Asphalt-based negative electrode material for sodium ion battery and preparation method and application thereof

A technology of sodium ion battery and negative electrode material, applied in electrode manufacturing, battery electrode, chemical electrode manufacturing, etc., can solve the problems of low sodium storage capacity and unfavorable sodium ion storage, and achieve good safety performance, high reversible capacity and energy density , the effect of high carbon production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

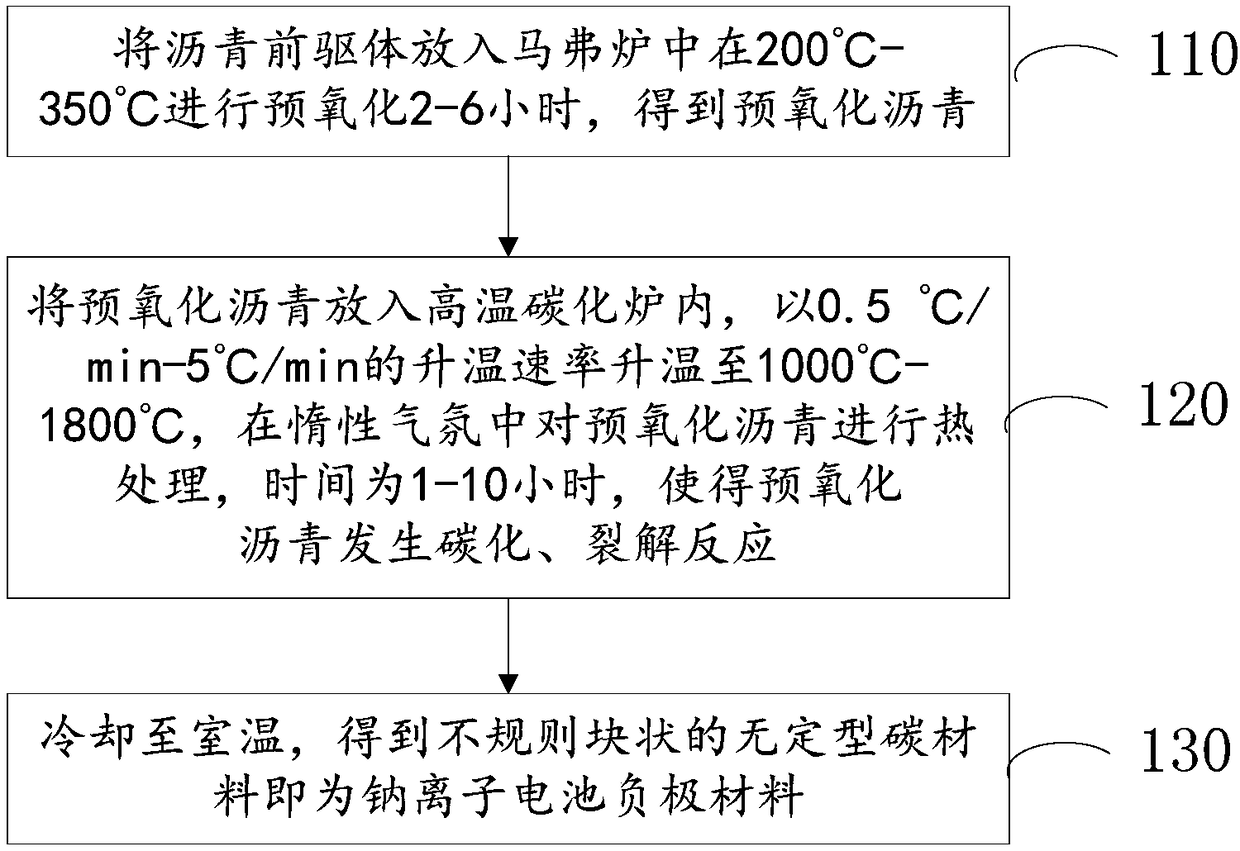

[0042] figure 1 The preparation method of the pitch-based sodium ion battery negative electrode material that the embodiment of the present invention provides, its steps are as follows figure 1 shown, including:

[0043] Step 110, putting the pitch precursor into a muffle furnace for pre-oxidation at 200°C-350°C for 2-6 hours to obtain pre-oxidized pitch;

[0044] Specifically, there may be multiple preferred combinations of the controlling conditions of the pitch pre-oxidation temperature, the pre-oxidation time in this temperature range, and the composition of the pre-oxidation atmosphere.

[0045] For example, pre-oxidation can be carried out in air or oxygen atmosphere. The pre-oxidation temperature preferably ranges from 280°C to 320°C, more preferably 300°C.

[0046] Specifically, the asphalt may be one or more mixtures of coal tar pitch, petroleum asphalt and natural asphalt.

[0047] Step 120, put the pre-oxidized pitch into a high-temperature carbonization furnace...

Embodiment 2

[0055] This example provides the negative electrode material for a sodium ion battery prepared in Example 1 above.

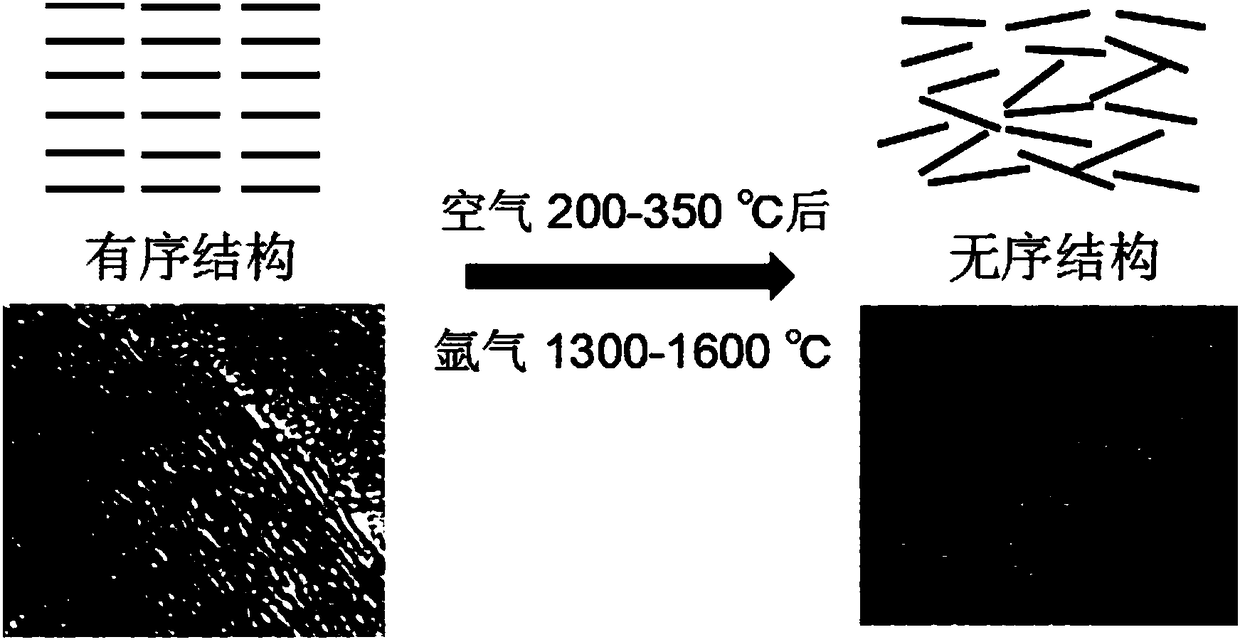

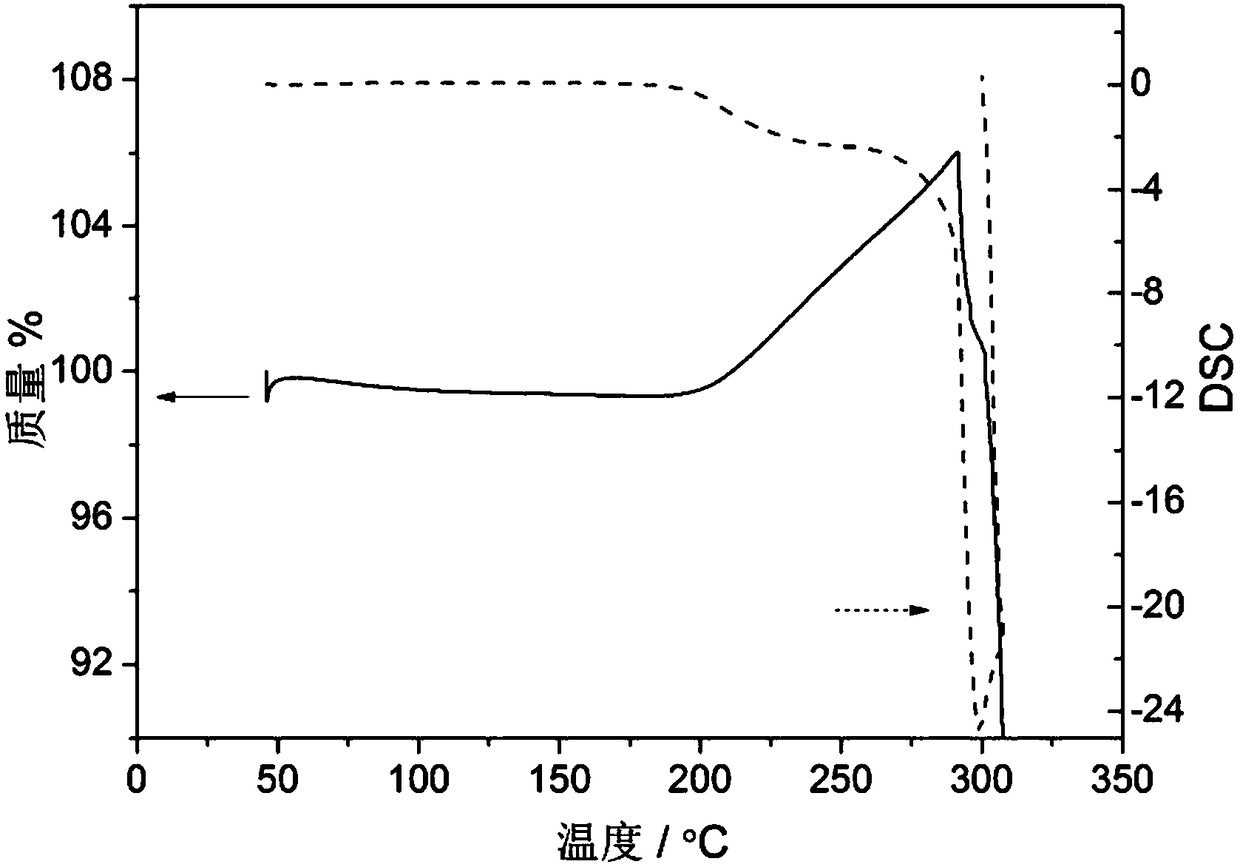

[0056] By controlling the pre-oxidation temperature, pre-oxidation time, pre-oxidation atmosphere and high-temperature carbonization of the pre-oxidized pitch under an inert atmosphere, the ordered structure of the pitch is broken, and an anode material with an irregular block shape is prepared. Irregular bulk amorphous carbon materials prepared by pitch preoxidation and carbonization process, size between 0.5-3 microns, d 002 The value is between 0.36-0.39nm, the Lc value is between 0.9-1.2nm, and the La value is between 3-5nm. image 3 The thermogravimetric curve and differential scanning calorimetry curve of asphalt raw materials held at 300°C for 6 hours in a mixed atmosphere of oxygen and argon are given. It can be seen that the quality of asphalt increases significantly when the pre-oxidation temperature is higher than 200°C. Accompanied by a large amount...

Embodiment 3

[0060] Weigh 2g of asphalt raw material, put it into a magnetic boat and put it in a muffle furnace, raise the temperature to 300°C at a rate of 3°C / min, and keep it warm for 3 hours to obtain pre-oxidized asphalt, the mass percentage of which is 103.9%. Medium asphalt has gained weight. Figure 5 It is the XRD pattern of preoxidized asphalt. Grind the pre-oxidized asphalt and put it into a magnetic boat and put it into a tube furnace, pass in argon as a protective gas, then raise the temperature to 1400°C at a rate of 3°C / min, and keep it warm for 2 hours; then cool naturally to room temperature, and take out the material , the final amorphous carbon material was obtained, and the carbon yield was 67.4%. The XRD spectrum of the amorphous carbon material obtained by carbonizing pitch is shown in Figure 6 . The d of the material can be obtained from the XRD pattern 002 = 0.362nm, L c = 1.161nm. Its Raman spectrum see Figure 7 , the L of the amorphous carbon material ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com