All-solid-state battery containing nano-solid electrolyte and method of manufacturing the same

A technology of all-solid-state batteries and solid electrolytes, applied in the manufacture of electrolyte batteries, solid electrolytes, non-aqueous electrolyte batteries, etc., can solve problems such as increasing discharge capacity, reducing interface resistance, and reducing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

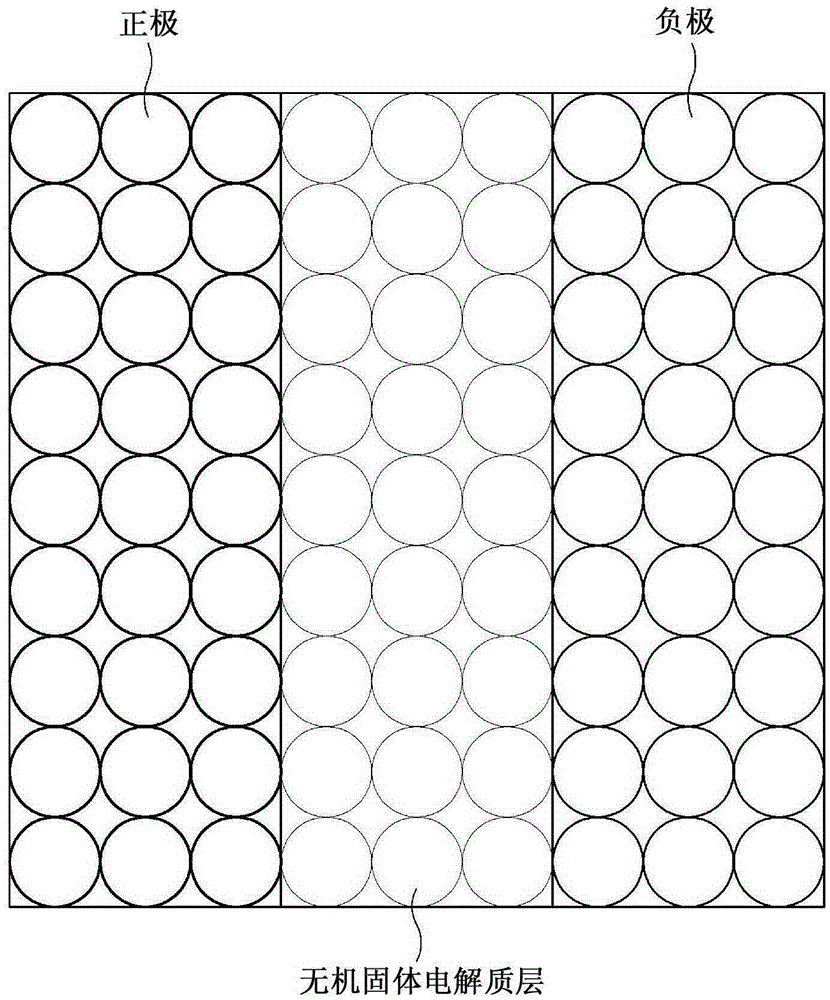

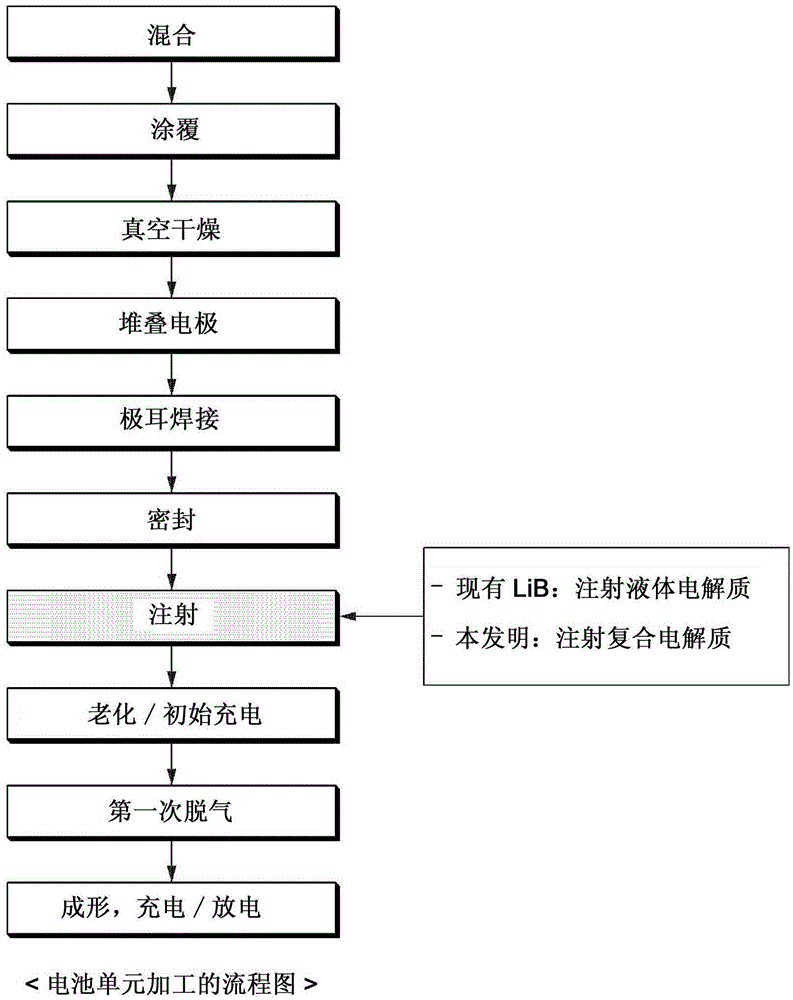

[0052] Example 1: Manufacture of an all-solid-state battery comprising a nano-solid electrolyte

[0053] 1. Fabrication of solid electrolyte

[0054] To fabricate stacks for all-solid-state batteries, a solid electrolyte is first prepared. By mixing Li at a molar ratio of 75:25 2 S (Alfa, 99.9%) (amorphous sulfide solid electrolyte) and P 2 S 5 Starting powder (Aldrich, 99%), followed by high-energy mechanical milling for 20 hours, to obtain a solid electrolyte. Because the sulfide-based solid electrolyte reacts with moisture, the above process was performed in a glove box under a nitrogen atmosphere to avoid contact with moisture in the air, and then heat-treated at a temperature of 230°C that can precipitate a metastable electrolyte with high ionic conductivity Amorphous solid electrolyte synthesized by milling method for 3 hours to become solid electrolyte in glass-ceramic state.

[0055] 2. Preparation of composite cathode slurry

[0056] Thoroughly mix lithium cob...

Embodiment 2

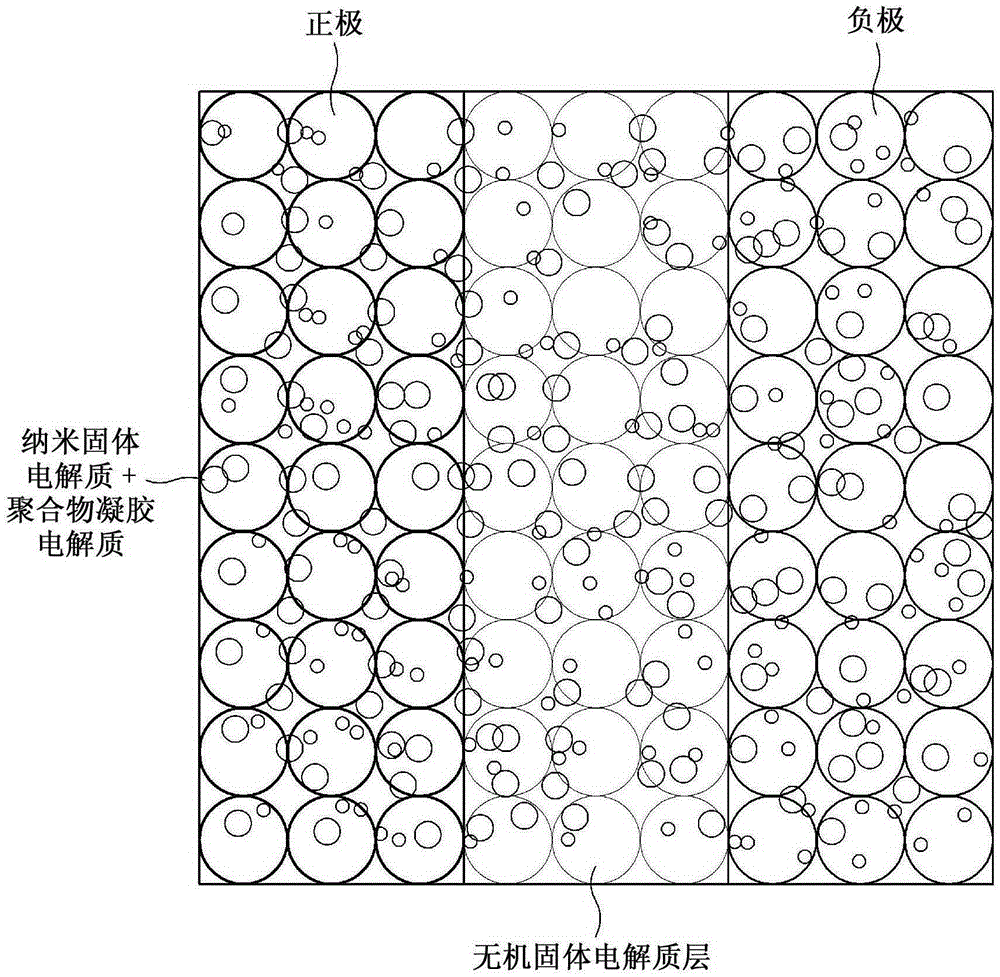

[0069] Example 2: When the ratio of polymer gel electrolyte and nano solid electrolyte is different

[0070] An all-solid-state battery was manufactured in the same manner as in Example 1, except that the polymer gel electrolyte and the nanoscale solid electrolyte (75Li 2 S·25P 2 S 5 ).

[0071] The all-solid-state battery was tested for evaluation in the same manner as the all-solid-state battery of the present invention. The results show that when the polymer gel electrolyte and the nanoscale solid electrolyte are mixed at a ratio of 15:85 by weight, the discharge capacity is 135mAh / g (average value of five times), while the all-solid-state battery of this embodiment The discharge capacity is 77mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com