Patents

Literature

104results about How to "Ingenious design ideas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

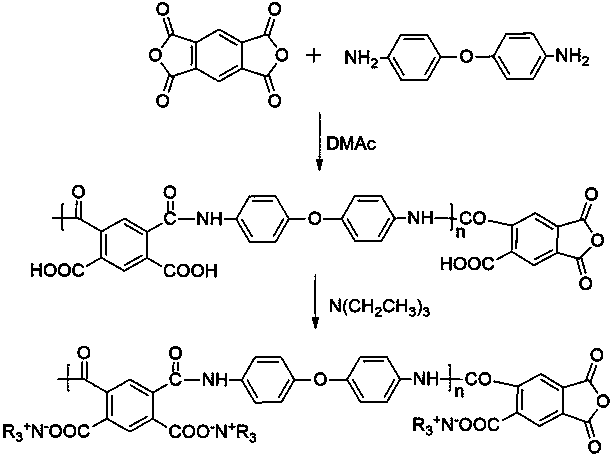

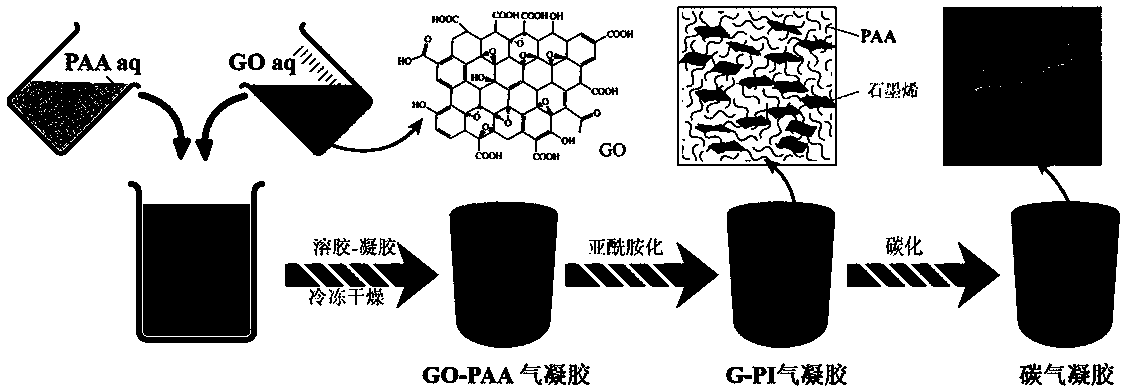

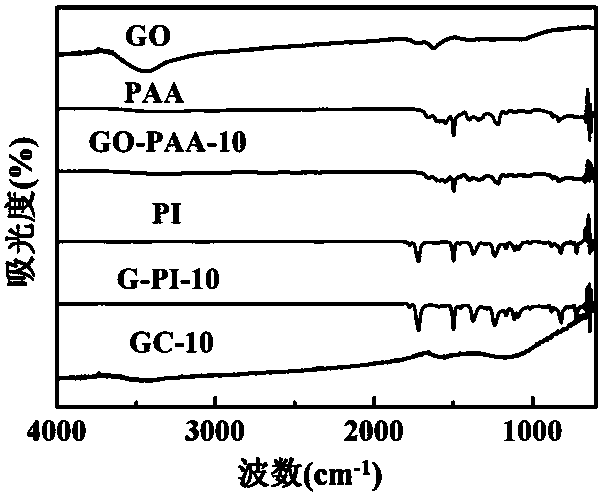

Preparation method of graphene/polyimide-based carbon aerogel

InactiveCN104355302AEasy to makeThe preparation process is environmentally friendlyFreeze-dryingNew energy

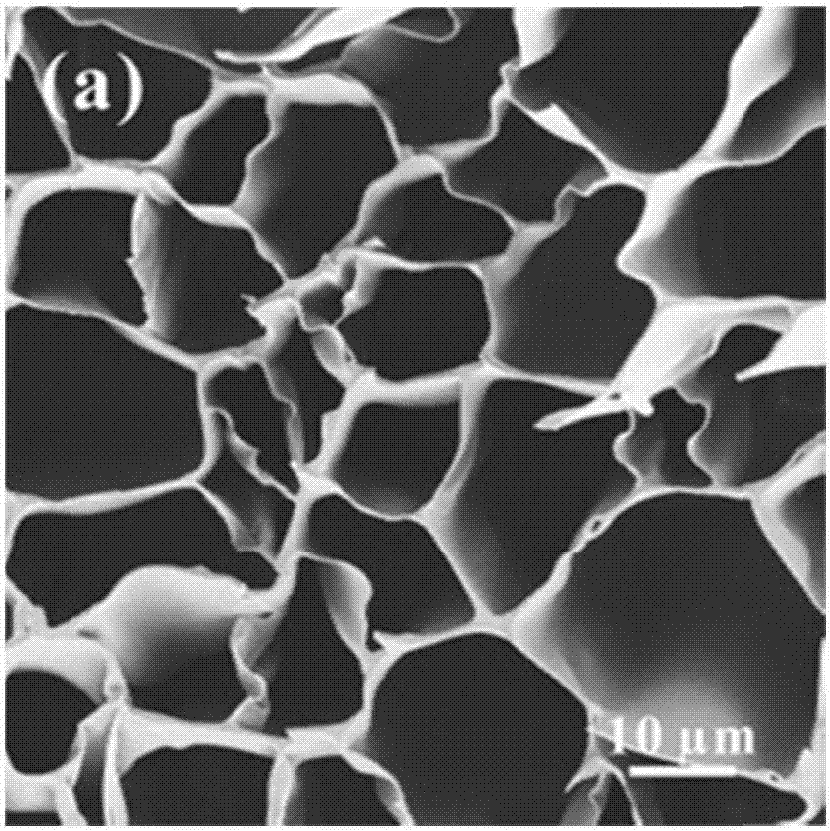

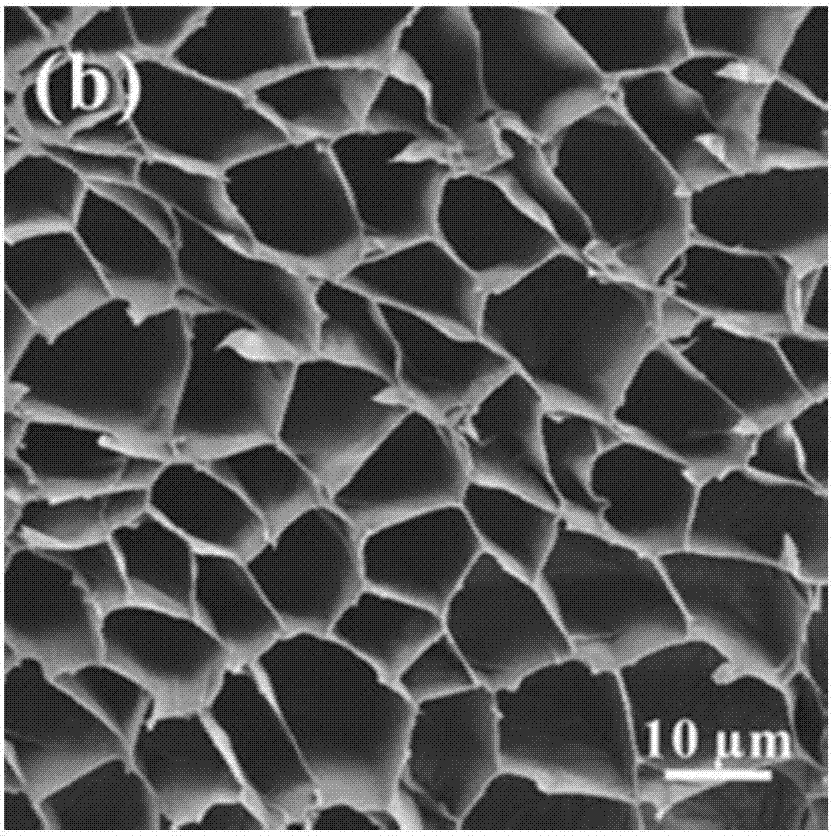

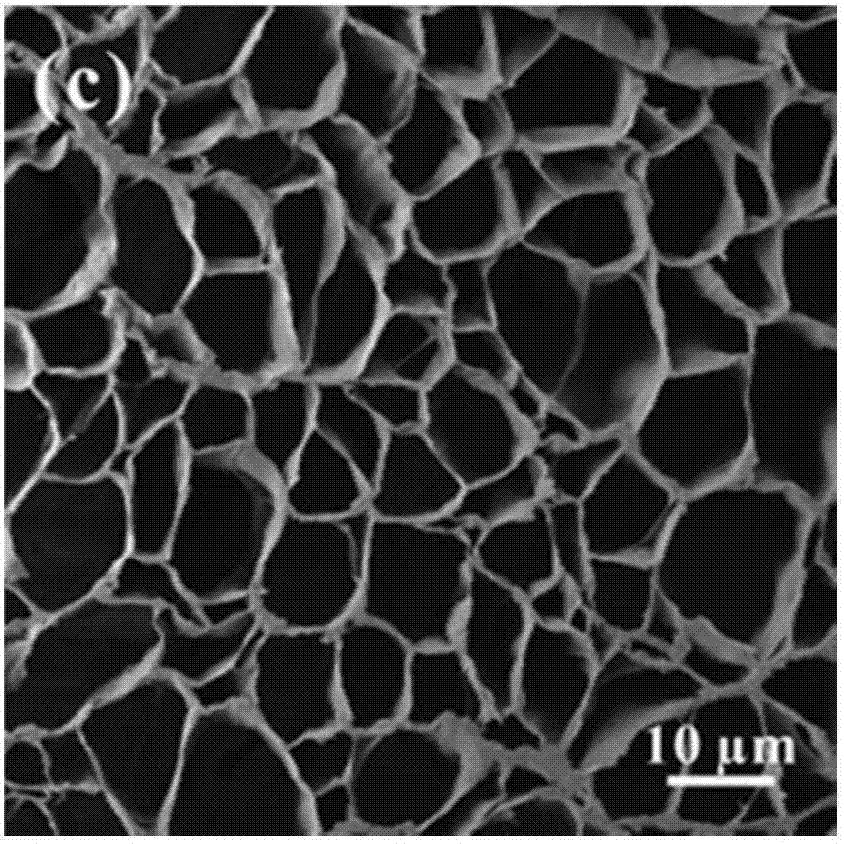

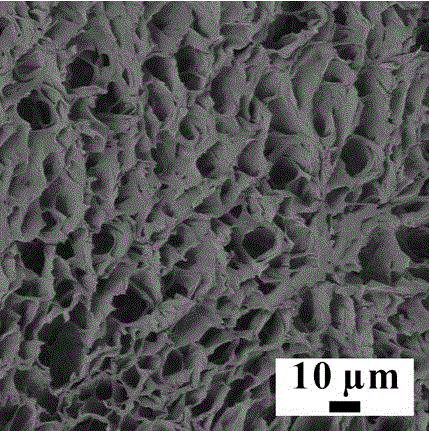

The invention belongs to the technical field of nanoporous material, namely carbon aerogel, and particularly relates to graphene oxide-crosslinked polyimide-based carbon aerogel and a preparation method thereof. The invention carbon aerogel is prepared by crosslinking polyamide acid aerogel by graphene oxide, and comprises the components of graphene oxide and one or more water-soluble polyimide precursor-polyamide acids. The preparation method comprises the following steps: mixing an aqueous graphene oxide solution with the water-soluble polyimide precursor-polyamide acid, and preparing graphene oxide / polyamide acid aerogel through sol-gel and freeze-drying processes; preparing the graphene / polyimide-based carbon aerogel through thermal imidization and high temperature carbonization. According to the preparation method, a toxic reagent formaldehyde is not used; the prepared carbon aerogel has a mesoporous, microporous and macroporous three-level three-dimensional network porous structure, high specific surface area, high conductivity and stable physical and chemical properties, and is an ideal electrode material for preparing a supercapacitor and other new energy devices and a high-performance adsorbent material.

Owner:FUDAN UNIV

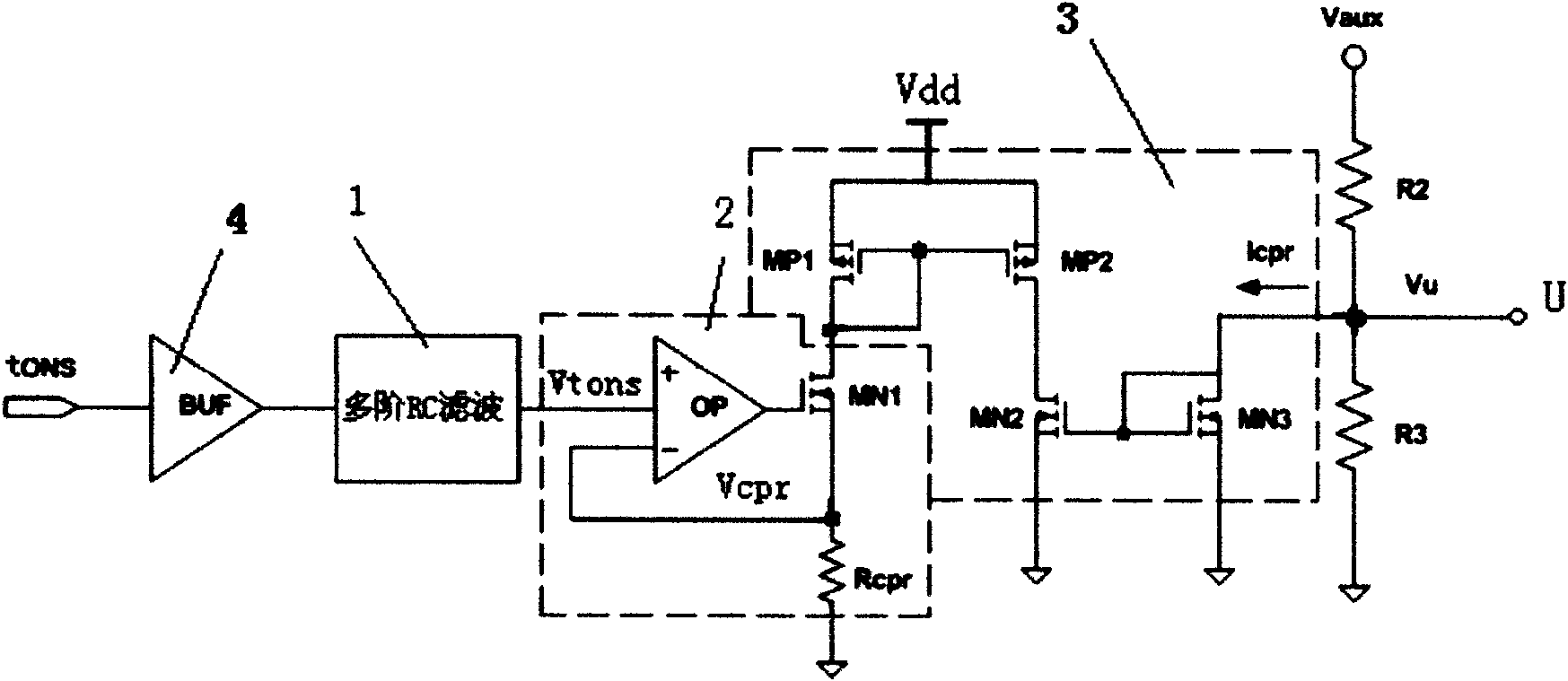

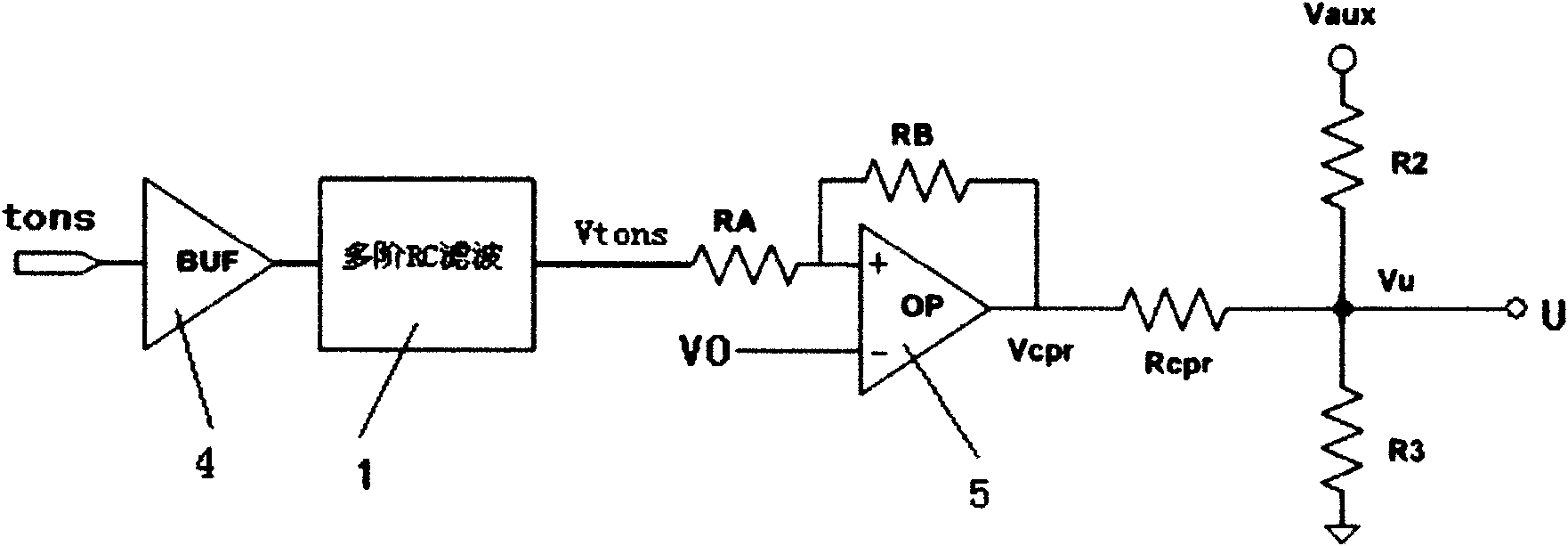

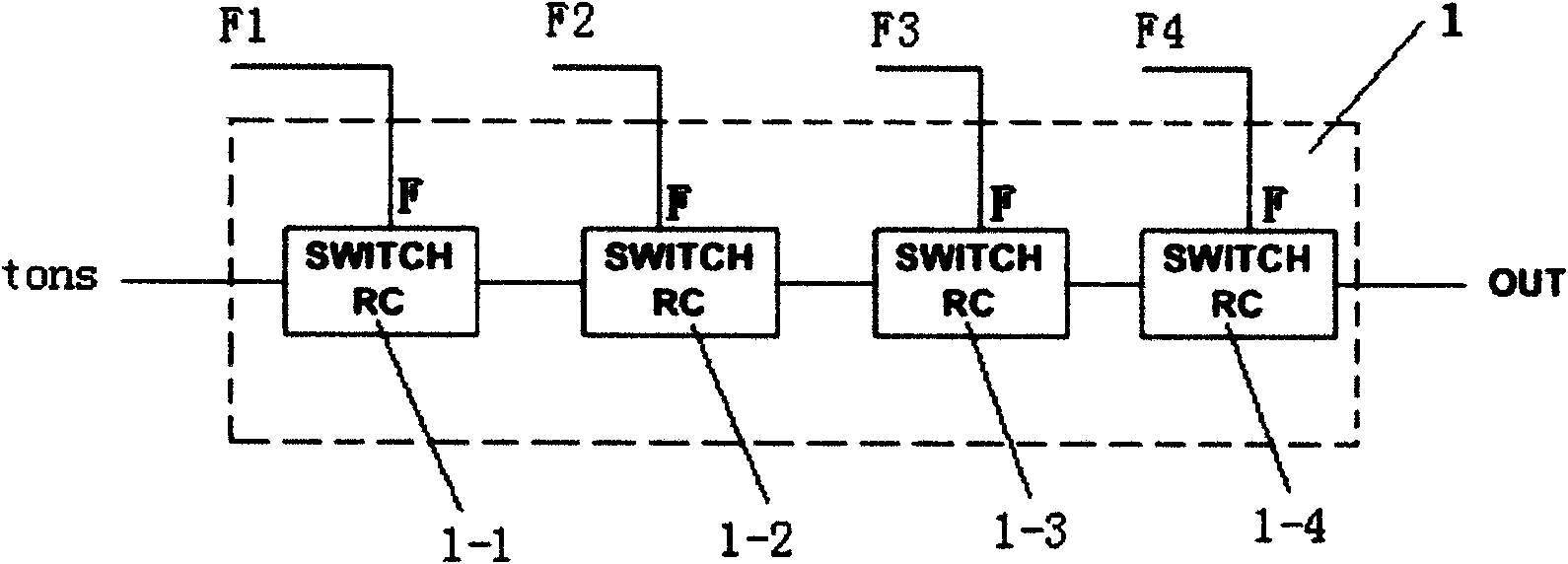

Line loss compensation circuit for switch power supply

InactiveCN101860243AImprove performanceSimple structureAc-dc conversionCapacitanceElectrical resistance and conductance

The invention relates to a line loss compensation circuit for a switch power supply, which is divided into a current-type line loss compensation circuit and a voltage-type line loss compensation circuit, wherein the current-type circuit comprises a multi-stage RC low pass filter, a voltage / current switching circuit and a current mirroring circuit, and the voltage-type circuit comprises a multi-stage RC low pass filter, a subtractor and a compensating resistance. The invention can produce a compensating current of Icpr or a compensating voltage of Vcpr which is proportionable to an output current of Iout, and the compensating current or the compensating voltage is used for offsetting voltage drop of an output wire caused by change of Iout, thereby recovering voltage stabilizing control function of a control loop to secure constant output. The invention has the advantages of skilful design idea and simple circuit and is easy to realize. The improvement of the invention is that: the switch RC filter is adopted to greatly reduce volume of an electric capacity of the RC filter, thereby facilitating integration, further improving circuit performance and simplifying circuit structure, and strengthening operation reliability of the switch power supply.

Owner:西安英洛华微电子有限公司

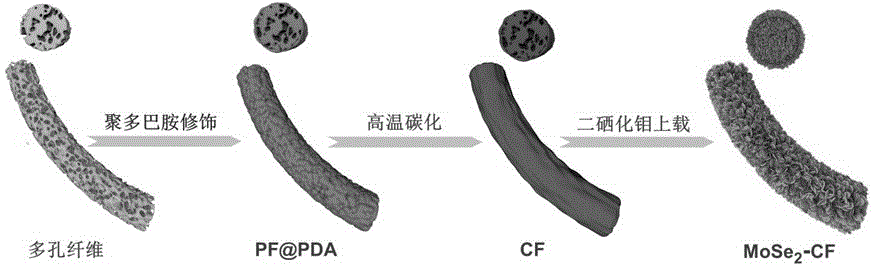

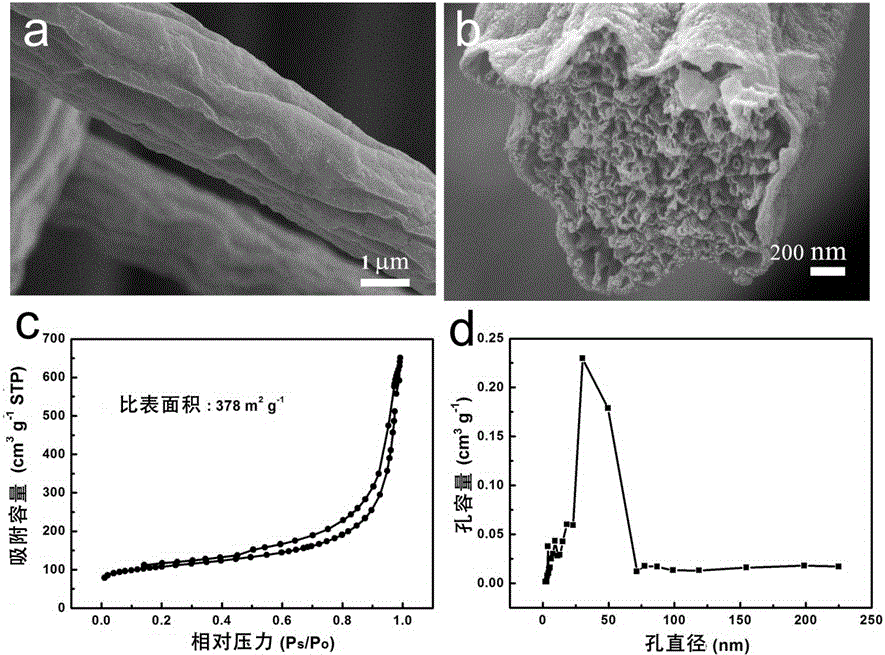

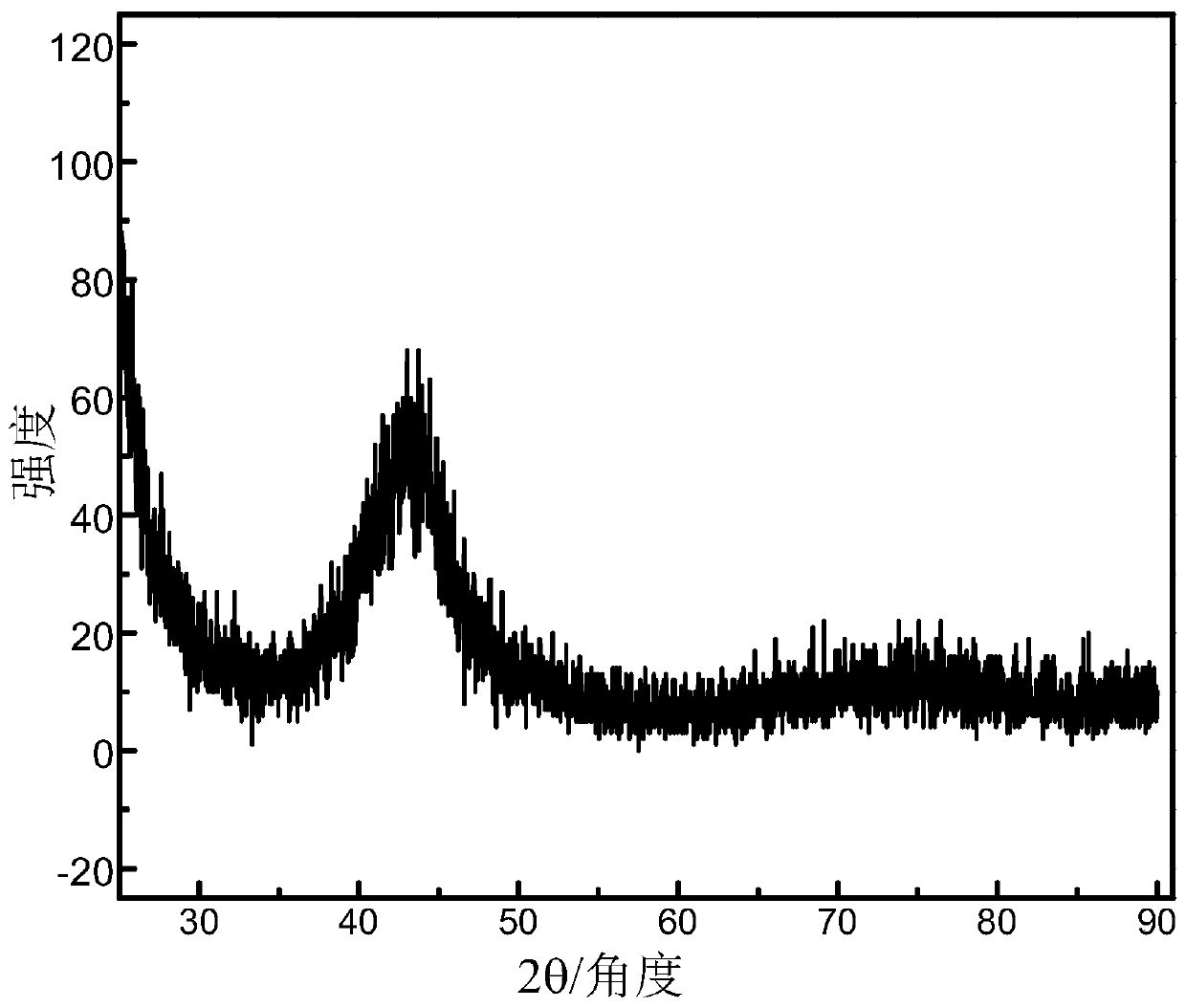

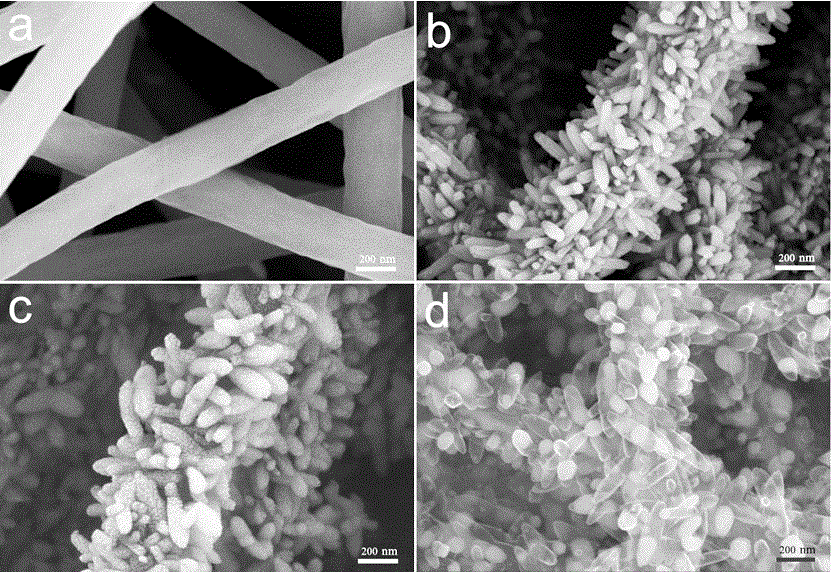

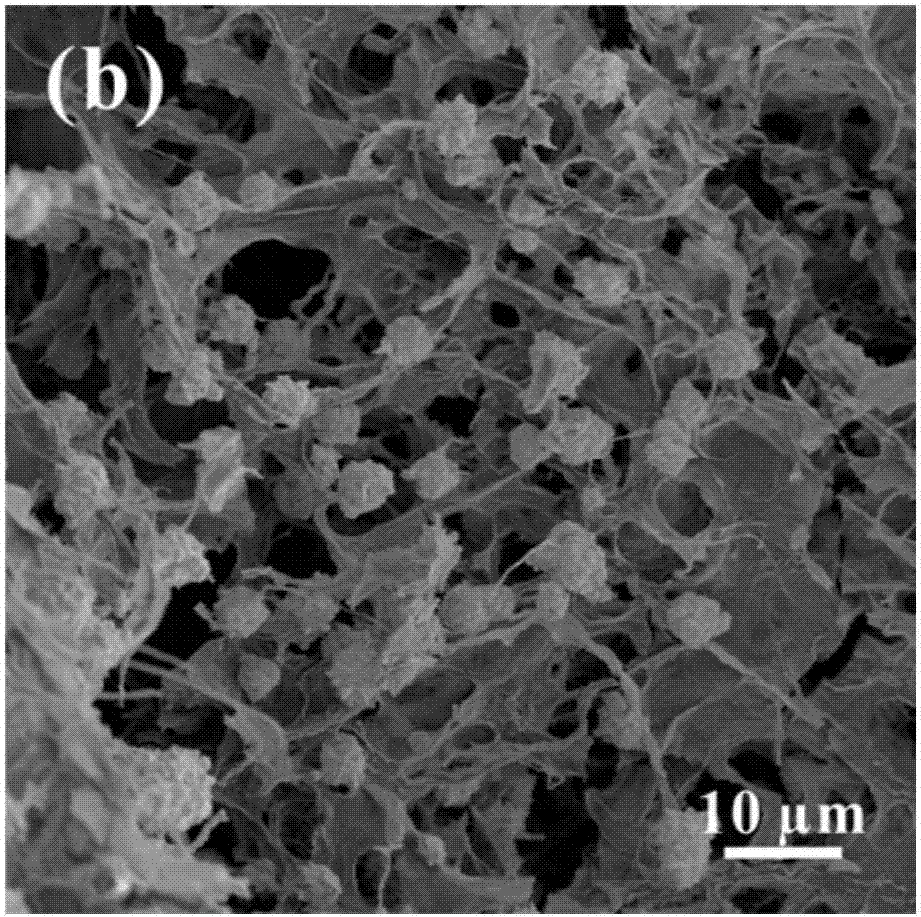

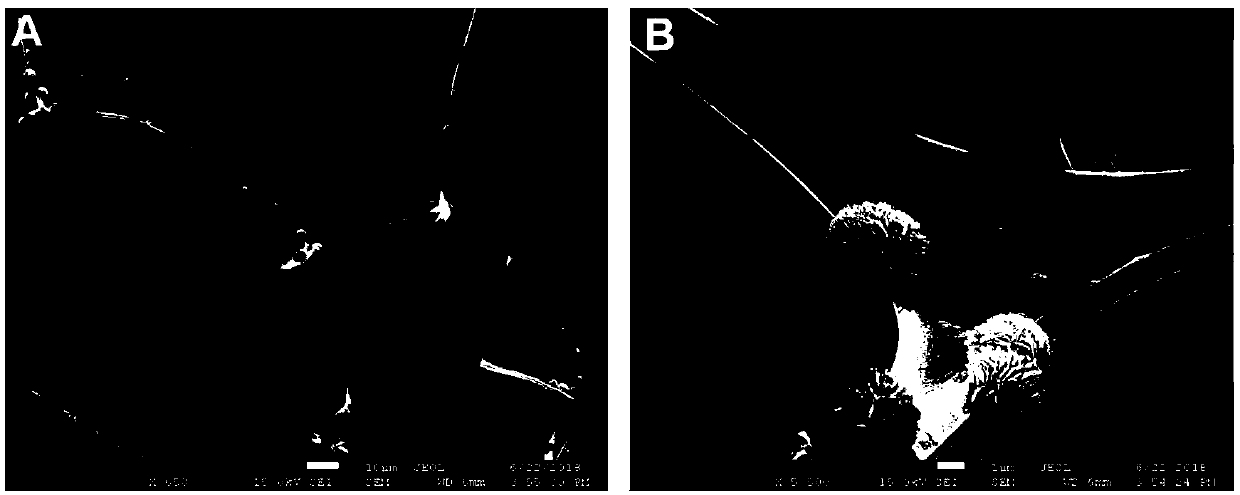

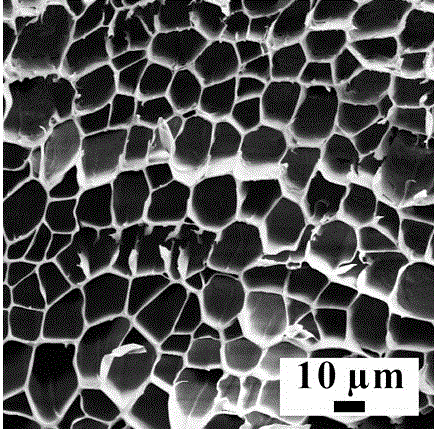

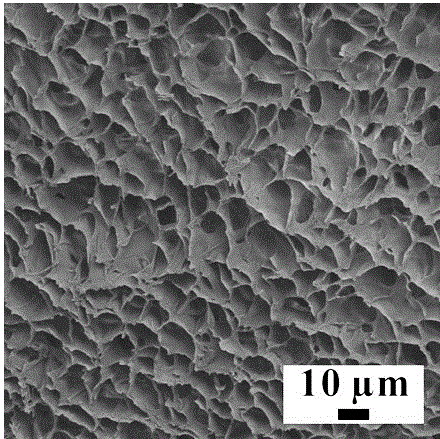

Poly-dopamine based porous carbon fiber/MoSe2 composite material and preparation method thereof

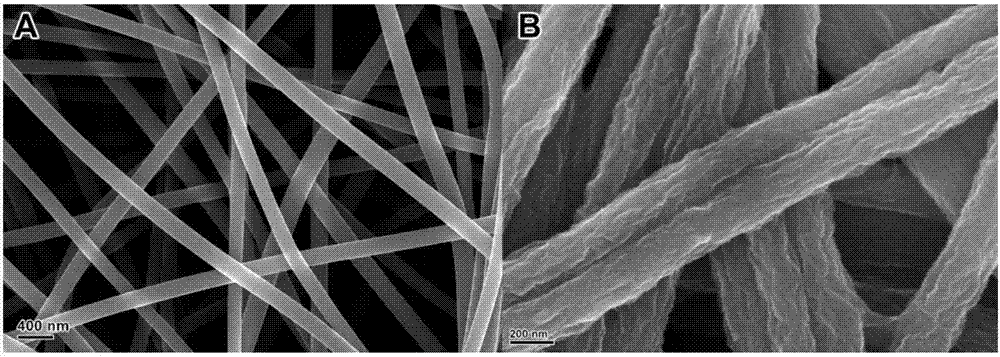

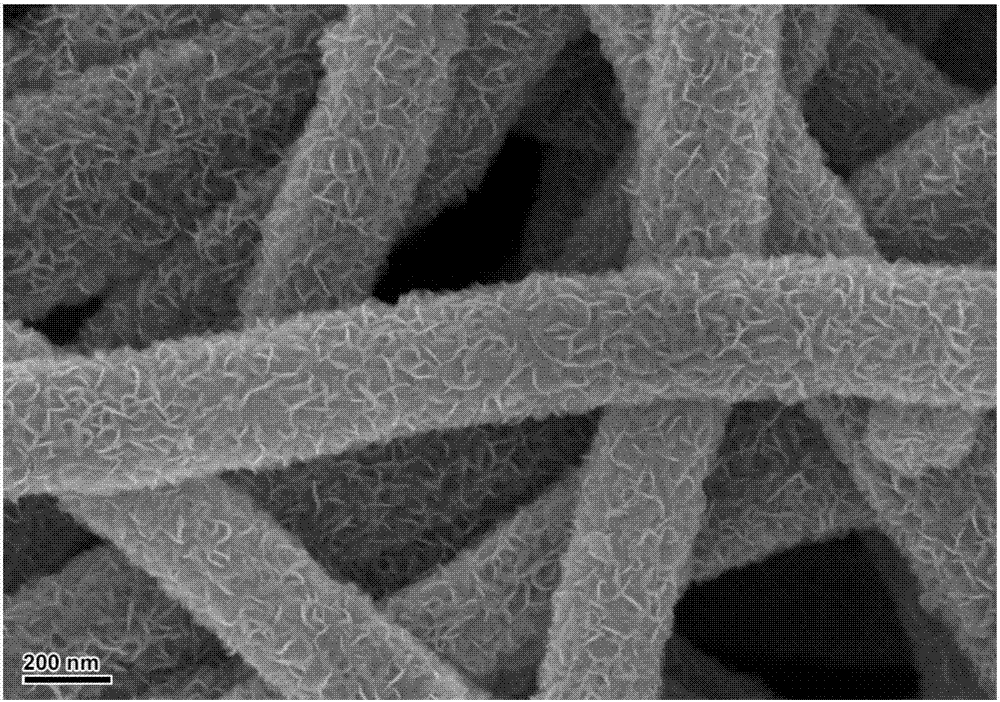

InactiveCN105742074AGentle preparationThe preparation process is environmentally friendlyHybrid capacitor electrodesCell electrodesElectro catalystCarbon fibers

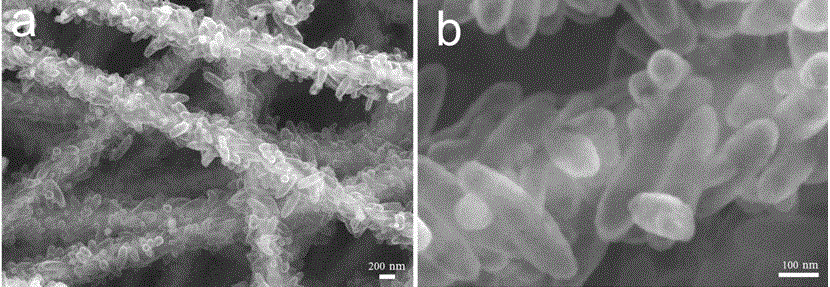

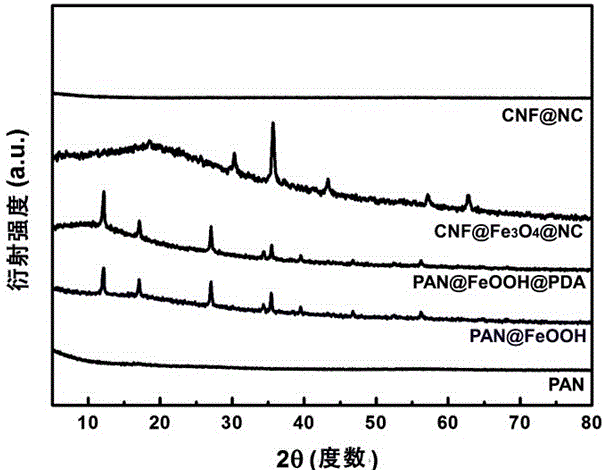

The invention belongs to the technical field of a composite fiber material, in particular relates to a poly-dopamine based porous carbon fiber / MoSe2 nanosheet composite material and a preparation method thereof. The method comprises the following steps of preparing a spinning solution with a spinnable high-polymer material, and preparing to obtain porous fiber with an uniform structure by an electrostatic spinning device; immersing the porous fiber in a dopamine solution, and controlling the thickness of a poly-dopamine cladding layer by adjusting the concentration and the reaction time of the dopamine solution; carrying out high-temperature carbonization to achieve carbonization on the poly-dopamine modified porous fiber material; and uniformly arranging MoSe2 nanosheets on the surface of the porous fiber by a hydrothermal method. The method disclosed by the invention is safe and environment-friendly, and the prepared porous carbon fiber / MoSe2 has the advantages of high active substance content, high specific area, high conductivity, stable physical and chemical performance and the like, and is an ideal electrode material for preparing an active electric catalyst for a hydrogen evolution reaction.

Owner:FUDAN UNIV

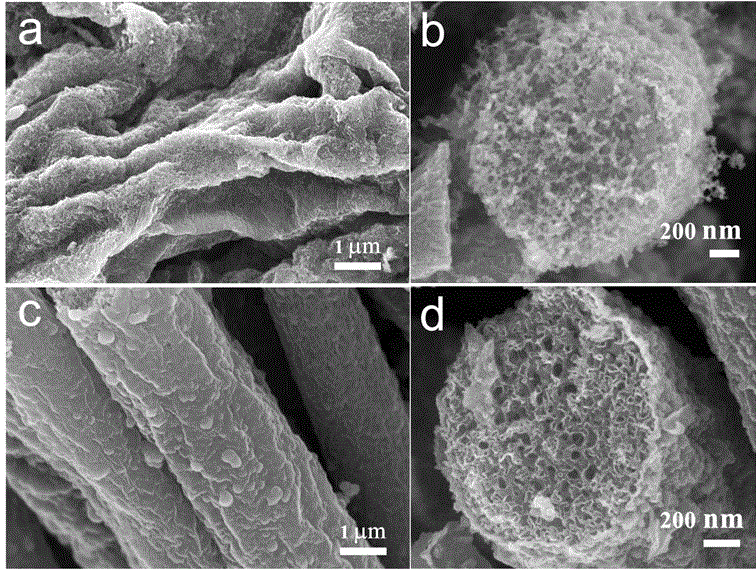

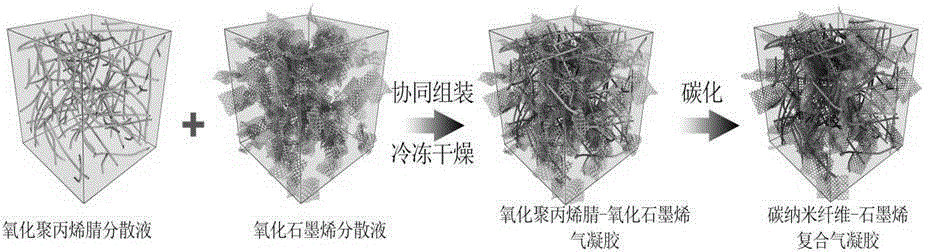

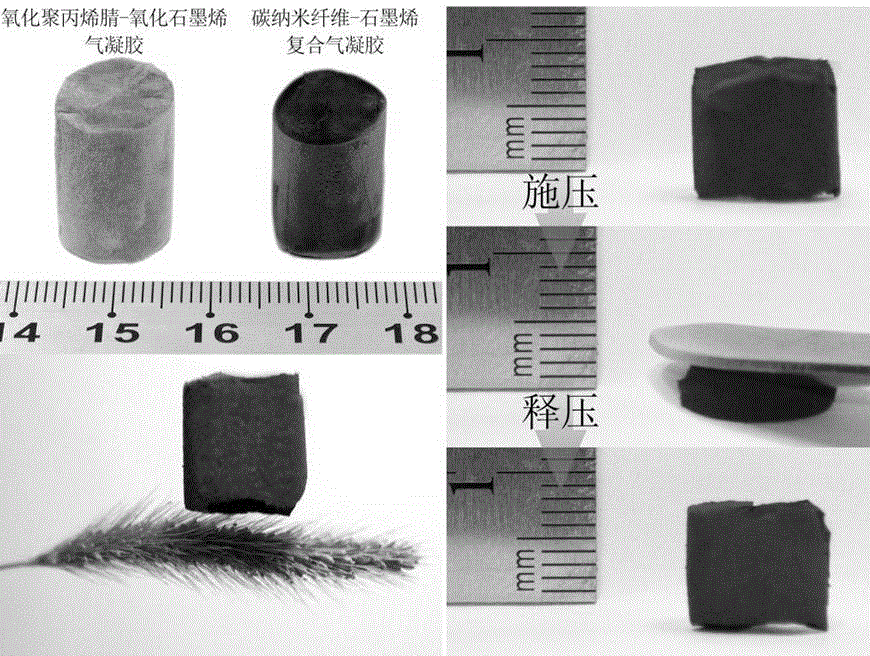

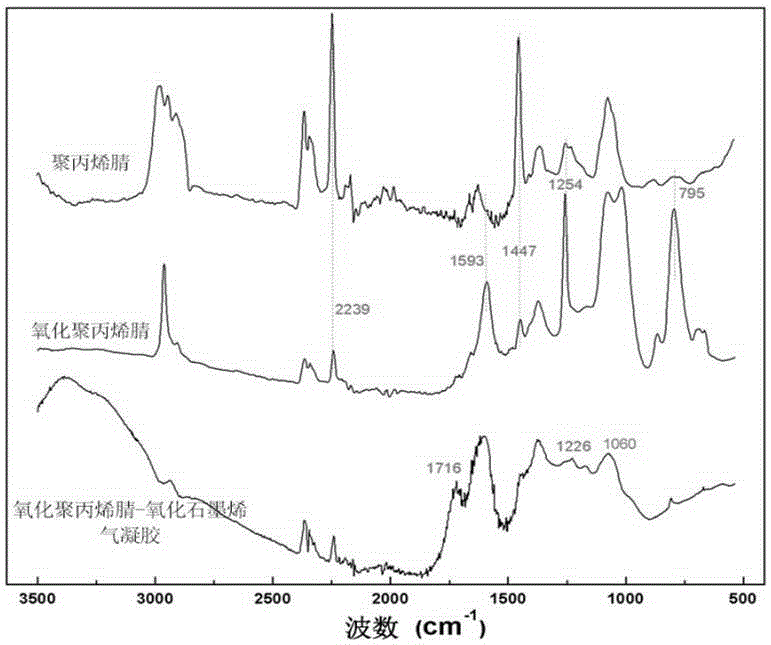

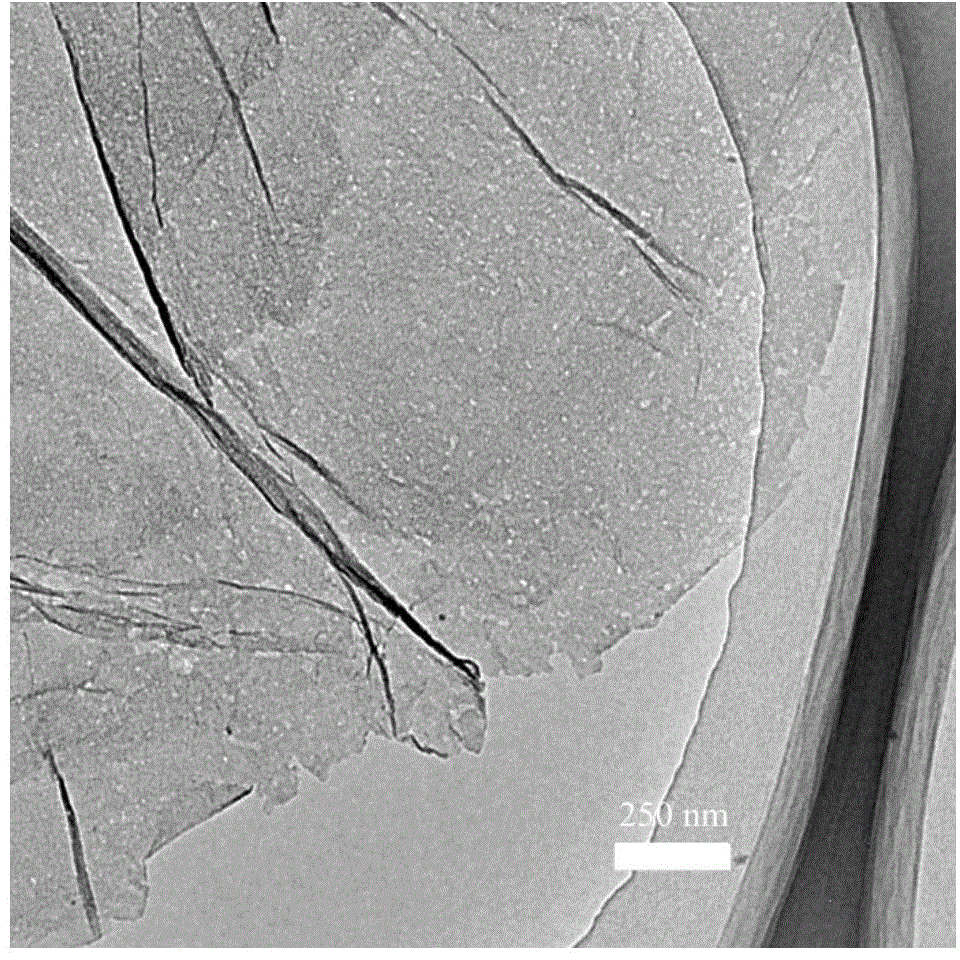

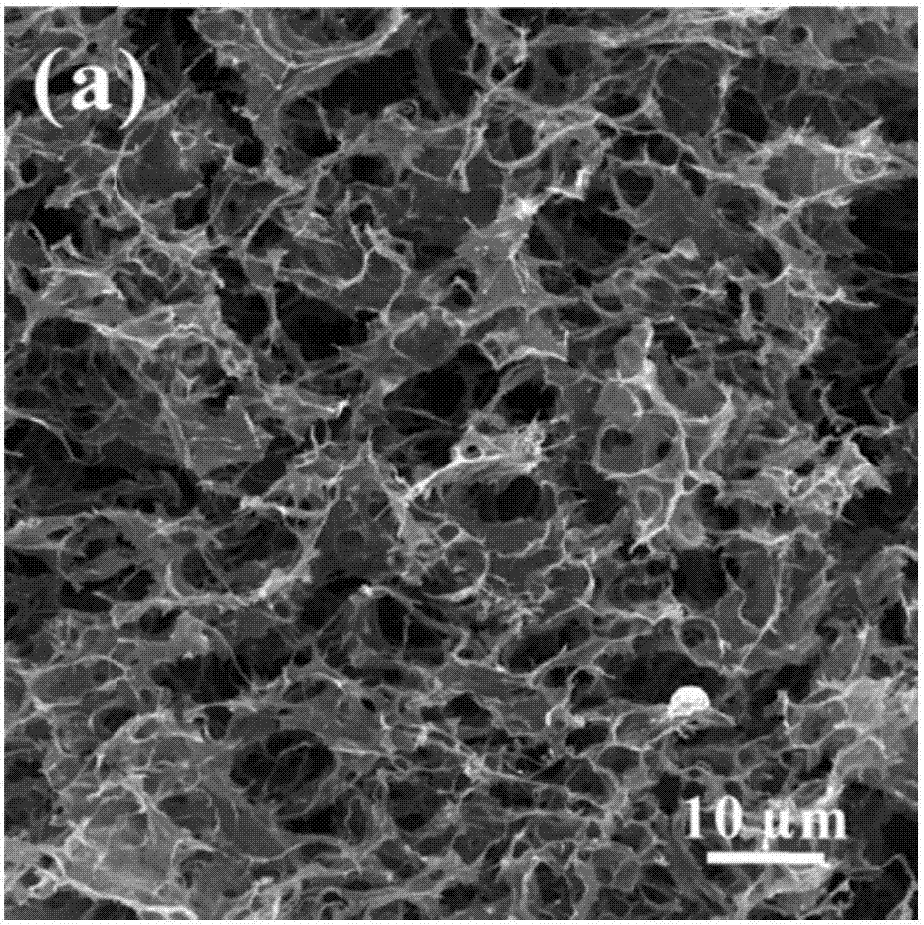

Carbon nano fiber-graphene composite aerogel and cooperative assembly preparation method thereof

InactiveCN105161312AEnvironmentally friendlyEasy to makeHybrid capacitor electrodesSpinningFreeze-drying

The invention belongs to the field of nano fiber carbon aerogel, and specifically discloses a carbon nano fiber-graphene composite aerogel and a cooperative assembly preparation method thereof. The method comprises: preparing polyacrylonitrile nano fibers by adopting an electrostatic spinning method; preparing surface-functionalized oxidized polyacrylonitrile nano fibers by temperature programmed pre-oxidation; and homogenizing the oxidized polyacrylonitrile nano fibers, then performing cooperative assembly on the oxidized polyacrylonitrile nano fibers and graphene oxide, and performing freeze drying and high-temperature carbonization to obtain the carbon nano fiber-graphene composite aerogel. The preparation method is simple, efficient and environment-friendly, and does not adopt any toxic reagent; the prepared carbon nano fiber-graphene composite aerogel has the advantages of light weight, multiple pores, good elasticity and the like; and the method solves the problem that the traditional film-like electrostatic spinning fiber material is difficult in three-dimensional forming. The prepared carbon nano fiber-graphene composite aerogel serving as a super-capacitor electrode material has excellent capacitance performance.

Owner:FUDAN UNIV

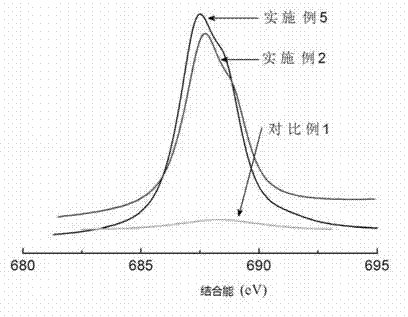

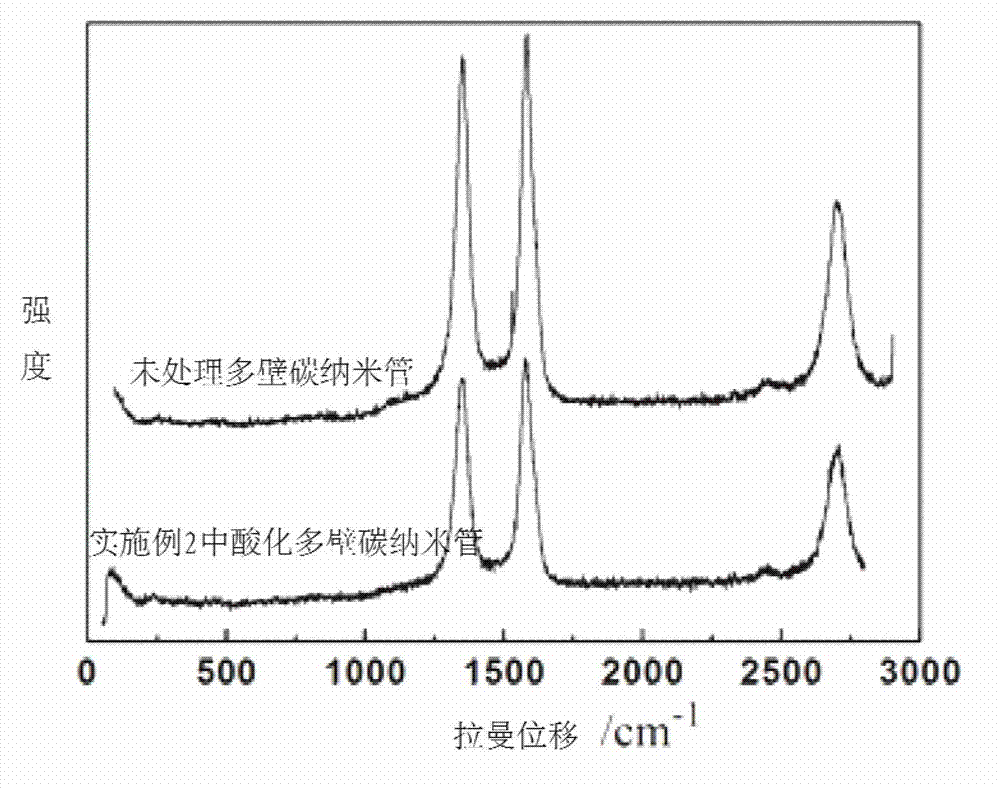

Carbon nano-tube with fluorine-containing surface and preparation method thereof

ActiveCN102730664AImprove heat resistanceEasy generationMaterial nanotechnologyCarbon fluoridesReaction temperatureStrong acids

The invention discloses a carbon nano-tube with a fluorine-containing surface, wherein the surface of the carbon nano-tube is of a carbon-fluorine covalent bond structure, the content of fluorine in the surface is 4-14%, and the decrease rate of the content of the fluorine is smaller than 5% after a produced fluorocarbon nano-tube is treated for 1 hour under a vacuum condition at 350 DEG C. The preparation method of the carbon nano-tube comprises the following steps of: firstly treating the carbon nano-tube by utilizing strong acid, secondly placing the carbon nano-tube in a vacuum reactor, charging fluorine / inert gas mixture with fluorine partial pressure of 10-100KPa in nitrogen atmosphere under room temperature to react for 0.5-4 hours at 150-300 DEG C, and cooling down to be the room temperature to obtain the carbon nano-tube. The fluorocarbon nano-tube prepared by the preparation method disclosed by the invention has the advantages of high fluorine content, low reaction temperature, high safety, energy conservation, and simple process, a fluorine-containing group of the surface of the treated prepared fluorocarbon nano-tube has good heat resistance and lower cost, and the fluorocarbon nano-tube is suitable for large-batch production and has stronger application prospect.

Owner:SICHUAN UNIV

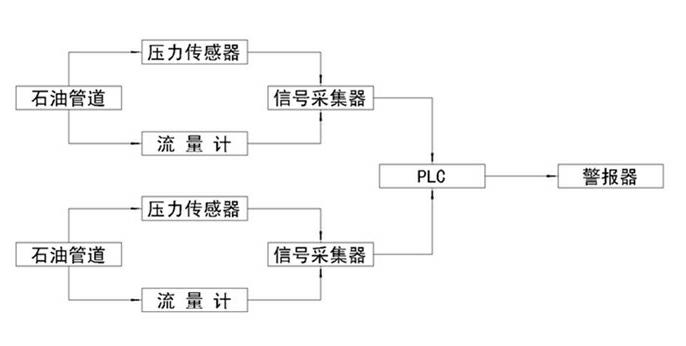

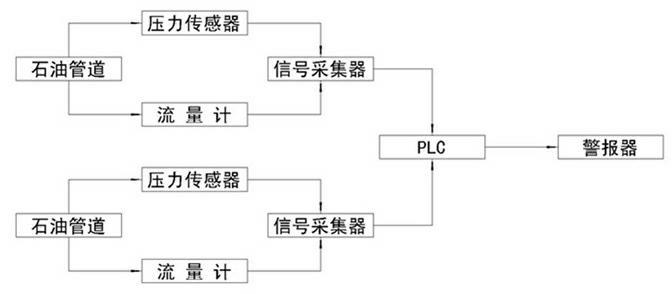

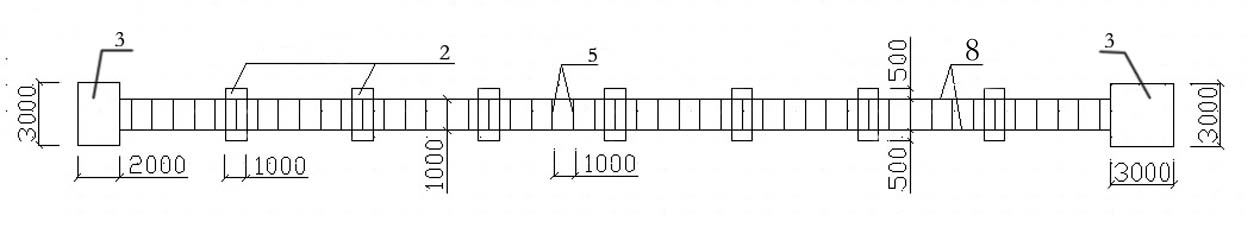

Monitoring system for petroleum pipeline

InactiveCN102367913ASimple structureIngenious design ideasPipeline systemsProgrammable logic controllerPetroleum

The invention discloses a monitoring system for a petroleum pipeline, which is characterized in that: the pipe wall of the petroleum pipeline is provided with a detection unit which comprises a pressure sensor and a flowmeter, both the pressure sensor and the flowmeter are connected with a signal acquisition amplifier which is connected with a PLC (programmable logic controller ), and an alarm is further connected with the PLC; and a plurality of the detection unit are arranged in an equidistance mode in the longitudinal direction of the petroleum pipeline. The monitoring system for the petroleum pipeline has the advantages of simple structure, ingenious design and operation convenience and is capable of accurately judging whether a leak source exists.

Owner:大连市金州区登沙河云峰管路配件厂

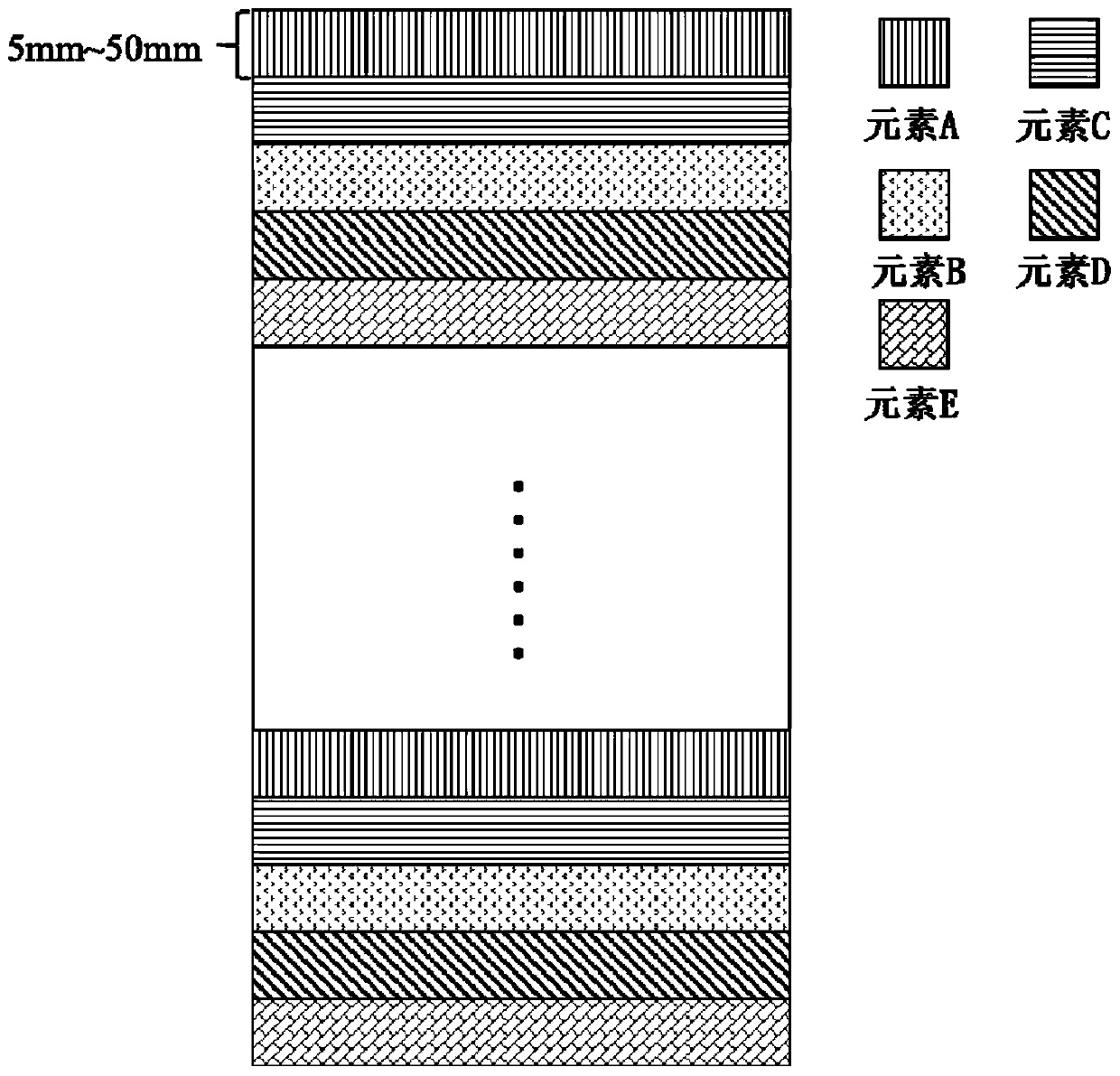

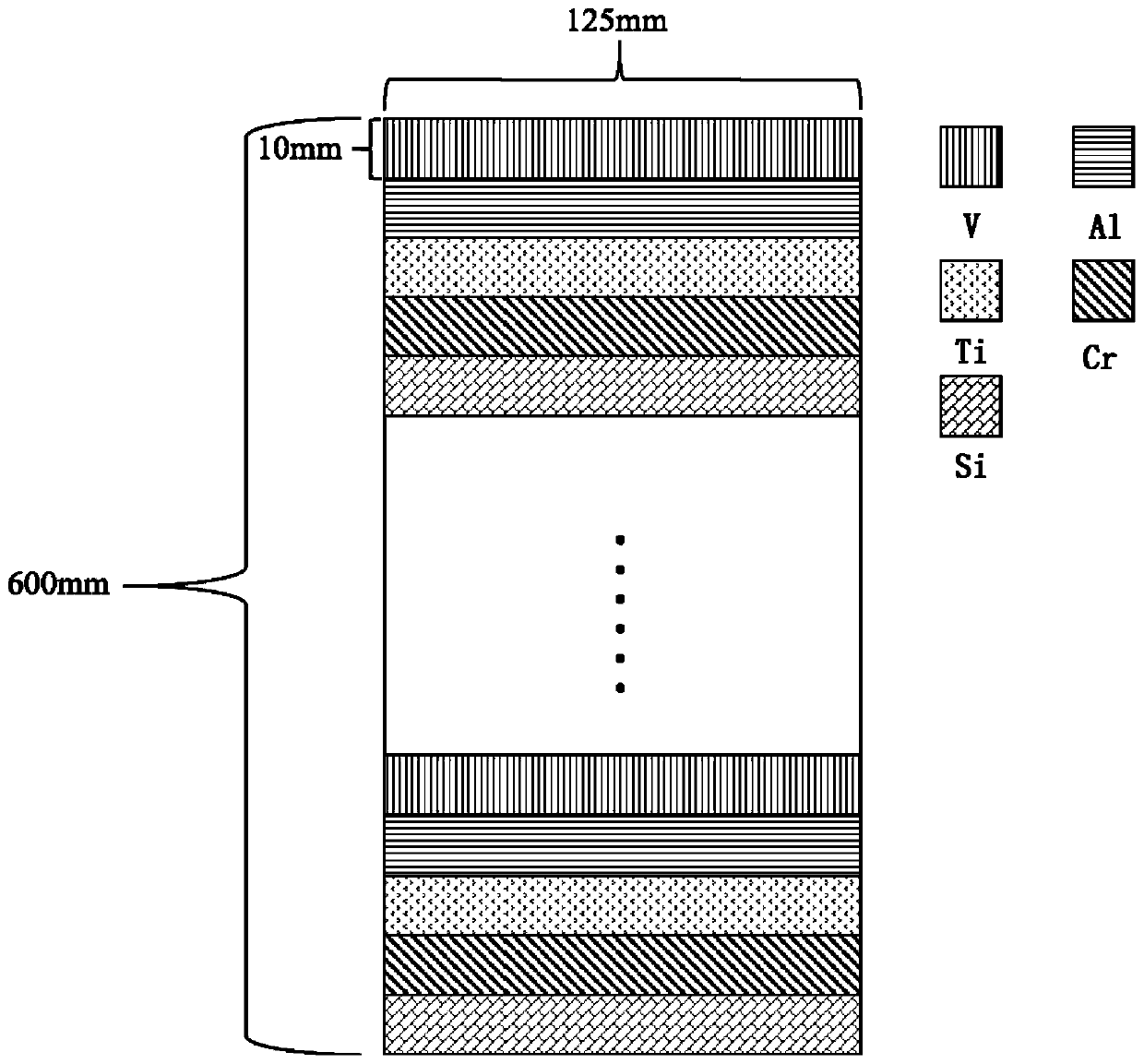

Physical vapor deposition preparation method for high-entropy alloy film with uniform and controllable components

InactiveCN111074223AFlexible and convenient combinationUniform compositionVacuum evaporation coatingSputtering coatingHigh entropy alloysAlloy thin film

The invention discloses a physical vapor deposition preparation method for a high-entropy alloy film with uniform and controllable components. The preparation method comprises the steps that a magnetron sputtering technology is adopted, a magnetron sputtering composite target serves as a target material, one or more kinds of gas serve as working gas, negative bias voltage is applied to a base body, and therefore the high-entropy alloy thin film with the uniform and controllable components is obtained on the surface of the base body through deposition; and the magnetron sputtering composite target comprises at least one target period which is periodically arranged in the vertical direction, and each target period comprises single alloy target materials which are sequentially stacked in thevertical direction. According to the provided preparation method, the method is simple, the overall design idea is ingenious, all pure targets are independent of one another and are flexible and convenient to combine, the adjustment can be carried out according to needs, and the high-entropy alloy thin film with the controllable and uniform components can be economically and efficiently prepared;and according to the method, the thin-layer target materials are stacked and spliced together, so that compared with combination of large pure target materials, the method can enable various components in a product to be uniform, so that the product with a single phase is obtained.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Pure carbon fiber material adopting 'vesical string' structure and preparation method of pure carbon fiber material

InactiveCN105734725ALarge specific surface areaHigh porosityMaterial nanotechnologyElectroconductive/antistatic filament manufactureFiberCarbon fibers

The invention belongs to the technical field of nano-fiber materials, in particular to a pure carbon fiber material adopting a 'vesical string' structure and a preparation method of the pure carbon fiber material. The preparation method comprises the following steps: preparing a spinning solution from a spinnable polymer material, and preparing nanofibers of uniform structures with an electrostatic spinning device; uploading iron oxide hydroxide cambiform nanorods on the surfaces of the nanofibers uniformly via a water bath or hydrothermal method; soaking an iron oxide hydroxide-modified fiber membrane in a dopamine solution, and controlling the thickness of a polydopamine coating layer by adjusting the concentration of the dopamine solution and the reaction time; carrying out high-temperature carbonization treatment, so as to realize fiber carbonization, and conversion of iron oxide hydroxide to ferroferric oxide as well as polydopamine to a N-doped carbon material; removing ferroferric oxide via soaking in an acid solution. The preparation method is safe and environmentally friendly; the prepared pure carbon fiber material is high in nitrogen content, specific surface area and electric conductivity, and stable in physical and chemical properties, so as to be an ideal electrode material for production of new energy devices such as a supercapacitor.

Owner:FUDAN UNIV

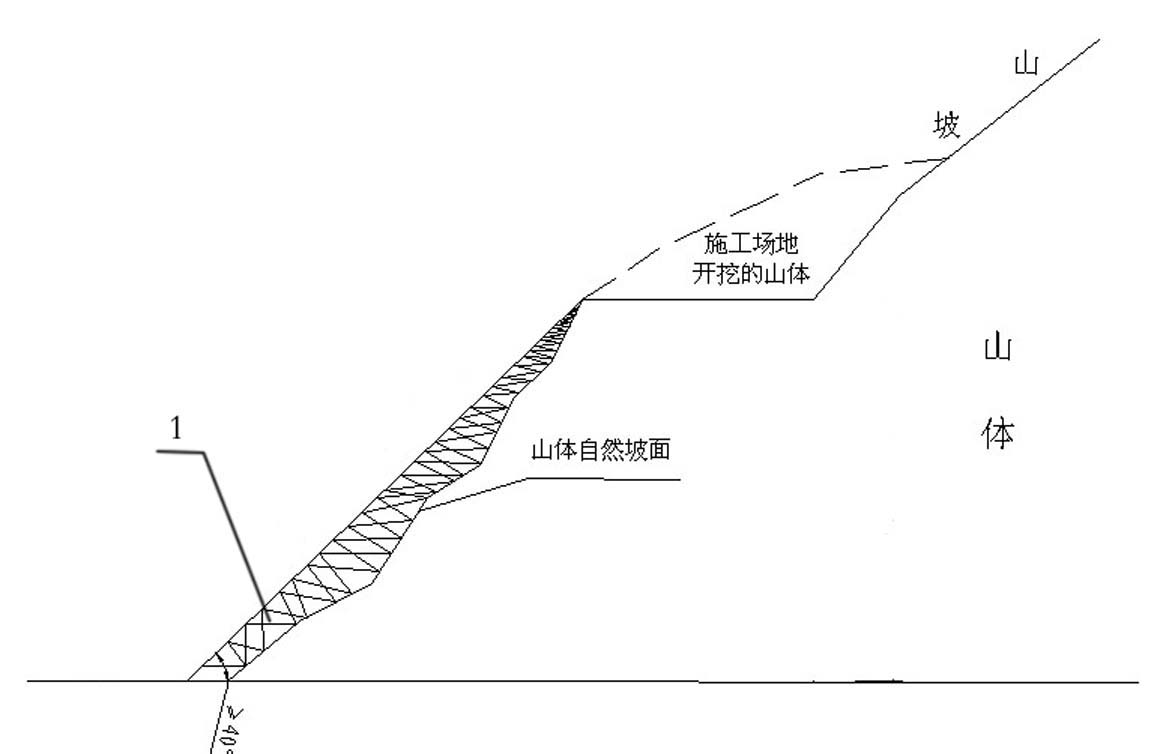

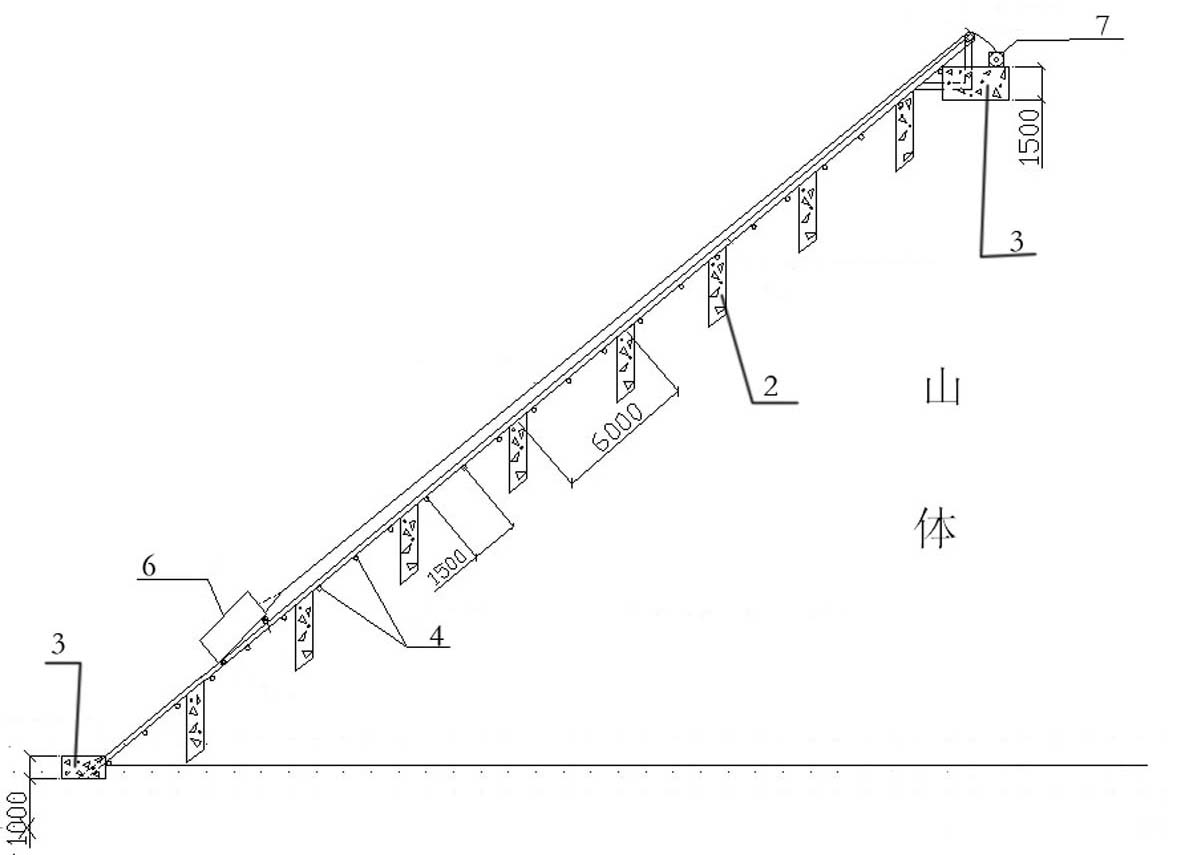

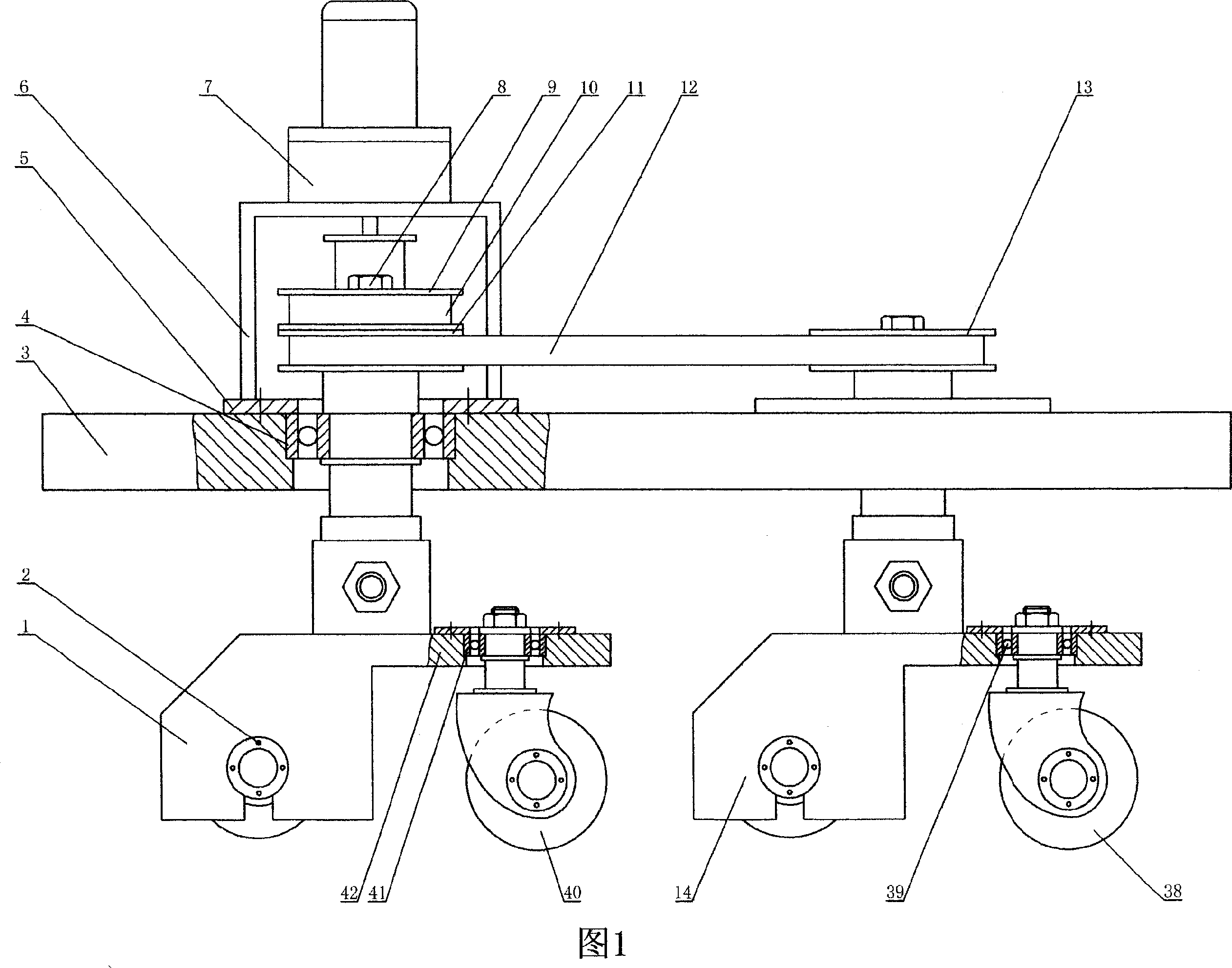

Transportation method for constructing high mountain building

ActiveCN102060199AMeet the bearing capacity requirementsInnovative design ideasStorage devicesEngineeringDesign thinking

The invention relates to a construction method of a high mountain building, in particular to a transportation method for constructing a high mountain building. In the method, the problems that materials and construction tools are difficult to transport when constructing a new structure or building, and the exiting transportation method has various defects are solved. The method comprises the steps: building a base layer on a slope surface which is relatively flat by the earth excavated on the field; paving two tracks on the base layer; and arranging a transporting hopper car on the tracks, wherein the transporting hopper car is driven by a winding engine at the top of the slope surface to move up and down along the tracks, so that the transportation during constructing the high mountain building is realized. The method is novel and ingenious in design thinking, is reasonable and definite in design parameters, and offers a novel transportation method for the transportation during constructing the high mountain building. The method has the technical effects as follows: 1, the construction cost and the project cost are reduced; 2, the work efficiency is high; 3, the method is convenient and flexible; and 4, the method improves the application, i.e. a beautiful and practical passing steel ladder can be formed only with a little improvement.

Owner:山西太行建设开发有限公司

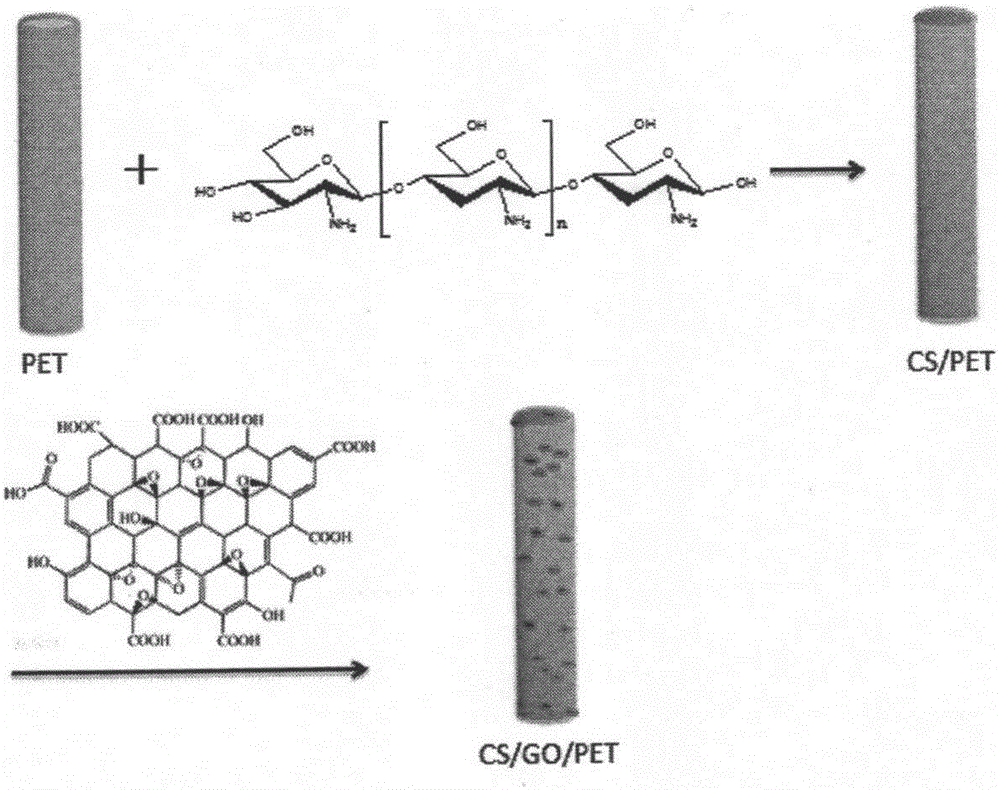

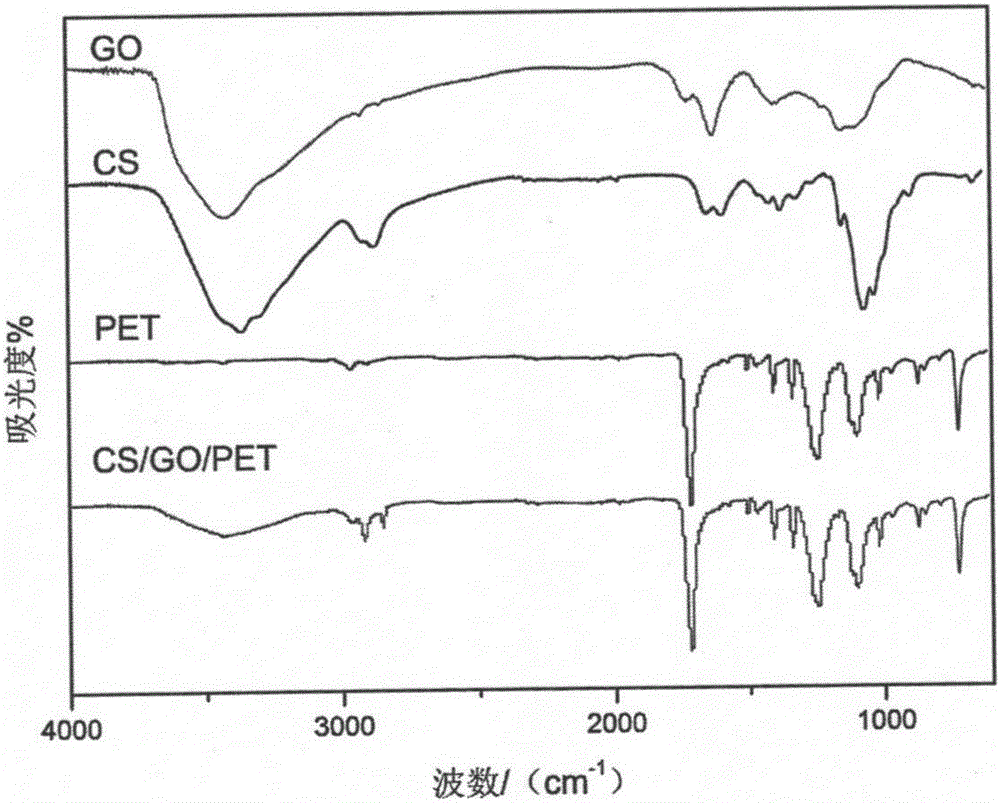

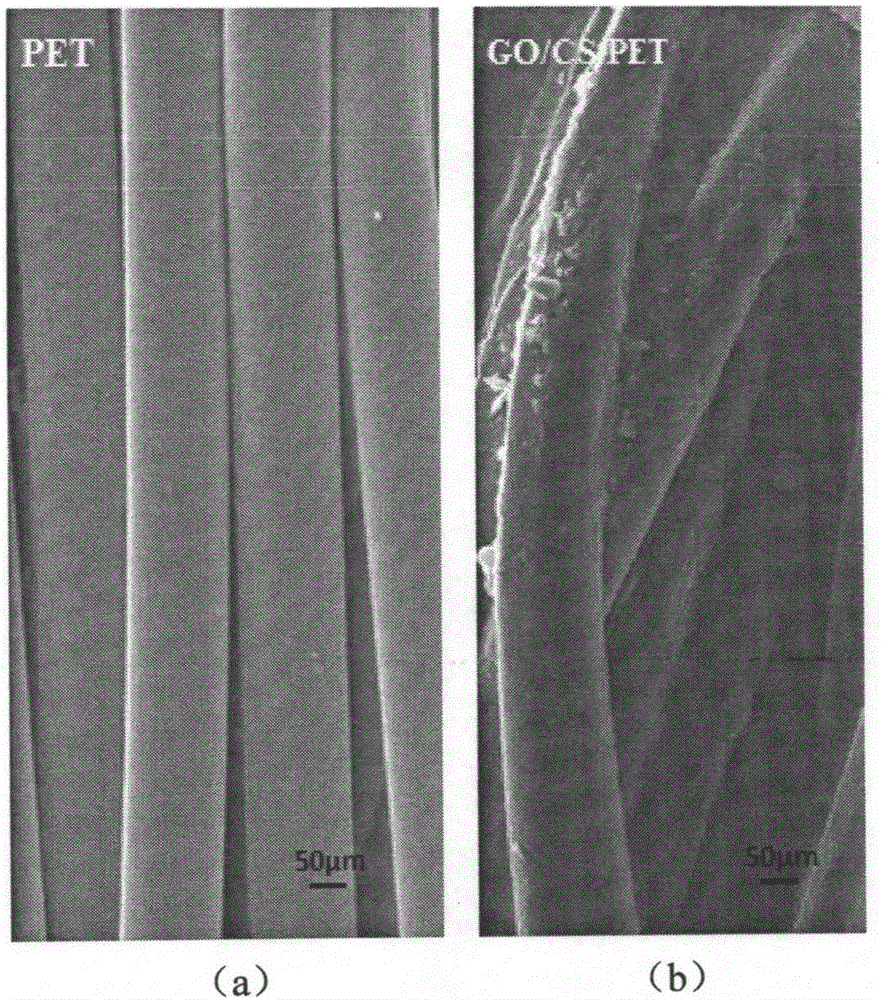

Preparation method of hydrophilic and antistatic polyester fiber

The invention provides a preparation method of a hydrophilic and antistatic polyester fiber. The preparation method comprises the steps that a carbonic acid solution is adopted as a solvent of chitosan gel, and chitosan is applied to the surface of a polyester fiber; a stable graphene oxide-chitosan coating is formed on the surface of the polyester fiber through interaction between graphene oxide and the chitosan; after washing and drying are conducted, the hydrophilic and antistatic polyester fiber is obtained. According to the preparation method, carbonic acid is adopted as the solvent of the chitosan, a chitosan film can be directly formed to be deposited on the surface of the polyester fiber through heating, and a solvent removing step is not needed; the polyester fiber with the chitosan film and the graphene oxide have a high bonding effect; the prepared chitosan-graphene oxide-polyester fiber has the very good hydrophily and antistatic property. The green chemical preparation method is simple in preparation process, environmentally friendly and low in equipment requirement and has a wide application prospect.

Owner:DONGHUA UNIV

Preparation method and application of sulfur-doped graphene and derivatives thereof

The invention relates to a preparation method of sulfur-doped graphene and derivatives thereof. The method includes the following steps: 1) uniformly mixing a solution of the graphene and the derivatives thereof with an sulfur-containing ionic group solution to prepare a suspension liquid; 2) freeze-drying the suspension liquid to obtain a solid mixture of the graphene and the derivatives thereof with the sulfur-containing ionic salt; 3) under protective atmosphere, calcining the solid mixture of the graphene and the derivatives thereof with the sulfur-containing ionic salt to obtain an intermediate of the sulfur-doped graphene and derivatives thereof; and 4) cooling, washing and drying the intermediate to obtain a finish product of the sulfur-doped graphene and derivatives thereof. The preparation method is simple in operation, employs common devices, is low in cost and achieves industrial production. The sulfur-doped graphene and derivatives thereof has very high specific surface area, has penetrated porous structure and has high pore capacity and high electric conductivity.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

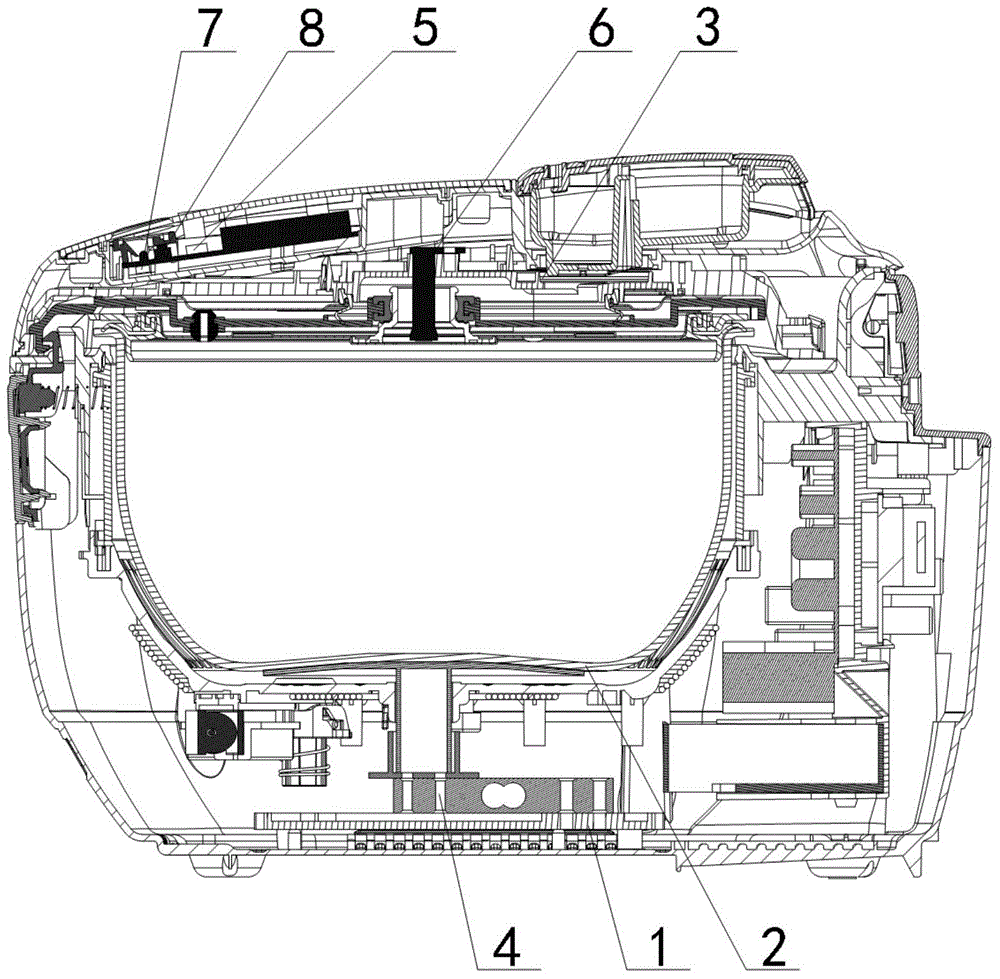

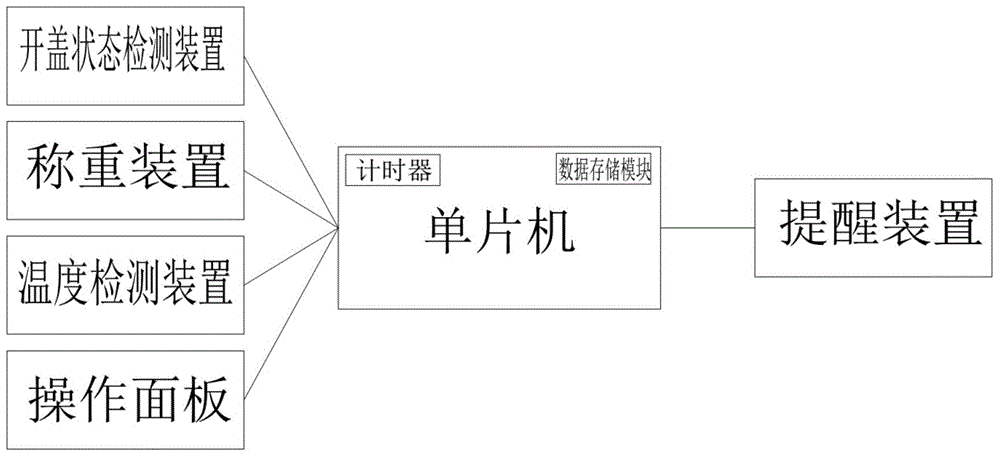

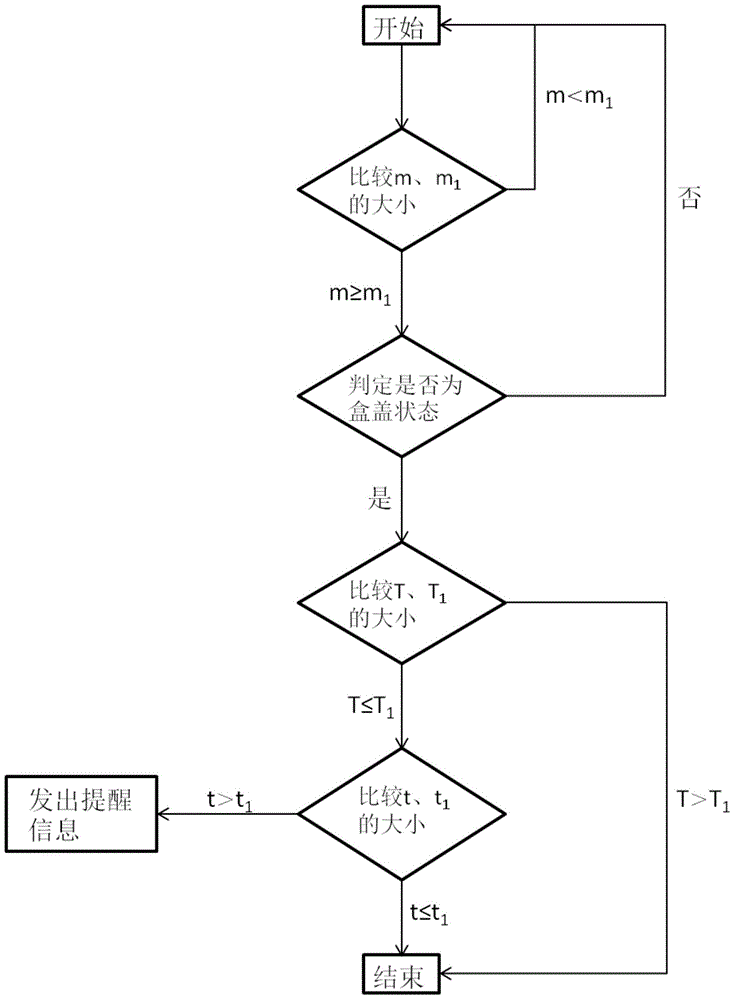

Electric cooker and automatic reminding control method thereof

ActiveCN106308447AIngenious design ideasReliable designProgramme controlComputer controlDesign thinkingCooker

The invention relates to an electric cooker and an automatic reminding control method thereof. The electric cooker comprises a cooker body, a cooker cover and a tank, and further comprises a weighing device, an uncovering state detecting device, a temperature detecting device and an operating panel which are electrically connected to a single chip microcomputer, wherein the single chip microcomputer is additionally electrically connected to a reminding device. The electric cooker, when used, can conduct automatic reminding control firstly and sequentially judge whether food materials are added by a user or not, the covering / uncovering state of the electric cooker, the temperature state of the food materials and a user operating state so as to determine the situation of the food materials cooked in the electric cooker, then the use state of the electric cooker can be determined once again by the user and reminding information can be also transmitted so as to remind the user to start the electric cooker when the use state conforms to requirements. According to the technical scheme, the electric cooker disclosed by the invention is delicate in design thinking and is simple and reliable in design scheme.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

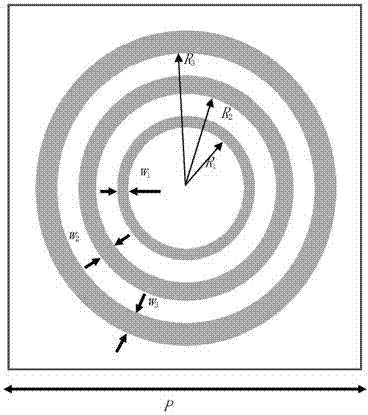

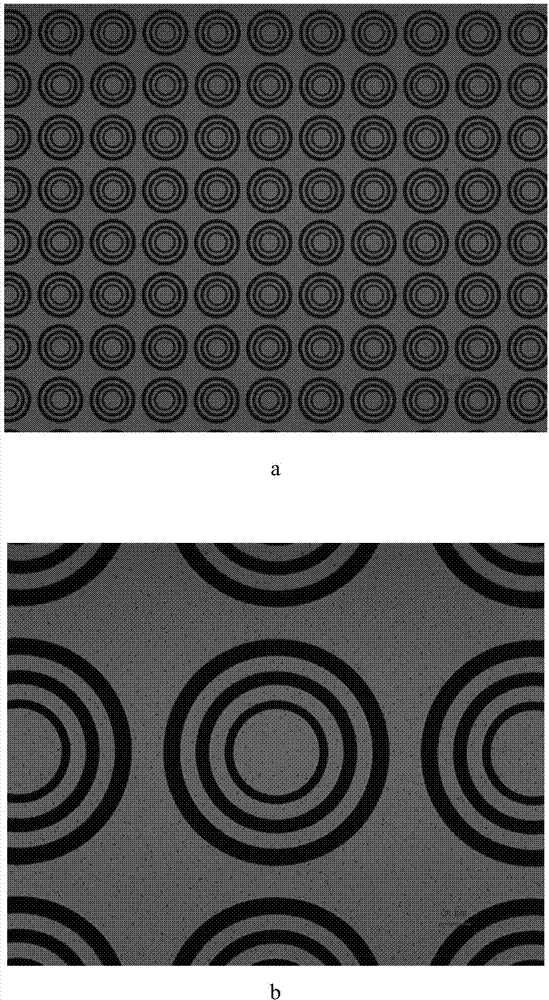

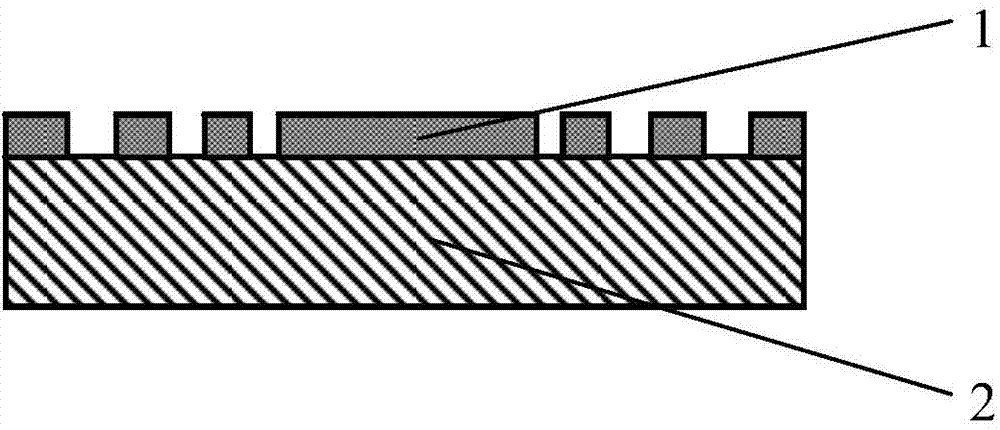

Multiband terahertz filter and manufacture method of multiband terahertz filter

ActiveCN104505561AImprove out-of-band rejection performanceGood polarization insensitivityWaveguide type devicesOut of band rejectionControllability

The invention relates to a multiband terahertz filter. The terahertz filter comprises a substrate and a metal film which are arranged in sequence from bottom to top, wherein a periodic structure is etched on the metal film; the periodic structure consists of n concentric annuli; n is a wave band quantity of the terahertz filter; the widths of the n concentric annuli are gradually increased from circle centre to outside. The invention also discloses a manufacture method of the multiband terahertz filter. As passing bands are increased, the multiband terahertz filter provided by the invention has the advantages of having good out-of-band rejection performance of the middle passing bands, polarization insensitivity and wide acceptance angle, and realizing the controllability of filtering frequency band and wave band quantity of the filter; the manufacture method is simple to operate; the multi-step technologies of the manufacture method all refer to conventional operations in the semiconductor field; the large-scale and integrated production is easy.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Preparation method of nickel sulfide particles/cellulose-based carbon aerogel materials

ActiveCN107369563ALow priceIngenious design ideasLight-sensitive devicesHybrid capacitor electrodesSolventLithium electrode

The present invention discloses a preparation method of nickel sulfide particles / cellulose-based carbon aerogel materials. The nickel sulfide / cellulose-based carbon aerogel takes one or more than one types of celluloses, nickel salt and sulfur sources as raw materials. The preparation process comprises: dissolving the celluloses to cellulose concentrated solution, and preparing cellulose aerogel through the collosol-gel process and the freeze drying technology; preparing and obtaining cellulose-based carbon aerogel through the high-temperature carbonization processing; and performing in-situ growth of nickel sulfide particles on the cellulose-based carbon aerogel through a single-step solvothermal method. The method provided by the invention employs celluloses with wide sources and low cost as a precursor without usage of poisonous and harmful reagent, the prepared nickel sulfide particles / cellulose-based carbon aerogel is uniform in distribution of nickel sulfide particles, high in specific surface area and high in conductivity, and therefore the nickel sulfide particles / cellulose-based carbon aerogel materials are ideal electrode materials of a new energy device such as a supercapacitor, a lithium ion battery and the like.

Owner:FUDAN UNIV +1

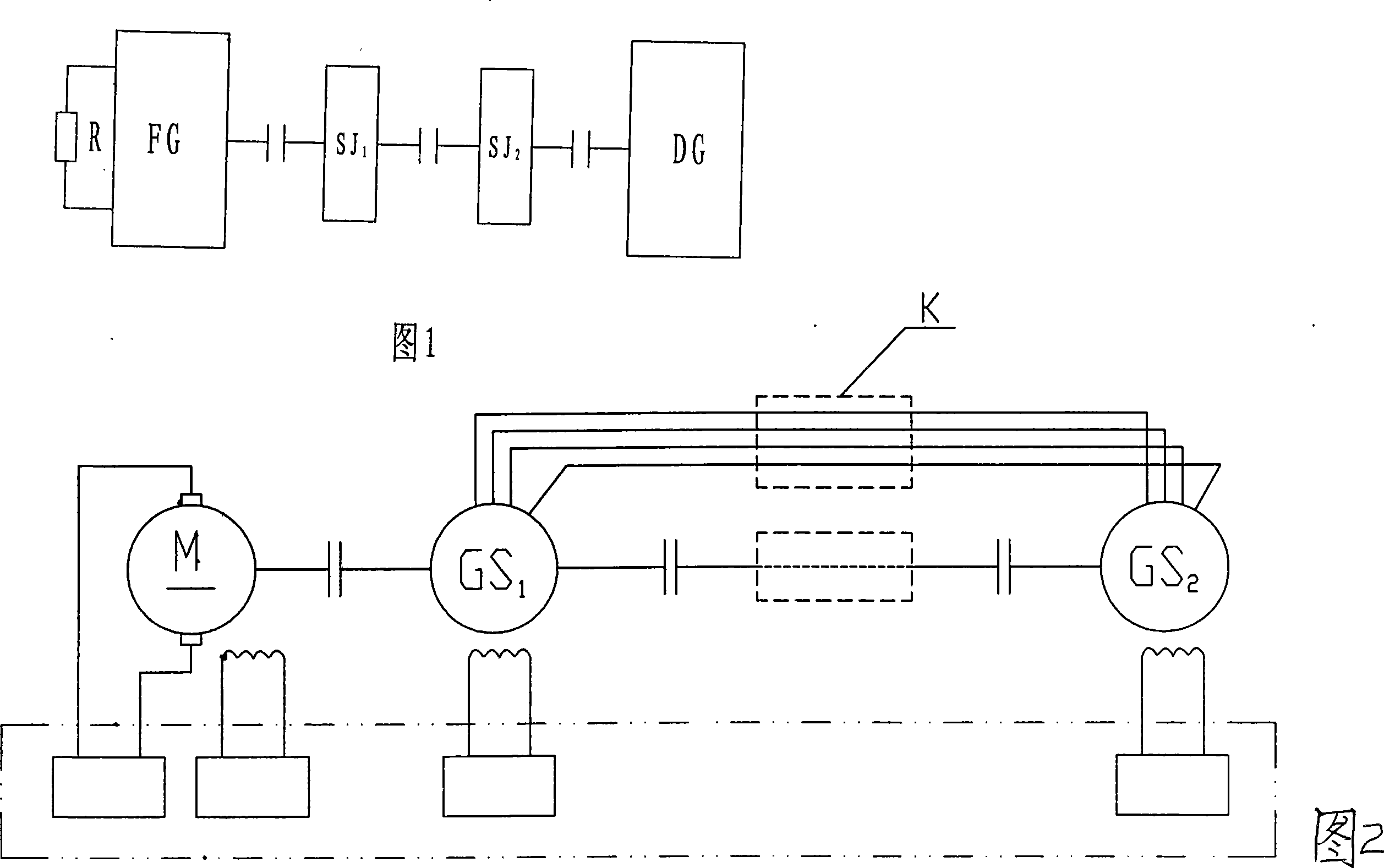

Synchronous generator and method for constructing mutual feedback system of synchronous motor

InactiveCN101114805AInnovative design ideasIngenious design ideasMotor/generator/converter stoppersDynamo-electric converter controlSynchronous motorElectric machine

The invention relates to a motor linkage technology, in particular to a construction method of mutual feedback system of synchronous generators and synchronous motors, which aims to solve the problems that the existing reducer power-load testing system has high cost and wastes energy. The invention has the following steps: two synchronous motors with the same performance parameters are chosen and then a stator of one motor can rotate relative to a rotor; the two synchronous motors are connected coaxially on the condition that the mechanical phases of the rotors are maintained the same; an electric motor is connected coaxially with the two synchronous motors; the armature outputs of the two synchronous motors are connected through the same phase, and then the angle of one synchronous motor stator is artificially rotated, and the rotated synchronous motor is operated in a state of the generator or the electric motor, while the other synchronous motor is operated in a state of the electric motor or the generator. The testing system constructed with the method is low-cost and energy-saving, and is applicable to the performance testing of reducers, synchronous motors, shafts, torque sensors, electric appliances, cables, and switch devices.

Owner:永济电机天作电气股份有限公司

Omnibearing servo magnetic wheel type four-wheel drive vehicle

InactiveCN101088834ASimple structureIngenious design ideasVehiclesMagnetic tension forceFriction torque

The omnibearing servo magnetic wheel type four-driver vehicle is adsorbed magnetically onto the workpiece and may be steered freely in 360 deg. It has four driving motors connected directly to several magnetic wheels for walking, servo magnetic wheel holders connected through servo shaft onto the servo bearing seats, one steering shaft connected through steering bearing to the vehicle board, and one sync wheel and one sync belt for the connection to the steering motor to reach in-situ 360 deg horizontal turning. All the versatile magnetic wheels are fixed through bearings onto the tail boards, and this results in reduced steering friction torque and certain barrier crossing capacity.

Owner:韩宏波

Method for preparing cobaltous oxide manganese nano flower/carbon sponge flexible composite material

ActiveCN109671575AEasy to makeEasy to operateHybrid capacitor electrodesCell electrodesArgon atmosphereManganese

The invention belongs to the field of functionalized porous nano materials, and particularly relates to a method for preparing a cobaltous oxide manganese nano flower / carbon sponge flexible compositematerial. The method comprises the steps of: taking a commercial melamine sponge, then performing washing with distilled water and absolute ethanol, performing drying, and then performing process temperature rise calcining of the melamine sponge under the nitrogen or argon atmosphere to obtain a carbon sponge after cooling; preparing a mixed solution containing a manganese salt and a cobalt salt,immersing the carbon sponge into the mixed solution for the hydrothermal reaction, taking out the carbon sponge after the reaction is finished, washing the carbon sponge with distilled water and performing drying to obtain a manganese-cobalt hydroxide precursor-carbon sponge composite material; and further, performing annealing reaction in the argon atmosphere to obtain a cobaltous oxide manganesenano flower / carbon sponge flexible composite material. The flexible, porous and self-support carbon sponge is taken as a growth template to successfully solve the problem that the nano material is easily gathered, and the obtained composite material has a lot of exposure active sites, abundant pores and good electrical conductivity.

Owner:JIANGSU UNIV

Boron-nitrogen co-doped carbon/manganese oxide composite nanosheet material, preparation method and application

ActiveCN110648854AIncrease contact areaMany active sitesMaterial nanotechnologyHybrid capacitor electrodesCapacitancePtru catalyst

The invention discloses a boron-nitrogen co-doped carbon / manganese oxide composite nanosheet material, a preparation method, and an application of the composite nanosheet material in capacitive deionization or in an electrode material of an electrochemical energy storage device. The preparation method comprises the following steps: adding boric acid into chitosan hydrogel, uniformly mixing the boric acid and the chitosan hydrogel, freeze-drying the mixture, and carbonizing the mixture to obtain boron-nitrogen co-doped carbon nanosheets; and putting the boron-nitrogen co-doped carbon nanosheetsin a potassium permanganate solution for reaction to obtain the boron-nitrogen co-doped carbon / manganese oxide composite nanosheet material. The boron-nitrogen co-doped carbon / manganese oxide composite nanosheet material is of a mutually connected three-dimensional sheet structure. The preparation method provided by the invention is simple and feasible, the reaction conditions are mild, and the carbon nanosheets are of a three-dimensional mutual connection structure. The prepared carbon / manganese oxide composite nanosheet material is rich in nitrogen and boron and is of a mesoporous-dominatedporous structure. The composite nanosheet material shows a good prospect in the fields of preparation of capacitive deionization and super capacitor electrodes and catalyst carriers.

Owner:DONGHUA UNIV

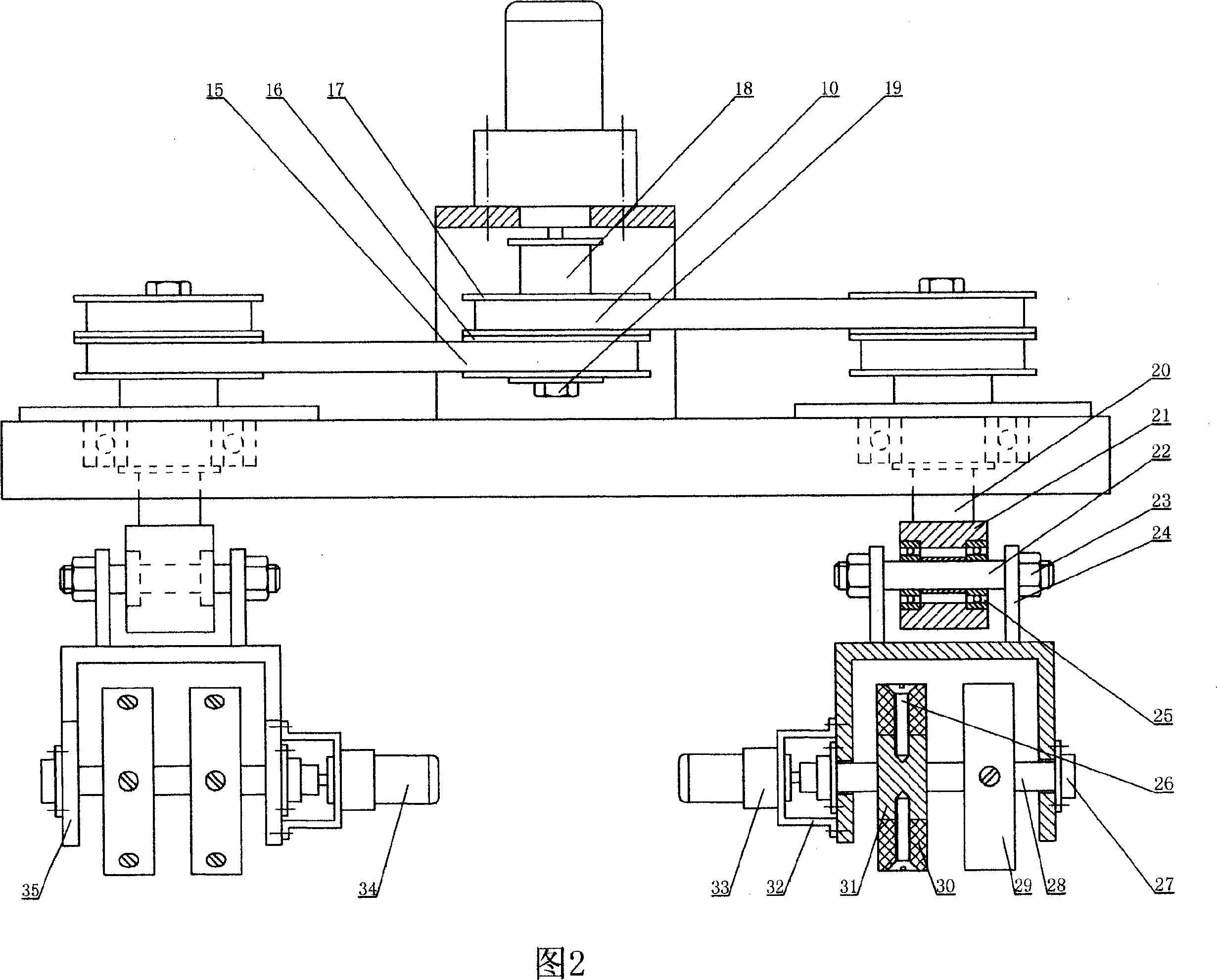

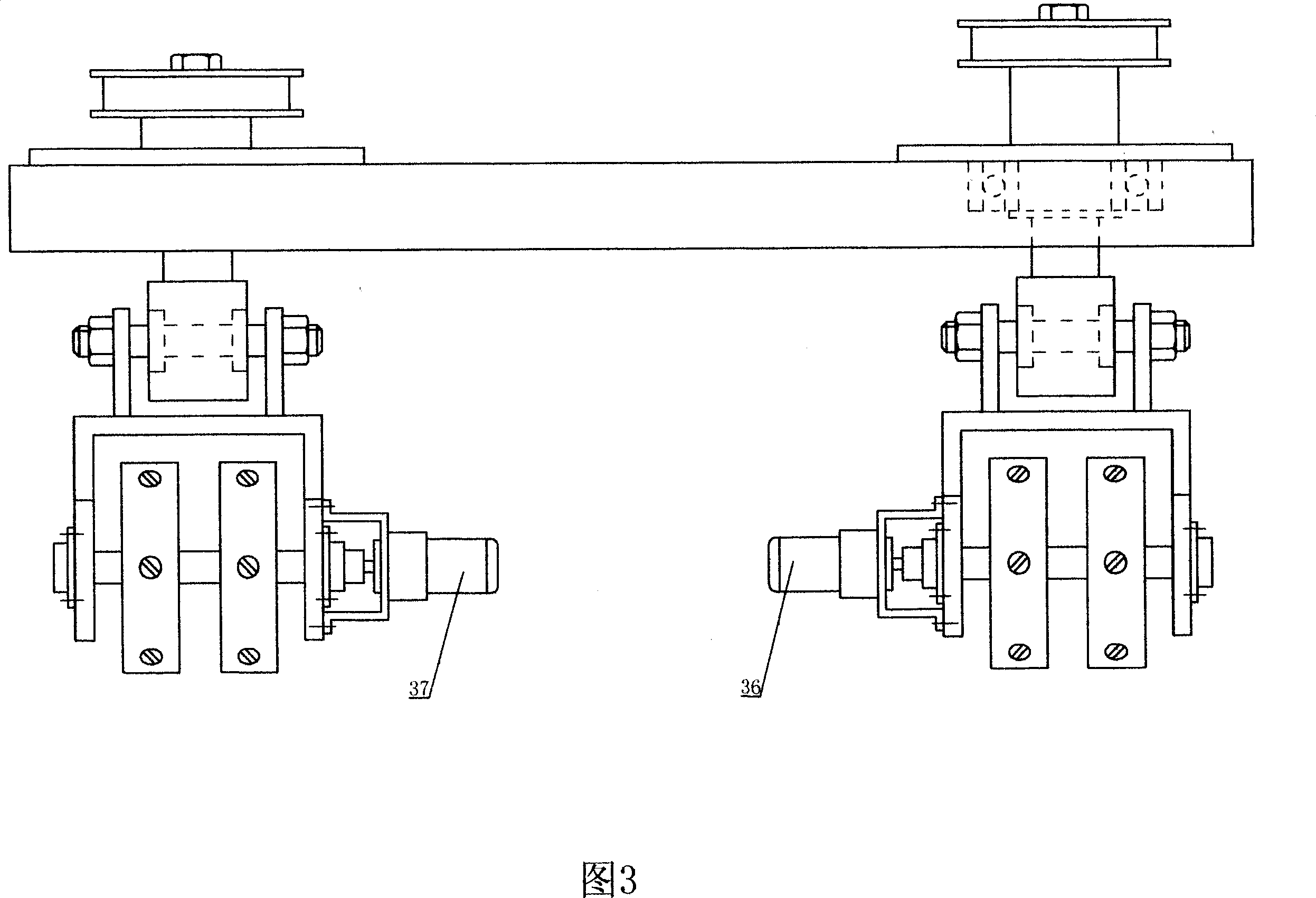

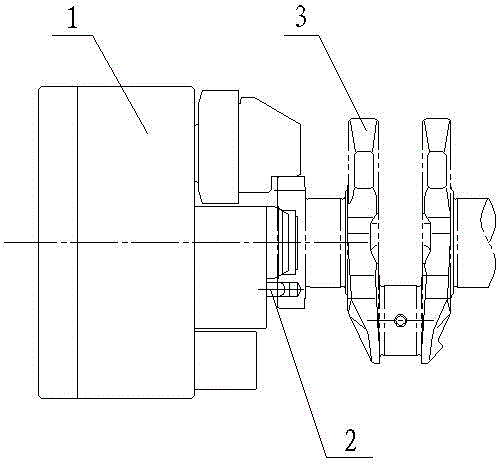

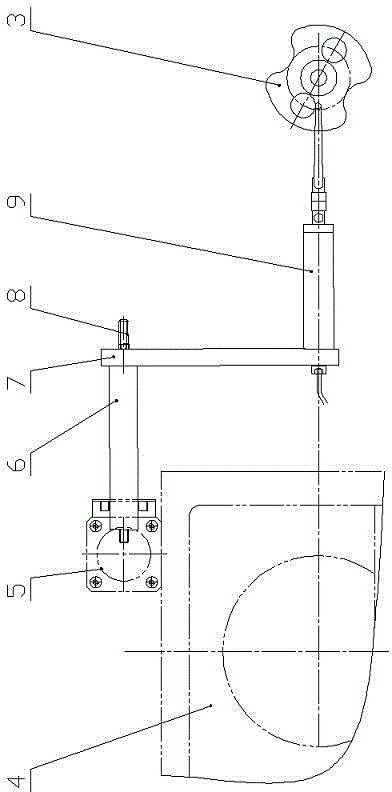

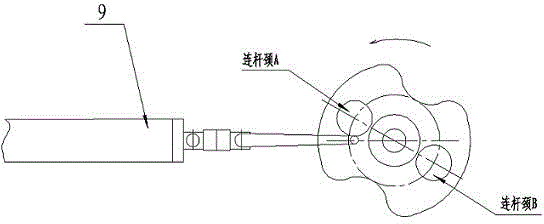

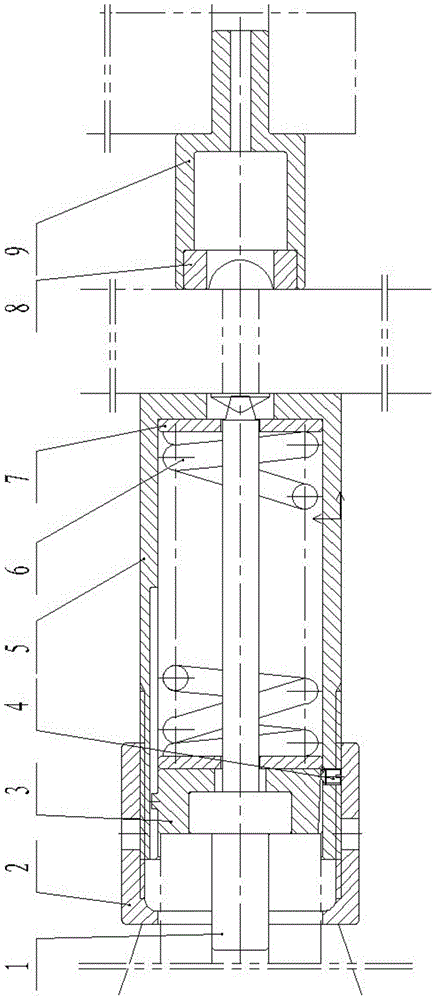

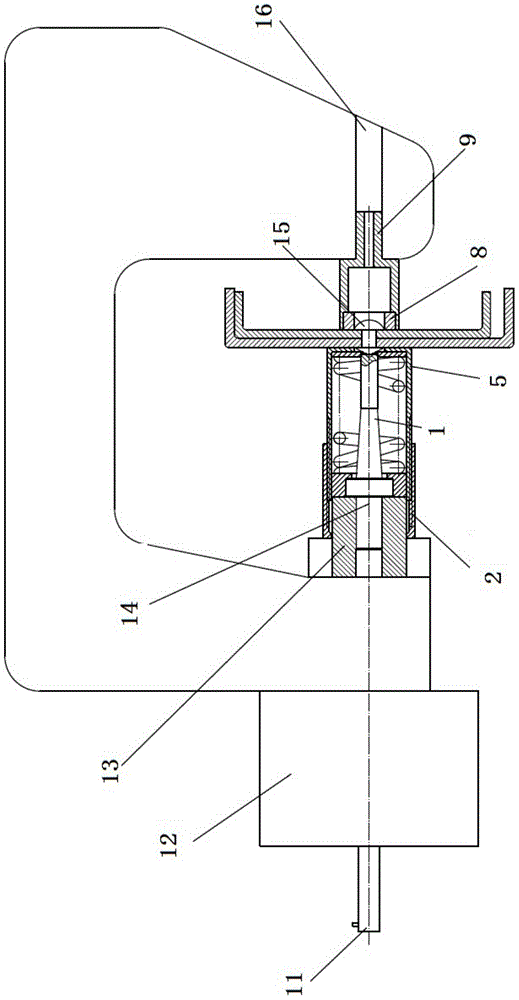

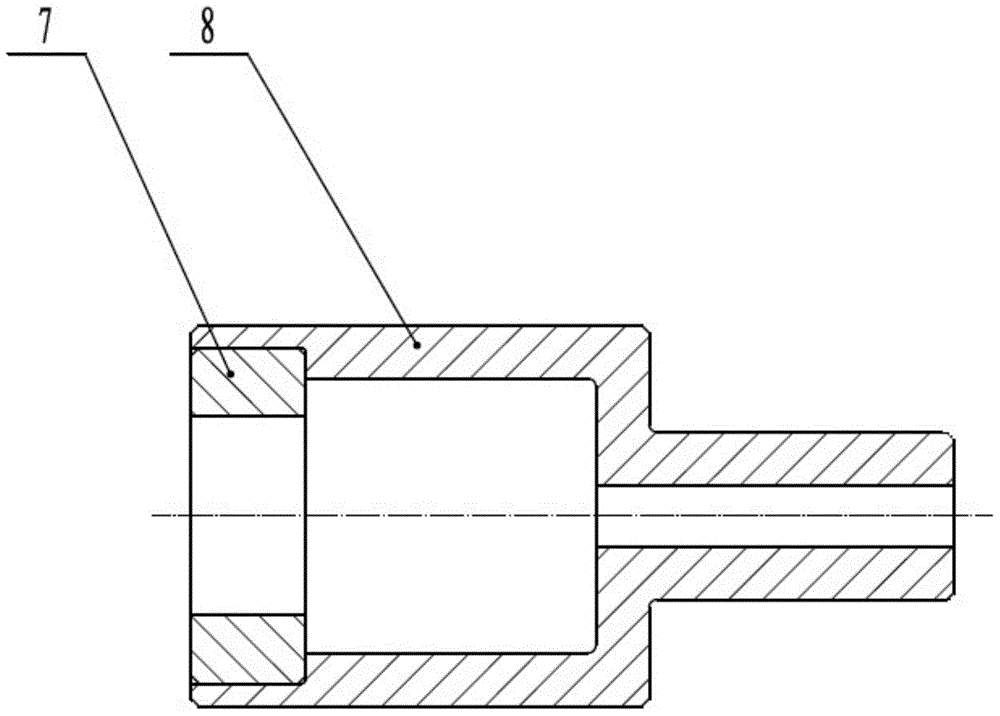

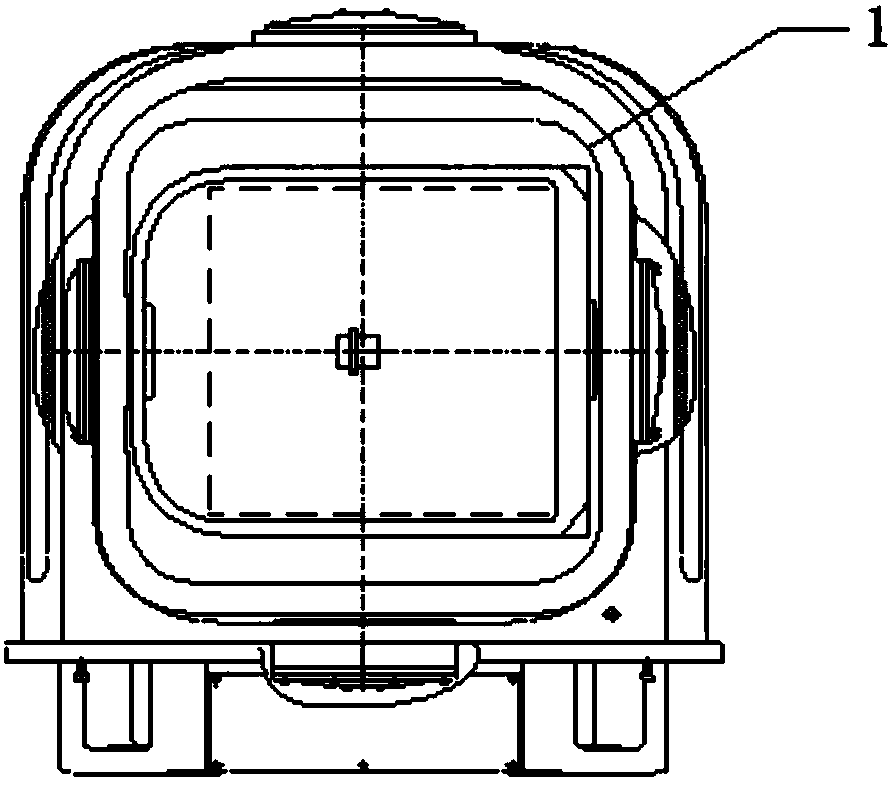

Automatic online phase measuring device for crankshaft connecting rod neck

The invention discloses an automatic online phase measuring device and method for a crankshaft connecting rod neck. The device comprises a touch sensor, a driving device of the touch sensor, a main rotating shaft, a driving device of the main rotating shaft, and a rotating angle sensor; a measuring head center line of the touch sensor and an axis of the main rotating shaft are in the same plane, and the vertical position is used as the measuring position of the touch sensor. The method comprises the steps of driving the main rotating shaft at the measuring position to drive a crankshaft to rotate in two directions from the initial position to the position in contact with a measuring head to obtain angle coordinates A1 and A2 of the main rotating shaft at two positions; calculating (A1+A2-360) / 2 to obtain the angle coordinate of the main rotating shaft when the connecting rod neck rotates to reach the horizontal position. The device is accurate to position and high in efficiency; the problem of automatic fixing the phase in the automatic processing of the crankshaft connecting rod neck can be solved well; the requirements on softness and high efficiency under automatic processing can be met.

Owner:BEIJING NO 2 MACHINE TOOL WORKS

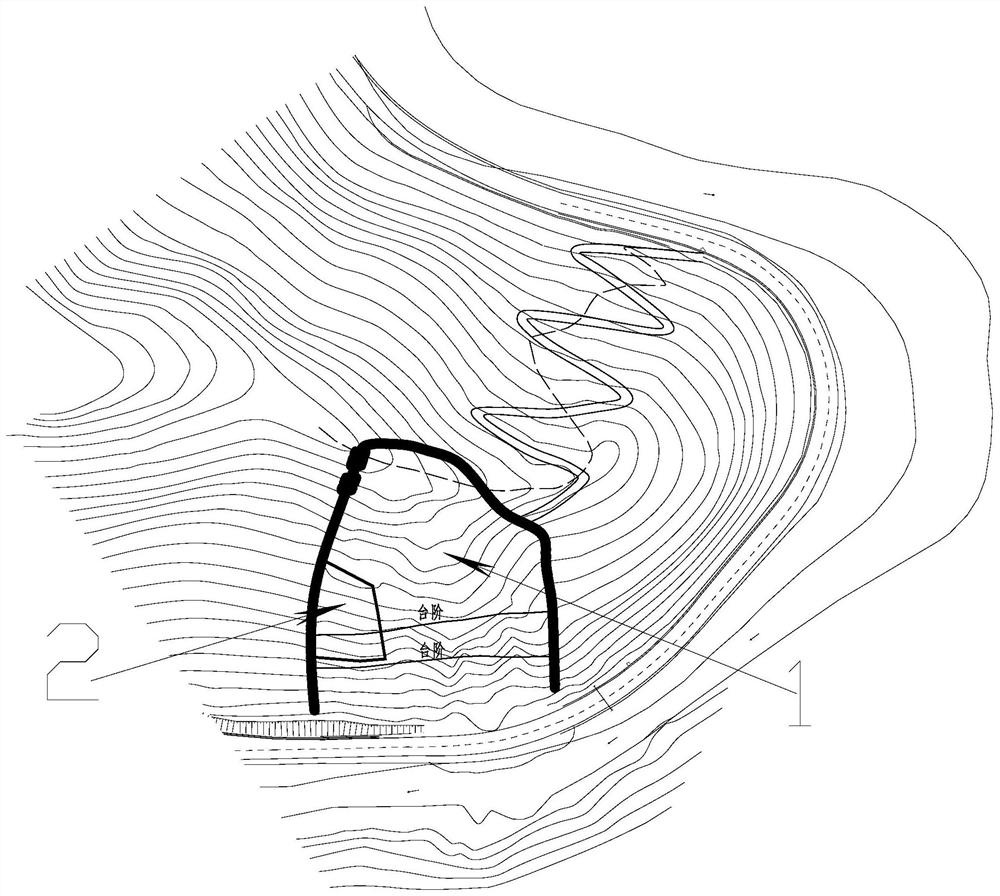

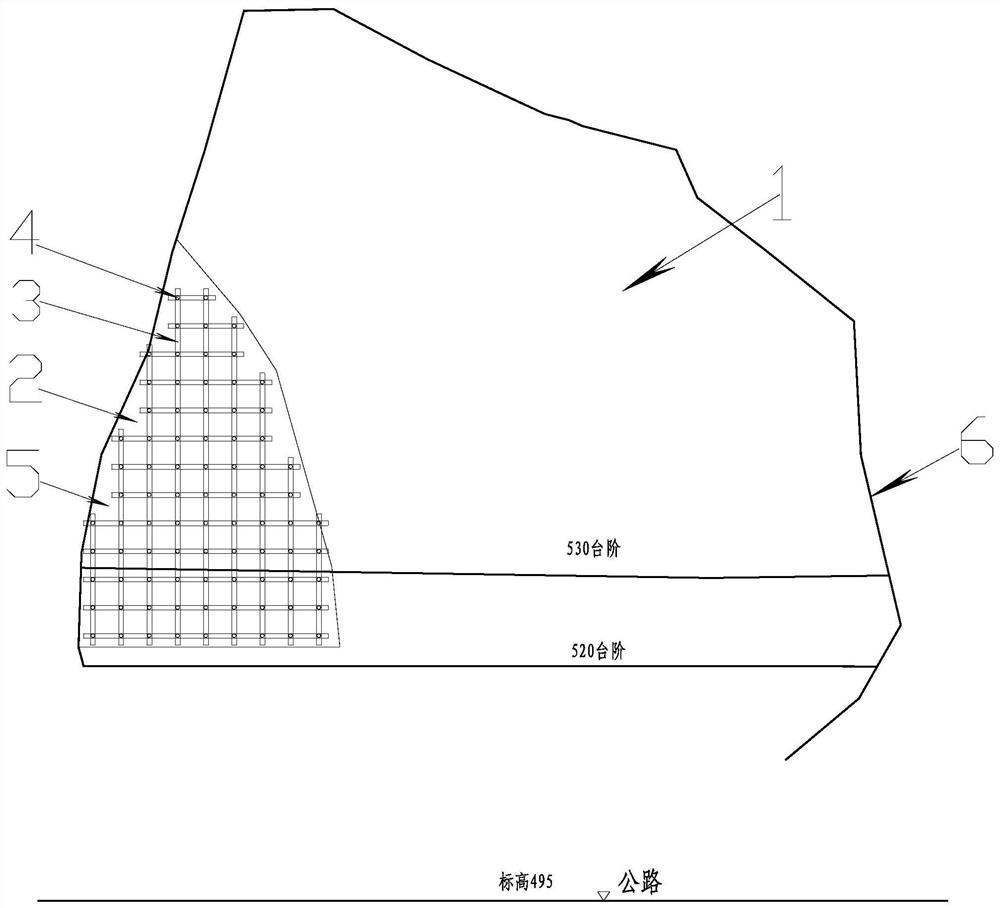

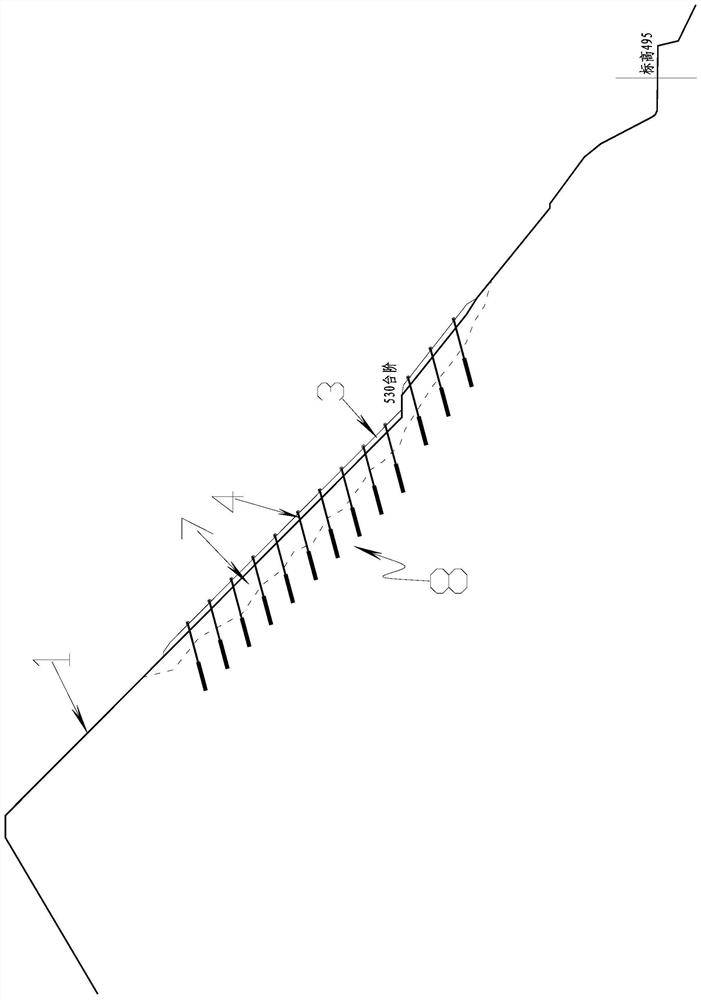

Construction process of mold-free concrete spraying beam

PendingCN112095633APromote rapid formationIngenious design ideasFoundation testingExcavationsShotcretePre stress

The invention relates to the field of civil engineering construction, and provides a construction process of a mold-free concrete spraying beam. The construction process is used for reinforcing engineering of anchor rod lattice beams in slope protection engineering, foundation pit engineering and the like. The construction process of the mold-free concrete spraying beam comprises the following steps that A, slope treatment is carried out, specifically, a mountain body is excavated in a graded mode according to the designed slope rate, the height of each grade is 8-10m, and the slope surface isleveled or sprayed concrete is adopted for initial protection; B, anchor rod installation (including prestressed anchor rods and non-prestressed full-length bonding anchor rods) is carried out; C, full-length steel bars are arranged along the slope surface in a # shape, a square steel bar cage is formed through binding of stirrups, the sprayed concrete is sprayed back and forth for a plurality oftimes along the steel bar cage in a wet spraying mode to form the lattice beams, and the anchor rods are located at the cross joints of the lattice beams; and D, after the strength of the concrete meets the requirement, the prestressed anchor rods are tensioned and locked, the step A to the step C are repeated to enter the next grade of slope prestressed anchor rod lattice beam construction, andthe construction process is worthy of application and popularization.

Owner:浙江佳途勘测设计有限公司

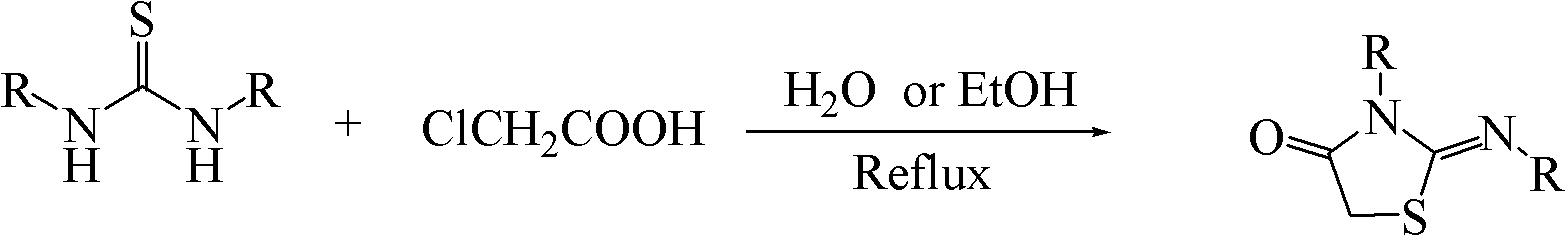

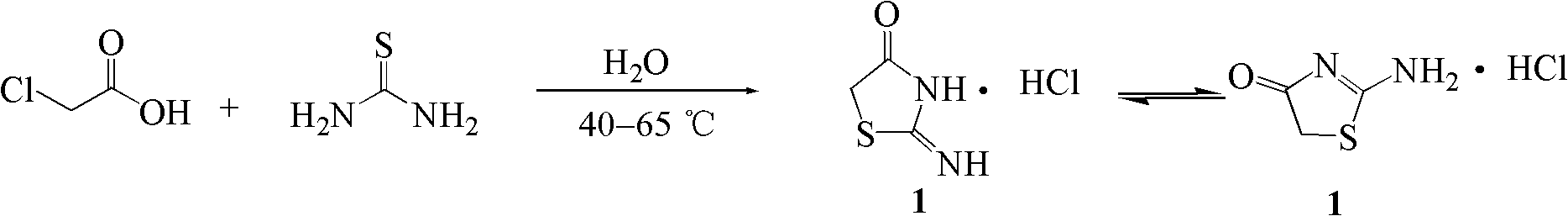

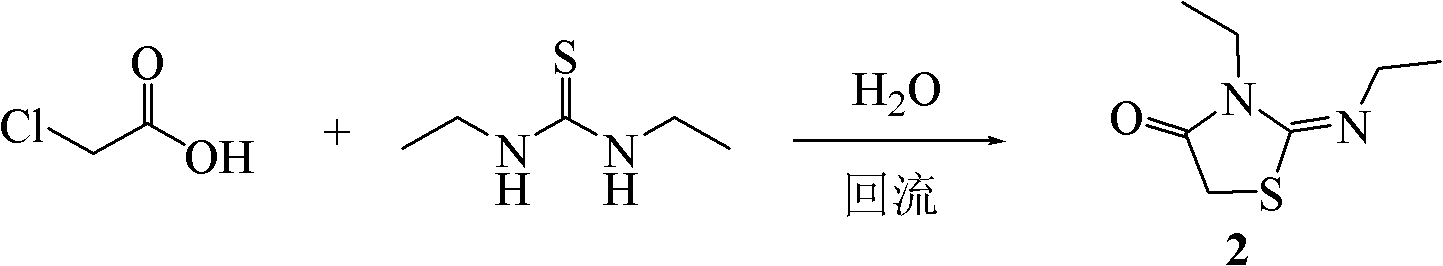

A kind of synthetic method of 2-iminothiazolidin-4-ketone and its derivatives

InactiveCN102276548AAvoid the tedious process of post-processingFacilitate the cyclization reactionOrganic chemistryThioureaKetone

The invention discloses a method for synthesizing 2-iminothiazolidine-4-one and derivatives thereof. The method comprises the following steps of: reacting water or ethanol serving as a solvent and 1 molar part of thiourea or N,N'-disubstituted thiourea and 1 to 1.5 molar parts of chloroacetic acid which are taken as reaction raw materials at the temperature of between 40 and 100 DEG C for 1 to 10hours; and thus obtaining the 2-iminothiazolidine-4-one or the derivatives thereof after reaction. In the method, the water or the ethanol is taken as the solvent, and the chloroacetic acid is a reaction substrate and also a reaction catalyst; and the acidity of the chloroacetic acid is smartly utilized to self-catalyze the reaction, thiazole heterocycles can be formed through cyclization at higher reaction yield (32.5 to 86.4 percent) under the condition that additional catalysts are not used, and the process that a fussy esterification or amidation reaction is used for derivatization of thechloroacetic acid and the aftertreatment process of waste acid obtained after reaction are avoided. The method for synthesizing the 2-iminothiazolidine-4-one and the derivatives thereof is an environment-friendly synthetic process, is easy to operate, and is particularly suitable for industrialized clean production, and design thought is ingenious.

Owner:XI AN JIAOTONG UNIV

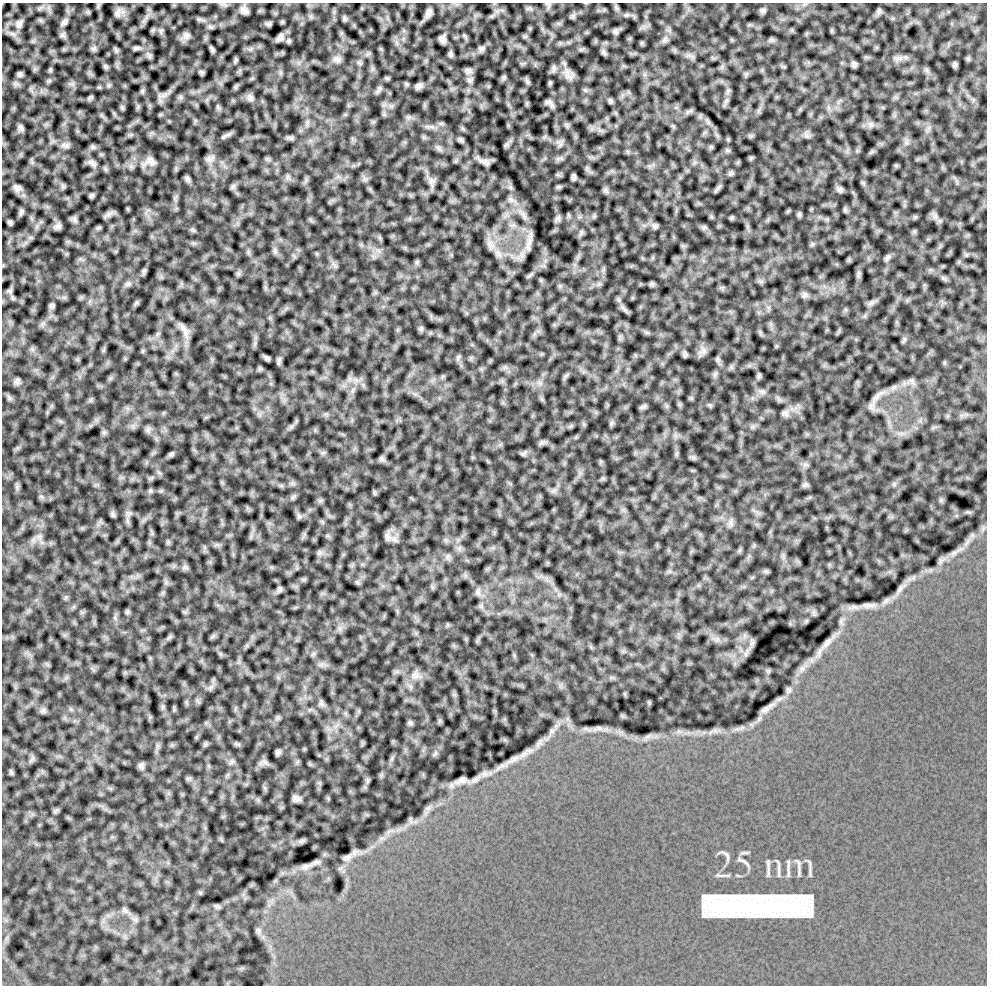

Polyimide-based composite aerogel, controllable preparation method thereof and application of aerogel

The invention discloses polyimide-based composite aerogel, a controllable preparation method thereof and an application of the aerogel. The polyimide-based composite aerogel provided in the invention comprises carbon nano tubes and polyimide, the atomic ratio of oxygen-containing groups to nitrogen-containing groups at the surfaces of the carbon nano tubes is (1:0.1)-(1:0.19). Raw material components comprise one or more water-soluble polyimide precursors polyamic acids, and one or more carbon nano tubes. The preparation method comprises the following steps: performing amination on carbon nano tubes subjected to acidification to prepare acidified and aminated carbon nano tubes, performing reaction on the acidified and aminated carbon nano tubes and the water-soluble polyamic acid to obtain acidified and aminated carbon nano tube polyamic acid hydrogel, and performing thermal imidization to prepare the acidified and aminated carbon nano tube polyimide-based composite aerogel. The method for preparing the polyimide-based composite aerogel is simple and easy to implement, the prepared composite aerogel is controllable in micro morphology and adjustable in performance, and is an ideal heat-insulation material and a flame-retardant material.

Owner:FUDAN UNIV +1

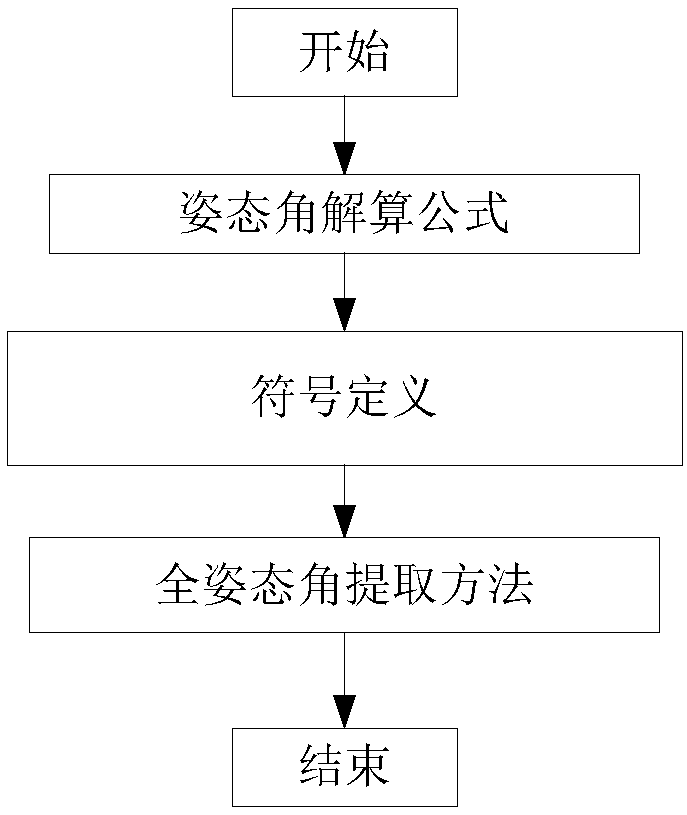

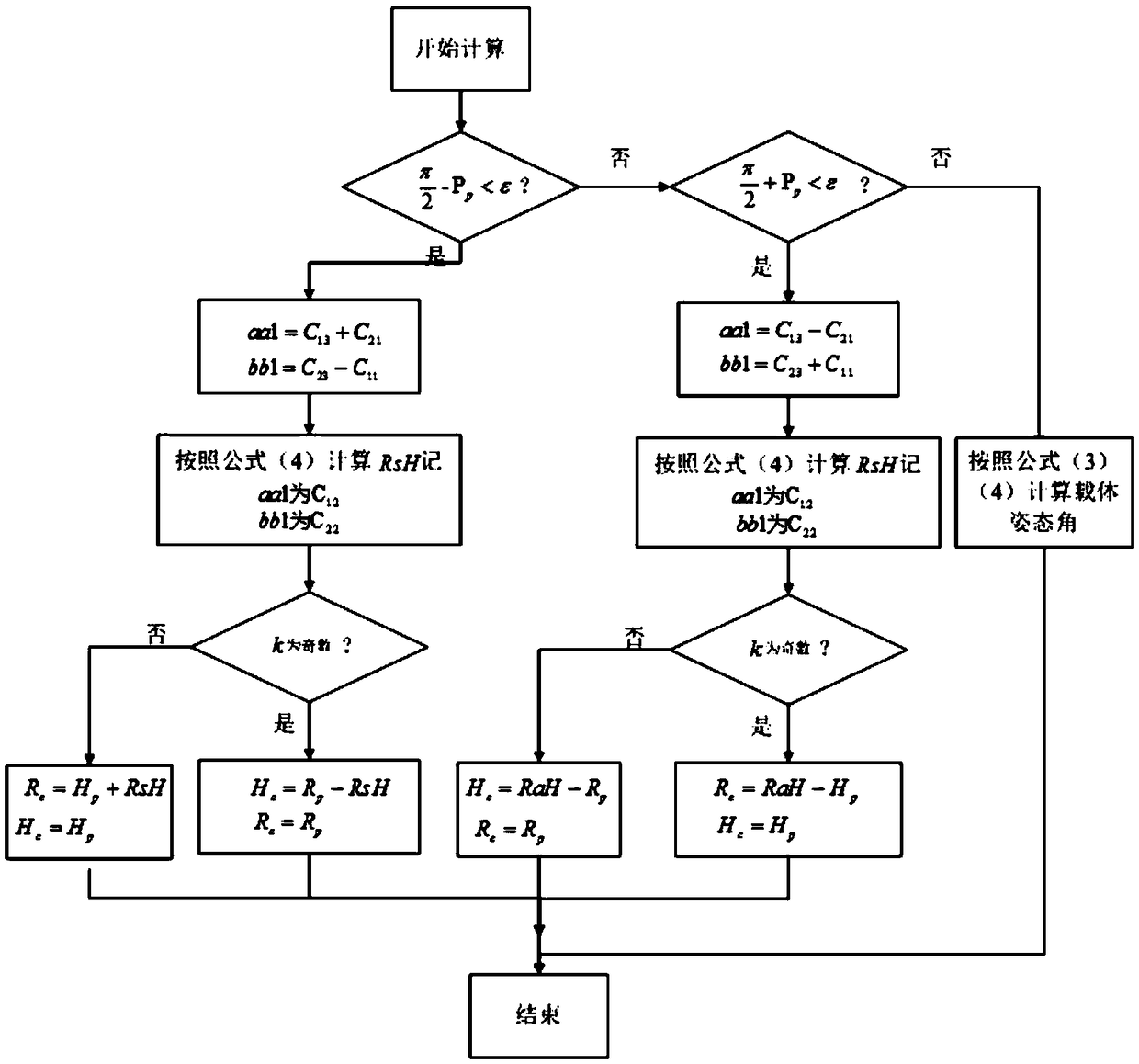

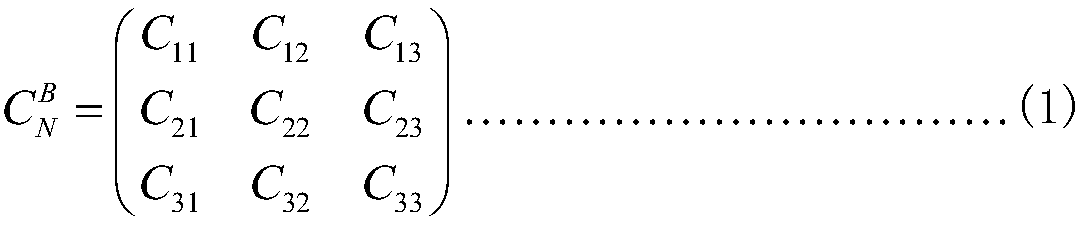

Method for extracting full-range attitude angles of inertial navigation system

ActiveCN109115212AImplement extractionEasy to useNavigation by speed/acceleration measurementsRolling angleInertial navigation system

The invention relates to a method for extracting full-range attitude angles of an inertial navigation system. The method for respectively blocking roll angles and course angles is adopted for realizing the extraction for roll angles and course angles with pitching angles approximate to + / - 90 degrees. The design though of the product of the invention is smart and novel, the practical engineering application problem of extracting full-range attitude angles of the inertial navigation system can be effectively solved, the application of the inertial navigation system in full-attitude scope can beguaranteed and the method has a promotional value.

Owner:TIANJIN NAVIGATION INSTR RES INST

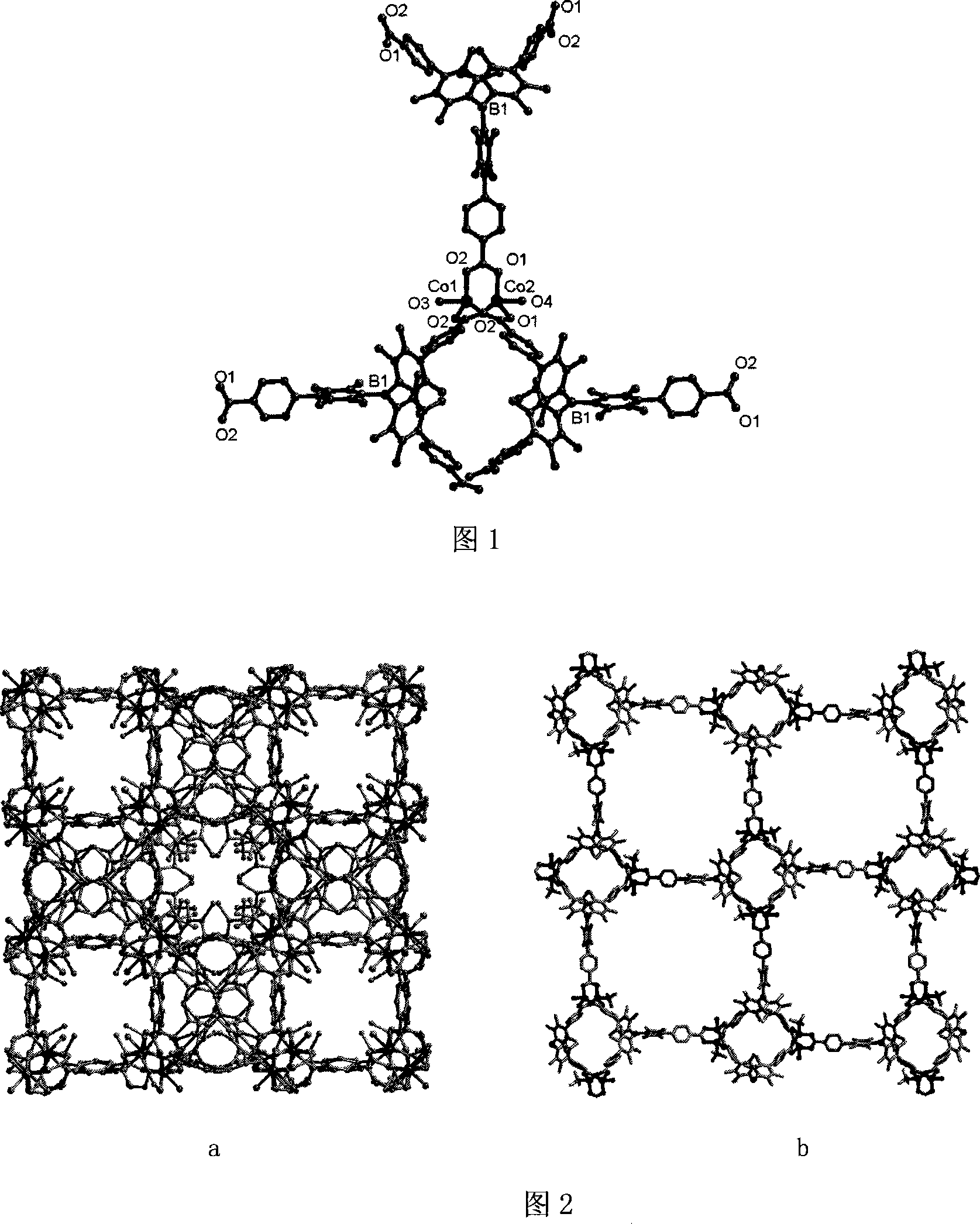

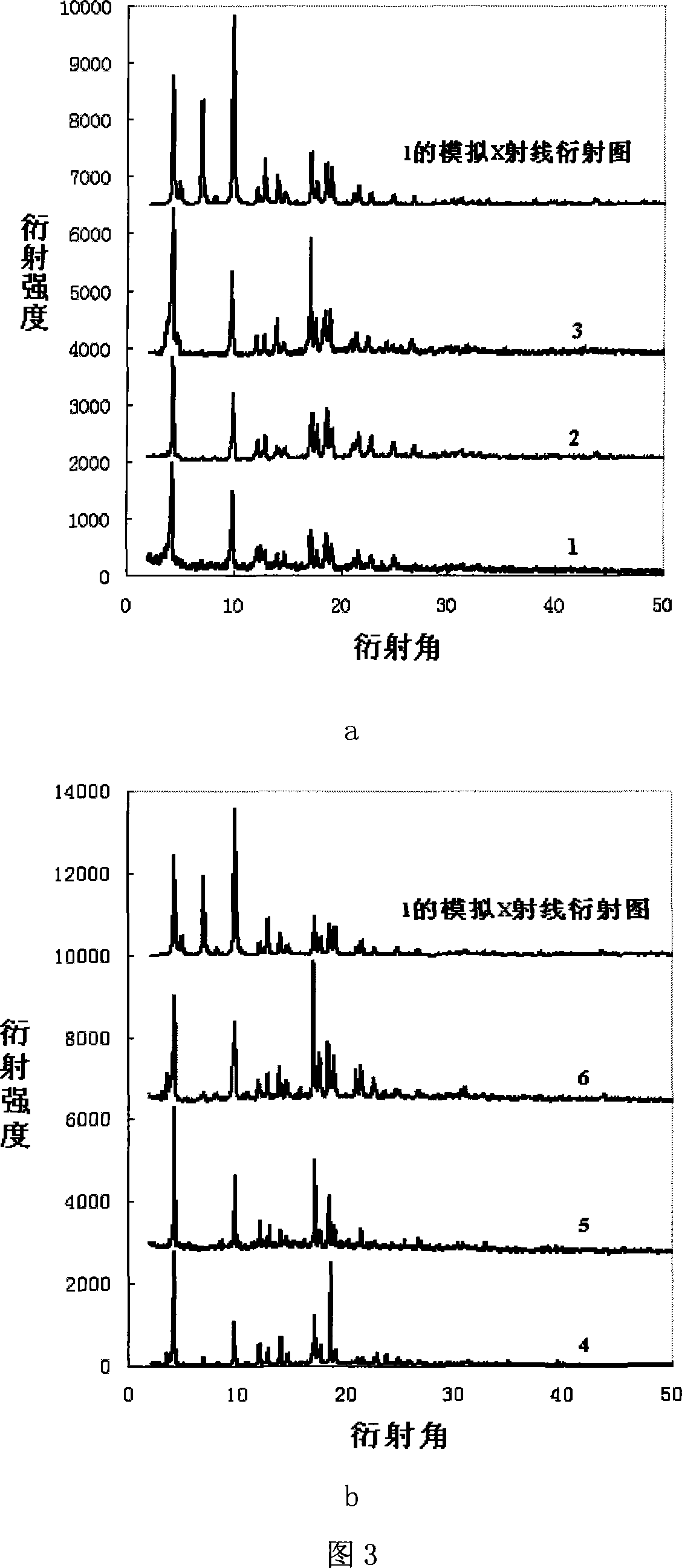

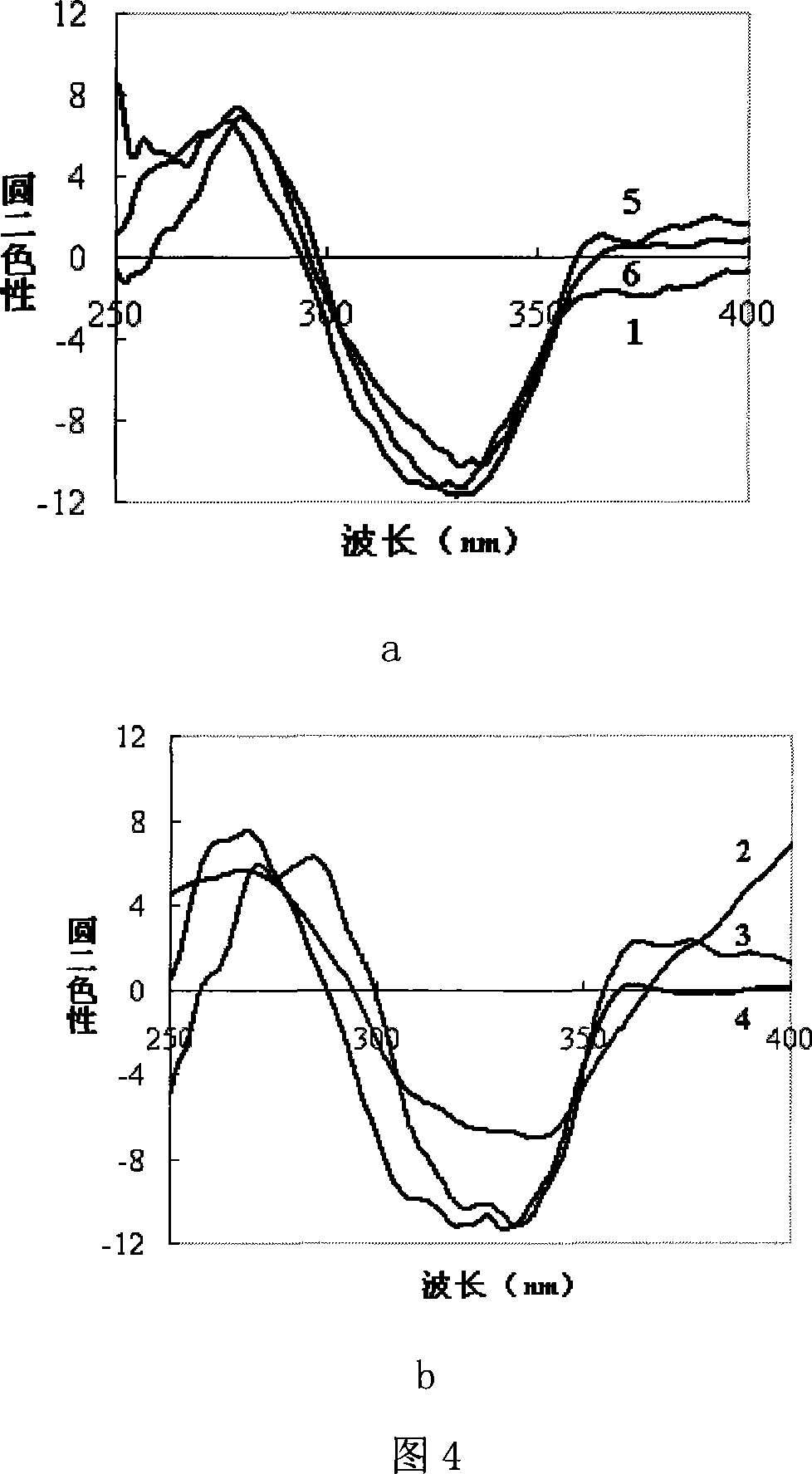

Method for preparing chirality non-linear optical metal-organic boron polymer crystal material

InactiveCN101230077AGood second-order nonlinear optical propertiesIngenious design ideasCopper organic compoundsCobalt organic compoundsBenzoic acidManganese

The invention relates to a preparation method for nonlinear optical metal-organic boron polymer crystal material provided with equal chirality. The method adopts the steps that firstly, ligand H3L, namely tri-(4-para benzoic acid-2, 3, 5, 6-tetramethylbenzene) borane is synthesized, and then nonlinear optical metal-organic boron polymer crystal material with equal chirality is prepared, namely, ligand H3L and metal salt are mixed according to 1: 2, and dissolved by using N, N-dimethyl acetamide and methyl alcohol, the reaction liquid is positioned into a sample bottle for reaction, after the reaction is finished, the sample bottle is cooled to room temperature, the generated metal-organic polymeric material is taken out, and washed with ether for multiple times and air dried to obtain the material. The structural general formula is <M2L (OH) (MeOH)>.3H2O, wherein, metal M represents cobalt, manganese, nickel, copper, zinc or cadmium. The material produced through the invention has very good second order nonlinear optical property, and compared with KDP, and the generation effect of second harmonics is 1.5 times higher.

Owner:SHANGHAI JIAO TONG UNIV

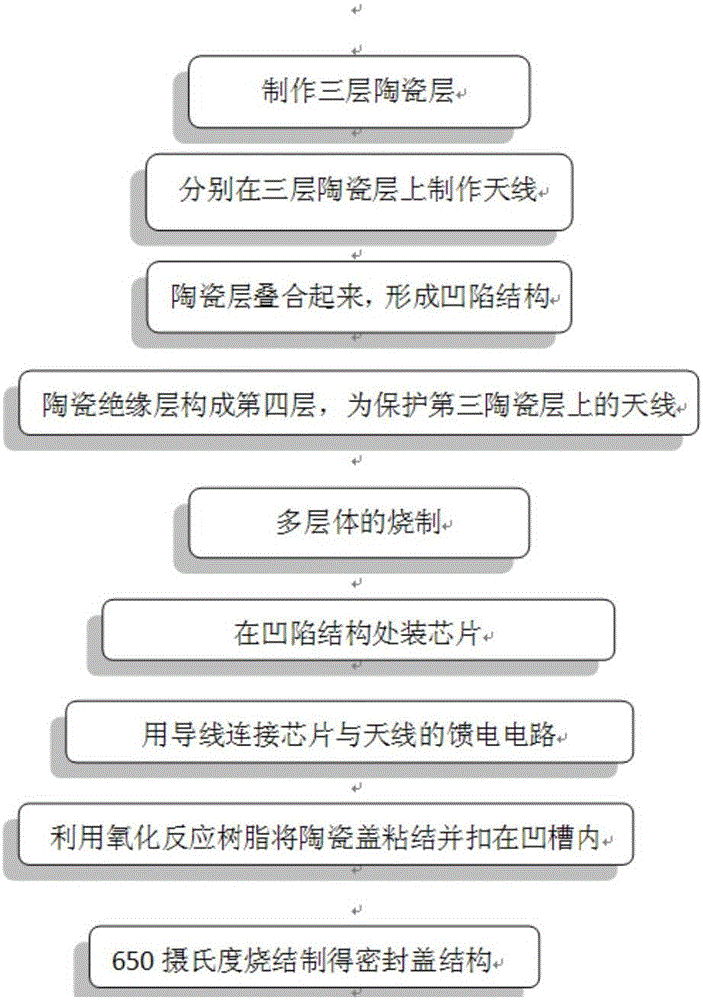

Novel electronic tag production process

The invention discloses a novel electronic tag production process, which comprises the following steps of step 1.sintering and curing a printed antenna and a substrate to form an antenna substrate through the existing conventional process; step 2.placing an IC chip into a groove structure of the antenna substrate and adopting the existing conventional technical method to bind the IC chip on a feeding point of the antenna in the groove without epoxy resin dripping protection; step 3.providing a ceramic cover; step 4.bucklling the cover in the step 3 on the groove structure of the substrate and pre-coating oxidizing reaction glue on a contact place, wherein the IC chip is arranged in the cover, and two sides of the cover are ends of the antenna, which are used for adjusting a tag frequency band; and step 5.sintering at high temperature (the field is usually within the range of 600-700 DEG C), and reacting and sintering the oxidizing reaction to make the ceramic cover and the ceramic substrate form a whole body on the groove structure and form a closed space. A product obtained by the process of the invention is suitable for various high and low temperature application environments.

Owner:SHANGHAI BIZGRID INFORMATION TECH

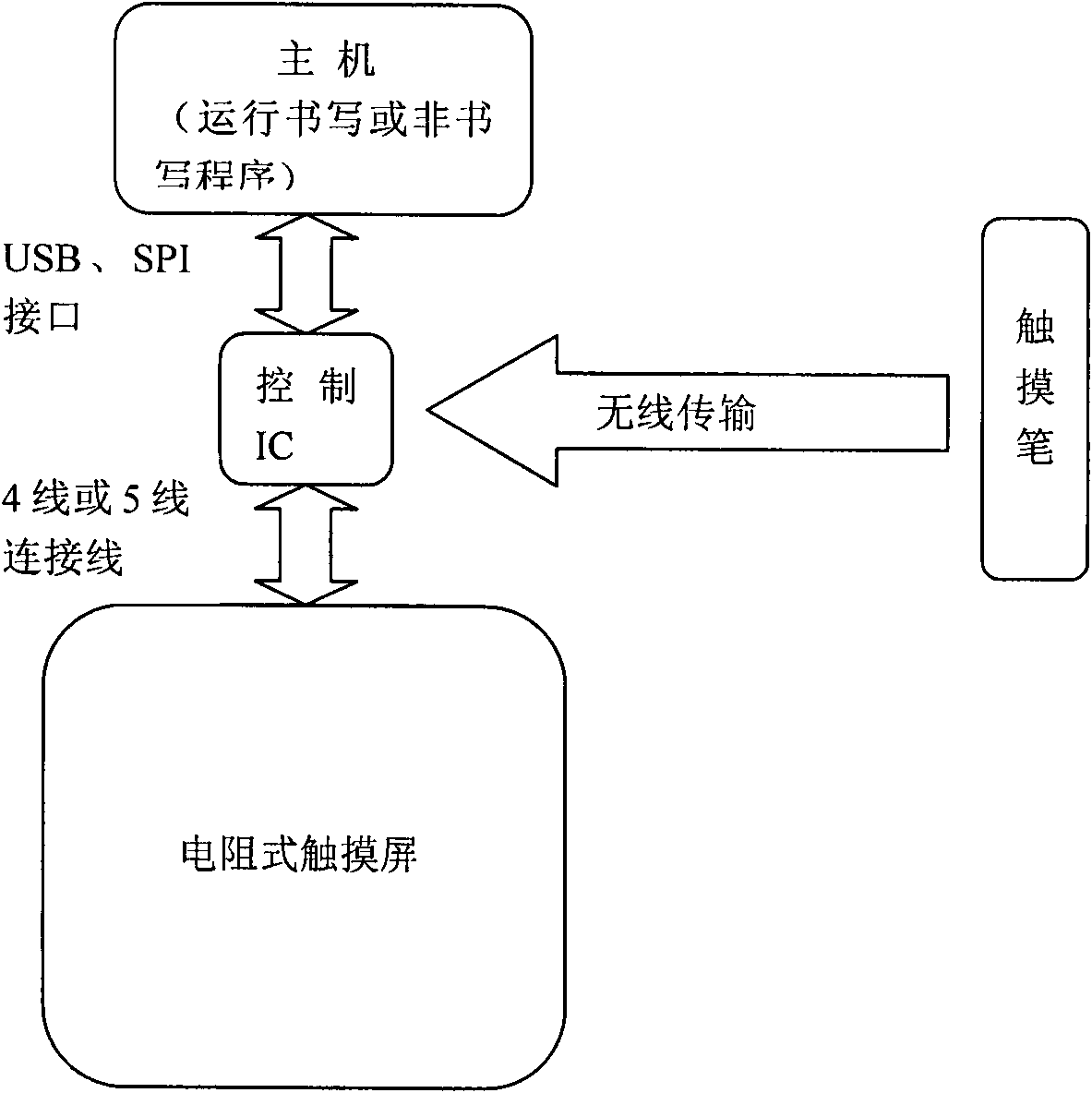

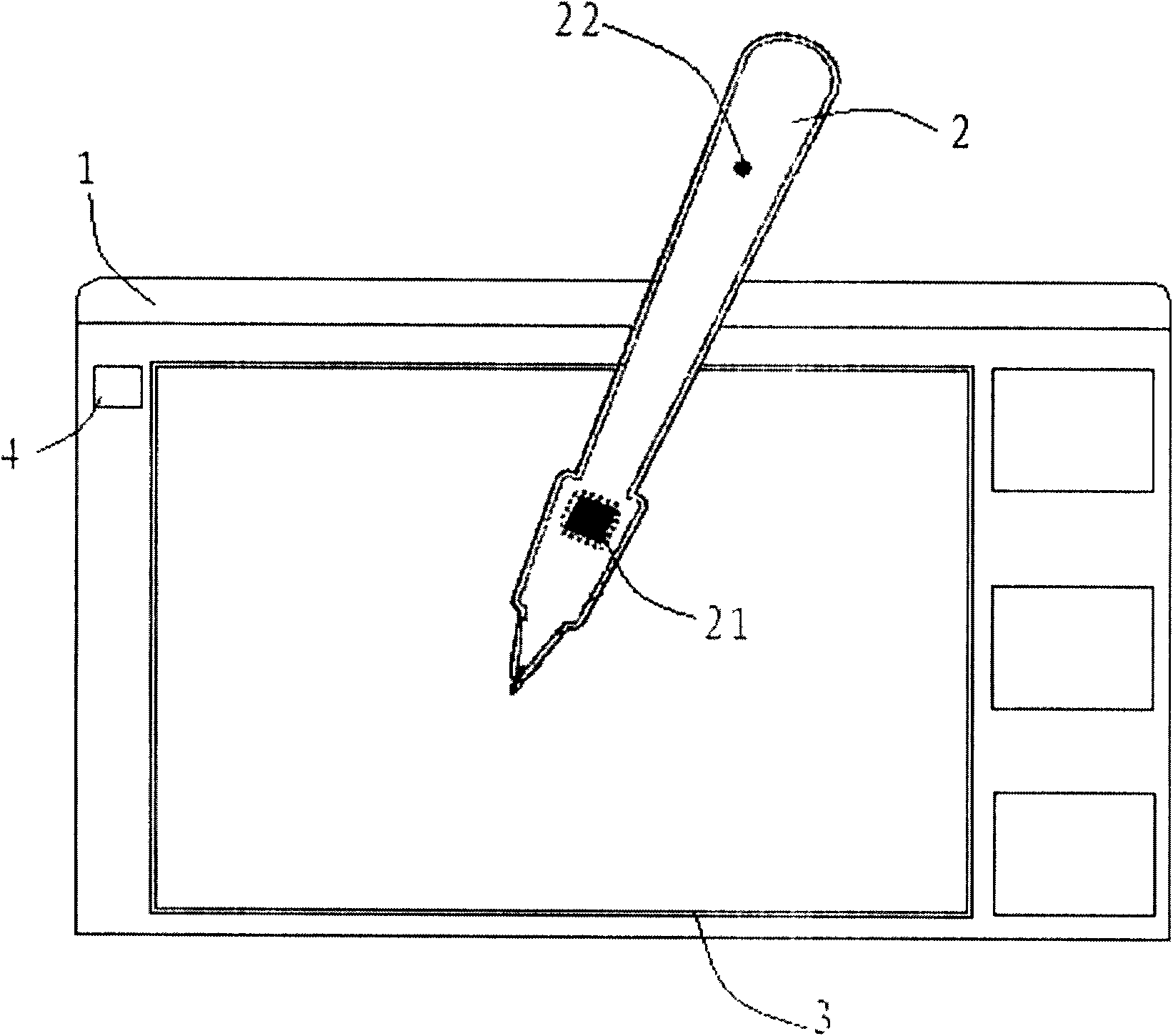

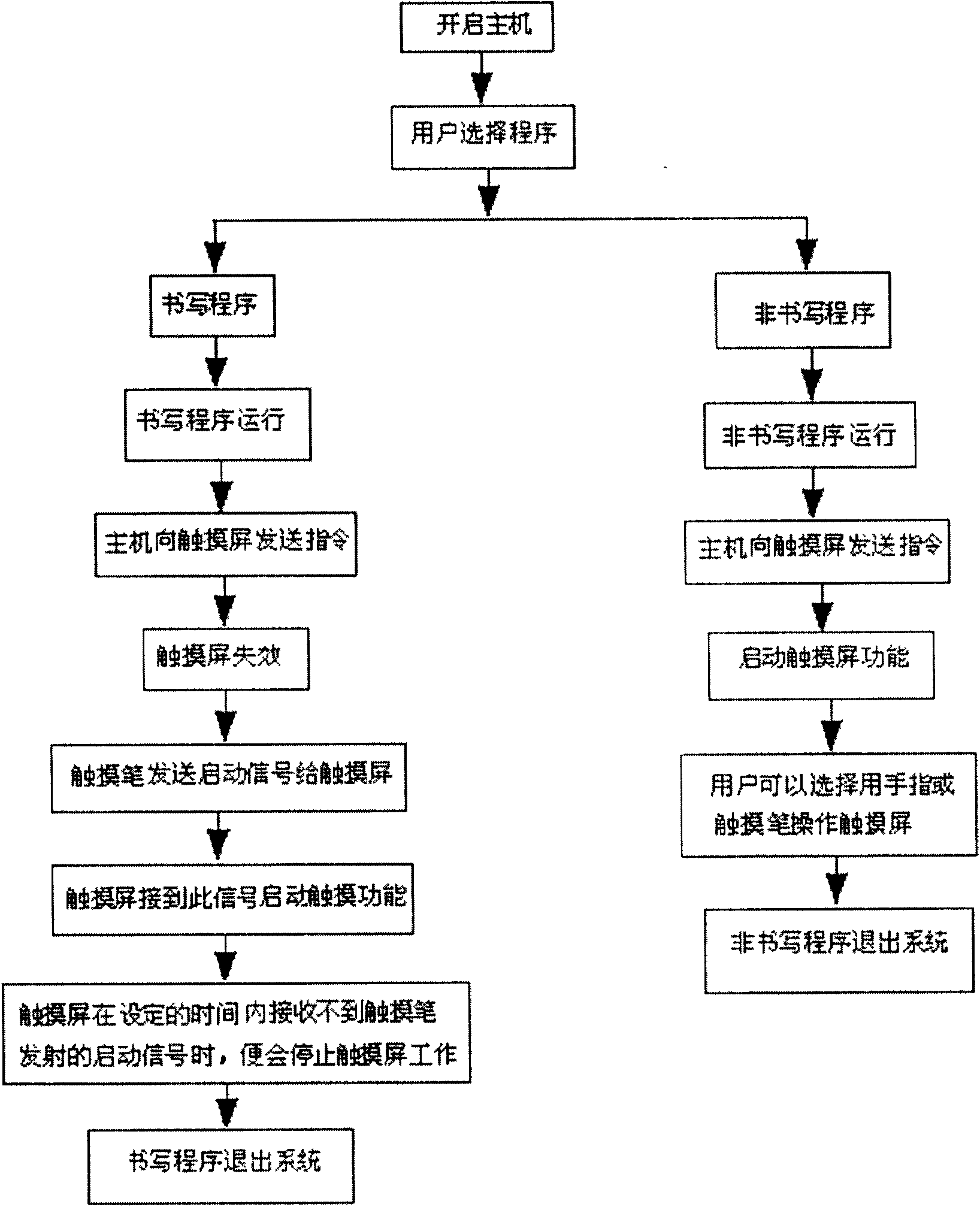

Touch terminal and touch control method thereof

InactiveCN102157090AStrengthen hand-holding pen writing abilitySimple structureElectrical appliancesInput/output processes for data processingComputer terminalTouchscreen

The invention discloses a touch terminal and a touch control method thereof. The touch terminal comprises a host machine, a touch screen linked with the host machine, and a touch pen matched with the touch screen in use; wherein the host machine is provided with a writing program and a non-writing program; the touch screen further comprises a special control integrated circuit chip; the special control integrated circuit chip is used for controlling the start and the stop of the touch screen, can receive a wireless signal of the touch pen through a peripheral circuit and respond accordingly, and also can receive, analyze and executing instructions sent by the host machine; and the host machine performs different control operations on the touch screen according the difference of application programs selected by users. The touch terminal and the touch control method thereof keep the advancement of touch products and purposely enhance the capability of writing with the pen in the hand of students, and also can correct the bad habit that the students do not want to write with the pen, so that the touch terminal is an ideal audio-visual education product.

Owner:深圳市摩拓触摸科技有限公司

Rivet removing tool and method

The invention provides a rivet removing tool and method. No special tool for removing skew rivets is available at present, rivet heads are removed with a sledge hammer by workers through a self-made tool, then rivet rods are ejected out by means of a sharp tool, the risk is extremely high, and a large number of industrial accidents are caused. A hydraulic station of a field riveting machine is used for supplying power to the rivet removing tool, and the rivet removing tool comprises a removing knife, a fixing sleeve, a positioning sliding block, a movable rivet head, a guide washer, a fixed rivet mold, a fixed rivet head and a spring. The removing knife is clamped in the positioning sliding block and makes contact with a rod of a rivet. The fixed rivet head is fixed to the other end of a rivet clamp. The fixed rivet mold is used for fixing a cap of the rivet. The rod of the rivet is removed out of an inner cavity of the fixed rivet head by applying force through a hydraulic piston rod and then taken out after being clamped. The removing knife is made of a high-strength high-plasticity material and can meet the requirements for hardness and the like, and thus the effect that the rivet removing tool is prevented from being broken in the use process is guaranteed. By the adoption of the rivet removing tool, the effect is quite remarkable, and skew rivets and redundant rivets can be removed rapidly and conveniently.

Owner:SHAANXI HEAVY DUTY AUTOMOBILE

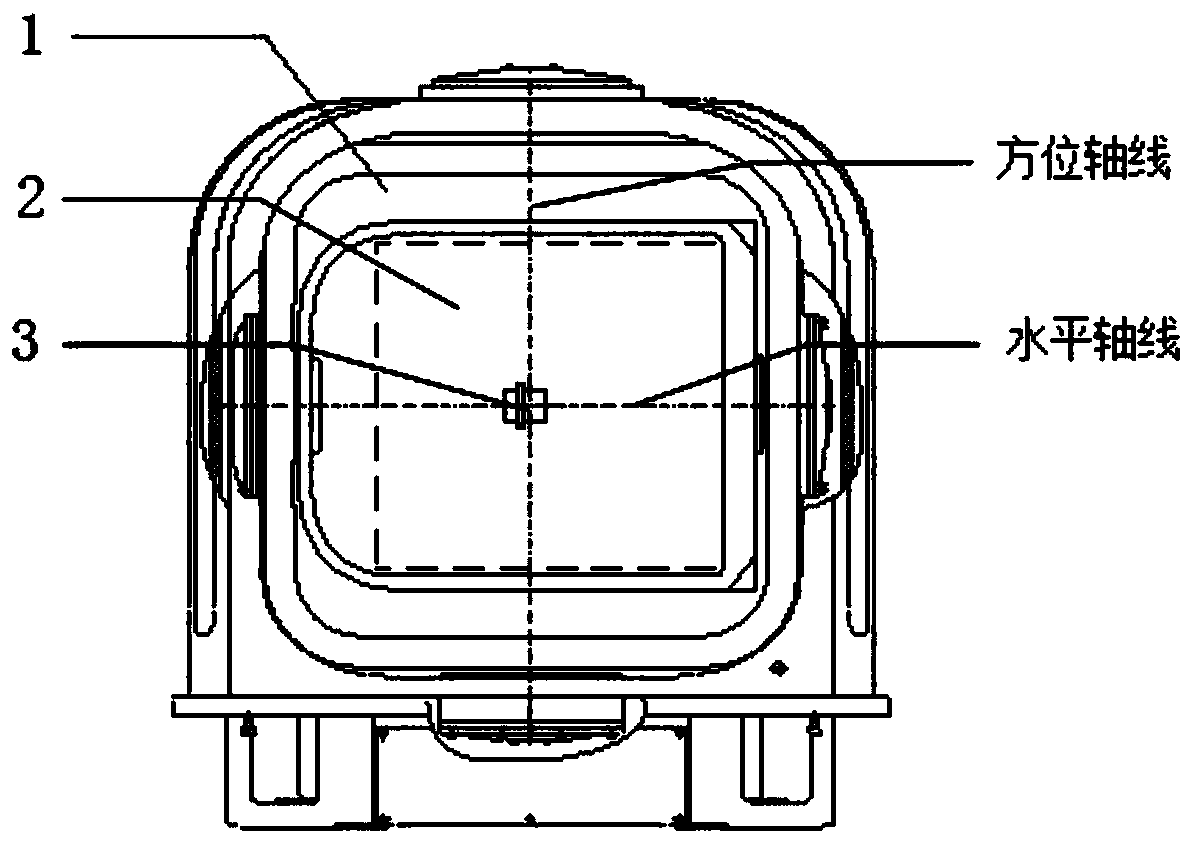

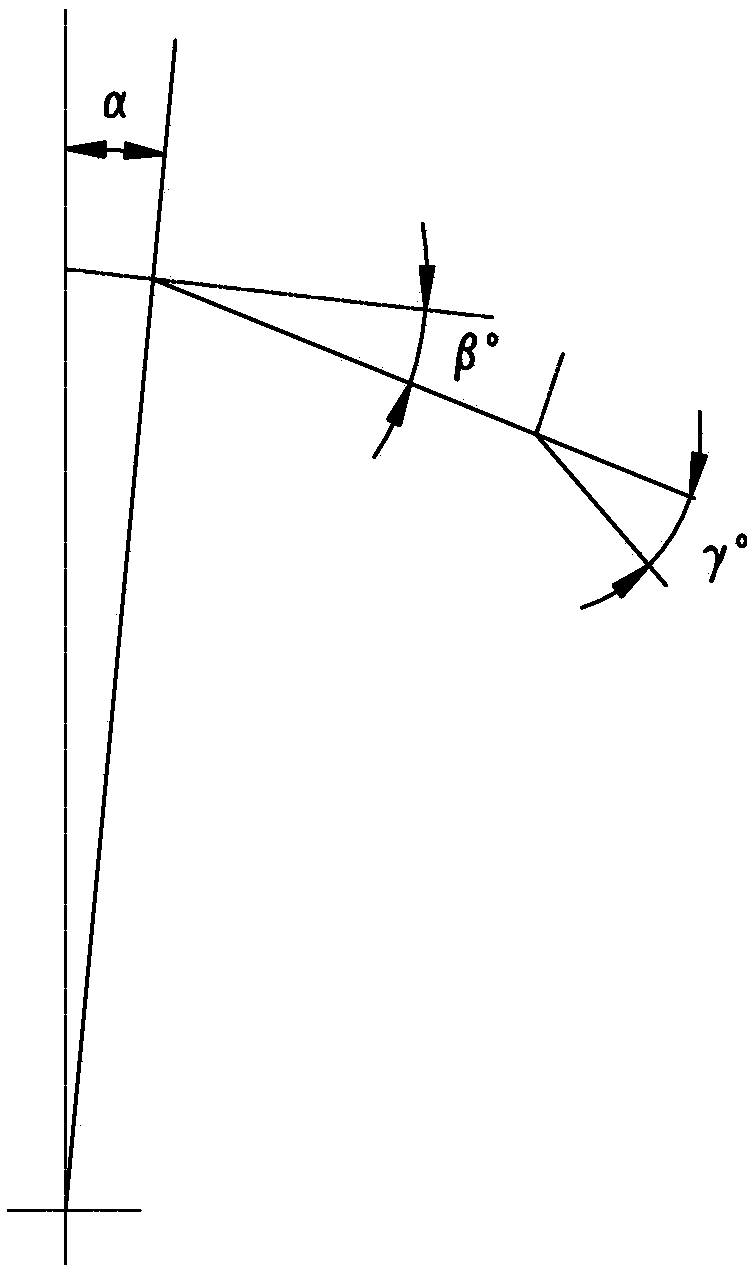

Method for checking perpendicularity between adjacent axes of dual-axis rotary inertial measurement device by using accelerometer

ActiveCN108036756AIngenious design ideasGuaranteed suitabilityMeasurement devicesDual axisMeasurement device

The invention relates to a method for checking the perpendicularity between the adjacent axes of a dual-axis rotary inertial measurement device by using an accelerometer, including the following steps: (1) determining the composition of perpendicularity error, wherein beta is the perpendicularity between an inner frame axis and an outer frame axis; (2) leveling a dual-axis rotary inertial measurement device; (3) setting the horizontal axis to 0 degrees, and obtaining A; (4) setting the horizontal axis to 180 degrees, and obtaining B; and (5) obtaining the perpendicularity beta between the inner frame axis and the outer frame axis through calculation. The practical engineering application problem about the perpendicularity between the horizontal axis and the azimuth axis of a dual-axis rotary inertial measurement device is solved, and the applicability of a dual-axis rotary inertial measurement device shafting test method is guaranteed. By using the method of the invention, the dependence of measurement on external means can be reduced, the cost can be reduced, and the efficiency can be improved. The method is of promotion value.

Owner:TIANJIN NAVIGATION INSTR RES INST

Nano-diamond filled polyimide based compound aerogel material and preparation method thereof

The invention belongs to the technical field of porous compound aerogel and specifically relates to a nano-diamond filled polyimide based compound aerogel material and a preparation method thereof. The compound aerogel provided by the invention comprises the following raw materials: one or more of water-soluble polyimide precursor-polyamide acids and one or more of nano-diamonds. The preparation method of the compound aerogel comprises the following steps: preparing nano-diamond dispersion liquid; preparing polyamide acid-nano-diamond aerogel through a sol-gel process; preparing polyamide acid-nano-diamond aerogel through freeze drying; and preparing polyimide-nano-diamond compound aerogel through thermal amidation. The method provided by the invention is simple in process and low in cost; the compounding process is green and environment-friendly; the microstructure of the prepared compound aerogel is uniform; the aerogel is easy to stably disperse in water; and in addition, the compound aerogel has excellent mechanical strength and heat resistance and is an ideal heat-insulating flame-resistant material.

Owner:FUDAN UNIV

Tungsten selenide/graphene/carbon nanofiber composite material and preparing method thereof

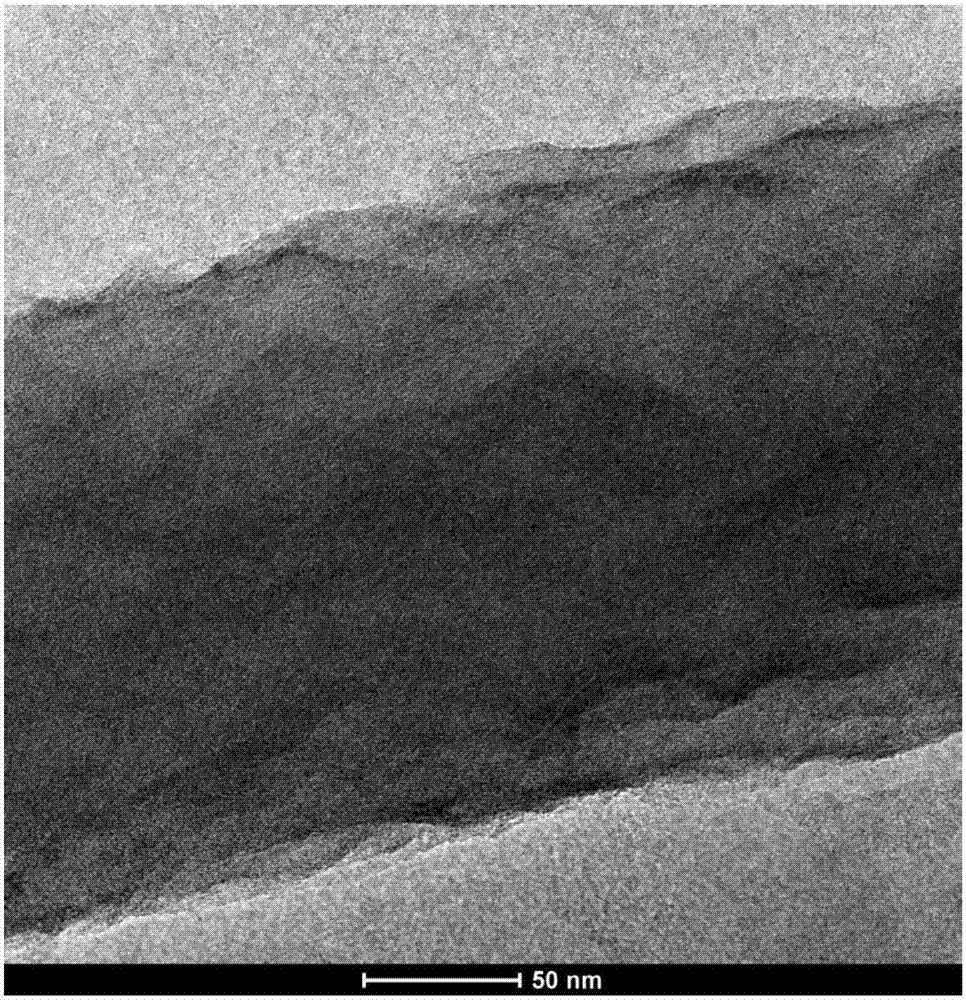

InactiveCN107190361ALow costEasy to makeCarbon fibresInorganic material artificial filamentsCarbonizationNanofiber

The invention provides a tungsten selenide / graphene / carbon nanofiber composite material and a preparing method thereof. The preparing method comprises the steps of 1, preparing a polyacrylonitrile spinning solution; 2, preparing polyacrylonitrile nanofiber; 3, conducting pre-oxidation treatment on the polyacrylonitrile nanofiber; 4, preparing graphene oxide dispersion liquid; 5, soaking the polyacrylonitrile oxide nanofiber into the graphene oxide dispersion liquid to conduct self-assembly to obtain graphene oxide / polyacrylonitrile oxide nanofiber; 6, conducting high temperature carbonization on the graphene oxide / polyacrylonitrile oxide nanofiber to obtain a graphene / carbon nanofiber composite material; 7, growing tungsten selenide nanosheets on the surface of the graphene / carbon nanofiber composite material to obtain the tungsten selenide / graphene / carbon nanofiber composite material. The preparing method of the tungsten selenide / graphene / carbon nanofiber composite material is simple in preparing process and easy to operate, and the adopted raw materials are low in cost and environmentally friendly.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com