Patents

Literature

134results about How to "High carbon yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

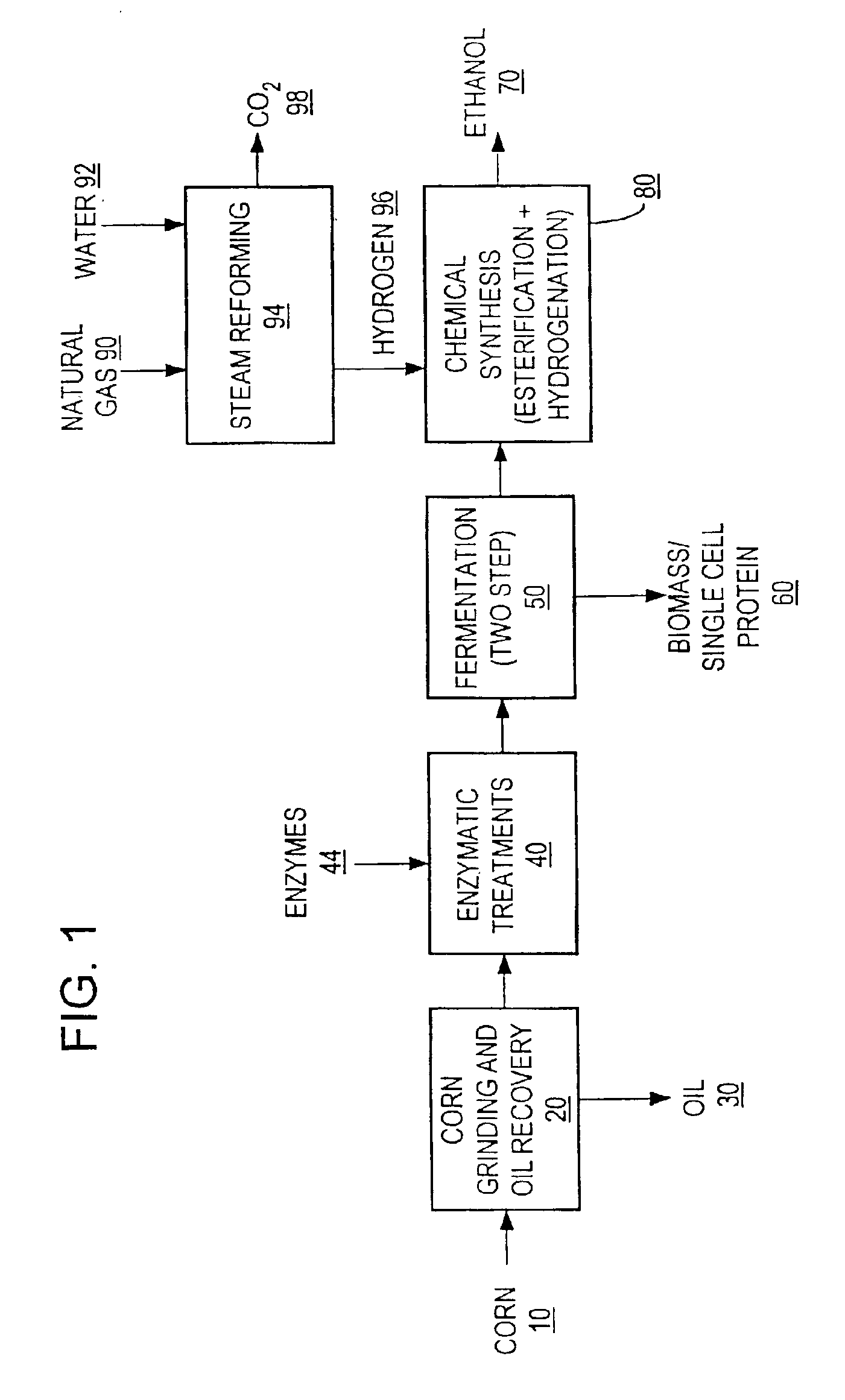

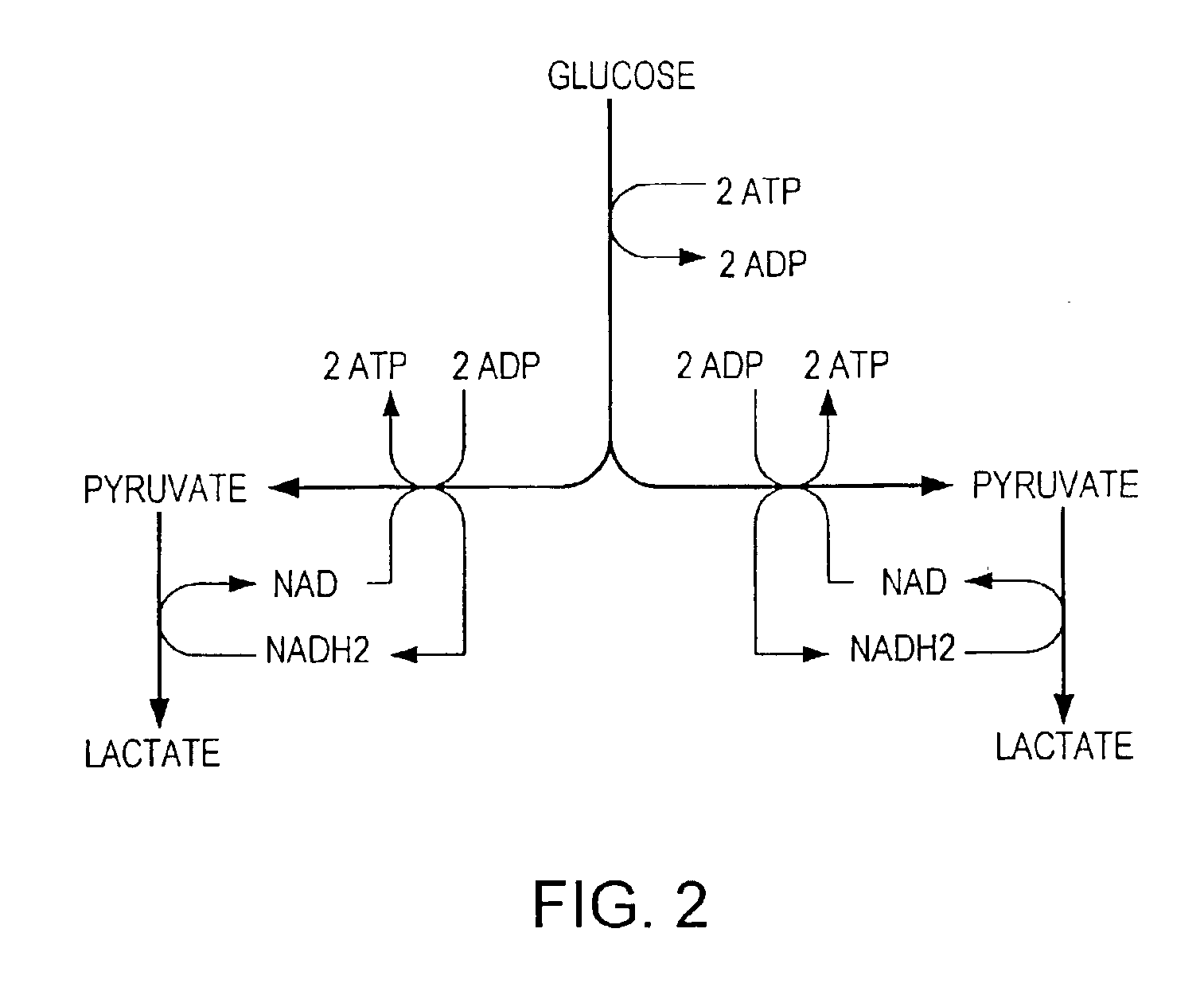

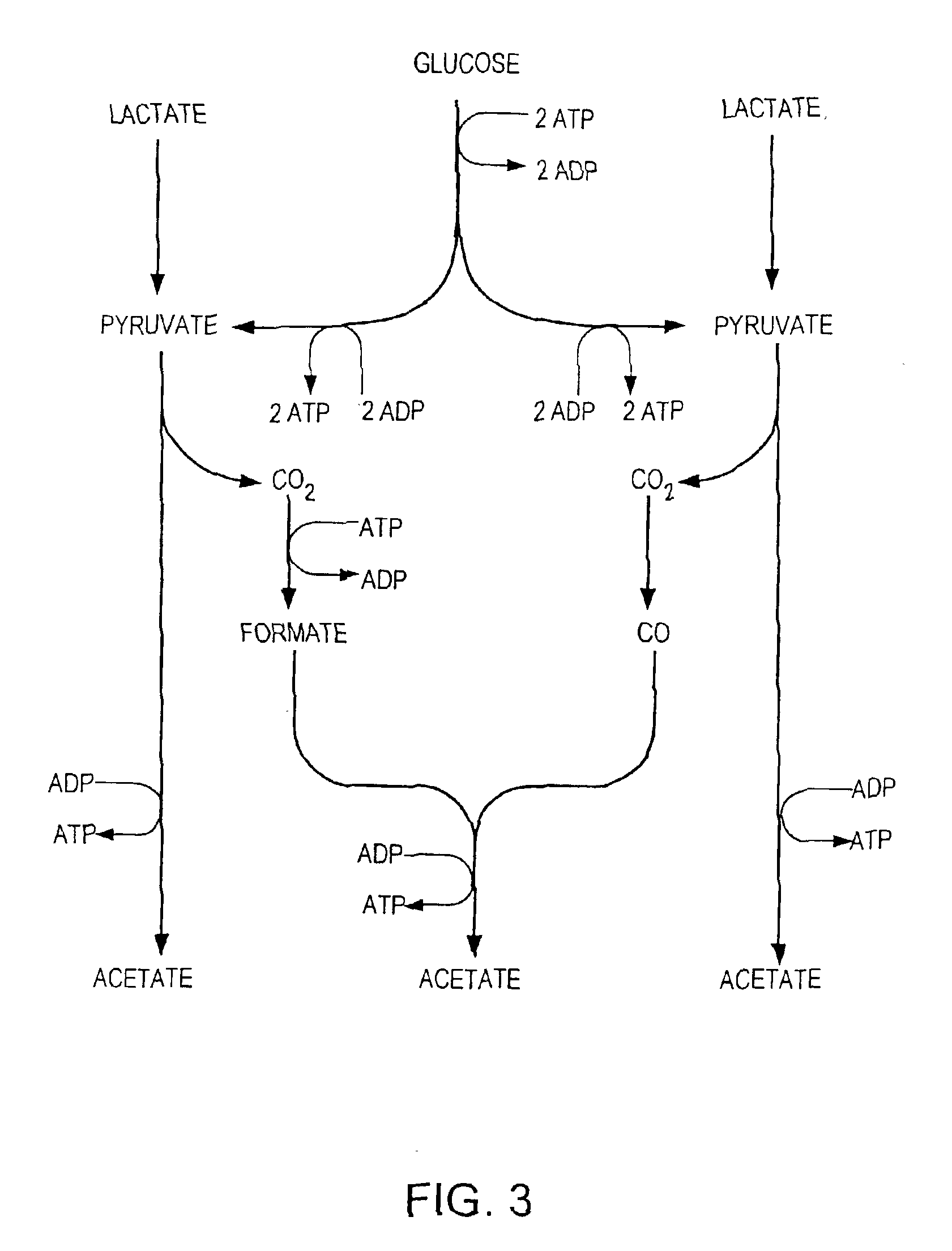

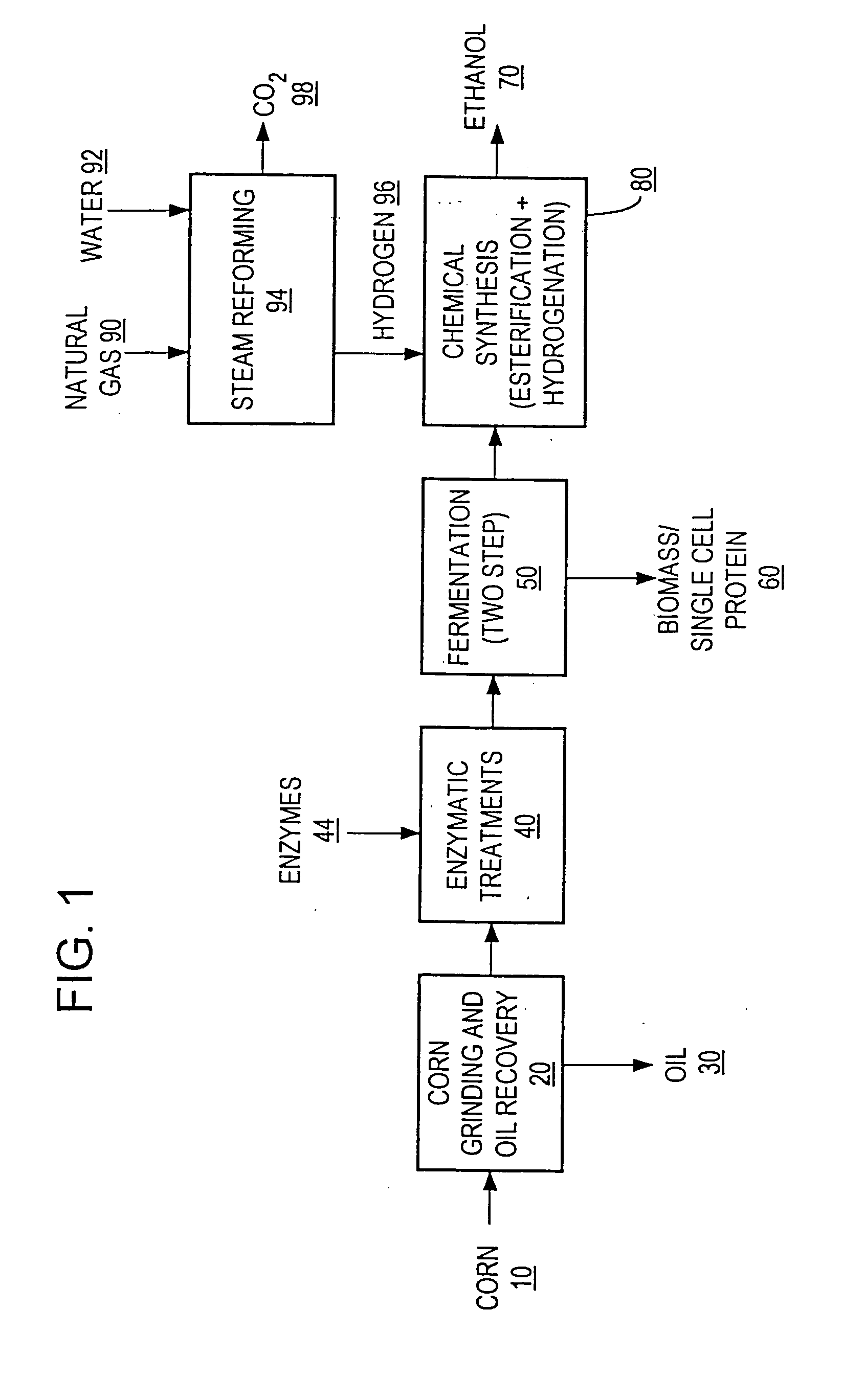

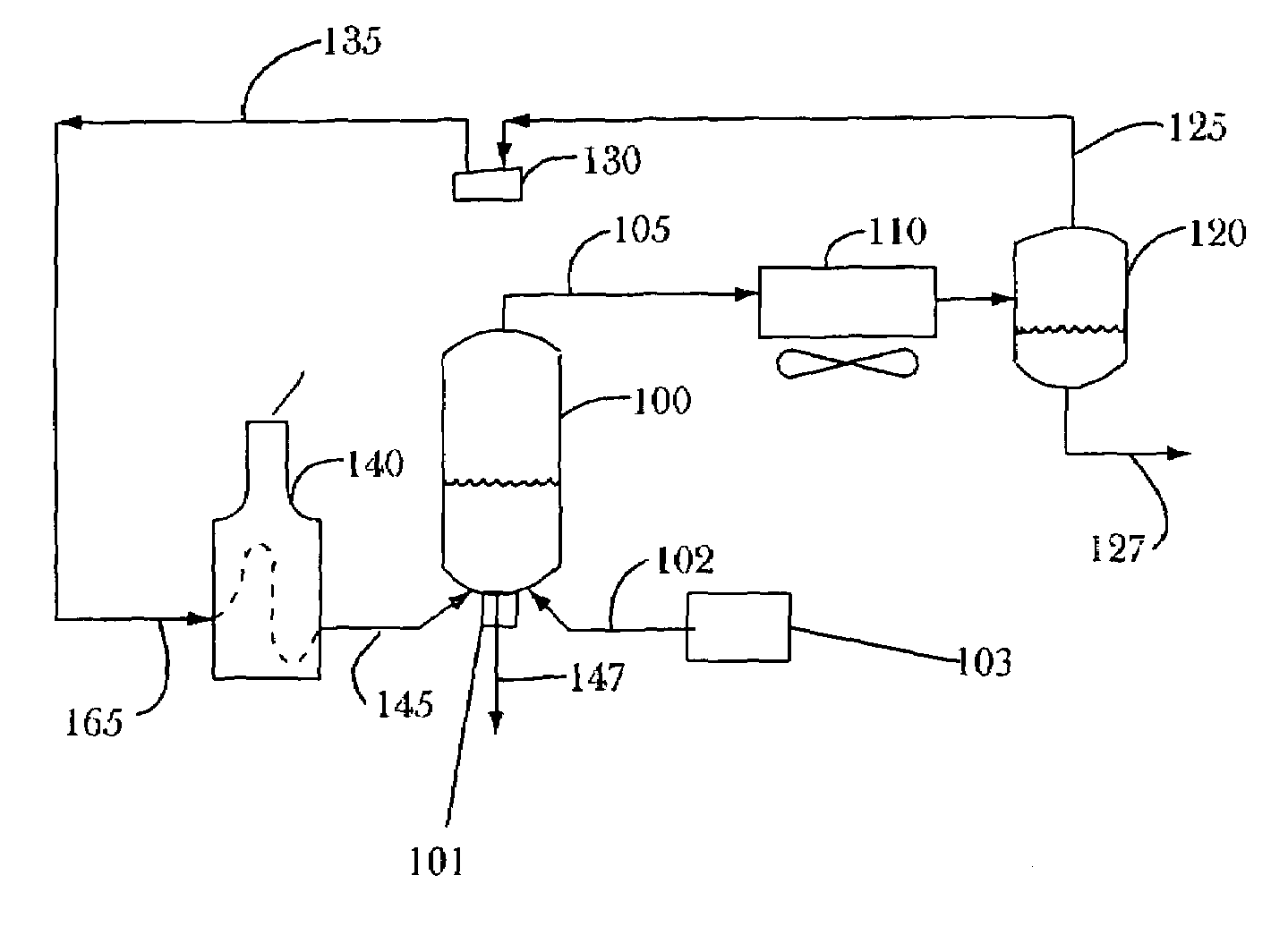

Process for producing ethanol

InactiveUS6927048B2High carbon yieldHigh protein concentrationOrganic compound preparationCarboxylic acid esters preparationAcetic acidHydrogenation reaction

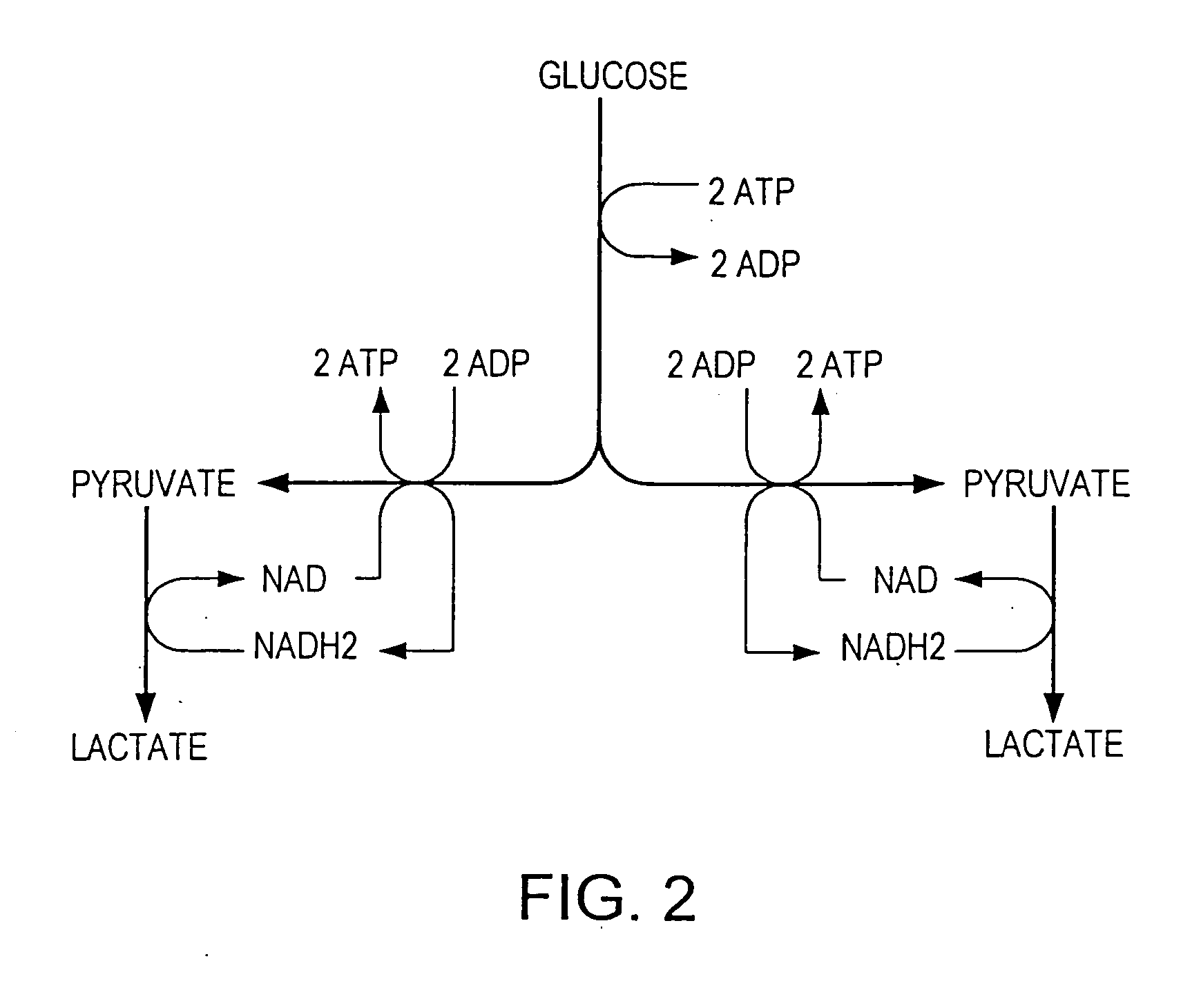

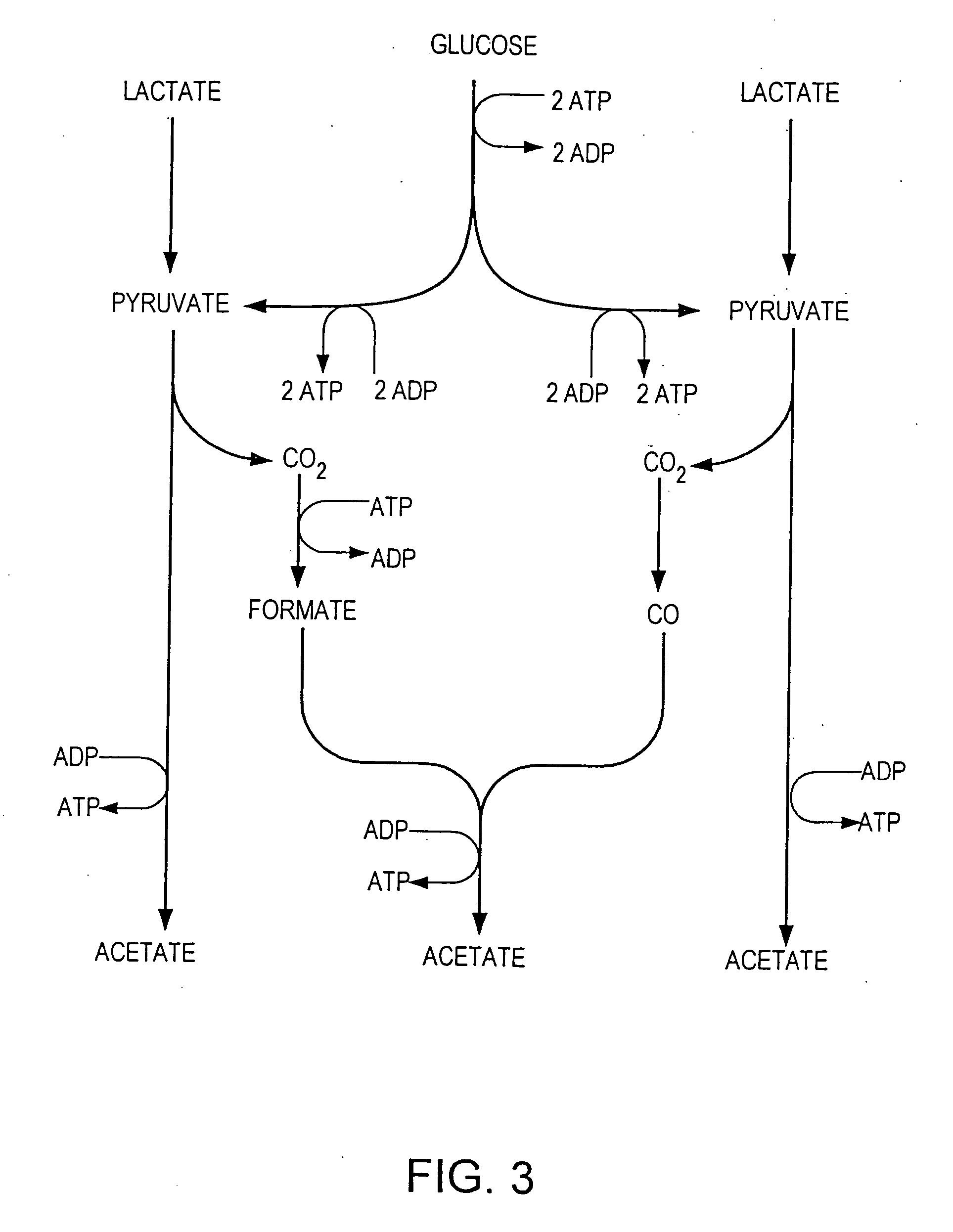

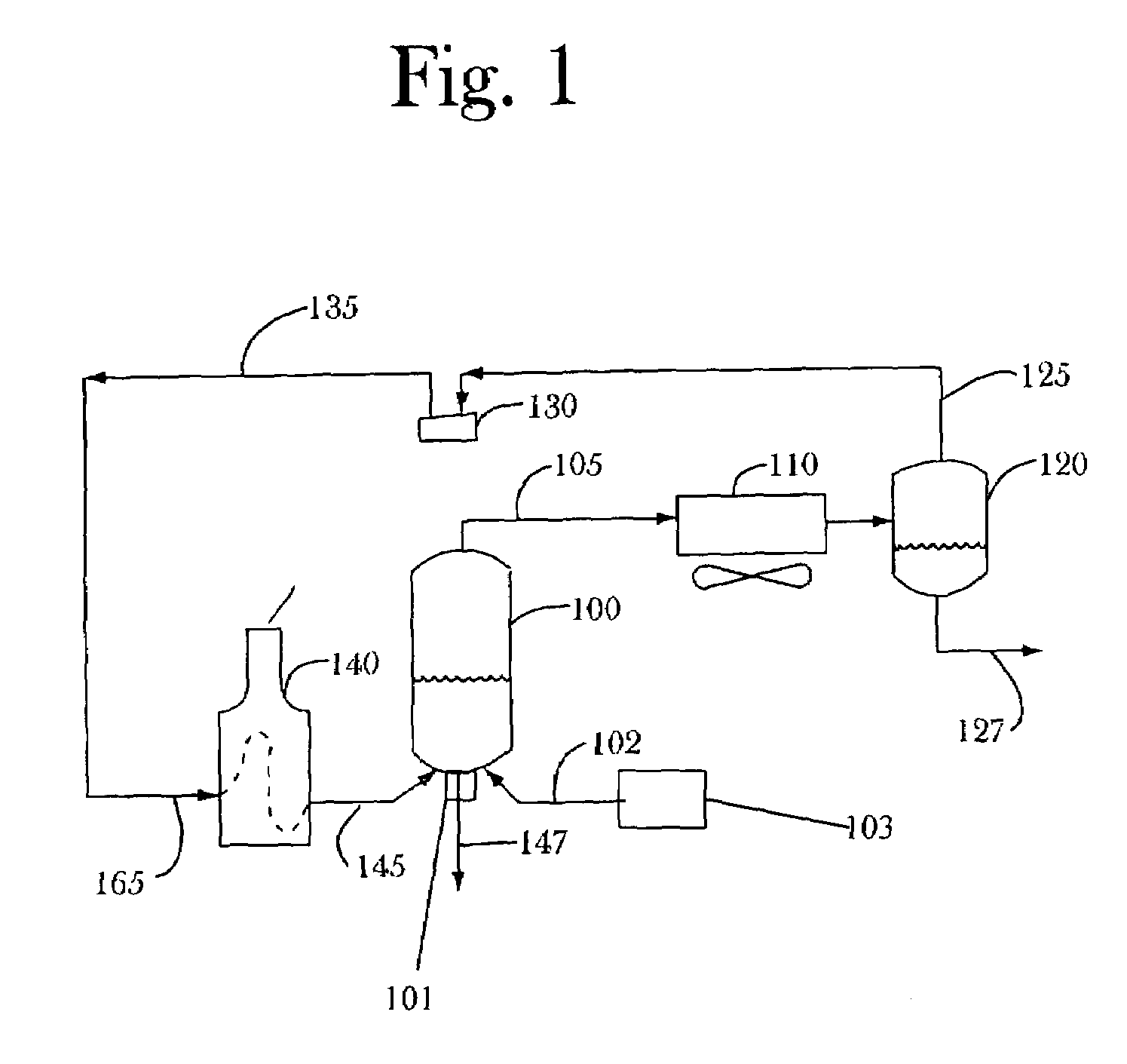

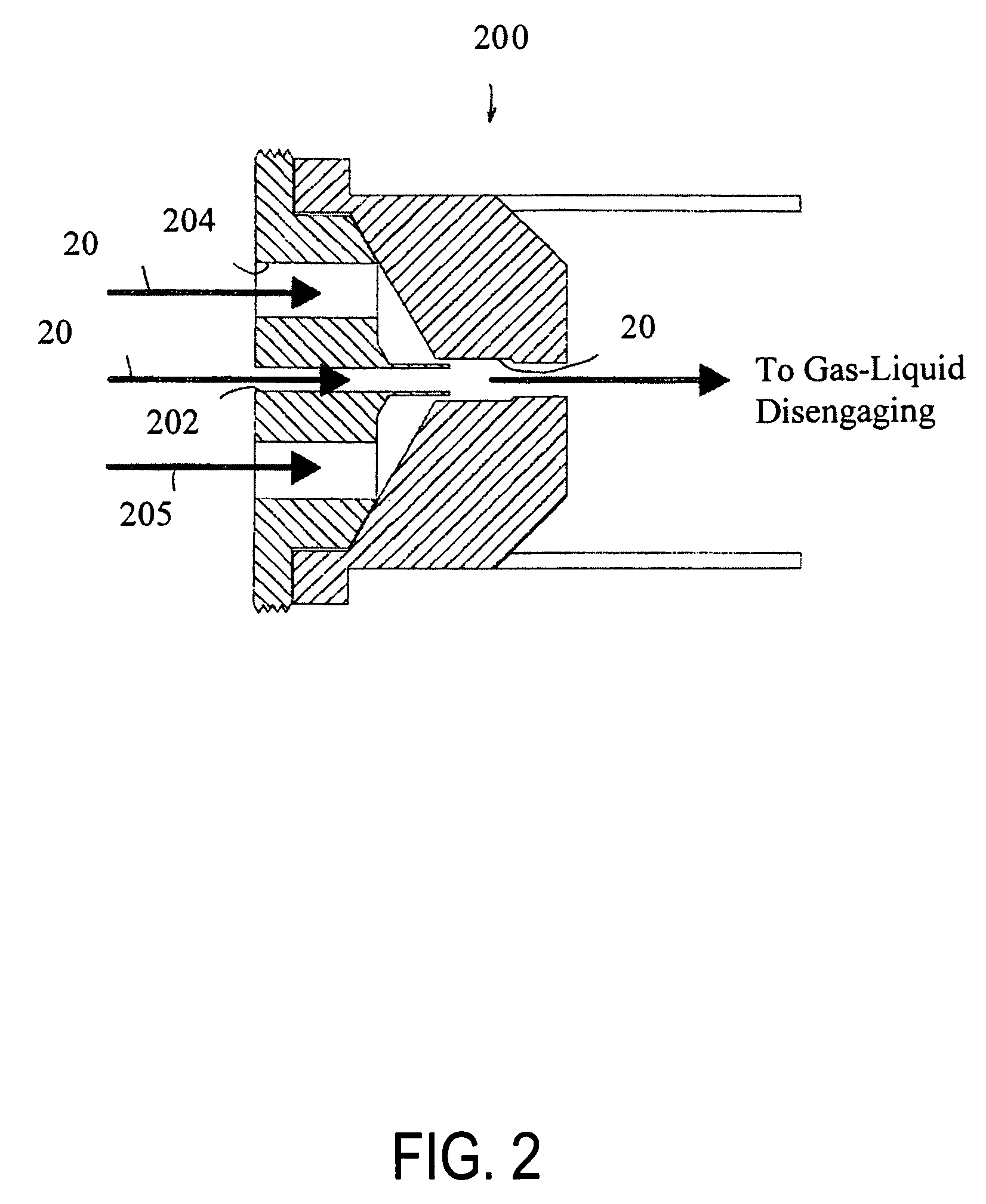

A process for producing ethanol including a combination of biochemical and synthetic conversions results in high yield ethanol production with concurrent production of high value coproducts. An acetic acid intermediate is produced from carbohydrates, such as corn, using enzymatic milling and fermentation steps, followed by conversion of the acetic acid into ethanol using esterification and hydrogenation reactions. Coproducts can include corn oil, and high protein animal feed containing the biomass produced in the fermentation.

Owner:ZEACHEM

Process for producing ethanol

InactiveUS20060019360A1High carbon yieldHigh protein concentrationOrganic compound preparationChemical industryAcetic acidHydrogenation reaction

A process for producing ethanol including a combination of biochemical and synthetic conversions results in high yield ethanol production with concurrent production of high value coproducts. An acetic acid intermediate is produced from carbohydrates, such as corn, using enzymatic milling and fermentation steps, followed by conversion of the acetic acid into ethanol using esterification and hydrogenation reactions. Coproducts can include corn oil, and high protein animal feed containing the biomass produced in the fermentation.

Owner:ZEACHEM

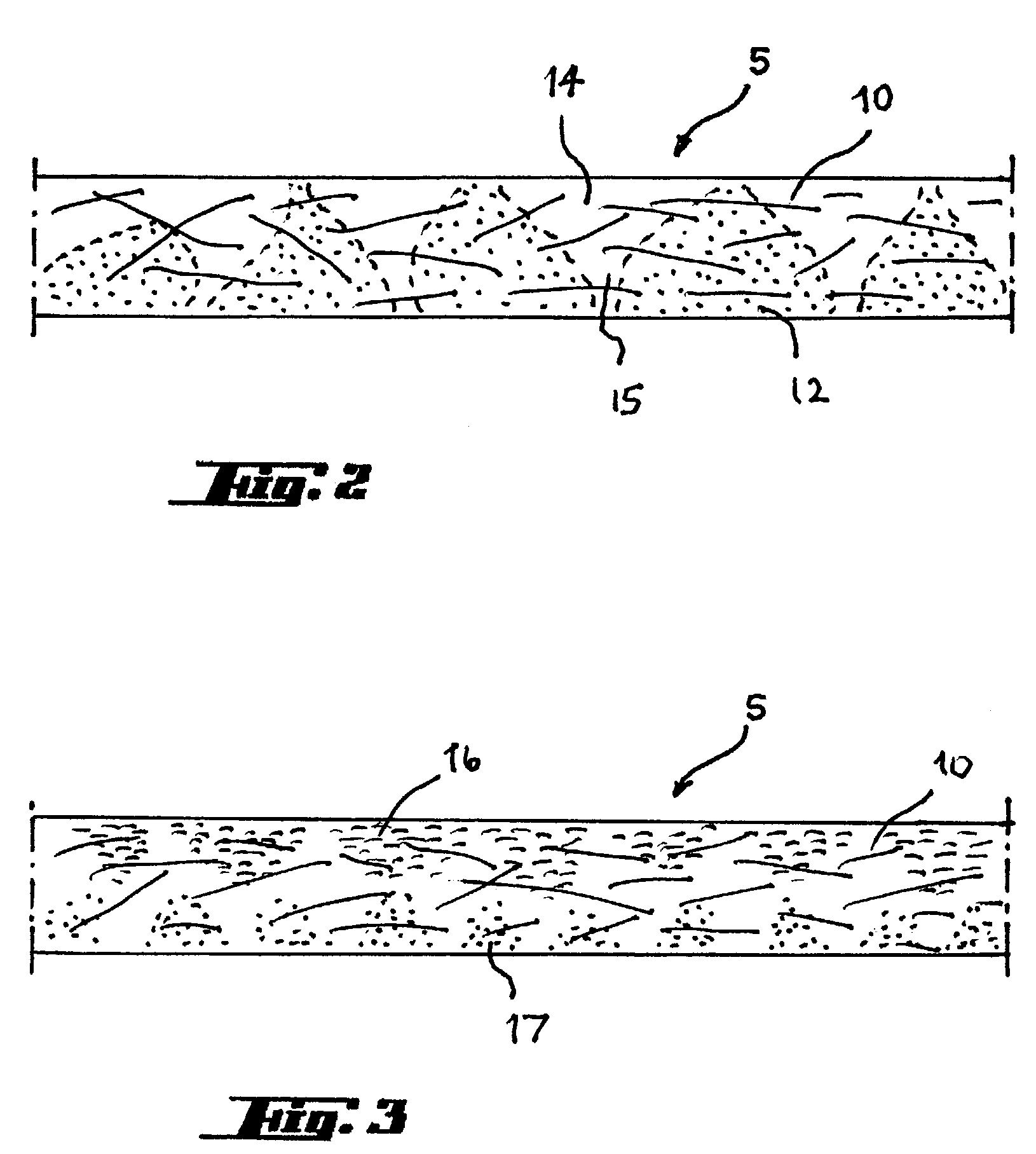

Carbon fiber electrode substrate for electrochemical cells

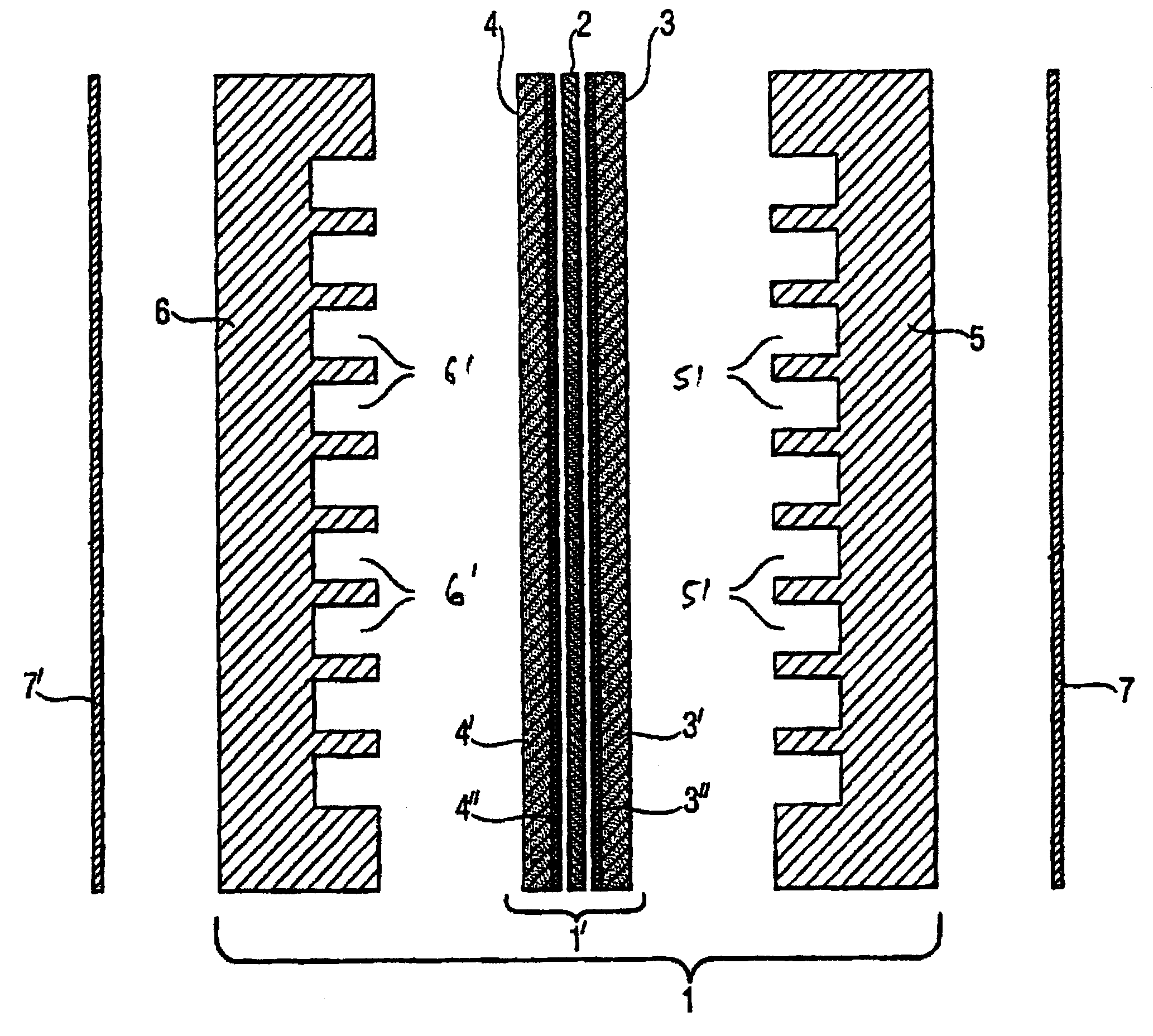

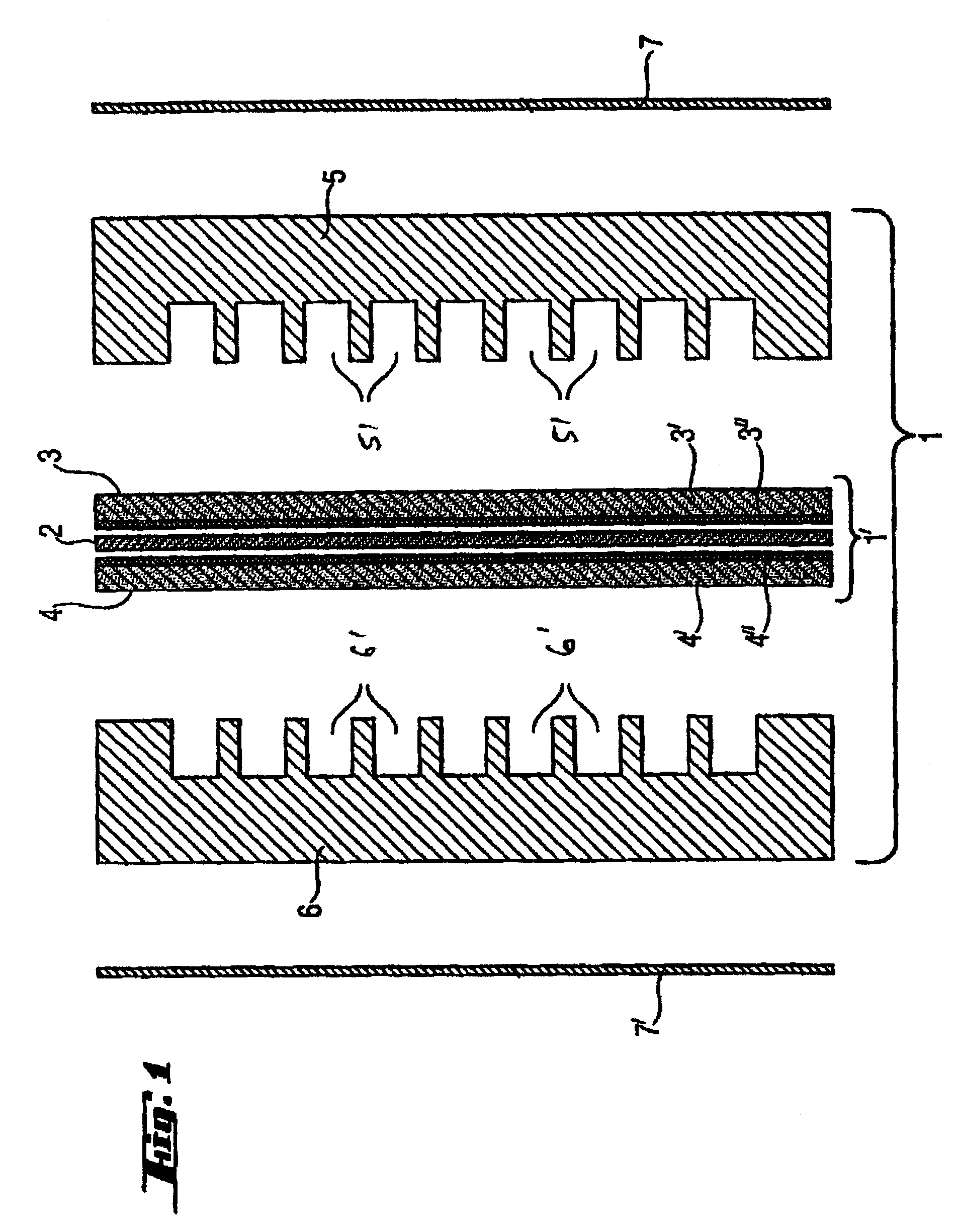

ActiveUS7144476B2High carbon contentImprove conductivityNon-fibrous pulp additionNatural cellulose pulp/paperFiberCarbon fibers

This invention relates to electrode substrates for electrochemical cells, particularly low-temperature fuel cells, and processes for their production. Low-cost carbon fiber paper structures are used as precursor for preparation of an all-carbon product that has a high electric conductivity and porosity and can be processed in a continuous reel-to-reel mode. These paper materials are further impregnated and processed to adjust the final product properties. This all-carbon electrode substrate is not brittle thereby avoiding the main disadvantage of the prior art.

Owner:SGL CARBON SE

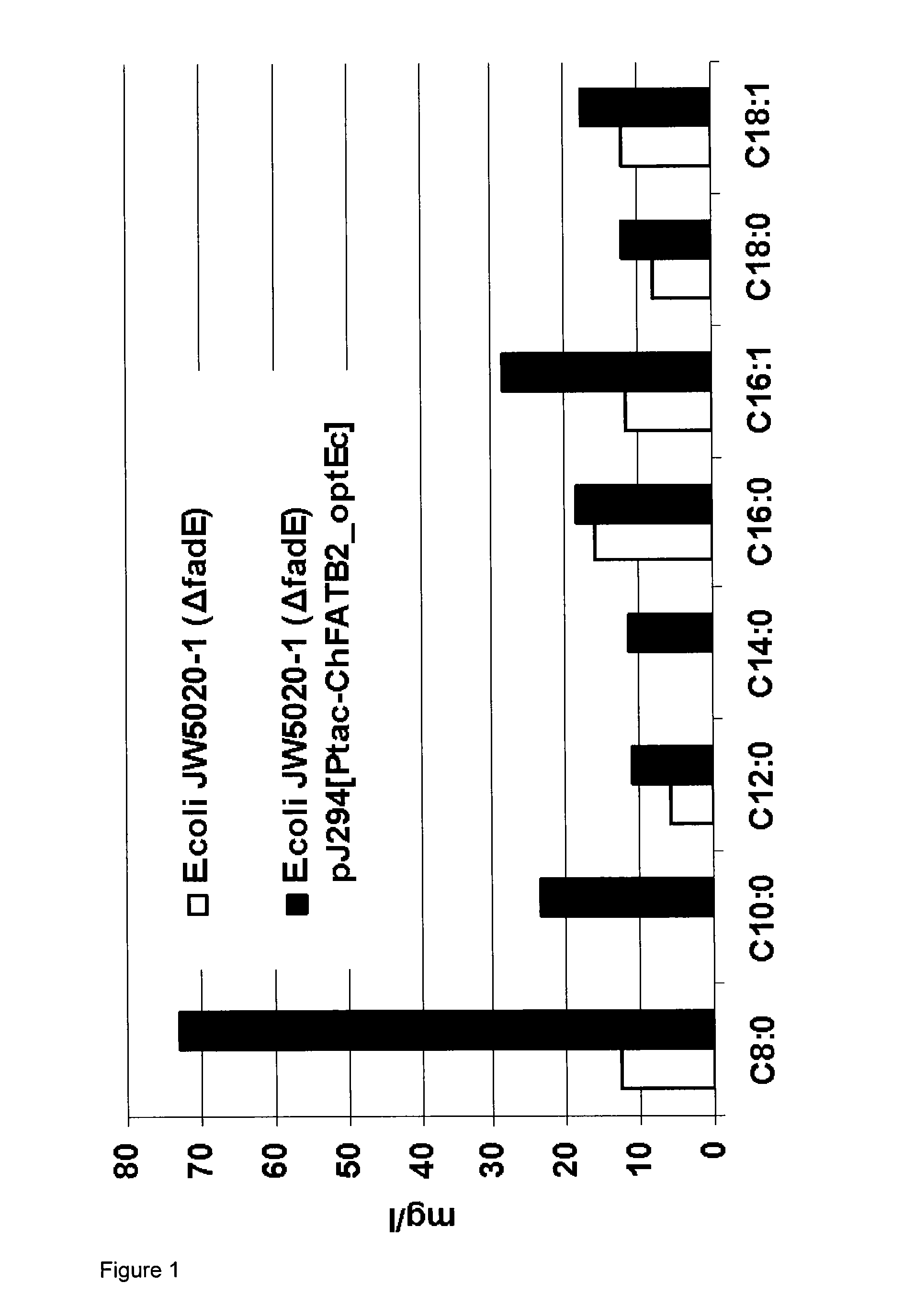

Method of Producing Organic Compounds

InactiveUS20170260552A1Favorable CO2/CO mixture of raw materialHigh carbon yieldFungiBacteriaAcetic acidMicroorganism

There is provided a mixed culture of a first and second microorganism in an aqueous medium, wherein the first microorganism is an acetogenic microorganism capable of converting a carbon source comprising CO and / or CO2 to acetate and / or ethanol, the second microorganism is a non-acetogenic microorganism capable of metabolising acetate and / or ethanol and the first and second microorganisms are in a homogenous mixture and wherein the aqueous medium comprises oxygen. There is also provided a method of producing substituted and / or unsubstituted organic compounds using the mixed culture.

Owner:EVONIK DEGUSSA GMBH

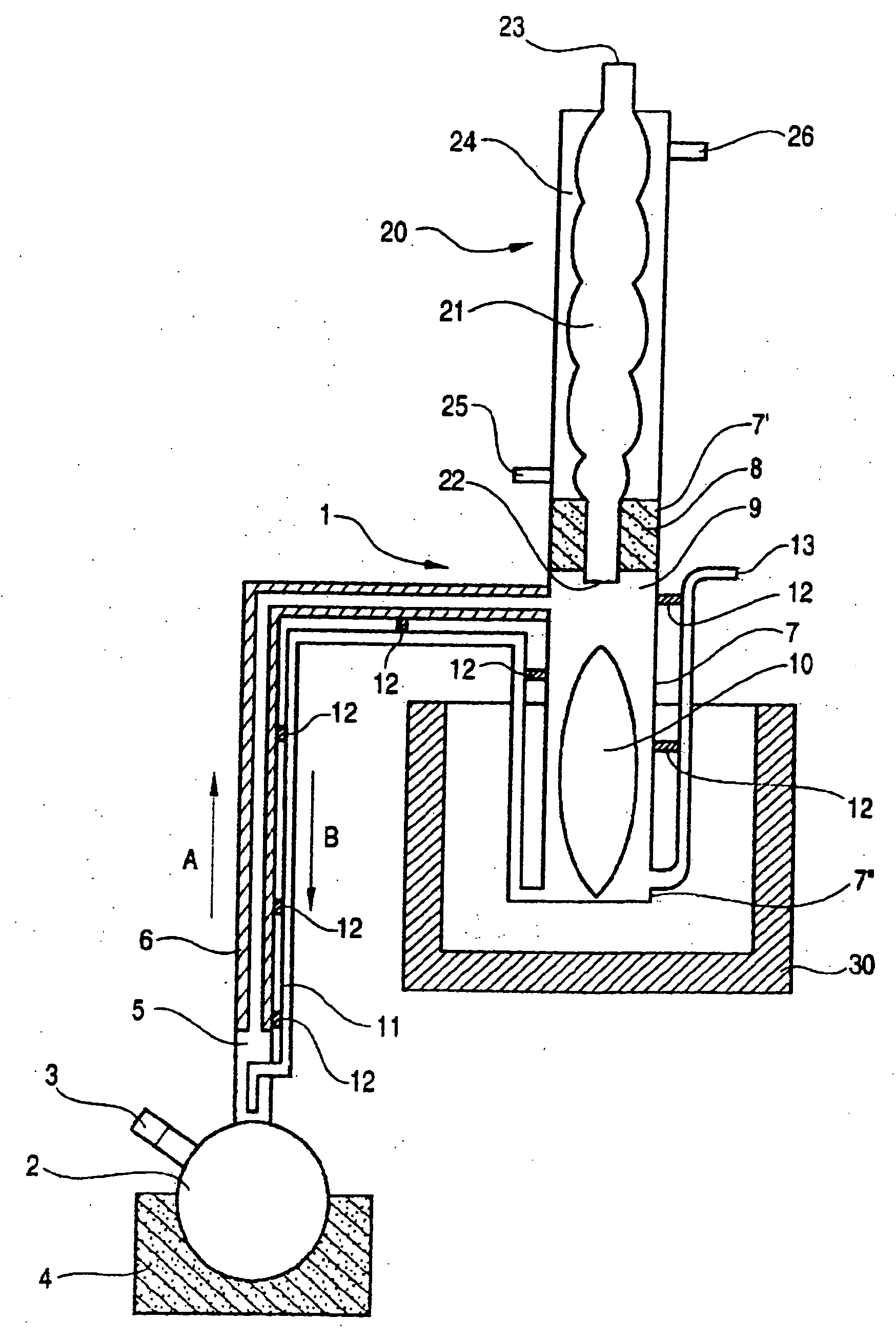

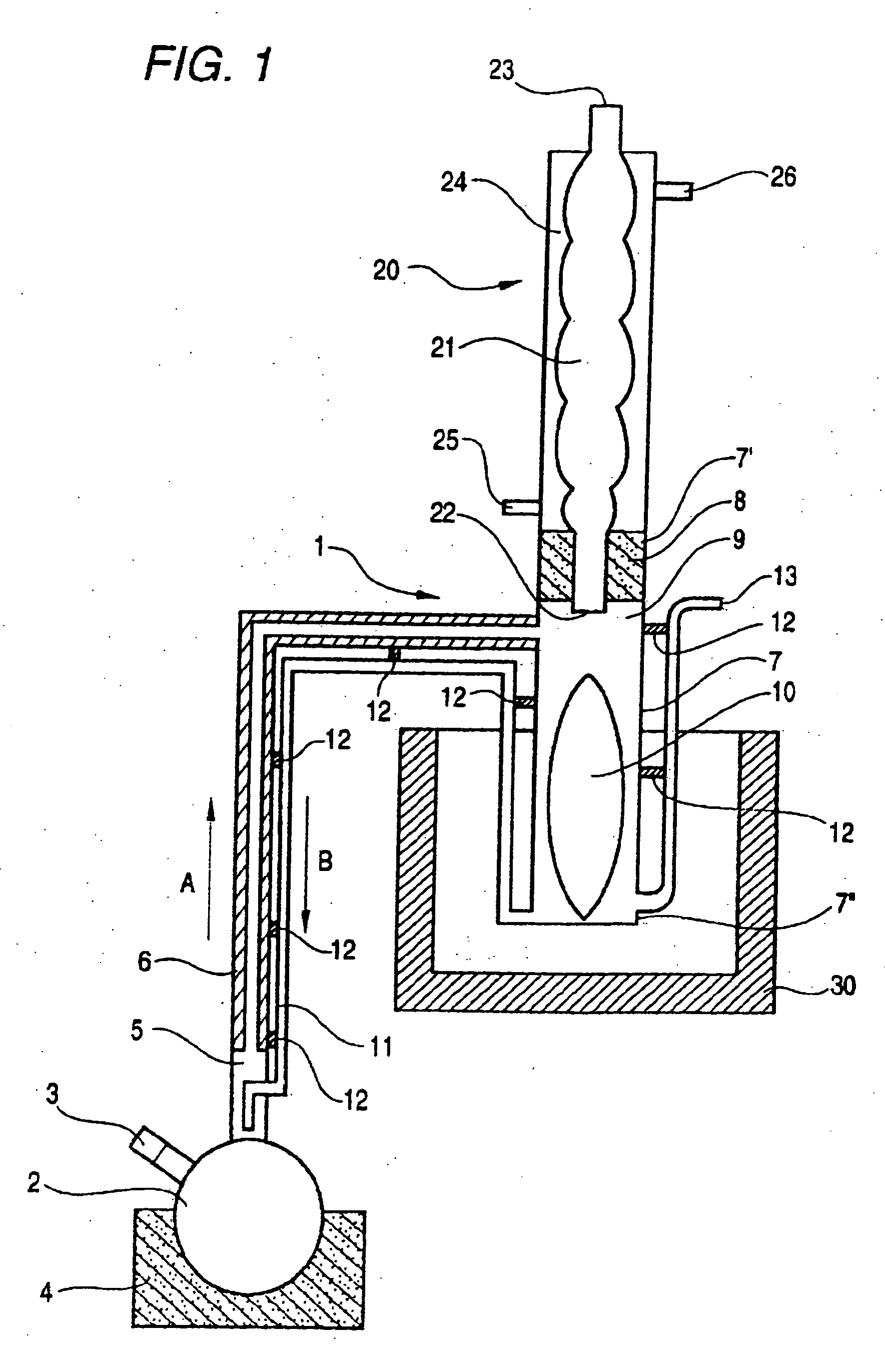

Ultrasonic reflux system for one-step purification of carbon nanostructures

InactiveUS20050069480A1Improve efficiencyIncrease percentageMaterial nanotechnologyNanostructure manufactureRefluxSolvent

Reflux systems and methods for purifying carbon nanostructures using same are provided. The reflux system includes a solvent flask, an extraction tube connected to the solvent flask by a siphon tube and a vapor tube each extending between the extraction tube and the solvent flask, and an energy application disposed around the bottom portion of the extraction tube. The reflux systems can be used in a one-step method of purifying carbon nanostructures that includes placing a soot sample that contains the carbon nanostructures and amorphous carbon in a filter and disposing the filter in the extraction tube.

Owner:SONY CORP

Method of producing high softening point pitch

InactiveUS7220348B1Reduce partial pressureMinimizes decompositionWorking-up pitch/asphalt/bitumen by distillationCatalytic crackingSuperheated steamHydrocarbon

The present invention provides a way to increase the softening point of heavier hydrocarbons in a relatively low cost and low pressure process using superheated steam to i) increase the carbon yield of the heavier hydrocarbons, while simultaneously ii) removing volatile components with a steam stripping process.

Owner:MARATHON PETROLEUM

Carbon-carbon composite preform made with carbon fiber and pitch binder

Owner:HONEYWELL INT INC

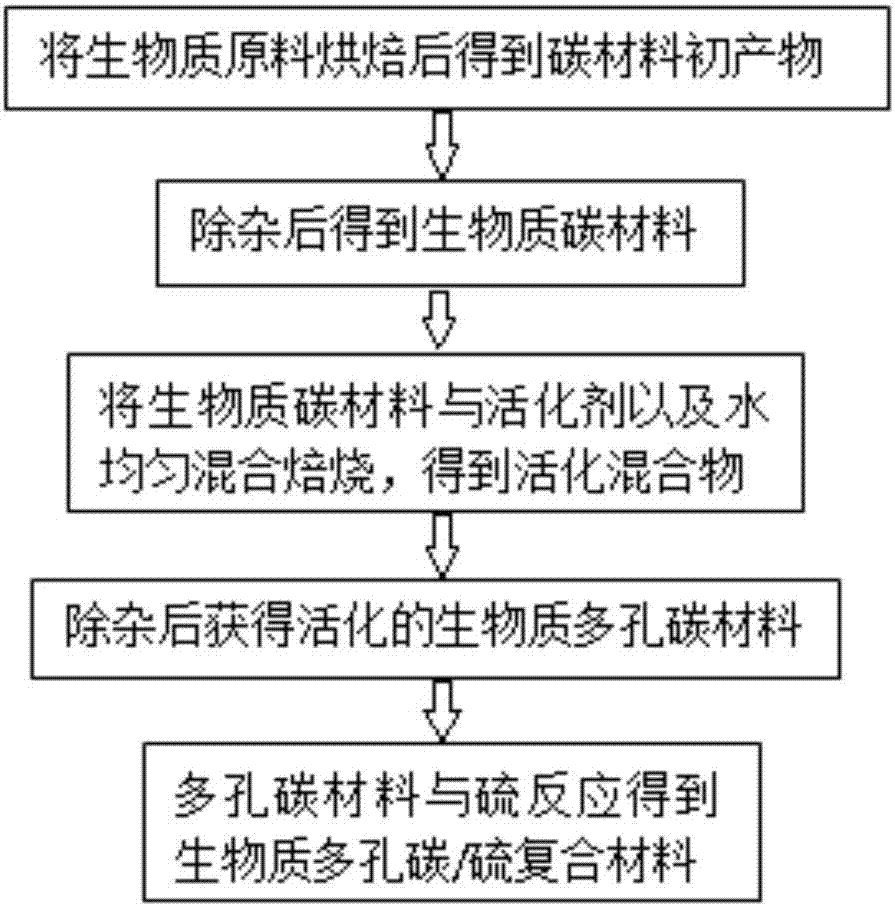

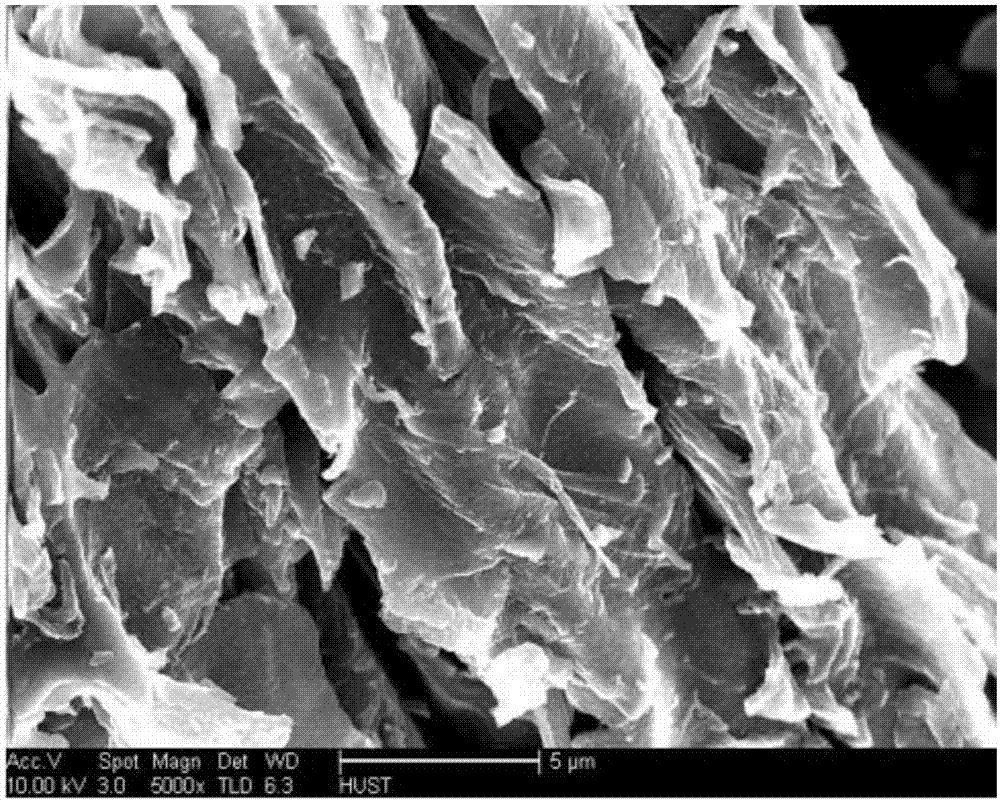

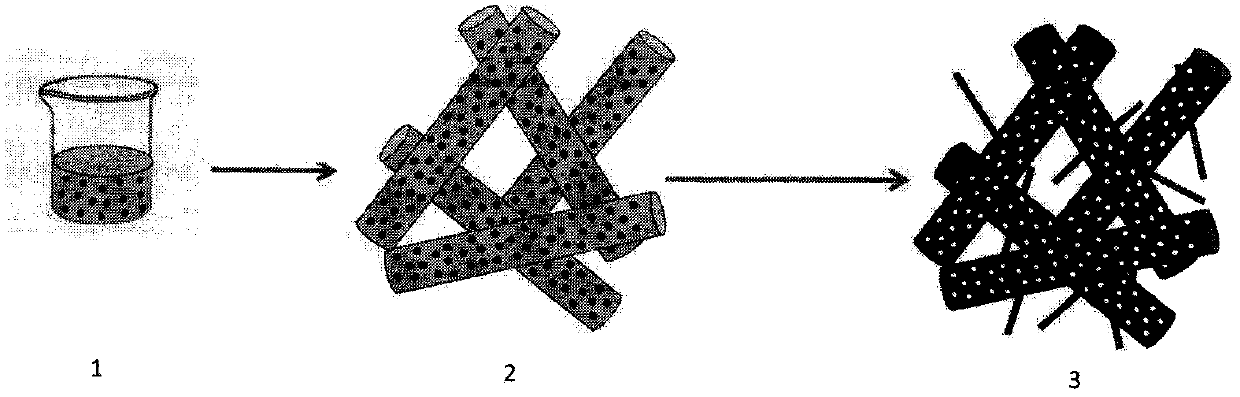

Preparation method and application of biomass-based porous carbon/sulfur composite

InactiveCN106981644AHigh value utilizationImprove cycle stabilityHybrid capacitor electrodesCell electrodesBiomass carbonPorous carbon

The invention belongs to the field of lithium-sulfur battery cathode materials and particularly relates to a preparation method of a preparation method of biomass-based porous carbon / sulfur composite, comprising the specific steps of S1, calcining biomass material to obtain a primary product of carbon material; S2, removing impurities from the primary product of carbon material to obtain biomass carbon material; S3, mixing well the biomass carbon material with an activator and water, and calcining to obtain activated mixture; S4, removing impurities from the mixture to obtain activated porous carbon material; S5, mixing the porous carbon material with sulfur for the purpose of reacting to obtain the porous carbon / sulfur composite. The invention also discloses application of the porous carbon / sulfur composite as a cathode material in batteries or supercapacitors. A battery prepared with the biomass carbon / sulfur composite prepared herein has high discharge capacity, good cycle stability and high coulombic efficiency, and has a promising application.

Owner:HUAZHONG UNIV OF SCI & TECH

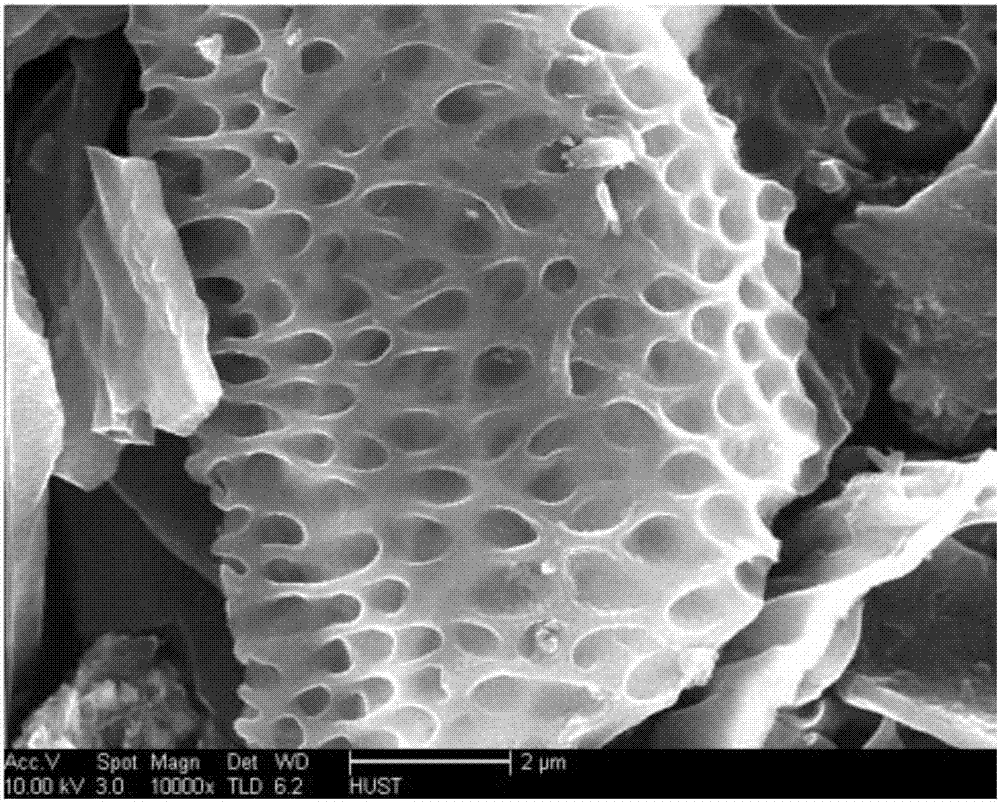

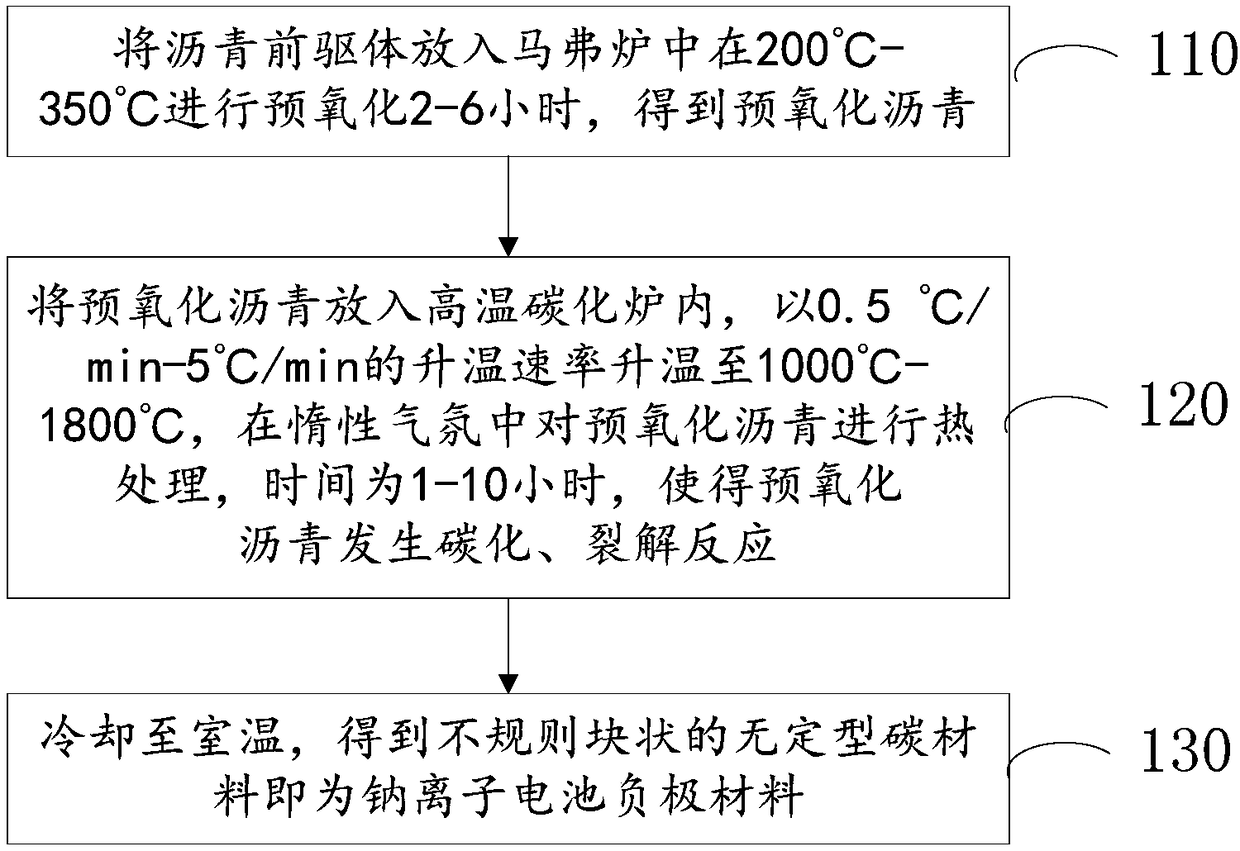

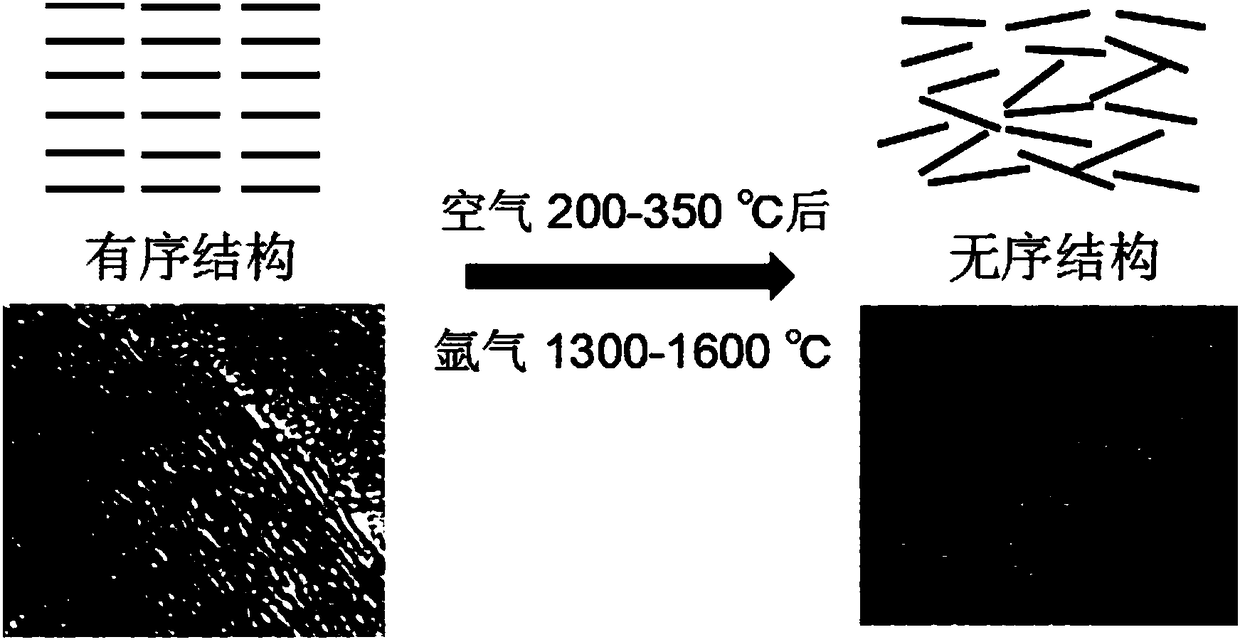

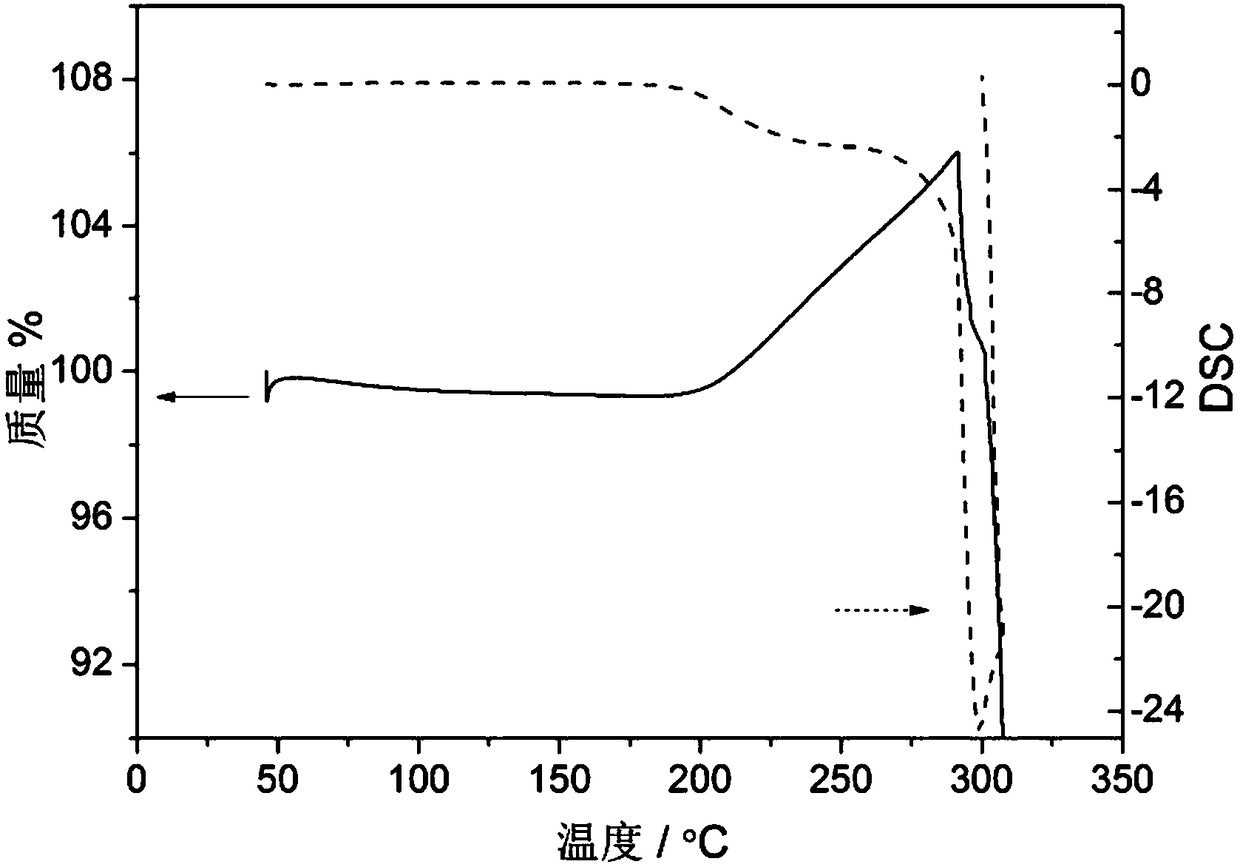

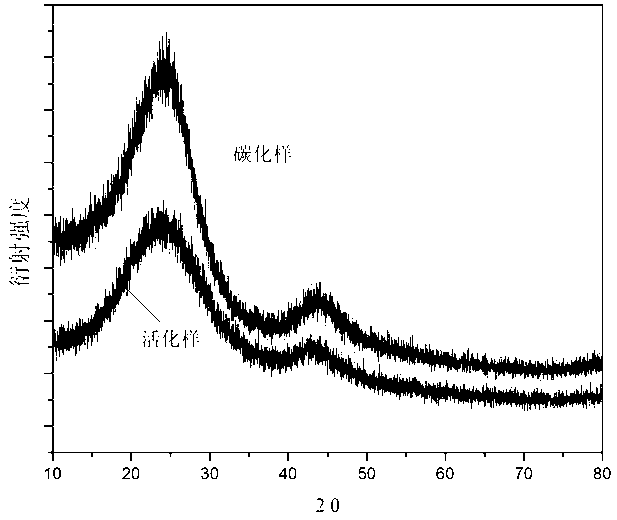

Asphalt-based negative electrode material for sodium ion battery and preparation method and application thereof

InactiveCN109148883AImproved magnification performanceLow costElectrode thermal treatmentSecondary cellsElectrical batteryPhysical chemistry

The embodiment of the invention relates to an asphalt-based negative electrode material for a sodium ion battery and a preparation method and application thereof. The method comprises the following steps: putting an asphalt precursor into a muffle furnace at 200 DEG C to 350 DEG C for preoxidation for 2 to 6 hours to obtain preoxidized asphalt; putting the preoxidized asphalt into a high-temperature carbonization furnace, and the temperature of the preoxidized asphalt rising to 1300 DEG C to 1600 DEG C at a heating rate of 0.5 DEG C / min to 5 DEG C / min, performing heat treatment on the preoxidized asphalt in an inert atmosphere for 1 to 10 hours to cause carbonization and cracking reaction of that preoxidized asphalt; wherein oxygen in the preoxidized asphalt is used for breaking the ordered structure of the asphalt in the carbonization process of the preoxidized asphalt to form a disordered structure with wedge-shaped cracks, and the carbon yield is improved and the cost is further reduced; and cooling is performed to reach room temperature to obtain an irregular lumpy amorphous carbon material, that is the negative electrode material for the sodium ion battery.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI +1

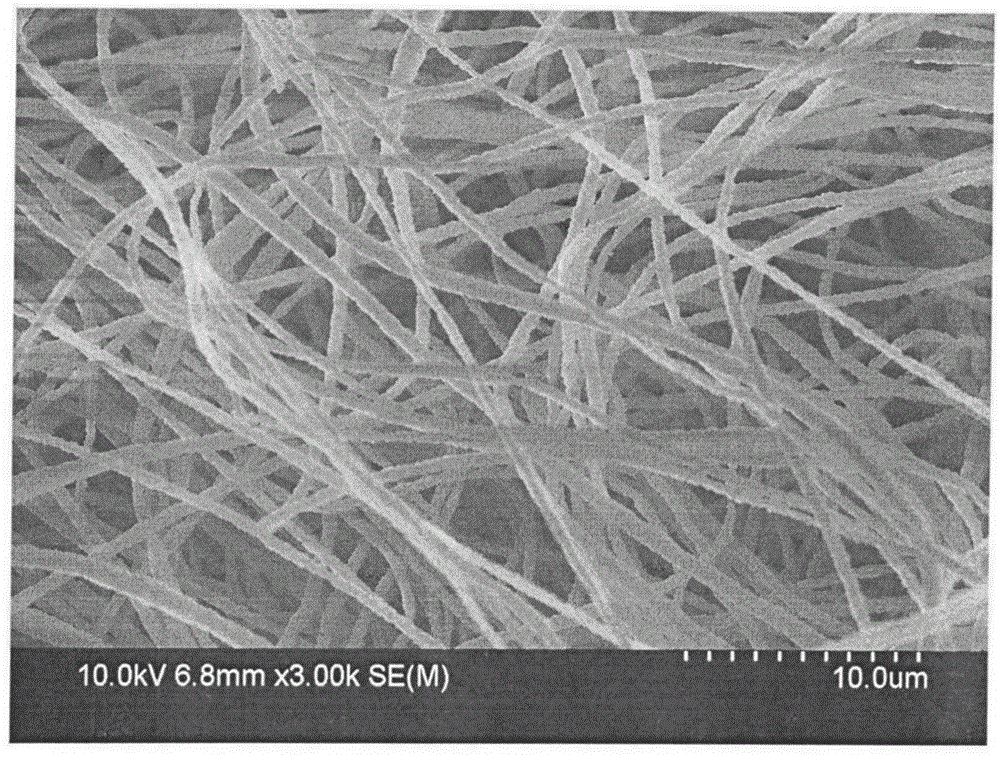

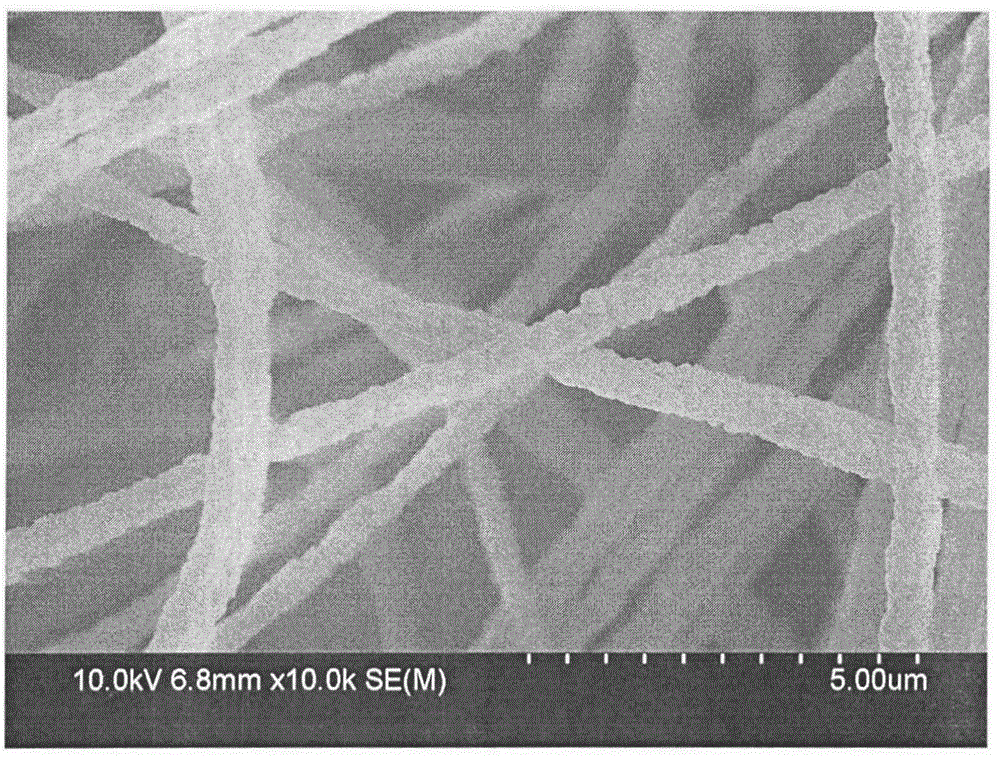

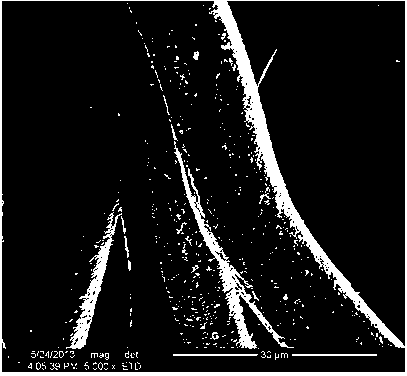

Porous carbon nanofiber membrane for positive electrode material of lithium-sulfur battery and preparation method thereof

InactiveCN105161722ANo pollution in the processLow costMaterial nanotechnologyCell electrodesFiberPorous carbon

The invention relates to a porous carbon nanofiber membrane for positive electrode material of a lithium-sulfur battery and a preparation method thereof. The porous carbon nanofiber membrane is characterized in that the diameters of the fibers range from 150nm to 500nm, the corpus fibrosums contain continuous through holes with the hole diameters being 30-100nm, and the porosities of the corpus fibrosums are more than 70%. The preparation method comprises three steps of preparation of precursor preparation, low-temperature pretreatment and high-temperature carbonization treatment. The porous carbon nanofiber membrane is provided with the continuous through holes, has super-large specific surface areas, is filled with elemental sulfur to be applied to the lithium-sulfur battery, and has relatively high cycle performance and long service life. In addition, the porous carbon nanofiber membrane can be widely applied to the fields of super capacitors, adsorption and the like.

Owner:TIANJIN POLYTECHNIC UNIV

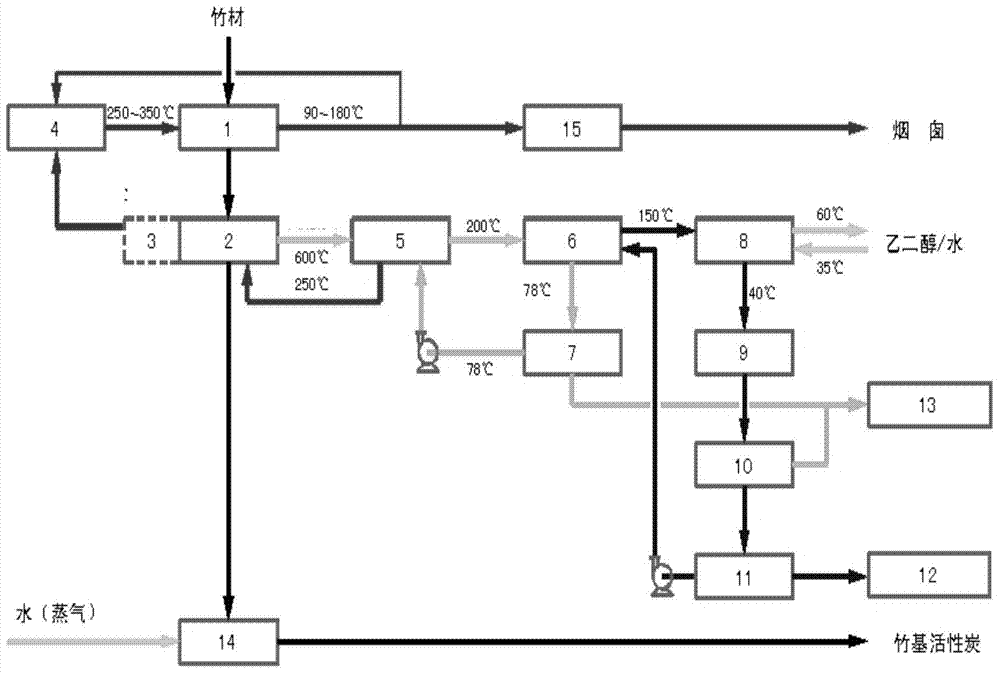

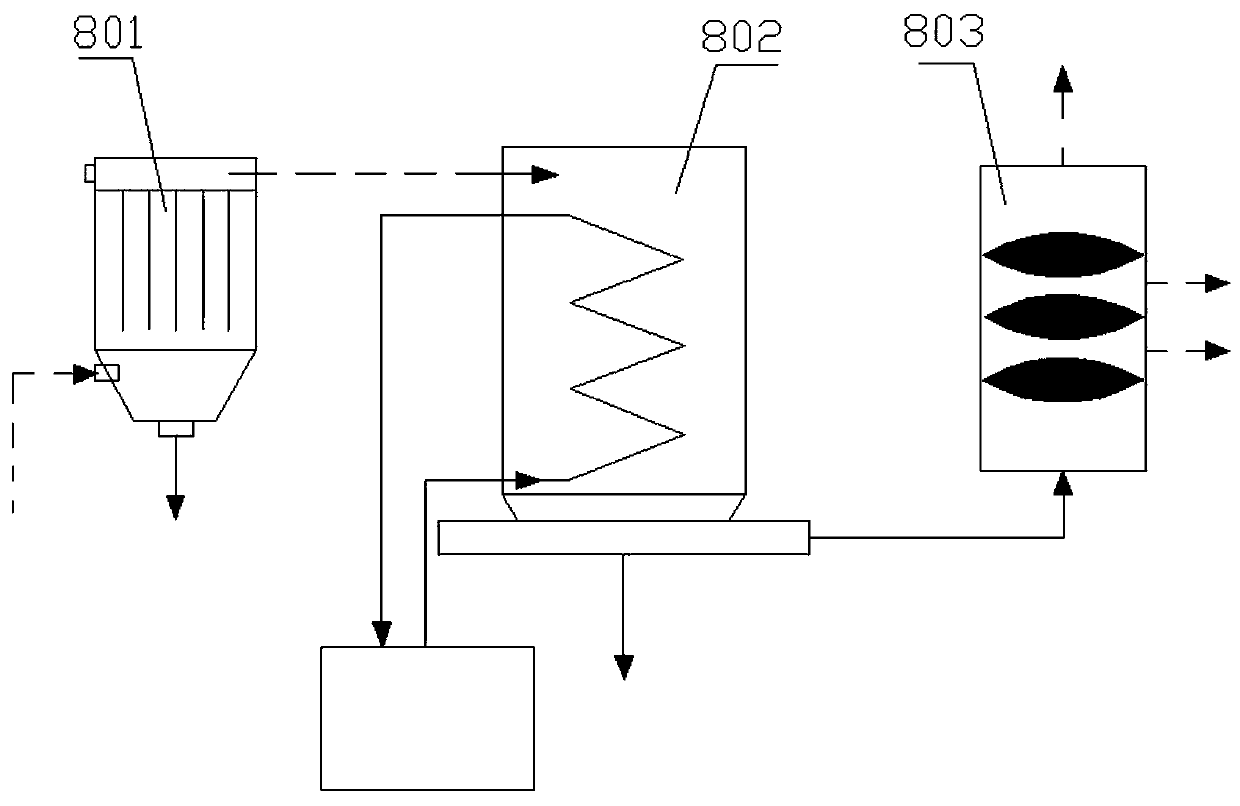

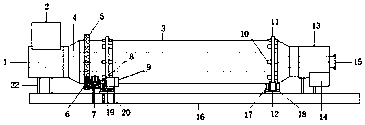

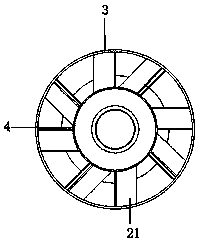

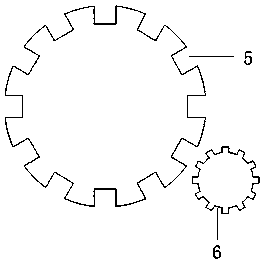

Method for preparing bamboo-based activated carbon and production device thereof

The invention provides a method for preparing a bamboo-based activated carbon and a preparation device thereof. The method comprises the following steps: A, drying, namely crushing bamboo materials at 250-350 DEG G and drying the crushed bamboo materials by drying air; B charring, namely charring the dry bamboo materials under the oxygen deficit condition by using 550-700 DEG C pyrolysis gas as thermal supports; C activating, namely spraying water steam to the charred bamboo materials, activating the bamboo carbon under the oxygen deficit condition at the activating temperature of 900-1000 DEG C, and cooling the activated bamboo carbon to obtain the bamboo-based activated carbon. The reaction is uniform and complete, the water steam in the activating process is completely contacted with the charred material, the generated activated carbon does not easily head and scale in the furnace, and the stability of product quality and the rate of carbon are improved. Moreover, the charring dry-distillation residual heat is completely utilized, the energy consumption is reduced, the charring dry-distillation by-products are recovered, the fume emission is reduced, the pollution to environment is reduced, and the comprehensive utilization rate of the bamboo materials is improved.

Owner:HUNAN HUAYIN ENERGY TECH

Sugar additive blend useful as a binder or impregnant for carbon products

InactiveUS20060239889A1High carbon yieldReduce foamingLayered productsPretreated surfacesTolueneSucrose

A sugar / additive blend useful as a binder or impregnant for carbon products. Simple sugars as well as sucrose are combined either in solution or in solid form with reactive additives such as ammonium hydrogen phosphate, ammonium chloride and para-toluene sulfuric acid. The sugar / additive blends form more and denser carbon residue than sugar alone when subjected to pyrolysis.

Owner:GRAFTECH INT HLDG INC

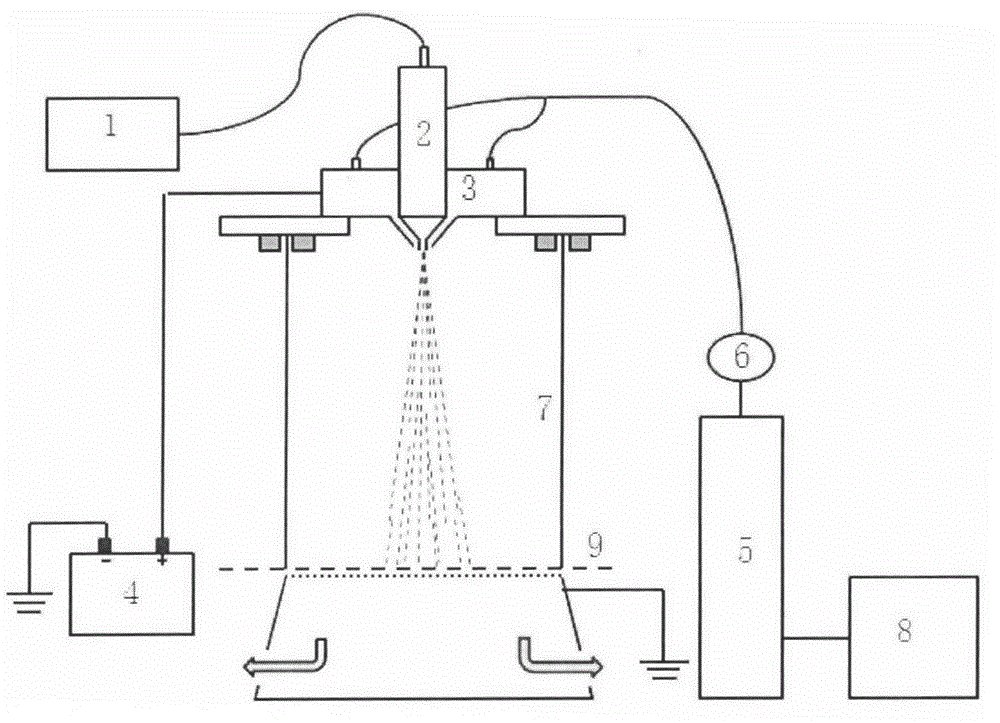

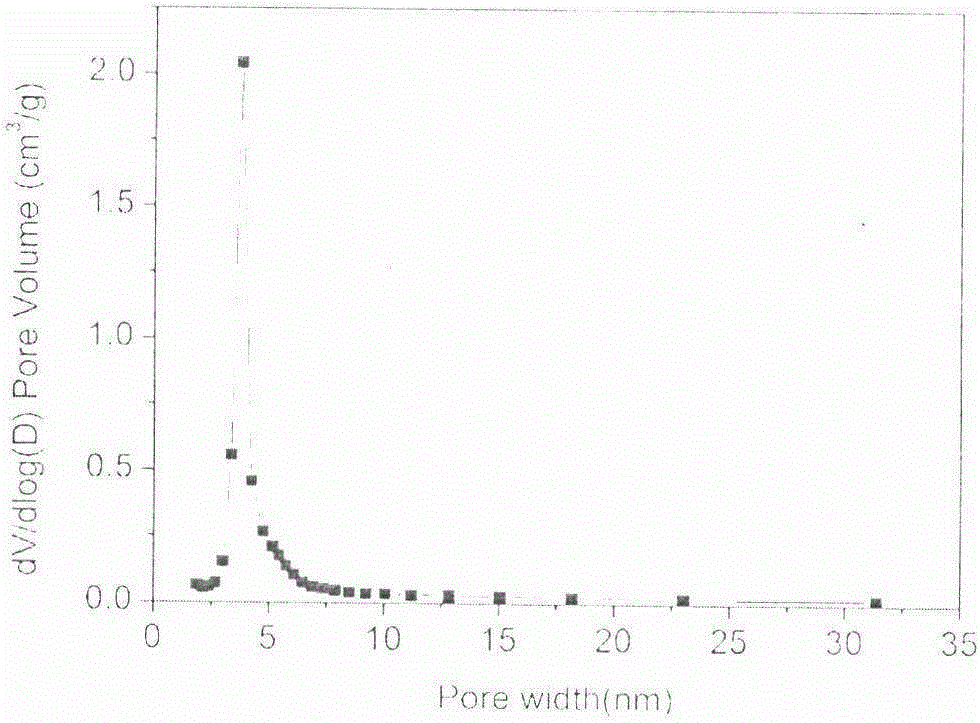

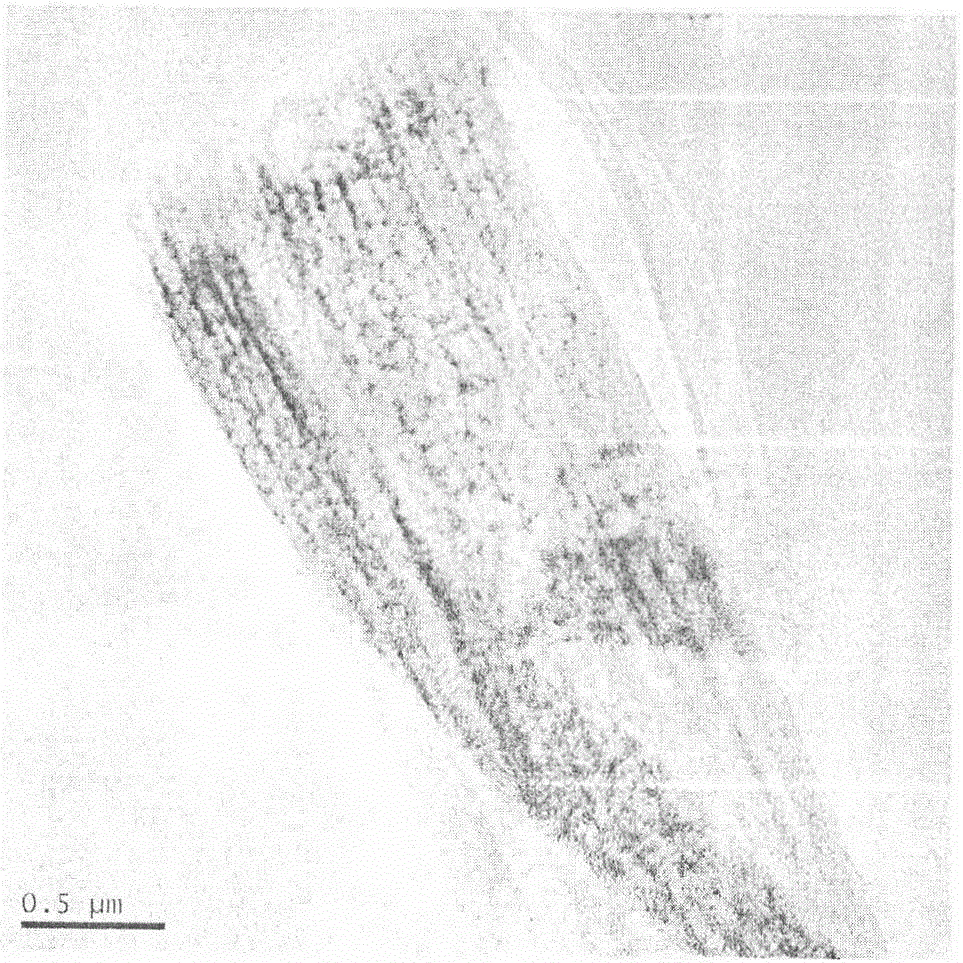

Preparation method of ordered mesoporous carbon nanofibers

The invention relates to a preparation method of carbon nanofibers with ordered mesoporous structures and a product prepared from the carbon nanofibers. The preparation method of the carbon nanofibers comprises the following steps of firstly, preparing phenolic resin, polyvinylpyrrolidone, an amphiphilic copolymer, inorganic salts and ethanol into a solution according to a certain proportion; secondly, preparing carbon nanofiber precursors by electrostatic spinning; thirdly, curing the carbon nanofiber precursors; fourthly, performing carbonizing and acid pickling to obtain the carbon nanofibers. The method is simple in process, low in cost and suitable for large-scale continuous production. The prepared carbon fibers contain abundant ordered mesopores; pore canals are parallel to the direction of a fiber axis, the diameters of the fibers are 300 to 900nm, pore sizes can be adjustable between 3nm and 20nm, the porosity is 80 to 97 percent, and the specific surface area is 100 to 1000m<2> / g; the carbon nanofibers have potential application in aspects of capacitors, lithium batteries, catalyst carriers, drug carriers, adsorbents and the like.

Owner:TIANJIN POLYTECHNIC UNIV

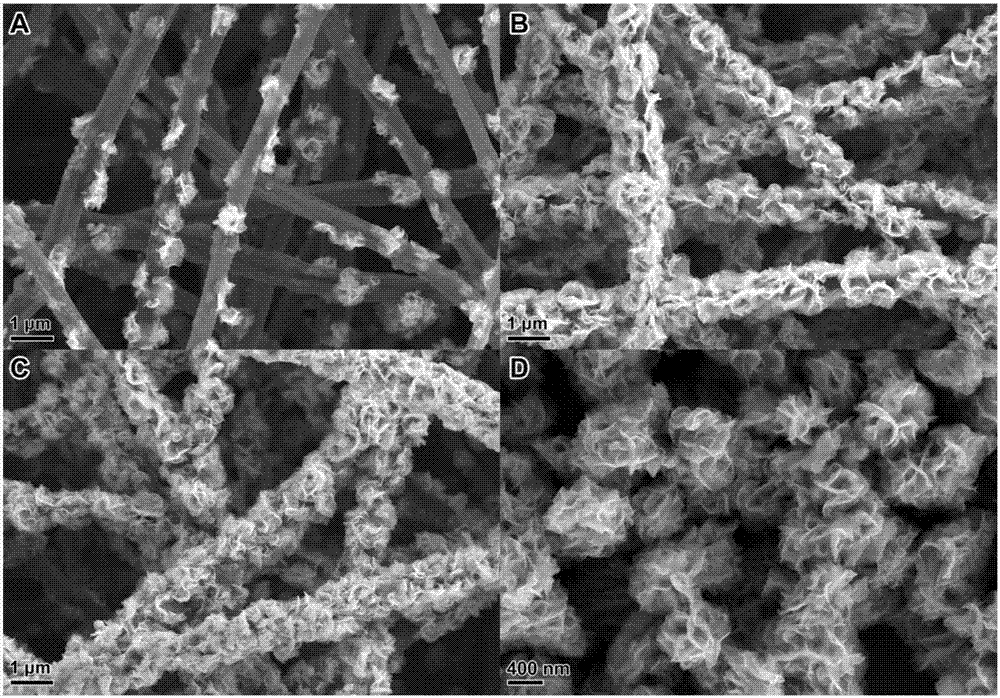

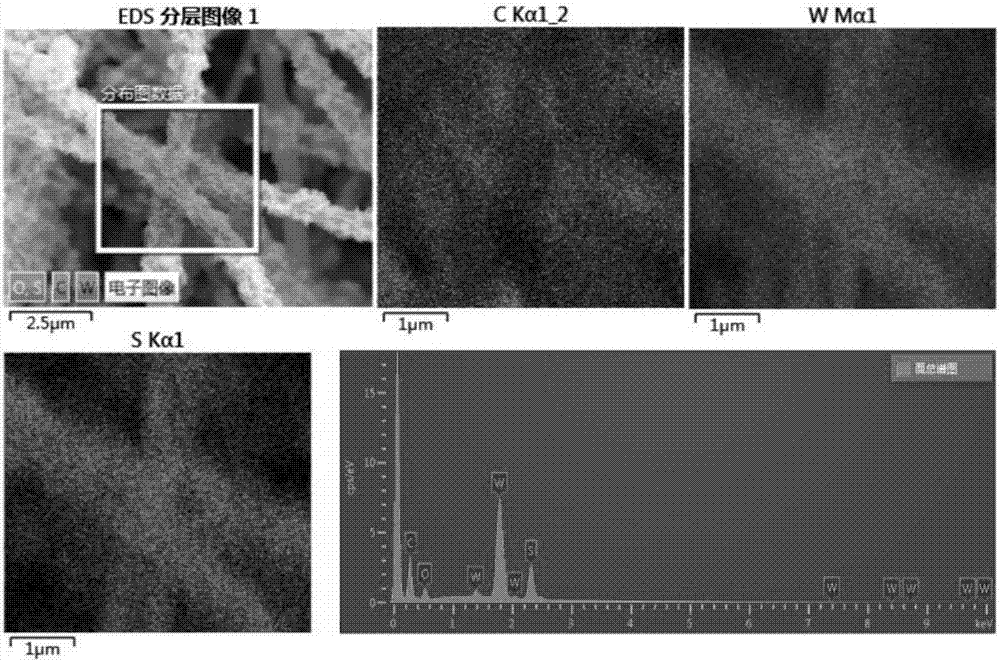

Tungsten disulfide/carbon nanofiber composite material, and preparation method and use thereof

InactiveCN107034663AMany poresImprove conductivityMaterial nanotechnologyPhysical/chemical process catalystsElectrospinningNanofiber

The invention provides a tungsten disulfide / carbon nanofiber composite material, and a preparation method and a use thereof. The preparation method comprises the following steps: (1) preparing a polyacrylonitrile spinning solution under high-speed stirring and oil bath conditions; (2) producing polyacrylonitrile nanofibers through adopting an electrostatic spinning technology; (3) pre-oxidizing the polyacrylonitrile nanofibers obtained in step (2) through temperature programmed control; (4) carbonizing the pre-oxidized polyacrylonitrile nanofibers obtained in step (3) through stepwise heating; (5) adding a certain amount of a tungsten disulfide precursor compound into a solvent, and carrying out ultrasonic treatment to obtain a tungsten disulfide precursor solution; and (6) immersing the above obtained carbon nanofiber membrane in the tungsten disulfide precursor solution, placing the obtained mixture in a high pressure reactor, and carrying out a solvothermal reaction at a certain temperature to obtain the tungsten disulfide / carbon nanofiber composite material. The preparation method has the advantages of simple process, easiness in operation, and environmental protection of used polymer and reagents.

Owner:JIANGSU UNIV

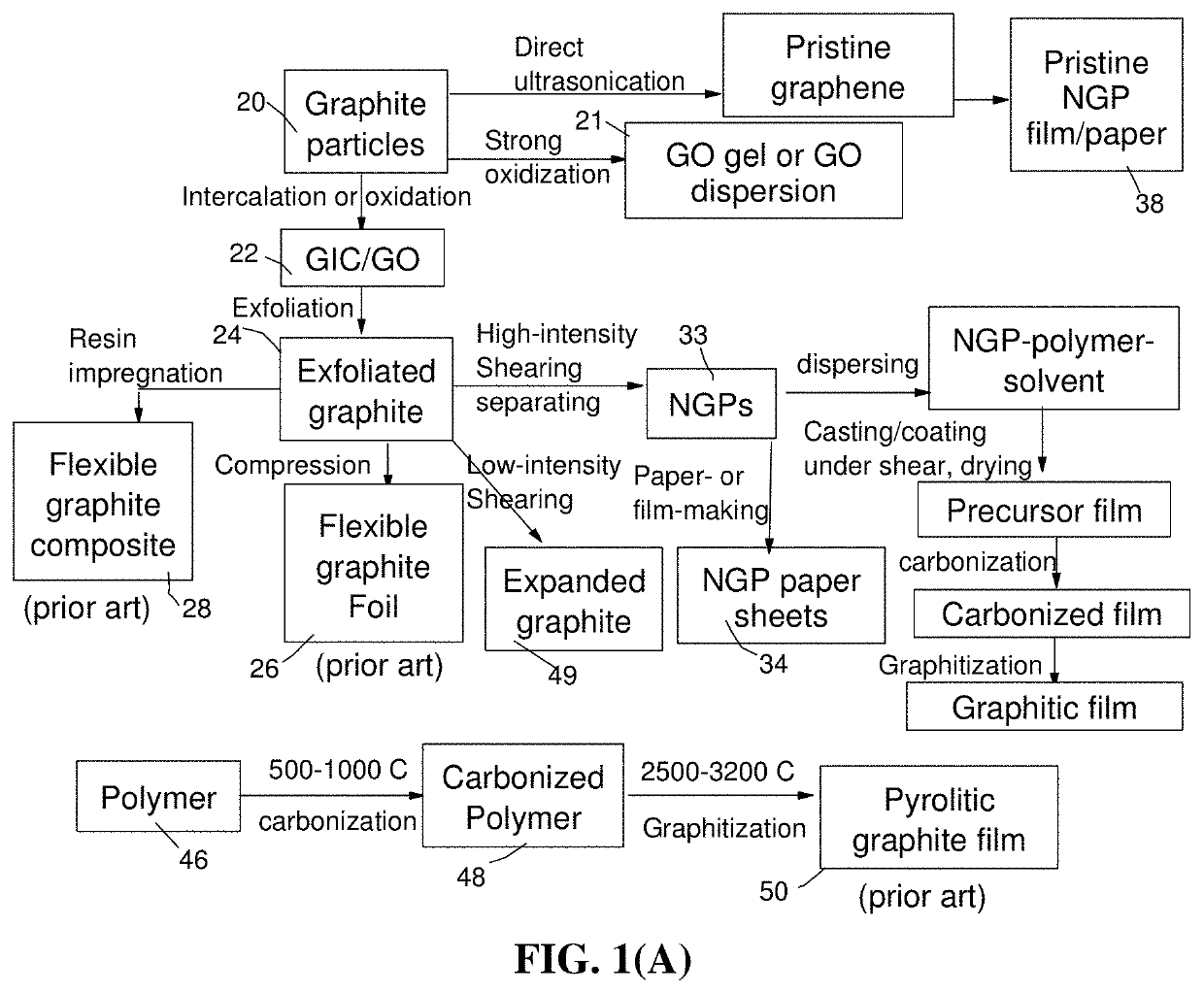

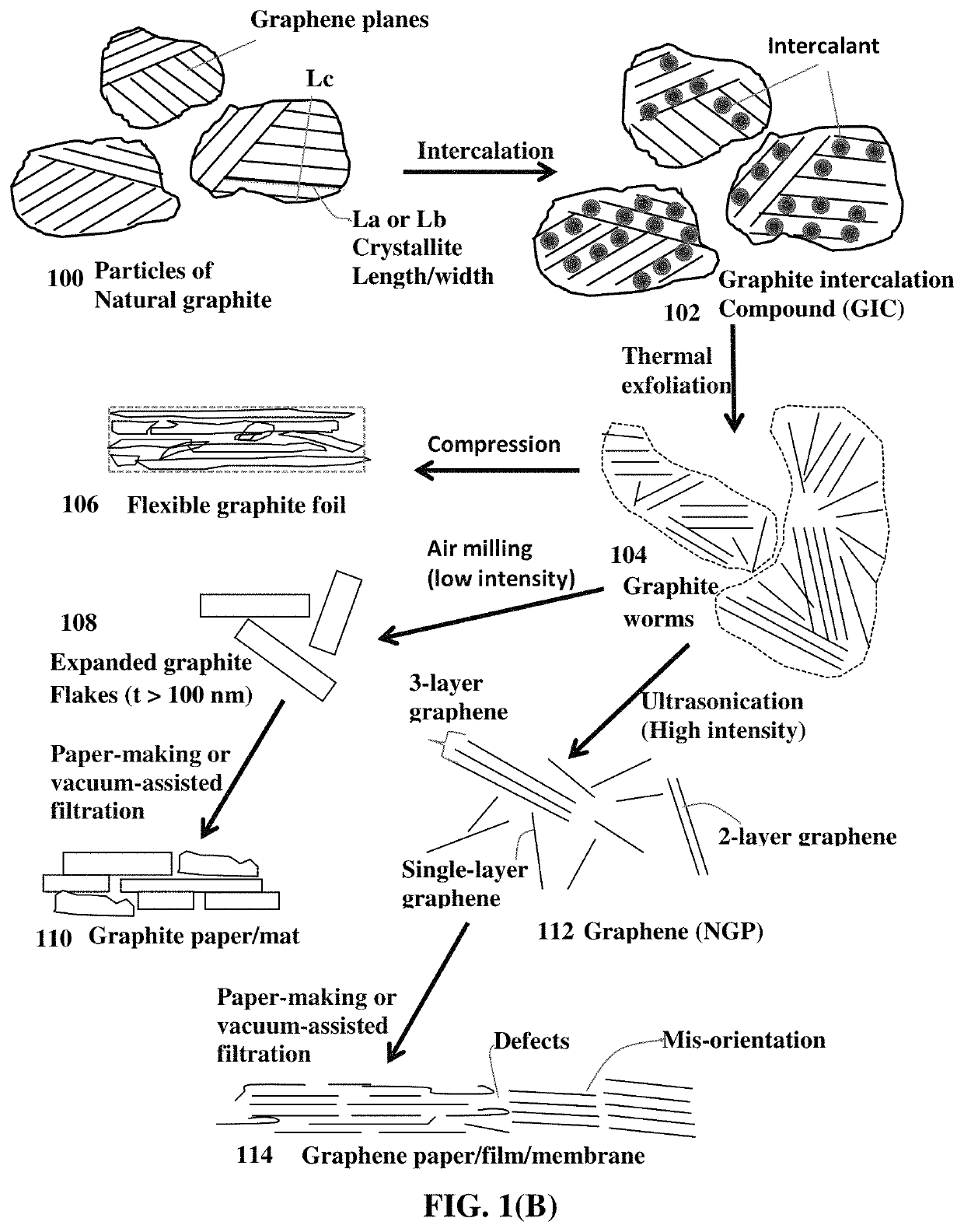

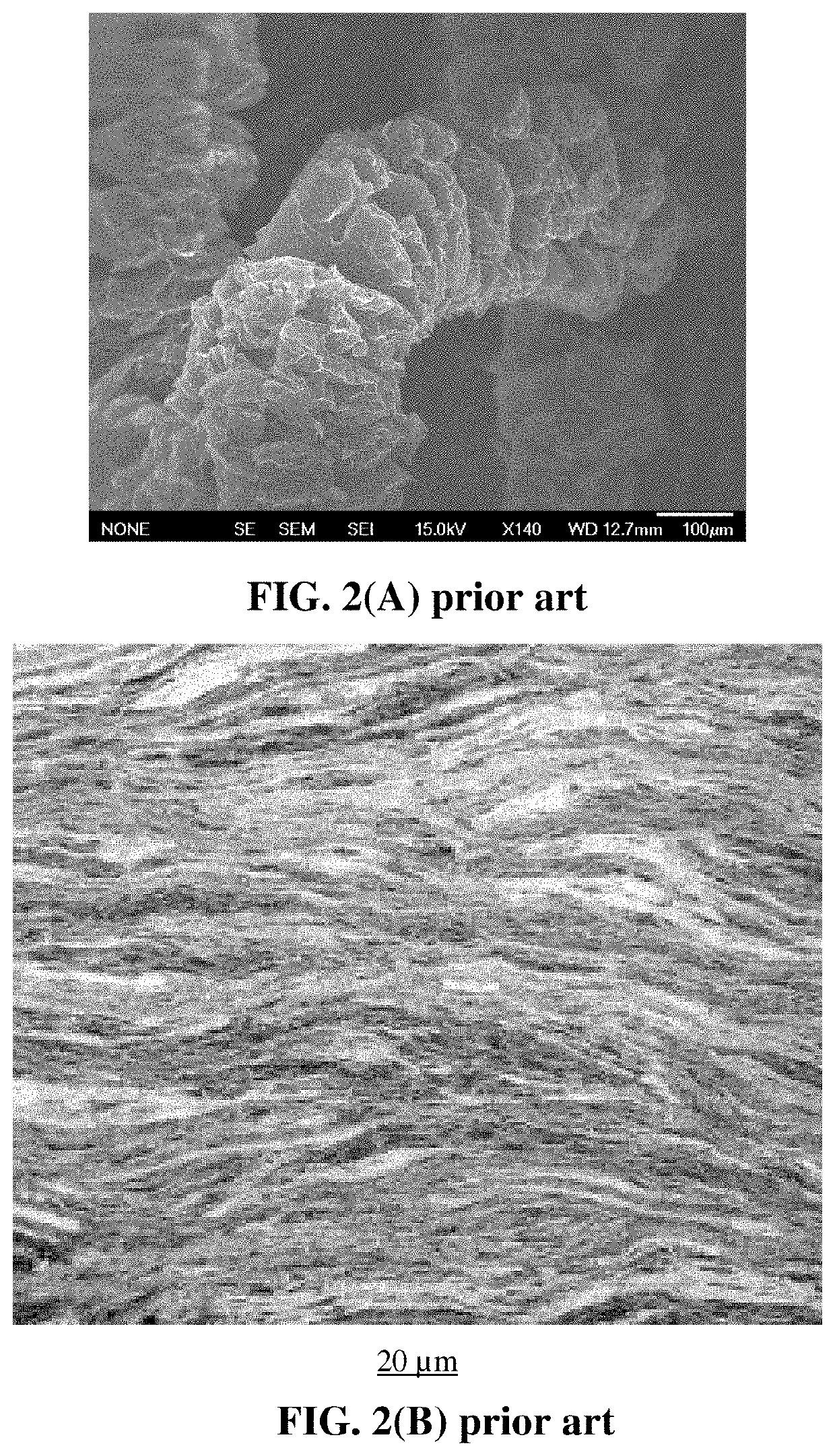

Process for highly conductive graphitic thick films

PendingUS20200114622A1High carbon yieldReduce required heat treatment temperature and timeCarbon compoundsLaminationPolymer scienceGraphene flake

Provided is a process for producing a multi-layer graphitic laminate, the process comprising: (A) providing a plurality of graphitic films or graphene layers, wherein at least one of said graphene layers is selected from a sheet of graphene paper, graphene fabric, graphene film, graphene membrane, or graphene foam; and (B) laminating at least two of the graphitic films and graphene layers and a conductive adhesive layer disposed between the two graphitic films or graphene layers to form the multi-layer graphitic laminate, wherein the conductive adhesive layer comprises graphene sheets or expanded graphite flakes dispersed in or bonded by an adhesive resin and the graphene sheets or expanded graphite flakes occupy a weight fraction from 0.01% to 99% based on the total conductive adhesive weight.

Owner:GLOBAL GRAPHENE GRP INC

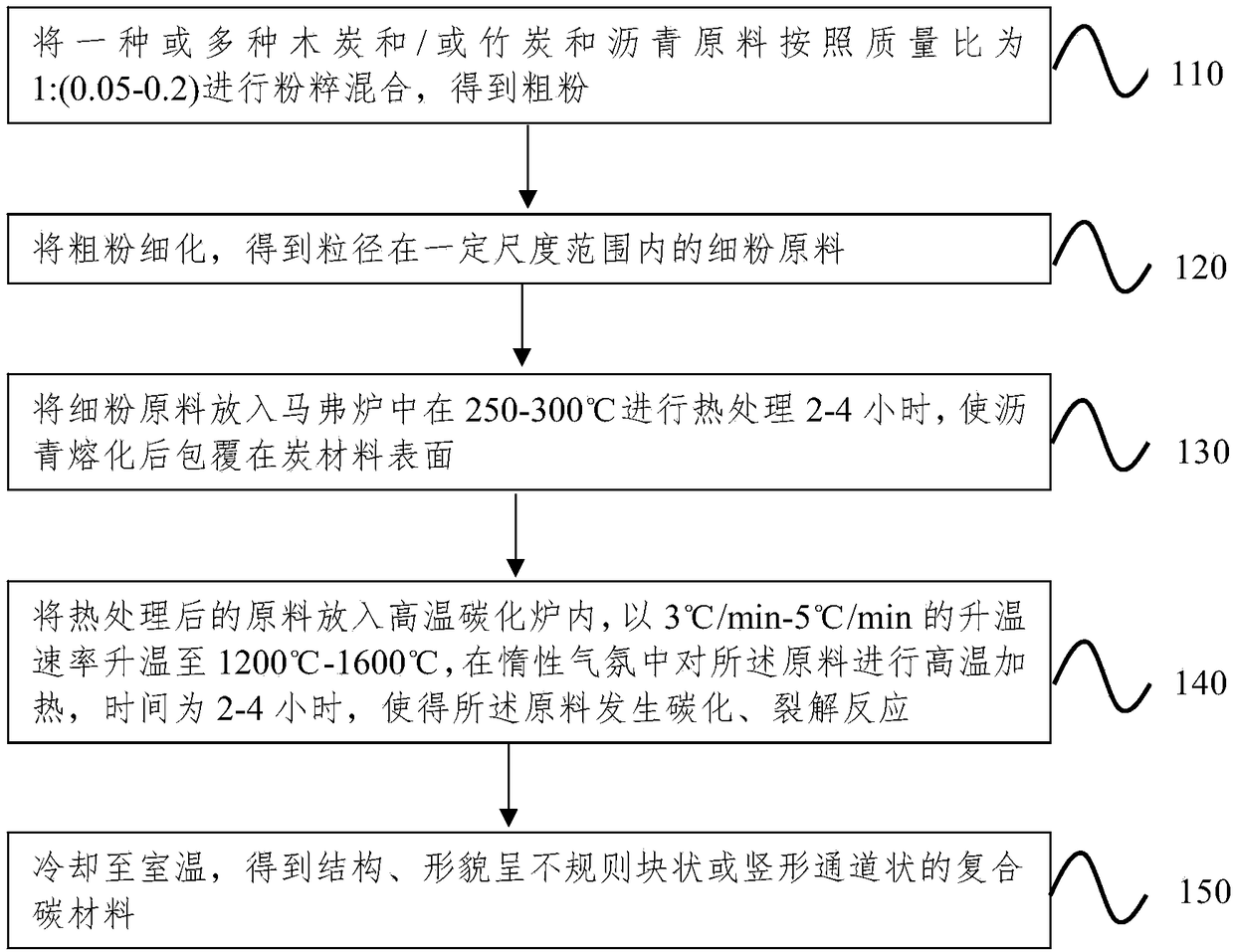

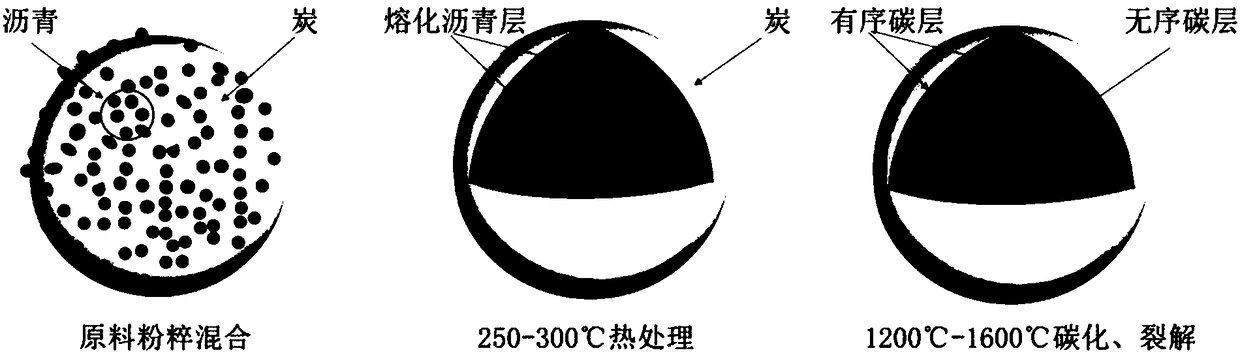

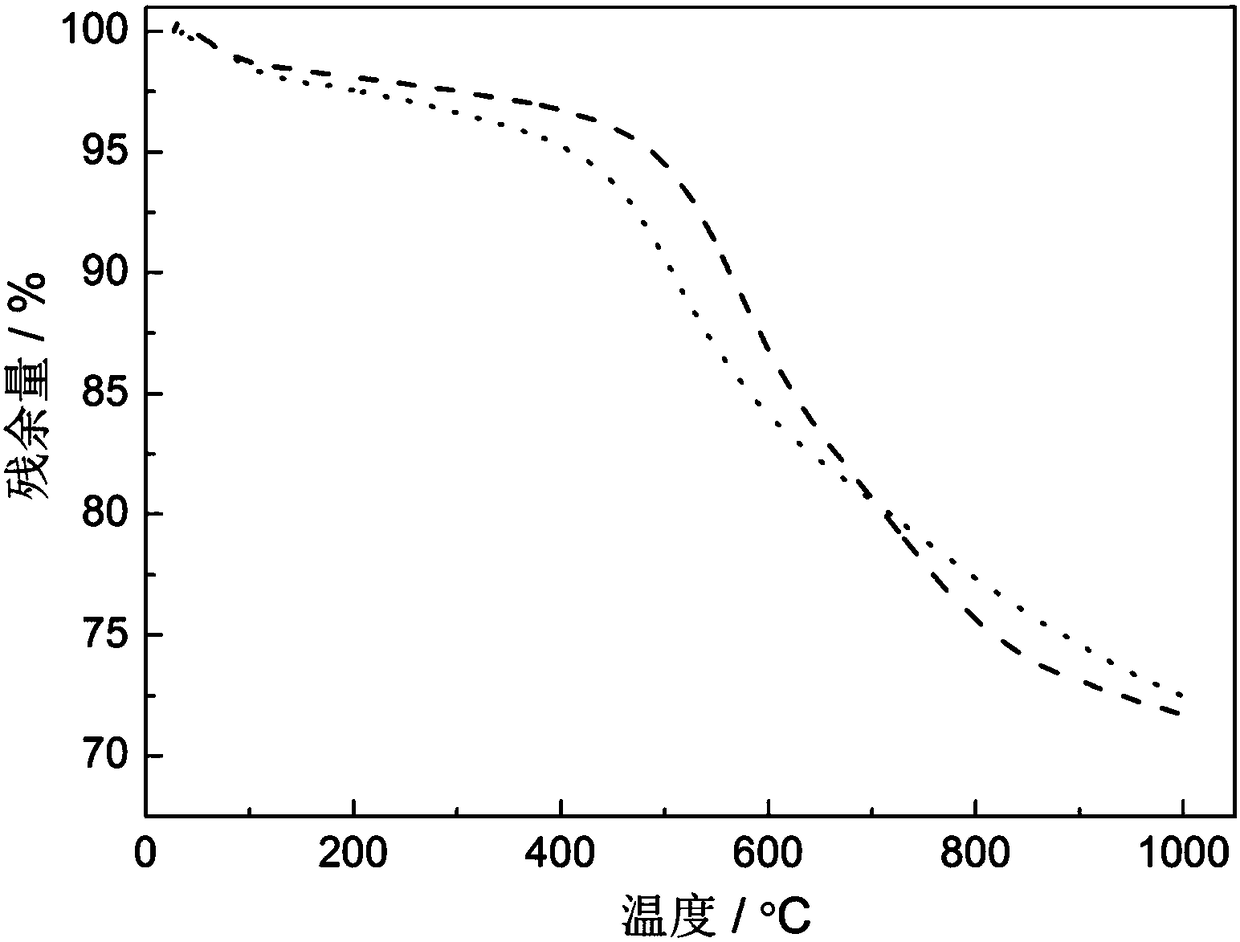

Sodium ion battery negative electrode material based on carbon material and pitch and preparation method and application thereof

ActiveCN109148838AWork lessIncrease energy densityCell electrodesSecondary cellsActivated carbonElectrical battery

The invention discloses a sodium ion battery negative electrode material based on carbon material and pitch and a preparation method and application thereof, wherein the sodium ion battery negative electrode material is a composite carbon material of which the surface is coated with pitch-based ordered carbon structure and appearance is an irregular block shape or vertical channel shape. The carbon material and the pitch are used as precursor raw materials, the pitch is melted and coated on the surface of the carbon material by heat treatment in the air after mechanical mixing, and then the pitch and the carbon material are carbonized and cracked in an inert atmosphere at the same time to obtain a composite carbon material with a surface orderly structure and an internal disorderly structure; Wherein the kind of charcoal comprises charcoal and bamboo charcoal, the charcoal comprises one or more mixtures of white charcoal, black charcoal, activated carbon and machine charcoal, the bamboo charcoal comprises one or more mixtures of carbonized materials of bamboo, pale bamboo, bitter bamboo, thunder bamboo and yellow bamboo, and the pitch is one or more mixtures of coal tar pitch, petroleum pitch and natural pitch.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI +1

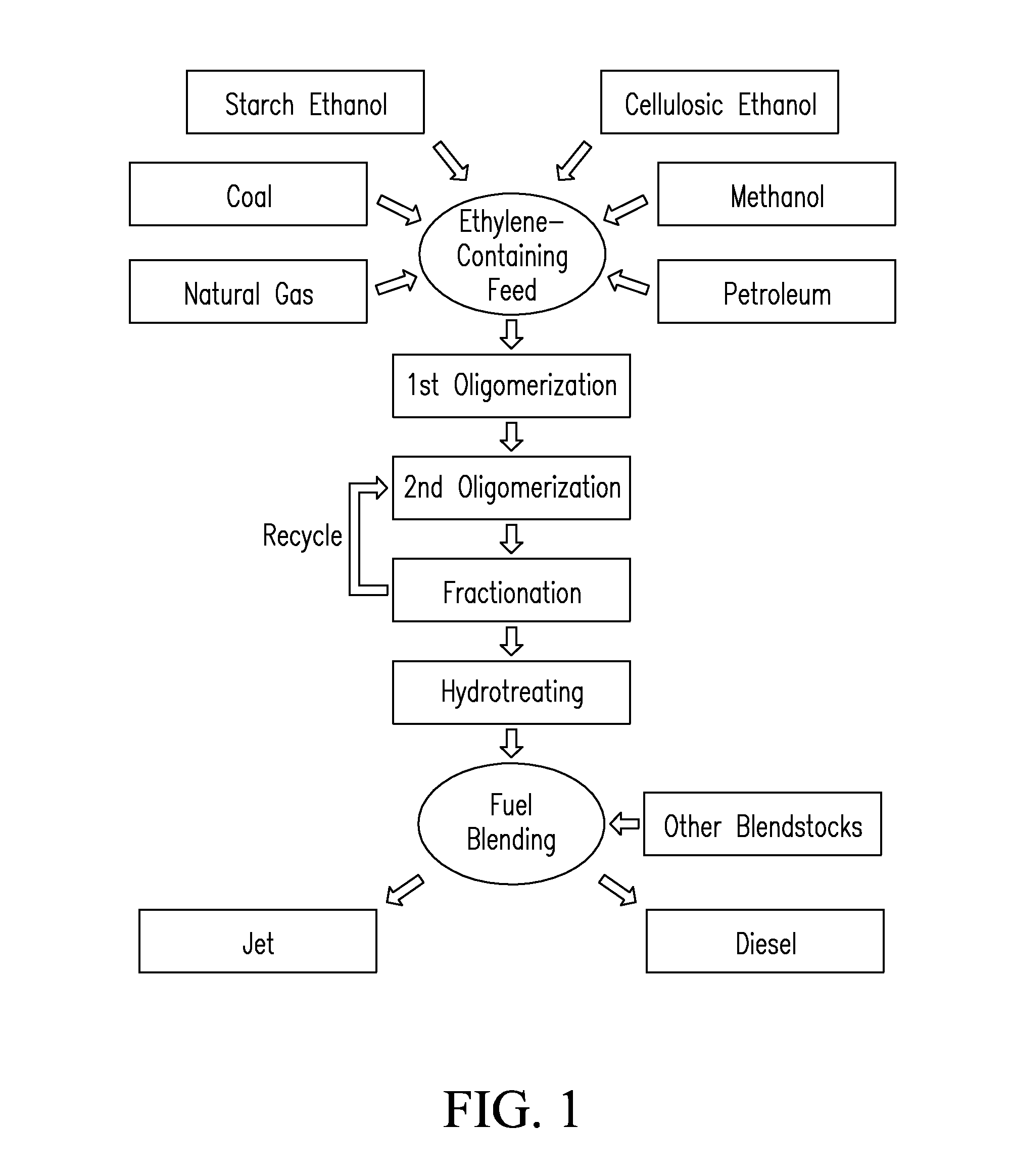

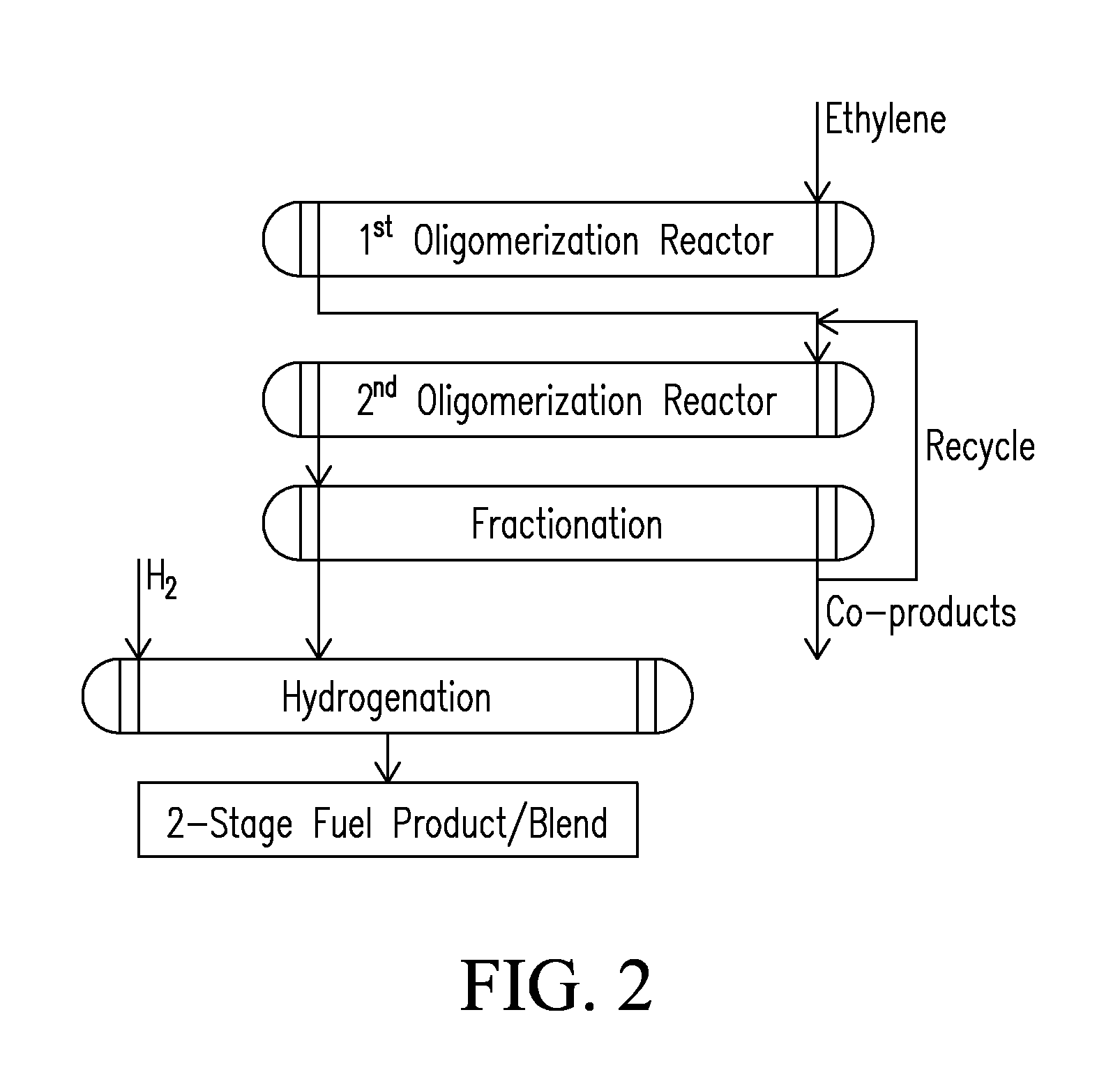

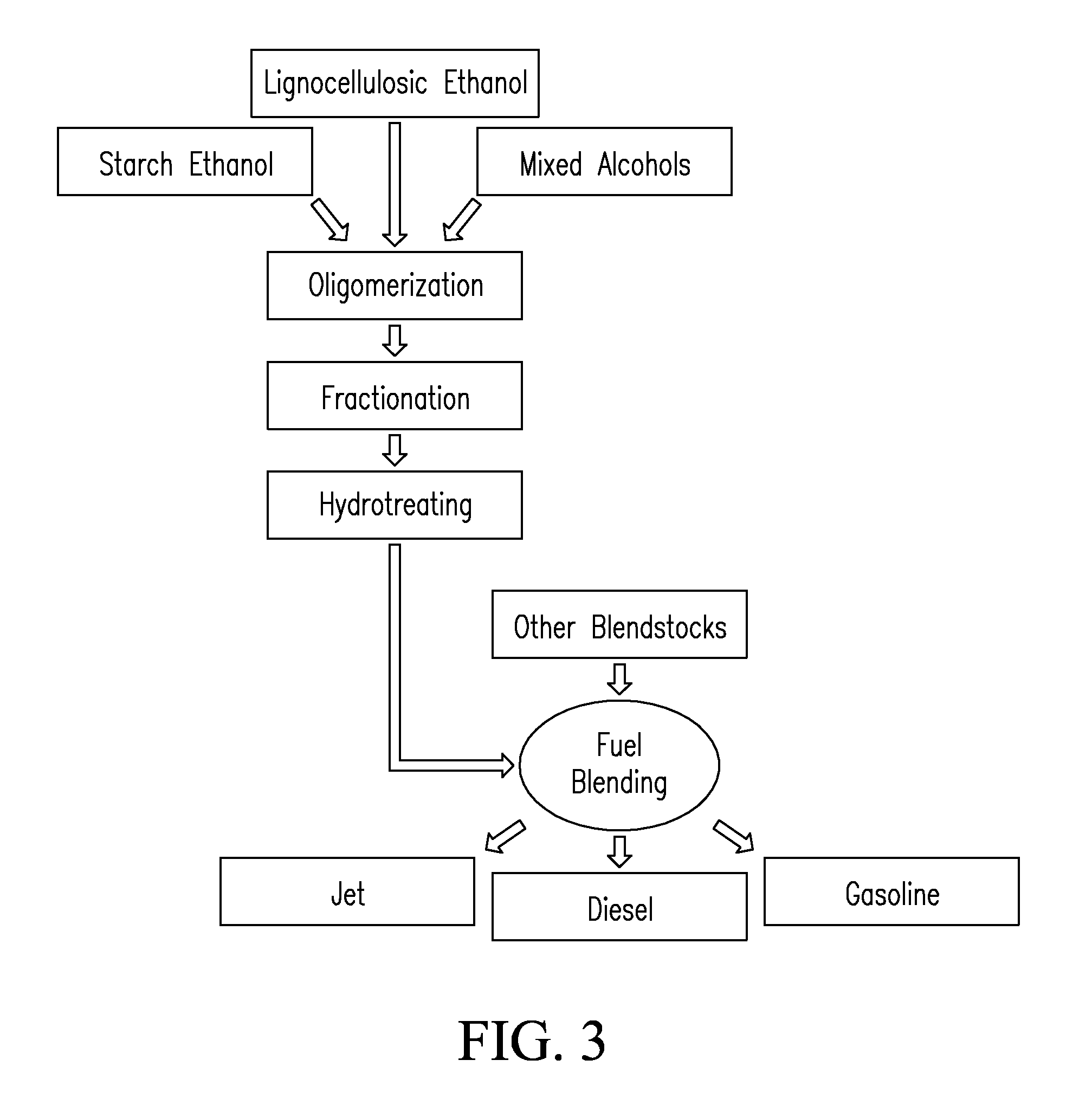

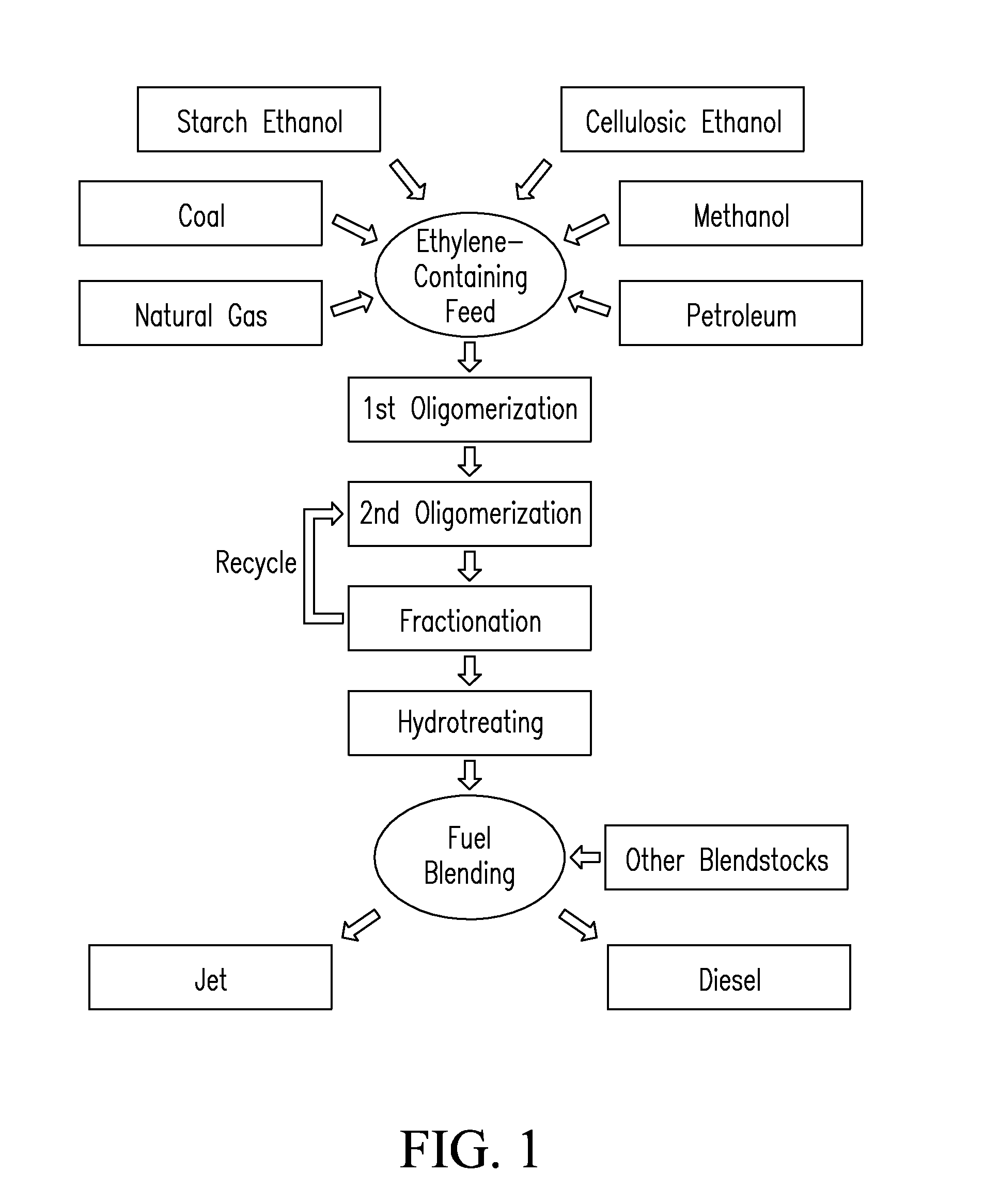

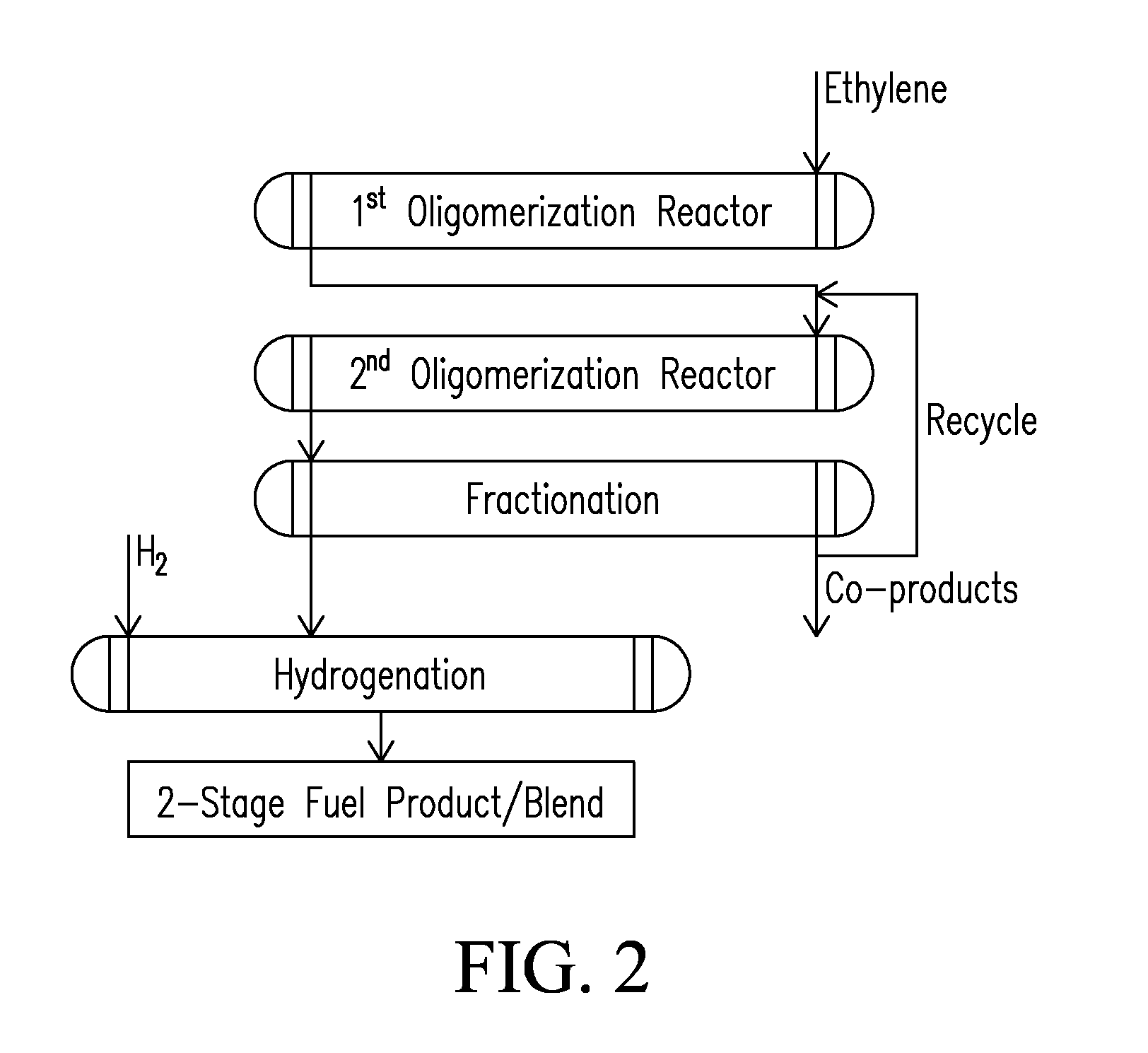

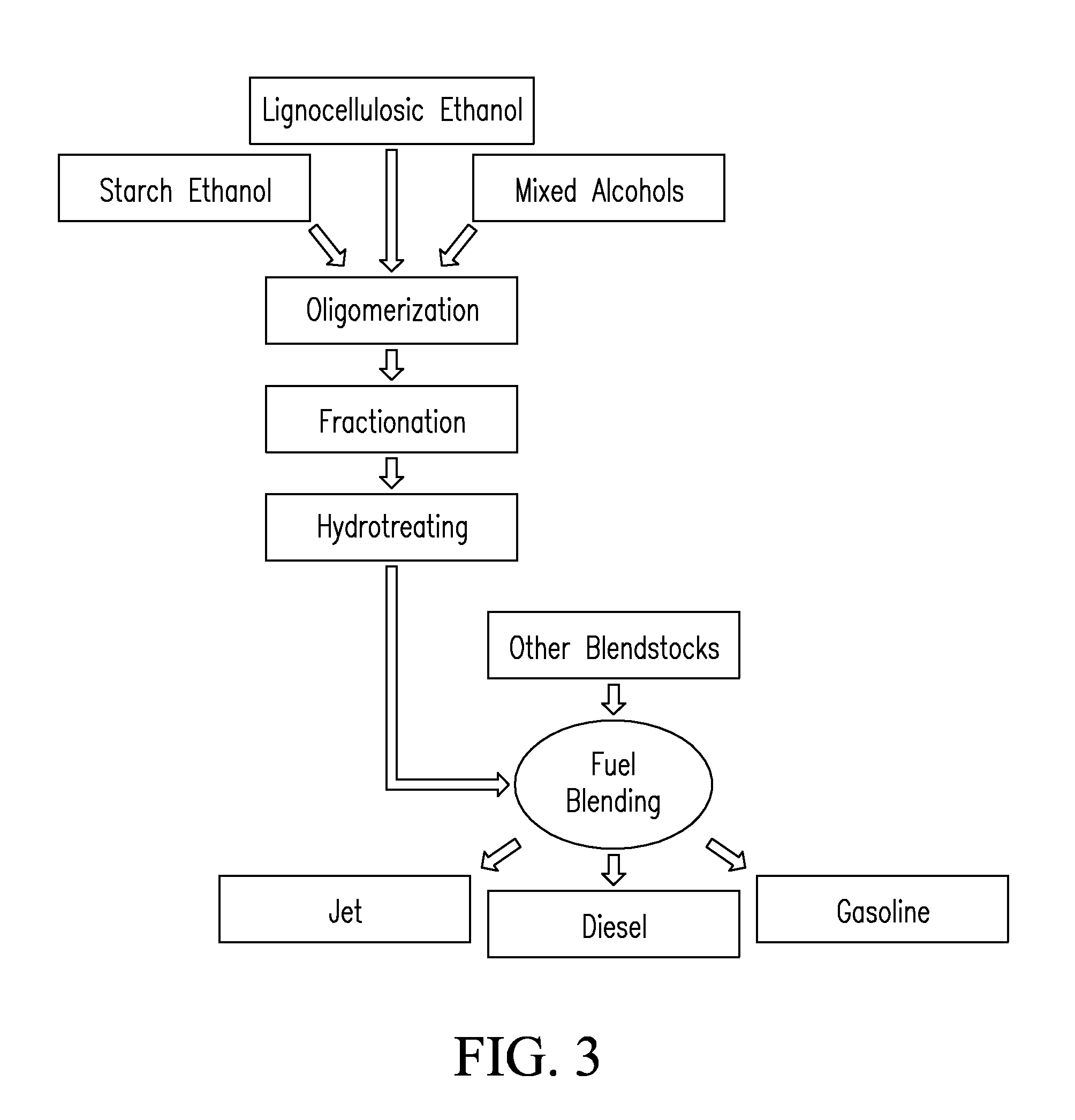

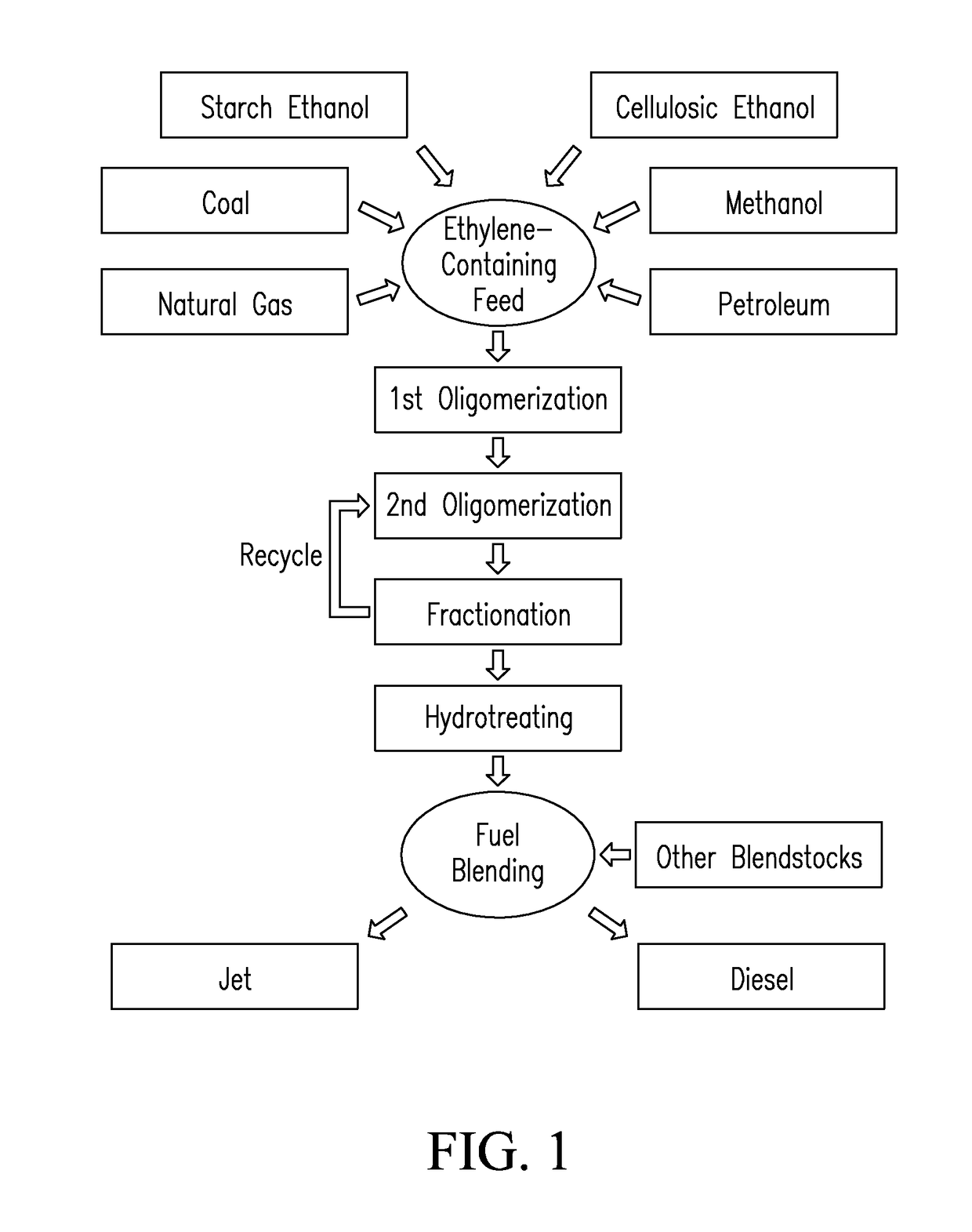

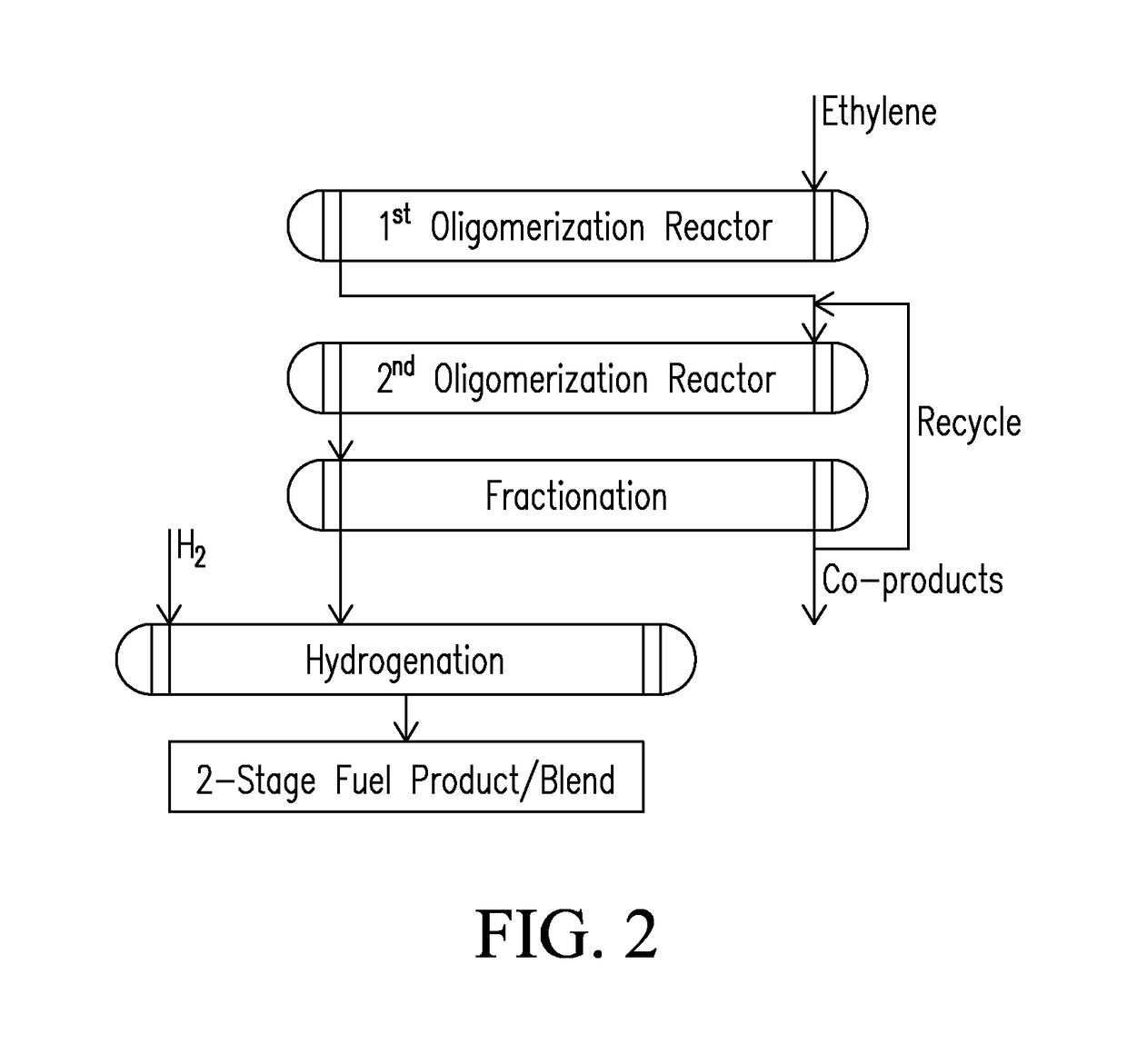

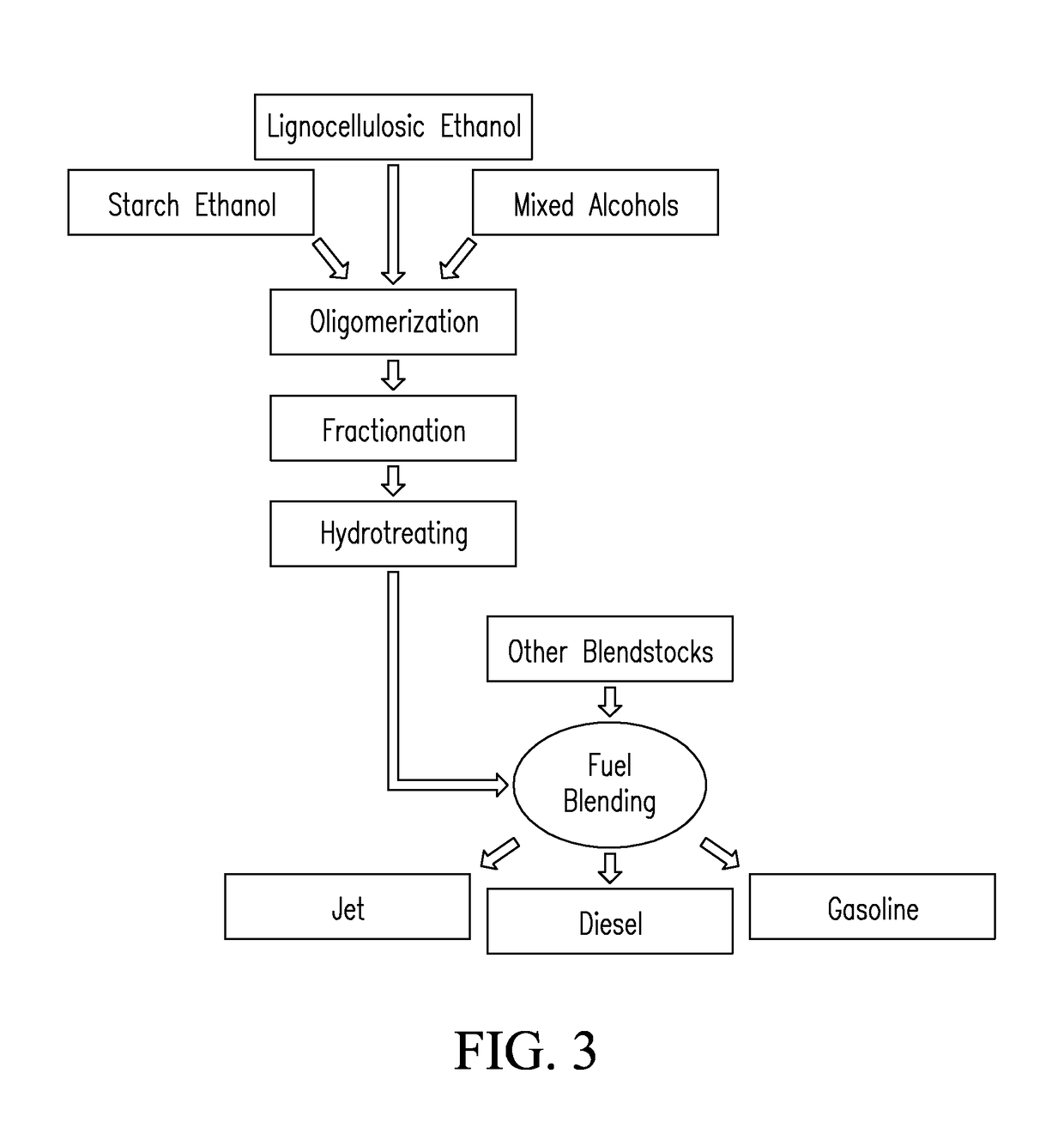

Systems and processes for conversion of ethylene feedstocks to hydrocarbon fuels

ActiveUS20160194257A1Increase fuel yieldHigh ethylene conversionHydrocarbon by hydrogenationLiquid hydrocarbon mixture productionGasolineJet fuel

Systems, processes, and catalysts are disclosed for obtaining fuel and fuel blends containing selected ratios of open-chain and closed-chain fuel-range hydrocarbons suitable for production of alternate fuels including gasolines, jet fuels, and diesel fuels. Fuel-range hydrocarbons may be derived from ethylene-containing feedstocks and ethanol-containing feedstocks.

Owner:BATTELLE MEMORIAL INST

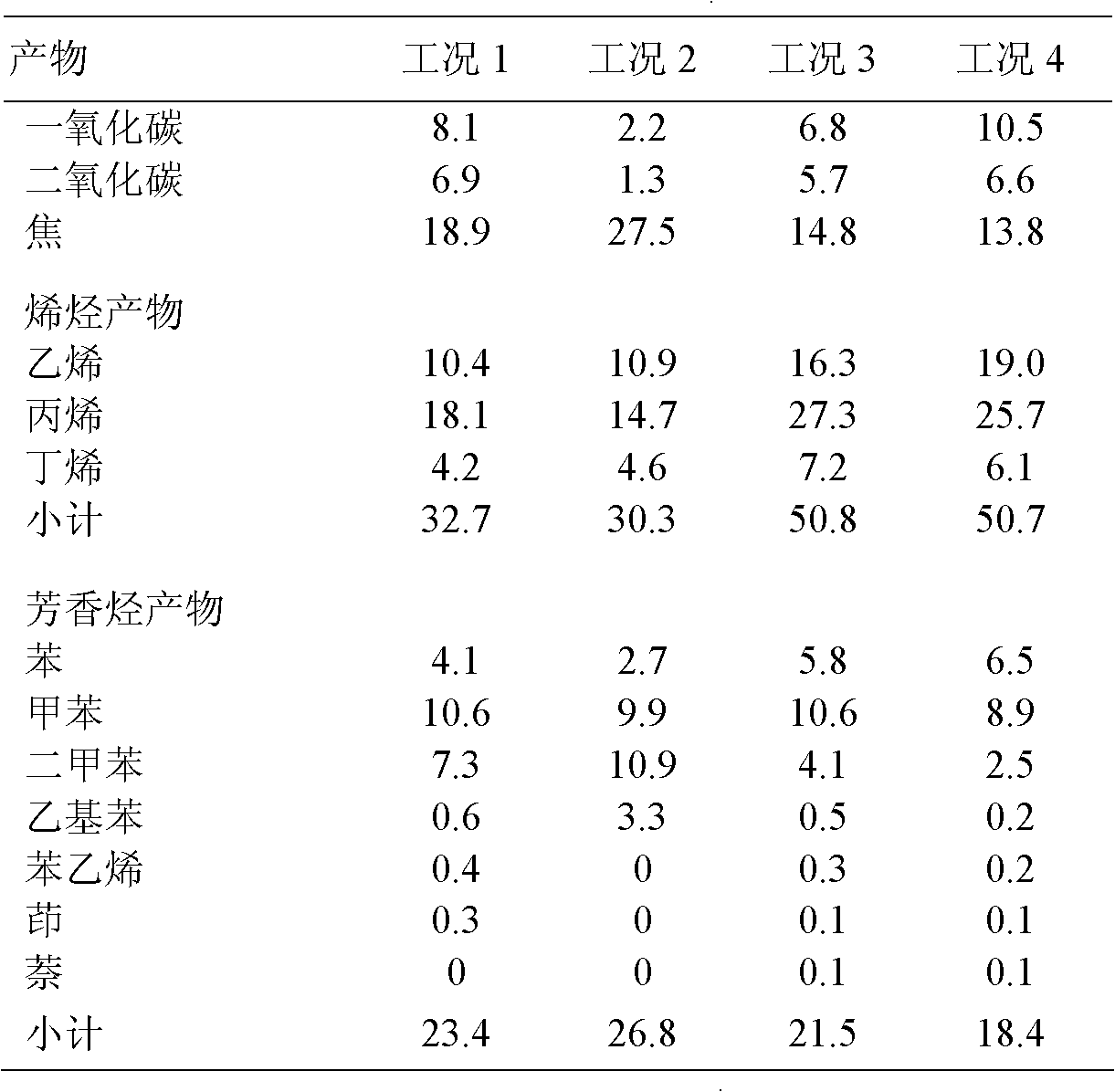

Two-step method for preparing olefin and aromatic hydrocarbon by catalyzing and upgrading bio-oil

InactiveCN102070386ANot easy to polymerizeHigh carbon yieldMolecular sieve catalystsHydrocarbon from oxygen organic compoundsHydrogenNitrogen

The invention discloses a two-step method for preparing olefin and aromatic hydrocarbon by catalyzing and upgrading bio-oil. Aqueous-phase bio-oil serves as a raw material, and the method comprises the following steps of: performing selective hydrogenation the aqueous-phase bio-oil, converting into stable compounds, and performing zeolite catalytic conversion on the stable compounds to obtain hydrocarbon compounds, wherein the selective hydrogenation is performed in a pressurized reactor, and the reaction conditions are that: the reaction atmosphere is hydrogen, a Ru / C and a Pt / C are catalysts, the temperature is between 100 and 300 DEG C, the mass space velocity is 1 to 5h<-1>, and the pressure is 5 to 15 MPa; the zeolite catalysis is performed in a normal pressure reactor, and the reaction conditions are that: the reaction atmosphere is hydrogen or nitrogen, the catalyst is HZSM-5, the temperature is between 350 and 650 DEG C, and the mass space velocity is 5 to 50h<-1>. The obtained olefin and aromatic hydrocarbon have the carbon yield of 30.3 to 50.8 percent and 18.4 to 26.8 percent respectively, and the catalysts for hydrogenation and zeolite catalysis have high stability.

Owner:SOUTHEAST UNIV

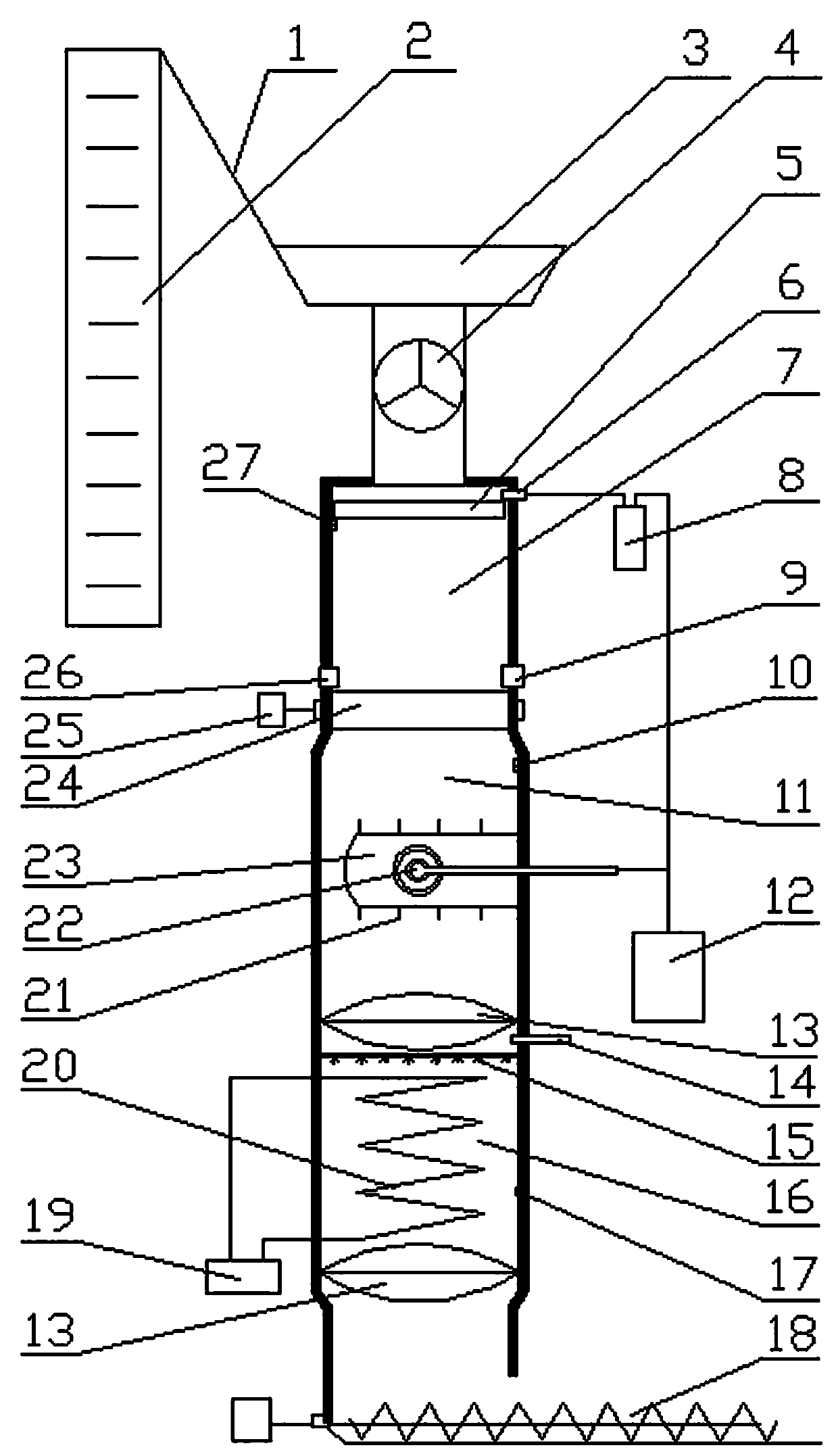

Carbonization furnace capable of recycling biomass pyrolysis gas and biomass carbonization method

ActiveCN110079337ARealize continuous productionAchieve self-sufficiencySpecial form destructive distillationStationary retortsCombustion chamberFuel tank

The invention relates to the field of carbonization furnace, specifically to a carbonization furnace capable of recycling biomass pyrolysis gas and a biomass carbonization method. The carbonization furnace capable of recycling the biomass pyrolysis gas comprises a material hopper, a drying pyrolysis chamber, a carbonization chamber and a cooling chamber; a pyrolysis gas outlet is formed in the topof the drying pyrolysis chamber; the pyrolysis gas outlet is connected with a pyrolysis gas separating and purifying device; a fire grate is arranged between the bottom of the drying pyrolysis chamber and the top of the carbonization chamber; a smouldering pyrolysis ignition opening and a smouldering pyrolysis air inlet are formed in the side wall of the drying pyrolysis chamber and formed in positions above the fire grate; a combustion chamber is formed in the carbonization furnace; a combustion disc used for heating the combustion chamber is arranged in the combustion chamber; a fuel inletof the combustion disc is correspondingly connected with a gas outlet of the pyrolysis gas separating and purifying device and an external fuel tank; and heat insulation plates which can be opened andclosed are correspondingly arranged at the bottom of the carbonization chamber and the bottom of the cooling chamber. The carbonization furnace capable of recycling the biomass pyrolysis gas, provided by the invention, has the advantages that the pyrolysis gas generated in the biomass carbonization can be sufficiently utilized to reduce energy consumption, and the biomass raw materials can be more sufficiently collected and utilized.

Owner:HENAN UNIV OF SCI & TECH

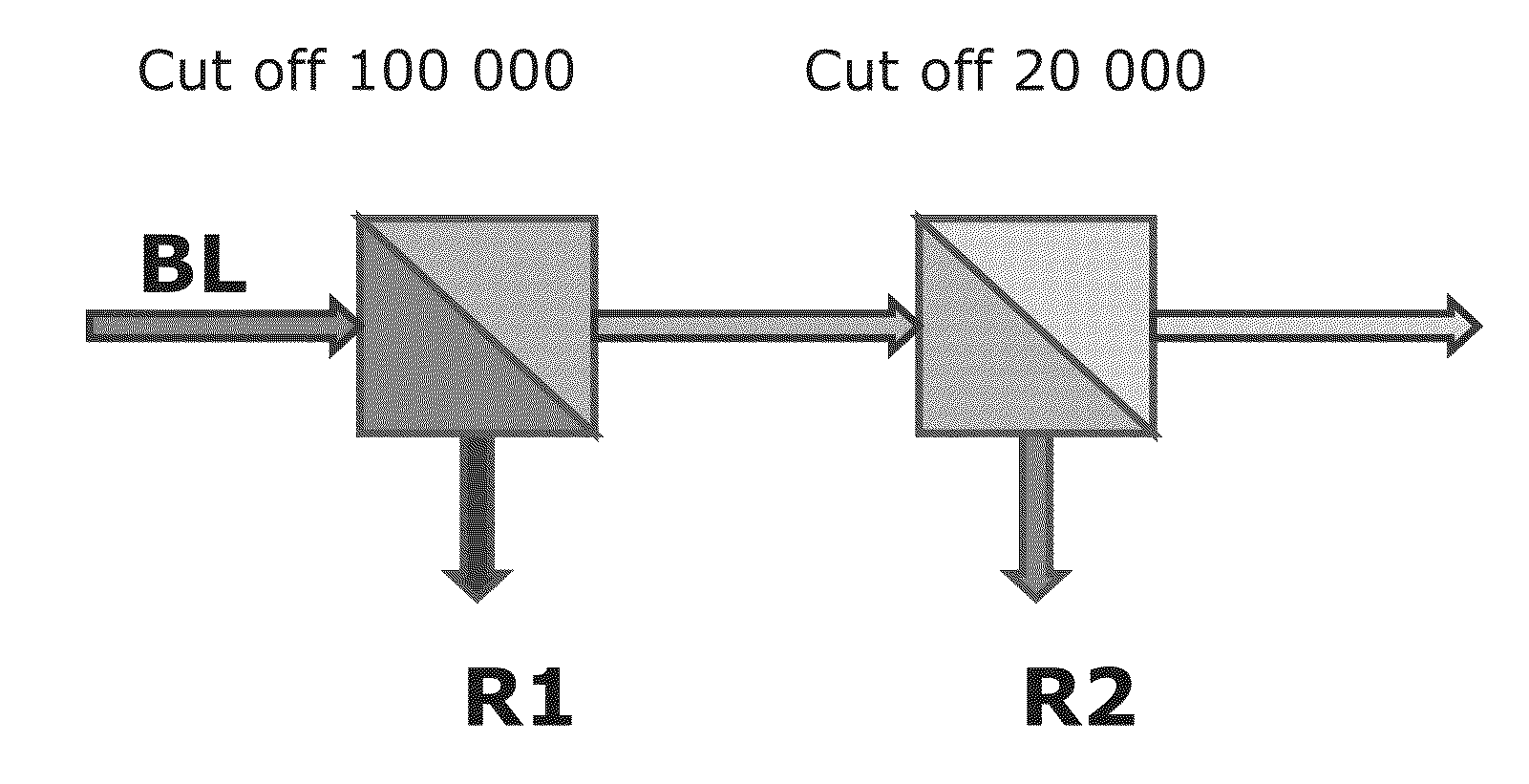

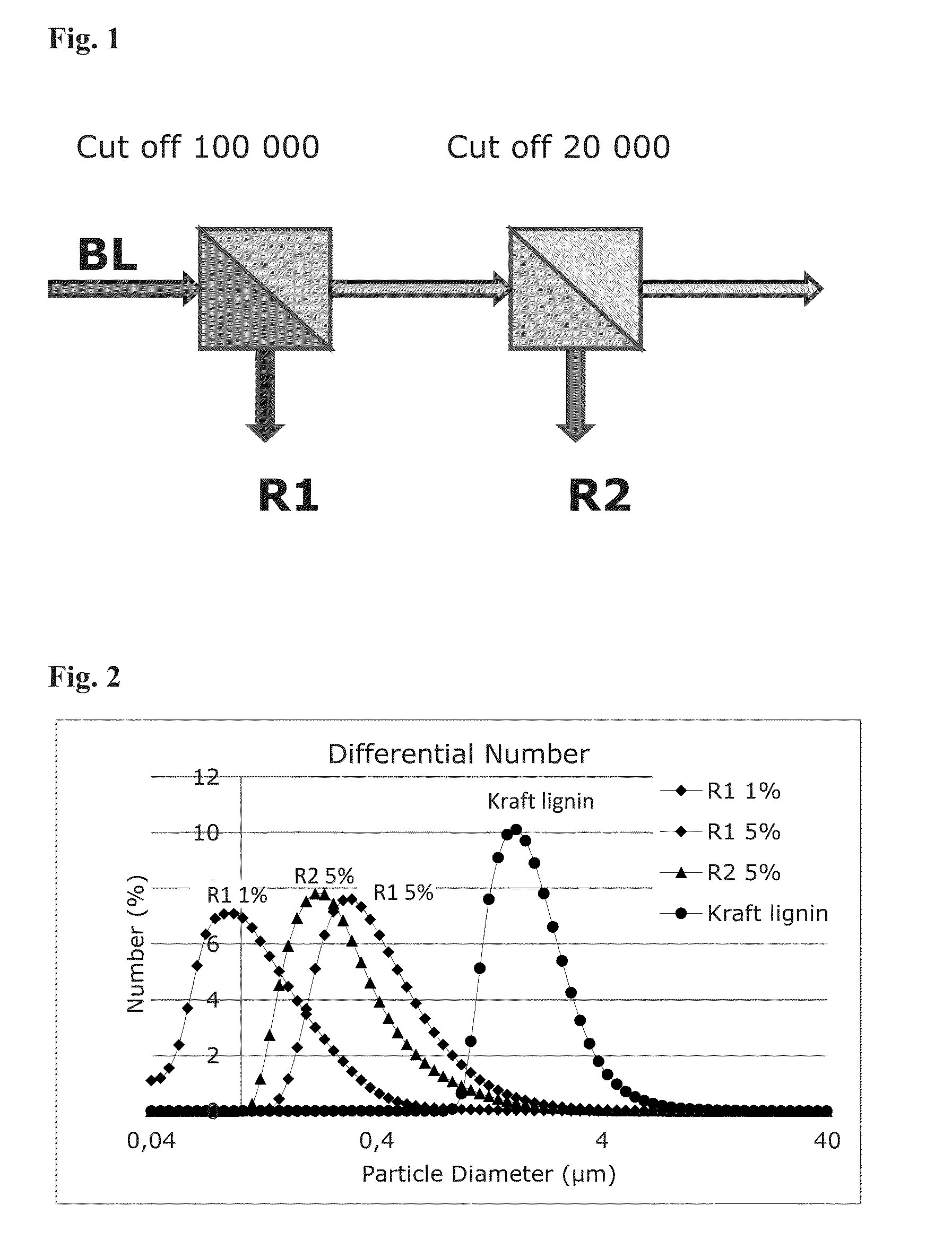

Process for the hydrothermal treatment of high molar mass biomaterials

ActiveUS20150321173A1Speed up the processHigh carbon yieldPigmenting treatmentAlkali metal halidesPolymer scienceCompound (substance)

The present invention concerns a process for the conversion of biomaterials into structural carbon products, particularly utilizing a hydrothermal treatment step that is carried out on a high molar mass organic starting material having a carbon content of >40 wt % of the dry matter. The invention also concerns a structural carbon product obtained using such a process, which has well-defined physico-chemical properties, e.g. in terms of surface area, carbon content, density, size and shape.

Owner:VALMET TECH OY

Systems and processes for conversion of ethylene feedstocks to hydrocarbon fuels

ActiveUS20160194572A1Easily recycleIncreased yieldHydrocarbon by hydrogenationLiquid hydrocarbon mixture productionAlternative fuelsHydrocarbon

Systems, processes, and catalysts are disclosed for obtaining fuels and fuel blends containing selected ratios of open-chain and closed-chain fuel-range hydrocarbons suitable for production of alternate fuels including gasolines, jet fuels, and diesel fuels. Fuel-range hydrocarbons may be derived from ethylene-containing feedstocks and ethanol-containing feedstocks.

Owner:BATTELLE MEMORIAL INST

Systems and processes for conversion of ethylene feedstocks to hydrocarbon fuels

ActiveUS9771533B2Increase conversionsHigh selectivityMolecular sieve catalystHydrocarbon by hydrogenationAlternative fuelsGasoline

Systems, processes, and catalysts are disclosed for obtaining fuels and fuel blends containing selected ratios of open-chain and closed-chain fuel-range hydrocarbons suitable for production of alternate fuels including gasolines, jet fuels, and diesel fuels. Fuel-range hydrocarbons may be derived from ethylene-containing feedstocks and ethanol-containing feedstocks.

Owner:BATTELLE MEMORIAL INST

Multi-stage synthesis method with synthesis gas

ActiveUS20150125912A1Raw materials are simpleHigh carbon yieldHydrolasesBiofuelsAcetic acidSynthesis methods

The invention provides a process for the preparation of hydrocarbons substituted with at least one group containing at least one oxygen atom, comprising the process stepsA) reaction of a carbon source comprising at least one selected from CO2 and CO to give acetate and / or ethanol with a first microorganism,B) separating off of the acetate from the first microorganism,C) reaction of the acetate to give a hydrocarbon substituted with at least one group containing at least one oxygen atom with a second microorganism and optionallyD) purification of the hydrocarbon substituted with at least one group containing at least one oxygen atom.

Owner:EVONIK OPERATIONS GMBH

Preparation method of filter material base activated carbon fiber

ActiveCN103272562ARaw materials are easy to getLow costOther chemical processesActivated carbonFiber

The invention discloses a preparation method of filter material base activated carbon fiber, which takes waste punched felt fiber as a carbon source to prepare the activated carbon fiber through carbonization and KOH chemical activation. The method is low in cost, has high feasibility, can achieve an effect of resource reuse, and simultaneously provides ideal thought for the industrial waste disposal.

Owner:FUZHOU UNIV

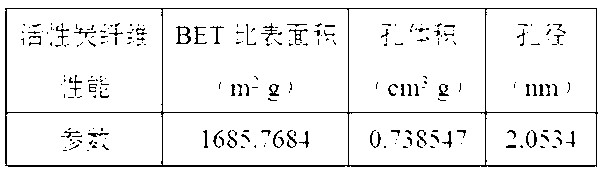

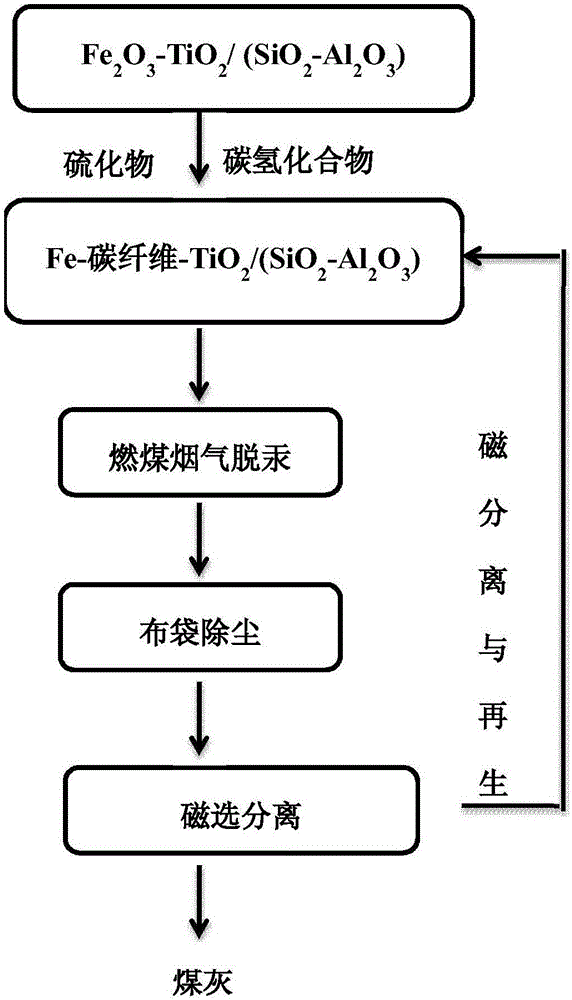

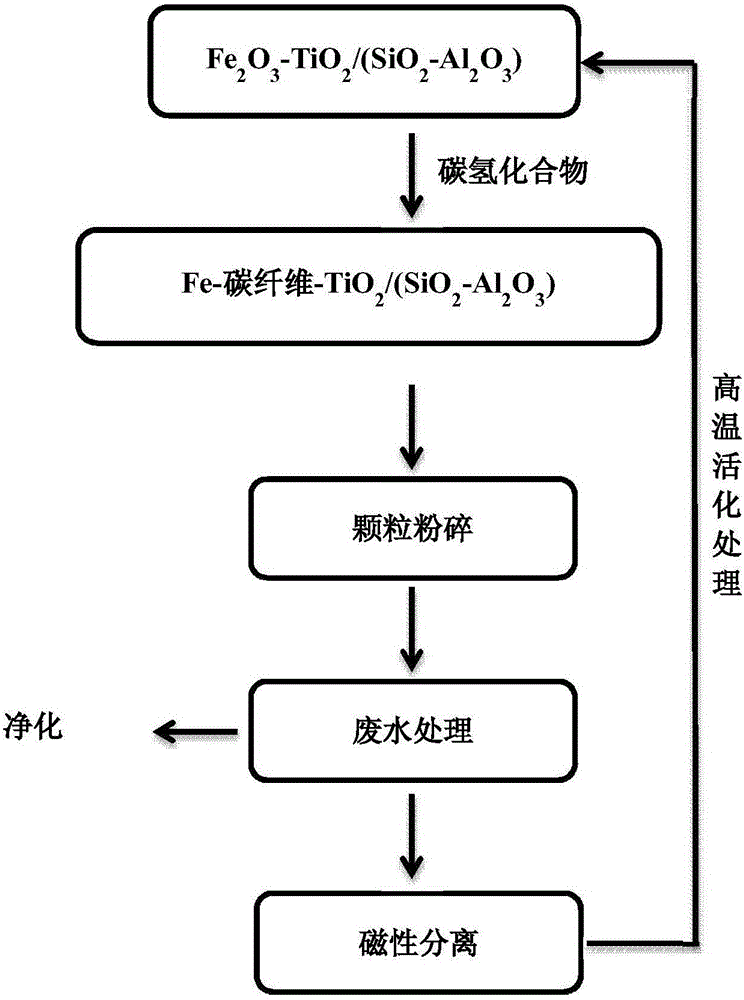

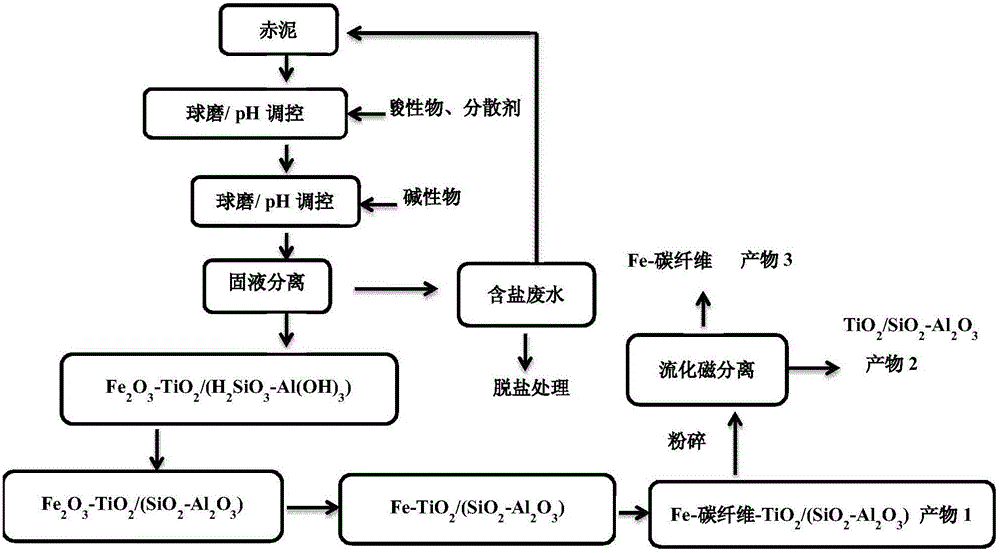

Carbon-iron-titanium-silicon-aluminum oxide compound and preparation method and application thereof

ActiveCN105727886ARealize high-value utilizationHigh activityGas treatmentOther chemical processesFiberCarbon fibers

The invention provides a carbon-iron-titanium-silicon-aluminum oxide compound and a preparation method and application thereof. The preparation method of the carbon-iron-titanium-silicon-aluminum oxide compound comprises the following steps that water is added into red mud, and a first slurry is obtained through grinding; acid is added into the first slurry to adjust the pH value to be 2 to 4, surface dispersant is added, alkaline matter is added to adjust the pH value to be 5 to 10 during the grinding process, and a second slurry is obtained; solid-liquid separation is conducted on the second slurry, calcination is conducted on a solid, and a coated iron-titanium-silicon-aluminum oxide is obtained; reduction is conducted on the coated iron-titanium-silicon-aluminum oxide in a reducing gas atmosphere, carbon fiber generation is conducted in a hydrocarbon atmosphere, cooling is conducted, and the carbon-iron-titanium-silicon-aluminum oxide compound is obtained. According to the carbon-iron-titanium-silicon-aluminum oxide compound and the preparation method and application thereof, high-value utilization of the red mud can be achieved, and extremely high industrial application potential is achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

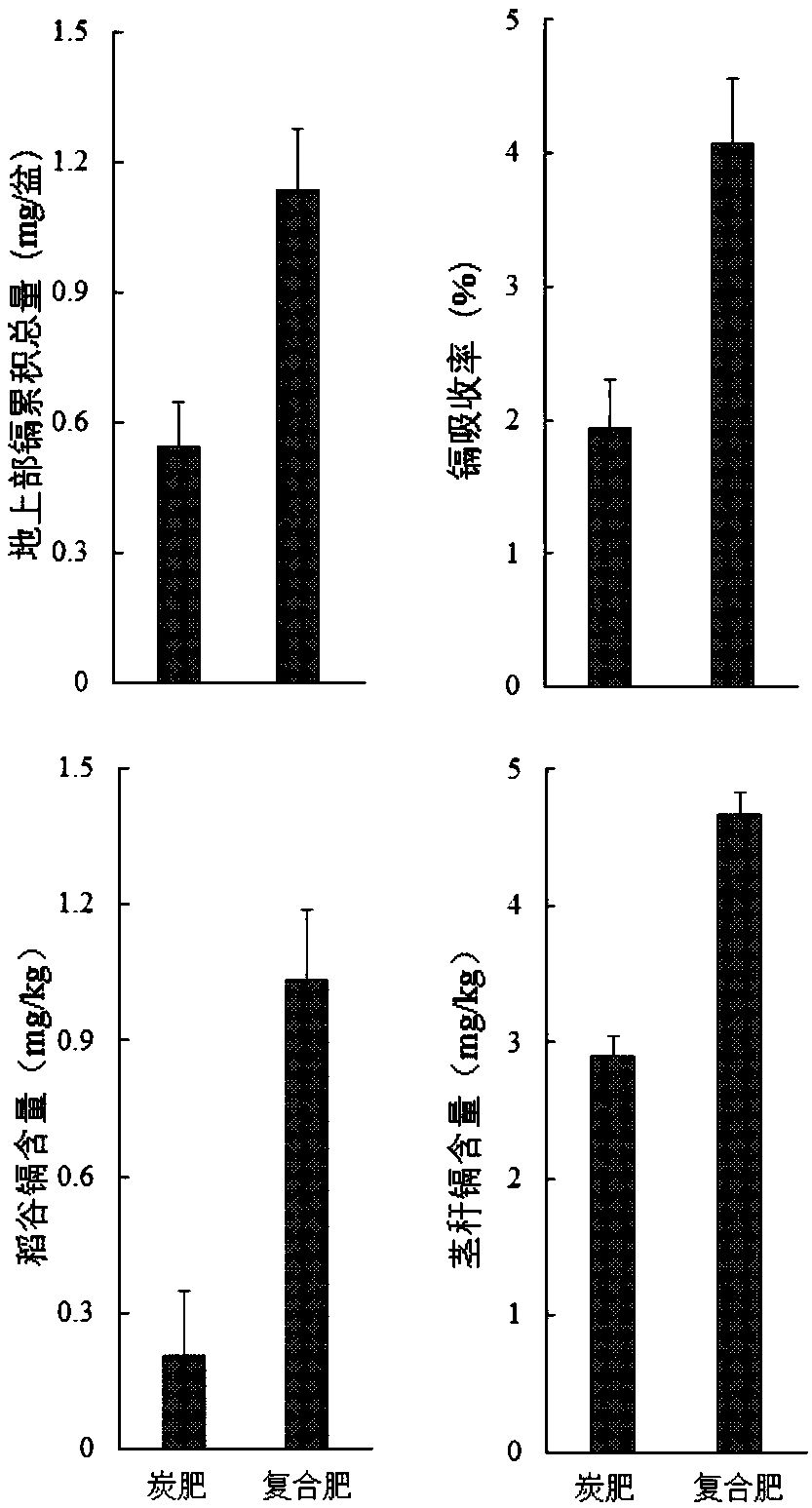

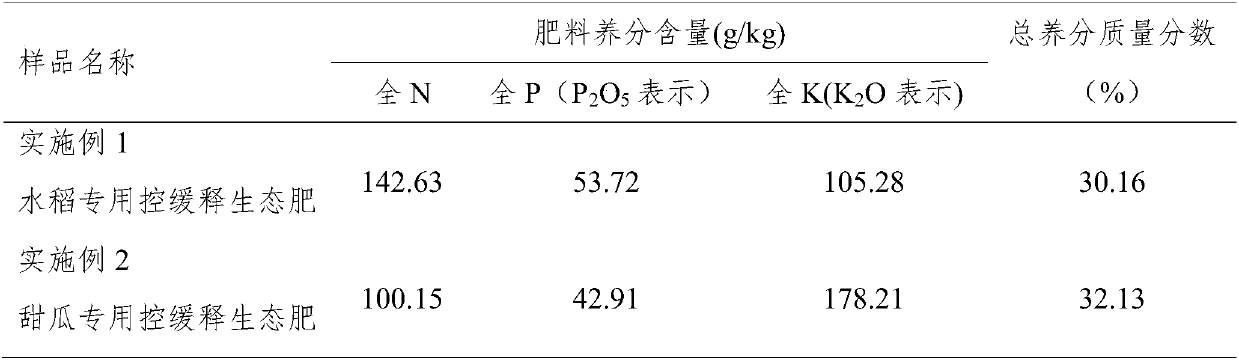

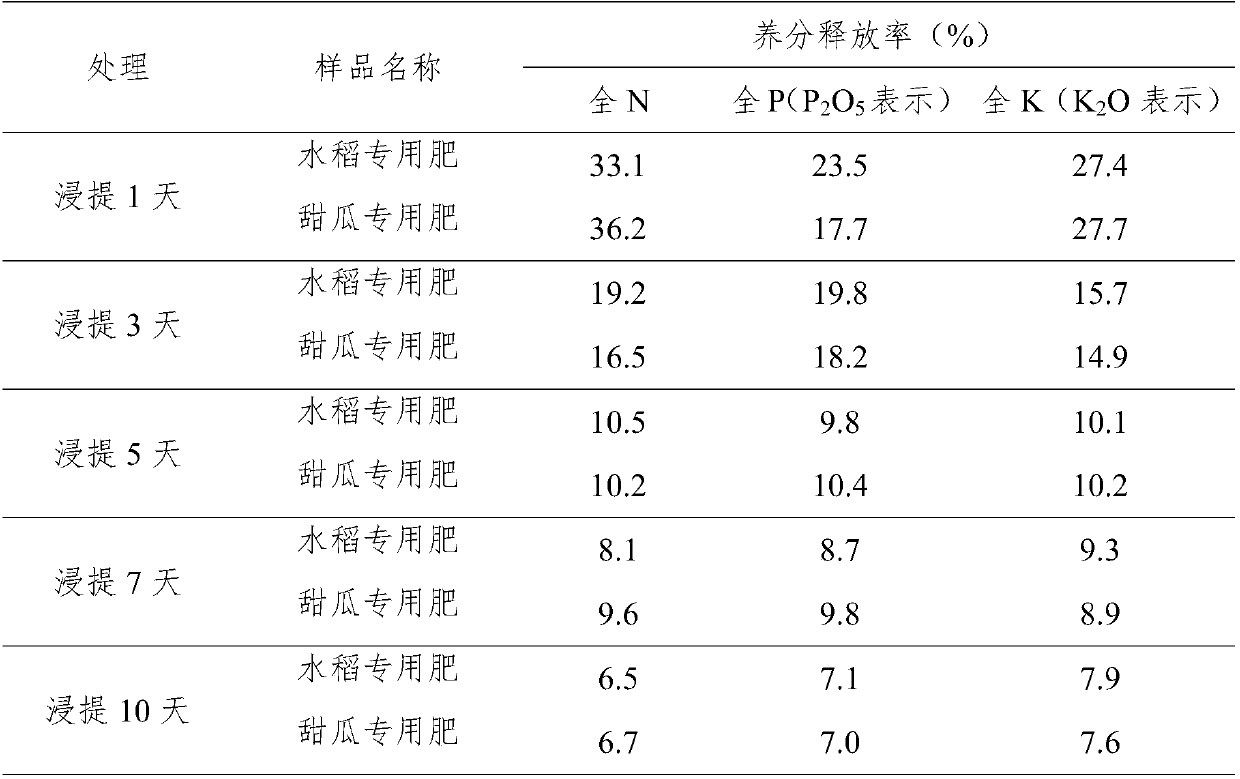

Fast growing turf-based controlled/slow-release ecological fertilizer as well as preparation method and application thereof

ActiveCN107721610AHigh carbon yieldHigh self-nutrient element contentAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersMass contentNutrient

The invention relates to a fast growing turf-based controlled / slow-release ecological fertilizer as well as a preparation method and application thereof. The ecological fertilizer contains active components or other beneficial components, wherein the active components include a slow-release fertilizer component, a quick-acting fertilizer component and a cytokinin production bacterial agent. The mass content of total nutrients (N+P2O5+K2O) in the ecological fertilizer is more than or equal to 30%; carrier carbon used in a slow-release fertilizer is fast growing turf; the cytokinin production bacterial agent contains florae of bacillus megatherium, bacillus subtilis, bacillus mucilaginosus and trichoderma. The fast growing turf-based controlled / slow-release ecological fertilizer has the beneficial effects that the quality of the adopted fast growing turf is superior to that of charcoal prepared from traditional agricultural waste: the charcoal yield is high, and the preparation cost of charcoal can be lowered; the prepared fertilizer for paddy fields is beneficial to the sedimentation of charcoal base; the adsorption capacity to nutrient elements is enhanced; and the soil acidification caused by the overusing of a chemical fertilizer can be improved, and meanwhile, the bio-availability can be reduced by passivating heavy metal ions in soil through strong basicity.

Owner:HUNAN AGRICULTURAL UNIV

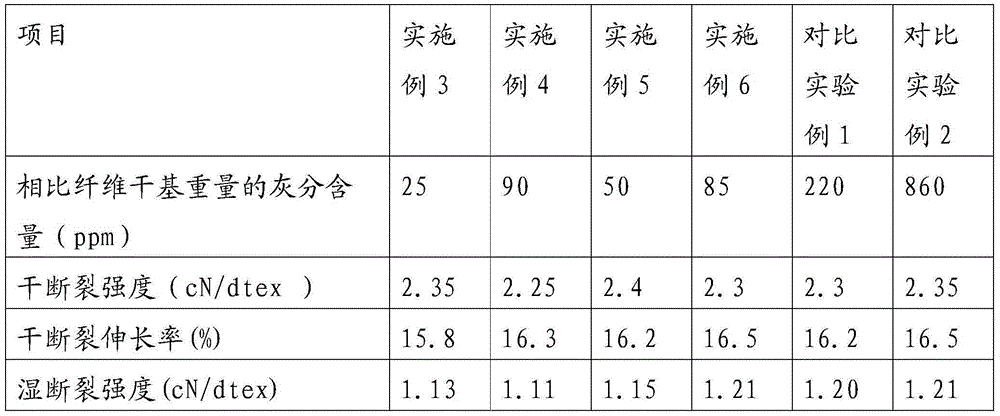

High-purity viscose fiber and preparation method thereof

ActiveCN105063782APerformance is not affectedLow ash contentArtificial filament washing/dryingArtificial filaments from viscoseBreaking strengthPolymer science

The invention discloses high-purity viscose fiber and a preparation method thereof. The high-purity viscose fiber is characterized in that the content of ash in the high-purity viscose fiber accounts for 10-200ppm of the dry-based weight of the high-purity viscose fiber; the dry breaking strength is more than or equal to 2.2cN / dtex, the dry breaking elongation is more than or equal to 15%, and the wet breaking elongation is more than or equal to 1.1cN / dtex. When the high-purity viscose fiber is prepared, the fiber is desulfurized and water-washed after being formed, is firstly pre-impregnated by hydrochloric acid, then is bleached, oiled, alcohol-washed, impregnated and washed by hydrochloric acid for multiple times, more than 99% of impurities, lignin and hemicellulose in the fiber are dissolved out by water washing for multiple times, and the cellulose can be safely melted for compound processing, so that the application field of the viscose fiber is expanded.

Owner:赛得利(盐城)纤维有限公司

Internal combustion horizontal rotary continuous carbonization furnace

PendingCN110499166AAvoid deformationSolve the blockageHorizontal chamber coke ovensSpecial form destructive distillationTarCombustible gas

The invention discloses an internal combustion horizontal rotary continuous carbonization furnace. The furnace includes a feeding end, which is fixedly connected to a feed inlet, and the feed inlet and the feeding end are intercommunicated. The invention has the beneficial effects that: a combustible gas can be generated when a material is heated and carbonized, the combustible gas is guided intoan inner roller, in which air is also introduced, and the combustible gas contacts oxygen and combusts, thus forming cyclic utilization of combustible gas in the carbonization process, according to the design, in the carbonization process, the material is heated and carbonized to generate combustible gas and vaporized tar, the combustible gas and vaporized tar are both introduced into the inner roller, in which air is also introduced for combustion to provide a heat source for material carbonization, thus forming cyclic utilization of energy sources, and solving the problem of flue blockage caused by tar, the heat source is disposed in the inner roller, and can prevent deformation of the roller at high temperature, in the material carbonization process, the furnace is sealed strictly, thecarbon yield is high, the structure is simple, the equipment failure rate is reduced, and the manufacturing cost is low.

Owner:吉林省金福一农业科技有限公司

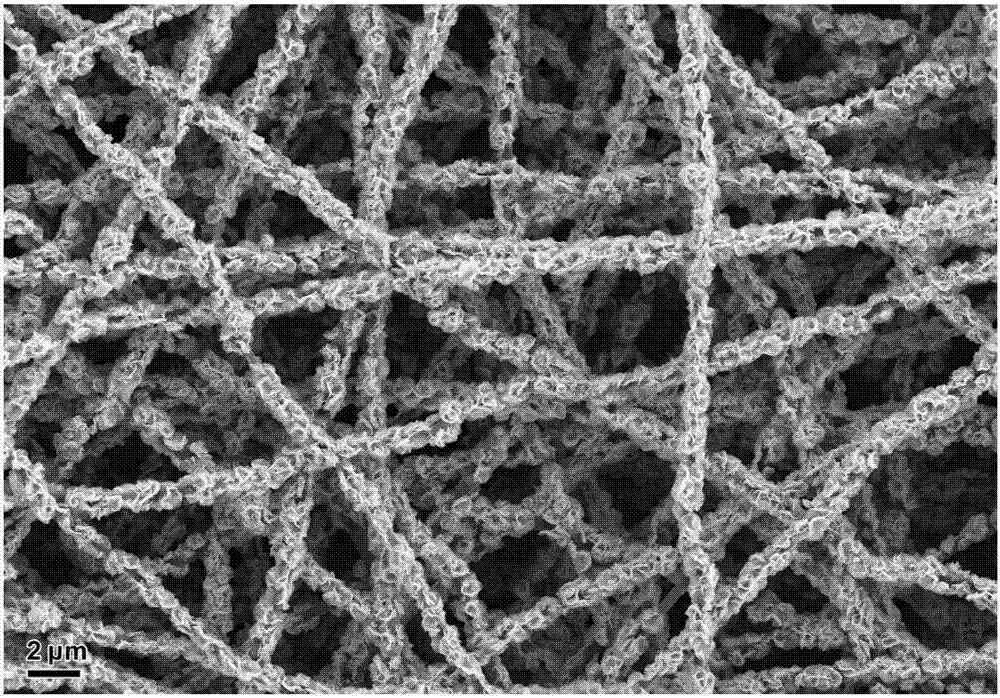

Magnetic cellular porous carbon nanometer fiber@carbon nanotube composite material prepared by carbonization & magnetization & vapor deposition

InactiveCN108054365AIncrease productivityLow viscosityMaterial nanotechnologyCell electrodesAir atmosphereFiber

The invention relates to a magnetic cellular porous carbon nanometer fiber@carbon nanotube composite material prepared by high-temperature carbonization & magnetization & vapor deposition for a lithium-sulfur battery positive electrode material. The method comprises the following steps of uniformly mixing aqueous emulsion containing polyvinyl alcohol and polytetrafluoroethylene and a small amountof boric acid, adding a certain mass of iron salt or ferrite to prepare a spinning solution, spinning to form a fiber under a joint effect of a high-voltage electrostatic field and high-speed air flow, performing low-temperature pre-processing under an air atmosphere, and further performing high-temperature carbonization & magnetization & chemical vapor deposition to obtain the magnetic cellular porous carbon nanometer fiber@carbon nanotube composite material. The magnetic cellular porous carbon nanometer fiber@carbon nanotube composite material prepared by the method is large in specific area, good in magnetism and high in bonding capability of materials, carbonization and growth (chemical vapor deposition) of a carbon nanotube are simultaneously achieved during the carbonization process,the preparation method is simple and practical and is good in controllability, and mass production can be achieved.

Owner:TIANJIN POLYTECHNIC UNIV

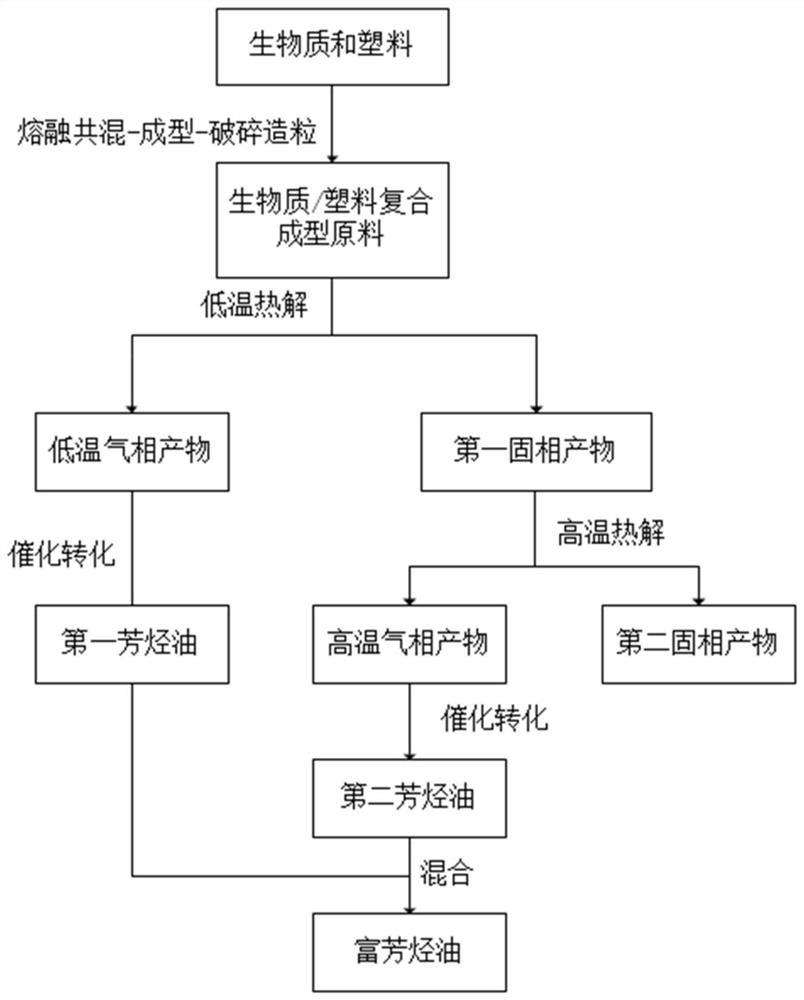

Method for directionally preparing aromatic hydrocarbon through co-pyrolysis of biomass and plastic

ActiveCN112300824AWell mixedEnhanced interactionProductsReagentsCatalytic transformationCo pyrolysis

The invention provides a method for directionally preparing aromatic hydrocarbon through co-pyrolysis of biomass and plastic. The method comprises the following steps: firstly, carrying out melt blending, crushing and granulation on the biomass and the plastic to obtain a homogenized material; secondly, sequentially carrying out low-temperature pyrolysis and catalytic conversion on the homogenizedmaterial to obtain first aromatic hydrocarbon oil, and activating a lignin structure in the biomass; and finally, sequentially carrying out pyrolysis and catalytic conversion on the activated ligninand the residual plastic at high temperature to obtain second aromatic hydrocarbon oil. According to the method disclosed by the invention, the process of preparing the aromatic hydrocarbon from biomass / plastic is strengthened by virtue of a raw material composite molding and step-by-step pyrolysis method, so that the aromatic hydrocarbon product with high yield and high selectivity is obtained, and the method has a relatively good industrial application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com