Lithium metal negative electrode dual protection method and application

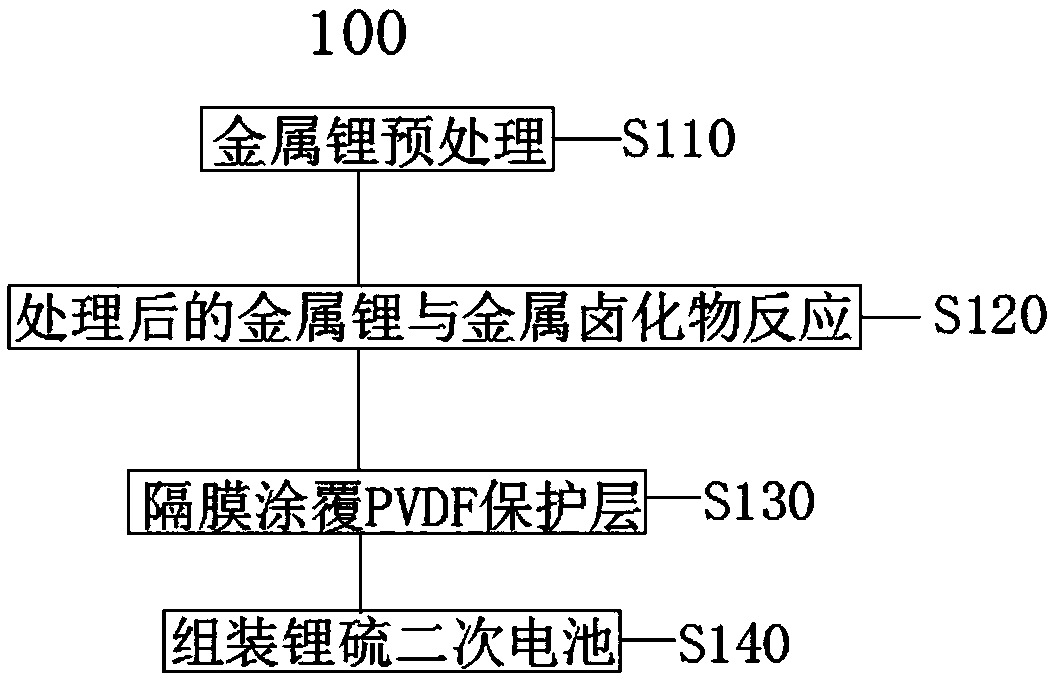

A lithium metal negative electrode and double protection technology, applied in the field of material science, can solve problems such as difficult to meet the requirements of power batteries, loss of electronic conductivity, and restricted cycle performance, to achieve excellent ion conductivity, improve electrochemical performance and safety performance, Effect of reducing lithium deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

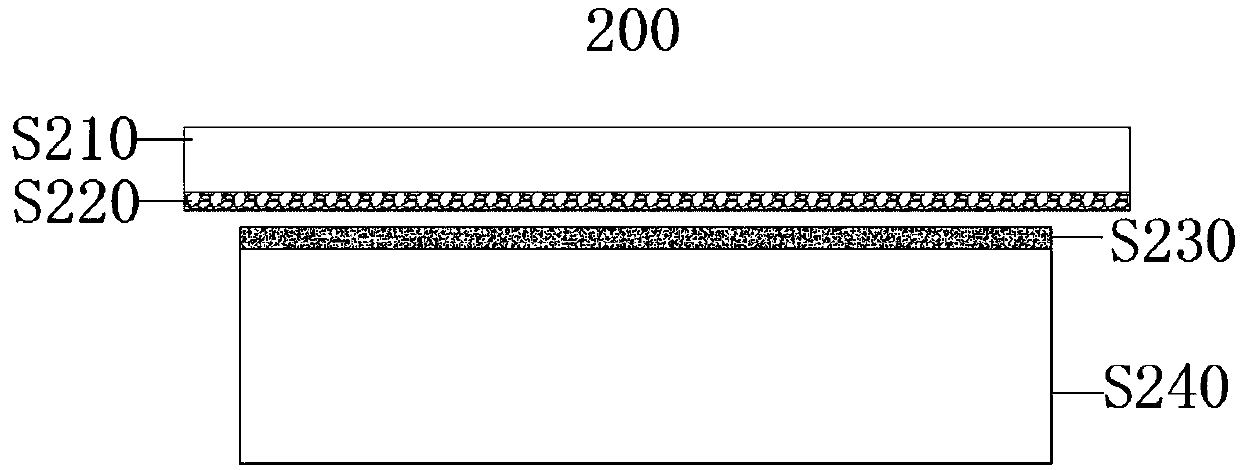

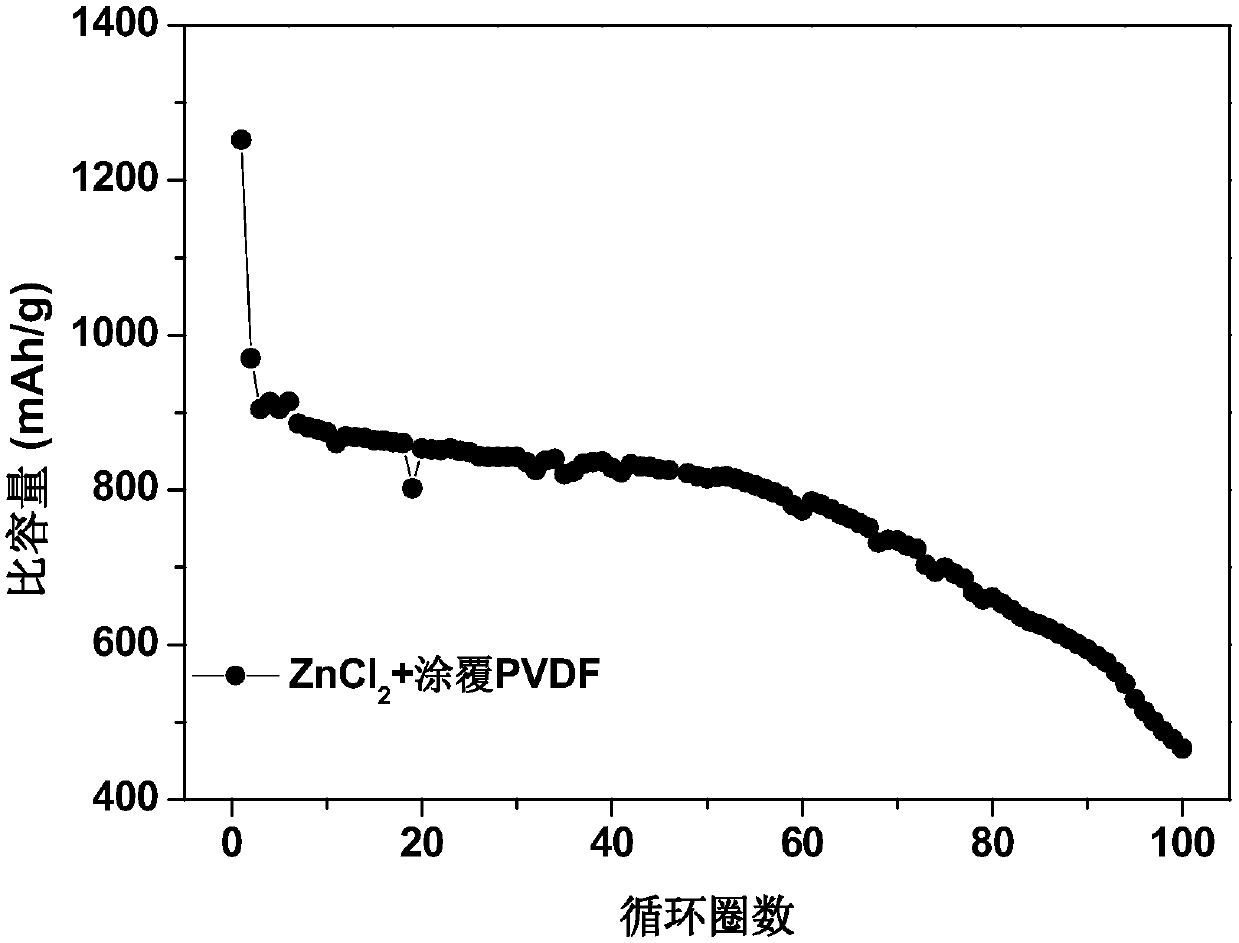

Embodiment 1

[0103] In the glove box, a commercially purchased lithium strip (thickness 200 μm) was cut with long-blade scissors to obtain a rectangular lithium metal negative electrode sheet with a size of 6 × 8.5 cm. The surface of the negative electrode is scratched horizontally once, and the surface of the lithium metal negative electrode presents a silver-white metallic luster. Then, the ZnCl was heated using a magnetic stirrer 2 Solid and LiNO 3 Dry the solid at 75°C for 8-12 hours to remove trace moisture that may be contained, and dry 0.10g of ZnCl 2 solid with 0.10 g of dried LiNO 3 The solids were dissolved together in 40 mL of THF solvent, and then magnetically stirred at 100 rpm for 40 min to form a clear and transparent solution. Pour the prepared solution into a watch glass, flatten and completely soak the polished lithium sheet in the solution, and react at 35°C for 100 seconds. After the reaction is completed, immediately take out the lithium sheet and rinse the lithium ...

Embodiment 2

[0105] This embodiment is basically the same as Embodiment 1 above. In this example LiNO 3 The mass of the solid is 0.05g, ZnCl 2 / LiNO 3 The reaction time of the mixed solution at 40° C. was 60 s. The other specific preparation process was the same as that of Example 1, and the cycle performance of the assembled secondary battery was basically similar to that of Example 1.

Embodiment 3

[0107] This embodiment is basically the same as Embodiment 1 above. In this example ZnCl 2 The mass of the solid is 0.40g, ZnCl 2 / LiNO 3 The reaction time of the mixed solution at 45° C. was 10 s. The other specific preparation process was the same as that of Example 1, and the cycle performance of the assembled secondary battery was basically similar to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Gap height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com