Tungsten disulfide/carbon nanofiber composite material, and preparation method and use thereof

A carbon nanofiber and tungsten disulfide technology, which is applied in the field of tungsten disulfide/carbon nanofiber composite materials and its preparation, can solve the problems of easy agglomeration, conductivity, and performance suppression, and achieve easy agglomeration, rich pores, and enhanced The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment includes the following steps:

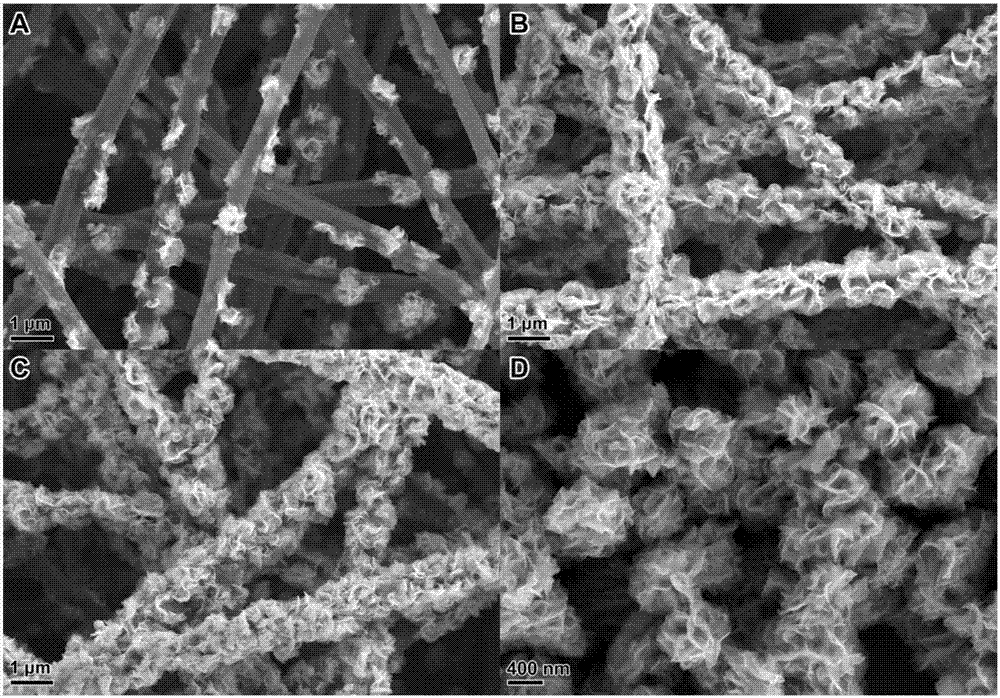

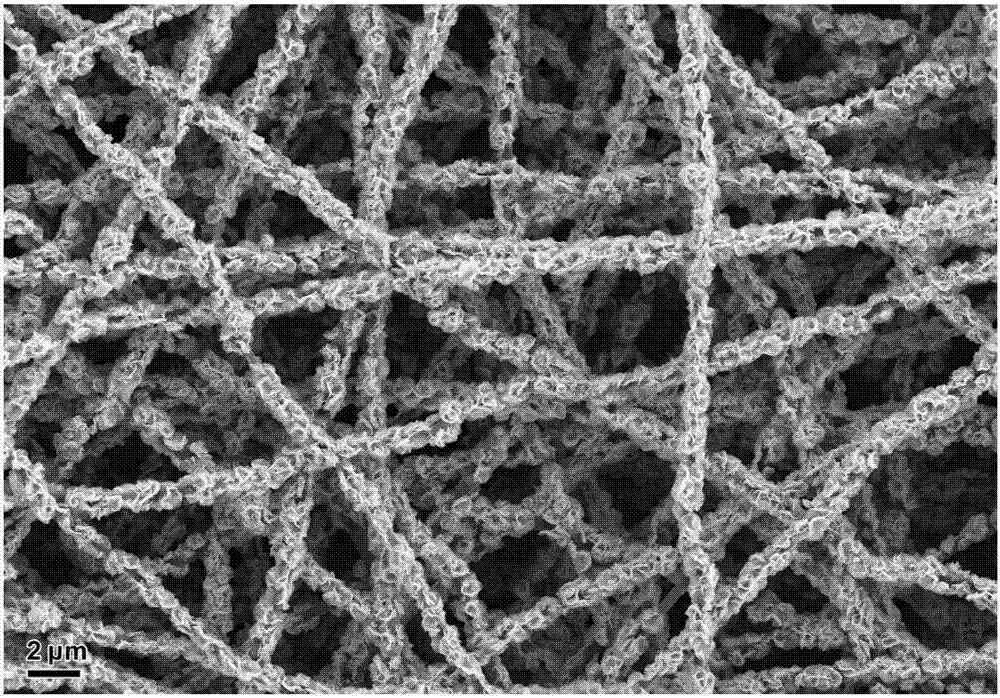

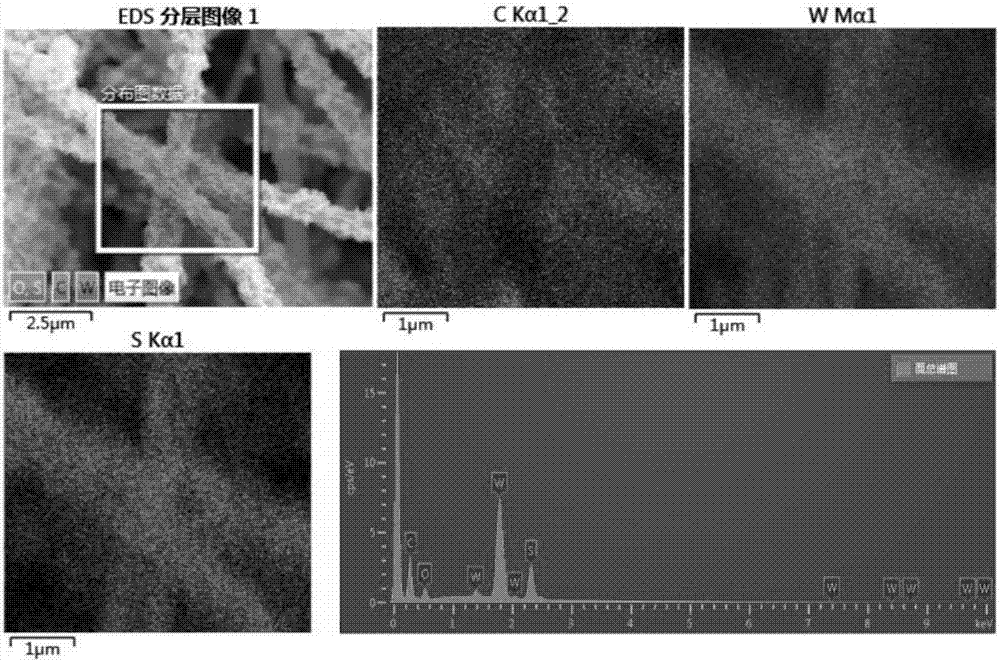

[0041]Weigh 1.2 g of polyacrylonitrile powder and add it into 10 mL of DMF, and stir at a high speed for 8 hours under heating in an oil bath at 85° C. to obtain a clear polyacrylonitrile solution. Electrospinning was carried out on the above polyacrylonitrile solution, and the spinning parameters were set as: flow rate 0.28mm / min, voltage 22kV, receiving distance 18cm. The prepared polyacrylonitrile nanofibers were finally deposited on the roller receiver in the form of nanofiber film, and the fiber film was peeled off and stored in a vacuum oven for 24 hours to remove residual DMF. The dried polyacrylonitrile fiber membrane was fixed on a flat plate and transferred to a temperature-programmed oven for pre-oxidation treatment. The temperature was raised from room temperature to 250 °C at a rate of 1.5 °C / min and kept for 2.5 h, and then cooled down to room temperature naturally. The color of the polyacrylonitrile fiber m...

Embodiment 2

[0049] This embodiment includes the following steps:

[0050] The steps for preparing the electrospun carbon nanofiber membrane are the same as in Example 1.

[0051] Weigh 180mg and 300mg ammonium tetrathiotungstate respectively and add them to 30mL DMF, ultrasonicate and stir to prepare ammonium tetrathiotungstate solutions with concentrations of 6mg / mL and 10mg / mL respectively. Weigh two 30mg carbon nanofiber membranes and add them to the above two solutions respectively, transfer them to a polytetrafluoroethylene-lined reaction kettle, react in an oven at 200°C for 12 hours, take them out, wash and dry the products to obtain Two tungsten disulfide / carbon nanofiber composite membrane materials with higher loading capacity.

Embodiment 3

[0053] This embodiment includes the following steps:

[0054] Weigh 60 mg of ammonium tetrathiotungstate powder, add it into 30 mL of DMF, ultrasonicate and stir to obtain ammonium tetrathiotungstate solution with a concentration of 2 mg / mL. Transfer the above solution to a polytetrafluoroethylene-lined reactor, react in an oven at 200°C for 12 hours, take it out, and centrifuge, wash, and dry the product to obtain pure tungsten disulfide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com