Omnibearing servo magnetic wheel type four-wheel drive vehicle

A kind of work vehicle, all-round technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problem of reducing steering friction torque, etc., and achieve the effect of wide application field, good controllability and ingenious design ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

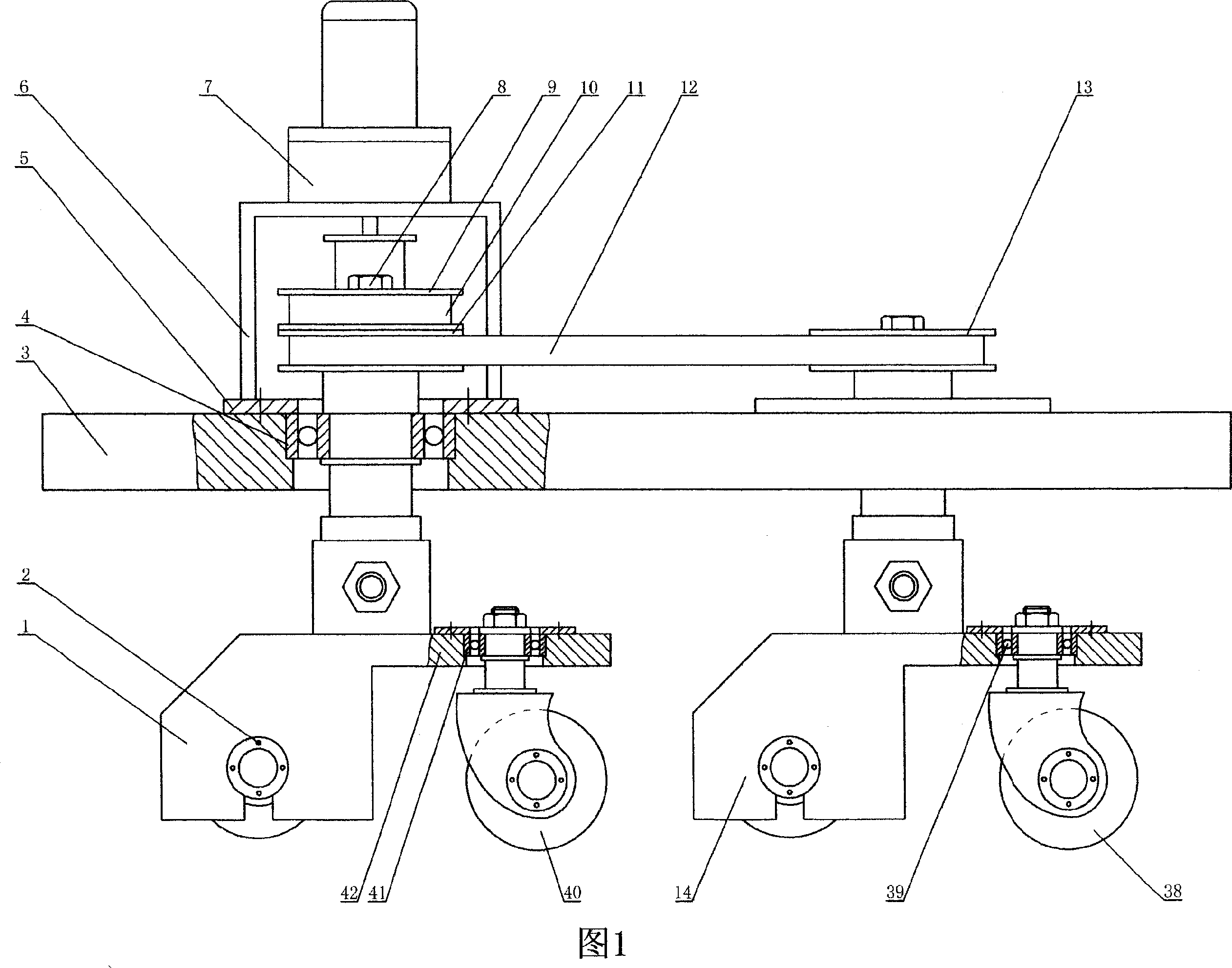

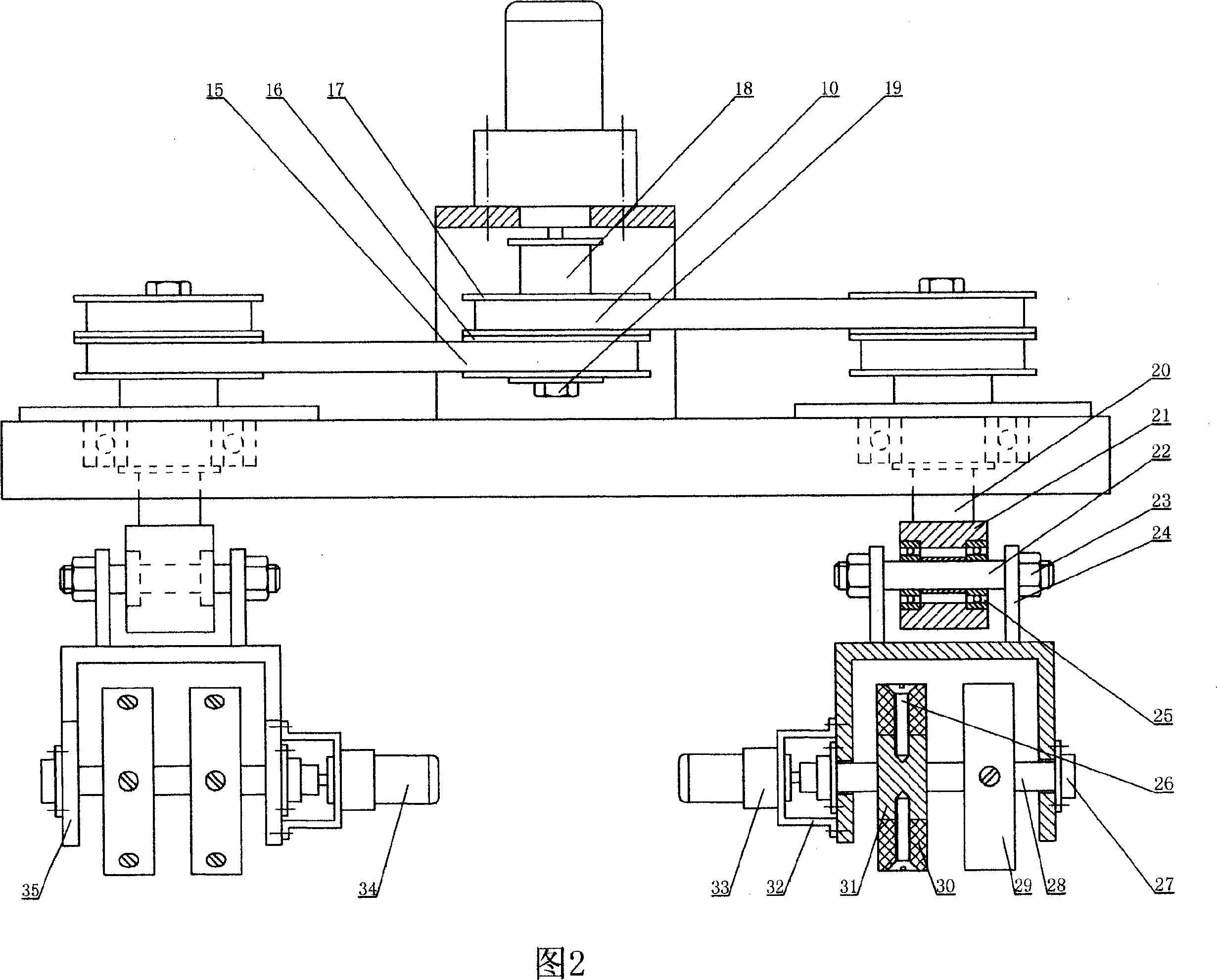

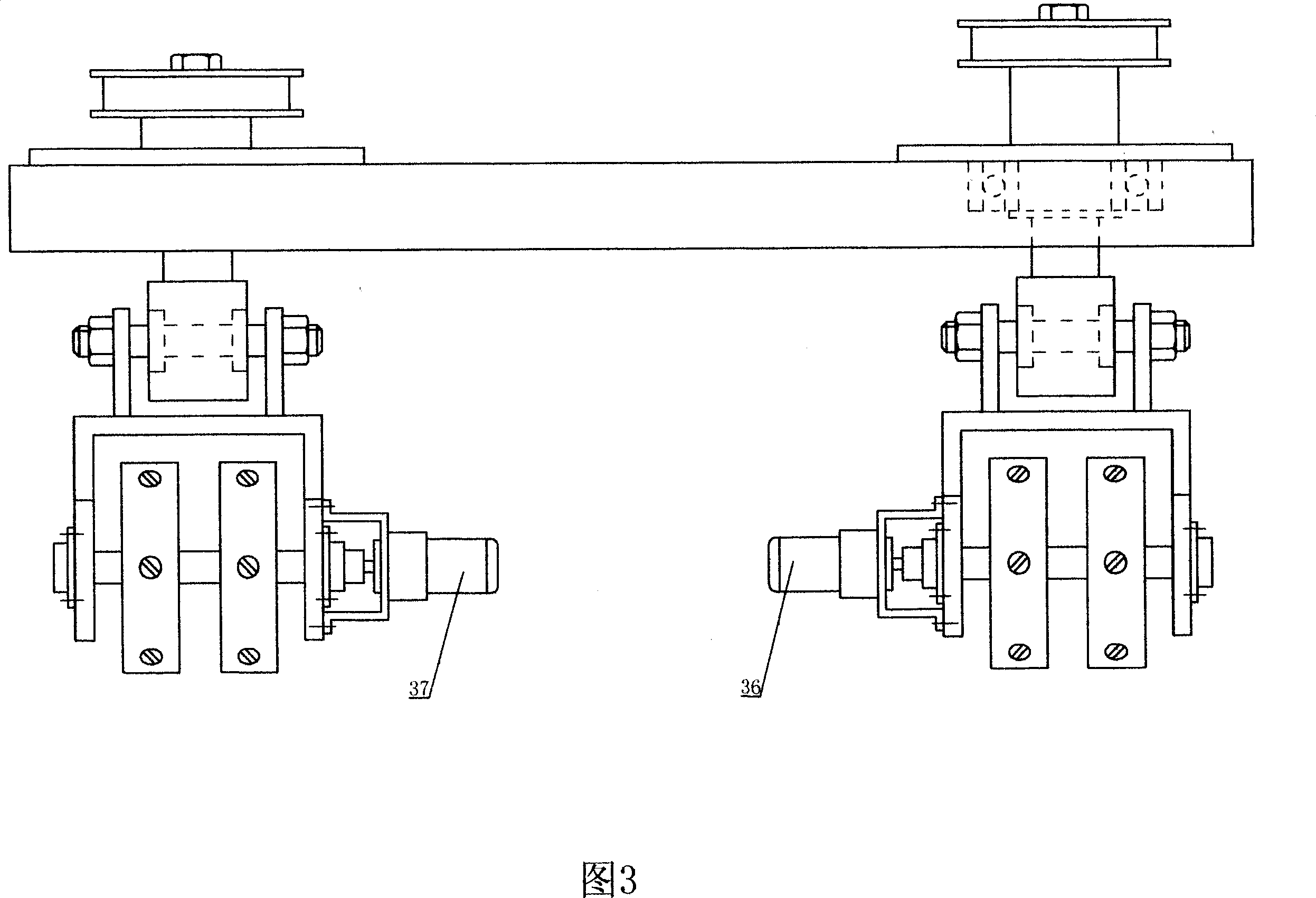

[0026] Magnet (30) is fixed on two magnet axle blocks (31) of magnet wheel axle (28) with magnet fixed screw rod (26), has formed magnet wheel group (29). Put the two magnet wheel bearing seats (27) on the two ends of the magnet wheel shaft (28), and then fix the magnet wheel shaft (28) on the follower magnet frame (1) through the two magnet wheel bearing seats (27) , fix the right drive motor (33) on the right drive motor frame (32), then connect the output shaft of the right drive motor (33) with the inner end of the magnet wheel shaft (28), and fix the right drive motor frame (32) On the inner side of the follower magnet wheel frame (1); the front and rear universal follower magnet wheel assemblies (40), (38) are fixed on the tail plate through the front and rear universal follower bearings (41), (39) (42) up. Install the two follower bearings (25) on both ends of the follower bearing seat (21), pass the follower shaft (22) through the follower shaft frame (24) and the fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com