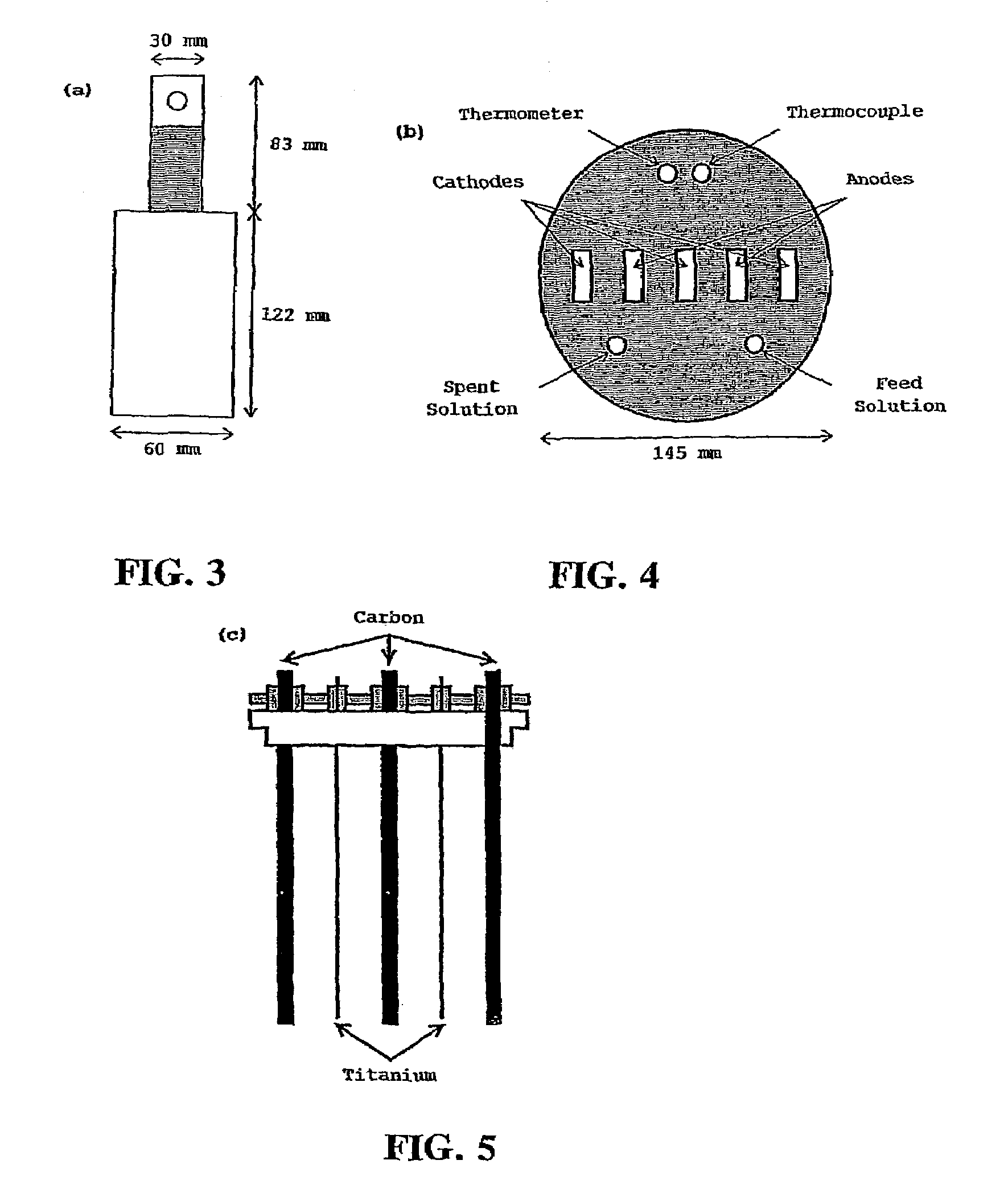

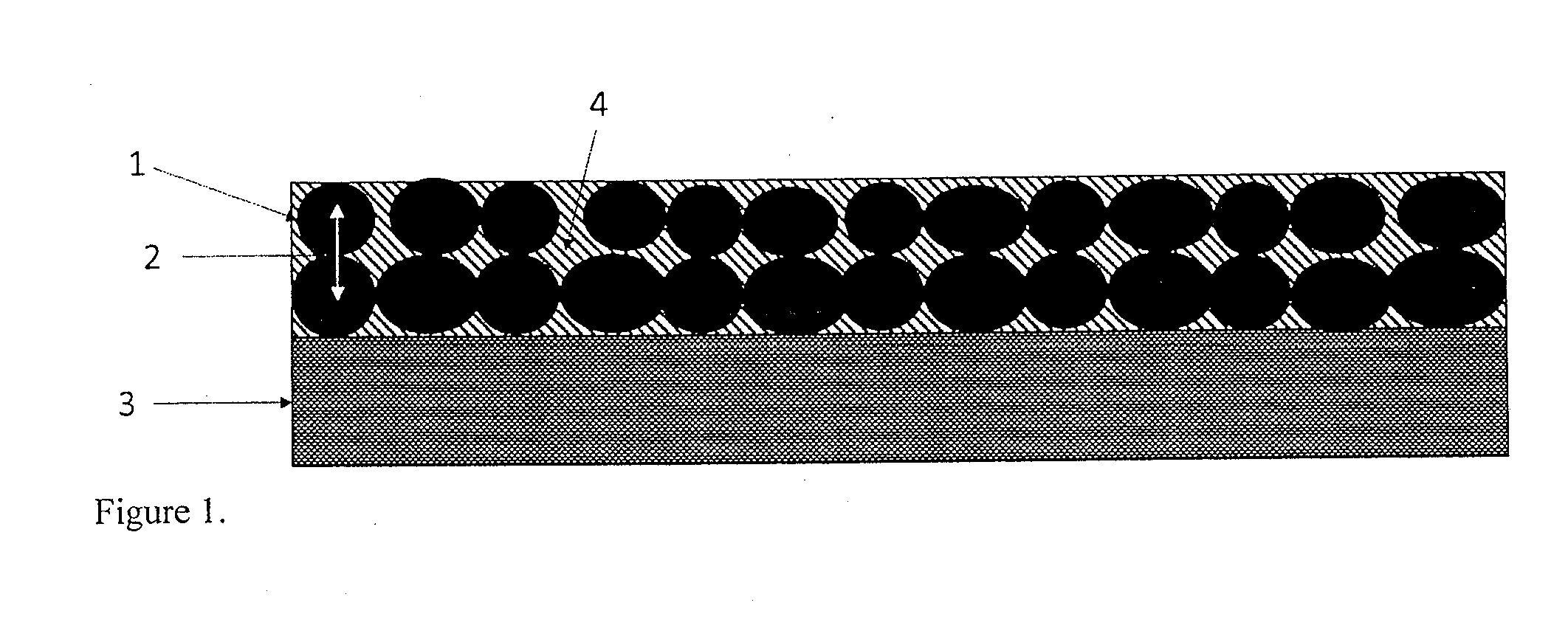

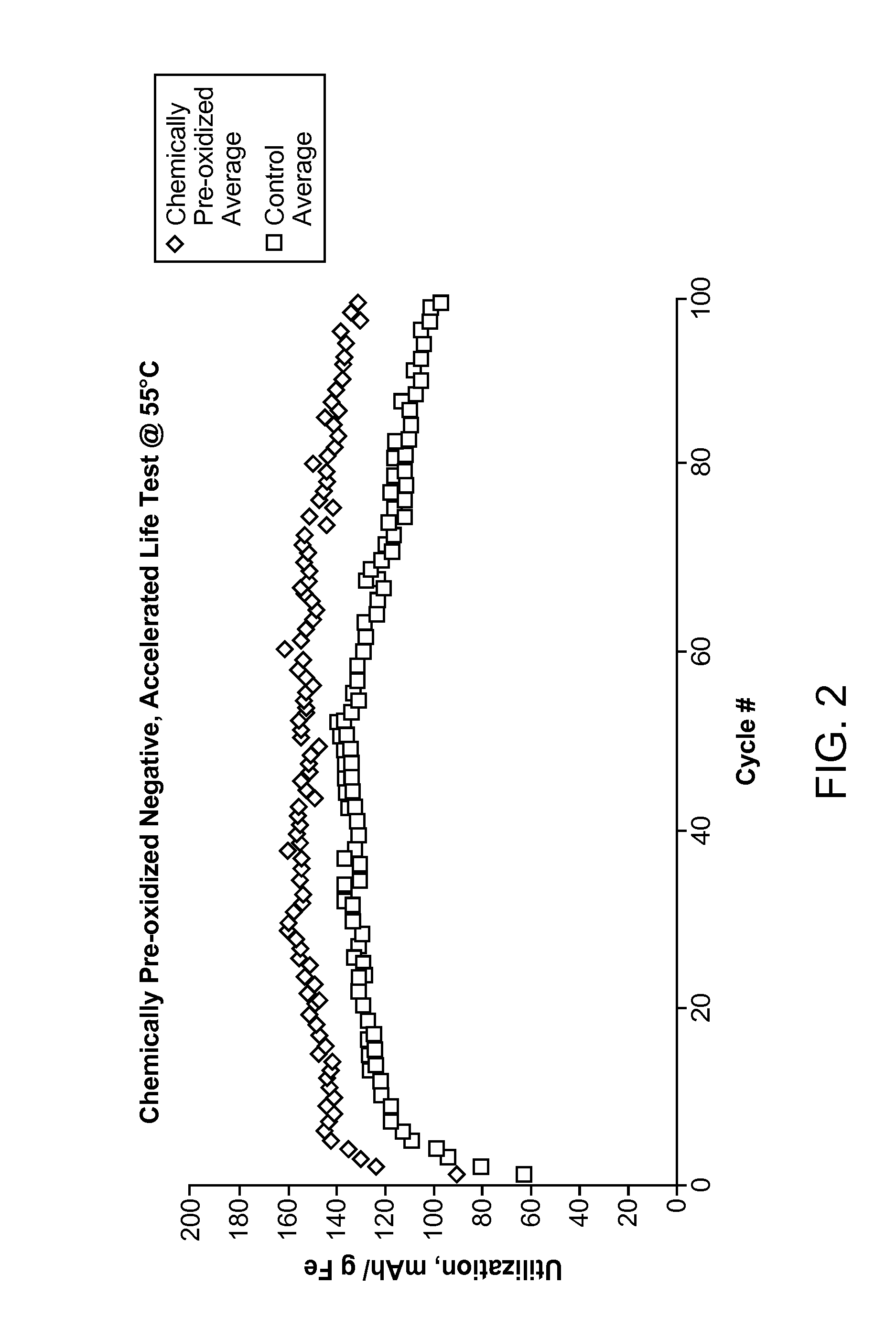

Nickel-iron battery with a chemically pre-formed (CPF) iron negative electrode

ActiveUS20150064562A1Improved iron utilizationReduce the amount requiredChemical electrode manufacturingAlkaline accumulator electrodesCharge dischargePre treatment

Provided is a Ni—Fe battery comprising an iron electrode which is preconditioned prior to any charge-discharge cycle. The preconditioned iron electrode used in the Ni—Fe battery is prepared by first fabricating an electrode comprising an iron active material, and then treating the surface of the electrode with an oxidant to thereby create an oxidized surface.

Owner:ENCELL TECHNOLOGY LLC

Graphitic nanostructured battery

InactiveUS20060172189A1Improve battery performanceImprove battery lifeMaterial nanotechnologyElectrode thermal treatmentDielectricNanopillar

A method and apparatus are disclosed wherein a battery comprises at least one electrode formed from a graphitic carbon nanostructured surface wherein the nanostructured surface consists of a plurality of nanoposts formed from graphitic carbon such that the graphitic nanoposts serve both as an operational feature (i.e., dielectric / electrode) and control feature of the battery itself. In one embodiment, the nanostructured surface consists of a plurality of nanoposts wherein a select portion of each nanopost is formed to serve as the dielectric of the nanostructured battery, and the balance of each nanopost is utilized to impart the control features to the nanostructured battery.

Owner:LGS INNOVATIONS +1

Method of forming a solid state cathode for high energy density secondary batteries

ActiveUS20120137508A1Increase energy densityElectrode rolling/calenderingElectrode thermal treatmentAlkali freeHigh energy

A method for making a solid state cathode comprises the following steps: forming an alkali free first solution comprising at least one transition metal and at least two ligands; spraying this solution onto a substrate that is heated to about 100 to 400° C. to form a first solid film containing the transition metal(s) on the substrate; forming a second solution comprising at least one alkali metal, at least one transition metal, and at least two ligands; spraying the second solution onto the first solid film on the substrate that is heated to about 100 to 400° C. to form a second solid film containing the alkali metal and at least one transition metal; and, heating to about 300 to 1000° C. in a selected atmosphere to react the first and second films to form a homogeneous cathode film. The cathode may be incorporated into a lithium or sodium ion battery.

Owner:QUANTUMSCAPE BATTERY INC

Nickel-cobalt compound hydroxide and method and device for producing same, positive electrode active substance for nonaqueous electrolyte secondary cell and method for producing same, and nonaqueous electrolyte secondary cell

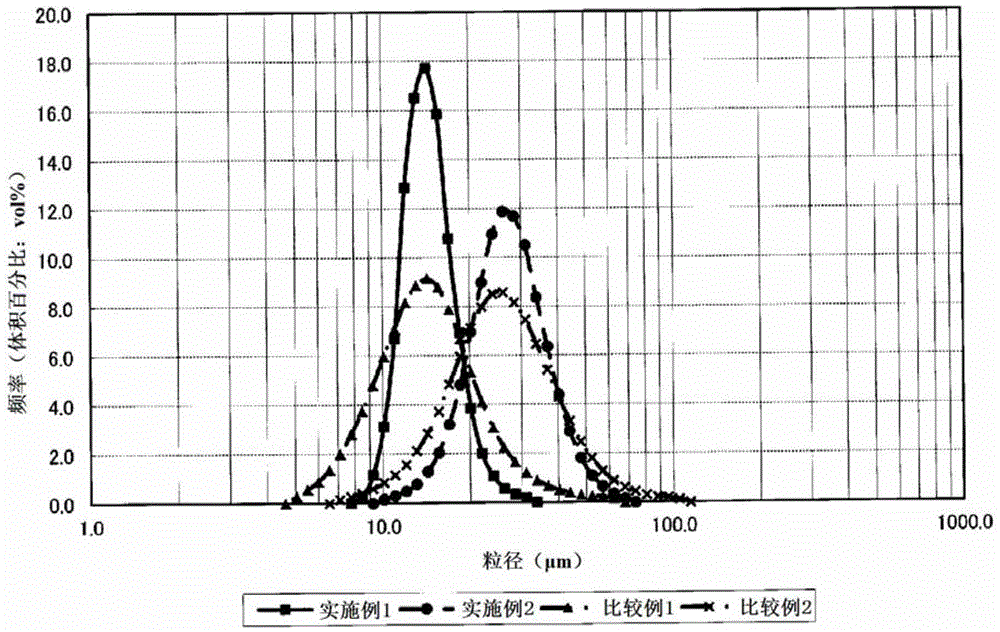

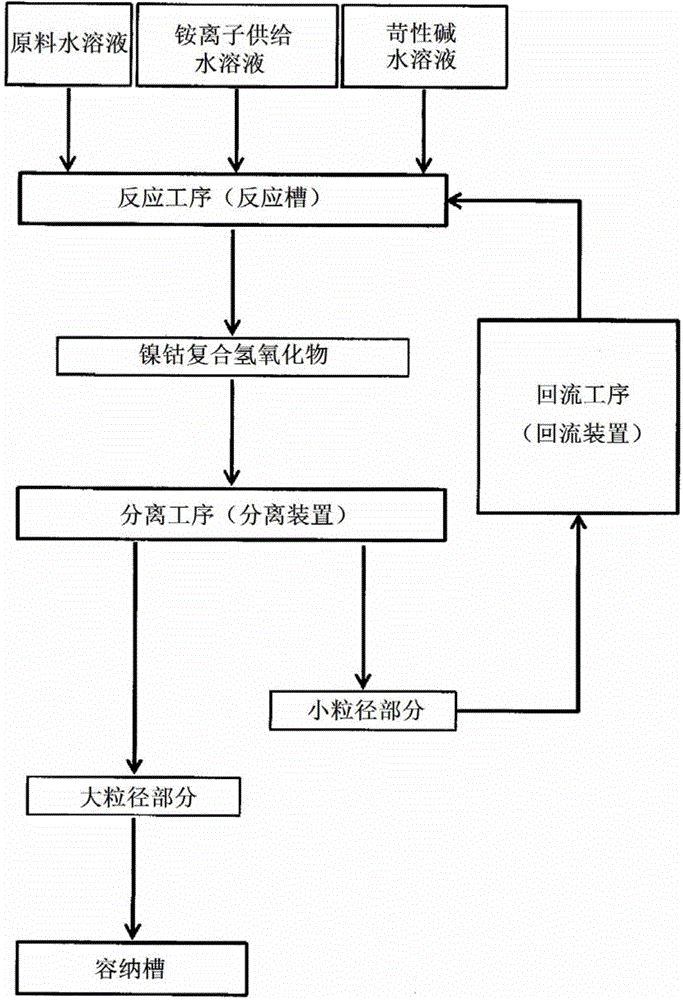

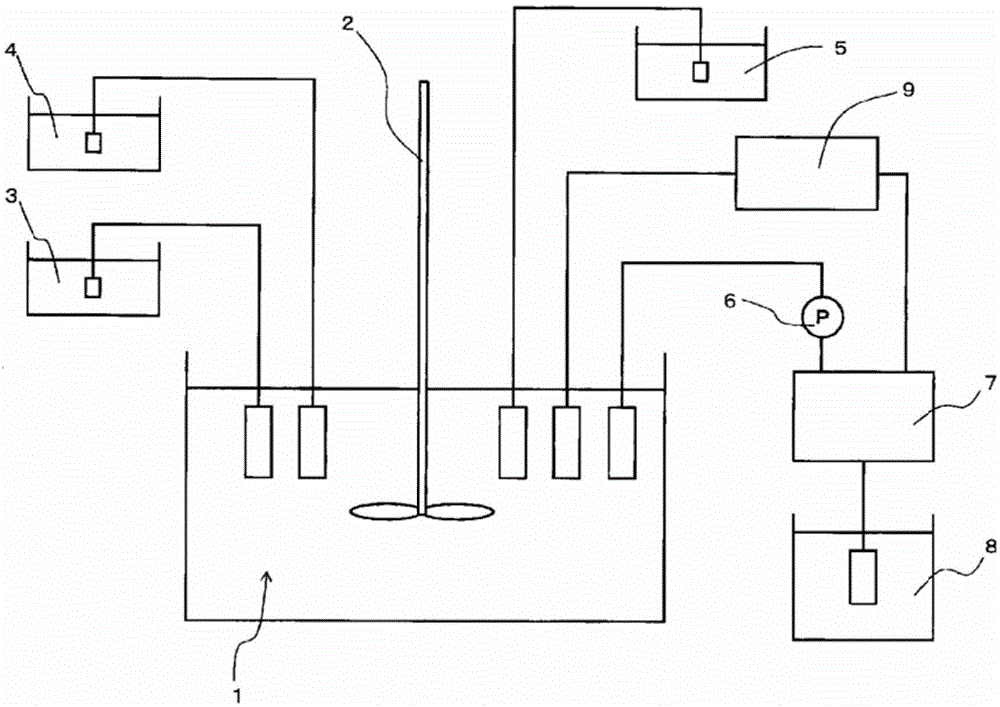

ActiveCN104661963ASharp particle size distributionExcellent cycle characteristicsSecondary cellsChemical electrode manufacturingSlurryAqueous solution

[Problem] By obtaining a compound hydroxide that has a sharp particle diameter distribution, the present invention aims to improve the cycle properties of a nonaqueous electrolyte secondary cell obtained using the nickel-cobalt compound hydroxide as the precursor. [Solution] In the present invention, a slurry contains a nickel-cobalt compound hydroxide that is obtained by reacting and continuously feeding to a reactor an aqueous solution containing at least nickel and cobalt, an aqueous solution that serves as an ammonium ion donor, and an aqueous caustic alkali solution. The slurry is continuously extracted and the slurry is separated by grading into large particle diameter portions and small particle diameter portions. The small particle diameter portion is continuously circulated back to the reactor. The resulting nickel-cobalt compound hydroxide is represented by the general formula Ni1-x-yCoxMy (OH)2 (where 0.05 ≤ x ≤ 0.50, 0 ≤ y ≤ 0.10, 0.05 ≤ x + y ≤ 0.50, M is at least one metal element selected from Al, Mg, Mn, Ti, Fe, Cu, Zn, and Ga), wherein the correlations of (D50-D10) / D50 ≤ 0.30 and (D90-D50) / D50 ≤ 0.30 are established between D10, D50, and D90.

Owner:SUMITOMO METAL MINING CO LTD

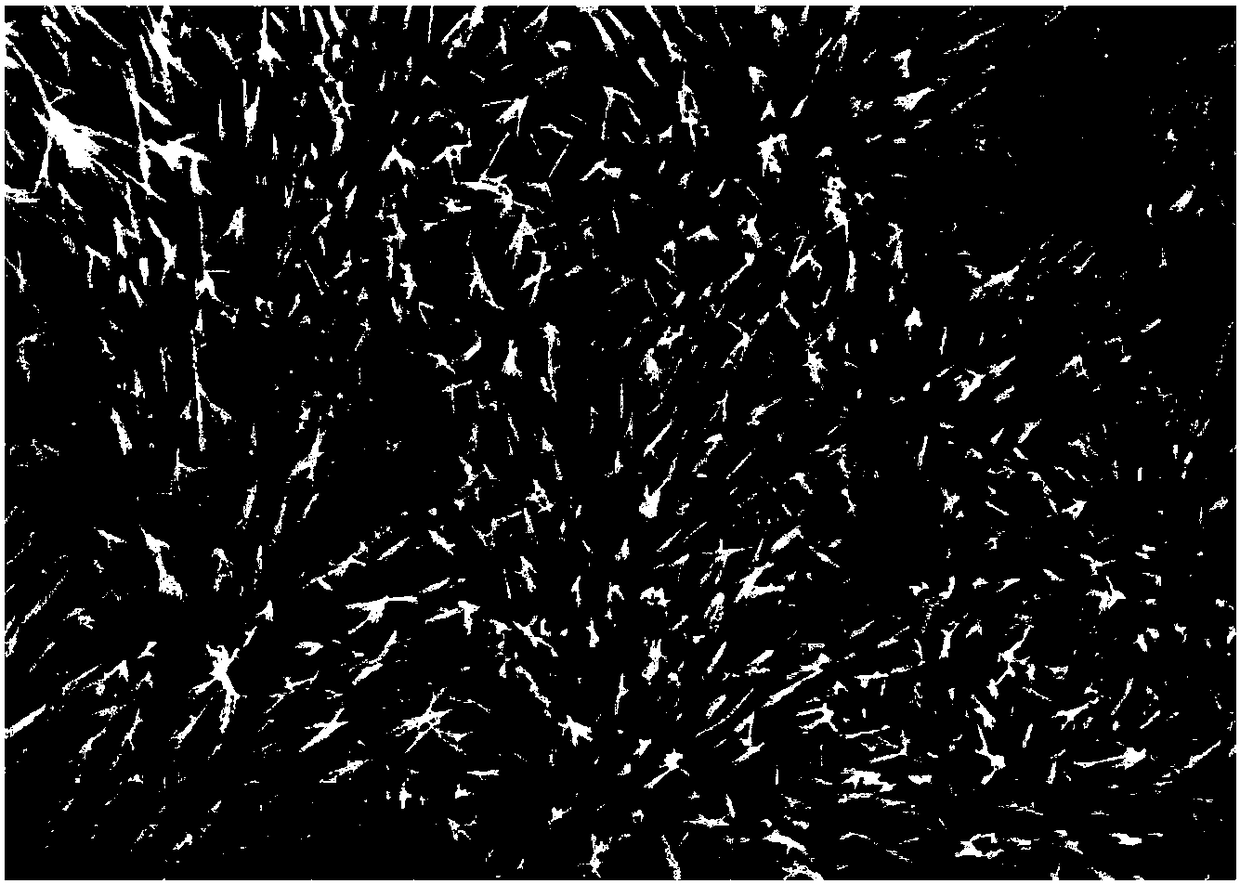

Method for realizing in-situ growth of cobalt-manganese double-metal hydroxide composite material through using nickel foam as substrate

InactiveCN108615610ALarge specific surface areaHigh specific capacitanceHybrid capacitor electrodesChemical electrode manufacturingNew energyManganese

The invention discloses a method for realizing in-situ growth of cobalt-manganese double-metal hydroxide composite material through using nickel foam as a substrate. The method comprises the steps ofperforming in-water ultrasonic dispersion of cobalt salt, manganese salt, urea and ammonium fluoride to uniform, thereby obtaining cobalt-manganese double-metal hydroxide precursor solution; immersingthe preprocessed nickel foam into the cobalt-manganese double-metal hydroxide precursor solution, performing a hydro-thermal reaction, and after reaction, performing filtering, washing and drying forobtaining a nickel foam / cobalt-manganese double-metal hydroxide composite electrode material. The composite material according to the invention has advantages of excellent conductive performance, stable chemical property and controllable morphology. The needle-shaped cobalt-manganese double-metal hydroxide is uniformly arranged on the three-dimensional nickel foam, thereby sufficiently increasingspecific surface area of the composite material. Furthermore the prepared composite material does not require a binder in electrochemical testing, thereby realizing simple and convenient operation. The material can be used as an ideal supercapacitor, a high-performance electrocatalysis material and an electrode material of new energy devices such as a lithium ion battery.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com