Method for realizing in-situ growth of cobalt-manganese double-metal hydroxide composite material through using nickel foam as substrate

A hydroxide, in-situ growth technology, applied in the field of material chemistry, can solve the problems of reducing the specific capacitance of transition metals, and achieve the effects of simple equipment, high performance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The invention provides a method for preparing a foamed nickel / cobalt-manganese double metal hydroxide electrode material, more specifically, a composite material in which needle-shaped cobalt-manganese double metal hydroxides are grown in situ on a base based on three-dimensional foamed nickel. To improve the cycle stability and poor specific capacitance of transition metal hydroxides. And it does not need the characteristics of binding agent to improve the electrochemical performance of the composite material. The present invention comprises the following experimental steps:

[0020] (1) Foamed nickel pretreatment: ultrasonically clean the foamed nickel several times with water, ethanol, acetone, and water respectively, dry it in a vacuum drying oven, and finally weigh it.

[0021] (2) Preparation of cobalt-manganese double metal hydroxide: Weigh a certain amount of manganese sulfate hydrate and cobalt nitrate hexahydrate, dissolve them in deionized water, and obtain a...

Embodiment 1

[0026] (1) Foamed nickel pretreatment: ultrasonically clean the foamed nickel several times with water, ethanol, acetone, and water respectively, dry it in a vacuum drying oven, and finally weigh it.

[0027] (2) Preparation of cobalt-manganese double hydroxide: Weigh manganese sulfate hydrate and cobalt nitrate hexahydrate, dissolve them in 35 mL deionized water, and obtain a homogeneous solution with a cobalt-manganese molar ratio of 4:1 after ultrasonication. Then dissolved in urea and ammonium fluoride and ultrasonically treated; in the mixed solution, the molar concentration of manganese sulfate hydrate was 1mol / L, the molar concentration of cobalt nitrate hexahydrate was 4mol / L, the concentration of urea was 2mol / L, ammonium fluoride The concentration is 0.2mol / L;

[0028] (3) Preparation of foamed nickel / cobalt-manganese double metal hydroxide: transfer the ultrasonically mixed solution to a polytetrafluoroethylene stainless steel reactor, soak nickel foam with a size o...

Embodiment 2

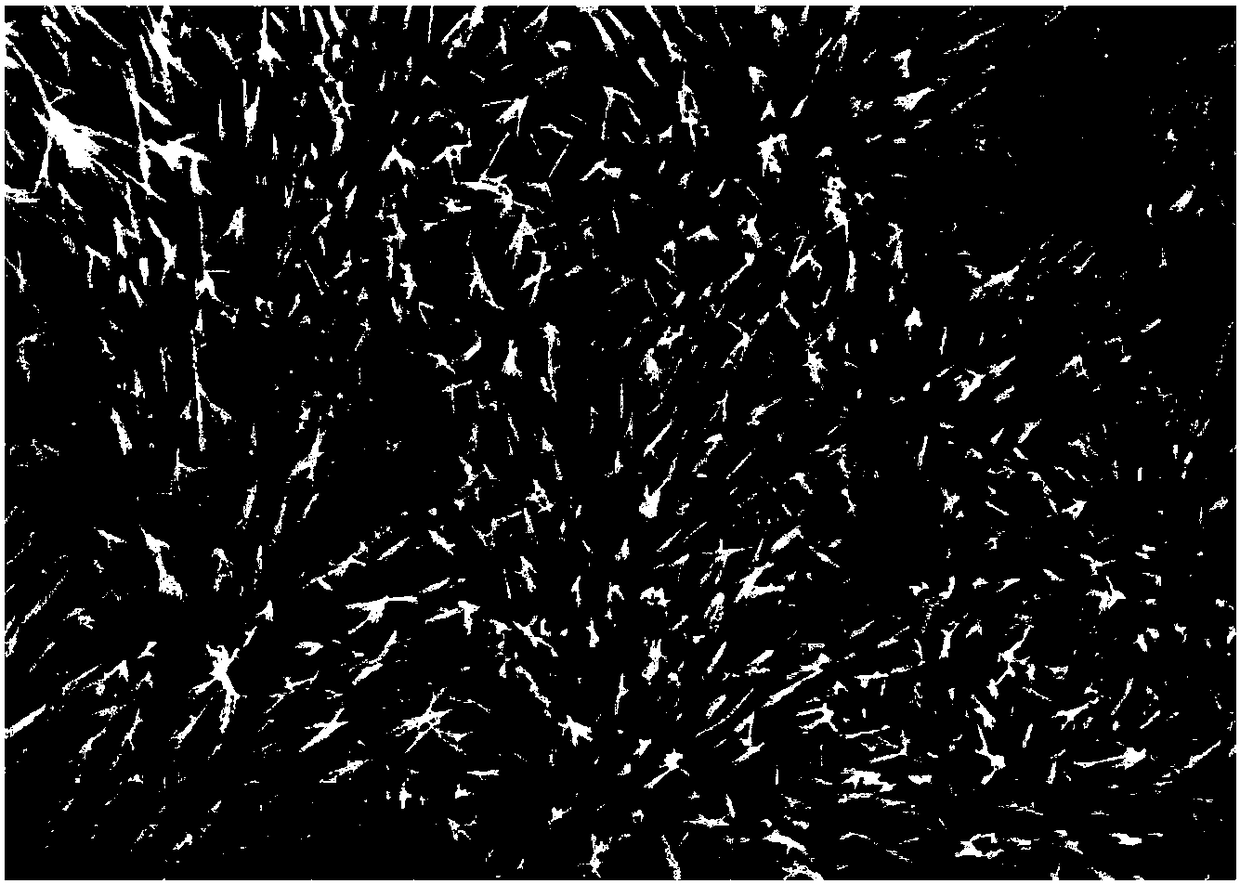

[0031] The difference between Example 2 and Example 1 is that in (2) the process of preparing the solution, the molar ratio of cobalt to manganese is 3:1, and the rest of the steps are the same as in Example 1. figure 2 It is a scanning electron micrograph of the foamed nickel / cobalt-manganese double metal hydroxide composite electrode material prepared in Example 2 of the present invention when the molar ratio Co:Mn=3:1. Figure 4 It is the XRD pattern of the foamed nickel / cobalt-manganese double metal hydroxide composite electrode material prepared in Example 2 of the present invention.

[0032] Electrochemical performance test results show that: when the current density is 0.5Ag -1 , the specific capacitance value is 1550F g -1 , and the efficiency is 93.2% after 3000 cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com